Study on Surface Longitudinal Crack Formation of Typical Hypoeutectoid Steel Produced on a Caster with Billet and Slab

Abstract

1. Introduction

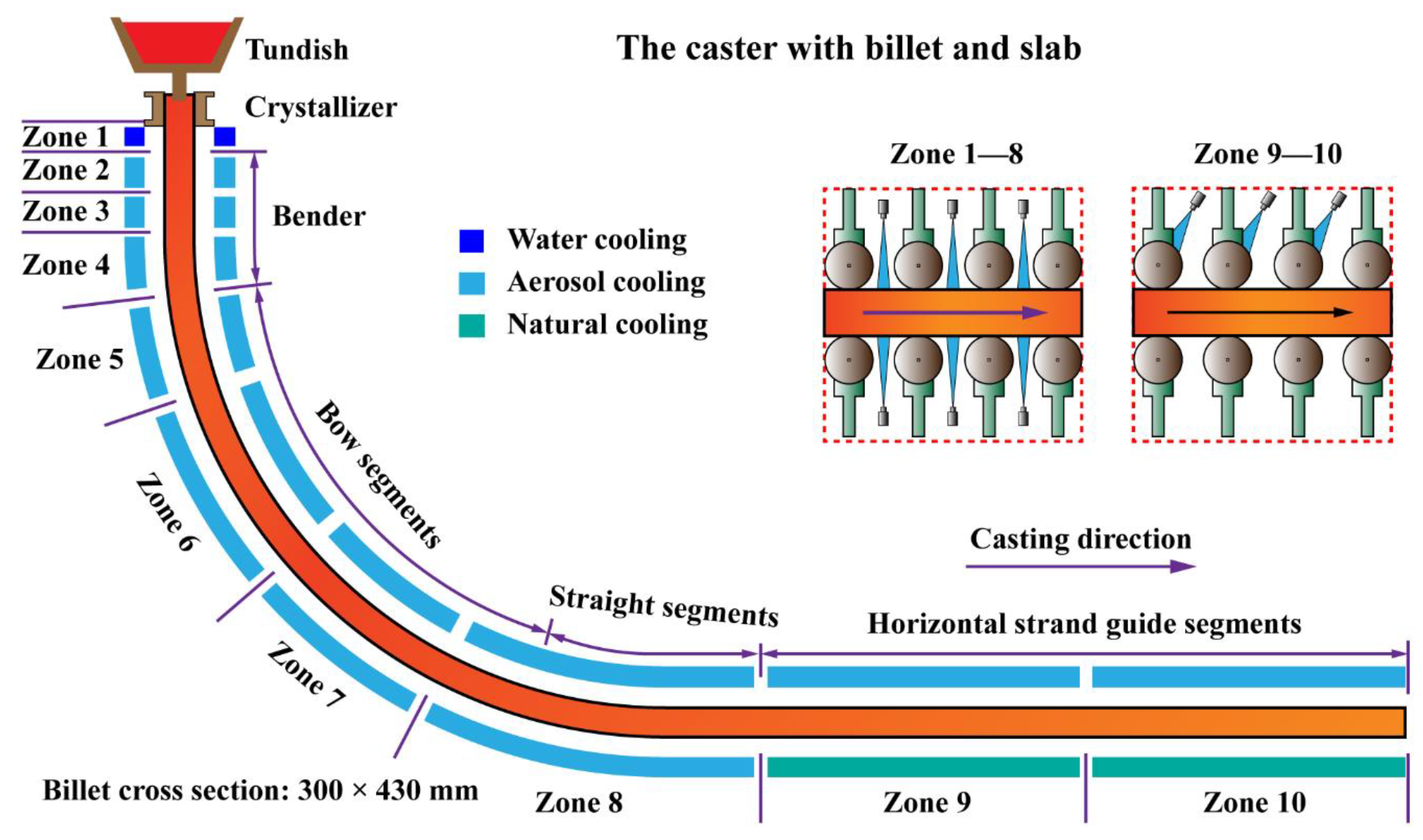

2. Materials and Methods

2.1. Materials and Experimental Procedure

2.2. Numerical Model

- (1)

- Heat transfer in the direction of continuous casting was ignored.

- (2)

- The heat flow rate in the mold can be expressed by

- (3)

- The heat transfer coefficient in water spray cooling can be represented by

- (4)

- The heat transfer coefficient in mist (water + air) cooling can be represented by

- (5)

- The heat flow rate in the radiation cooling zone can be expressed by

3. Results and Discussion

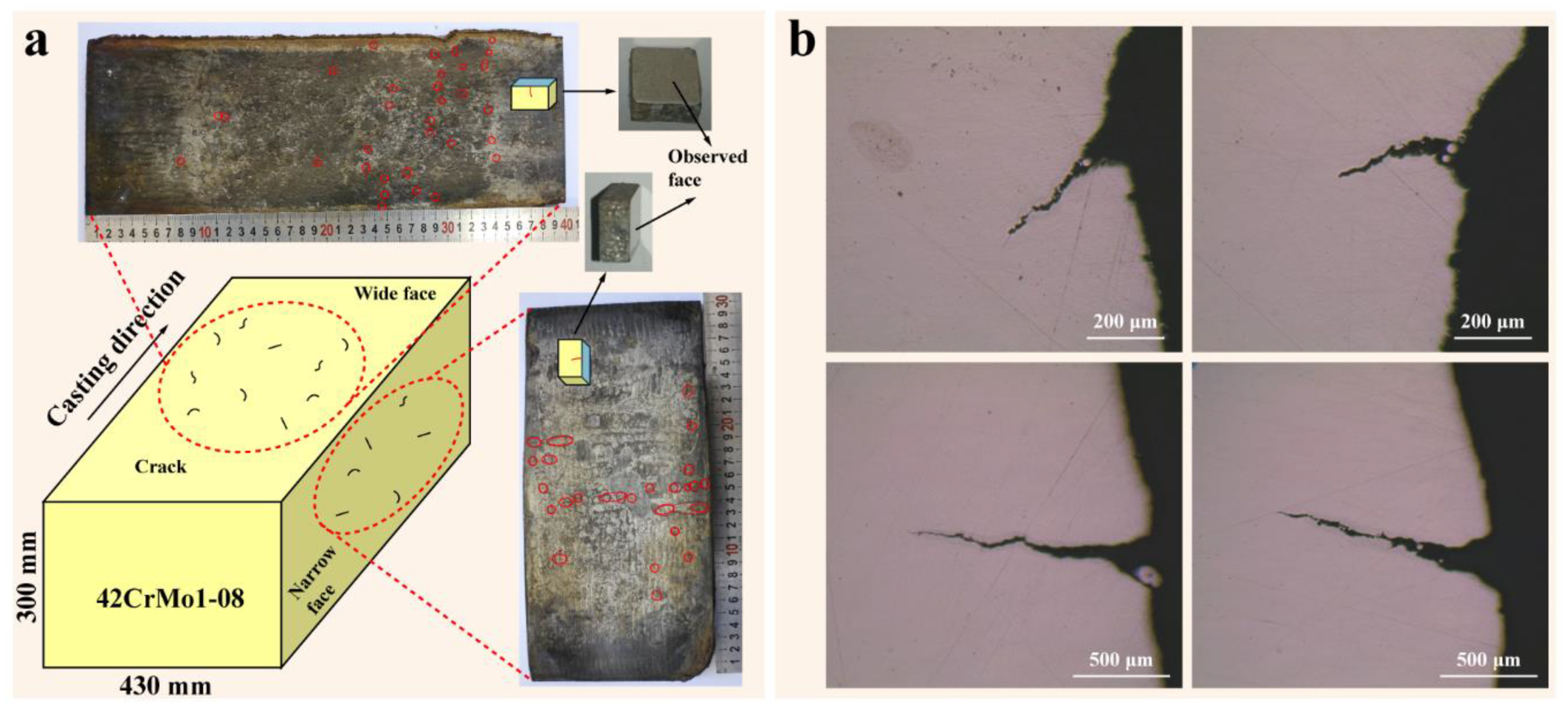

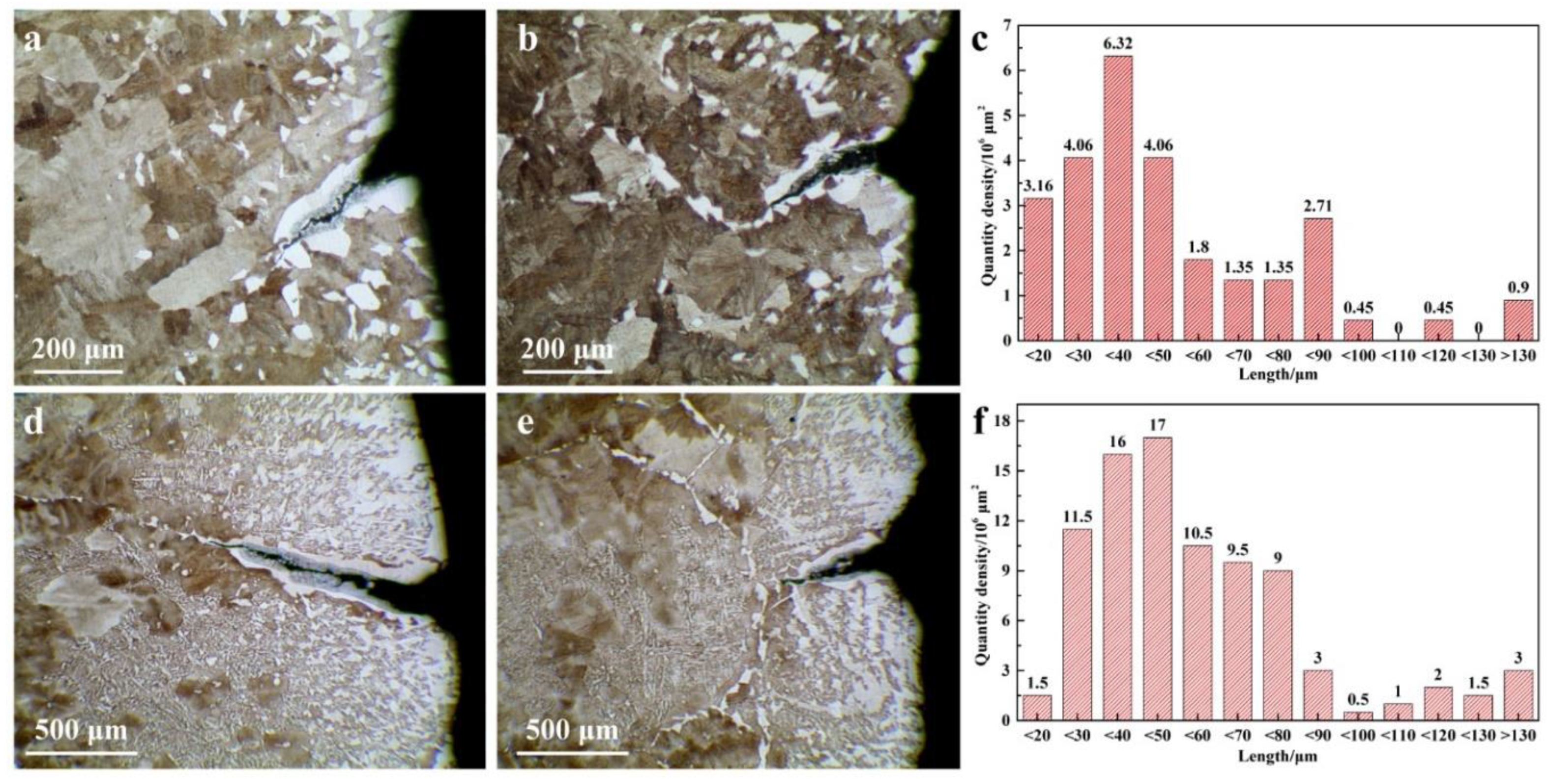

3.1. Longitudinal Crack Distribution and Features

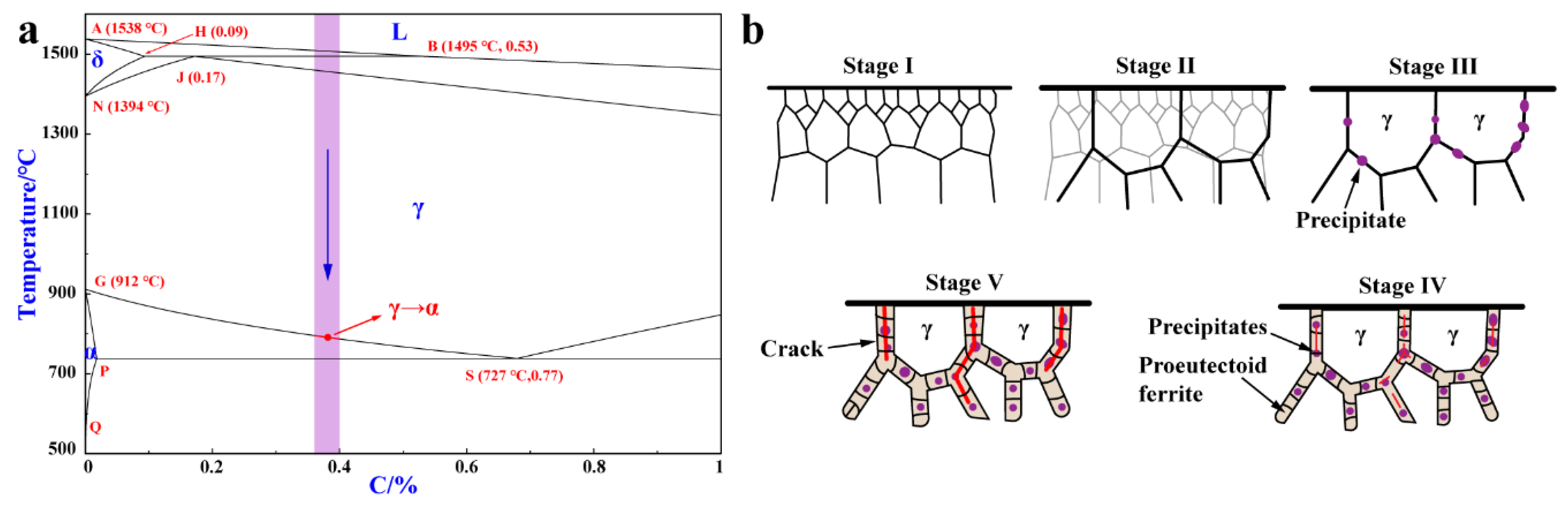

3.2. Analysis of the Causes of Longitudinal Cracks

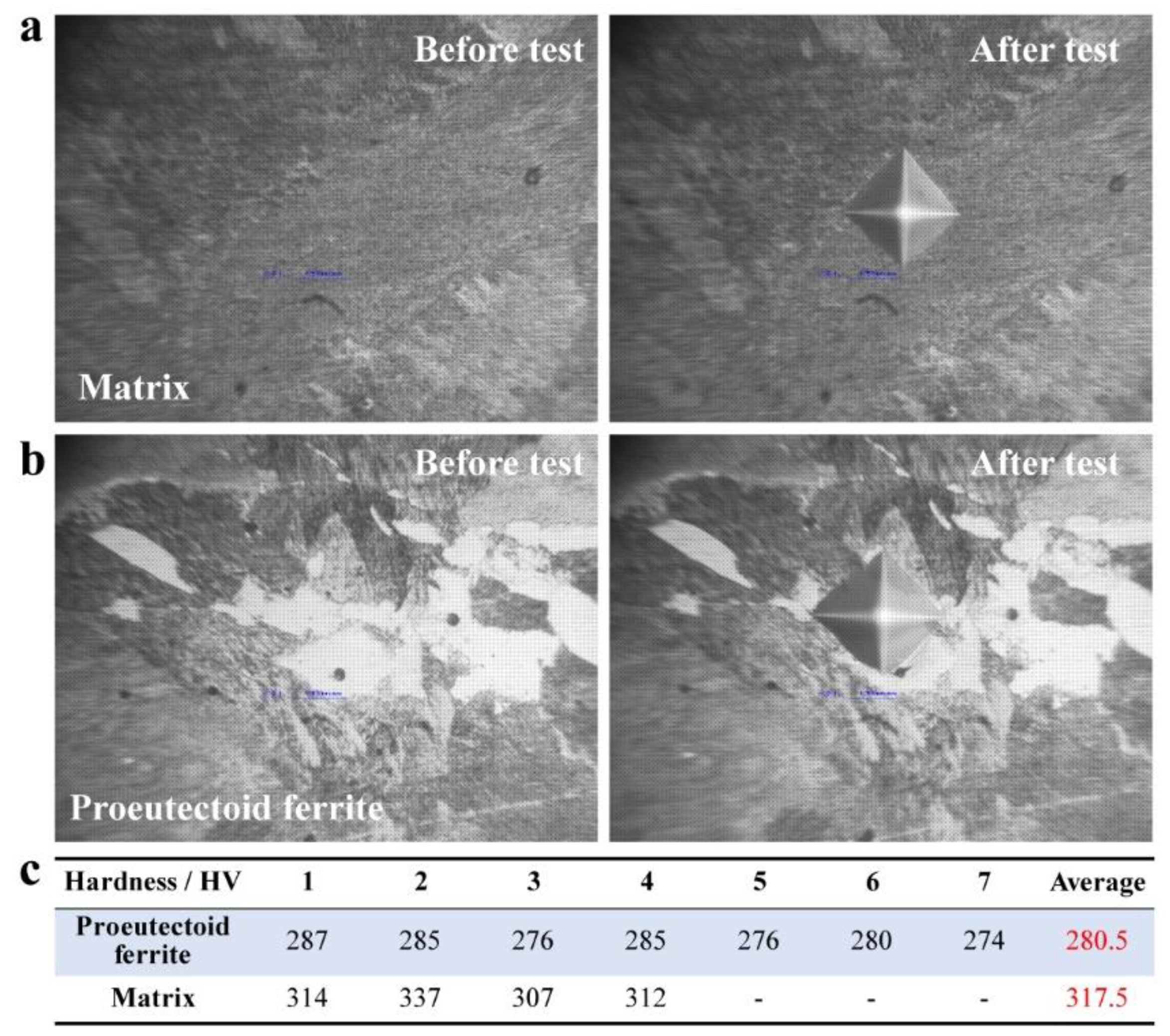

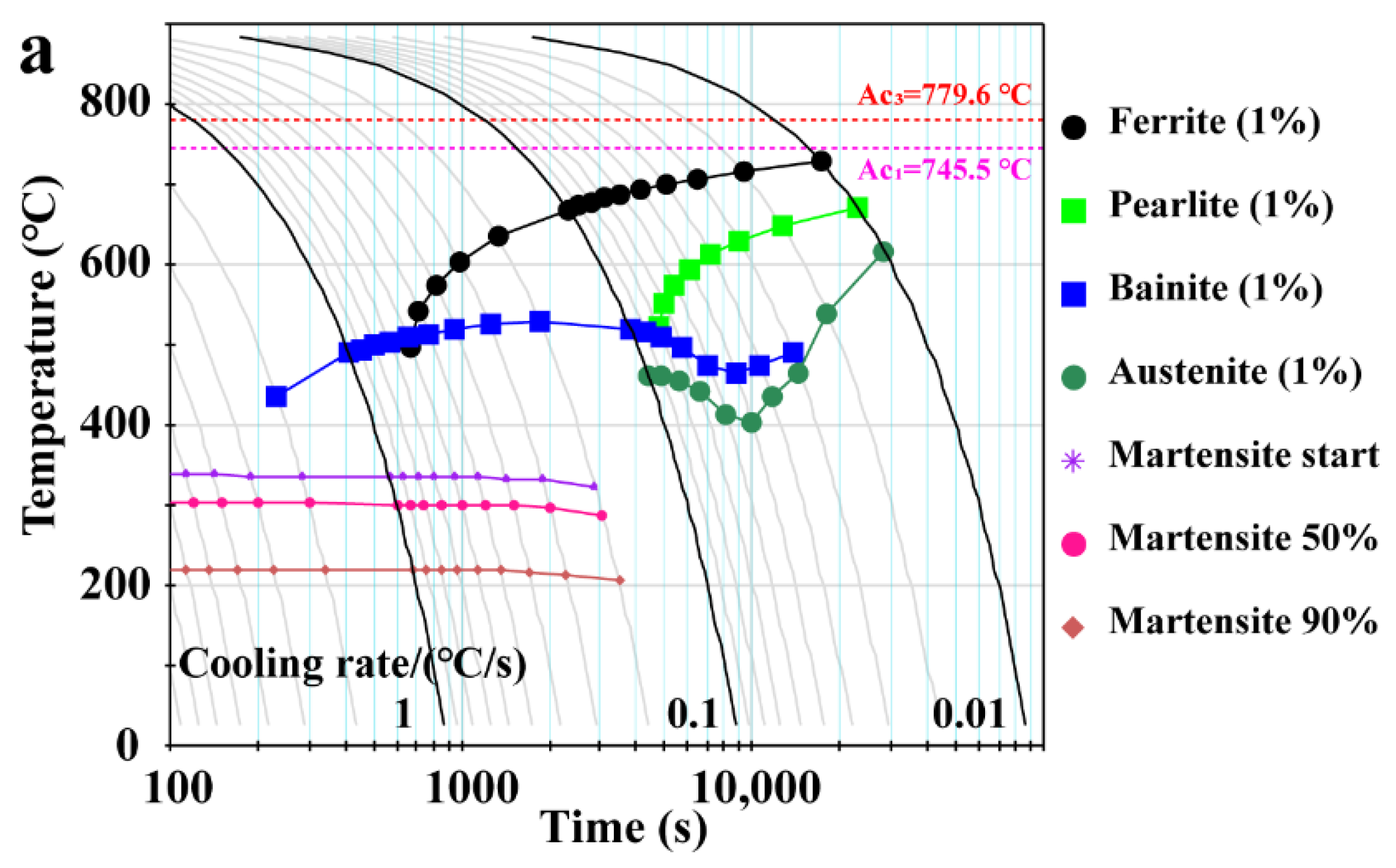

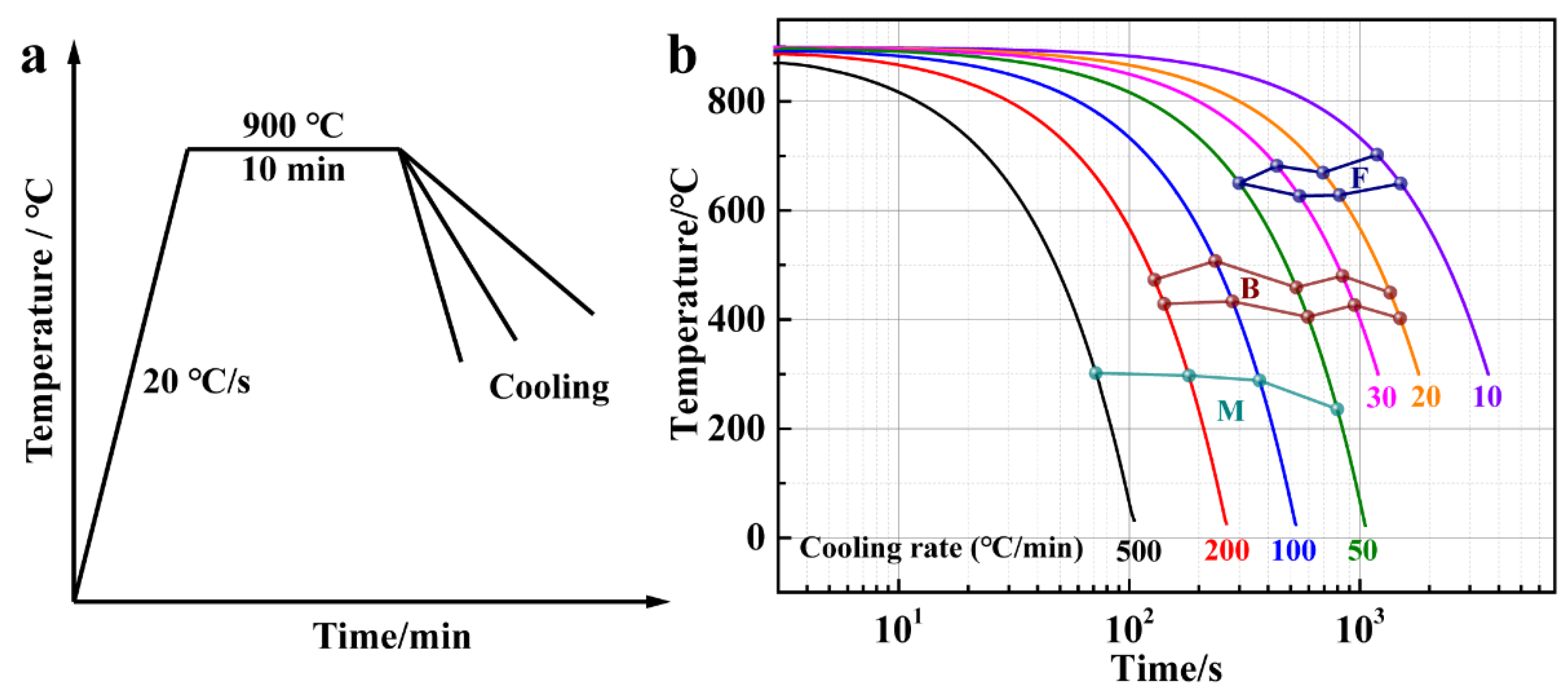

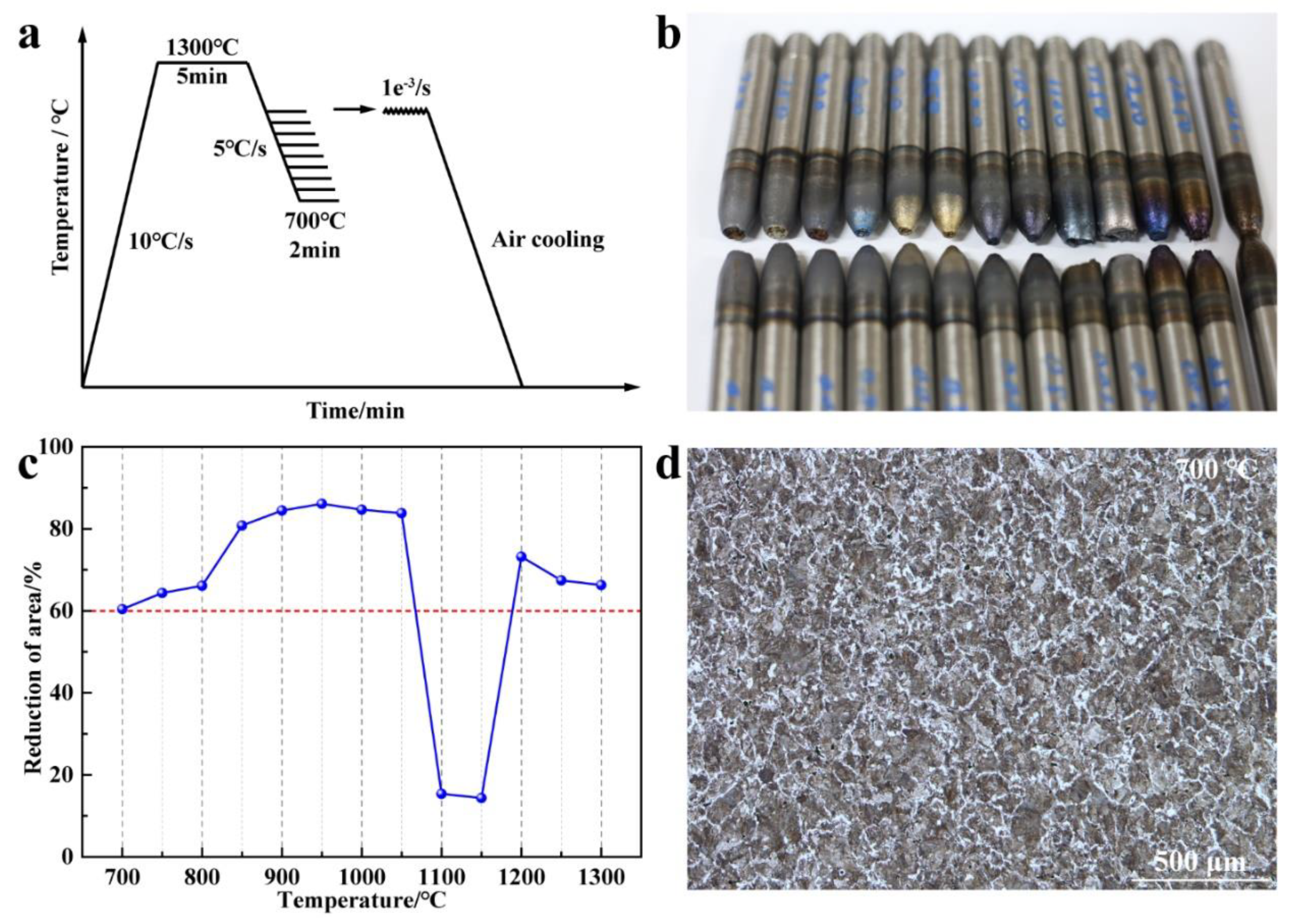

3.3. Determining the Conditions for the Formation of Proeutectoid Ferrite

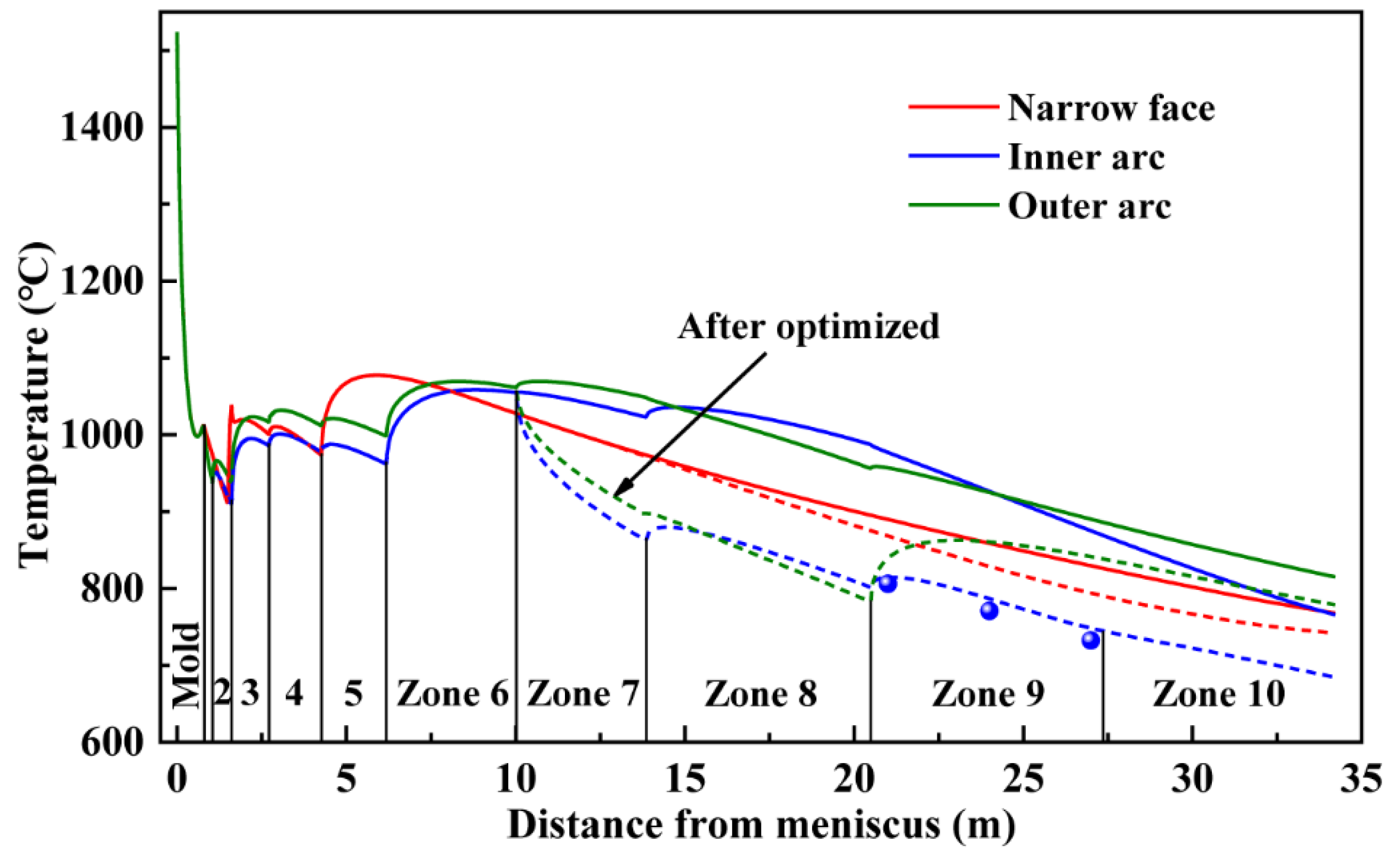

3.4. Optimization of Local Secondary Cooling

4. Conclusions

Author Contributions

Funding

Conflicts of Interest

References

- Xie, H.; Jiang, Z.; Yuen, W.Y.D. Analysis of Microstructure Effects on Edge Crack of Thin Strip During Cold Rolling. Metall. Mater. Trans. B 2011, 42, 1244–1252. [Google Scholar] [CrossRef]

- Brimacombe, J.K.; Sorimachi, K. Crack formation in the continuous casting of steel. Metall. Trans. B 1977, 8, 489–505. [Google Scholar] [CrossRef]

- Ma, F.J.; Wen, G.H.; Tang, P.; Yu, X.; Li, J.Y.; Xu, G.D.; Mei, F. Causes of transverse corner cracks in microalloyed steel in vertical bending continuous slab casters. Ironmak. Steelmak. 2013, 37, 73–79. [Google Scholar] [CrossRef]

- Saleem, S.; Vynnycky, M.; Fredriksson, H. The Influence of Peritectic Reaction/Transformation on Crack Susceptibility in the Continuous Casting of Steels. Metall. Mater. Trans. B 2017, 48, 1625–1635. [Google Scholar] [CrossRef]

- Tsuprun, A.Y.; Fedosov, A.V.; Pashchuk, D.V.; Tskitishvili, E.O.; Ottsevich, V.V. Reduction in Slab Surface Corner Crack Damage due to Development of Rational Secondary Cooling Regimes. Metallurgist 2014, 57, 824–829. [Google Scholar] [CrossRef]

- Ozturk, S.; Arikan, M.M.; Kacar, Y. Effects of Nickel Coating of Mold Plates on Star Crack Defects. Metall. Mater. Trans. B 2013, 44, 706–710. [Google Scholar] [CrossRef]

- Hui, Z.; Minglin, W.; Yeming, W.; Mei, W.; Xilin, L. Novel Casting Technology Preventing Slab Transverse Corner Cracks of Typical Micro-alloyed Steels. In Adv. High Strength Steel; Springer: Singapore, 2018; pp. 159–170. [Google Scholar]

- Zhang, H.; Yang, C.Z.; Wang, M.L.; Tao, H.B.; Liu, H.P.; Wang, X.B. Technology Development for Controlling Slab Transverse Corner Crack of Typical Micro-alloyed Steels. J. Iron Steel Res. Int. 2015, 22, 99–105. [Google Scholar] [CrossRef]

- Takeuchi, E.; Brimacombe, J.K. Effect of oscillation-mark formation on the surface quality of continuously cast steel slabs. Metall. Trans. B 1985, 16, 605–625. [Google Scholar] [CrossRef]

- Sinel’nikov, V.A.; Filippov, G.A. Production of high-quality slabs during continuous casting of cracking-sensitive steel: Part 2. Russ. Metall. 2015, 2014, 956–960. [Google Scholar] [CrossRef]

- Kong, Y.; Chen, D.; Liu, Q.; Long, M.A. Prediction Model for Internal Cracks during Slab Continuous Casting. Metals 2019, 9, 587. [Google Scholar] [CrossRef]

- Guo, J.; Wen, G. Influence of Alloy Elements on Cracking in the Steel Ingot during Its Solidification. Metals 2019, 9, 836. [Google Scholar] [CrossRef]

- Gu, C.; Bao, Y.P.; Gan, P.; Wang, M.; He, J.S. Effect of main inclusions on crack initiation in bearing steel in the very high cycle fatigue regime. Int. J. Miner. Metall. Mater. 2018, 25, 623–629. [Google Scholar] [CrossRef]

- Wang, Q.Y.; Bathias, C.; Kawagoishi, N.; Chen, Q. Effect of inclusion on subsurface crack initiation and gigacycle fatigue strength. Int. J. Fatigue 2002, 24, 1269–1274. [Google Scholar] [CrossRef]

- Zhang, L.; Yang, X.; Li, S.; Li, M.; Ma, W. Control of Transverse Corner Cracks on Low-Carbon Steel Slabs. JOM 2014, 66, 1711–1720. [Google Scholar] [CrossRef]

- Brimacombe, J.K.; Weinberg, F.; Hawbolt, E.B. Formation of longitudinal, midface cracks in continuously-cast slabs. Metall. Trans. B 1979, 10, 279–292. [Google Scholar] [CrossRef]

- Li, Y.F.; Wen, G.H.; Tang, P.; Li, J.Q.; Xiang, C.L. Effect of Slab Subsurface Microstructure Evolution on Transverse Cracking of Microalloyed Steel during Continuous Casting. J. Iron Steel Res. 2014, 21, 737–744. [Google Scholar] [CrossRef]

- Tehovnik, F.; Vodopivec, F.; Celin, R.; Arzenšek, B.; Gontarev, J. Effect of δ-ferrite, lead and sulphur on hot workability of austenitic stainless steels with solidification structure. Mater. Sci. Technol. 2013, 27, 774–782. [Google Scholar] [CrossRef]

- Mintz, B. The Influence of Composition on the Hot Ductility of Steels and to the Problem of Transverse Cracking. ISIJ Int. 1999, 39, 833–855. [Google Scholar] [CrossRef]

- Zhang, Y.; Wang, W.; Zhang, H. Development of a Mold Cracking Simulator: The Study of Breakout and Crack Formation in Continuous Casting Mold. Metall. Mater. Trans. B 2016, 47, 2244–2252. [Google Scholar] [CrossRef]

- Lyu, P.; Wang, W.; Zhang, H. Mold Simulator Study on the Initial Solidification of Molten Steel Near the Corner of Continuous Casting Mold. Metall. Mater. Trans. B 2016, 48, 247–259. [Google Scholar] [CrossRef]

- Sun, Y.H.; Ni, Y.J.; Wang, H.T.; Xu, Z.B.; Cai, K.K. Longitudinal surface cracks of thin slabs. Int. J. Miner. Metall. Mater. 2010, 17, 159–166. [Google Scholar] [CrossRef]

- Terčelj, M.; Turk, R.; Kugler, G.; Peruš, I. Neural network analysis of the influence of chemical composition on surface cracking during hot rolling of AISI D2 tool steel. Comput. Mater. Sci. 2008, 42, 625–637. [Google Scholar] [CrossRef]

- Shabovta, V.P.; Torgovets, A.K.; Maksimov, E.V. Formation of longitudinal cracks on slabs. Steel Transl. 2010, 40, 558–561. [Google Scholar] [CrossRef]

- Yang, G.; Zhu, L.; Chen, W.; Yu, X.; He, B. Initiation of Surface Cracks on Beam Blank in the Mold during Continuous Casting. Metals 2018, 8, 712. [Google Scholar] [CrossRef]

- Xu, L.J.; Zhang, S.L.; Qiu, C.G.; Qiu, S.T.; Zhang, X.Z. Surface microstructure control of microalloyed steel during slab casting. J. Iron Steel Res. Int. 2017, 24, 803–810. [Google Scholar] [CrossRef]

- Liu, Z.Q.; Yang, Z.G.; Li, Z.D.; Zhang, C. Transformation character of ferrite formation by a ledge mechanism under a mixed-control model. Int. J. Miner. Metall. Mater. 2012, 19, 428–433. [Google Scholar] [CrossRef]

- Ma, F.; Wen, G.; Wang, W. Effect of Cooling Rates on the Second-Phase Precipitation and Proeutectoid Phase Transformation of a Nb-Ti Microalloyed Steel Slab. Steel Res. Int. 2013, 84, 370–376. [Google Scholar] [CrossRef]

- Enomoto, M.; Yang, J.B. Simulation of Nucleation of Proeutectoid Ferrite at Austenite Grain Boundaries during Continuous Cooling. Metall. Mater. Trans. A 2008, 39, 994–1002. [Google Scholar] [CrossRef]

- Yamashita, T.; Enomoto, M.; Tanaka, Y.; Matsuda, H.; Nagoshi, M. Analysis of Carbon Partitioning at an Early Stage of Proeutectoid Ferrite Transformation in a Low Carbon Mn–Si Steel by High Accuracy FE-EPMA. ISIJ Int. 2018, 58, 1079–1085. [Google Scholar] [CrossRef]

| Steel | C | Si | Mn | P | S | Cr | Mo | Al |

|---|---|---|---|---|---|---|---|---|

| 42CrMo1-08 | 0.39 | 0.21 | 0.75 | 0.02 | 0.024 | 1.12 | 0.18 | 0.016 |

| Spray Zone | Length (m) | Water Flow Rate (L/min) | Suggested Water Flow Rate (L/min) |

|---|---|---|---|

| 1N | 0.7 | 128 | 128 |

| 1IO | 0.24 | 87 | 87 |

| 2IO | 0.56 | 75 | 75 |

| 3N | 1.11 | 35 | 35 |

| 3IO | 1.11 | 42 | 42 |

| 4N | 1.55 | 35 | 35 |

| 4IO | 1.55 | 40 | 40 |

| 5IO | 1.92 | 36 | 36 |

| 6I | 3.84 | 16 | 16 |

| 6O | 3.84 | 21 | 21 |

| 7I | 3.84 | 8 | 31 |

| 7O | 3.84 | 8 | 31 |

| 8I | 6.63 | 8 | 30 |

| 8O | 6.63 | 9 | 46 |

| 9I | 6.87 | 18 | 35 |

| 10I | 6.86 | 18 | 35 |

| Parameters | Value | Unit |

|---|---|---|

| Billet cross section | 300 × 430 | mm2 |

| Pouring temperature | 1522 | °C |

| Liquidus temperature | 1504 | °C |

| Solidus temperature | 1421 | °C |

| Mold length (Z) | 0.8 | m |

| Casting speed (Vc) | 0.65 | m/min |

| Latent heat of solidification | 272 | KJ/Kg |

| Density | 7400 | Kg/m3 |

© 2019 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (http://creativecommons.org/licenses/by/4.0/).

Share and Cite

Xing, L.; Wang, M.; Guo, J.; Zhang, Z.; Zeng, F.; Chen, B.; Bao, Y. Study on Surface Longitudinal Crack Formation of Typical Hypoeutectoid Steel Produced on a Caster with Billet and Slab. Metals 2019, 9, 1269. https://doi.org/10.3390/met9121269

Xing L, Wang M, Guo J, Zhang Z, Zeng F, Chen B, Bao Y. Study on Surface Longitudinal Crack Formation of Typical Hypoeutectoid Steel Produced on a Caster with Billet and Slab. Metals. 2019; 9(12):1269. https://doi.org/10.3390/met9121269

Chicago/Turabian StyleXing, Lidong, Min Wang, Jianlong Guo, Zefeng Zhang, Fanzheng Zeng, Botao Chen, and Yanping Bao. 2019. "Study on Surface Longitudinal Crack Formation of Typical Hypoeutectoid Steel Produced on a Caster with Billet and Slab" Metals 9, no. 12: 1269. https://doi.org/10.3390/met9121269

APA StyleXing, L., Wang, M., Guo, J., Zhang, Z., Zeng, F., Chen, B., & Bao, Y. (2019). Study on Surface Longitudinal Crack Formation of Typical Hypoeutectoid Steel Produced on a Caster with Billet and Slab. Metals, 9(12), 1269. https://doi.org/10.3390/met9121269