Effect of Intermetallic Compound Layer on Peel Strength and Crack Propagation Behavior in Cu/Al/Cu Clad Composites

Abstract

:1. Introduction

2. Experimental Details

3. Results and Discussion

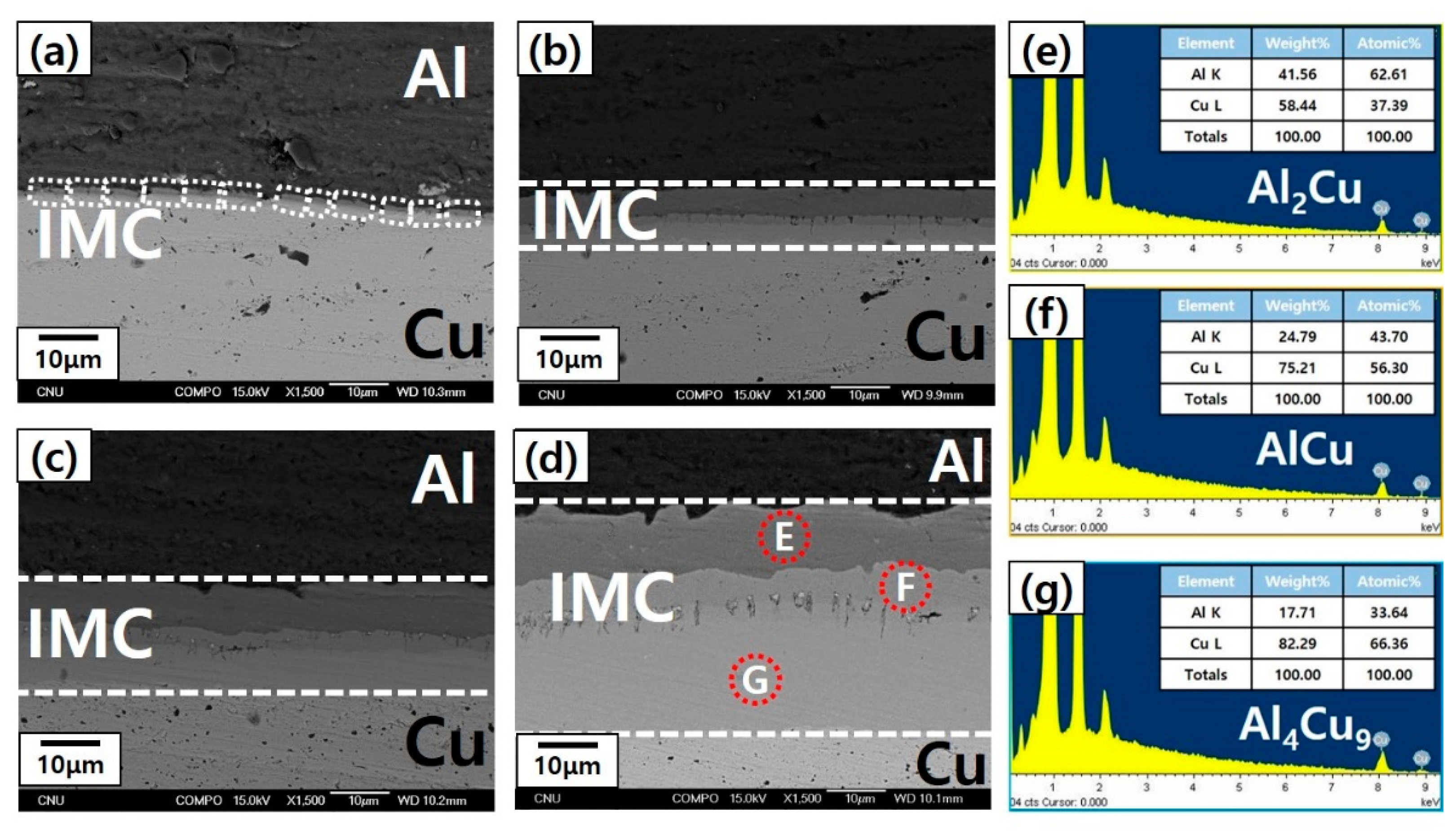

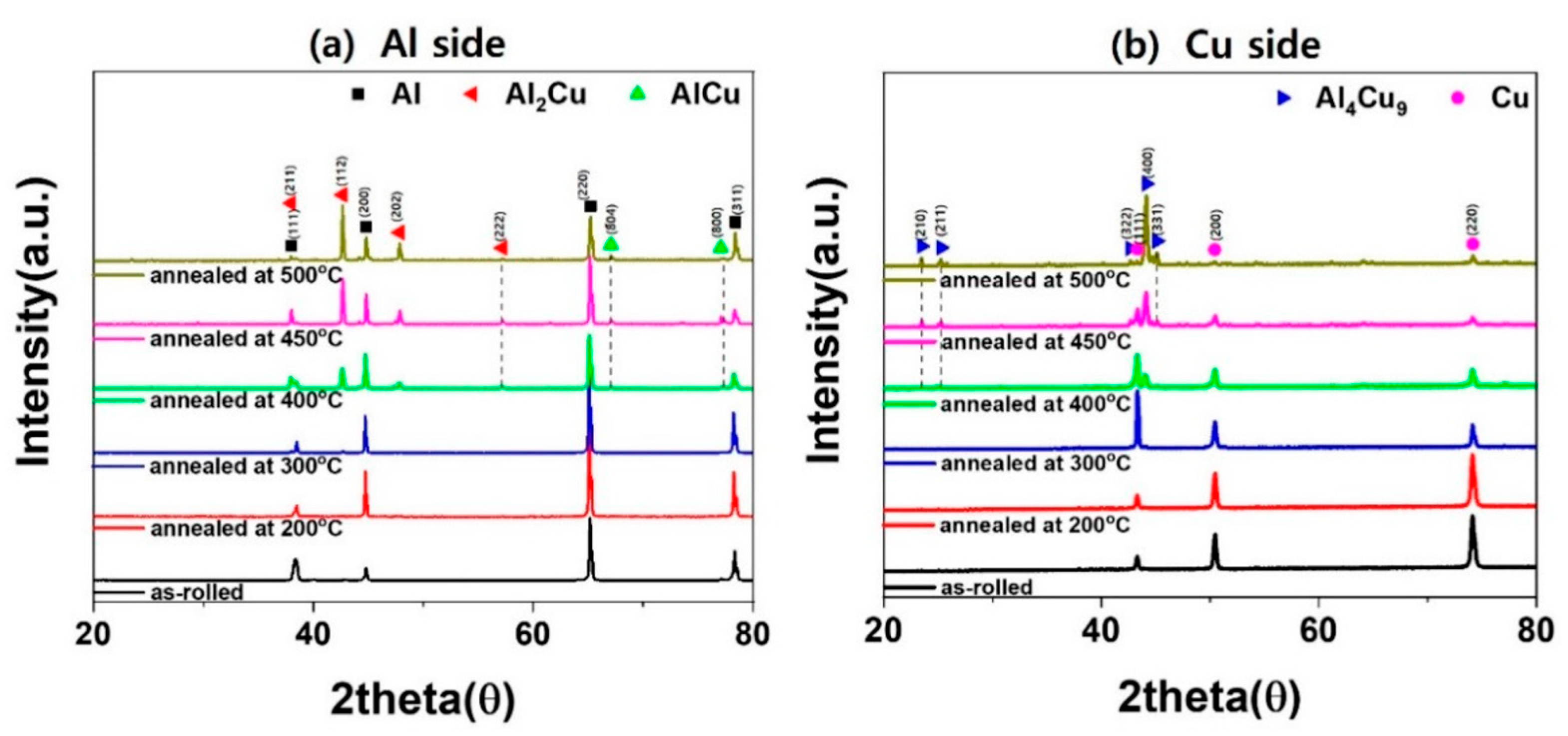

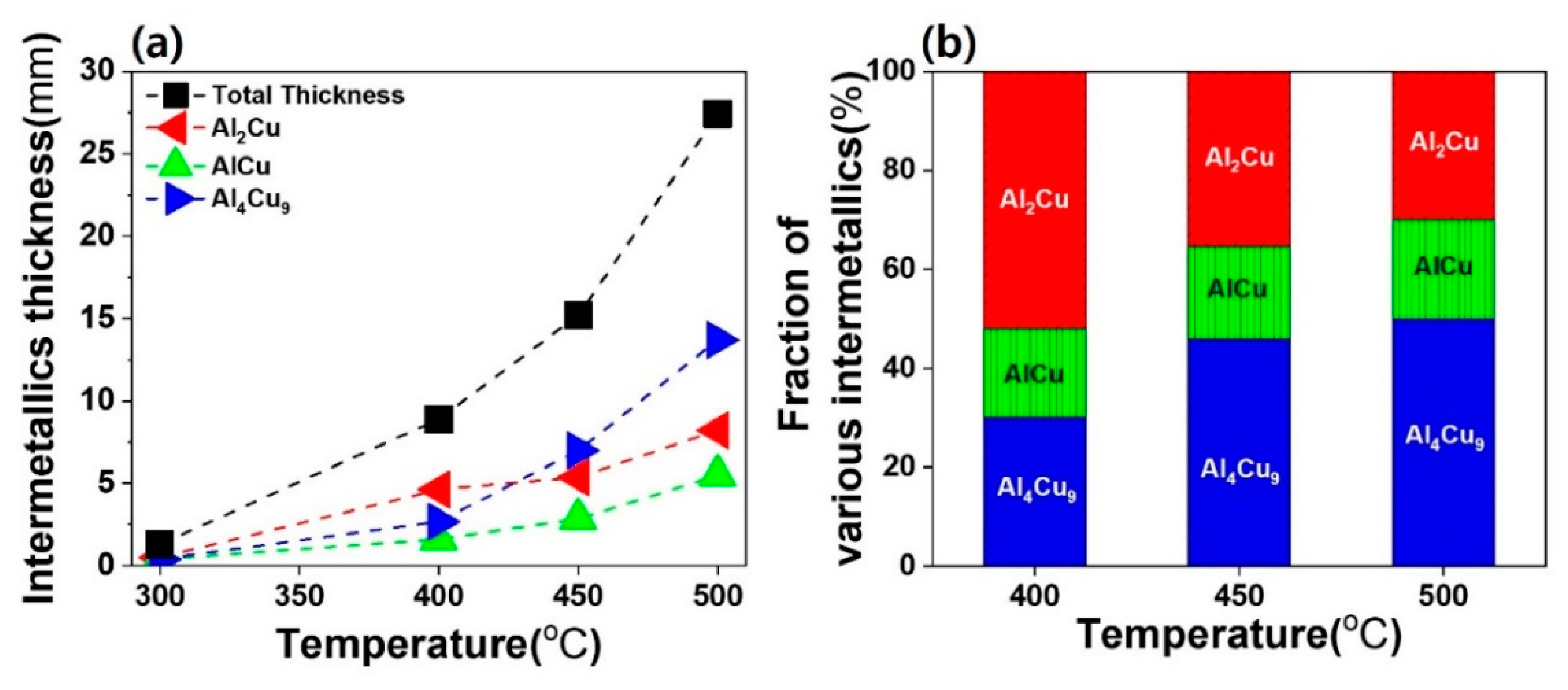

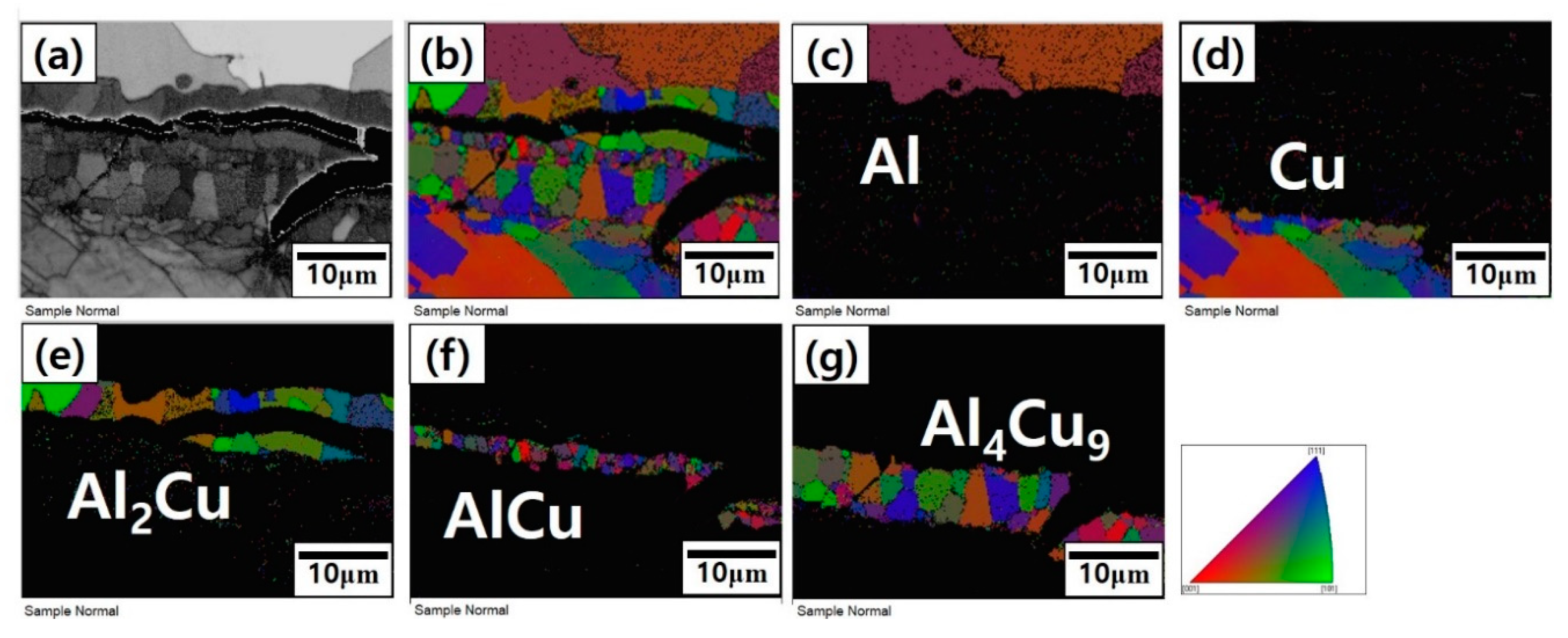

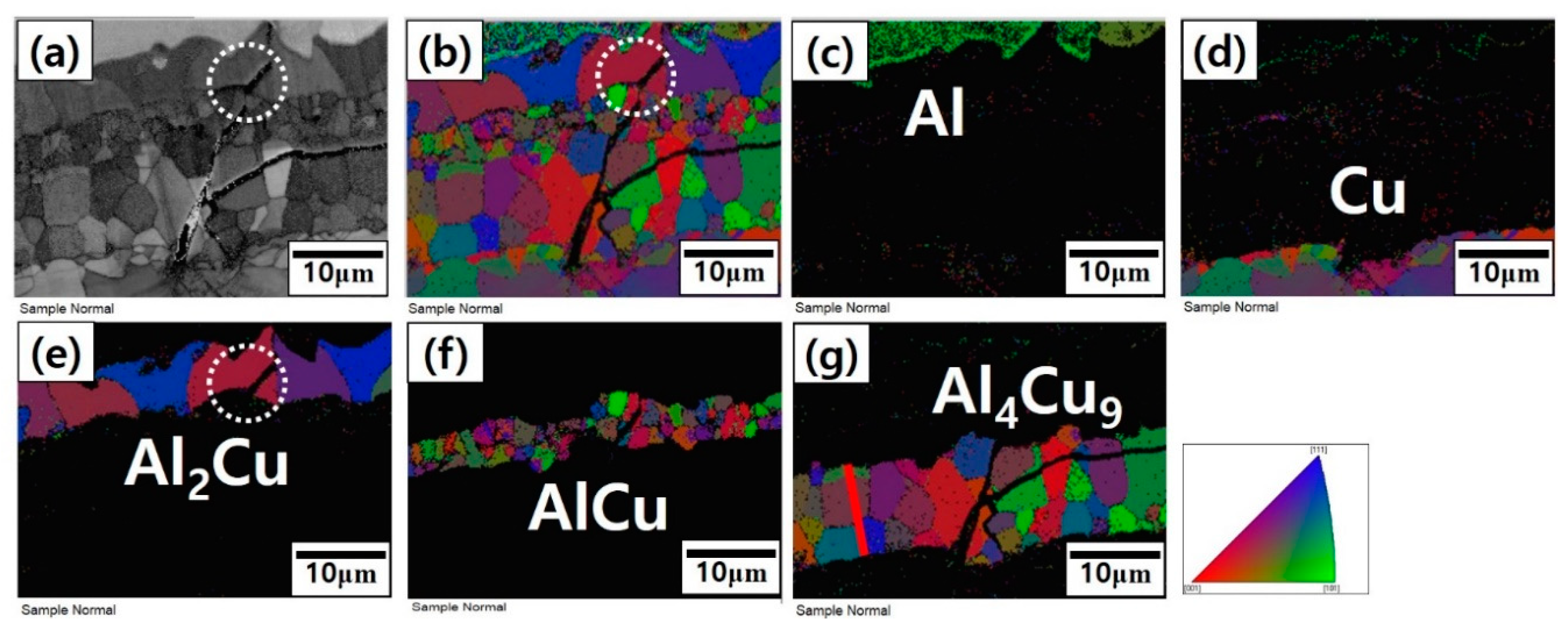

3.1. Characterization of Interface Layers

3.2. Peel Strength during Crack Propagation along Intermetallic Layers

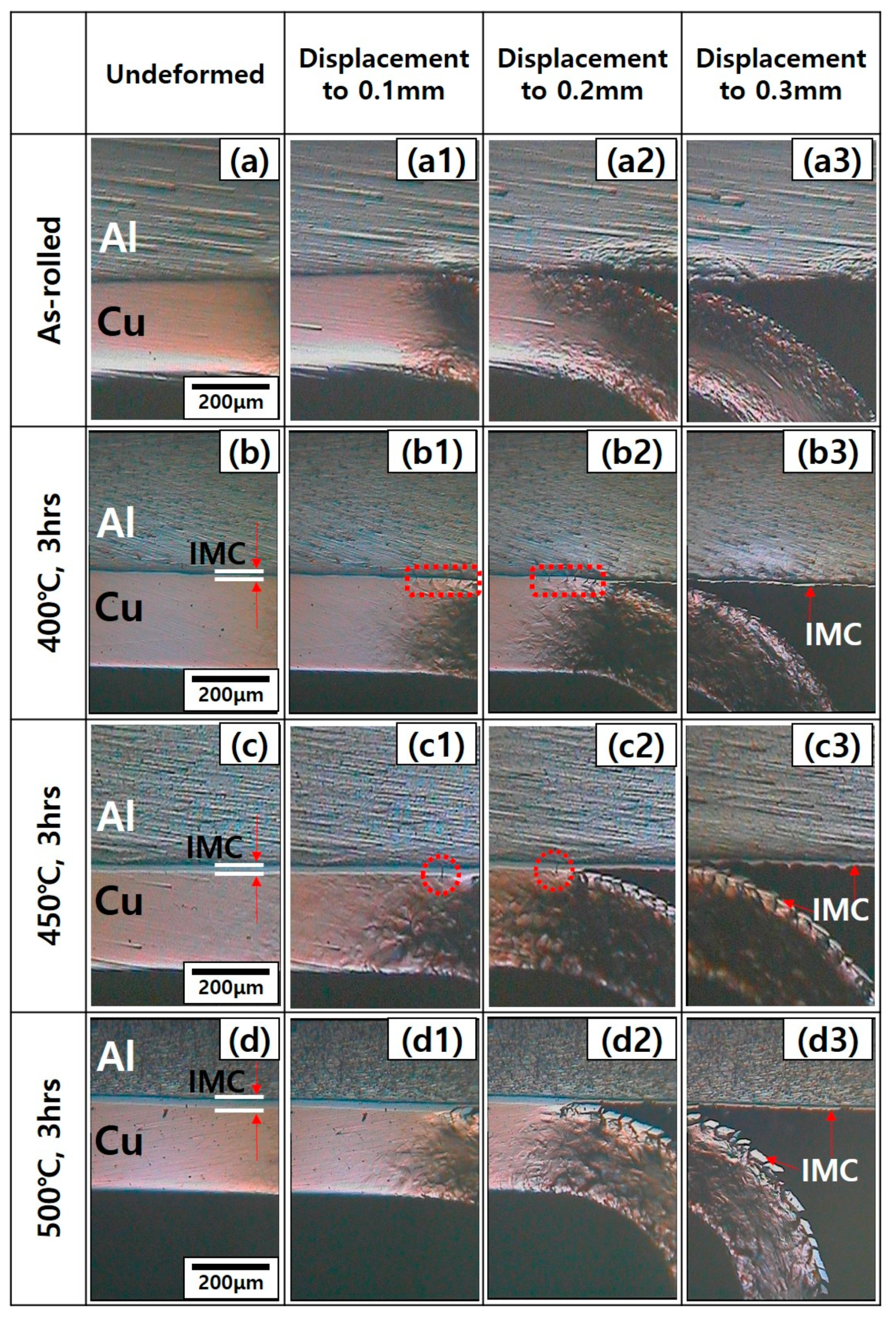

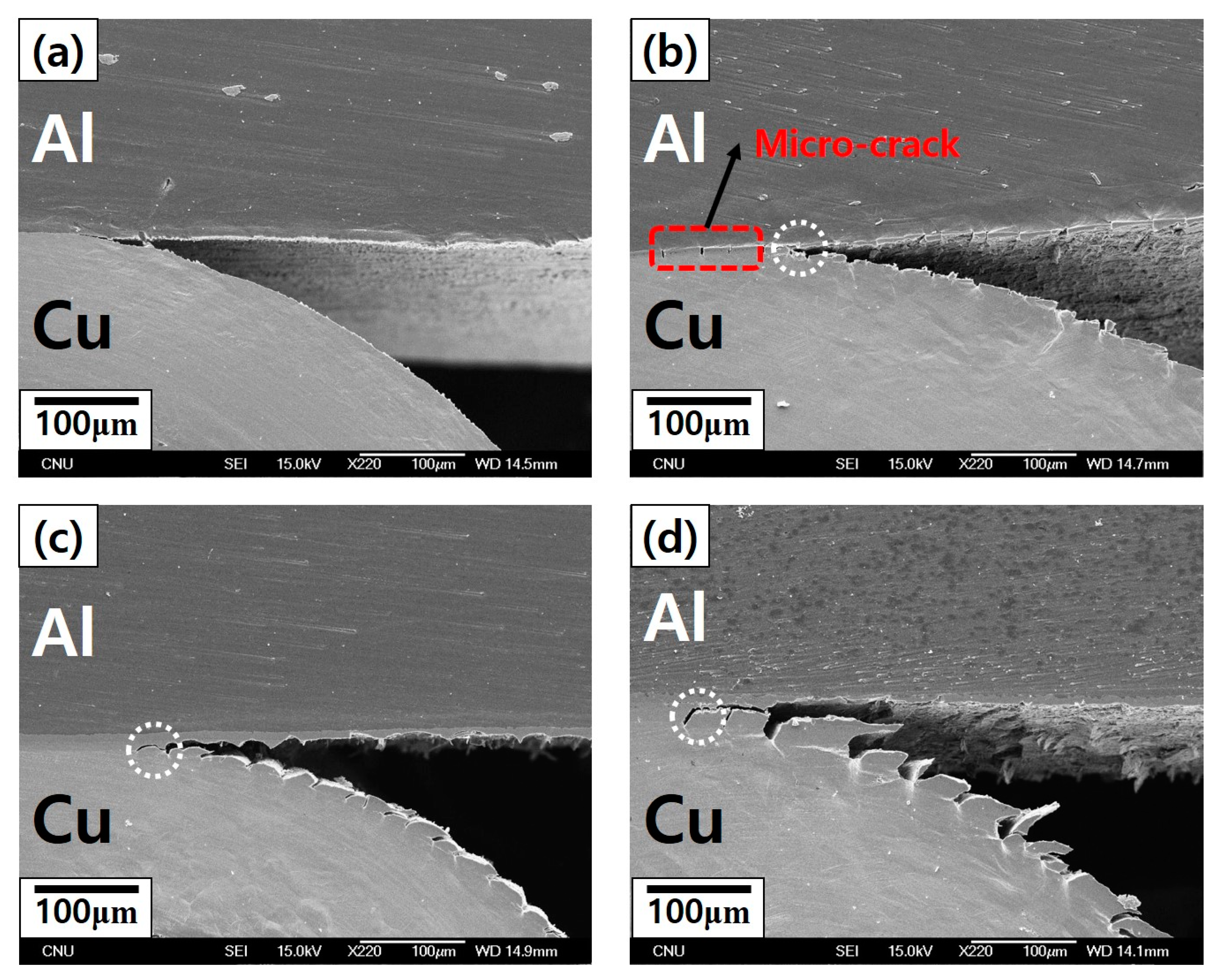

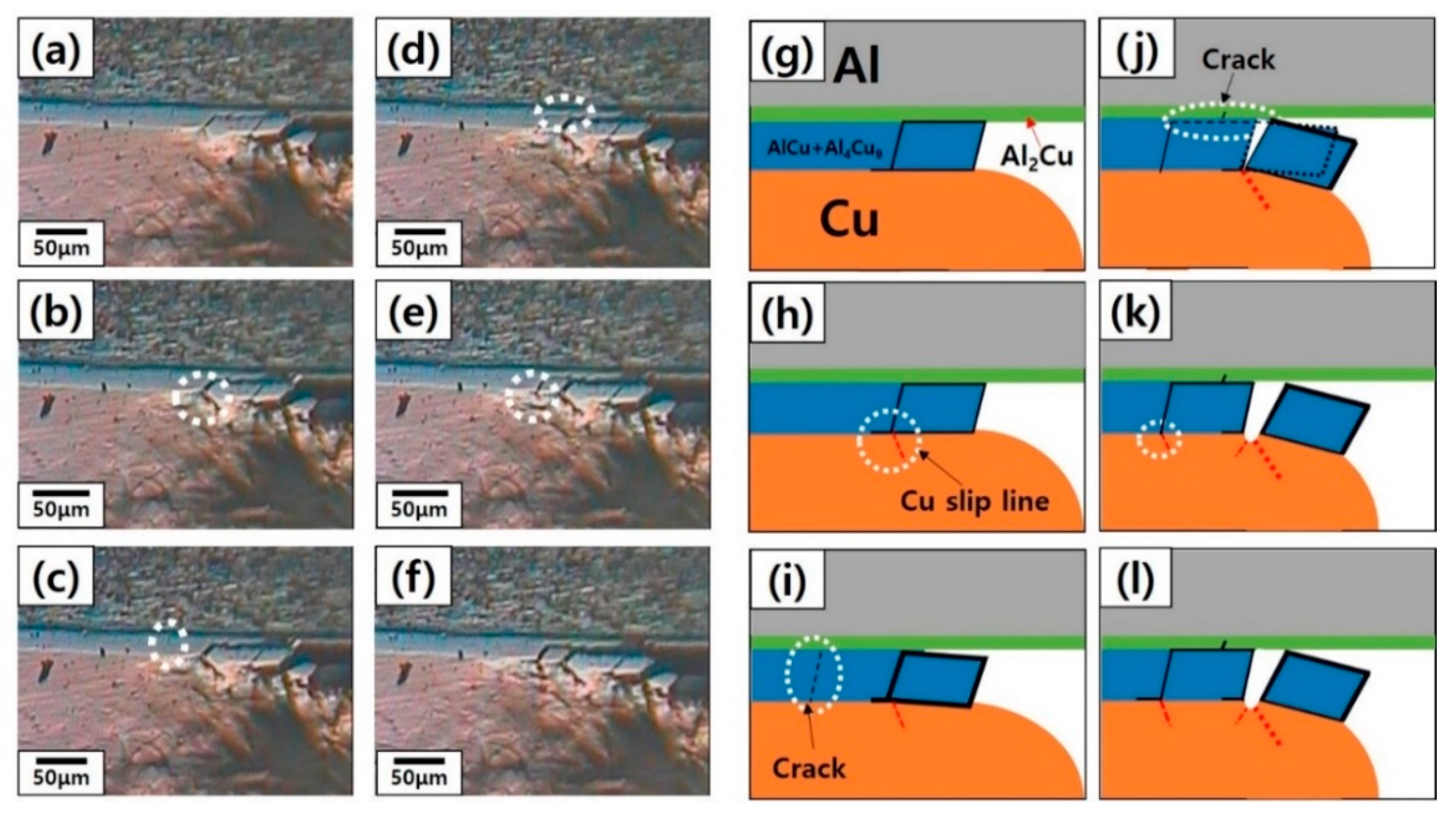

3.3. Crack Propagation and Crack Deflection in Intermetallic Layers

3.4. Effect of Intermetallic Layer on Interface Toughening

4. Conclusions

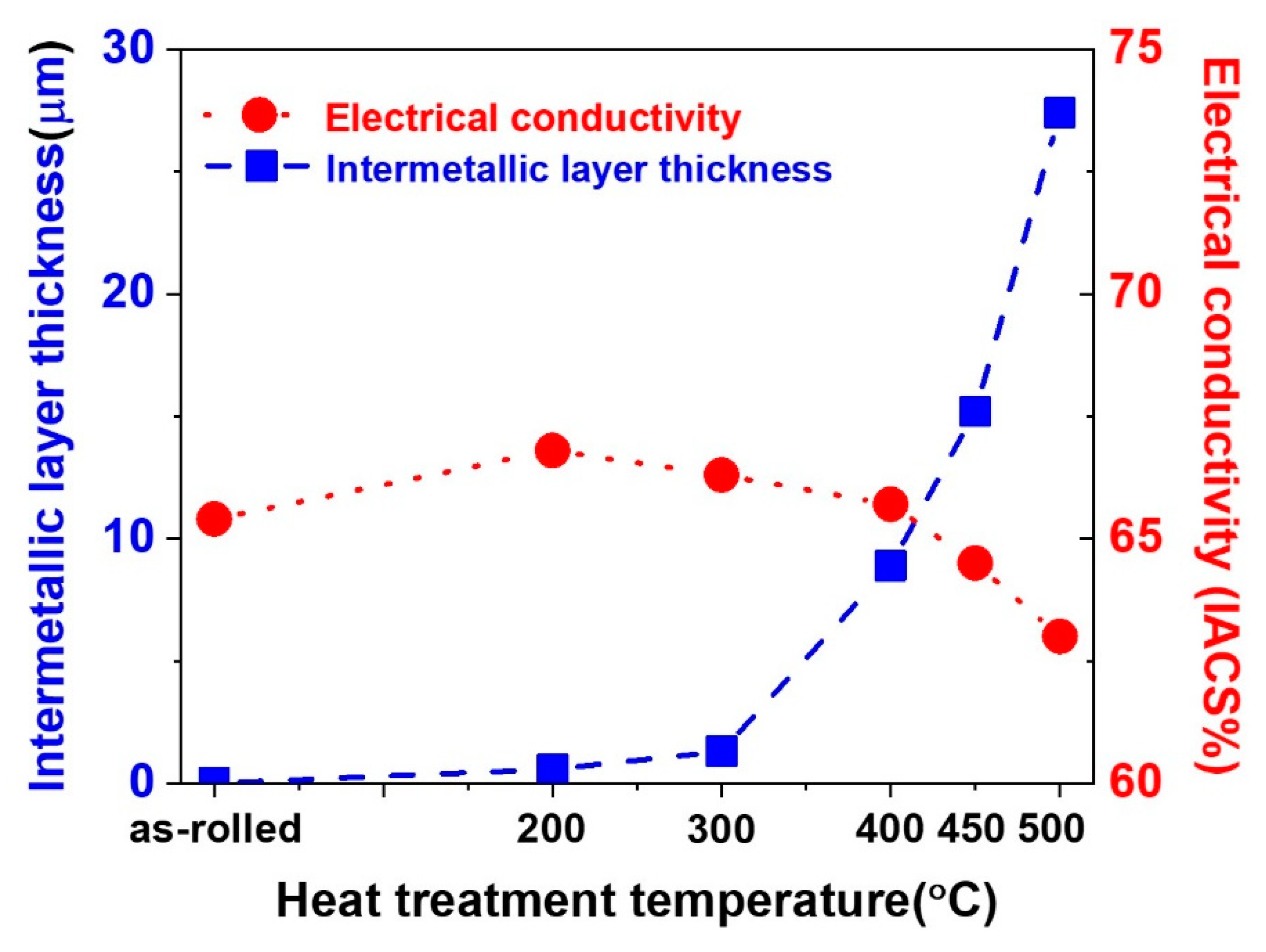

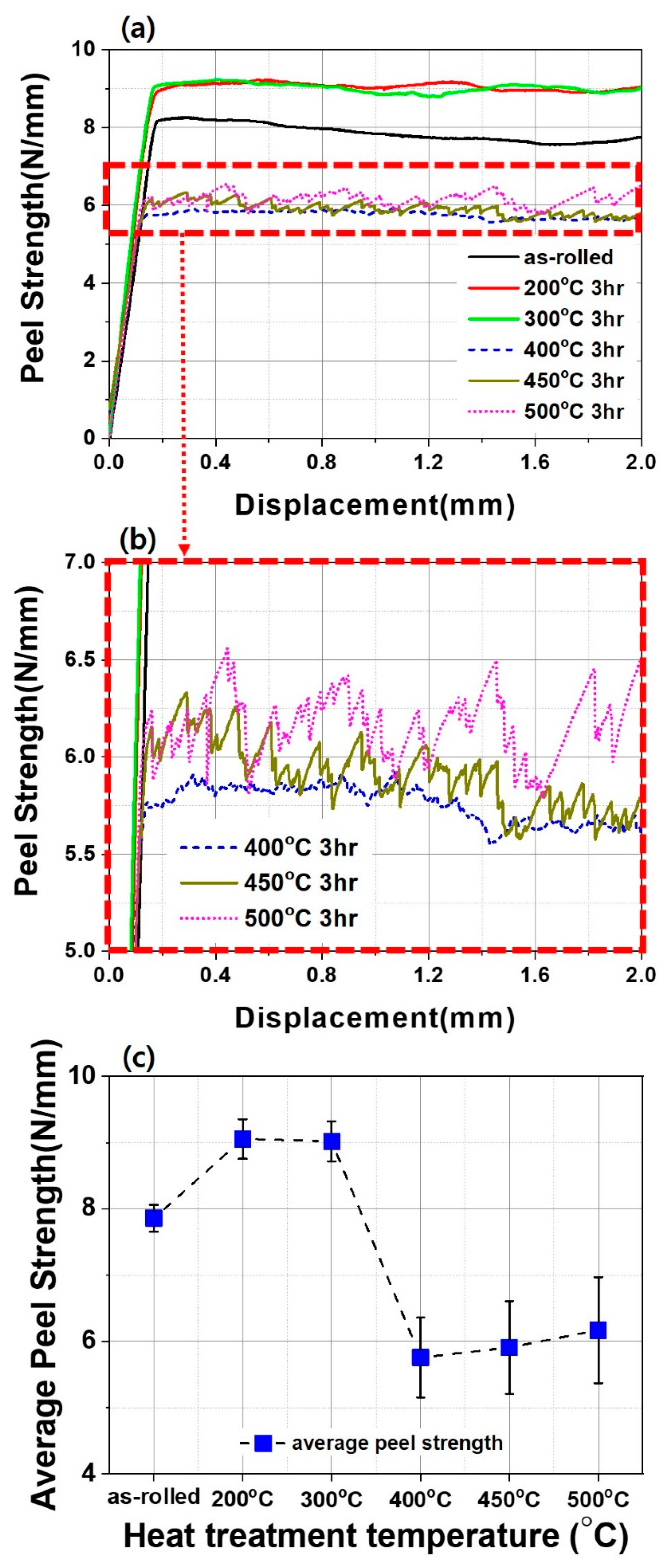

- The peel strengths of the Cu/Al/Cu clad annealed at 200 °C (9.05 N/mm) and 300 °C (9.01 N/mm) were higher than that of the as-rolled specimen (7.8 N/mm). Interface toughening of Cu/Al/Cu was achieved by forming thin discontinuous intermetallic layers through enhanced the interface diffusion bonding of a weakly roll-bonded region by lower-temperature heat treatment at 200–300 °C.

- The increase of peel strength in the Cu/Al/Cu composite in the presence of thin discontinuous IMCs with heat treatment at 200–300 °C was accompanied by the increase of electrical conductivity from 65.3% IACS (International Annealed Copper Standard) to 66.8% IACS. The increase of the conductivity after heat treatment at 200 and 300 °C is thought to be due to the enhanced interface diffusion bonding of the weakly bonded region. As the IMC layer thickness increased with temperatures above 400 °C, the conductivity dropped rapidly because of the rapid growth of intermetallic layer.

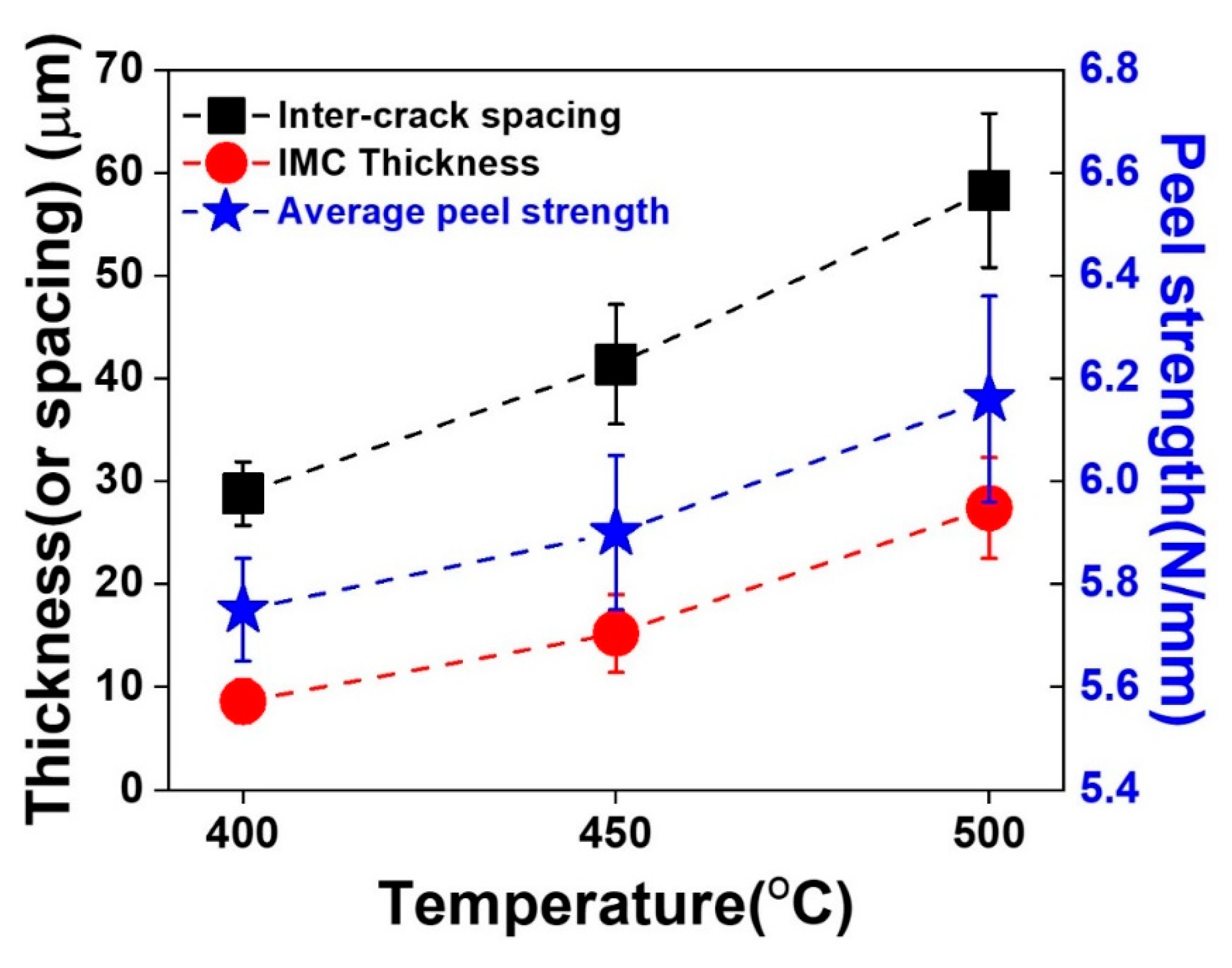

- The peel strength decreased noticeably after annealing at 400 °C (5.75 N/mm) because of the thick brittle intermetallic layers and stress levels of the curves increased as the annealing temperature further increased from 400 to 500 °C. The increased peel strength levels of Cu/Al/Cu clad heat-treated at 450 °C (5.91 N/mm) and 500 °C (6.16 N/mm) compared to that heat-treated at 400 °C were accompanied by pronounced serrations of the peel strength–displacement curves.

- The major crack along the interface propagated through the IMC layer, mostly along the Al2Cu/AlCu boundary with some inclined cracks, propagated through the AlCu and Al4Cu9 intermetallic layers. The interruption of continuous crack propagation and deflection of propagating crack away from Al2Cu/AlCu boundary toward the inclined crack would require more energy and contribute to interface toughening.

- Peel strength, intermetallic layer thickness, and inter-crack spacing of the IMC layer on the peeled-off Cu plate increased in parallel with increase of heat treatment temperature, supporting the correlations between peel strength and the intermetallic layer in the presence of thick continuous IMC layers after heat treatment between 400 and 500 °C.

Supplementary Materials

Author Contributions

Funding

Conflicts of Interest

References

- Burger, G.; Gupta, A.; Jeffrey, P.; Lloyd, D. Microstructural control of aluminum sheet used in automotive applications. Mater. Charact. 1995, 35, 23–39. [Google Scholar] [CrossRef]

- Cole, G.; Sherman, A. Light weight materials for automotive applications. Mater. Charact. 1995, 35, 3–9. [Google Scholar] [CrossRef]

- Moisy, F.; Gueydan, A.; Sauvage, X.; Guillet, A.; Keller, C.; Guilmeau, E.; Hug, E. Influence of intermetallic compounds on the electrical resistivity of architectured copper clad aluminum composites elaborated by a restacking drawing method. Mater. Des. 2018, 155, 366–374. [Google Scholar] [CrossRef]

- Duan, J.Q.; Quadir, M.Z.; Xu, W.; Kong, C.; Ferry, M. Texture balancing in a fcc/bcc multilayered composite produced by accumulative roll bonding. Acta Mater. 2017, 123, 11–23. [Google Scholar] [CrossRef]

- Manesh, H.D.; Taheri, A.K. Bond strength and formability of an aluminum-clad steel sheet. J. Alloys Compd. 2003, 361, 138–143. [Google Scholar] [CrossRef]

- Ha, J.S.; Hong, S.I. Deformation and fracture of Ti/439 stainless steel clad composite at intermediate temperatures. Mater. Sci. Eng. A 2016, 651, 805–809. [Google Scholar] [CrossRef]

- Xiao, H.; Qi, Z.; Yu, C.; Xu, C. Preparation and properties for Ti/Al clad plates generated by differential temperature rolling. J. Mater. Process. Technol. 2017, 249, 285–290. [Google Scholar] [CrossRef]

- Kim, Y.K.; Hong, S.I. Influence of interface structure and stress distribution on fracture and mechanical performance of STS439/Al1050/STS304 clad composite. Mater. Sci. Eng. A 2019, 749, 35–47. [Google Scholar] [CrossRef]

- Wang, S.; Liu, B.X.; Chen, C.X.; Feng, J.H.; Yin, F.X. Microstructure, mechanical properties and interface bonding mechanism of hot-rolled stainless steel clad plates at different rolling reduction ratios. J. Alloys Compd. 2018, 766, 517–526. [Google Scholar] [CrossRef]

- Kim, I.-K.; Hong, S.I. Effect of component layer thickness on the bending behaviors of roll-bonded tri-layered Mg/Al/STS clad composites. Mater. Des. 2013, 49, 935–944. [Google Scholar] [CrossRef]

- Kim, I.-K.; Hong, S.I. Roll-bonded tri-layered Mg/Al/stainless steel clad composites and their deformation and fracture behavior. Metall. Mater. Trans. A 2013, 44, 3890–3900. [Google Scholar] [CrossRef]

- Kim, I.-K.; Hong, S.I. Mechanochemical joining in cold roll-cladding of tri-layered Cu/Al/Cu composite and the interface cracking behavior. Mater. Des. 2014, 57, 625–631. [Google Scholar] [CrossRef]

- Jin, J.Y.; Hong, S.I. Effect of heat treatment on tensile deformation characteristics and properties of Al3003/STS439 clad composite. Mater. Sci. Eng. A 2014, 596, 1–8. [Google Scholar] [CrossRef]

- Kocich, R.; Kunčická, L.; Král, P.; Strunz, P. Characterization of innovative rotary swaged Cu-Al clad composite wire conductors. Mater. Des. 2018, 160, 828–835. [Google Scholar] [CrossRef]

- Kim, W.N.; Hong, S.I. Interactive deformation and enhanced ductility of tri-layered Cu/Al/Cu clad composite. Mater. Sci. Eng. A 2016, 651, 976–986. [Google Scholar] [CrossRef]

- Kim, I.-K.; Hong, S.I. Effect of heat treatment on the bending behavior of tri-layered Cu/Al/Cu composite plates. Mater. Des. 2013, 47, 590–598. [Google Scholar] [CrossRef]

- Kocich, R.; Macháčková, A.; Kunčická, L.; Fojtík, F. Fabrication and characterization of cold-swaged multilayered Al–Cu clad composites. Mater. Des. 2015, 71, 36–47. [Google Scholar] [CrossRef]

- Kim, H.; Kang, G.T.; Hong, S.I. Thermomechanical processing and roll bonding of tri-layered Cu-Ni-Zn/Cu-Cr/Cu-Ni-Zn composite. Metall. Mater. Trans. A 2016, 47, 2267–2276. [Google Scholar] [CrossRef]

- Hong, S.I.; Hill, M.A. Mechanical stability and electrical conductivity of Cu–Ag filamentary microcomposites. Mater. Sci. Eng. A 1999, 264, 151–158. [Google Scholar] [CrossRef]

- Wang, Y.; Song, R.; Yanagimoto, J.; Li, H. Effect of heat treatment on bonding mechanism and mechanical properties of high strength Cu/Al/Cu clad composite. J. Alloys Compd. 2019, 801, 573–580. [Google Scholar] [CrossRef]

- Gueydan, A.; Domengès, B.; Hug, E. Study of the intermetallic growth in copper-clad aluminum wires after thermal aging. Intermetallics 2014, 50, 34–42. [Google Scholar] [CrossRef]

- Mathew, R.T.; Mule, D.; Balasubramaniam, K.R.; Prasad, M.J.N.V. Microstructure and tensile behavior of Cu/Sn/Zn trimetallic claddings produced by roll bonding process. J. Alloys Compd. 2017, 725, 818–823. [Google Scholar] [CrossRef]

- Abedi, R.; Akbarzadeh, A. Bond strength and mechanical properties of three-layered St/AZ31/St composite fabricated by roll bonding. Mater. Des. 2015, 88, 880–888. [Google Scholar] [CrossRef]

- Tolaminejad, B.; Hoseini Athar, M.M.; Arabi, H.; Karimi Taheri, A. Enhanced grain refinement of commercial pure copper using the ECAE of Al–Cu–Al tri-layer composite. Eng. Sci. Tech. Int. J. 2016, 19, 254–259. [Google Scholar] [CrossRef]

- Eslami, P.; Karimi Taheri, A.; Zebardast, M. A comparison between cold-welded and diffusion-bonded Al/Cu bimetallic rods produced by ECAE process. J. Mater. Eng. Perform. 2013, 22, 3014–3023. [Google Scholar] [CrossRef]

- Shiran, M.K.G.; Khalaj, G.; Pouraliakbar, H.; Jandaghi, M.R.; Dehnavi, A.S.; Bakhtiari, H. Multilayer Cu/Al/Cu explosive welded joints: Characterizing heat treatment effect on the interface microstructure and mechanical properties. J. Manuf. Processes 2018, 35, 657–663. [Google Scholar] [CrossRef]

- Xu, X.; Mi, G.; Chen, L.; Xiong, L.; Jiang, P.; Shao, X.; Wang, C. Research on microstructures and properties of Inconel 625 coatings obtained by laser cladding with wire. J. Alloys Compd. 2017, 715, 362–373. [Google Scholar] [CrossRef]

- Gueydan, A.; Hug, E. Secondary creep stage behavior of copper-clad aluminum thin wires submitted to a moderate temperature level. Mater. Sci. Eng. A 2018, 709, 134–138. [Google Scholar] [CrossRef]

- Okamoto, H.; Schlesinger, M.; Mueller, E. ASM handbook volume 3: Alloy phase diagrams; ASM International: Materials Park, OH, USA, 2016; p. 285. [Google Scholar]

- Xu, H.; Liu, C.; Silberschmidt, V.V.; Pramana, S.S.; White, T.J.; Chen, Z.; Acoff, V.L. Behavior of aluminum oxide, intermetallics and voids in Cu–Al wire bonds. Acta Mater. 2011, 59, 5661–5673. [Google Scholar] [CrossRef]

- den Broeder, F.J.A. Diffusion-induced grain boundary migration and recrystallization, exemplified by the system Cu-Zn. Thin Solid Films 1985, 124, 135–148. [Google Scholar] [CrossRef]

© 2019 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (http://creativecommons.org/licenses/by/4.0/).

Share and Cite

Kim, Y.K.; Hong, S.I. Effect of Intermetallic Compound Layer on Peel Strength and Crack Propagation Behavior in Cu/Al/Cu Clad Composites. Metals 2019, 9, 1155. https://doi.org/10.3390/met9111155

Kim YK, Hong SI. Effect of Intermetallic Compound Layer on Peel Strength and Crack Propagation Behavior in Cu/Al/Cu Clad Composites. Metals. 2019; 9(11):1155. https://doi.org/10.3390/met9111155

Chicago/Turabian StyleKim, Yong Keun, and Sun Ig Hong. 2019. "Effect of Intermetallic Compound Layer on Peel Strength and Crack Propagation Behavior in Cu/Al/Cu Clad Composites" Metals 9, no. 11: 1155. https://doi.org/10.3390/met9111155

APA StyleKim, Y. K., & Hong, S. I. (2019). Effect of Intermetallic Compound Layer on Peel Strength and Crack Propagation Behavior in Cu/Al/Cu Clad Composites. Metals, 9(11), 1155. https://doi.org/10.3390/met9111155