Effect of C Addition on as-Cast Microstructures of High Nb Containing TiAl Alloys

Abstract

1. Introduction

2. Experimental Procedures

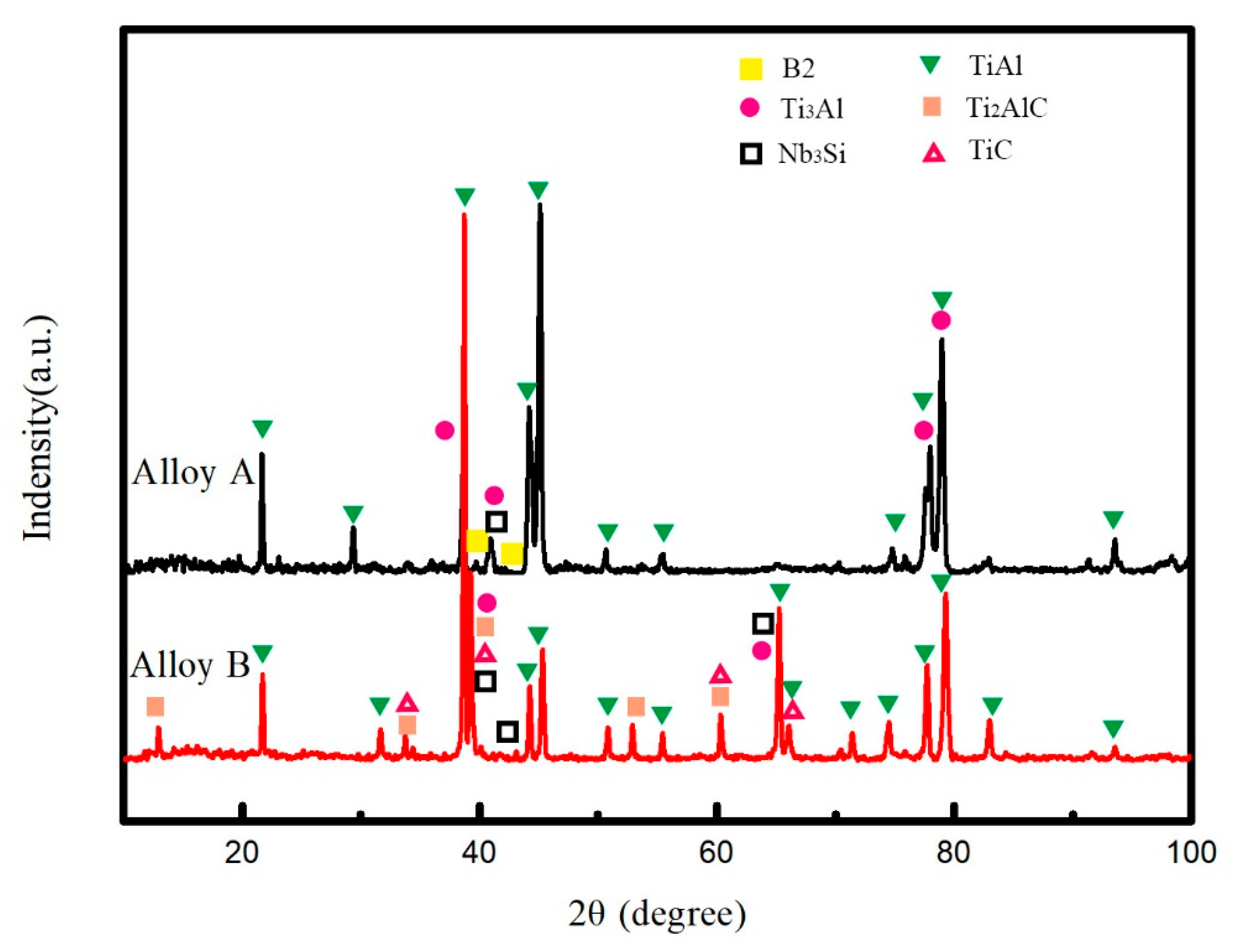

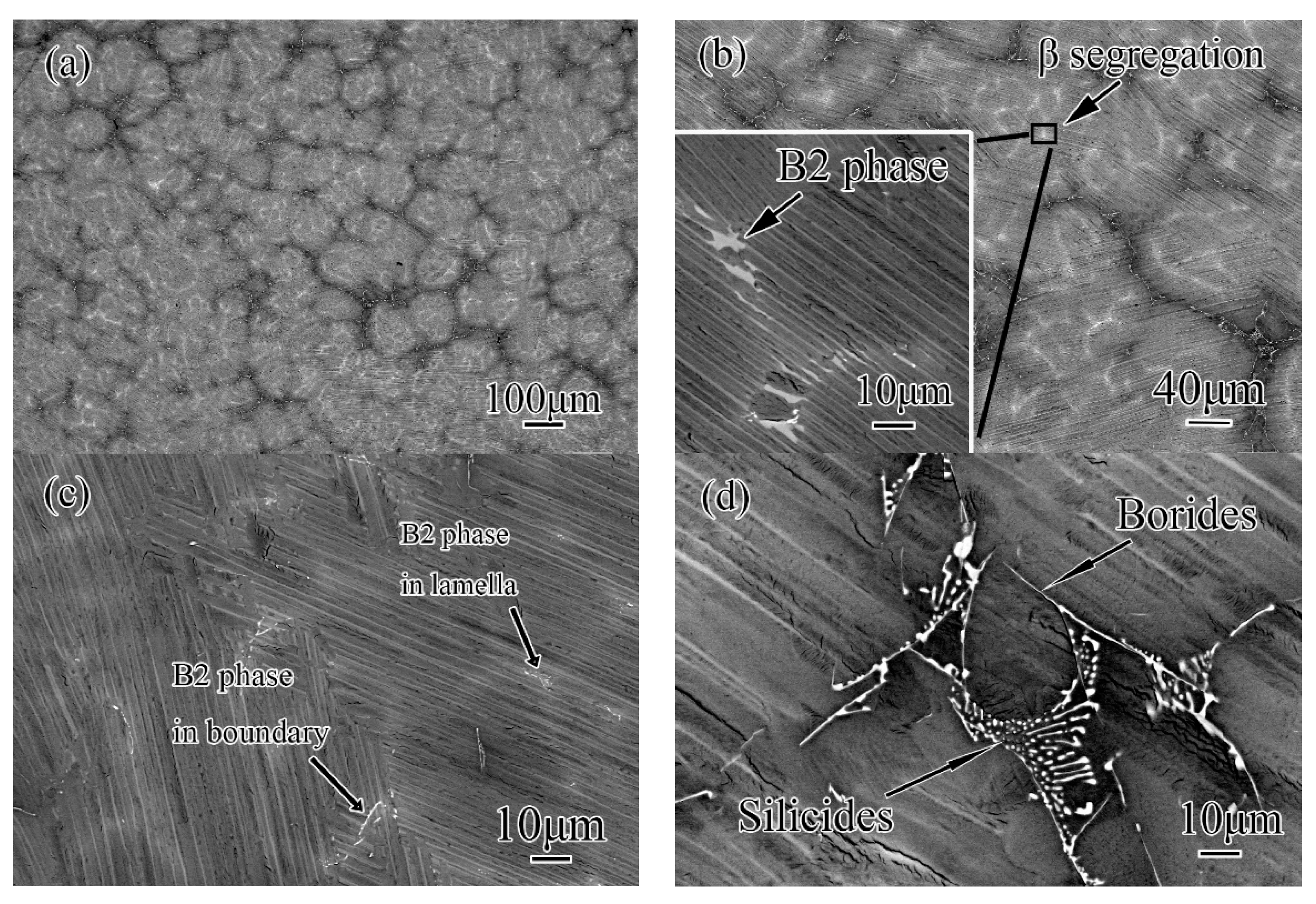

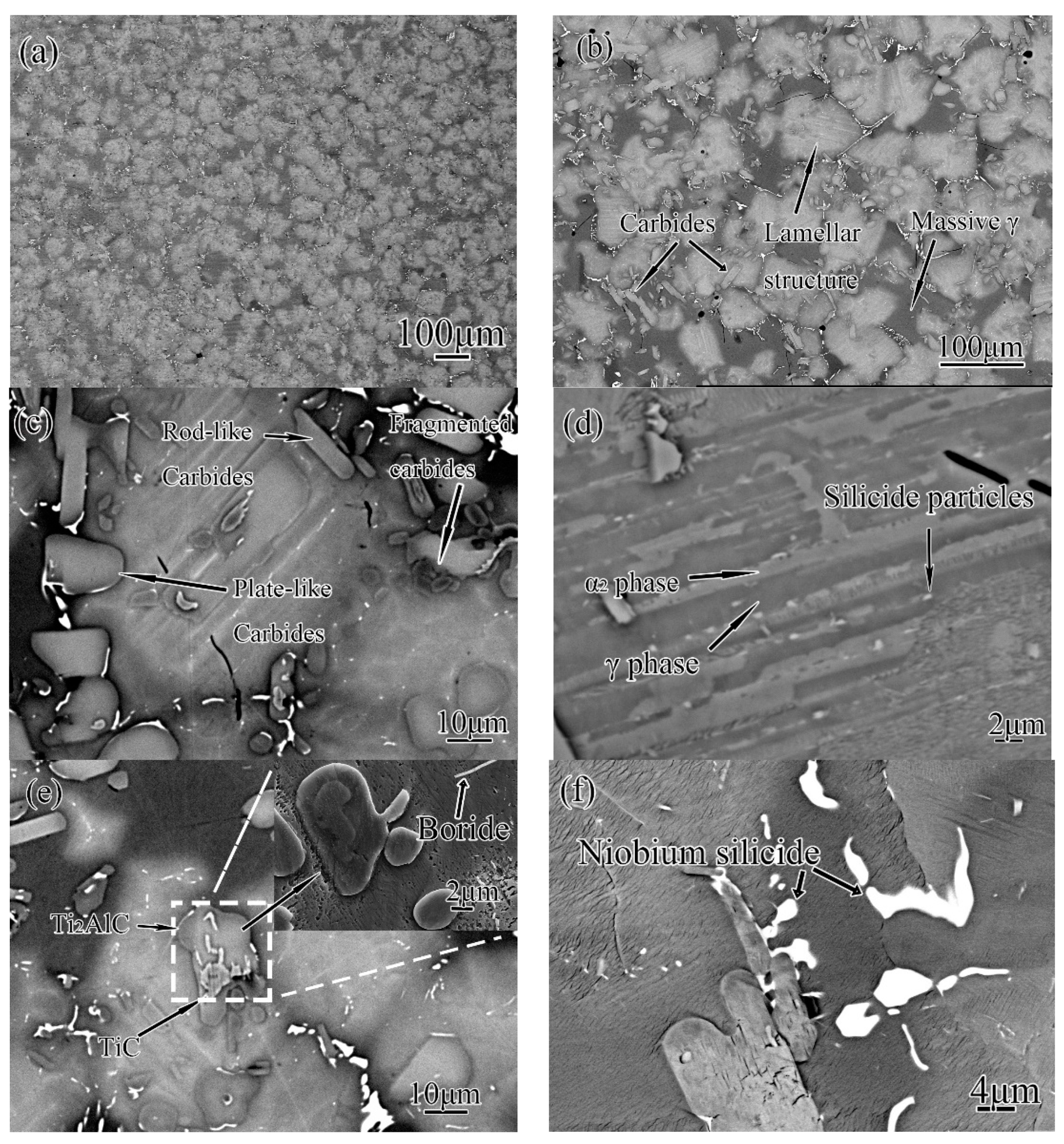

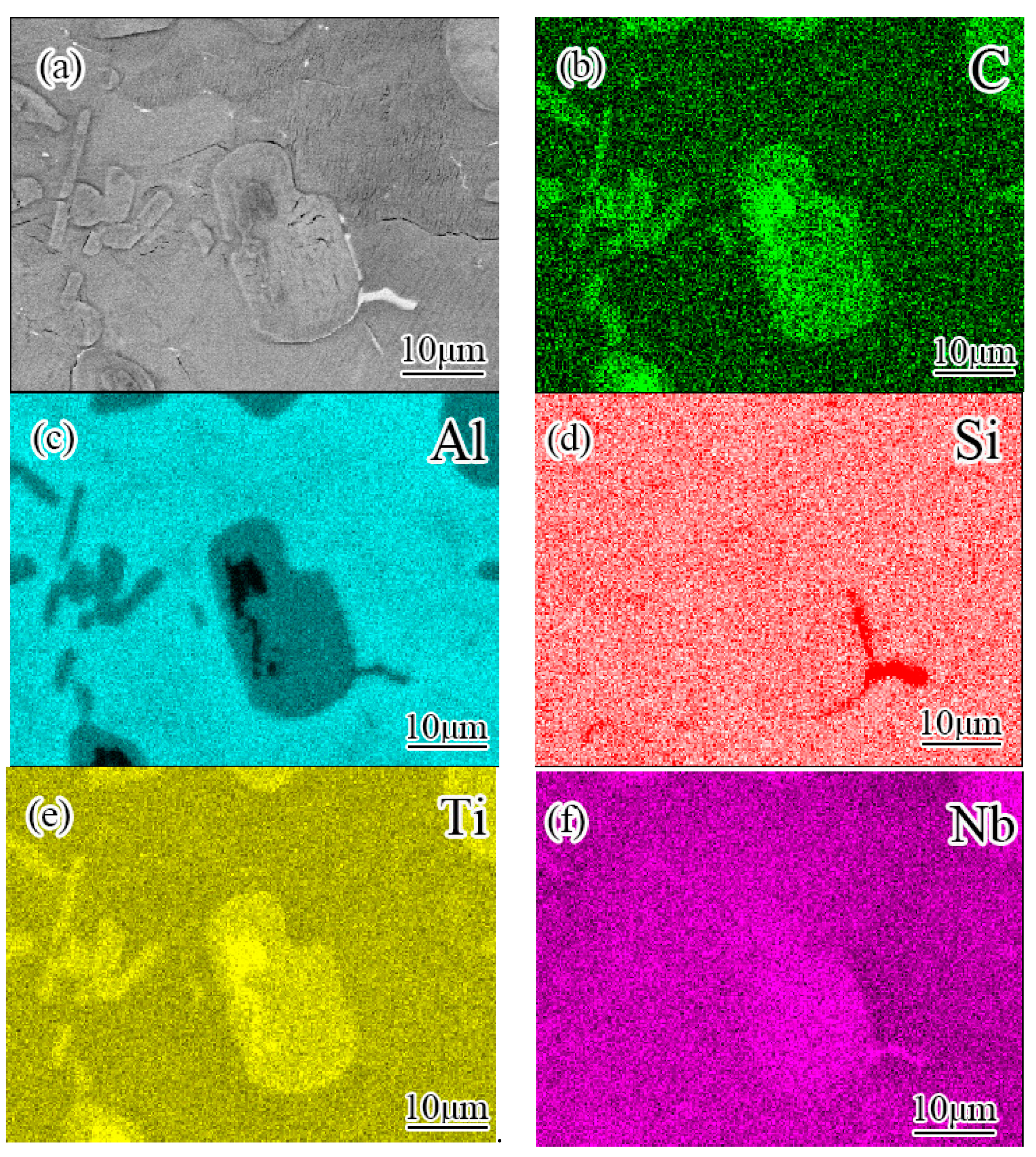

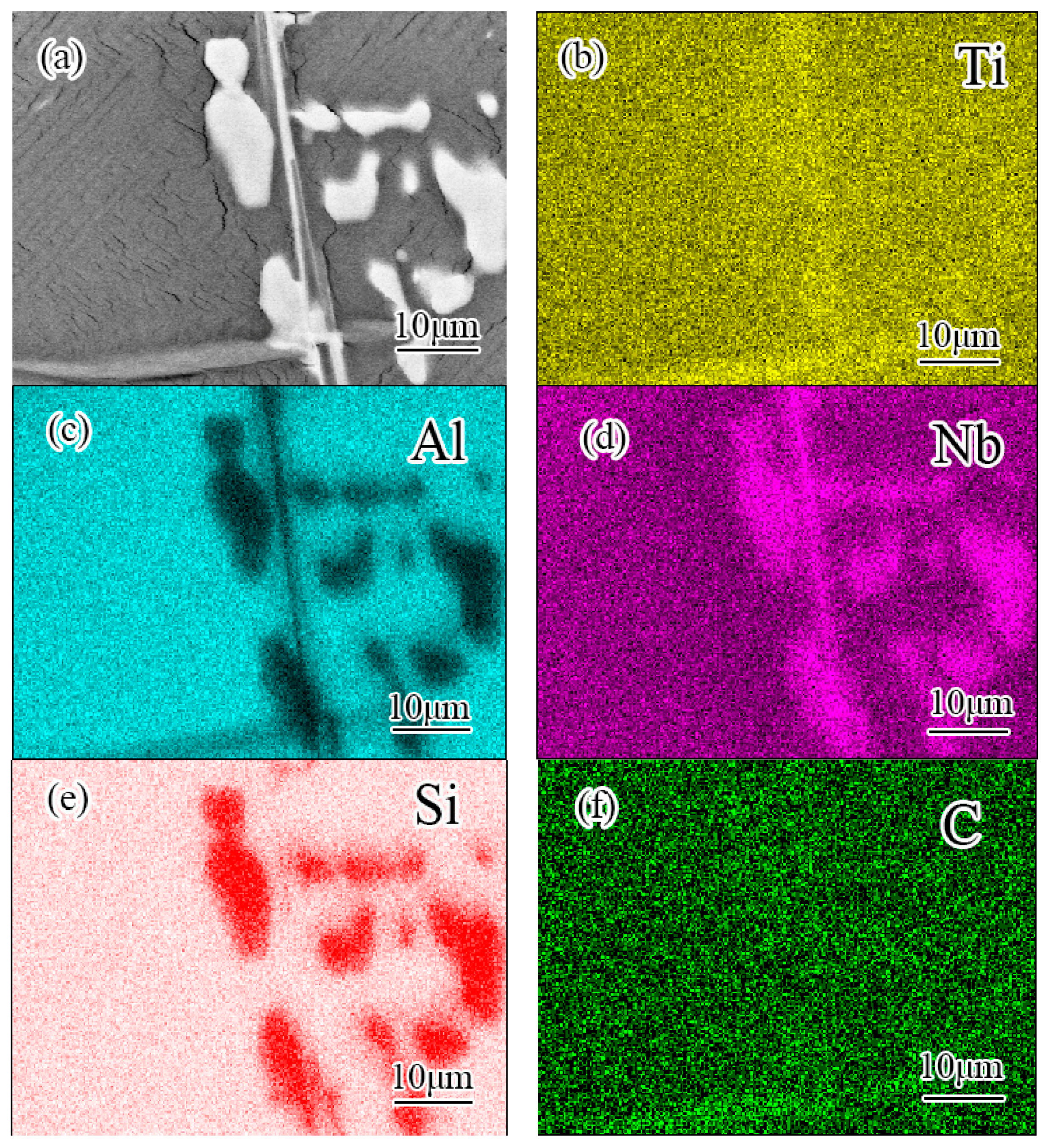

3. Results

4. Conclusions

Author Contributions

Funding

Conflicts of Interest

References

- Kim, Y.W.; Kim, S.L. Advances in Gammalloy Materials–Processes–Application Technology: Successes, Dilemmas, and Future. JOM 2018, 70, 553–560. [Google Scholar] [CrossRef]

- Clemens, H.; Mayer, S. Design, Processing, Microstructure, Properties, and Applications of Advanced Intermetallic TiAl Alloys. Adv. Eng. Mater. 2013, 15, 191–215. [Google Scholar] [CrossRef]

- Li, M.; Xiao, S.; Chen, Y.; Xu, L.; Tian, J. The effect of carbon addition on the high-temperature properties of β solidification TiAl alloys. J. Alloys Compd. 2018, 775, 441–448. [Google Scholar] [CrossRef]

- Lapin, J.; Štamborská, M.; Kamyshnykova, K.; Pelachová, T.; Klimová, A.; Bajana, O. Room temperature mechanical behaviour of cast in-situ TiAl matrix composite reinforced with carbide particles. Intermetallics 2019, 105, 113–123. [Google Scholar] [CrossRef]

- Kim, Y.W. Strength and ductility in TiAl alloy. Intermetallics 1998, 6, 623–628. [Google Scholar] [CrossRef]

- Kim, Y.W.; Kim, S.L. Effects of microstructure and C and Si additions on elevated temperature creep and fatigue of gamma TiAl alloys. Intermetallics 2014, 53, 92–101. [Google Scholar] [CrossRef]

- Lin, J.P.; Zhao, L.L.; Li, G.Y. Effect of Nb on oxidation behavior of high Nb containing TiAl alloys. Intermetallics 2011, 19, 131–136. [Google Scholar] [CrossRef]

- Chen, G.L.; Xu, X.J.; Teng, Z.K.; Wang, Y.L.; Lin, J.P. Microsegregation in high Nb containing TiAl alloy ingots beyond laboratory scale. Intermetallics 2007, 15, 625–631. [Google Scholar] [CrossRef]

- Chen, G.L.; Zhang, W.J.; Liu, Z.C.; Li, S.J. Microstructures and properties of high-Nb containing TiAl-base alloys. Gamma Titan. Alum. 1999, 1999, 371–380. [Google Scholar]

- Perdrix, F.; Trichet, M.F.; Bonnentien, J.L.; Cornet, M.; Bigot, J. Influence of nitrogen on the microstructure and mechanical properties of Ti–48Al alloy. Intermetallics 2001, 9, 147–155. [Google Scholar] [CrossRef]

- Karadge, M.; Gouma, P.I.; Kim, Y.W. Precipitation strengthening in K5-series γ -TiAl alloyed with silicon and carbon. Metall. Mater. Trans. A 2003, 34, 2129–2138. [Google Scholar] [CrossRef]

- Gerling, R.; Schimansky, F.P.; Stark, A.; Bartels, A.; Kestler, H.; Cha, L.; Scheu, C.; Clemens, H. Microstructure and mechanical properties of Ti 45Al 5Nb + (0–0.5C) sheets. Intermetallics 2008, 16, 689–697. [Google Scholar] [CrossRef]

- Scheu, C.; Stergar, E.; Schober, M.; Cha, L.; Clemens, H.; Bartels, A.; Schimansky, F.; Cerezo, A.; Stergar, E.; Schober, M. High carbon solubility in a γ-TiAl-based Ti–45Al–5Nb–0.5C alloy and its effect on hardening. Acta Mater. 2009, 57, 1504–1511. [Google Scholar] [CrossRef]

- Gabrisch, H.; Stark, A.; Schimansky, F.P.; Wang, L.; Schell, N. Investigation of carbides in Ti-45Al-5Nb-xC alloys (0 <= x <= 1) by; transmission electron microscopy and high energy-XRD. Intermetallics 2013, 33, 44–53. [Google Scholar]

- Schwaighofer, E.; Rashkova, B.; Clemens, H.; Stark, A.; Mayer, S. Effect of carbon addition on solidification behavior, phase evolution and creep properties of an intermetallic β-stabilized γ-TiAl based alloy. Intermetallics 2014, 46, 173–184. [Google Scholar] [CrossRef]

- Song, X.J.; Cui, H.Z.; Nan, H.; Na, W.; Ye, H.; Jian, T.; Qiang, S. Lamellar structure and effect of Ti 2 AlC on properties of prepared in-situ TiAl matrix composites. Ceram. Int. 2016, 42, 13586–13592. [Google Scholar] [CrossRef]

- Song, X.; Cui, H.; Ye, H.; Nan, H.; Na, W.; Lei, D.; Qiang, S. Effect of carbon reactant on microstructures and mechanical properties of TiAl/Ti2 AlC composites. Mater. Sci. Eng. A 2017, 684, 406–412. [Google Scholar] [CrossRef]

- Tan, Y.; Chen, R.; Fang, H.; Liu, Y.; Ding, H.; Su, Y.; Guo, J.; Fu, H. Microstructure evolution and mechanical properties of TiAl binary alloys added with SiC fibers. Intermetallics 2018, 98, 69–78. [Google Scholar] [CrossRef]

- Cui, S.; Cui, C.; Xie, J.; Liu, S.; Shi, J. Carbon fibers coated with graphene reinforced TiAl alloy composite with high strength and toughness. Sci. Rep. 2018, 8, 2364. [Google Scholar] [CrossRef]

- Wang, Q.; Ding, H.; Zhang, H.; Chen, R.; Guo, J.; Fu, H. Variations of microstructure and tensile property of γ-TiAl alloys with 0–0. 5at% C additives. Mater. Sci. Eng. A 2017, 700, 198–208. [Google Scholar] [CrossRef]

- Tian, W.H.; Nemoto, M. Effect of carbon addition on the microstructures and mechanical properties of γ-TiAl alloys. Intermetallics 1997, 5, 237–244. [Google Scholar] [CrossRef]

- Witusiewicz, V.T.; Hallstedt, B.; Bondar, A.A.; Hecht, U.; Sleptsov, S.V.; Velikanova, T.Y. Thermodynamic description of the Al–C–Ti system. J. Alloys Compd. 2015, 623, 480–496. [Google Scholar] [CrossRef]

- Wang, L.; Gabrisch, H.; Lorenz, U.; Schimansky, F.; Schreyer, A.; Stark, A.; Pyczak, F. Nucleation and thermal stability of carbide precipitates in high Nb containing TiAl alloys. Intermetallics 2015, 66, 111–119. [Google Scholar] [CrossRef]

- Klein, T.; Schachermayer, M.; Mendez-Martin, F.; Schöberl, T.; Rashkova, B.; Clemens, H.; Mayer, S. Carbon distribution in multi-phase γ-TiAl based alloys and its influence on mechanical properties and phase formation. Acta Mater. 2015, 94, 205–213. [Google Scholar] [CrossRef]

- Imayev, R.M.; Imayev, V.M.; Oehring, M.; Appel, F. Alloy design concepts for refined gamma titanium aluminide based alloys. Intermetallics 2007, 15, 451–460. [Google Scholar] [CrossRef]

- Witusiewicz, V.T.; Bondar, A.A.; Hecht, U.; Velikanova, T.Y. The Al–B–Nb–Ti system: IV. Experimental study and thermodynamic re-evaluation of the binary Al–Nb and ternary Al–Nb–Ti systems. J. Alloys Compd. 2009, 472, 133–161. [Google Scholar] [CrossRef]

- Lapin, J.; Štamborská, M.; Pelachová, T.; Bajana, O. Fracture behaviour of cast in-situ TiAl matrix composite reinforced with carbide particles. Mater. Sci. Eng. A 2018, 721, 1–7. [Google Scholar] [CrossRef]

- Lapin, J.; Klimová, A.; Gabalcová, Z.; Pelachová, T.; Bajana, O.; Štamborská, M. Microstructure and mechanical properties of cast in-situ TiAl matrix composites reinforced with (Ti,Nb)2AlC particles. Mater. Des. 2017, 133, 404–415. [Google Scholar] [CrossRef]

- Lapin, J.; Kamyshnykova, K. Processing, microstructure and mechanical properties of in-situ Ti3Al+TiAl matrix composite reinforced with Ti2AlC particles prepared by centrifugal casting. Intermetallics 2018, 98, 34–44. [Google Scholar] [CrossRef]

- Wu, Z.; Rui, H.; Zhang, T.; Fan, Z.; Kou, H.; Li, J. Understanding the role of carbon atoms on microstructure and phase transformation of high Nb containing TiAl alloys. Mater. Charact. 2017, 124, 1–7. [Google Scholar] [CrossRef]

- Gerstl, S.S.A.; Kim, Y.W.; Seidman, D.N. Atomic Scale Chemistry of α 2/γ Interfaces in a Multi-Component TiAl Alloy. Interface Sci. 2004, 12, 303–310. [Google Scholar] [CrossRef]

- Daloz, D.; Hecht, U.; Zollinger, J.; Combeau, H.; Hazotte, A.; Založnik, M. Microsegregation, macrosegregation and related phase transformations in TiAl alloys. Intermetallics 2011, 19, 749–756. [Google Scholar] [CrossRef]

- Bewlay, B.P.; Jackson, M.R.; Lipsitt, H.A. The Nb-Ti-Si ternary phase diagram: Evaluation of liquid- solid phase equilibria in Nb-and Ti-rich alloys. J. Phase Equilib. 1997, 18, 264. [Google Scholar] [CrossRef]

| Alloy | Ti | Al | Nb | Si | B | C |

|---|---|---|---|---|---|---|

| A (Ti45Al8Nb0.5Si0.2B) | Bal. | 46.6 | 7.5 | 0.5 | 0.2 | - |

| B (Ti45Al8Nb5C 0.5Si0.2B) | Bal. | 46.1 | 7.4 | 0.5 | 0.2 | 4.6 |

| Phases | Alloy A|Alloy B | |||||

|---|---|---|---|---|---|---|

| Ti | Al | Nb | Si | B | C | |

| Lamellar γ | 45.1 ± 0.5|37.2 ± 0.2 | 48.4 ± 0.3|54.7 ± 0.3 | 6.1 ± 0.2|5.6 ± 0.1 | 0.4 ± 0.1|0.4 ± 0.1 | 0.2 ± 0.1|0.2 ± 0.1 | -|2.0 ± 0.2 |

| Lamellar α2 | 50.5 ± 0.6|39.5 ± 0.2 | 43.3 ± 0.3|50.2 ± 0.5 | 5.9 ± 0.1|6.9 ± 0.2 | 0.42 ± 0.1|0.3 ± 0.1 | 0.1 ± 0.1|0.1 ± 0.1 | -|3.0 ± 0.1 |

| Massive γ | -|32.6 ± 0.3 | -|59.2 ± 0.6 | -|5.8 ± 0.8 | -|0.3 ± 0.1 | -|0.1 ± 0.1 | -|2.0 ± 0.2 |

| B2 particle | 51.4 ± 0.8|- | 38.6 ± 0.4|- | 9.8 ± 0.7|- | 0.1 ± 0.1|- | 0.1 ± 0.1|- | -|- |

| Ti2AlC | \|42 ± 1.3 | \|26.4 ± 0.9 | \|7.2 ± 0.3 | \|0.2 ± 0.1 | \|0.1 ± 0.1 | \|24.2 ± 1.1 |

| TiC | \|42.1 ± 0.7 | \|10.6 ± 0.5 | \|6.6 ± 0.2 | \|0.2 ± 0.1 | \|0.1 ± 0.1 | \|40.6 ± 1.8 |

| Nb3Si | 48.0 ± 0.2|44.11 ± 0.2 | 24.4 ± 0.2|42.3 ± 0.2 | 8.0 ± 0.2|10.4 ± 0.1 | 19.5 ± 0.2|3.23 ± 0.1 | 0.1 ± 0.1|0.1 ± 0.1 | \|2.7 ± 0.2 |

| Phase and Matrix | Hv Value |

|---|---|

| Ti2AlC carbide | 1068 ± 8.5 |

| Carbon-containing matrix | 917 ± 5.7 |

| Carbon-free matrix | 325 ± 4.9 |

© 2019 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (http://creativecommons.org/licenses/by/4.0/).

Share and Cite

Liu, J.; Zhang, F.; Nan, H.; Feng, X.; Ding, X. Effect of C Addition on as-Cast Microstructures of High Nb Containing TiAl Alloys. Metals 2019, 9, 1201. https://doi.org/10.3390/met9111201

Liu J, Zhang F, Nan H, Feng X, Ding X. Effect of C Addition on as-Cast Microstructures of High Nb Containing TiAl Alloys. Metals. 2019; 9(11):1201. https://doi.org/10.3390/met9111201

Chicago/Turabian StyleLiu, Jinhu, Fuqiang Zhang, Hai Nan, Xin Feng, and Xianfei Ding. 2019. "Effect of C Addition on as-Cast Microstructures of High Nb Containing TiAl Alloys" Metals 9, no. 11: 1201. https://doi.org/10.3390/met9111201

APA StyleLiu, J., Zhang, F., Nan, H., Feng, X., & Ding, X. (2019). Effect of C Addition on as-Cast Microstructures of High Nb Containing TiAl Alloys. Metals, 9(11), 1201. https://doi.org/10.3390/met9111201