Effect of Heat Treatment on the Microstructure and Mechanical Properties of a Composite Made of Al-Si-Cu-Mg Aluminum Alloy Reinforced with SiC Particles

Abstract

1. Introduction

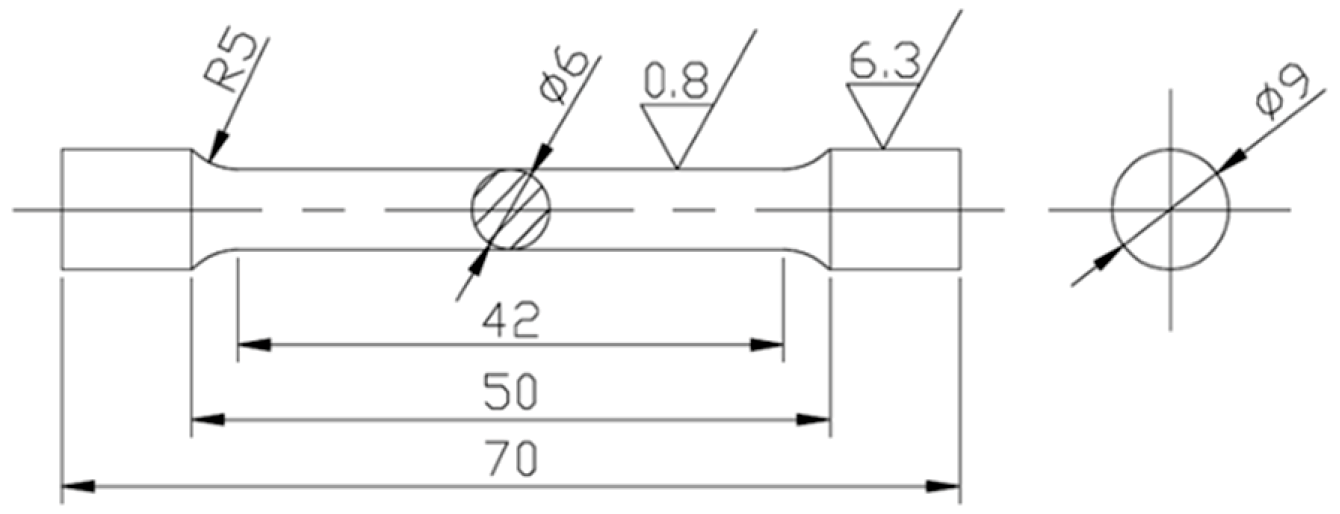

2. Experimental Procedure

3. Results and Discussion

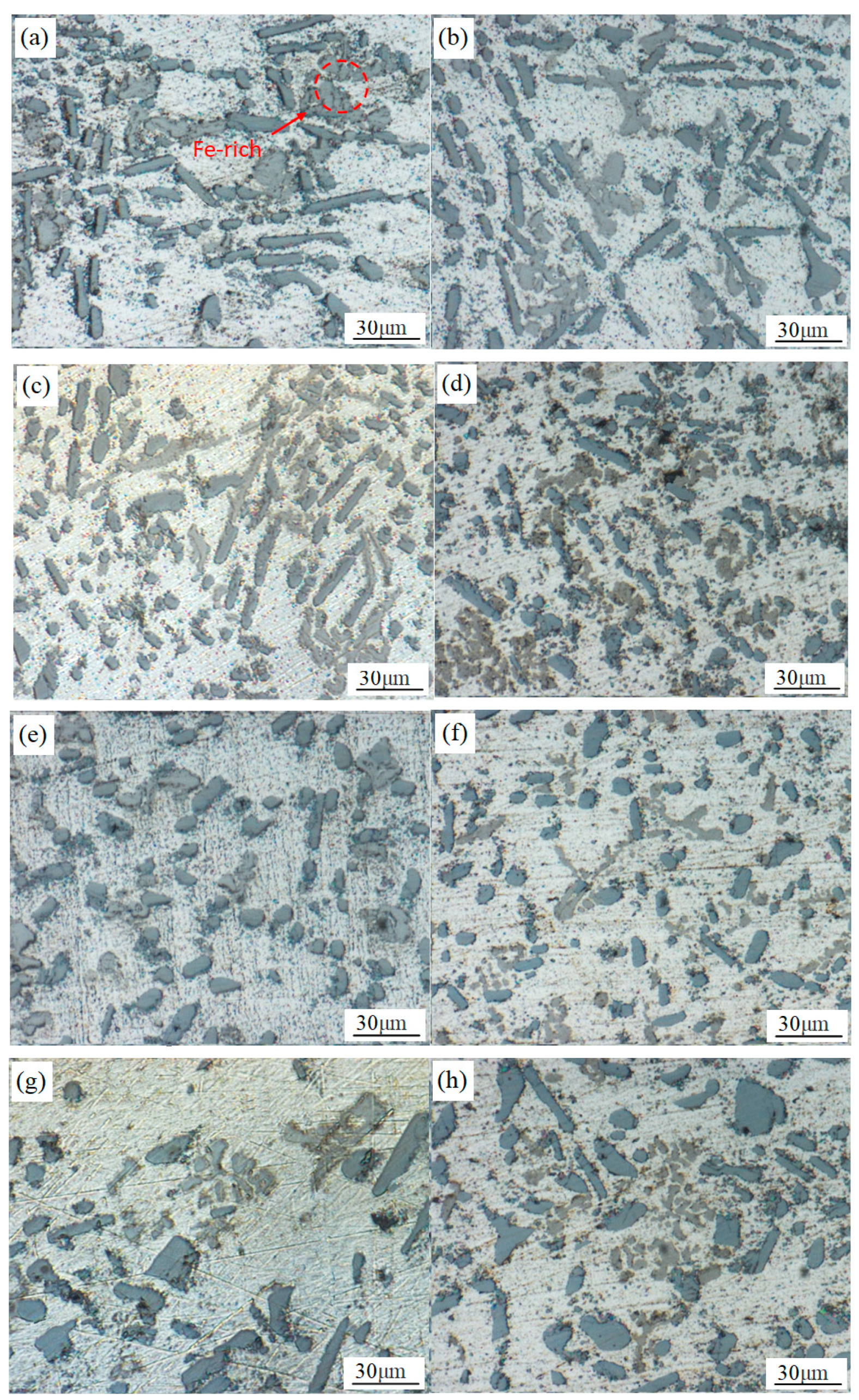

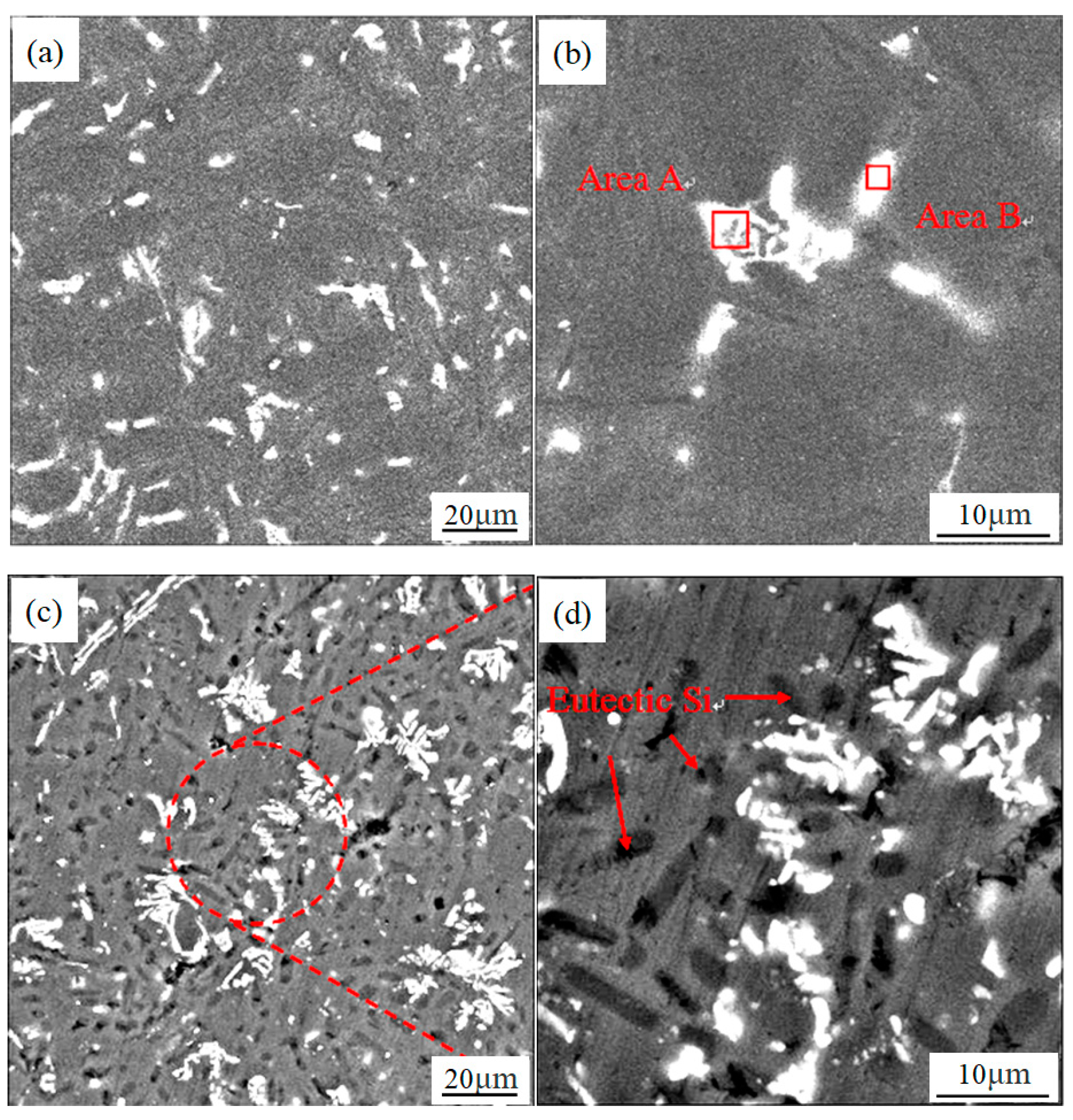

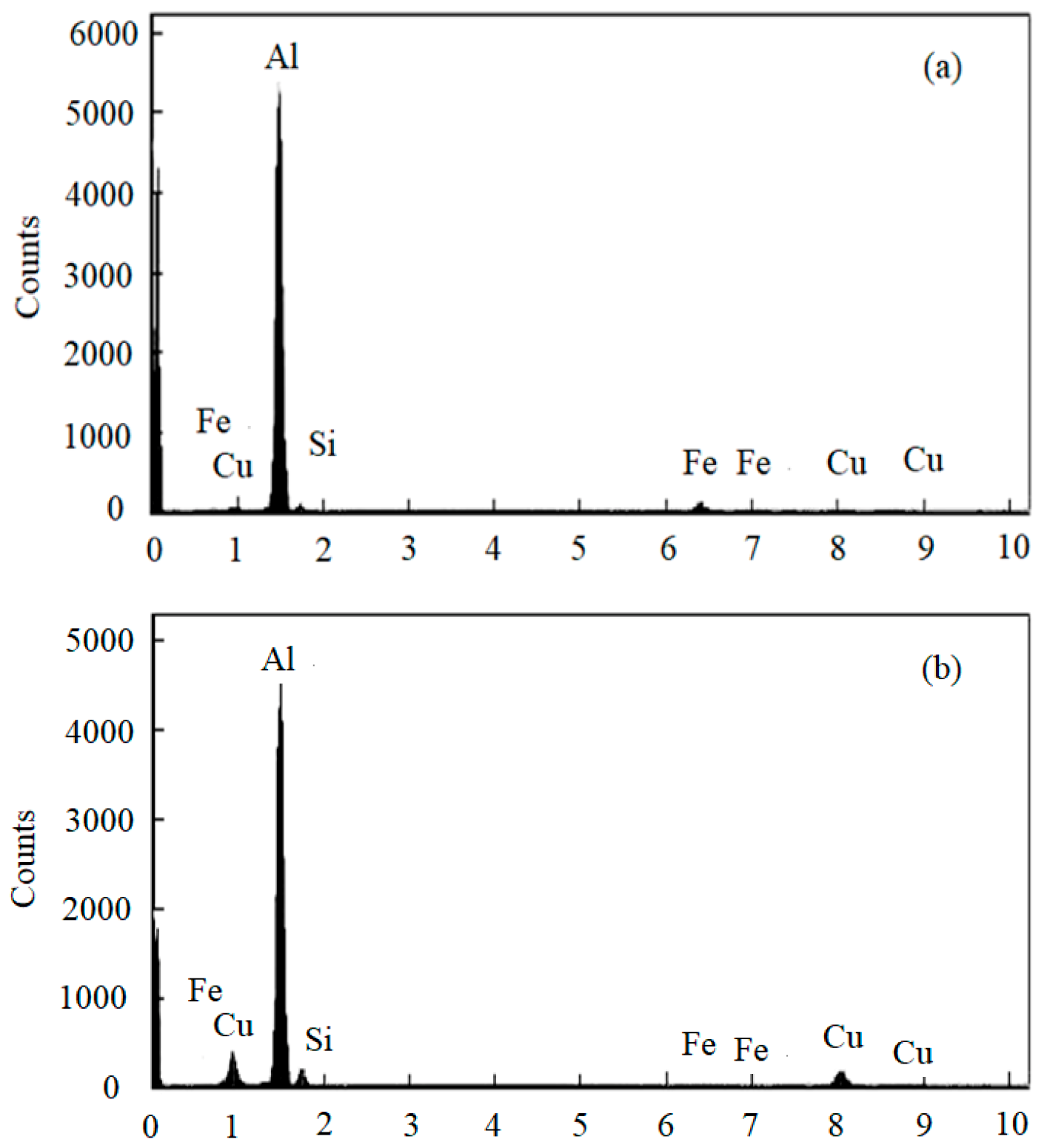

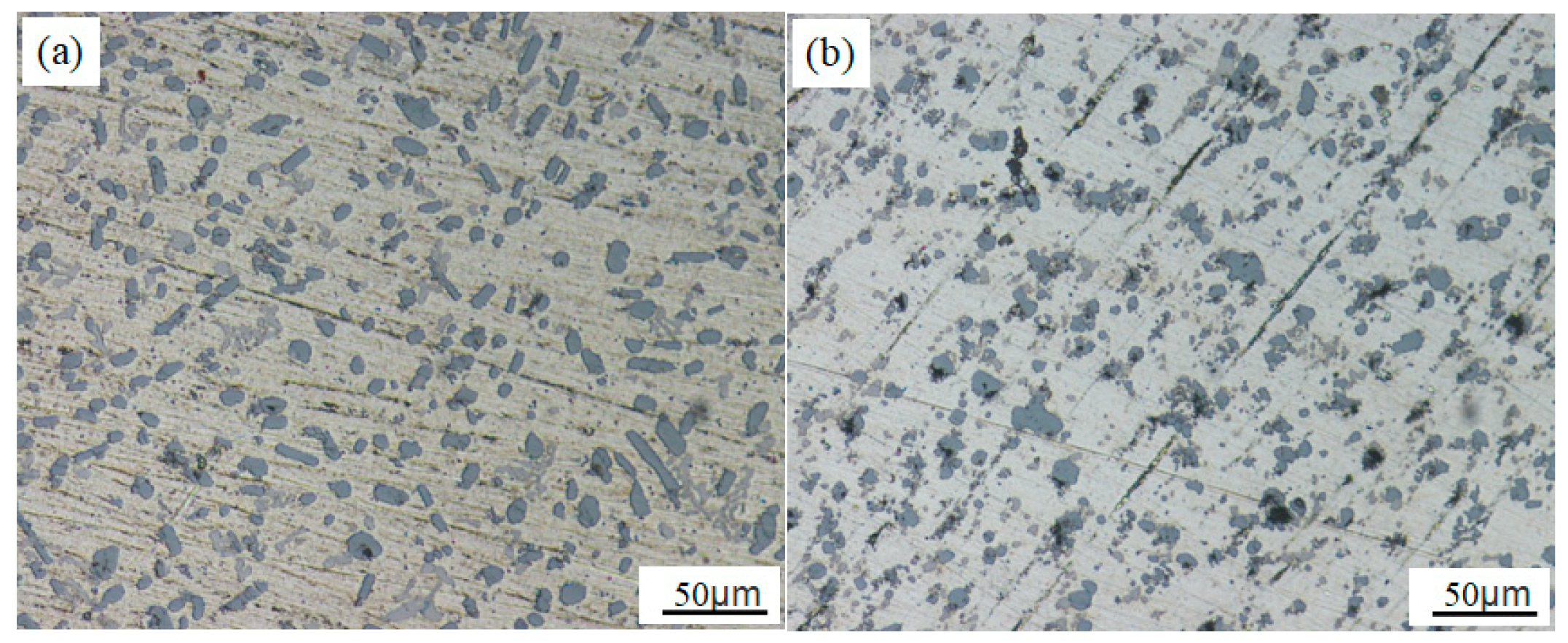

3.1. Solution Treatment

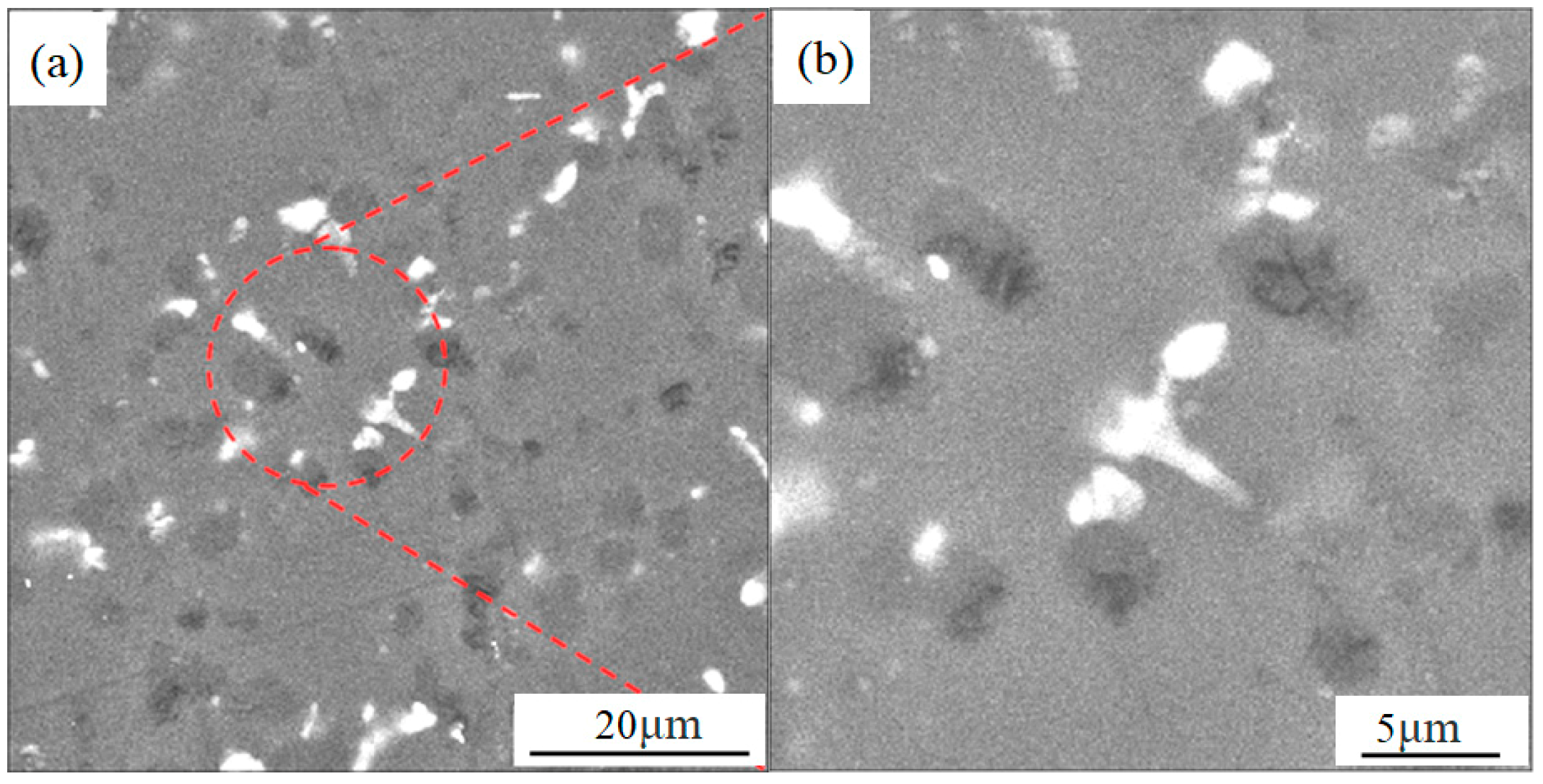

3.2. Aging Treatment

3.3. Effect of T6 Heat Treatment on Mechanical Properties of Al5Si1Cu0.5Mg Matrix Alloy and Composite

3.3.1. Microhardness

3.3.2. Tensile Properties

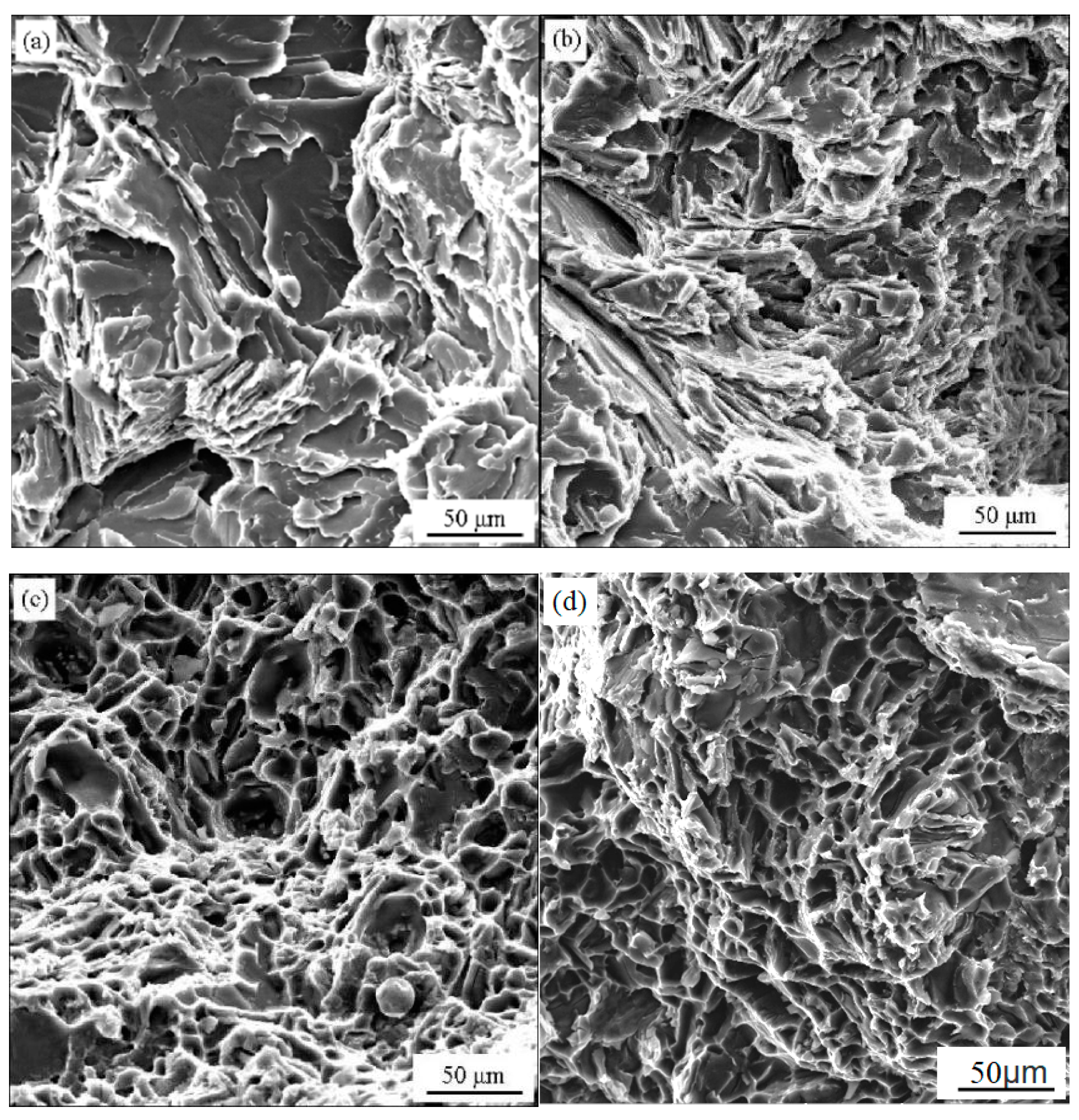

3.3.3. Fractography

4. Conclusions

- The solution treatment of Al5Si1Cu0.5Mg matrix alloy and its composite leads to the morphological changes of the eutectic Si and iron-rich γ phase and causes the Al2Cu phase to dissolve. At 520 °C, the optimal time of solution treatment is 9 h and 6 h for Al5Si1Cu0.5Mg matrix alloy and its composite, respectively.

- After an aging treatment with 6 h at the temperature of 175 °C, the microstructure of the composite is more dispersed and finer than that of Al5Si1Cu0.5Mg matrix alloy on the whole and Al2Cu will be precipitated.

- Irrespective of T6 heat treatment, the microhardness, ultimate tensile strength, and elongation of the composite are consistently higher than those of Al5Si1Cu0.5Mg matrix alloy. The microhardness, ultimate tensile strength, and elongation of Al5Si1Cu0.5Mg matrix alloy and its composite after T6 heat treatment are higher than those of the as-casts.

- After T6 heat treatment, a large area of cleavage plane is replaced by a large number of dimples and the tearing ridges become thicker in the fracture surfaces of both Al5Si1Cu0.5Mg matrix alloy and its composite.

Author Contributions

Funding

Conflicts of Interest

References

- Ma, Z.; Samuel, E.; Mohamed, A.M.A.; Samuel, A.M.; Samuel, F.H.; Doty, H.W. Influence of aging treatments and alloying additives on the hardness of Al–11Si–2.5Cu–Mg alloys. Mater. Des. 2010, 31, 3791–3803. [Google Scholar] [CrossRef]

- Amerioon, A.; Emamy, M.; Ashuri, G.H. Investigation the effect of Al-5Ti-1B grain refiner and T6 heat treatment on tensile properties of Al-8%Mg. Proced. Mater. Sci. 2015, 11, 32–37. [Google Scholar] [CrossRef][Green Version]

- Zhang, Y.G.; Cheng, H.F.; Huang, X.M.; Wu, J.; Hu, Z.J. Preparation of SiCp/ZL105 composite by intensity ultrasonic vibration under semi-solid temperature. Spec. Cast. Nonferrous Alloy. 2011, 31, 363–366. [Google Scholar]

- Sekar, K.; Allesu, K.; Joseph, M.A. Effect of T6 heat treatment in the microstructure and mechanical properties of A356 reinforced with nano Al2O3 particles by combination effect of stir and squeeze casting. Proced. Mater. Sci. 2014, 5, 444–453. [Google Scholar] [CrossRef][Green Version]

- Mohamed, A.M.A.; Samuel, F.H.; Alkahtani, S. Influence of Mg and solution heat treatment on the occurrence of incipient melting in Al-Si-Cu-Mg cast alloys. Mater. Sci. Eng. A 2012, 543, 22–34. [Google Scholar] [CrossRef]

- Samuel, A.M.; Doty, H.W.; Valtierra, S.; Samuel, F.H. Relationship between tensile and impact properties in Al-Si-Cu-Mg cast alloys and their fracture mechanisms. Mater. Des. 2014, 53, 938–946. [Google Scholar] [CrossRef]

- Costa, T.A.; Dias, M.; Gomes, L.G.; Rocha, O.L.; Garcia, A. Effect of solution time in T6 heat treatment on microstructure and hardness of a directionally solidified Al-Si-Cu alloy. J. Alloy. Compd. 2016, 683, 485–494. [Google Scholar] [CrossRef]

- Choi, S.W.; Cho, H.S.; Kang, C.S.; Kumai, S. Precipitation dependence of thermal properties for Al-Si-Mg-Cu-(Ti) alloy with various heat treatment. J. Alloy. Compd. 2015, 647, 1091–1097. [Google Scholar] [CrossRef]

- Sjölander, E.; Seifeddine, S. The heat treatment of Al-Si-Cu-Mg casting alloys. J. Mater. Process. Technol. 2010, 210, 1249–1259. [Google Scholar] [CrossRef]

- El-Menshawy, K.; El-Sayed, A.W.A.; El-Bedawy, M.E.; Ahmed, H.A.; El-Raghy, S.M. Effect of aging time at low aging temperatures on the corrosion of aluminum alloy 6061. Corros. Sci. 2012, 54, 167–173. [Google Scholar] [CrossRef]

- Ceschini, L.; Morri, A.; Morri, A.; Toschi, S.; Johansson, S.; Seifeddine, S. Effect of microstructure and overaging on the tensile behavior at room and elevated temperature of CAl5Si1Cu0.5Mg-T6 cast aluminum alloy. Mater. Des. 2015, 83, 626–634. [Google Scholar] [CrossRef]

- Rojas, J.I.; Siva, B.V.; Sahoo, K.L.; Crespo, D. Viscoelastic behavior of a novel aluminum metal matrix composite and comparison with pure aluminum, aluminum alloys, and a composite made of Al-Mg-Si alloy reinforced with SiC particles. J. Alloy. Compd. 2018, 744, 445–452. [Google Scholar] [CrossRef]

- Vajravelu, K.; Prasad, K.V.; Raju, B.T. Effect of variable fluid properties on the thin flow of Ostwald-de Waele fluid over a stretching surface. J. Hydrodyn. 2013, 25, 10–19. [Google Scholar] [CrossRef]

- Baradarani, B.; Raiszadeh, R. Precipitation hardening of cast Zr-containing A356 aluminium alloy. Mater. Des. 2011, 32, 935–940. [Google Scholar] [CrossRef]

- Wang, Q.G.; Davidson, C.J. Solidification and precipitation behaviour of Al-Si-Mg casting alloys. J. Mater. Sci. 2001, 36, 739–750. [Google Scholar] [CrossRef]

- Zhu, M.; Jian, Z.Y.; Yang, G.C.; Zhou, Y.H. Effects of T6 heat treatment on the microstructure, tensile properties, and fracture behavior of the modified A356 alloys. Mater. Des. 2012, 36, 243–249. [Google Scholar] [CrossRef]

- Li, N.; Yan, H.; Wang, Z.W. Effects of heat treatment on the tribological properties of SiCp/Al-5Si-1Cu-0.5Mg composite processed by electromagnetic stirring method. Appl. Sci. 2018, 8, 372. [Google Scholar] [CrossRef]

- Knowles, A.J.; Jiang, X.; Galano, M.; Audebert, F. Microstructure and mechanical properties of 6061 Al alloy based composites with SiC nanoparticles. J. Alloy. Compd. 2014, 615, s401–s405. [Google Scholar] [CrossRef]

- Chu, H.S.; Liu, K.S.; Yeh, J.W. Study of 6061-Al2O3p composites produced by reciprocasting extrusion. Metall. Mater. Trans. A 2000, 31, 2587–2596. [Google Scholar] [CrossRef]

- Sheu, C.Y.; Lin, S.J. Aging behavior of SiCp-reinforced AA 7075 composites. J. Mater. Sci. 1997, 32, 1741–1747. [Google Scholar] [CrossRef]

- Hu, Z.; Yan, H.; Rao, Y.S.; Qiu, H.X.; Ruan, X.M. Influence of samarium content on microstructure and mechanical properties of recycled die-cast YL112 aluminum alloys. Res. Dev. 2015, 12, 269–275. [Google Scholar]

| Materials | Solution Treatment (520 ± 2 °C) | Aging Treatment (175 ± 2 °C) |

|---|---|---|

| Al5Si1Cu0.5Mg | 1, 6, 9, 12 h | 6 h |

| Composite | 1, 3, 6, 9 h | 6 h |

| Samples | Al5Si1Cu0.5Mg | Composite | Al5Si1Cu0.5Mg + T6 | Composite + T6 | |

|---|---|---|---|---|---|

| Parameters | |||||

| UTS/MPa | 191.56 ± 2.00 | 238.62 ± 2.00 | 246.54 ± 2.00 | 273.64 ± 2.00 | |

| Elongation/% | 3.81 ± 0.50 | 5.23 ± 0.50 | 5.94 ± 0.50 | 6.12 ± 0.50 | |

© 2019 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (http://creativecommons.org/licenses/by/4.0/).

Share and Cite

Li, X.; Yan, H.; Wang, Z.-W.; Li, N.; Liu, J.-L.; Nie, Q. Effect of Heat Treatment on the Microstructure and Mechanical Properties of a Composite Made of Al-Si-Cu-Mg Aluminum Alloy Reinforced with SiC Particles. Metals 2019, 9, 1205. https://doi.org/10.3390/met9111205

Li X, Yan H, Wang Z-W, Li N, Liu J-L, Nie Q. Effect of Heat Treatment on the Microstructure and Mechanical Properties of a Composite Made of Al-Si-Cu-Mg Aluminum Alloy Reinforced with SiC Particles. Metals. 2019; 9(11):1205. https://doi.org/10.3390/met9111205

Chicago/Turabian StyleLi, Xin, Hong Yan, Zhi-Wei Wang, Ning Li, Jian-Long Liu, and Qiao Nie. 2019. "Effect of Heat Treatment on the Microstructure and Mechanical Properties of a Composite Made of Al-Si-Cu-Mg Aluminum Alloy Reinforced with SiC Particles" Metals 9, no. 11: 1205. https://doi.org/10.3390/met9111205

APA StyleLi, X., Yan, H., Wang, Z.-W., Li, N., Liu, J.-L., & Nie, Q. (2019). Effect of Heat Treatment on the Microstructure and Mechanical Properties of a Composite Made of Al-Si-Cu-Mg Aluminum Alloy Reinforced with SiC Particles. Metals, 9(11), 1205. https://doi.org/10.3390/met9111205