Microstructural Evolution from Dendrites to Core-Shell Equiaxed Grain Morphology for CoCrFeNiVx High-Entropy Alloys in Metallic Casting Mold

Abstract

1. Introduction

2. Materials and Methods

3. Results and Discussion

3.1. Alloy Composition

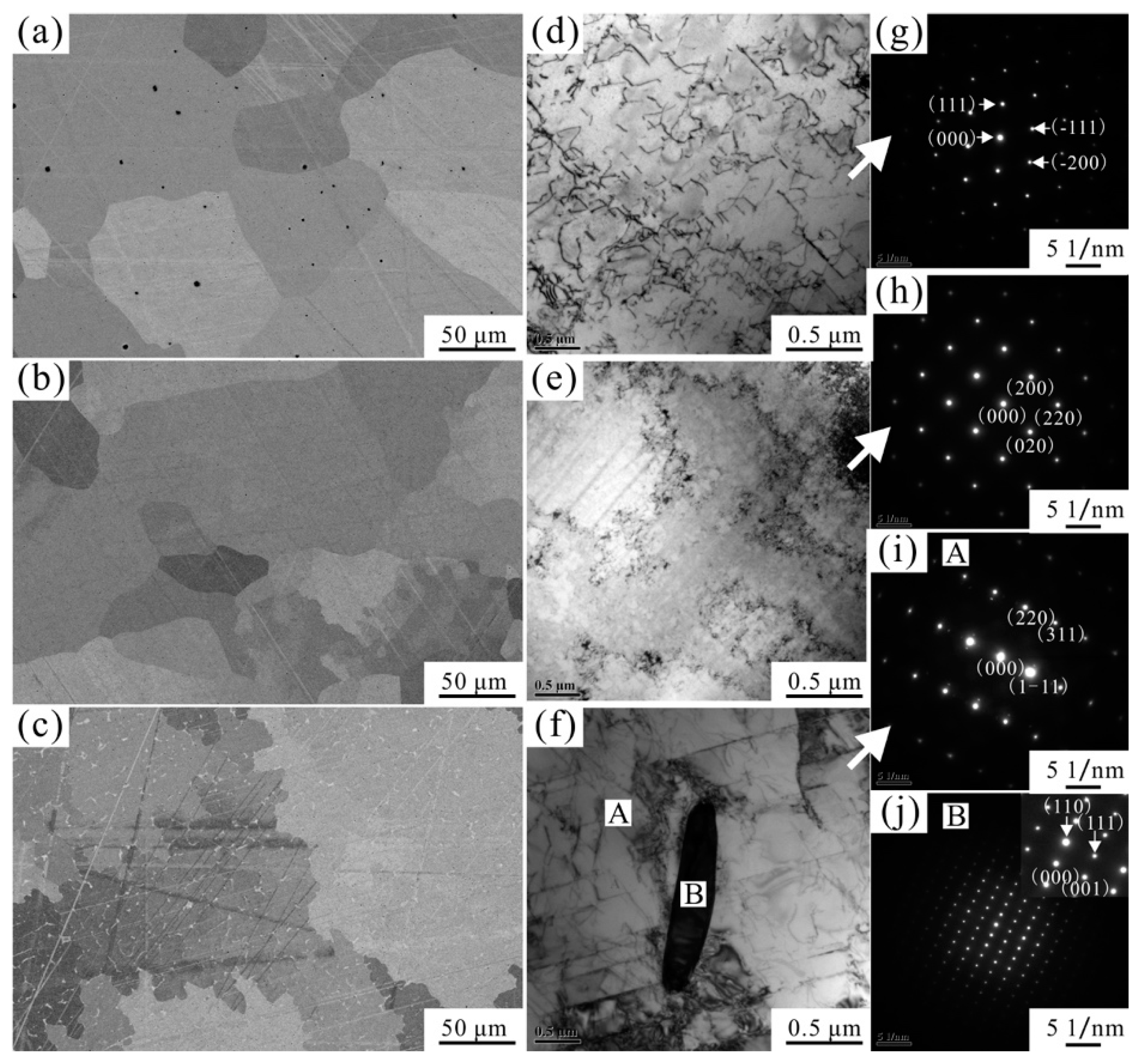

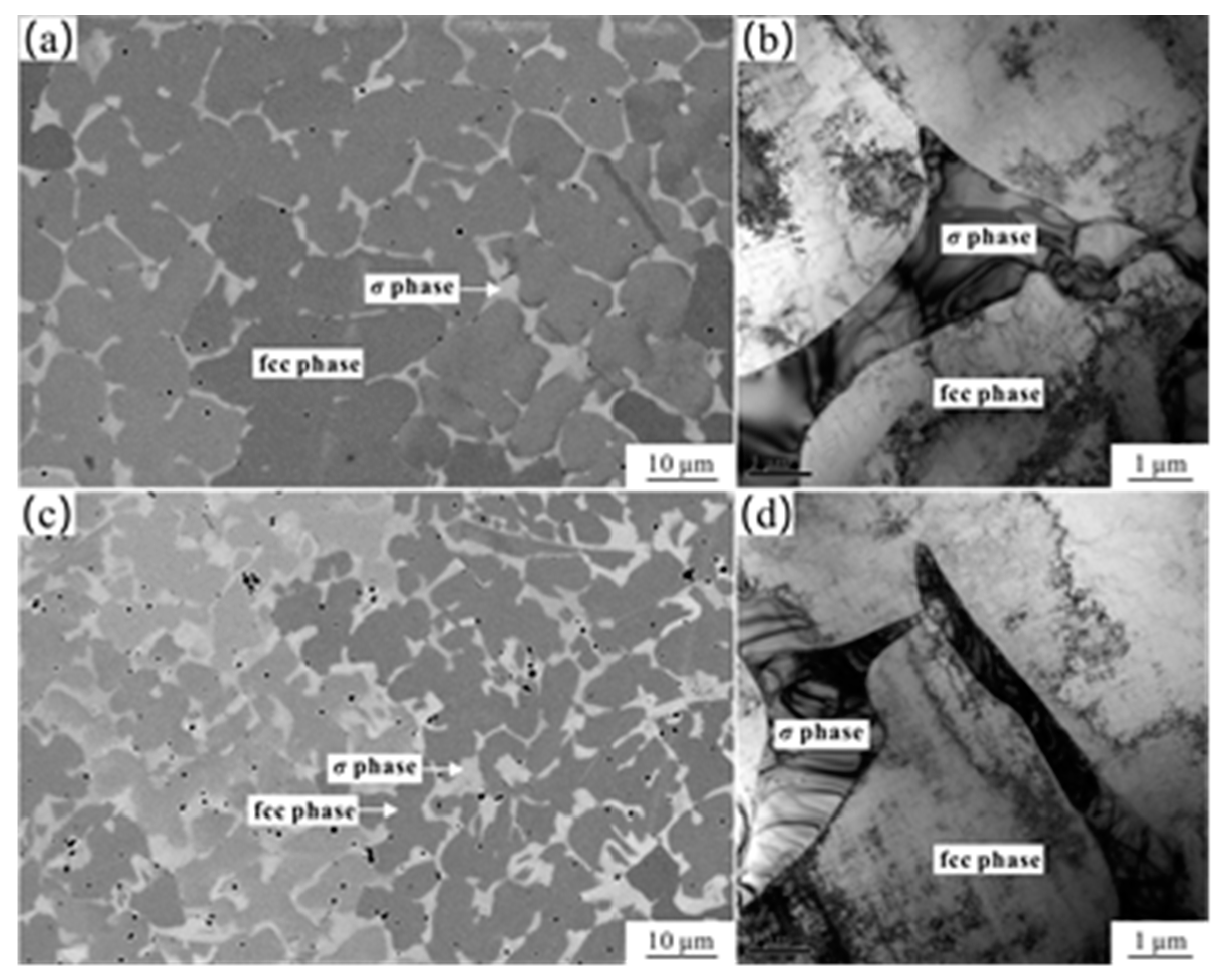

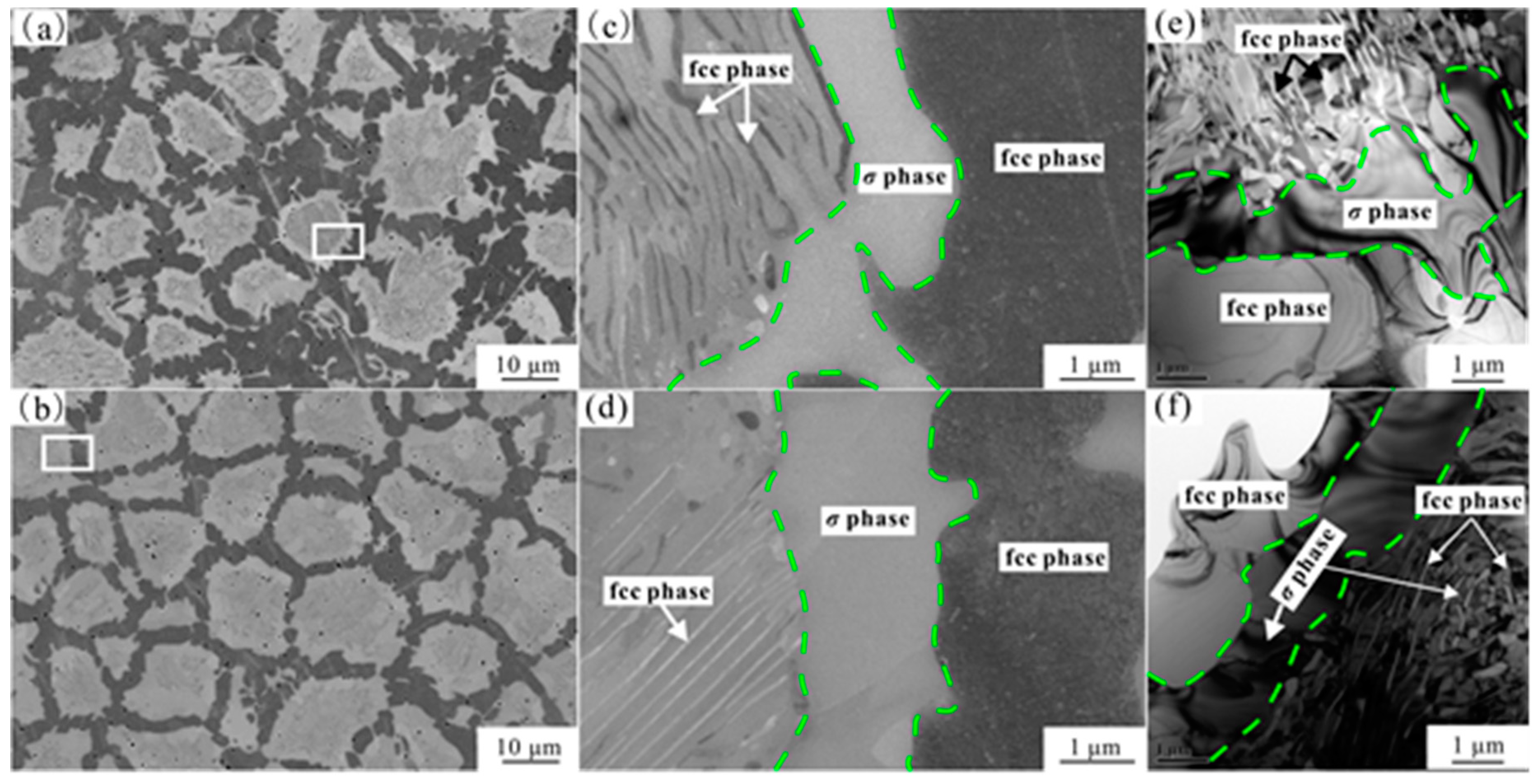

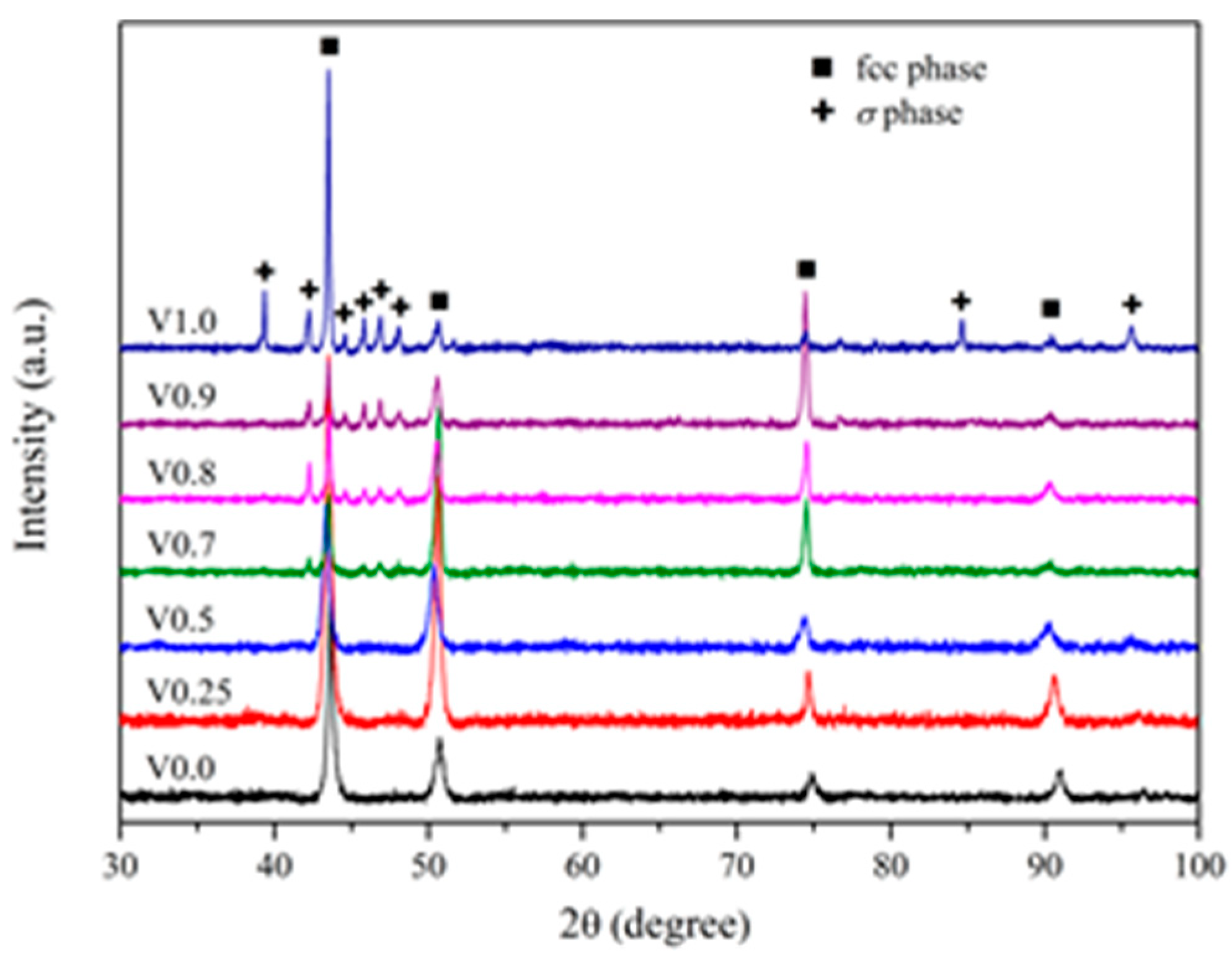

3.2. Microstructure Evolution

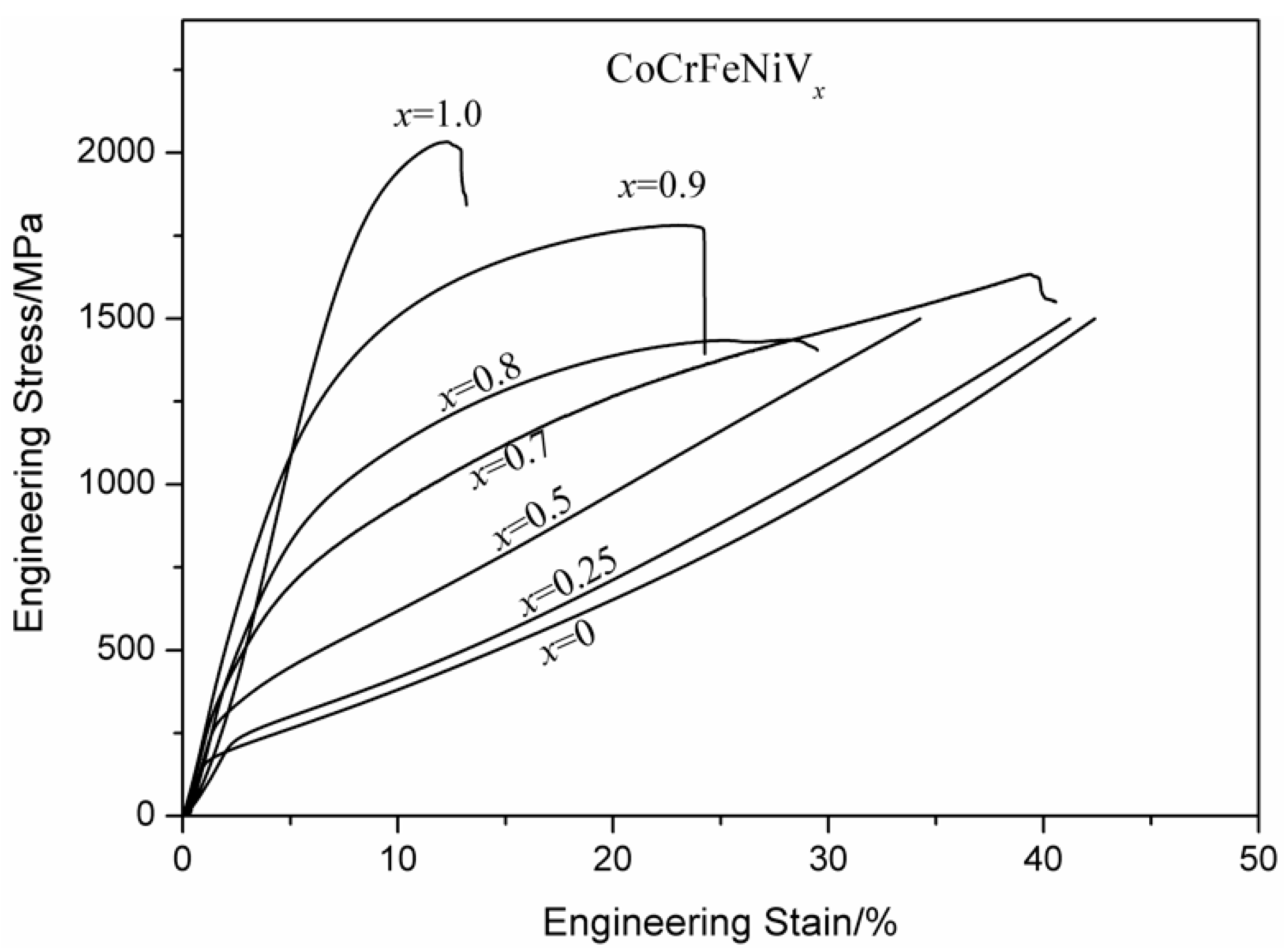

3.3. Mechanical Property

4. Conclusions

- (1)

- The addition of the V element facilitates the formation of the σ phase from the fcc matrix for the CoCrFeNiVx alloys, with a microstructure transition from a single fcc phase structure (x ≤ 0.25) to a dendrite structure (0.5 ≤ x ≤ 0.8), and finally to the distinct equiaxed grain structure (0.9 ≤ x ≤ 1.0).

- (2)

- The formation of the σ phase can effectively enhance the mechanical properties of the alloys. As the V content increased, the yield strength of the alloys first increased gradually from 164 MPa (x = 0) to 458 MPa (x = 0.8), and then increased dramatically from 722 MPa (x = 0.9) to 1493 MPa (x = 1.0).

- (3)

- The core region of the equiaxed grain in the V0.9 and V1.0 alloys presents the fcc + σ eutectoid microstructure, which is derived from the eutectoid decomposition of the unidentified metastable phase.

Author Contributions

Funding

Acknowledgments

Conflicts of Interest

References

- He, J.Y.; Liu, W.H.; Wang, H.; Wu, Y.; Liu, X.J.; Nieh, T.G.; Lu, Z.P. Effects of Al addition on structural evolution and tensile properties of the FeCoNiCrMn high-entropy alloy system. Acta Mater. 2014, 62, 105–113. [Google Scholar] [CrossRef]

- Li, X.; Lu, K. Playing with defects in metals. Nature Mater. 2017, 16, 700–701. [Google Scholar] [CrossRef]

- Wang, W.R.; Wang, W.L.; Yeh, J.W. Phases, microstructure and mechanical properties of AlxCoCrFeNi high-entropy alloys at elevated temperatures. J. Alloys Compd. 2014, 589, 143–152. [Google Scholar] [CrossRef]

- Cantor, B. Multicomponent and high entropy alloys. Entropy 2014, 16, 4749–4768. [Google Scholar] [CrossRef]

- Shahmir, H.; Mousavi, T.; He, J.; Lu, Z.P.; Kawasaki, M.; Langdon, T.G. Microstructure and properties of a CoCrFeNiMn high-entropy alloy processed by equal-channel angular pressing. Mater. Sci. Eng. A 2017, 705, 411–419. [Google Scholar] [CrossRef]

- Dong, Y.; Zhou, K.; Lu, Y.; Gao, X.; Wang, T.; Li, T. Effect of vanadium addition on the microstructure and properties of AlCoCrFeNi high entropy alloy. Mater. Des. 2014, 57, 67–72. [Google Scholar] [CrossRef]

- Takeuchi, A.; Amiya, K.; Wada, T.; Yubuta, K.; Zhang, W. High-Entropy alloys with a hexagonal close-packed structure designed by equi-atomic alloy strategy and binary phase diagrams. JOM 2014, 66, 1984–1992. [Google Scholar] [CrossRef]

- Cantor, B.; Chang, I.T.H.; Knight, P.; Vincent, A.J.B. Microstructural development in equiatomic multicomponent alloys. Mater. Sci. Eng. A 2004, 375–377, 213–218. [Google Scholar] [CrossRef]

- Ranganathan, S. Alloyed pleasures: Multimetallic cocktails. Curr. Sci. 2003, 85, 1404–1406. [Google Scholar]

- Yeh, J.W.; Chen, S.K.; Lin, S.J.; Gan, J.Y.; Chin, T.S.; Shun, T.T.; Tsau, C.H.; Chang, S.Y. Nanostructured high-entropy alloys with multiple principal elements: Novel alloy design concepts and outcomes. Adv. Eng. Mater. 2004, 6, 299–303. [Google Scholar] [CrossRef]

- Yeh, J.W. Recent progress in high-entropy alloys. Eur. J. Control 2006, 31, 633–648. [Google Scholar] [CrossRef]

- Lin, C.M.; Tsai, H.L. Evolution of microstructure, hardness, and corrosion properties of high-entropy Al0.5CoCrFeNi alloy. Intermetallics 2011, 19, 288–294. [Google Scholar] [CrossRef]

- Heczel, A.; Kawasaki, M.; Lábár, J.L.; Jang, J.; Langdon, T.G.; Gubicza, J. Defect structure and hardness in nanocrystalline CoCrFeMnNi high-entropy alloy processed by high-pressure torsion. J. Alloys Compd. 2017, 711, 143–154. [Google Scholar] [CrossRef]

- Lu, Y.; Dong, Y.; Guo, S.; Jiang, L.; Kang, H.; Wang, T.; Wen, B.; Wang, Z.; Jie, J.; Cao, Z.; et al. A promising new class of high-temperature alloys: Eutectic high-entropy alloys. Sci. Rep. 2014, 4, 6200. [Google Scholar] [CrossRef] [PubMed]

- He, J.Y.; Wang, H.; Huang, H.L.; Xu, X.D.; Chen, M.W.; Wu, Y.; Liu, X.J.; Nieh, T.G.; An, K.; Lu, Z.P. A precipitation-hardened high-entropy alloy with outstanding tensile properties. Acta Mater. 2016, 102, 187–196. [Google Scholar] [CrossRef]

- Park, J.M.; Moon, J.; Bae, J.W.; Jung, J.; Lee, S.; Kim, H.S. Effect of annealing heat treatment on microstructural evolution and tensile behavior of Al0.5CoCrFeMnNi high-entropy alloy. Mater. Sci. Eng. A 2018, 728, 251–258. [Google Scholar] [CrossRef]

- Gorr, B.; Azim, M.; Christ, H.J.; Mueller, T.; Schliephake, D.; Heilmaier, M. Phase equilibria, microstructure, and high temperature oxidation resistance of novel refractory high entropy alloys. J. Alloys Compd. 2015, 624, 270–278. [Google Scholar] [CrossRef]

- Zhang, Y.; Zuo, T.T.; Cheng, Y.Q.; Liaw, P.K. High-entropy alloys with high saturation magnetization, electrical resistivity, and malleability. Sci. Rep. 2013, 3, 1455. [Google Scholar] [CrossRef]

- Lu, Y.; Huang, H.; Gao, X.; Ren, C.; Gao, J.; Zhang, H.; Zheng, S.; Jin, Q.; Zhao, Y.; Lu, C.; et al. A promising new class of irradiation tolerant materials: Ti2ZrHfV0.5Mo0.2 high-entropy alloy. J. Mater. Sci. Technol. 2019, 35, 369–373. [Google Scholar] [CrossRef]

- Wang, W.R.; Wang, W.L.; Wang, S.C.; Tsai, Y.C.; Lai, C.H.; Yeh, J.W. Effects of Al addition on the microstructure and mechanical property of AlxCoCrFeNi high-entropy alloys. Intermetallics 2012, 26, 44–51. [Google Scholar] [CrossRef]

- Banerjee, T.; Chaudhary, V.; Gwalani, B.; Choudhuri, D.; Mikler, C.V.; Soni, V.; Alam, T.; Ramanujan, R.V.; Banerjee, R. A combinatorial approach for assessing the magnetic properties of high entropy alloys: Role of Cr in AlCoxCr1–xFeNi. Adv. Eng. Mater. 2017, 19, 1700048. [Google Scholar]

- Gwalani, B.; Soni, V.; Waseem, O.A.; Mantri, S.A.; Banerjee, R. Laser additive manufacturing of compositionally graded AlCrFeMoVx (x = 0 to 1) high-entropy alloy system. Optics Laser Technol. 2019, 113, 330–337. [Google Scholar] [CrossRef]

- Borkar, T.; Gwalani, B.; Choudhuri, D.; Mikler, C.V.; Yannetta, C.J.; Chen, X.; Ramanujan, R.V.; Styles, M.J.; Gibson, M.A.; Banerjee, R. A combinatorial assessment of AlxCrCuFeNi2 (0 < x < 1.5) complex concentrated alloys: Microstructure, microhardness, and magnetic properties. Acta Mater. 2016, 116, 63–76. [Google Scholar]

- Gludovatz, B.; Hohenwarter, A.; Catoor, D.; Chang, E.H.; George, E.P.; Ritchie, R.O. A fracture-resistant high-entropy alloy for cryogenic applications. Science 2014, 345, 1153–1158. [Google Scholar] [CrossRef] [PubMed]

- Zhang, J.Y.; Li, J.S.; Chen, Z.; Meng, Q.K.; Sun, F.; Shen, B.L. Microstructural evolution of a ductile metastable β titanium alloy with combined TRIP/TWIP effects. J. Alloys Compd. 2017, 699, 775–782. [Google Scholar] [CrossRef]

- Wu, Y.; Ma, D.; Li, Q.K.; Stoica, A.D.; Song, W.L.; Wang, H.; Liu, X.J.; Stoica, G.M.; Wang, G.Y.; An, K.; et al. Transformation-induced plasticity in bulk metallic glass composites evidenced by in-situ neutron diffraction. Acta Mater. 2017, 124, 478–488. [Google Scholar] [CrossRef]

- Li, Z.; Pradeep, K.G.; Deng, Y.; Raabe, D.; Tasan, C.C. Metastable high-entropy dual-phase alloys overcome the strength-ductility trade-off. Nature 2016, 534, 227–231. [Google Scholar] [CrossRef]

- Huang, H.; Wu, Y.; He, J.; Wang, H.; Liu, X.; Wu, W.; Lu, Z.P. Phase-transformation ductilization of Brittle high-entropy alloys via metastability engineering. Adv. Mater. 2017, 29, 1701678. [Google Scholar] [CrossRef]

- Salishchev, G.A.; Tikhonovsky, M.A.; Shaysultanov, D.G.; Stepanov, N.D.; Kuznetsov, A.V.; Kolodiy, I.V.; Tortika, A.S.; Senkov, O.N. Effect of Mn and V on structure and mechanical properties of high-entropy alloys based on CoCrFeNi system. J. Alloys Compd. 2014, 591, 11–21. [Google Scholar] [CrossRef]

- Li, J.; Jia, W.; Wang, J.; Kou, H.; Zhang, D.; Beaugnon, E. Enhanced mechanical properties of a CoCrFeNi high entropy alloy by supercooling method. Mater. Des. 2016, 95, 183–187. [Google Scholar] [CrossRef]

- Bazlov, A.I.; Churyumov, A.Y.; Louzguine-luzgin, D.V. Investigation of the structure and properties of the Fe-Ni-Co-Cu-V multiprincipal element alloys. Metall. Mater. Trans. A 2018, 49, 5646–5652. [Google Scholar] [CrossRef]

- Ahmad, R.; Cochrane, R.F.; Mullis, A.M. Disorder trapping during the solidification of βNi3Ge from its deeply undercooled melt. J. Mater. Sci. 2012, 47, 2411–2420. [Google Scholar] [CrossRef]

- Kozieł, T. Estimation of cooling rates in suction casting and copper-mould casting processes. Arch. Metall Mater. 2015, 60, 767–771. [Google Scholar] [CrossRef]

- Lindner, T.; Löbel, M.; Mehner, T.; Dietrich, D.; Lampke, T. The phase composition and microstructure of AlxCoCrFeNiTi alloys for the development of high-entropy alloy systems. Metals 2017, 7, 162. [Google Scholar] [CrossRef]

- Ahmad, R.; Cochrane, R.F.; Mullis, A.M. The formation of regular α Ni-γ (Ni31Si12) eutectic structures from undercooled Ni-25 at.% Si melts. Intermetallics 2012, 22, 55–61. [Google Scholar] [CrossRef]

- Tsai, M.H.; Yeh, J.W. High-entropy alloys: A critical review. Mater. Res. Lett. 2014, 2, 107–123. [Google Scholar] [CrossRef]

- Tsai, K.Y.; Tsai, M.H.; Yeh, J.W. Sluggish diffusion in Co-Cr-Fe-Mn-Ni high entropy alloys. Acta Mater. 2013, 61, 4887–4897. [Google Scholar] [CrossRef]

- Li, Q.; Chen, W.; Zhong, J.; Zhang, L.; Chen, Q.; Liu, Z.K. On sluggish diffusion in fcc Al–Co–Cr–Fe–Ni high-entropy alloys: An experimental and numerical study. Metals 2017, 8, 16. [Google Scholar] [CrossRef]

- Tan, Y.; Li, J.; Wang, J.; Kou, H. Seaweed eutectic-dendritic solidification pattern in a CoCrFeNiMnPd eutectic high-entropy alloy. Intermetallics 2017, 85, 74–79. [Google Scholar] [CrossRef]

- Chen, C.; Wong, K.; Krishnan, R.P.; Embs, J.P.; Chathoth, S.M. A slow atomic diffusion process in high-entropy glass-forming metallic melts. J. Phys. D: Appl. Phys. 2018, 51, 145301. [Google Scholar] [CrossRef]

- Divinski, S.V.; Pokoev, A.V.; Esakkiraja, N.; Paul, A. A mystery of “sluggish diffusion” in high-entropy alloys: The truth or a myth? Diffus. Found. 2018, 17, 69–104. [Google Scholar] [CrossRef]

- Osetsky, Y.N.; Beland, L.K.; Barashev, A.V.; Zhang, Y. On the existence and origin of sluggish diffusion in chemically disordered concentrated alloys. Curr. Opin. Solid State Mater. Sci. 2018, 22, 65–74. [Google Scholar] [CrossRef]

- Wang, R.; Chen, W.; Zhong, J.; Zhang, L. Experimental and numerical studies on the sluggish diffusion in face centered cubic Co-Cr-Cu-Fe-Ni high-entropy alloys. J. Mater. Sci. Technol. 2018, 34, 1791–1798. [Google Scholar] [CrossRef]

- Cao, L.; Cochrane, R.F.; Mullis, A.M. Solidification morphology and phase selection in drop-tube processed Ni-Fe-Si intermetallics. Intermetallics 2015, 60, 33–44. [Google Scholar] [CrossRef]

- Cao, L.; Cochrane, R.F.; Mullis, A.M. Microstructure evolution and phase formation in rapidly solidified Ni-25.3 at. pct Si alloy. Metall. Mater. Trans. A 2015, 46, 2015–4705. [Google Scholar] [CrossRef]

- Tung, C.C.; Yeh, J.W.; Shun, T.; Chen, S.K.; Huang, Y.S.; Chen, H.C. On the elemental effect of AlCoCrCuFeNi high-entropy alloy system. Mater. Lett. 2007, 61, 1–5. [Google Scholar] [CrossRef]

| Alloy | Co/at.% | Cr/at.% | Fe/at.% | Ni/at.% | V/at.% | |

|---|---|---|---|---|---|---|

| V0.0 | Nominal | 25.00 | 25.00 | 25.00 | 25.00 | - |

| Measured | 25.74 ± 0.20 | 24.97 ± 0.20 | 25.17 ± 0.19 | 24.12 ± 0.25 | - | |

| V0.25 | Nominal | 23.53 | 23.53 | 23.53 | 23.53 | 5.88 |

| Measured | 24.31 ± 0.26 | 23.47 ± 0.23 | 23.78 ± 0.36 | 22.75 ± 0.15 | 5.79 ± 0.07 | |

| V0.5 | Nominal | 22.22 | 22.22 | 22.22 | 22.22 | 11.11 |

| Measured | 22.92 ± 0.27 | 22.31 ± 0.22 | 22.38 ± 0.21 | 21.42 ± 0.32 | 10.95 ± 0.19 | |

| V0.7 | Nominal | 21.28 | 21.28 | 21.28 | 21.28 | 14.89 |

| Measured | 21.93 ± 0.25 | 21.26 ± 0.29 | 21.35 ± 0.14 | 20.67 ± 0.28 | 14.79 ± 0.14 | |

| V0.8 | Nominal | 20.83 | 20.83 | 20.83 | 20.83 | 16.67 |

| Measured | 21.46 ± 0.23 | 20.53 ± 0.26 | 21.02 ± 0.16 | 20.39 ± 0.25 | 16.60 ± 0.19 | |

| V0.9 | Nominal | 20.41 | 20.41 | 20.41 | 20.41 | 18.37 |

| Measured | 21.01 ± 0.24 | 20.35 ± 0.19 | 20.47 ± 0.20 | 19.93 ± 0.32 | 18.24 ± 0.18 | |

| V1.0 | Nominal | 20.00 | 20.00 | 20.00 | 20.00 | 20.00 |

| Measured | 20.71 ± 0.17 | 20.02 ± 0.17 | 20.09 ± 0.25 | 19.46 ± 0.23 | 19.72 ± 0.24 | |

| Alloy | Co/at.% | Cr/at.% | Fe/at.% | Ni/at.% | V/at.% | |

|---|---|---|---|---|---|---|

| V0.7 | Matrix (fcc phase) | 22.42 ± 0.22 | 20.75 ± 0.23 | 21.94 ± 0.49 | 21.23 ± 0.24 | 13.65 ± 0.52 |

| ID (σ phase) | 20.02 ± 0.37 | 25.35 ± 0.52 | 20.51 ± 0.16 | 15.91 ± 0.57 | 18.23 ± 0.33 | |

| V0.8 | Matrix (fcc phase) | 22.17 ± 0.15 | 19.79 ± 1.22 | 21.63 ± 0.24 | 21.26 ± 0.32 | 14.95 ± 0.24 |

| ID (σ phase) | 20.07 ± 0.26 | 23.34 ± 0.80 | 20.42 ± 0.32 | 16.57 ± 0.17 | 19.30 ± 0.40 | |

| V0.9 | ID (fcc phase) | 22.00 ± 0.14 | 17.72 ± 0.16 | 19.99 ± 0.11 | 23.21 ± 0.13 | 17.08 ± 0.11 |

| Shell (σ phase) | 20.13 ± 0.22 | 22.76 ± 0.58 | 20.75 ± 0.25 | 16.91 ± 0.38 | 19.46 ± 0.37 | |

| Core region | 20.72 ± 0.26 | 21.93 ± 0.22 | 21.09 ± 0.21 | 18.02 ± 0.09 | 18.25 ± 0.26 | |

| V1.0 | ID (fcc phase) | 21.66 ± 0.16 | 16.69 ± 0.45 | 19.34 ± 0.36 | 23.71 ± 0.65 | 18.60 ± 0.27 |

| Shell (σ phase) | 19.99 ± 0.23 | 21.80 ± 0.24 | 20.30 ± 0.20 | 17.22 ± 0.29 | 20.69 ± 0.20 | |

| Core region | 20.37 ± 0.26 | 21.63 ± 0.23 | 20.79 ± 0.31 | 17.85 ± 0.13 | 19.36 ± 0.32 | |

| Alloy | σy/MPa | σmax/MPa |

|---|---|---|

| V0.0 | 164 | - |

| V0.25 | 234 | - |

| V0.5 | 291 | - |

| V0.7 | 392 | 1600 |

| V0.8 | 458 | 1435 |

| V0.9 | 722 | 1825 |

| V1.0 | 1493 | 2032 |

© 2019 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (http://creativecommons.org/licenses/by/4.0/).

Share and Cite

Cao, L.; Zhu, L.; Shi, H.; Wang, Z.; Yang, Y.; Meng, Y.; Zhang, L.; Cui, Y. Microstructural Evolution from Dendrites to Core-Shell Equiaxed Grain Morphology for CoCrFeNiVx High-Entropy Alloys in Metallic Casting Mold. Metals 2019, 9, 1172. https://doi.org/10.3390/met9111172

Cao L, Zhu L, Shi H, Wang Z, Yang Y, Meng Y, Zhang L, Cui Y. Microstructural Evolution from Dendrites to Core-Shell Equiaxed Grain Morphology for CoCrFeNiVx High-Entropy Alloys in Metallic Casting Mold. Metals. 2019; 9(11):1172. https://doi.org/10.3390/met9111172

Chicago/Turabian StyleCao, Leigang, Lin Zhu, Hongde Shi, Zerui Wang, Yue Yang, Yi Meng, Leilei Zhang, and Yan Cui. 2019. "Microstructural Evolution from Dendrites to Core-Shell Equiaxed Grain Morphology for CoCrFeNiVx High-Entropy Alloys in Metallic Casting Mold" Metals 9, no. 11: 1172. https://doi.org/10.3390/met9111172

APA StyleCao, L., Zhu, L., Shi, H., Wang, Z., Yang, Y., Meng, Y., Zhang, L., & Cui, Y. (2019). Microstructural Evolution from Dendrites to Core-Shell Equiaxed Grain Morphology for CoCrFeNiVx High-Entropy Alloys in Metallic Casting Mold. Metals, 9(11), 1172. https://doi.org/10.3390/met9111172