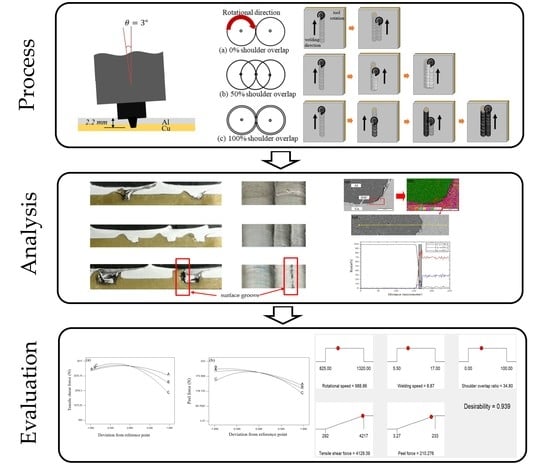

Effect of Process Parameters on Interfacial Bonding Properties of Aluminium–Copper Clad Sheet Processed by Multi-Pass Friction Stir-Welding Technique

Abstract

1. Introduction

2. Materials and Methods

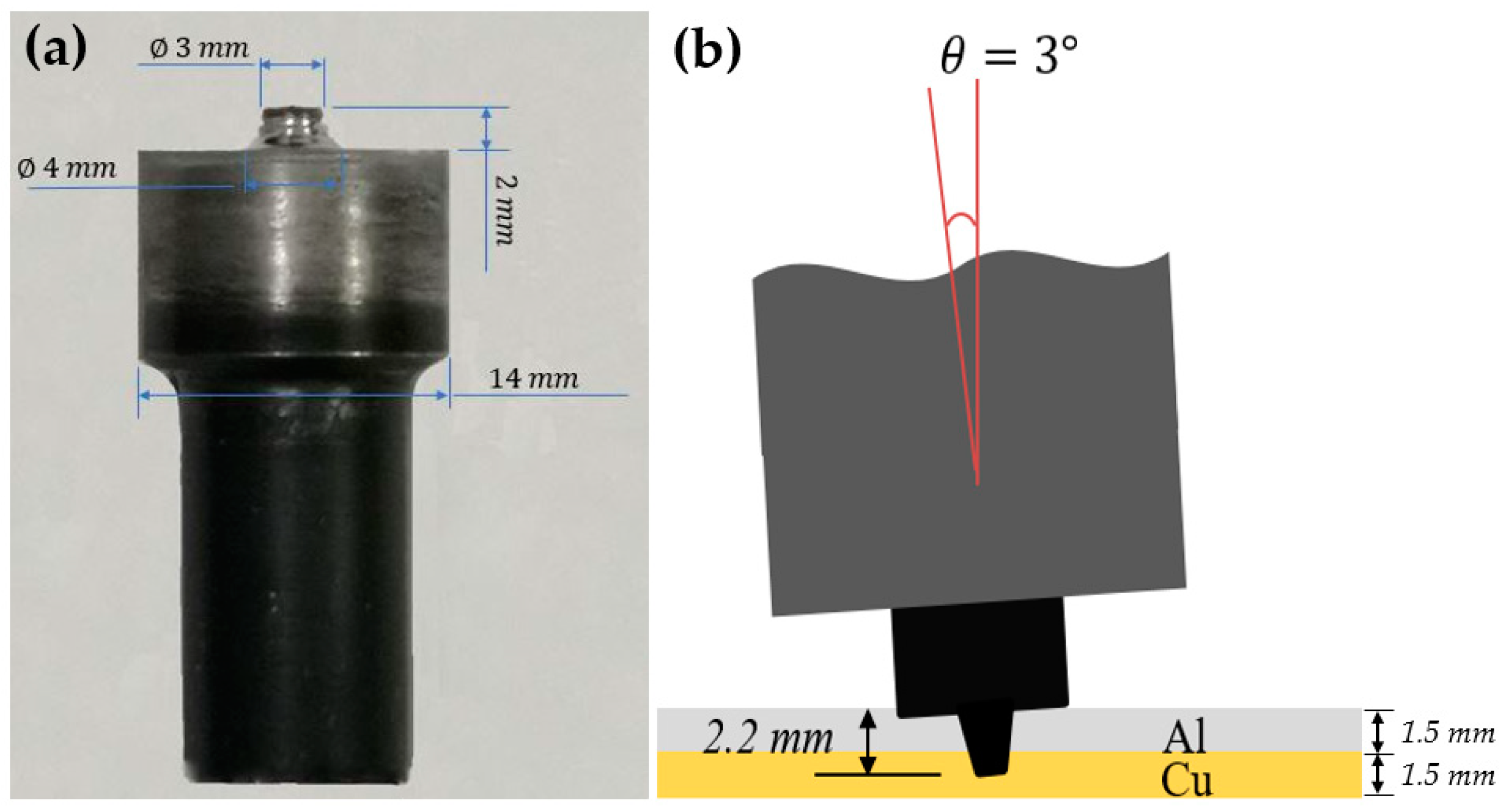

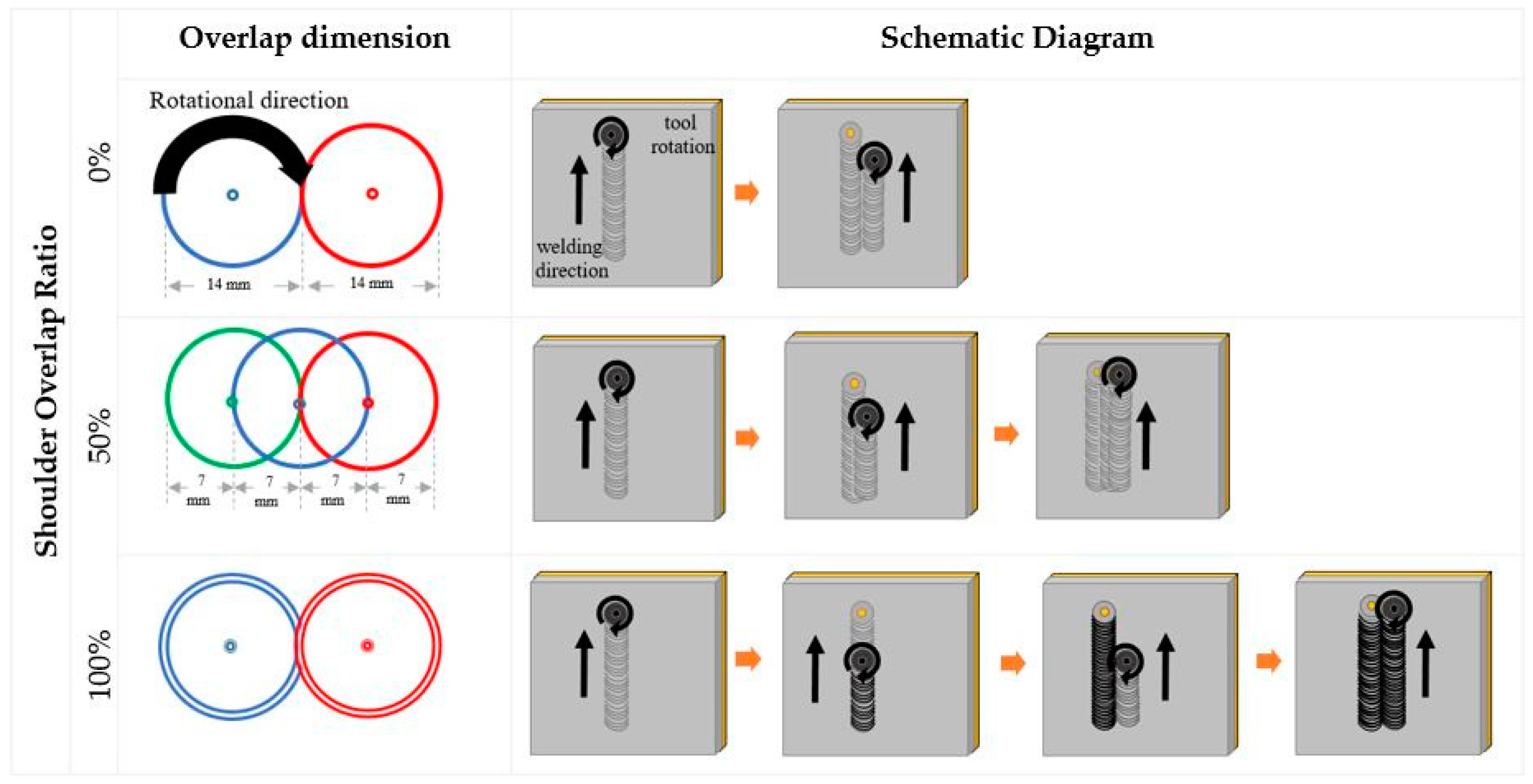

2.1. Materials Used and Identification of Process Parameters

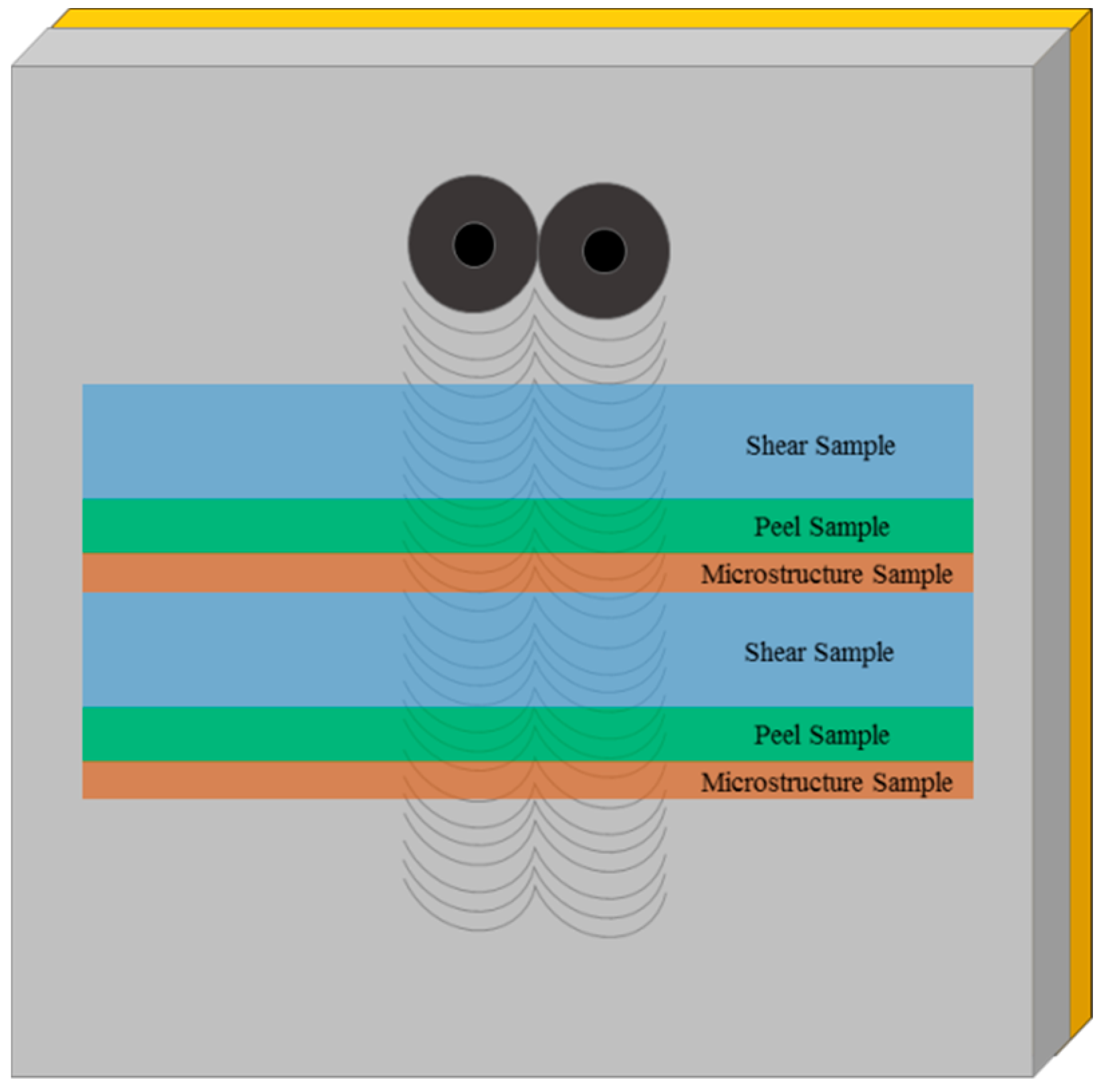

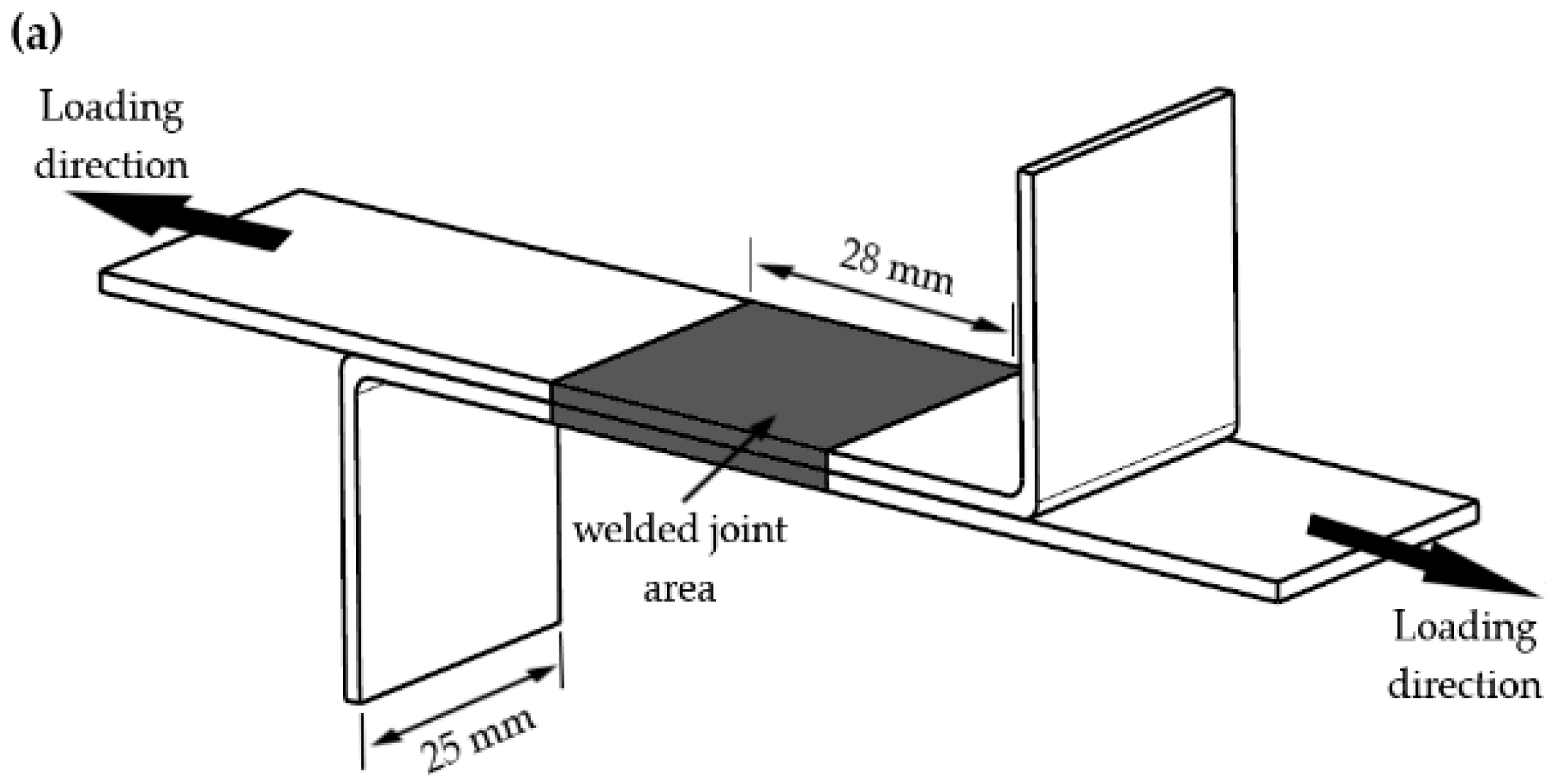

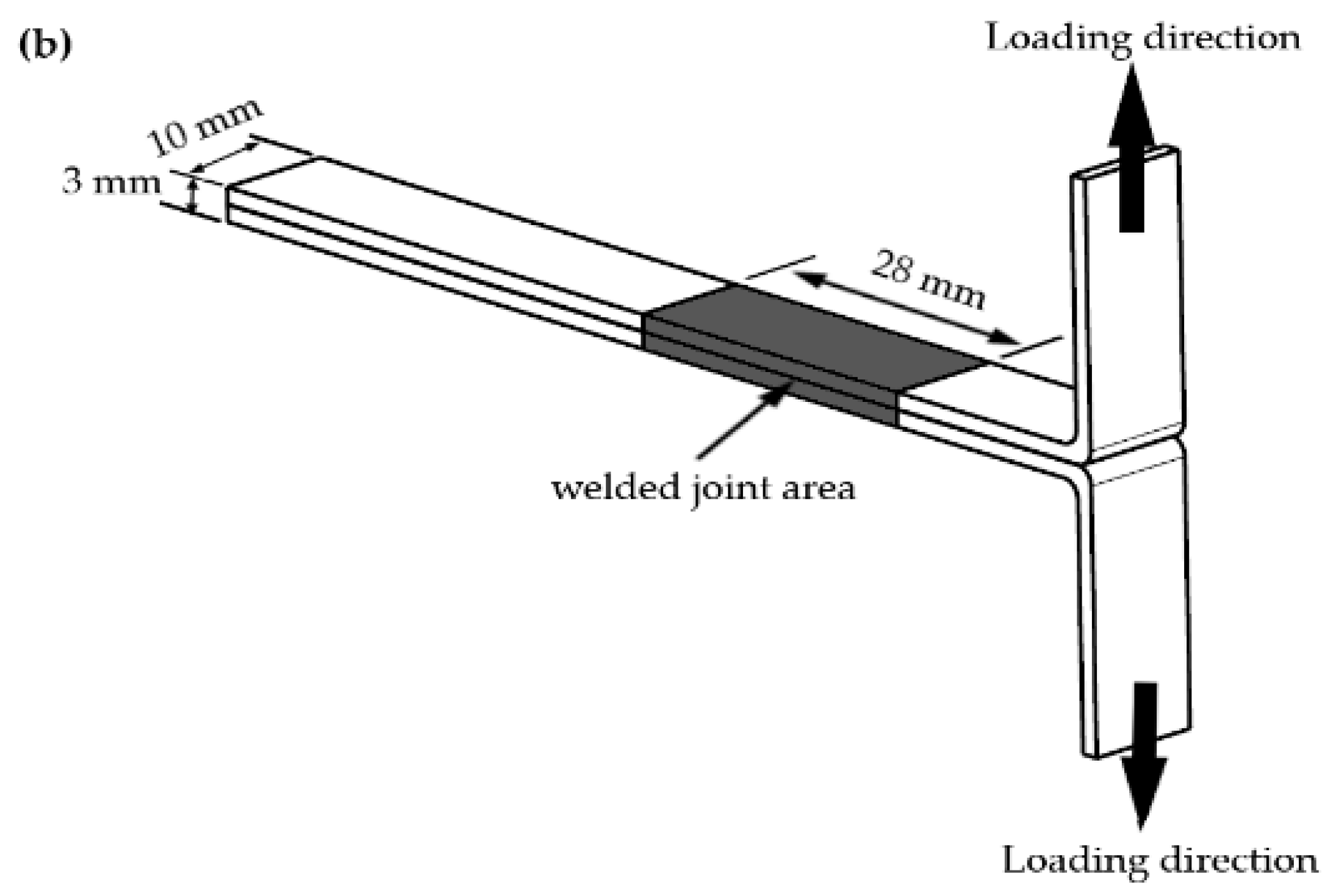

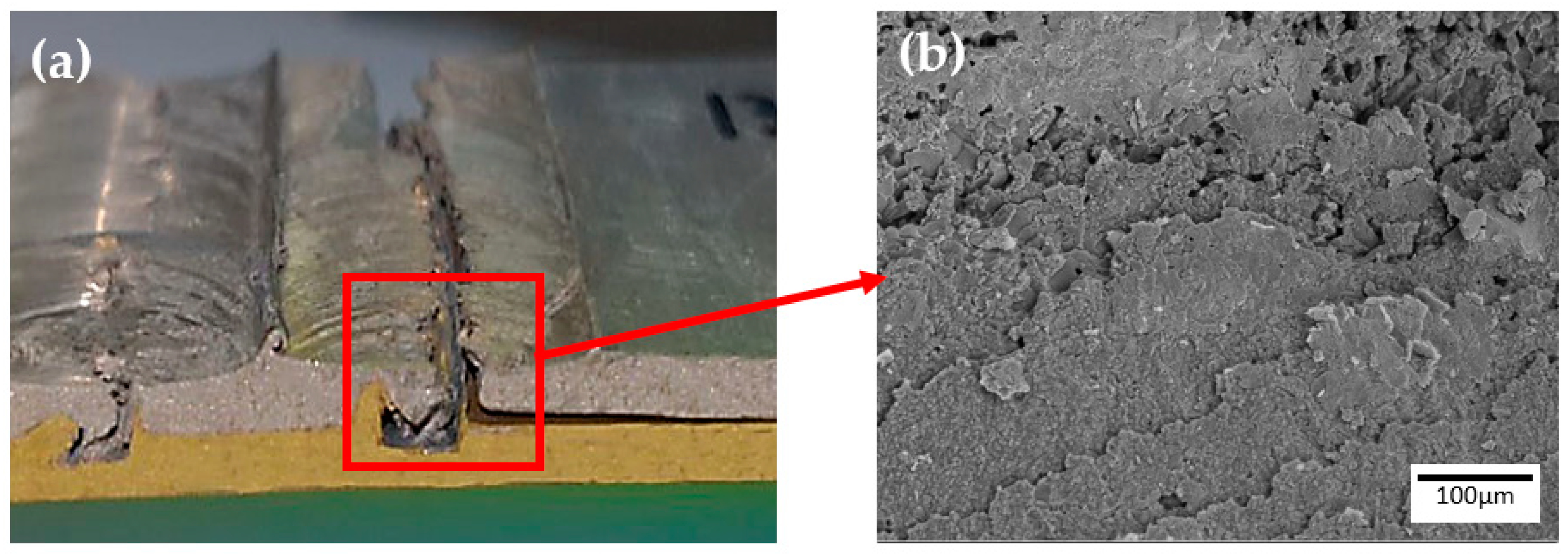

2.2. Evaluation of the Process Parameters

2.3. Design of Experiments

3. Results

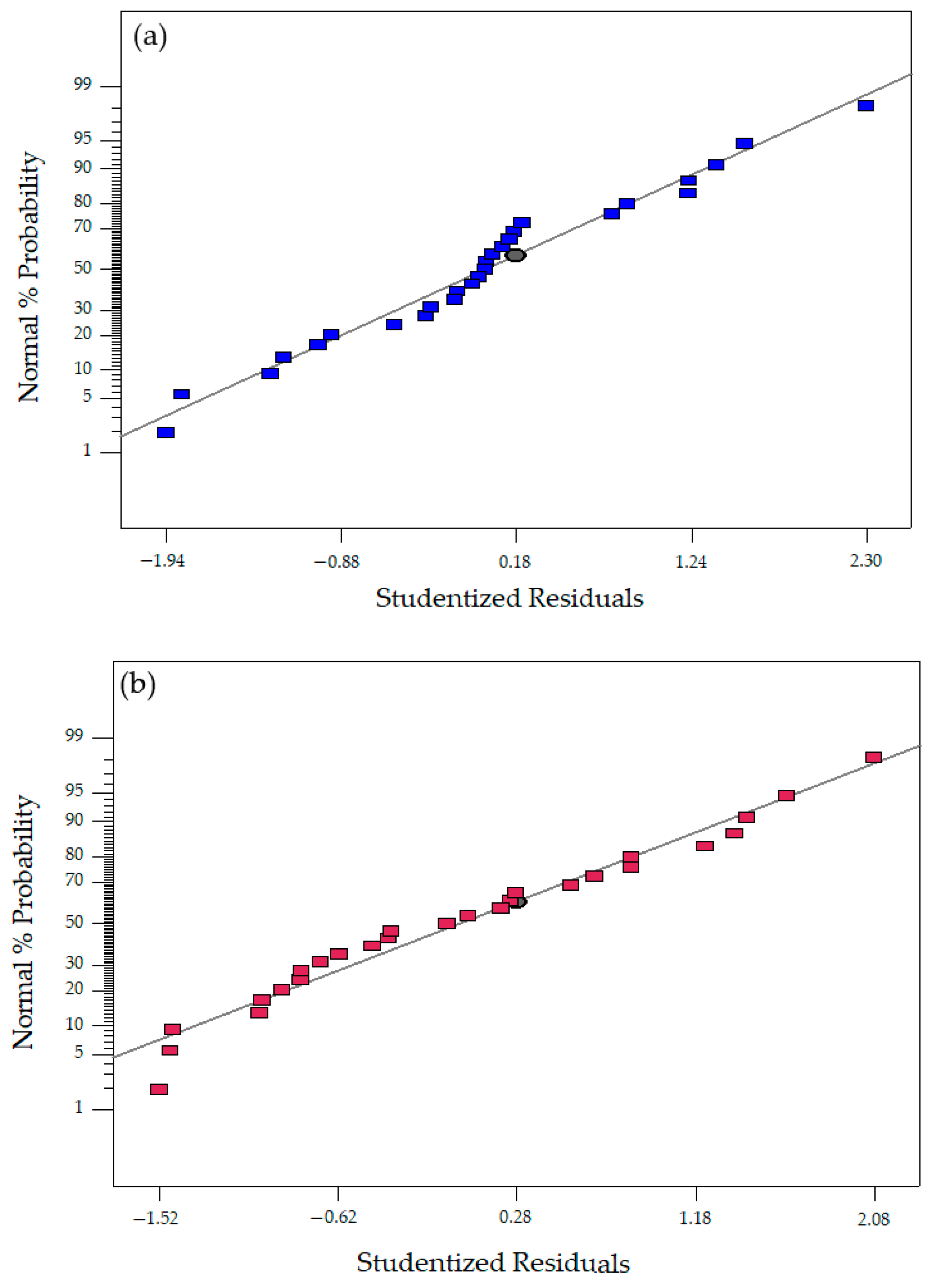

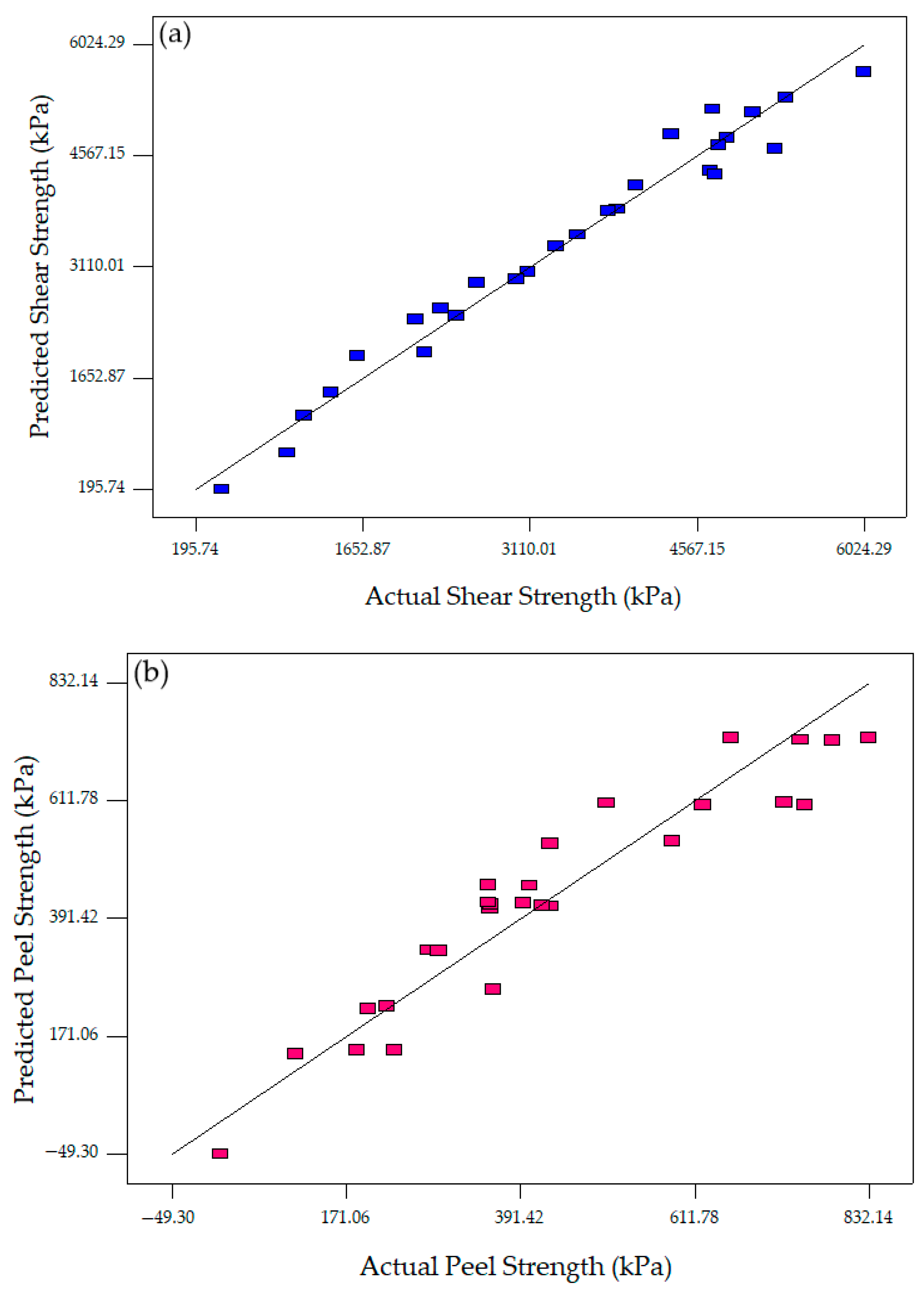

3.1. Analysis of Variance (ANOVA) Analysis and Regression Model

4. Discussions

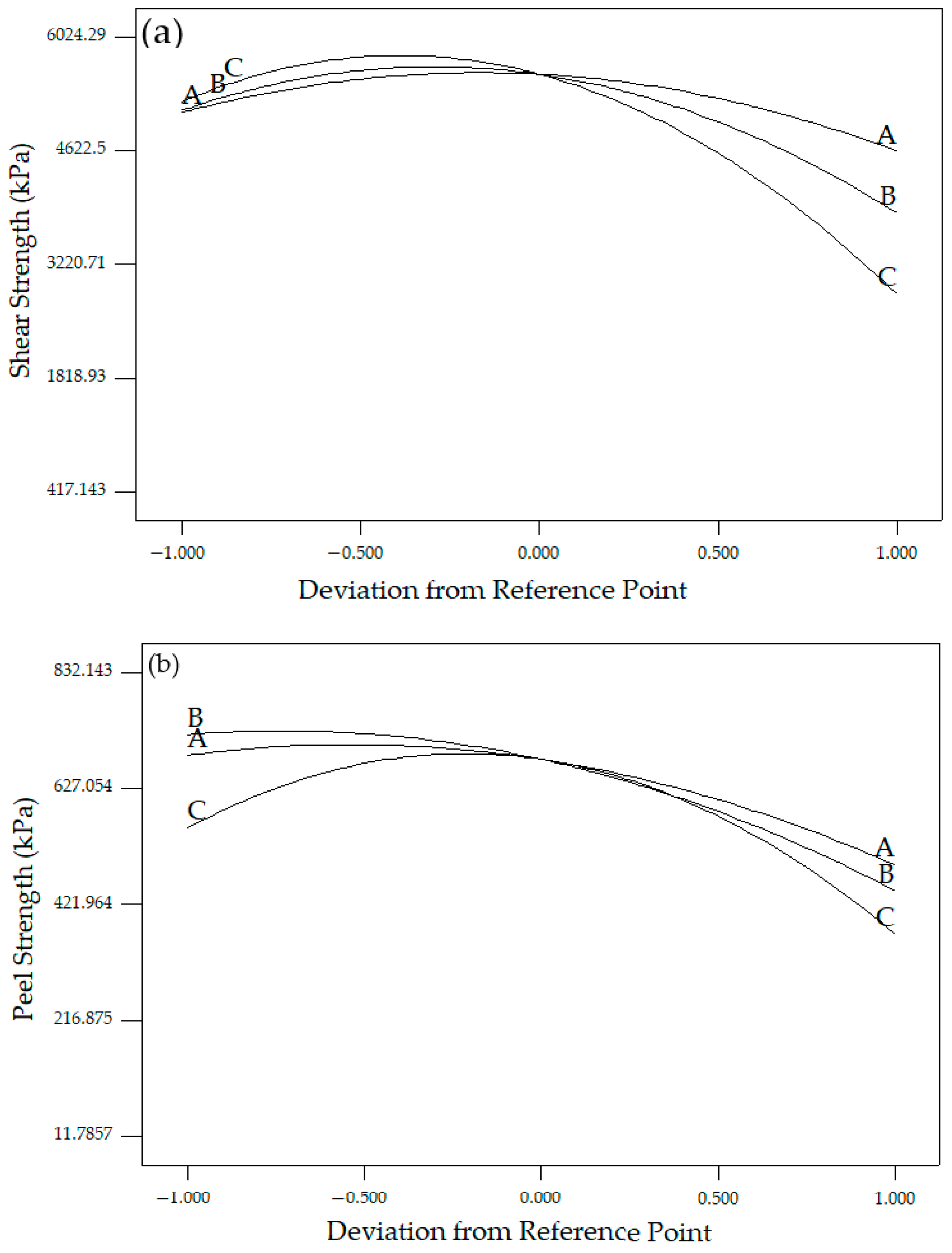

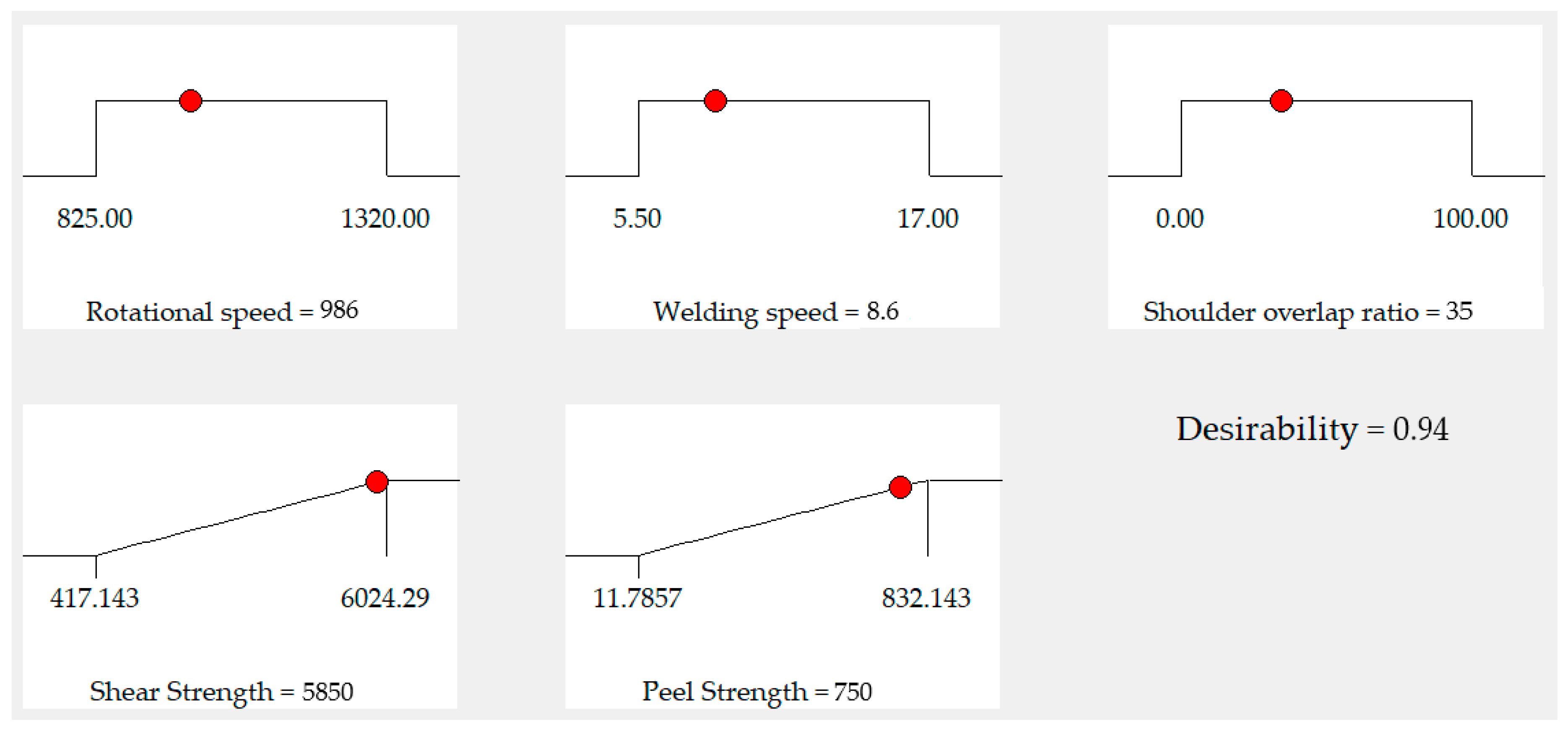

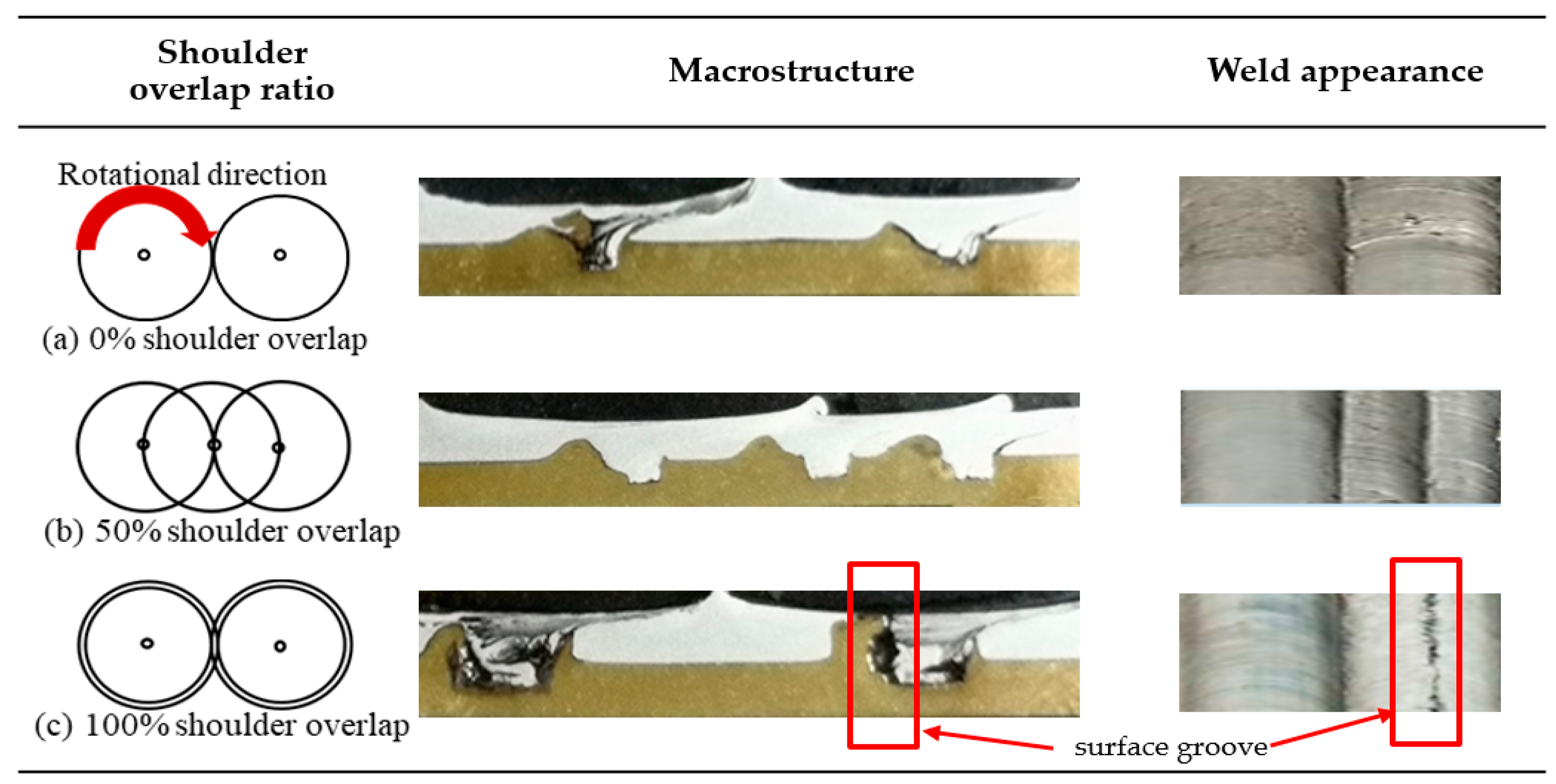

4.1. Effect of Friction Stir-Welding (FSW) Process Parameters on and

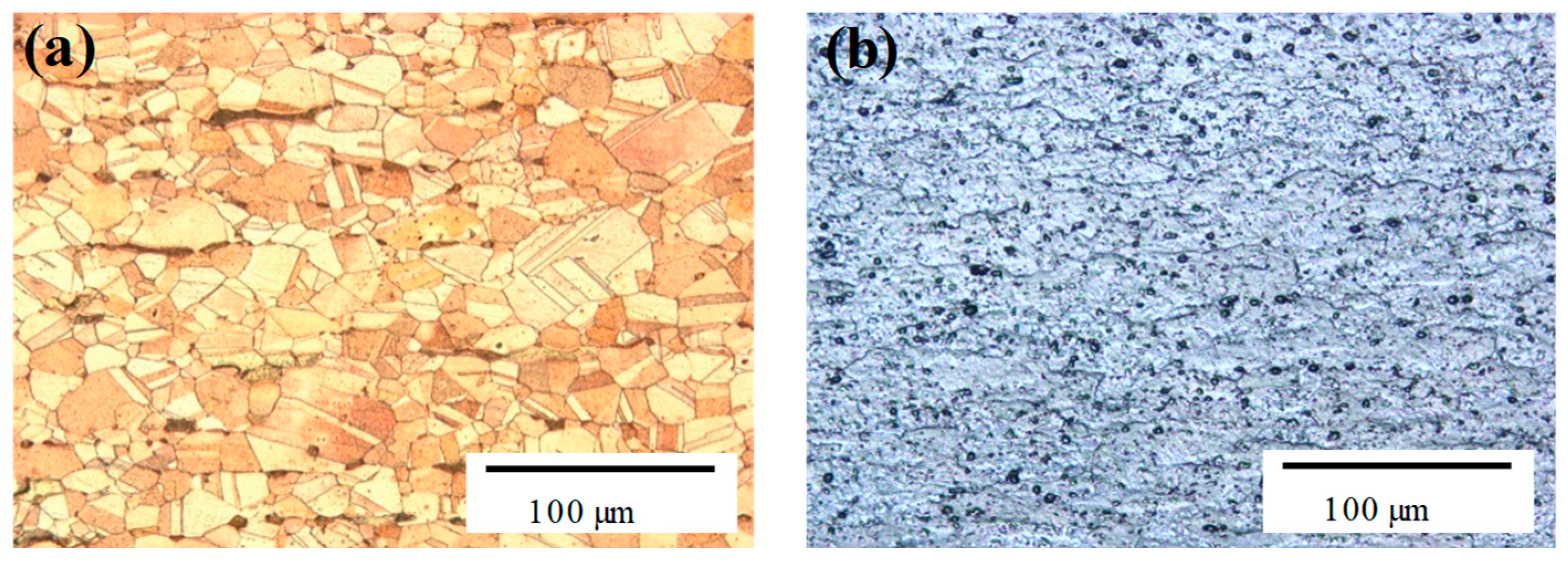

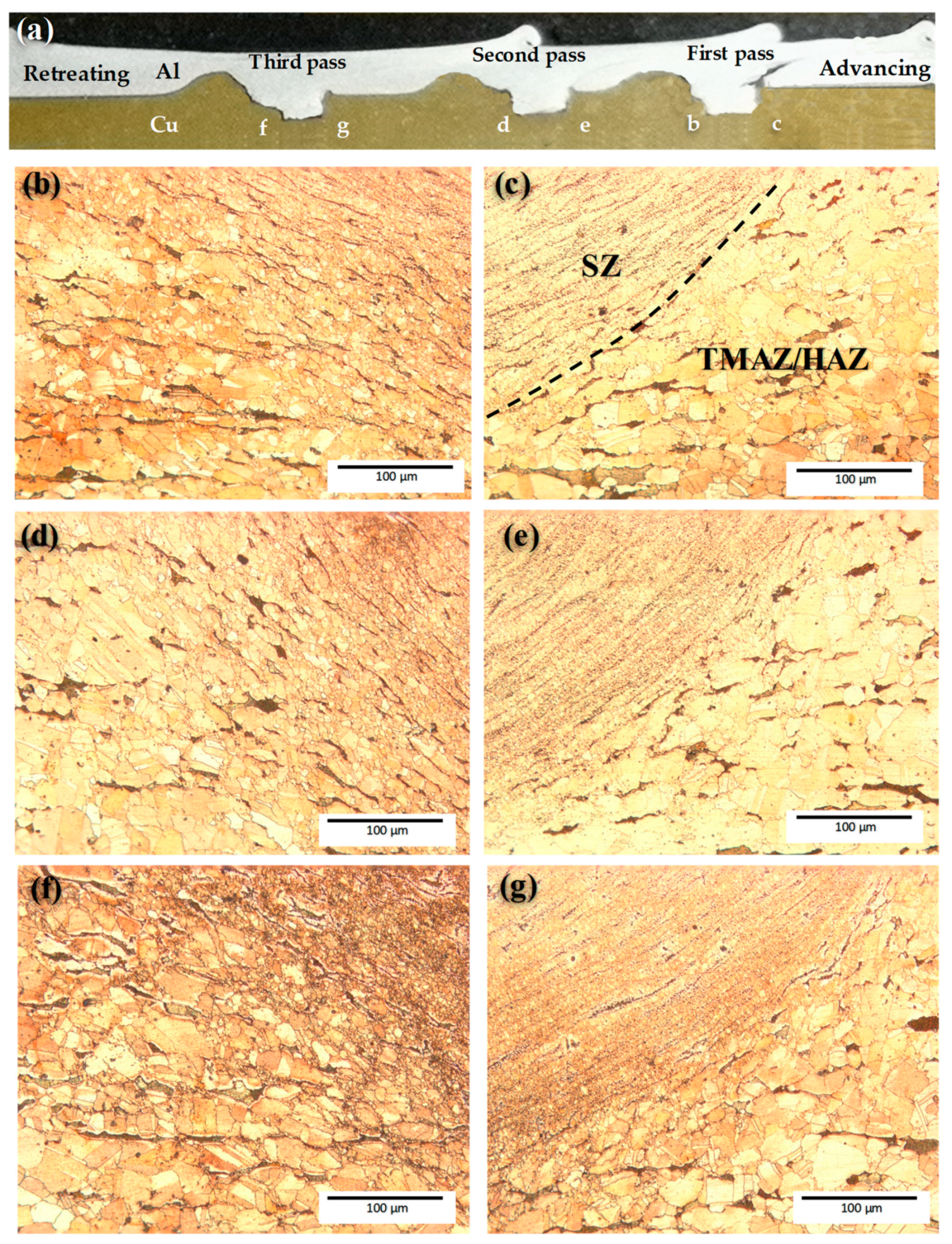

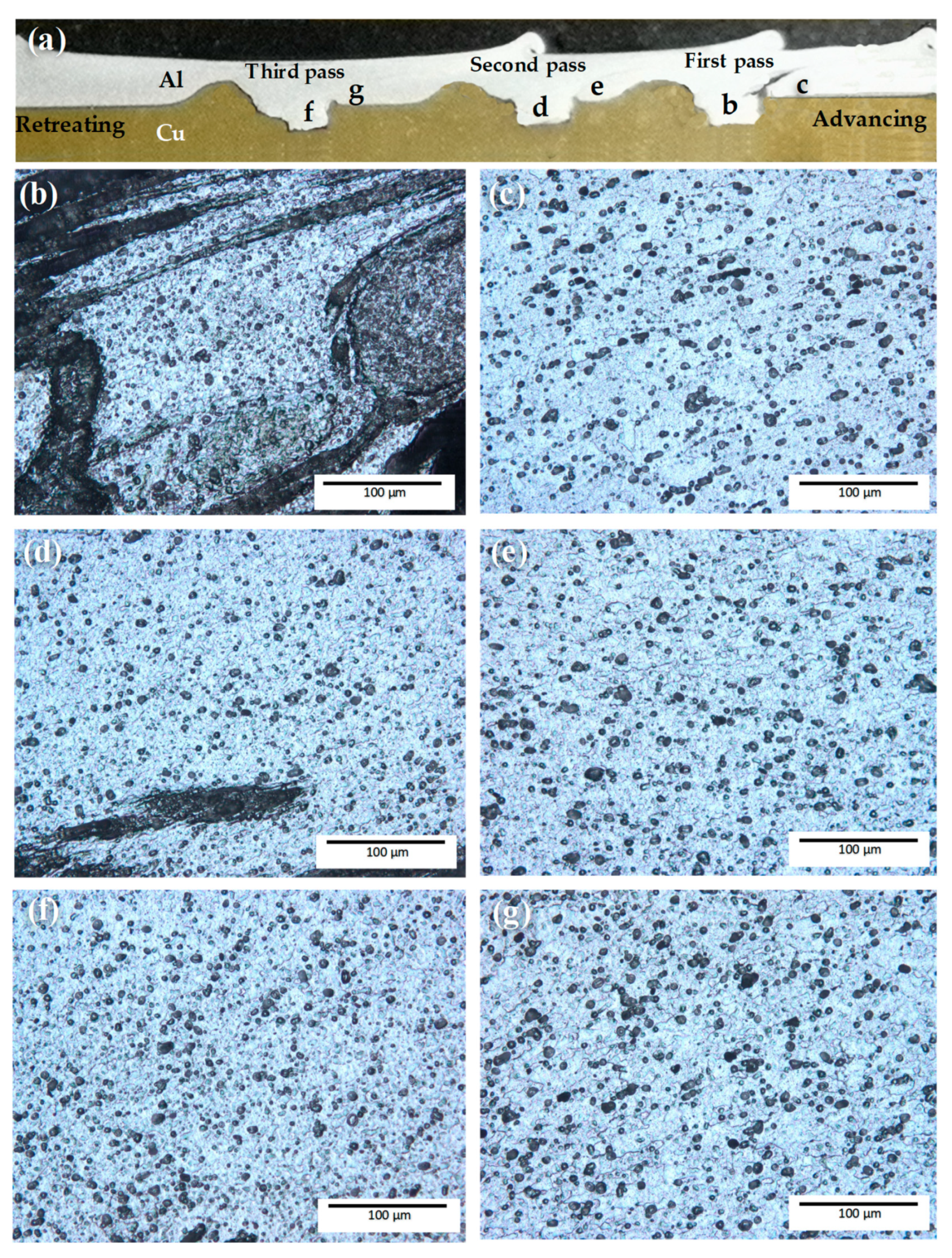

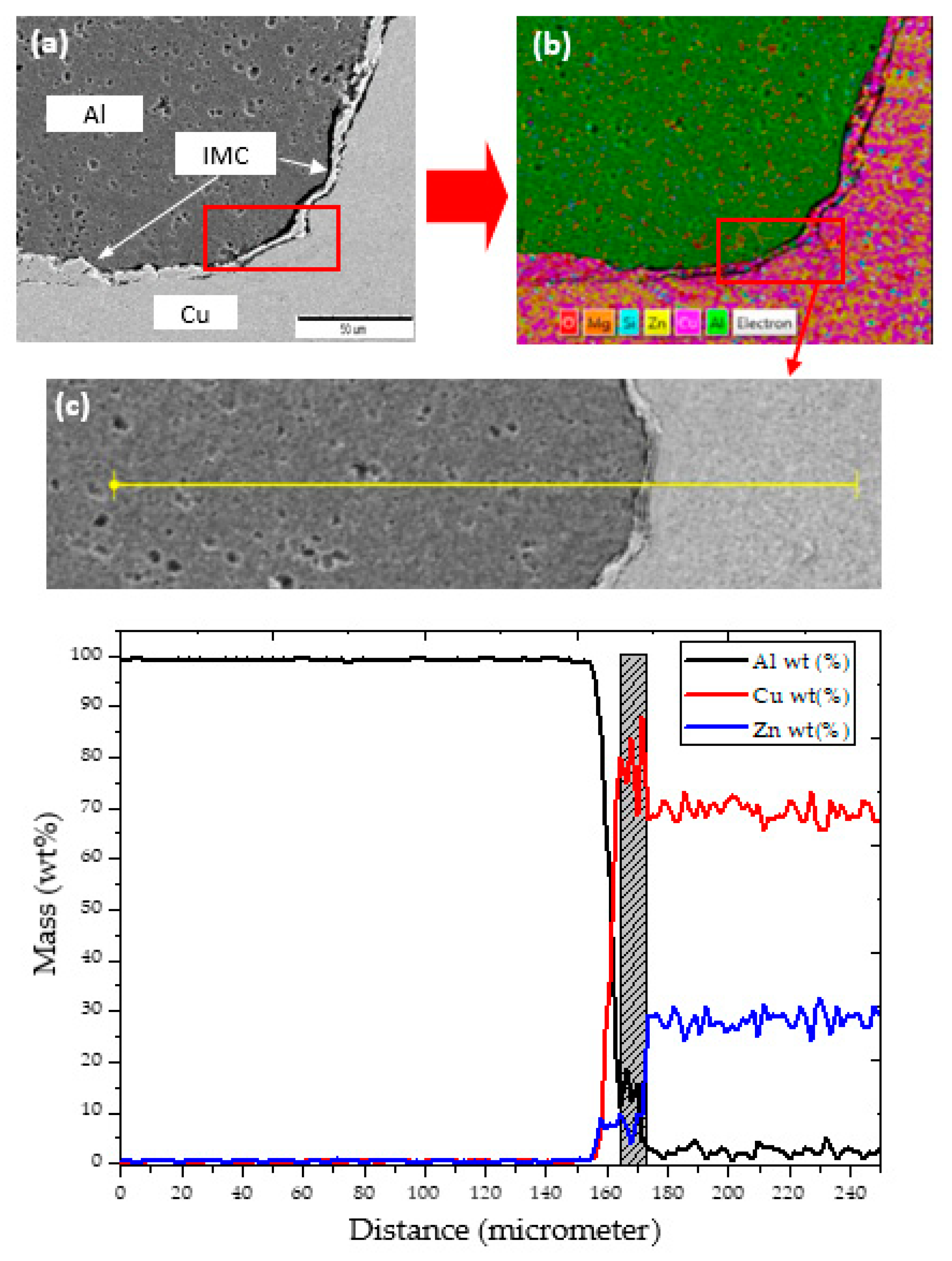

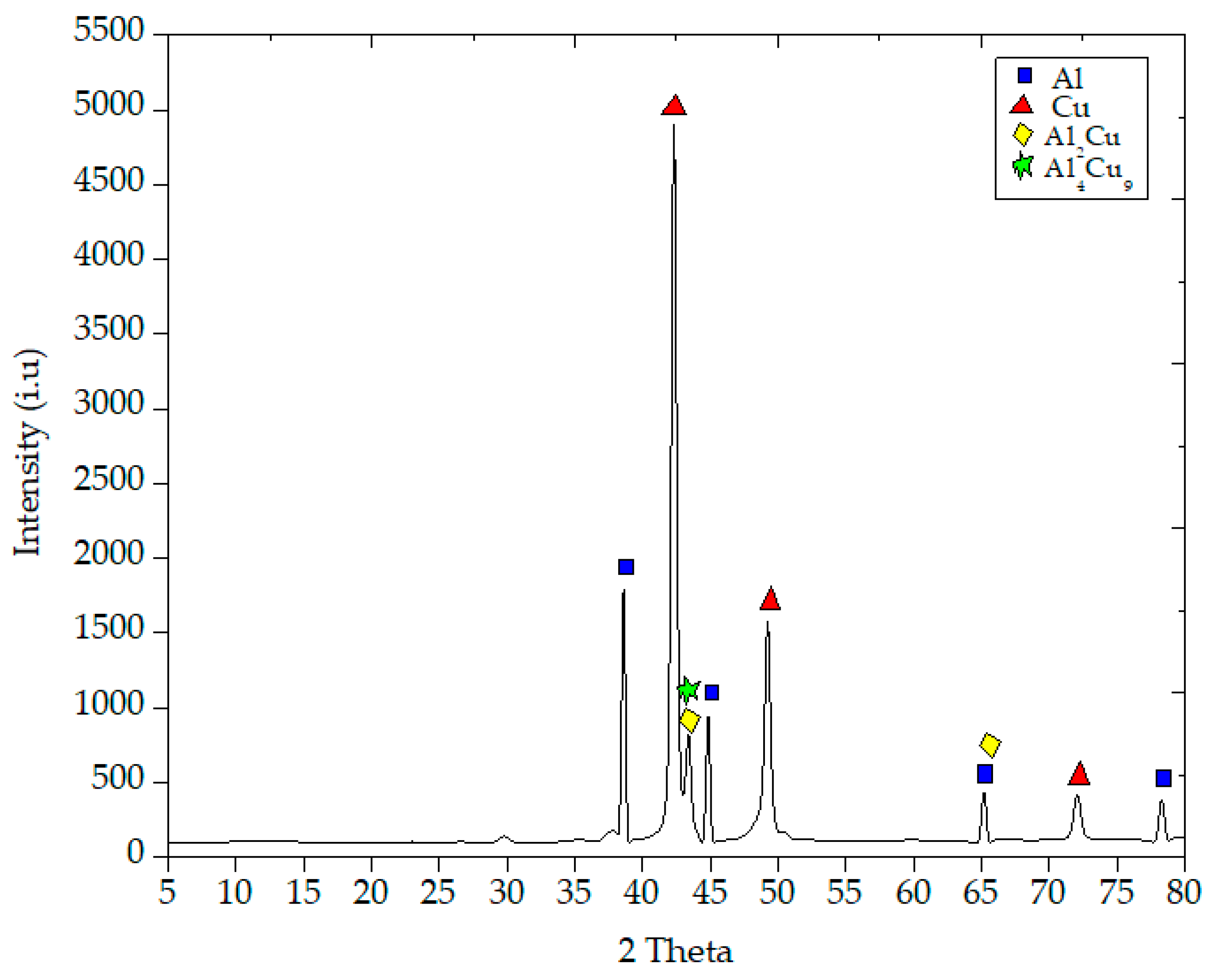

4.2. Effect of FSW Process Parameters on Cladded Al–Cu Microstructure

5. Conclusions

Author Contributions

Funding

Conflicts of Interest

References

- Acarer, M. Electrical, corrosion, and mechanical properties of aluminum-copper joints produced by explosive welding. J. Mater. Eng. Perform. 2012, 21, 2375–2379. [Google Scholar] [CrossRef]

- Panaskar, N.; Terkar, R. A review on recent advances in friction stir lap welding of aluminium and copper. Mater. Today Proc. 2017, 4, 8387–8393. [Google Scholar] [CrossRef]

- Sajuri, Z.; Baghdadi, A.; Mahmod, M.F.; Syarif, J. Fatigue and mechanical properties of aluminium-copper bi-metal tubes. Adv. Mater. Res. 2014, 896, 626–629. [Google Scholar] [CrossRef]

- Baghdadi, A.; Sajuri, Z.; Syarif, J. Study on microstructure and tensile properties of new Cu-al Bi-metal tubes versus pure copper tubes. Appl. Mech. Mater. 2013, 420, 160–166. [Google Scholar] [CrossRef]

- Pietrzyk, S.; Tora, B. Trends in global copper mining-A review. IOP Conf. Ser. Mater. Sci. Eng. 2018, 427, 012002. [Google Scholar] [CrossRef]

- Bergmann, J.P.; Petzoldt, F.; Schürer, R.; Schneider, S. Solid-state welding of aluminum to copper-Case studies. Weld. World 2013, 57, 541–550. [Google Scholar] [CrossRef]

- Eslami, N.; Hischer, Y.; Harms, A.; Lauterbach, D.; Böhm, S. Optimization of process parameters for friction stir welding of aluminum and copper using the taguchi method. Metals 2019, 9, 63. [Google Scholar] [CrossRef]

- Lehmhus, D.; Busse, M.; Herrmann, A.S.; Kayvantash, K. Structural Materials and Processes in Transportation; Wiley VCH: Weinheim, Germany, 2013. [Google Scholar]

- Al-Roubaiy, A.O.; Nabat, S.M.; Batako, A.D.L. Experimental and theoretical analysis of friction stir welding of Al-Cu joints. Int. J. Adv. Manuf. Technol. 2014, 71, 1631–1642. [Google Scholar] [CrossRef]

- Mehta, K.P.; Badheka, V.J. A review on dissimilar friction stir welding of copper to aluminum: Process, properties, and variants. Mater. Manuf. Process. 2016, 31, 233–254. [Google Scholar] [CrossRef]

- Sahin, M. Joining of aluminium and copper materials with friction welding. Int. J. Adv. Manuf. Technol. 2010, 49, 527–534. [Google Scholar] [CrossRef]

- Satpathy, M.P.; Das Mohapatra, K.; Sahoo, A.K.; Sahoo, S.K. Parametric Investigation on Microstructure and Mechanical Properties of Ultrasonic spot welded Aluminium to Copper sheets. IOP Conf. Ser. Mater. Sci. Eng. 2018, 338, 012024. [Google Scholar] [CrossRef]

- Liu, J.; Cao, B.; Yang, J. Modelling intermetallic phase growth during high-power ultrasonic welding of copper and aluminum. J. Manuf. Process. 2018, 35, 595–603. [Google Scholar] [CrossRef]

- Eizadjou, M.; Talachi, A.K.; Manesh, H.D.; Shahabi, H.S.; Janghorban, K. Investigation of structure and mechanical properties of multi-layered Al/Cu composite produced by accumulative roll bonding (ARB) process. Compos. Sci. Technol. 2008, 68, 2003–2009. [Google Scholar] [CrossRef]

- Toroghinejad, M.R.; Jamaati, R.; Dutkiewicz, J.; Szpunar, J.A. Investigation of nanostructured aluminum/copper composite produced by accumulative roll bonding and folding process. Mater. Des. 2013, 51, 274–279. [Google Scholar] [CrossRef]

- Loureiro, A.; Mendes, R.; Ribeiro, J.B.; Leal, R.M.; Galvão, I. Effect of explosive mixture on quality of explosive welds of copper to aluminium. Mater. Des. 2016, 95, 256–267. [Google Scholar] [CrossRef]

- Gulenc, B. Investigation of interface properties and weldability of aluminum and copper plates by explosive welding method. Mater. Des. 2008, 29, 275–278. [Google Scholar] [CrossRef]

- Xue, P.; Xiao, B.L.; Wang, D.; Ma, Z.Y. Achieving high property friction stir welded aluminium/copper lap joint at low heat input. Sci. Technol. Weld. Join. 2011, 16, 657–661. [Google Scholar] [CrossRef]

- Baghdadi, A.H.; Sajuri, Z.; Fazilah, N.; Selamat, M.; Omar, M.Z.; Miyashita, Y.; Kokabi, A.H. Effect of intermetallic compounds on the fracture behavior of dissimilar friction stir welding joints of Mg and Al alloys. Int. J. Miner. Metall. Mater. 2019, 26, 1285–1298. [Google Scholar] [CrossRef]

- Selamat, N.F.M.; Baghdadi, A.H.; Sajuri, Z.; Kokabi, A.H. Friction stir welding of similar and dissimilar aluminium alloys for automotive applications. Int. J. Automot. Mech. Eng. 2016, 13, 3401–3412. [Google Scholar] [CrossRef]

- Wei, H.; Latif, A.; Hussain, G.; Heidarshenas, B.; Altaf, K. Influence of tool material, tool geometry, process parameters, stacking sequence, and heat sink on producing sound Al/Cu lap joints through friction stir welding. Metals 2019, 9, 875. [Google Scholar] [CrossRef]

- Baghdadi, A.H.; Mohamad Selamat, N.F.; Sajuri, Z. Effect of tool offsetting on microstructure and mechanical properties dissimilar friction stir welded Mg-Al alloys. IOP Conf. Ser. Mater. Sci. Eng. 2017, 238, 2–11. [Google Scholar] [CrossRef]

- Baghdadi, A.H.; Rajabi, A.; Selamat, N.F.M.; Sajuri, Z.; Omar, M.Z. Effect of post-weld heat treatment on the mechanical behavior and dislocation density of friction stir welded Al6061. Mater. Sci. Eng. A 2019, 754, 728–734. [Google Scholar] [CrossRef]

- Celik, S.; Cakir, R. Effect of Friction Stir Welding Parameters on the mechanical and microstructure properties of the Al-Cu butt joint. Metals 2016, 6, 133. [Google Scholar] [CrossRef]

- Li, Y.; Sun, D.; Gong, W. Effect of tool rotational speed on the microstructure and mechanical properties of bobbin tool friction. Metals 2019, 9, 894. [Google Scholar] [CrossRef]

- Selamat, N.F.M.; Baghdadi, A.H.; Sajuri, Z.; Kokabi, A.H. Weldability and Mechanical properties of dissimilar Al-MgSi to pure aluminium and Al-Mg using friction welding process. J. Teknol. 2019, 1, 143–149. [Google Scholar] [CrossRef]

- Elangovan, K.; Balasubramanian, V. Influences of tool pin profile and tool shoulder diameter on the formation of friction stir processing zone in AA6061 aluminium alloy. Mater. Des. 2008, 29, 362–373. [Google Scholar] [CrossRef]

- Sibalic, N.; Vukcevic, M. Numerical simulation for FSW process at welding aluminium alloy AA6082-T6. Metals 2019, 9, 747. [Google Scholar] [CrossRef]

- Elrefaey, A.; Gouda, M.; Takahashi, M.; Ikeuchi, K. Characterization of aluminum/steel lap joint by friction stir welding. J. Mater. Eng. Perform. 2005, 14, 10–17. [Google Scholar] [CrossRef]

- Sun, Y.F.; Fujii, H.; Takaki, N.; Okitsu, Y. Microstructure and mechanical properties of dissimilar Al alloy/steel joints prepared by a flat spot friction stir welding technique. Mater. Des. 2013, 47, 350–357. [Google Scholar] [CrossRef]

- Sharma, H.K.; Bhatt, K.; Shah, K.; Joshi, U. Experimental Analysis of Friction Stir Welding of Dissimilar Alloys AA6061 and Mg AZ31 Using Circular Butt Joint Geometry. Procedia Technol. 2016, 23, 566–572. [Google Scholar] [CrossRef]

- Akinlabi, E.T. Characterisation of Dissimilar Friction Stir Welds between 5754 Aluminium Alloy and C11000 Copper; Nelson Mandela Metropolitan University: Port Elizabeth, South Africa, 2010. [Google Scholar]

- Zhang, Q.Z.; Gong, W.B.; Liu, W. Microstructure and mechanical properties of dissimilar Al-Cu joints by friction stir welding. Trans. Nonferr. Met. Soc. China 2015, 25, 1779–1786. (In English) [Google Scholar] [CrossRef]

- Rodrigues, D.M.; Loureiro, A.; Galvão, I.; Gesto, D.; Verdera, D. Influence of aluminium alloy type on dissimilar friction stir lap welding of aluminium to copper. J. Mater. Process. Technol. 2013, 213, 1920–1928. [Google Scholar]

- Mehta, K.P.; Badheka, V.J. Effects of tilt angle on the properties of dissimilar friction stir welding copper to aluminum. Mater. Manuf. Process. 2016, 31, 255–263. [Google Scholar] [CrossRef]

- Saeid, T.; Abdollah-zadeh, A.; Sazgari, B. Weldability and mechanical properties of dissimilar aluminum-copper lap joints made by friction stir welding. J. Alloys Compd. 2010, 490, 652–655. [Google Scholar] [CrossRef]

- Leitao, C.; Arruti, E.; Aldanondo, E.; Rodrigues, D.M. Aluminium-steel lap joining by multipass friction stir welding. Mater. Des. 2016, 106, 153–160. [Google Scholar] [CrossRef]

- Sorger, G.; Wang, H.; Vilaça, P.; Santos, T.G. FSW of aluminum AA5754 to steel DX54 with innovative overlap joint. Weld. World 2017, 61, 257–268. [Google Scholar] [CrossRef]

- Zhao, Y.; Ding, Z.; Shen, C.; Chen, Y. Interfacial microstructure and properties of aluminum-magnesium AZ31B multi-pass friction stir processed composite plate. Mater. Des. 2016, 94, 240–252. [Google Scholar] [CrossRef]

- Anderson, M.J.; Whitcomb, P.J. DOE Simplified: Practical Tools for Effective Experimentation, 3rd ed.; Productivity Press: New York, NY, USA, 2015. [Google Scholar]

- Shojaeefard, M.H.; Khalkhali, A.; Akbari, M.; Tahani, M. Application of Taguchi optimization technique in determining aluminum to brass friction stir welding parameters. Mater. Des. 2013, 52, 587–592. [Google Scholar] [CrossRef]

- Siddarth, S.; Senthilkumar, T.; Chandrasekar, M. Development of processing windows for friction stir spot welding of aluminium Al5052/copper C27200 dissimilar materials. Trans. Nonferr. Met. Soc. China 2017, 27, 1273–1284. (In English) [Google Scholar] [CrossRef]

- Palanivel, R.; Koshy Mathews, P.; Murugan, N. Optimization of process parameters to maximize ultimate tensile strength of friction stir welded dissimilar aluminum alloys using response surface methodology. J. Cent. South Univ. 2013, 20, 2929–2938. [Google Scholar] [CrossRef]

- Bisadi, H.; Tavakoli, A.; Tour Sangsaraki, M.; Tour Sangsaraki, K. The influences of rotational and welding speeds on microstructures and mechanical properties of friction stir welded Al5083 and commercially pure copper sheets lap joints. Mater. Des. 2013, 43, 80–88. [Google Scholar] [CrossRef]

- Sharma, N.; Khan, Z.A.; Sidddiquee, A.N. Friction stir welding of aluminum to copper—An overview. Trans. Nonferr. Met. Soc. China 2017, 27, 2113–2136. (In English) [Google Scholar] [CrossRef]

- Esmaeili, A.; Givi, M.K.B.; Rajani, H.R.Z. A metallurgical and mechanical study on dissimilar Friction Stir welding of aluminum 1050 to brass (CuZn30). Mater. Sci. Eng. A 2011, 528, 7093–7102. [Google Scholar] [CrossRef]

- Khodir, S.A.; Ahmed, M.M.Z.; Ahmed, E.; Mohamed, S.M.R.; Abdel-Aleem, H. Effect of Intermetallic Compound Phases on the Mechanical Properties of the Dissimilar Al/Cu Friction Stir Welded Joints. J. Mater. Eng. Perform. 2016, 25, 4637–4648. [Google Scholar] [CrossRef]

- Lakhminarayanan, A.K.; Annamalai, V.E. Fabrication and performance evaluation of dissimilar magnesium–aluminium alloy multi-seam friction stir clad joints. Trans. Nonferr. Met. Soc. China 2017, 27, 25–35. (In English) [Google Scholar] [CrossRef]

| Chemical Composition [wt%] | |||||||||||

|---|---|---|---|---|---|---|---|---|---|---|---|

| Alloys | Mg | Si | Cu | Zn | Fe | S | Cl | Cr | Na | Ni | Al |

| AA6061 | 1.00 | 0.91 | 0.30 | 0.02 | 0.21 | 0.11 | 0.09 | 0.08 | 0.07 | 0.01 | Balance |

| C2801P | - | - | 60 | 40 | - | - | - | - | - | - | - |

| Parameter | Range | Visual Inspection | Inference |

|---|---|---|---|

| Rotational speed | <825 r/min |  |

|

| >1320 r/min |  |

| |

| Welding speed | <5.5 mm/min |  |

|

| >17 mm/min |  |

|

| Factor | Notation | Level | ||

|---|---|---|---|---|

| −1 | 0 | 1 | ||

| Rotational speed, (r/min) | ω | 825 | 1055 | 1320 |

| Welding speed, (mm/min) | v | 5.5 | 9 | 17 |

| Shoulder overlap ratio, (%) | Sr | 0 | 50 | 100 |

| Test No. | Rotational Speed, ω (r/min) | Welding Speed, v (mm/min) | Shoulder Overlap Ratio, Sr (%) | s (kPa) | p (kPa) | ||||

|---|---|---|---|---|---|---|---|---|---|

| Actual | Predicted | Error (%) | Actual | Predicted | Error (%) | ||||

| 1 | 825.0 | 5.5 | 0.0 | 4723.9 | 4604.1 | 2.5 | 725.0 | 680.0 | 6.2 |

| 2 | 825.0 | 9.0 | 0.0 | 4342.9 | 4457.7 | 2.6 | 622.1 | 604.3 | 2.9 |

| 3 | 825.0 | 17.0 | 0.0 | 3092.4 | 3048.9 | 1.4 | 275.4 | 296.4 | 7.7 |

| 4 | 1055.0 | 5.5 | 0.0 | 4830.0 | 4803.6 | 0.5 | 500.0 | 536.1 | 7.2 |

| 5 | 1055.0 | 9.0 | 0.0 | 5339.0 | 5328.6 | 0.2 | 751.1 | 710.4 | 5.4 |

| 6 | 1055.0 | 17.0 | 0.0 | 3523.3 | 3534.0 | 0.3 | 287.9 | 295.7 | 2.7 |

| 7 | 1320.0 | 5.5 | 0.0 | 3791.4 | 3840.6 | 1.3 | 428.6 | 414.3 | 3.4 |

| 8 | 1320.0 | 9.0 | 0.0 | 4682.3 | 4365.6 | 6.8 | 352.9 | 374.3 | 6.1 |

| 9 | 1320.0 | 17.0 | 0.0 | 2329.0 | 2413.9 | 3.6 | 106.4 | 109.3 | 2.7 |

| 10 | 825.0 | 5.5 | 50.0 | 5248.6 | 5081.4 | 3.2 | 832.1 | 801.4 | 3.7 |

| 11 | 825.0 | 9.0 | 50.0 | 4701.4 | 4892.1 | 4.1 | 745.4 | 725.7 | 2.6 |

| 12 | 825.0 | 17.0 | 50.0 | 3338.1 | 3383.3 | 1.4 | 350.0 | 360.7 | 3.1 |

| 13 | 1055.0 | 5.5 | 50.0 | 5051.9 | 5138.0 | 1.7 | 657.1 | 714.6 | 8.8 |

| 14 | 1055.0 | 9.0 | 50.0 | 6024.3 | 5843.0 | 3.0 | 785.7 | 725.0 | 7.8 |

| 15 | 1055.0 | 17.0 | 50.0 | 3868.6 | 3868.4 | 0.0 | 402.5 | 417.1 | 3.6 |

| 16 | 1320.0 | 5.5 | 50.0 | 4031.4 | 4175.0 | 3.6 | 583.6 | 535.7 | 8.2 |

| 17 | 1320.0 | 9.0 | 50.0 | 4756.9 | 4700.0 | 1.2 | 428.6 | 460.0 | 7.3 |

| 18 | 1320.0 | 17.0 | 50.0 | 2642.9 | 2701.1 | 2.2 | 357.1 | 330.7 | 7.4 |

| 19 | 825.0 | 5.5 | 100.0 | 1605.7 | 1657.4 | 3.2 | 350.4 | 361.1 | 3 |

| 20 | 825.0 | 9.0 | 100.0 | 2466.1 | 2468.1 | 0.1 | 353.2 | 363.6 | 2.9 |

| 21 | 825.0 | 17.0 | 100.0 | 990.7 | 959.3 | 3.2 | 184.3 | 195.0 | 5.8 |

| 22 | 1055.0 | 5.5 | 100.0 | 2111.4 | 2142.6 | 1.5 | 394.6 | 420.4 | 6.5 |

| 23 | 1055.0 | 9.0 | 100.0 | 2990.0 | 2953.3 | 1.2 | 418.9 | 416.1 | 0.6 |

| 24 | 1055.0 | 17.0 | 100.0 | 1137.1 | 1158.7 | 1.9 | 231.4 | 213.6 | 7.7 |

| 25 | 1320.0 | 5.5 | 100.0 | 1370.9 | 1411.0 | 2.9 | 222.1 | 226.8 | 2.2 |

| 26 | 1320.0 | 9.0 | 100.0 | 2187.1 | 2133.1 | 2.5 | 197.9 | 215.7 | 9 |

| 27 | 1320.0 | 17.0 | 100.0 | 417.1 | 410.0 | 1.7 | 11.8 | 10.4 | 11.9 |

| Source | s (kPa) | p (kPa) | ||

|---|---|---|---|---|

| F-value | P-value, Prob > F | F-value | P-value, Prob > F | |

| Model | 108.44 | <0.0001 | 27.32 | <0.0001 |

| ω | 11.37 | 0.003 | 25.07 | <0.0001 |

| v | 80.28 | <0.0001 | 50.64 | <0.0001 |

| Sr | 281.02 | <0.0001 | 23.26 | 0.0001 |

| ω2 | 33.15 | <0.0001 | 7.06 | 0.0152 |

| v2 | 52.48 | <0.0001 | 5.37 | 0.0312 |

| Sr2 | 153.86 | <0.0001 | 40.91 | <0.0001 |

| R2 | 0.9702 | 0.8913 | ||

| Adjusted R2 | 0.9612 | 0.8586 | ||

| Adequate Precision | 35.72 | 18.58 | ||

| Significant | Yes | Yes | ||

| Lack of fit | Insignificant | Insignificant | ||

© 2019 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (http://creativecommons.org/licenses/by/4.0/).

Share and Cite

Osman, N.; Sajuri, Z.; Baghdadi, A.H.; Omar, M.Z. Effect of Process Parameters on Interfacial Bonding Properties of Aluminium–Copper Clad Sheet Processed by Multi-Pass Friction Stir-Welding Technique. Metals 2019, 9, 1159. https://doi.org/10.3390/met9111159

Osman N, Sajuri Z, Baghdadi AH, Omar MZ. Effect of Process Parameters on Interfacial Bonding Properties of Aluminium–Copper Clad Sheet Processed by Multi-Pass Friction Stir-Welding Technique. Metals. 2019; 9(11):1159. https://doi.org/10.3390/met9111159

Chicago/Turabian StyleOsman, Nora, Zainuddin Sajuri, Amir Hossein Baghdadi, and Mohd Zaidi Omar. 2019. "Effect of Process Parameters on Interfacial Bonding Properties of Aluminium–Copper Clad Sheet Processed by Multi-Pass Friction Stir-Welding Technique" Metals 9, no. 11: 1159. https://doi.org/10.3390/met9111159

APA StyleOsman, N., Sajuri, Z., Baghdadi, A. H., & Omar, M. Z. (2019). Effect of Process Parameters on Interfacial Bonding Properties of Aluminium–Copper Clad Sheet Processed by Multi-Pass Friction Stir-Welding Technique. Metals, 9(11), 1159. https://doi.org/10.3390/met9111159