B4C Particles Reinforced Al2024 Composites via Mechanical Milling

Abstract

:1. Introduction

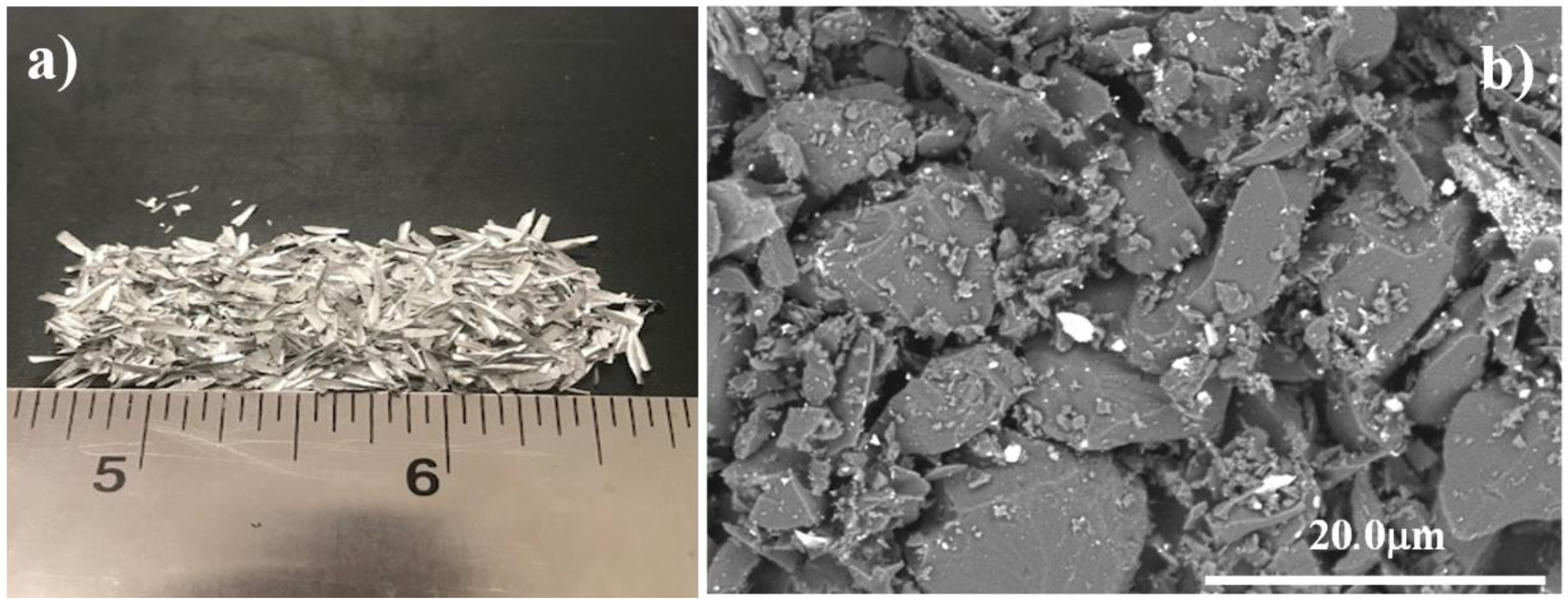

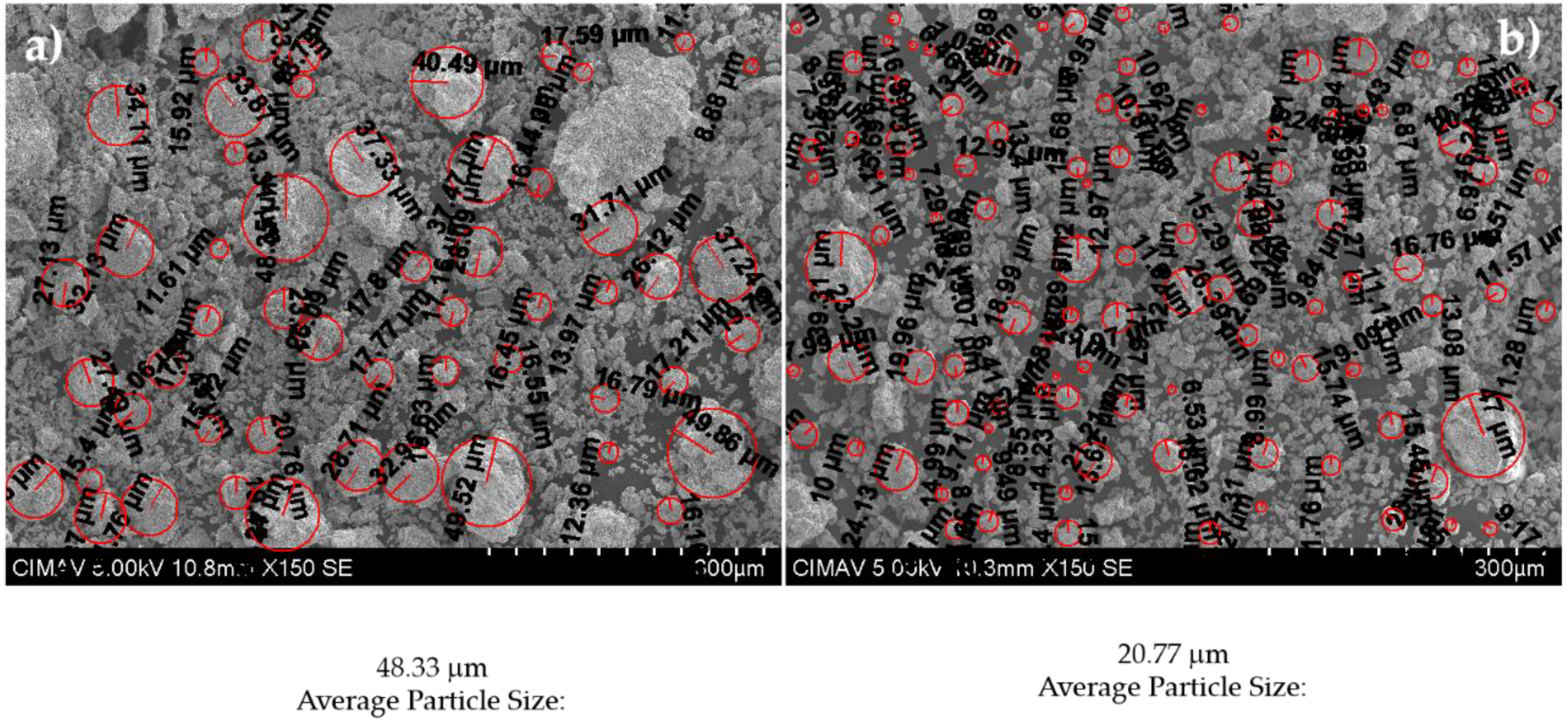

2. Materials and Methods

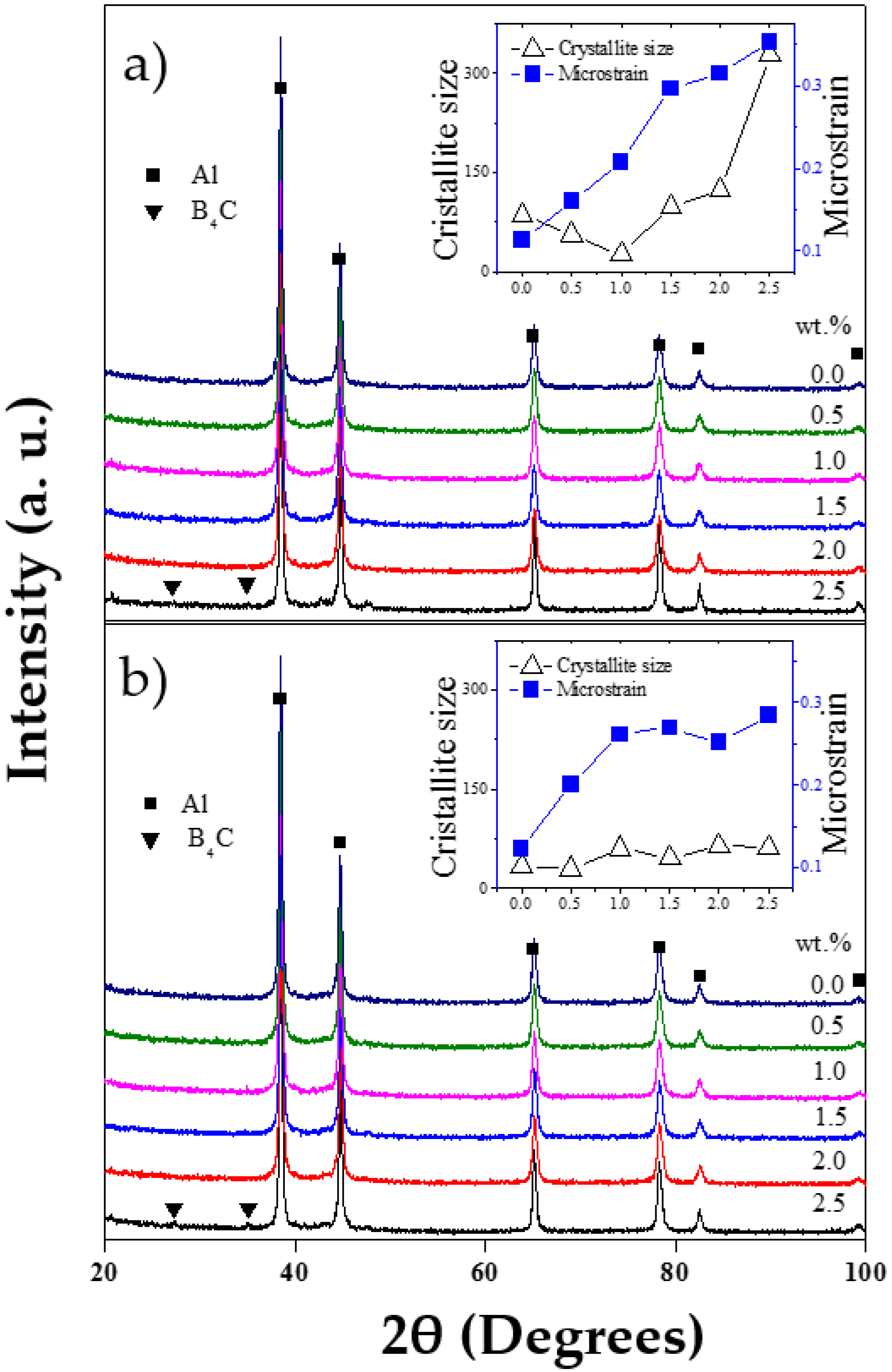

3. Results and Discussion

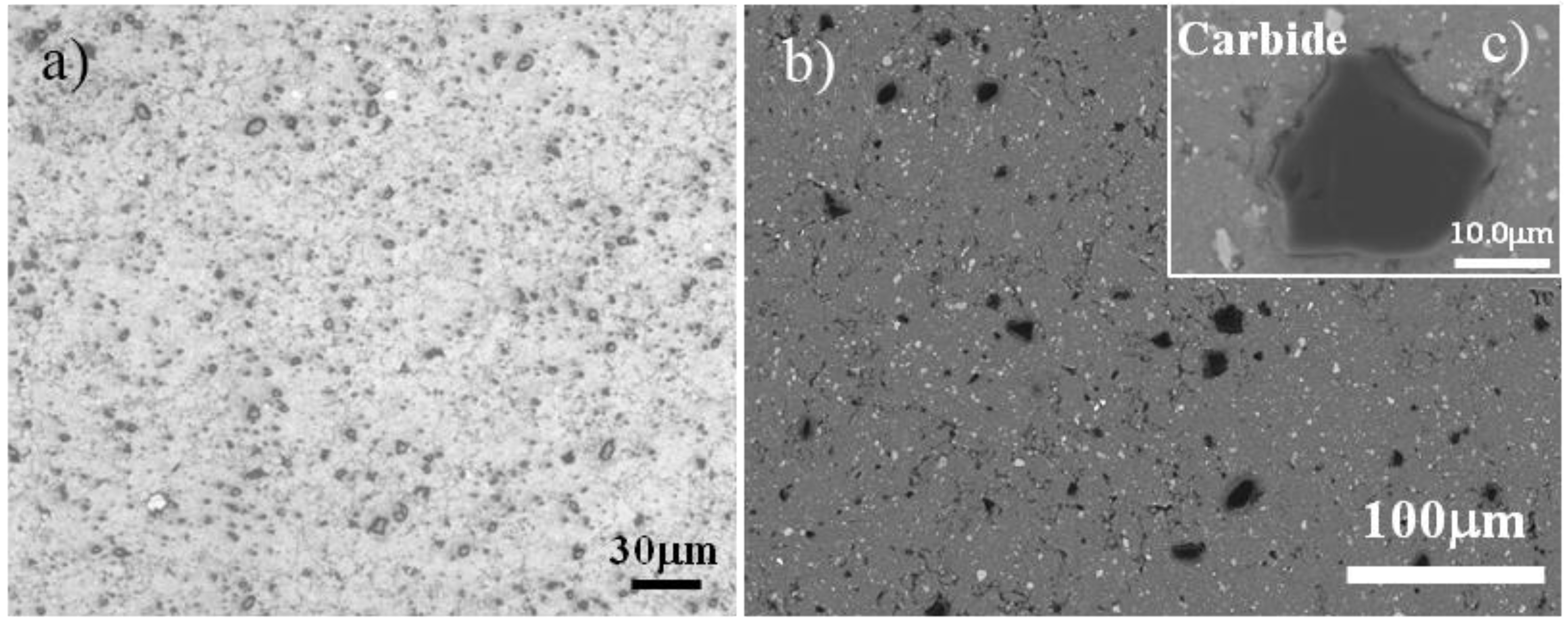

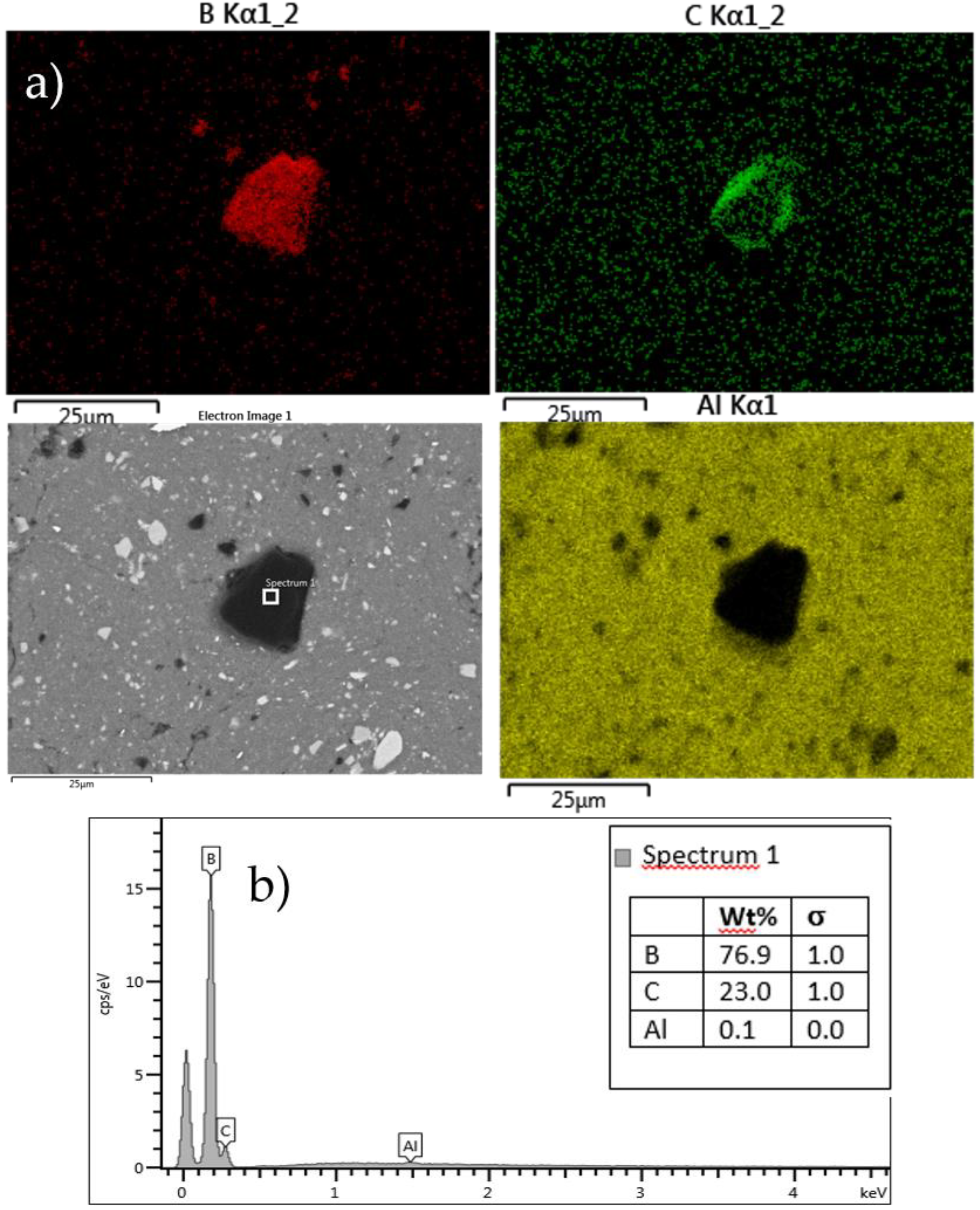

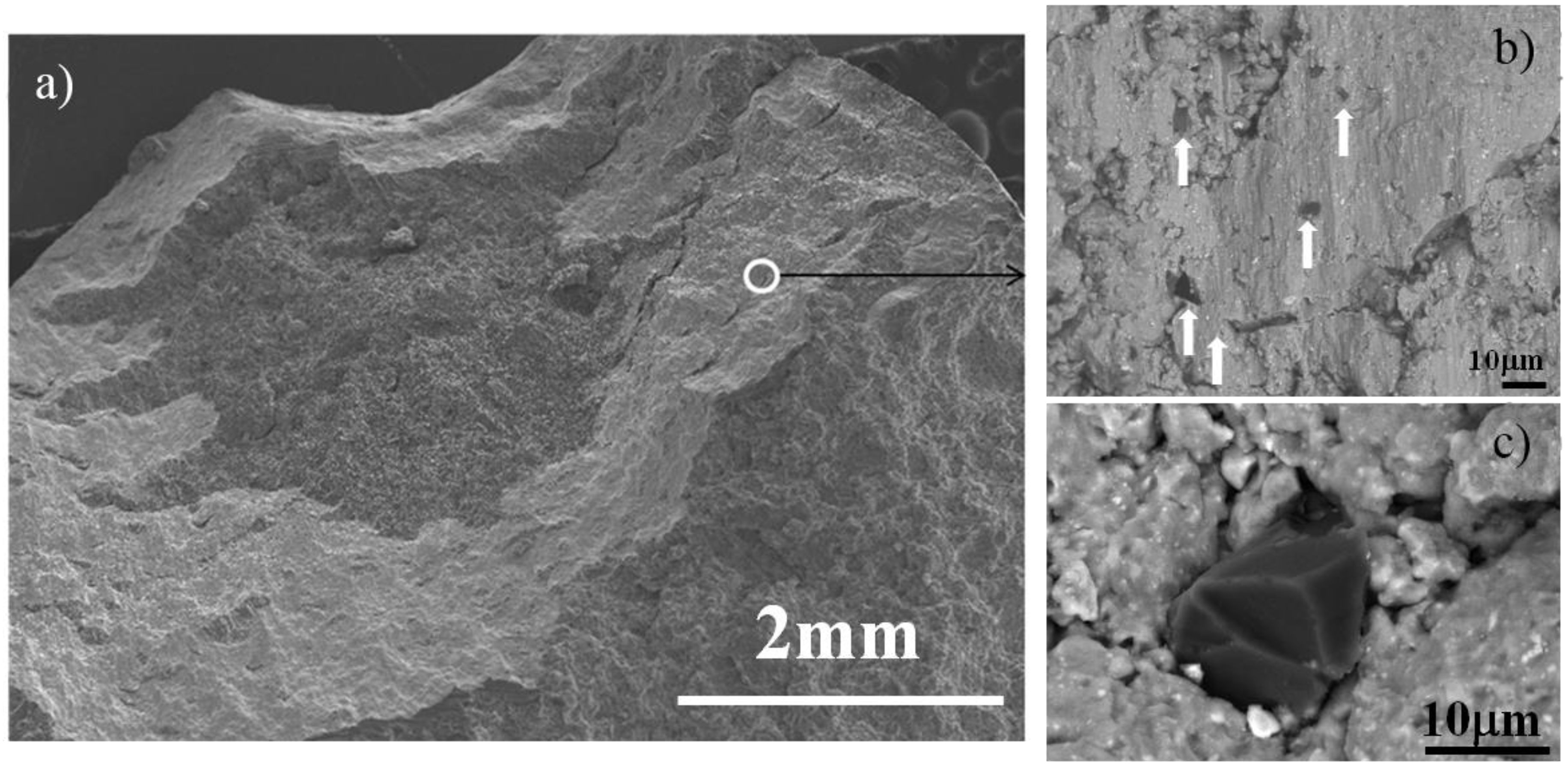

3.1. Microstructure Analysis

3.2. Mechanical Properties

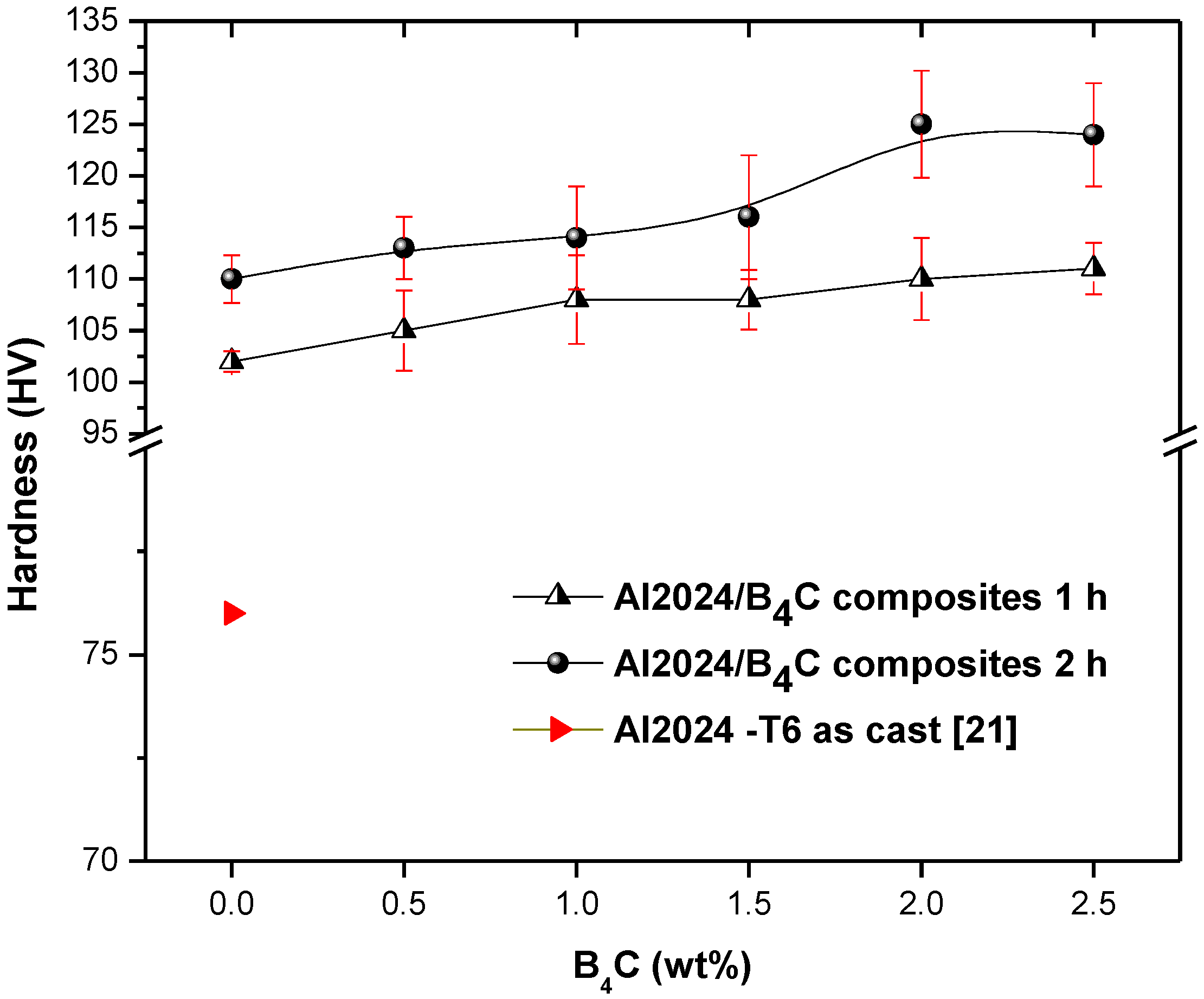

3.2.1. Microhardness Measurements

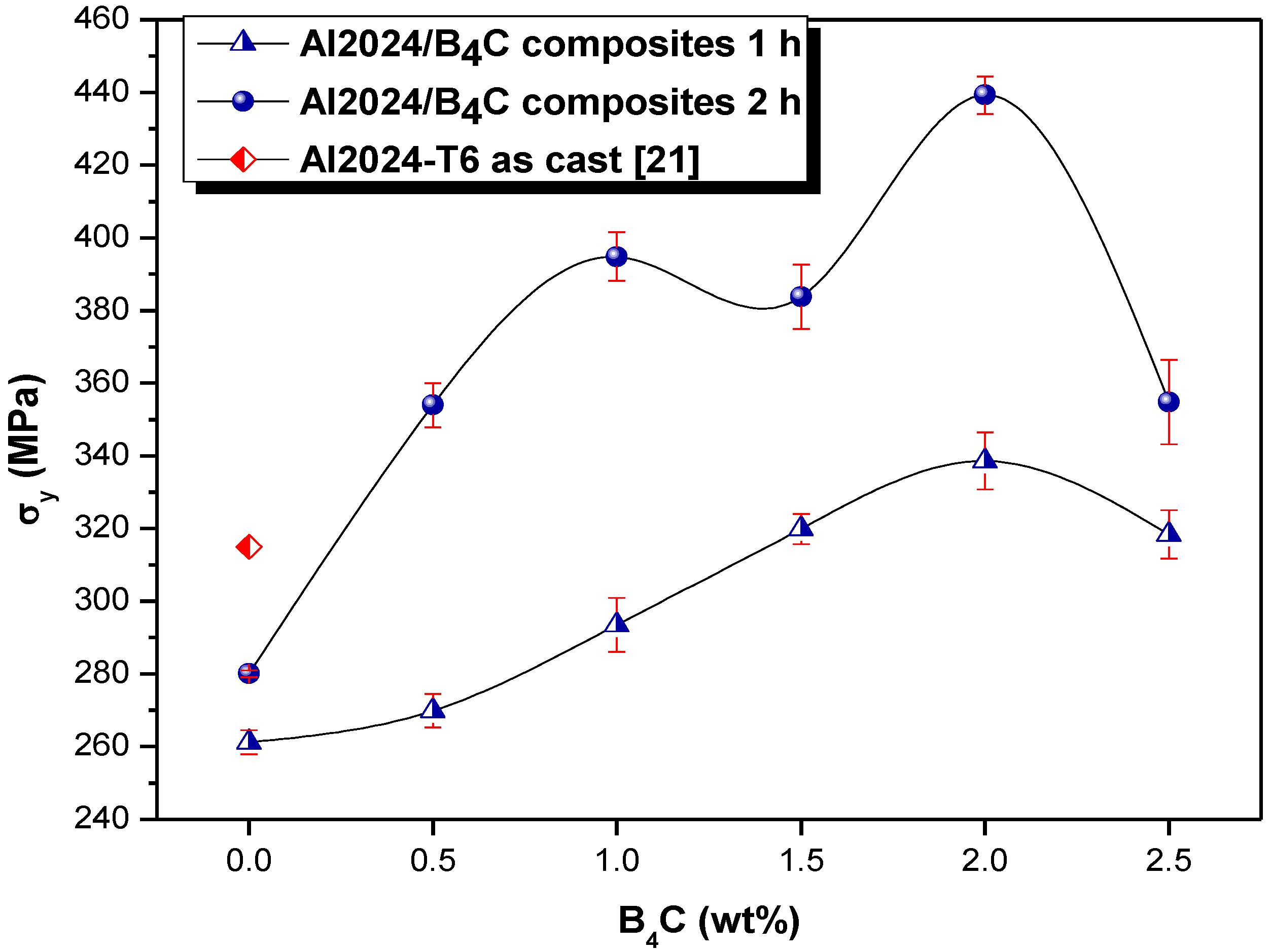

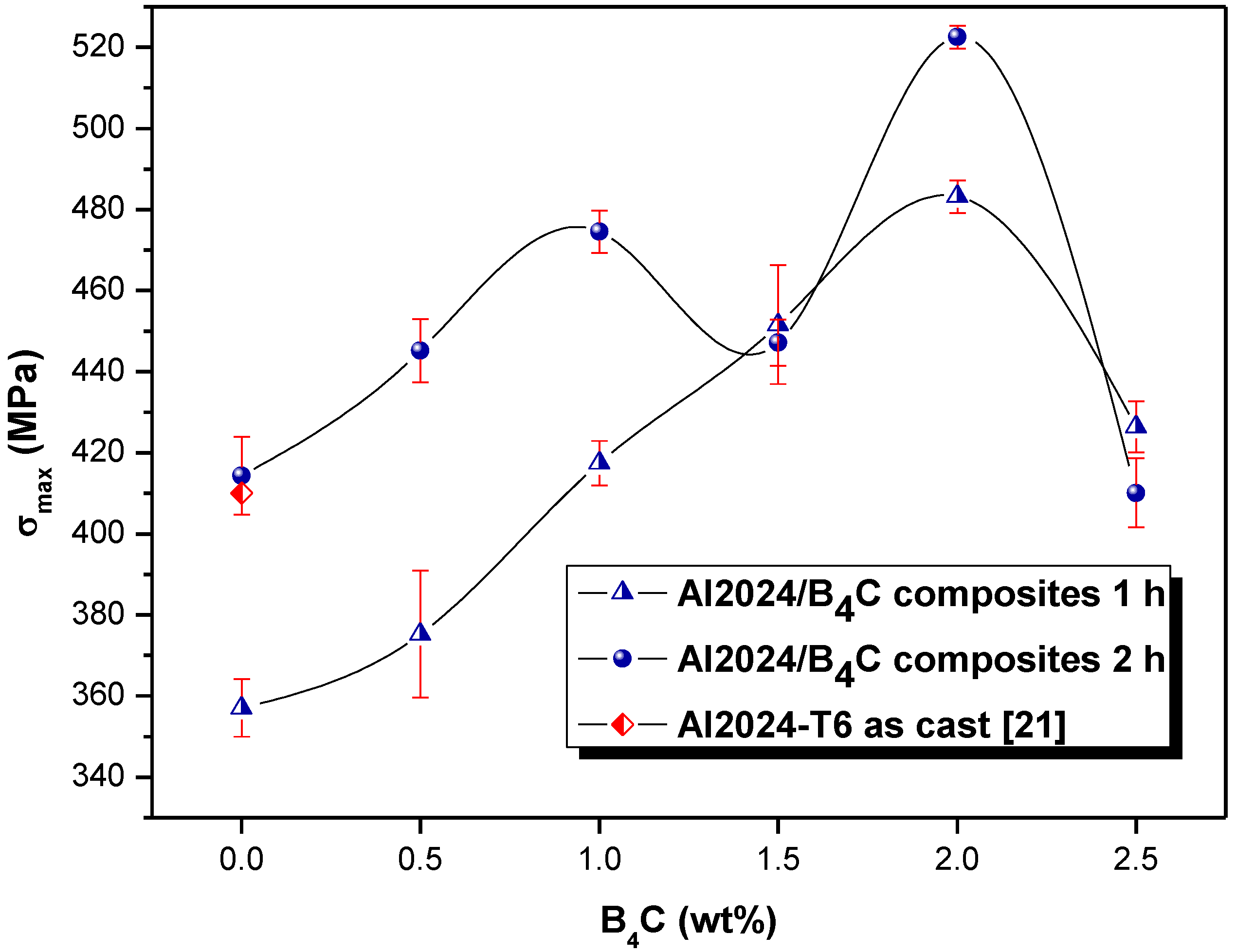

3.2.2. Compression Tests

3.3. Fractographic analysis

4. Conclusions

Author Contributions

Acknowledgments

Conflicts of Interest

References

- Zheng, R.X.; Hao, X.; Yuan, Y.; Ma, C. Effect of high volume fraction of B4C particles on the microstructure and mechanical properties of aluminum alloy based composites. J. Alloy. Compd. 2013, 576, 291–298. [Google Scholar] [CrossRef]

- Ganesh, V.V.; Chawla, N. Effect of particle orientation anisotropy on the tensile behavior of metal matrix composites: Experiments and microstructure-based simulation. Mater. Sci. Eng. A 2005, 391, 342–353. [Google Scholar] [CrossRef]

- Bethune, D.S.; Bethune, D.S.; Kiang, C.H.; De Vries, M.S.; Gorman, G.; Savoy, R.; Vazquez, J.; Beyers, R. Cobalt-catalysed growth of carbon nanotubes with single-atomic-layer walls. Nature 1993, 363, 605–607. [Google Scholar] [CrossRef]

- Friler, J.B.; Argon, A.S.; Cornie, J.A. Strength and toughness of carbon fiber reinforced aluminum matrix composites. Mater. Sci. Eng. A 1993, 162, 143–152. [Google Scholar] [CrossRef]

- Davies, C.H.J.; Raghunathan, N.; Sheppard, T. Structure–property relationships of SiC reinforced advanced Al–Zn–Mg–Cu alloy. Mater. Sci. Technol. 1992, 8, 977–984. [Google Scholar] [CrossRef]

- Zhang, Z.; Chen, D.L. Contribution of Orowan strengthening effect in particulate-reinforced metal matrix nanocomposites. Mater. Sci. Eng. A 2008, 483, 148–152. [Google Scholar] [CrossRef]

- Zhang, Z.; Chen, D.L. Consideration of orowan strengthening effect in particulate-reinforced metal matrix nanocomposites: A model for predicting their yield strength. Scr. Mater. 2006, 54, 1321–1326. [Google Scholar] [CrossRef]

- Sanaty-Zadeh, A. Comparison between current models for the strength of particulate-reinforced metal matrix nanocomposites with emphasis on consideration of hall–petch effect. Mater. Sci. Eng. A 2012, 531, 112–118. [Google Scholar] [CrossRef]

- Luo, P.; McDonald, D.T.; Xu, W.; Palanisamy, S.; Dargusch, M.S.; Xia, K. A modified hall–petch relationship in ultrafine-grained titanium recycled from chips by equal channel angular pressing. Scr. Mater. 2012, 66, 785–788. [Google Scholar] [CrossRef]

- Shehata, F.; Fathy, A.; Abdelhameed, M.; Moustafa, S.F. Preparation and properties of Al2O3 nanoparticle reinforced copper matrix composites by in situ processing. Mater. Des. 2009, 30, 2756–2762. [Google Scholar] [CrossRef]

- Carreño-Gallardo, C.; Estrada-Guel, I.; Romero-Romo, M.; Cruz-García, R.; López-Meléndez, C.; Martínez-Sánchez, R. Characterization of Al2O3NP–Al2024 and AgCNP–Al2024 composites prepared by mechanical processing in a high energy ball mill. J. Alloy. Compd. 2012, 536, 26–30. [Google Scholar] [CrossRef]

- Kollo, L.; Leparoux, M.; Bradbury, C.R.; Jäggi, C.; Carreño-Morelli, E.; Rodríguez-Arbaizar, M. Investigation of planetary milling for nano-silicon carbide reinforced aluminium metal matrix composites. J. Alloy. Compd. 2010, 489, 394–400. [Google Scholar] [CrossRef]

- De Cicco, M.; Turng, L.S.; Li, X.C.; Perepezko, J.H. Production of semi-solid slurry through heterogeneous nucleation in metal matrix nanocomposites (MMNC) using nano-scale ultrasonically dispersed inoculants. Solid State Phenom. 2008, 141–143, 487–492. [Google Scholar]

- Lai, M.O.; Lu, L.; Laing, W. Formation of magnesium nanocomposite via mechanical milling. Compos. Struct. 2004, 66, 301–304. [Google Scholar] [CrossRef]

- Thévenot, F. Boron carbide—A comprehensive review. J. Eur. Ceram. Soc. 1990, 6, 205–225. [Google Scholar] [CrossRef]

- Wu, C.; Shen, Q.; Luo, G.; Fang, P.; Li, C.; Wang, Y.; Zhang, L. Microstructure and mechanical properties of Al-7075/B4C composites fabricated by plasma activated sintering. J. Alloy. Compd. 2014, 588, 265–270. [Google Scholar]

- Bray, G.H.; Glazov, M.; Rioja, R.J.; Li, D.; Gangloff, R.P. Effect of artificial aging on the fatigue crack propagation resistance of 2000 series aluminum alloys. Int. J. Fatigue 2001, 23, 265–276. [Google Scholar] [CrossRef]

- Suryanarayana, C. Mechanical alloying and milling. Prog. Mater. Sci. 2001, 1–2, 1–184. [Google Scholar] [CrossRef]

- Sahin, Y. Preparation and some properties of SiC particle reinforced aluminium alloy composites. Mater. Des. 2003, 24, 671–679. [Google Scholar] [CrossRef]

- Saboori, A.; Moheimani, S.K.; Dadkhah, M.; Pavese, M.; Badini, C.; Fino, P. An overview of key challenges in the fabrication of metal matrix nanocomposites reinforced by graphene nanoplatelets. Metals 2018, 8, 172. [Google Scholar] [CrossRef]

- Matweb, Material Property Data. Available online: http://www.matweb.com. (accessed on 15 April 2018).

- Pérez-Bustamante, R.; Pérez-Bustamante, F.; Maldonado-Orozco, M.C.; Martínez-Sánchez, R. The effect of heat treatment on microstructure evolution in artificially aged carbon nanotube/Al2024 composites synthesized by mechanical alloying. Mater. Charact. 2017, 126, 28–34. [Google Scholar] [CrossRef]

- Xue, L.; Wierzbicki, T. Ductile fracture characterization of aluminum alloy 2024-T351 using damage plasticity theory. Int. J. Appl. Mech. 2009, 1, 267–304. [Google Scholar] [CrossRef]

- Angers, R.; Krishnadev, M.R.; Tremblay, R.; Corriveau, J.-F.; Dubé, D. Characterization of SiCp/2024 aluminum alloy composites prepared by mechanical processing in a low energy ball mill. Mater. Sci. Eng. A 1999, 262, 9–15. [Google Scholar] [CrossRef]

- Vaidya, R.U.; Song, S.G.; Zurek, A.K. Dynamic mechanical response and thermal expansion of ceramic particle reinforced aluminium 6061 matrix composites. Philos. Mag. A 1994, 70, 819–836. [Google Scholar] [CrossRef]

- Yang, Y.; Lan, J.; Li, X. Study on bulk aluminum matrix nano-composite fabricated by ultrasonic dispersion of nano-sized SiC particles in molten aluminum alloy. Mater. Sci. Eng. A 2004, 380, 378–383. [Google Scholar] [CrossRef]

- Martínez-Sánchez, R.; Reyes-Gasga, J.; Caudillo, R.; García-Gutierrez, D.I.; Márquez-Lucero, A.; Estrada-Guel, I.; Mendoza-Ruiz, D.C.; José-Yacaman, M. Mechanical and microstructural characterization of aluminum reinforced with carbon-coated silver nanoparticles. J. Alloy. Compd. 2007, 438, 195–201. [Google Scholar] [CrossRef]

© 2018 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (http://creativecommons.org/licenses/by/4.0/).

Share and Cite

Carreño-Gallardo, C.; Estrada-Guel, I.; López-Meléndez, C.; Ledezma-Sillas, E.; Castañeda-Balderas, R.; Pérez-Bustamante, R.; Herrera-Ramírez, J.M. B4C Particles Reinforced Al2024 Composites via Mechanical Milling. Metals 2018, 8, 647. https://doi.org/10.3390/met8080647

Carreño-Gallardo C, Estrada-Guel I, López-Meléndez C, Ledezma-Sillas E, Castañeda-Balderas R, Pérez-Bustamante R, Herrera-Ramírez JM. B4C Particles Reinforced Al2024 Composites via Mechanical Milling. Metals. 2018; 8(8):647. https://doi.org/10.3390/met8080647

Chicago/Turabian StyleCarreño-Gallardo, Caleb, Ivanovich Estrada-Guel, Claudia López-Meléndez, Ernesto Ledezma-Sillas, Rubén Castañeda-Balderas, Raúl Pérez-Bustamante, and José Martín Herrera-Ramírez. 2018. "B4C Particles Reinforced Al2024 Composites via Mechanical Milling" Metals 8, no. 8: 647. https://doi.org/10.3390/met8080647