Mechanisms for Improvement of Weld Appearance in Autogenous Fiber Laser Welding of Thick Stainless Steels

Abstract

1. Introduction

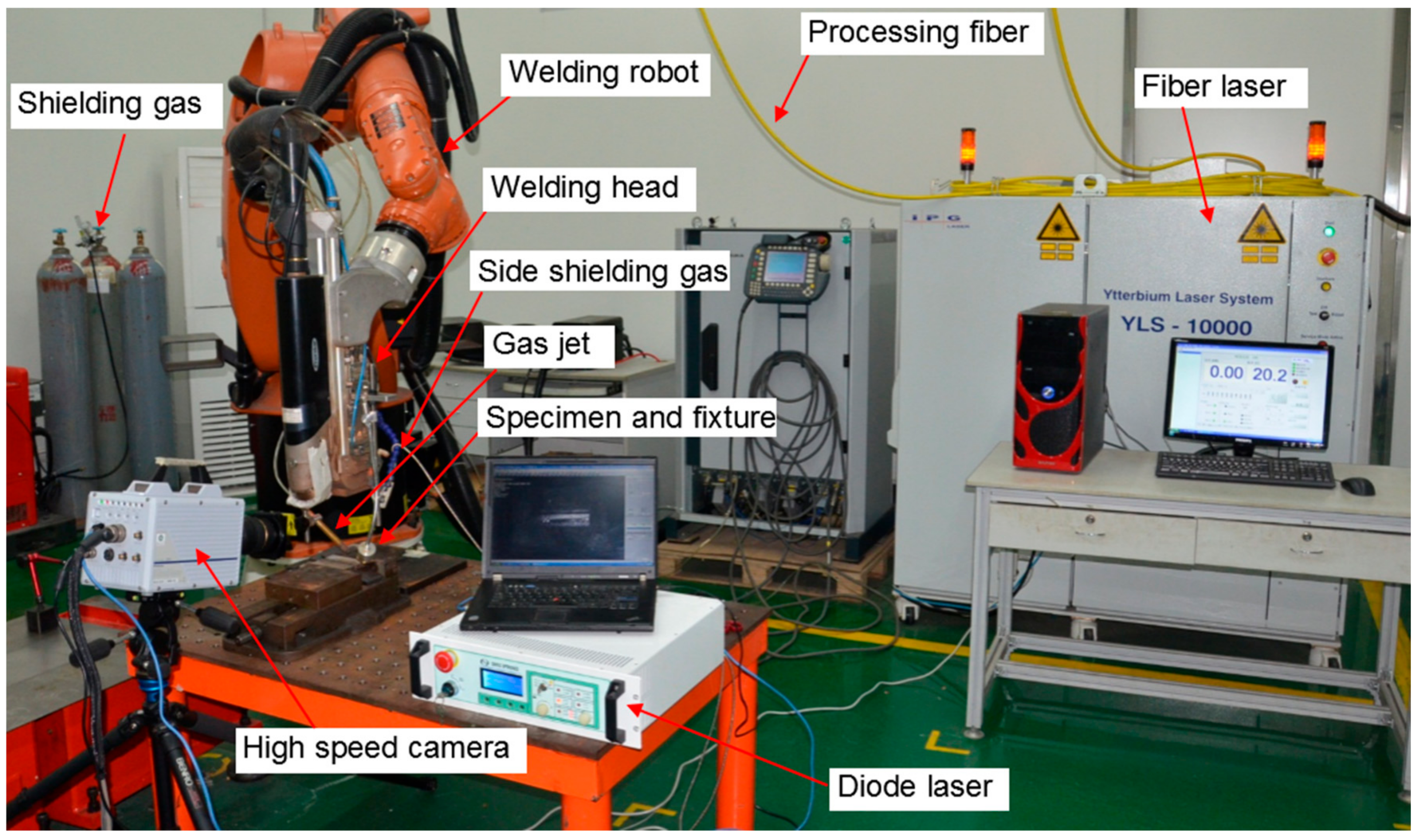

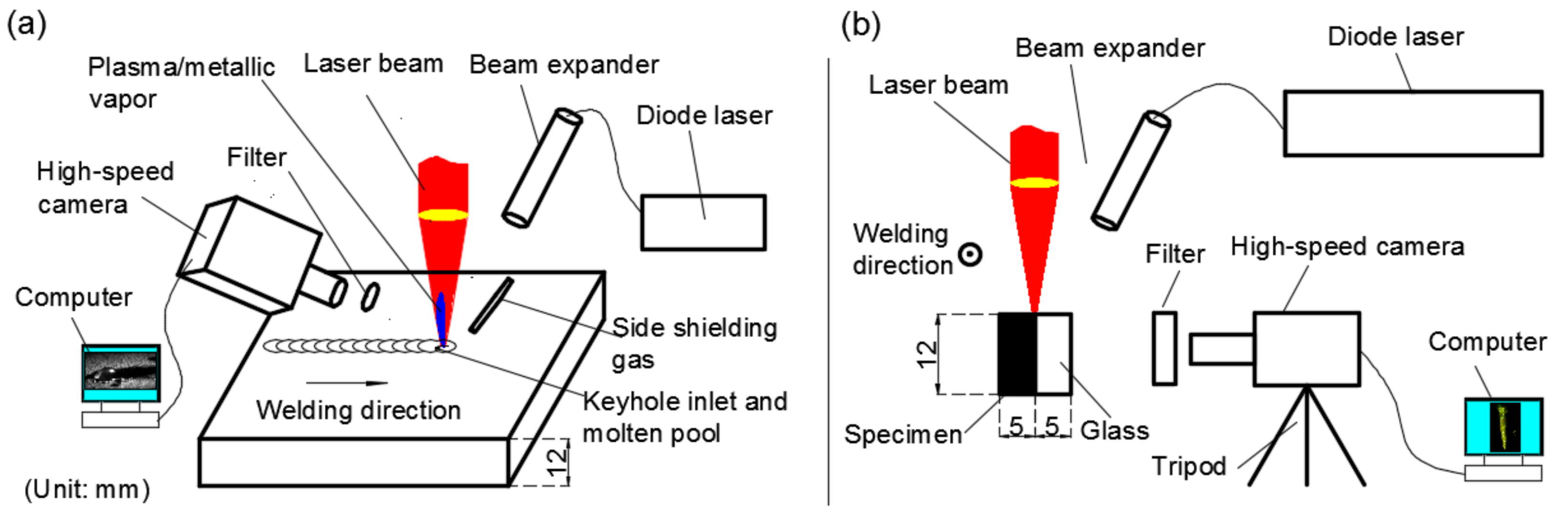

2. Design of Experiments (DoE)

3. Results and Discussion

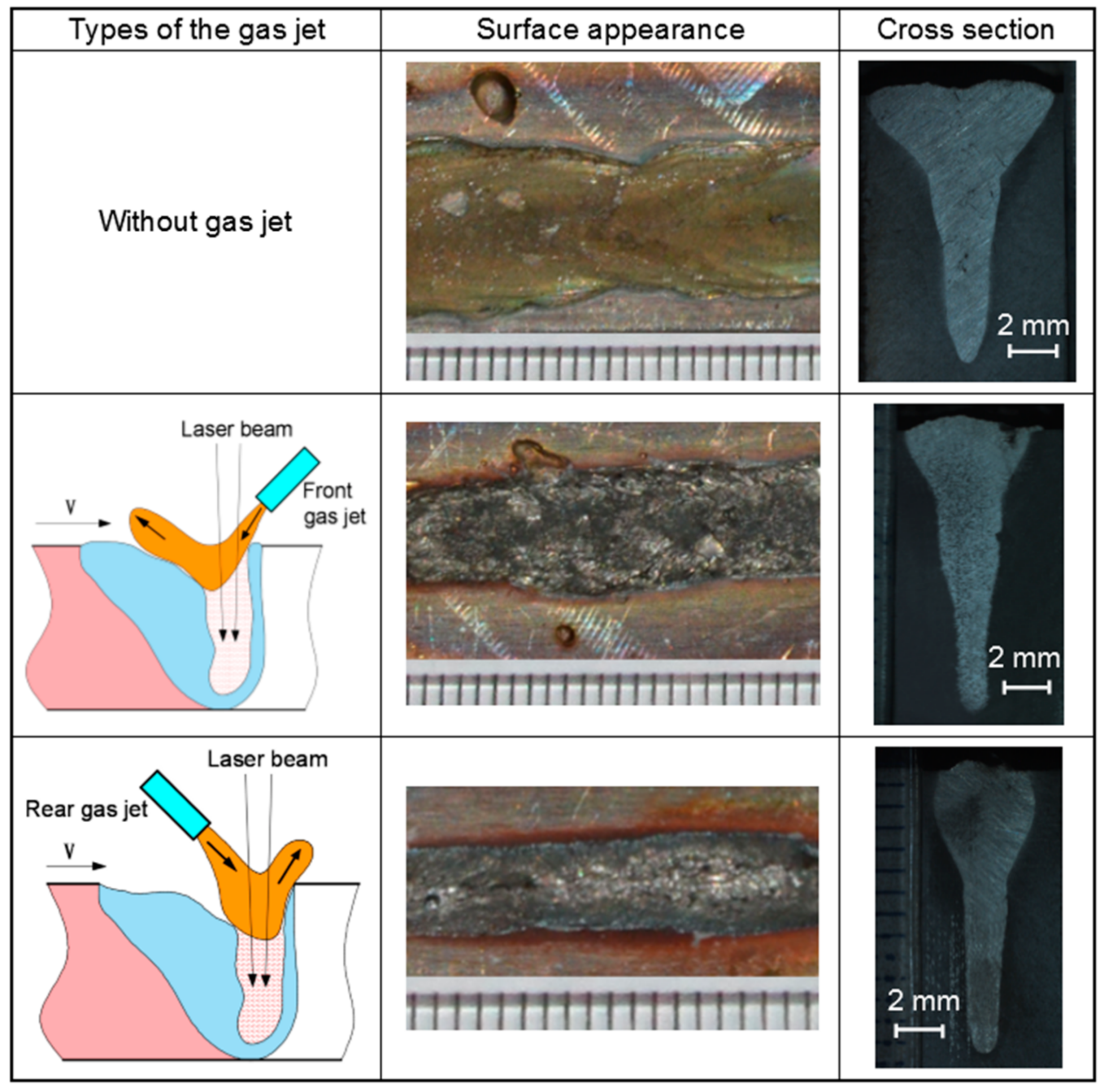

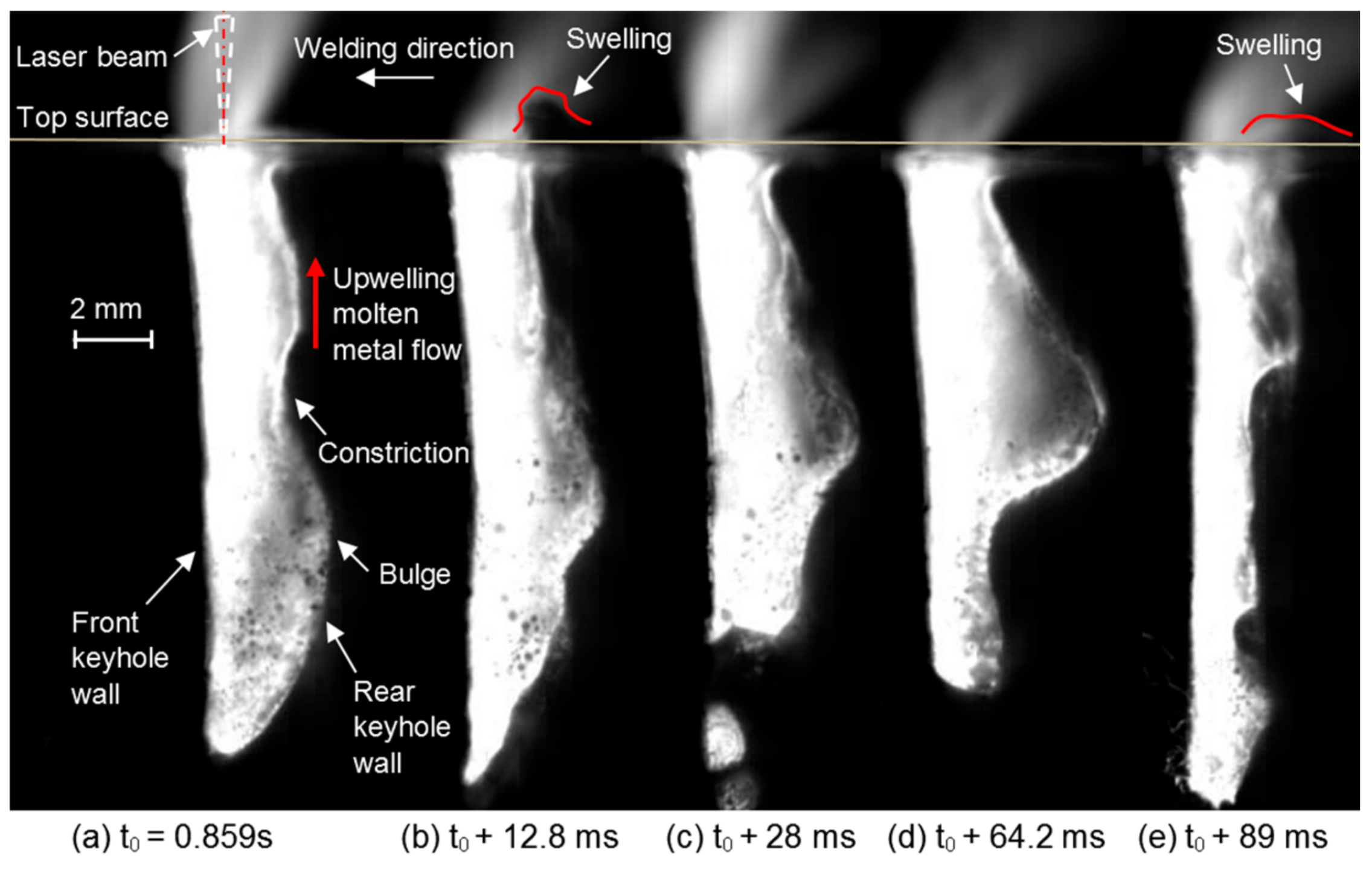

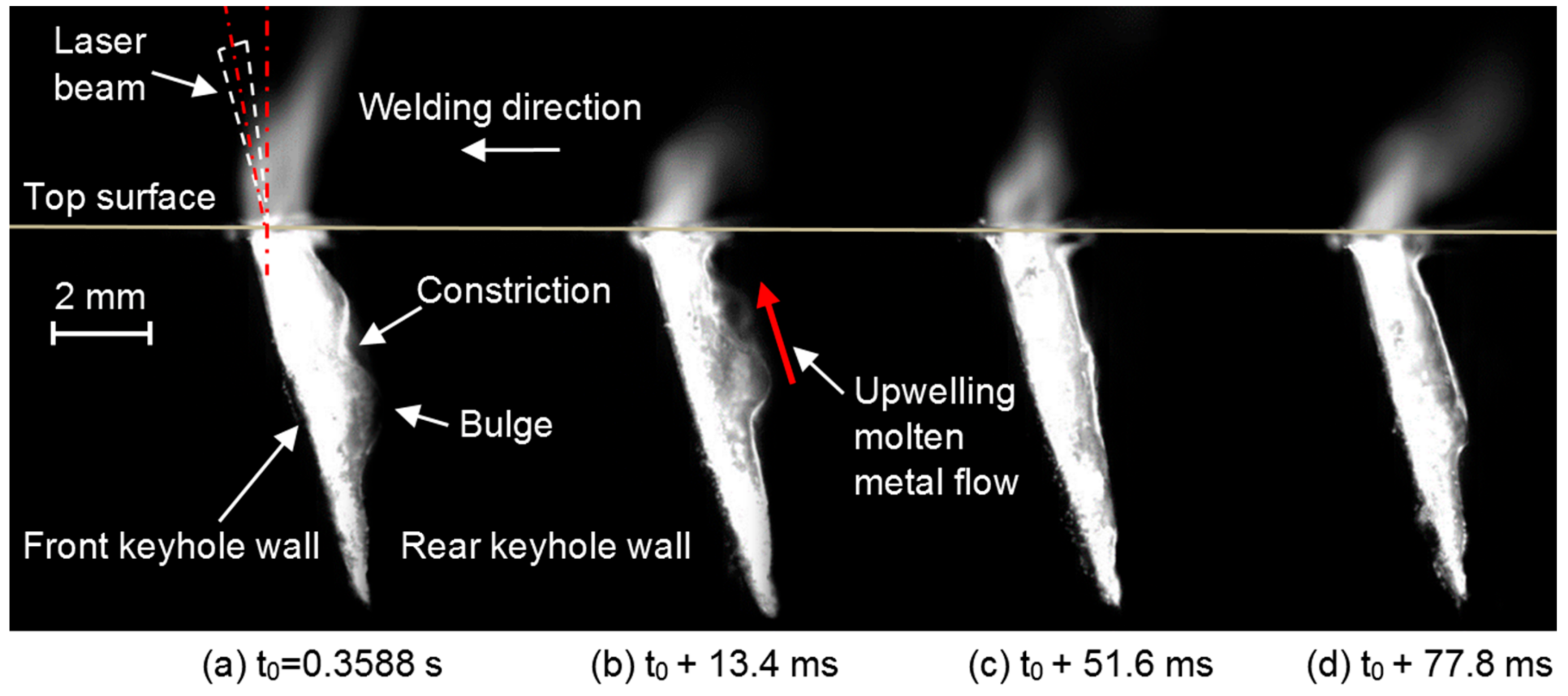

3.1. Effect of Gas Jet on Formation of Nail-Head-Shaped Weld

3.1.1. Weld Appearance

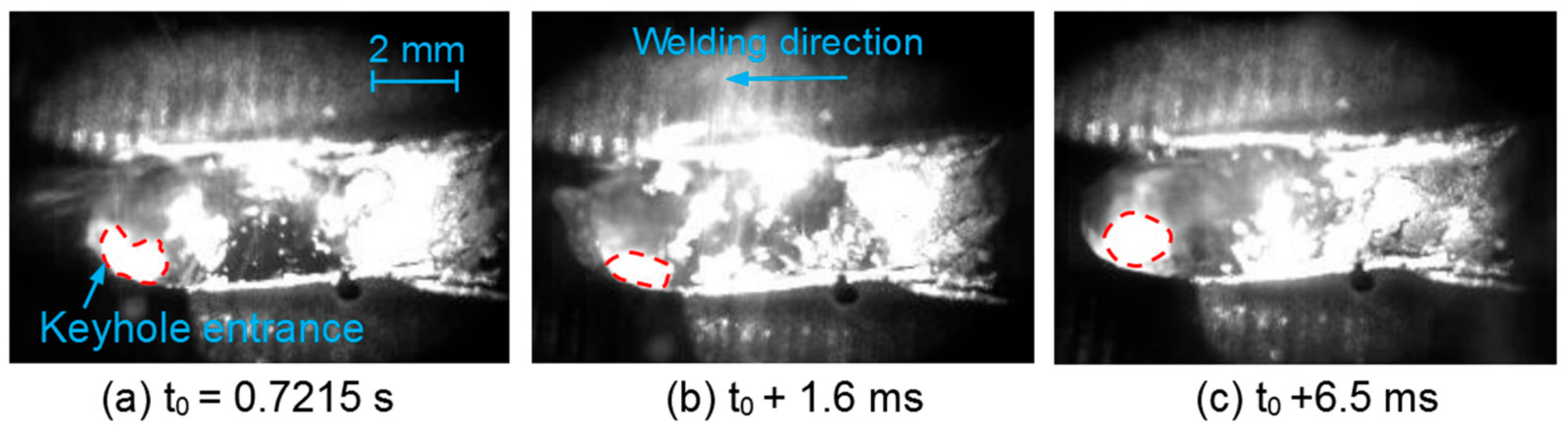

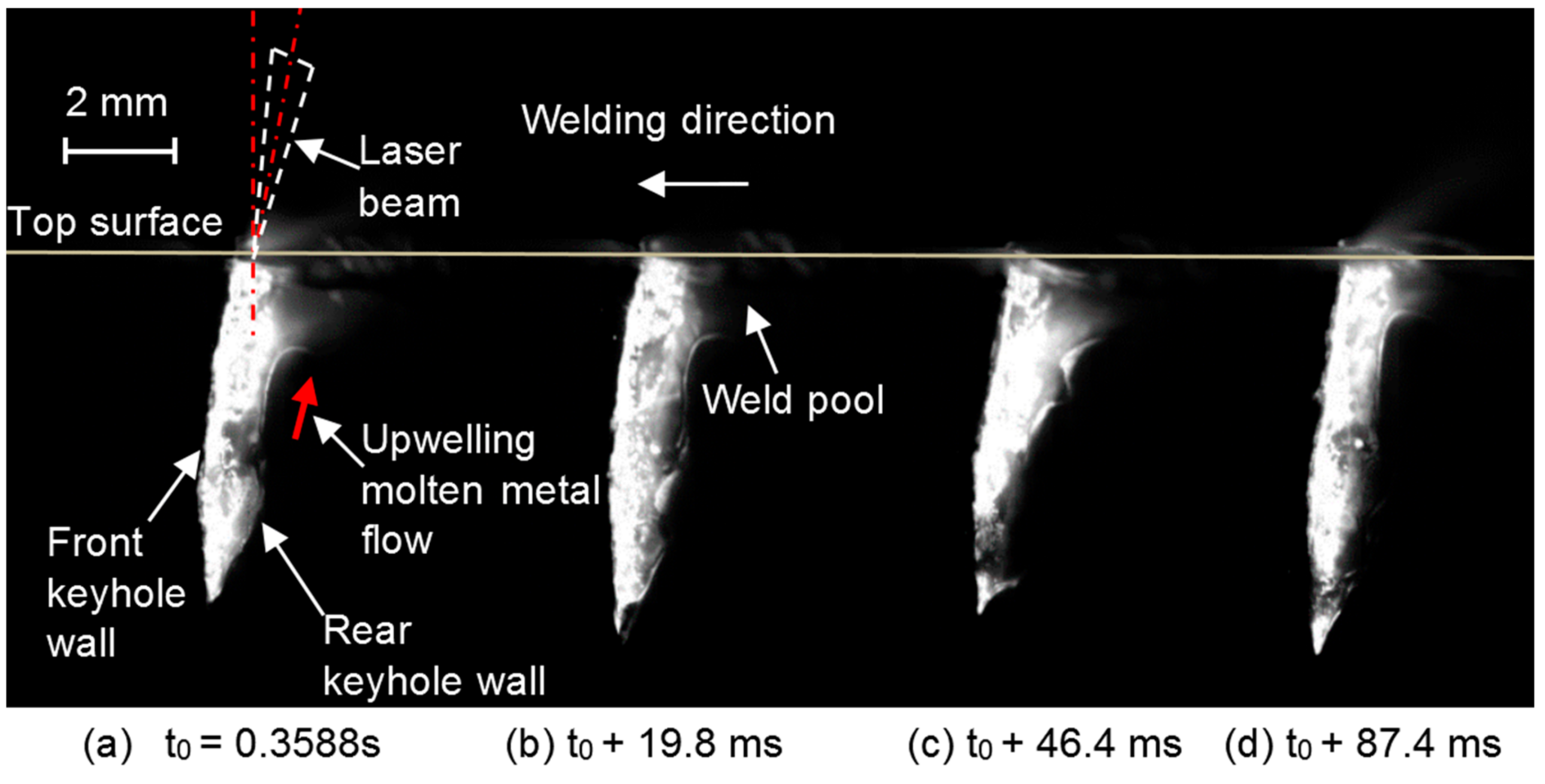

3.1.2. Control Mechanism of Nail-Head-Shaped Weld with a Gas Jet

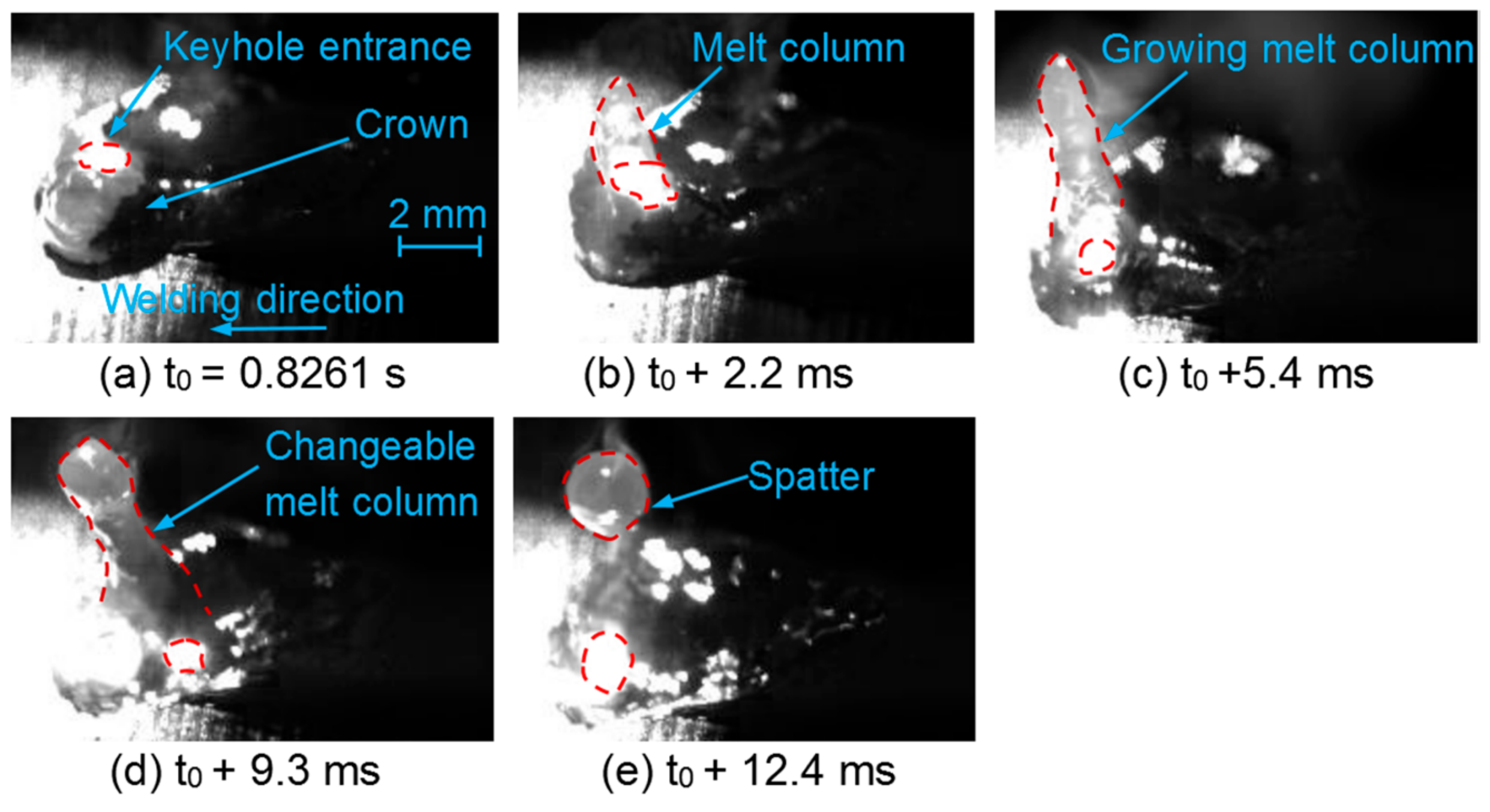

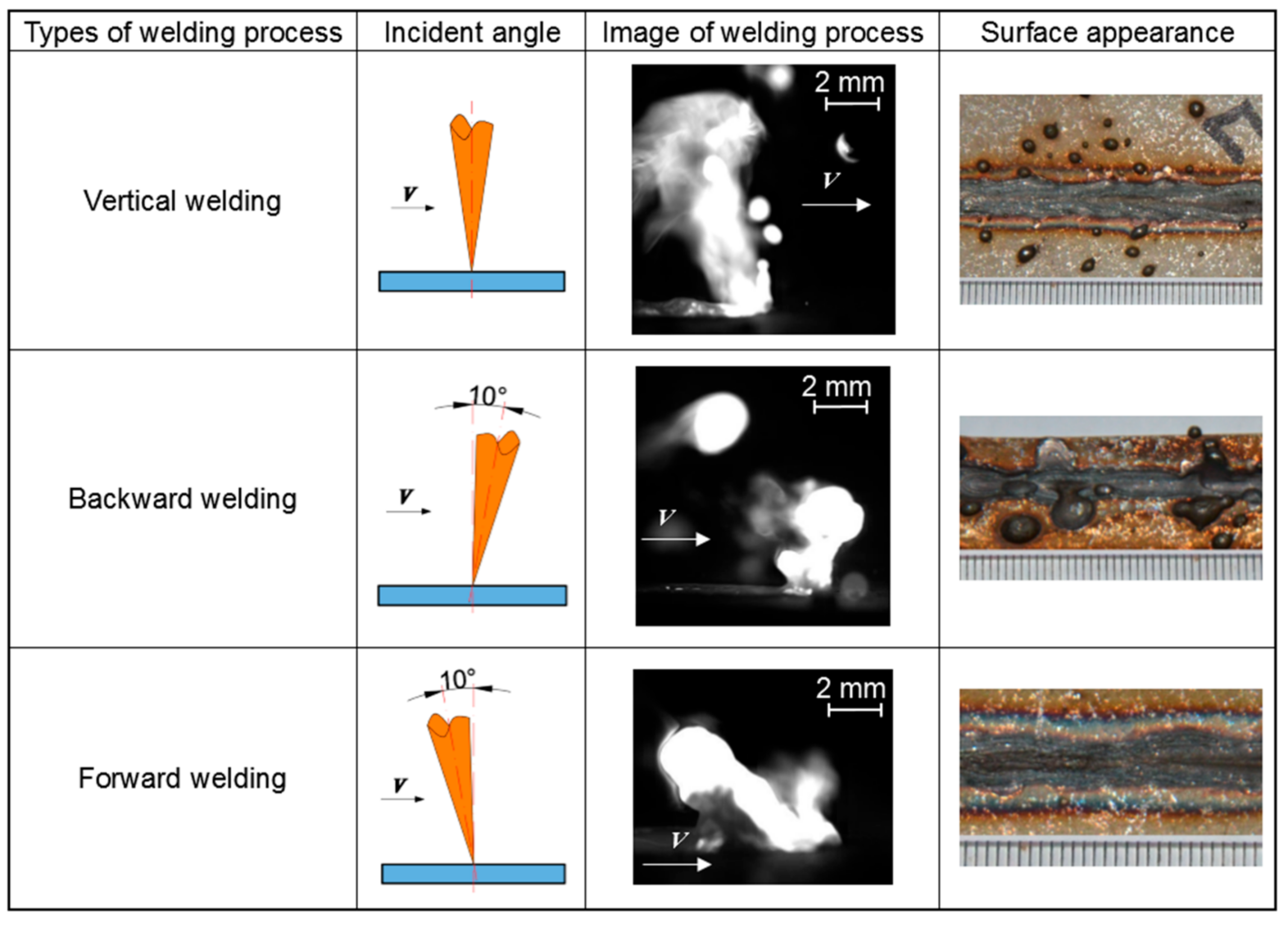

3.2. Effect of Laser Incident Angle on Formation of Spatters

3.2.1. Weld Appearance

3.2.2. Suppression Mechanism of Spatters in a Forward Welding

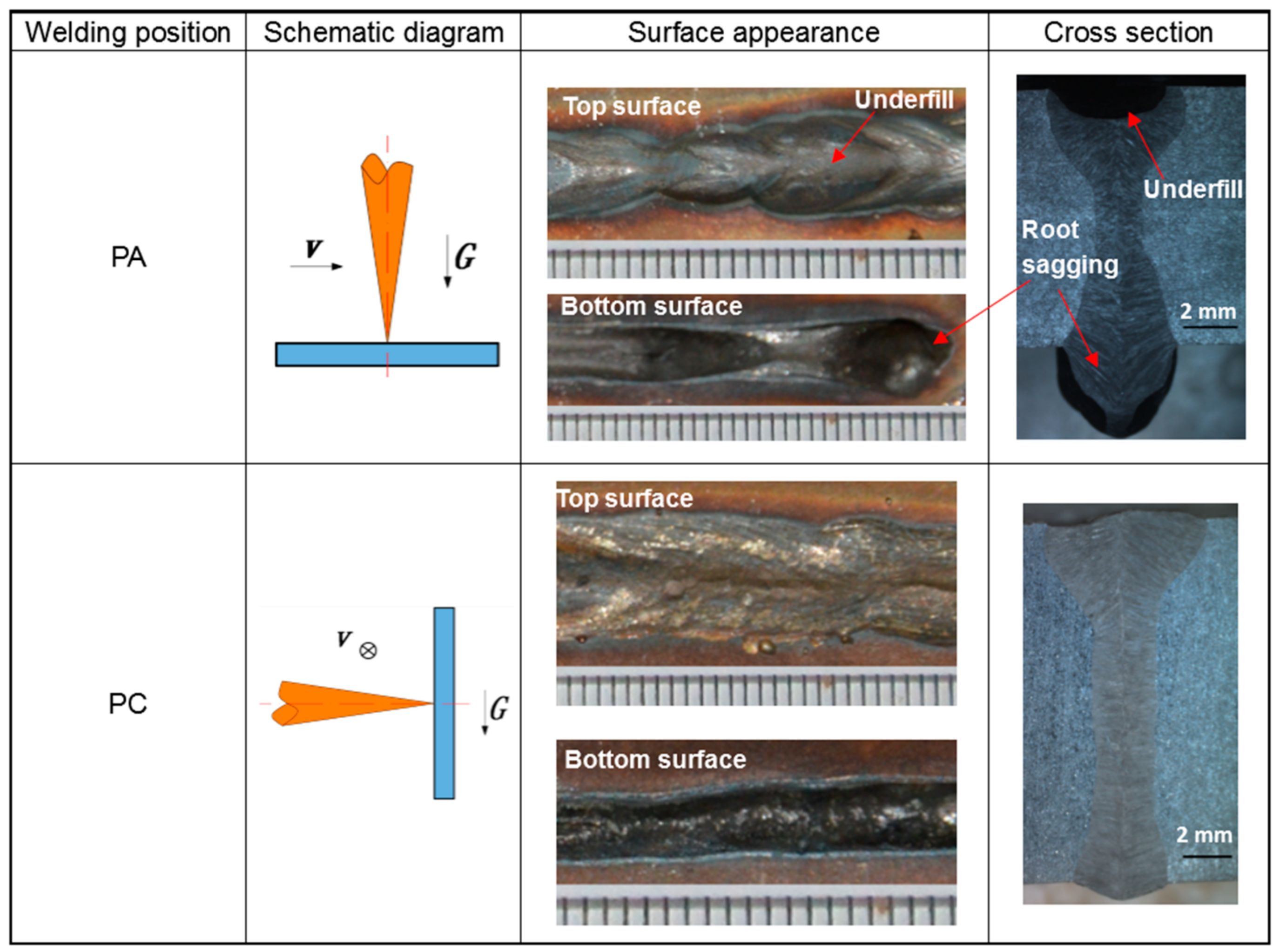

3.3. Effect of Welding Position on Formation of Root Sagging

3.3.1. Weld Appearance

3.3.2. Suppression Mechanism of Root Sagging in PC Welding Position

4. Conclusions

Author Contributions

Funding

Acknowledgments

Conflicts of Interest

References

- Vollertsen, F.; Thomy, C. Welding with fiber lasers from 200 to 17000 W. In Proceedings of the Laser 24th International Congress on Applications of Lasers and Electro-Optics, Miami, FL, USA, 1 January 2005; Laser Institute of America: Orlando, FL, USA, 2005. [Google Scholar]

- Fomin, V.; Gapontsev, V.; Shcherbakov, E.; Abramov, A.; Ferin, A.; Mochalov, D. 100 kW CW fiber laser for industrial applications. In Proceedings of the 2014 International Conference Laser Optics, Burbach, Germany, 28 August 2014; IEEE: St. Petersburg, Russia, 2014. [Google Scholar]

- Guo, W.; Crowther, D.; Francis, J.A.; Thompson, A.; Liu, Z.; Li, L. Microstructure and mechanical properties of laser welded S960 high strength steel. Mater. Des. 2015, 85, 534–548. [Google Scholar] [CrossRef]

- Zhang, L.J.; Bai, Q.L.; Ning, J.; Wang, A.; Yang, N.J.; Yin, X.Q.; Zhang, J.X. A comparative study on the microstructure and properties of copper joint between MIG welding and laser-MIG hybrid welding. Mater. Des. 2016, 10, 35–50. [Google Scholar] [CrossRef]

- Katayama, S.; Kawahito, Y.; Mizutani, M. Elucidation of laser welding phenomena and factors affecting weld penetration and welding defects. Phys. Procedia 2010, 5, 9–17. [Google Scholar] [CrossRef]

- Li, S.; Xu, W.; Su, F.; Deng, H.; Deng, Z. Influence of CO2 shielding gas on high power fiber laser welding performance. Metals 2018, 8, 449. [Google Scholar] [CrossRef]

- Popescu, A.; Delval, C.; Leparoux, M. Control of porosity and spatter in laser welding of thick AlMg5 parts using high-speed imaging and optical microscopy. Metals 2017, 7, 452. [Google Scholar] [CrossRef]

- Nishimoto, K.; Woo, I.; Ogita, T.; Shirai, M. The factors affecting HAZ crack susceptibility in the laser weld: Study on weldability of cast alloy 718 (report 4). Q. J. Jpn. Weld. Soc. 2001, 19, 308–316. [Google Scholar] [CrossRef]

- Rai, R.; Palmer, T.A.; Elmer, J.W.; Debroy, T. Heat transfer and fluid flow during electron beam welding of 304L stainless steel alloy. Weld. J. 2009, 88, 54–61. [Google Scholar]

- Zacharia, T.; David, S.A.; Vitek, J.M.; Debroy, T. Weld pool development during GTA and laser beam welding of type 304 stainless steel; Part II-experimental correlation. Weld. J. 1989, 68, 510–519. [Google Scholar]

- Bachmann, M.; Avilov, V.; Gumenyuk, A.; Rethmeier, M. About the influence of a steady magnetic field on weld pool dynamics in partial penetration high power laser beam welding of thick aluminium parts. Int. J. Heat Mass Transf. 2013, 60, 309–321. [Google Scholar] [CrossRef]

- Kaplan, A.F.H.; Powell, J. Spatter in laser welding. J. Laser Appl. 2011, 23, 3337–3344. [Google Scholar] [CrossRef]

- Semak, V.; Matsunawa, A. The role of recoil pressure in energy balance during laser materials processing. J. Phys. D Appl. Phys. 1997, 30, 2541–2552. [Google Scholar] [CrossRef]

- Blecher, J.J.; Palmer, T.A.; DebRoy, T. Mitigation of root defect in laser and hybrid laser-arc welding. Weld. J. 2015, 94, 73–82. [Google Scholar]

- Guo, W.; Liu, Q.; Francis, J.A.; Crowther, D.; Thompson, A.; Liu, Z. Comparison of laser welds in thick section S700 high-strength steel manufactured in flat (1G) and horizontal (2G) positions. CIRP Ann.-Manuf. Technol. 2015, 64, 197–200. [Google Scholar] [CrossRef]

- Eriksson, I.; Powell, J.; Kaplan, A. Measurements of fluid flow on keyhole front during laser welding. Sci. Technol. Weld. Join. 2011, 16, 636–641. [Google Scholar] [CrossRef]

- Kaplan, A.F. Local flashing events at the keyhole front in laser welding. Opt. Lasers Eng. 2015, 68, 35–41. [Google Scholar] [CrossRef]

- Kaplan, A.F. Fresnel absorption of 1 μm- and 10 μm-laser beams at the keyhole wall during laser beam welding: Comparison between smooth and wavy surfaces. Appl. Surf. Sci. 2012, 258, 3354–3363. [Google Scholar] [CrossRef]

- Haug, P.; Rominger, V.; Speker, N.; Weber, R.; Graf, T.; Weigl, M.; Schmidt, M. Influence of laser wavelength on melt bath dynamics and resulting seam quality at welding of thick plates. Phys. Procedia 2013, 41, 49–58. [Google Scholar] [CrossRef]

- Zhang, M.J.; Zhang, Z.; Tang, K.; Mao, C.; Hu, Y.L.; Chen, G.Y. Analysis of mechanisms of underfill in full penetration laser welding of thick stainless steel with a 10 kw fiber laser. Opt. Laser Technol. 2018, 98, 97–105. [Google Scholar] [CrossRef]

- Zhang, M.J.; Chen, G.Y.; Zhou, Y.; Li, S.C.; Deng, H. Observation of spatter formation mechanisms in high-power fiber laser welding of thick plate. Appl. Surf. Sci. 2013, 280, 868–875. [Google Scholar] [CrossRef]

- Kamimuki, K.; Inoue, T.; Yasuda, K.; Muro, M.; Nakabayashi, T.; Matsunawa, A. Prevention of welding defect by side gas flow and its monitoring method in continuous wave Nd: YAG laser welding. J. Laser Appl. 2002, 14, 136–145. [Google Scholar] [CrossRef]

- Fabbro, R.; Slimani, S.; Doudet, I.; Coste, F.; Briand, F. Experimental study of the dynamical coupling between the induced vapour plume and the melt pool for Nd Yag CW laser welding. J. Phys. D Appl. Phys. 2006, 39, 394. [Google Scholar] [CrossRef]

- Semak, V.V.; Hopkins, J.A.; Mccay, M.H.; Mccay, T.D. Melt pool dynamics during laser welding. J. Phys. D Appl. Phys. 1995, 28, 2443–2450. [Google Scholar] [CrossRef]

- Katayama, S.; Kawahito, Y. Elucidation of phenomena in high power fiber laser welding and development of prevention procedures of welding defects. In Proceedings of the SPIE LASE: Lasers and Applications in Science and Engineering, San Jose, CA, USA, 19 February 2009; Elsevier: Osaka, Japan, 2009. [Google Scholar]

- Ilar, T.; Eriksson, I.; Powell, J.; Kaplan, A. Root humping in laser welding—an investigation based on high speed imaging. Phys. Procedia 2012, 39, 27–32. [Google Scholar] [CrossRef]

- Berger, P.; Hügel, H.; Hess, A.; Weber, R.; Graf, T. Understanding of humping based on conservation of volume flow. Phys. Procedia 2011, 12, 232–240. [Google Scholar] [CrossRef]

| Weld No. | Weld Sample | Weld Speed (v) (m/min−1) | Defocus (Δ) (mm) | Shielding Gas Flow (q) (L/min) (N2) | Gas Jet (Ar) | Angle of Incidence (°) | Welding Position |

|---|---|---|---|---|---|---|---|

| 1 | Bead-on-plate | 0.9 | −5 | 10 | No | No | PA |

| 2 | Bead-on-plate | 0.9 | −5 | 10 | Front gas jet | No | PA |

| 3 | Bead-on-plate | 0.9 | −5 | 10 | Rear gas jet | No | PA |

| 4 | Bead-on-plate | 1.8 | +10 | 30 | No | No | PA |

| 5 | Bead-on-plate | 1.8 | +10 | 30 | No | +10 | PA |

| 6 | Bead-on-plate | 1.8 | +10 | 30 | No | −10 | PA |

| 7 | Modified ‘sandwich’ | 1.8 | +10 | 0 | No | No | PA |

| 8 | Modified ‘sandwich’ | 1.8 | +10 | 0 | No | +10 | PA |

| 9 | Modified ‘sandwich’ | 1.8 | +10 | 0 | No | −10 | PA |

| 10 | Bead-on-plate | 1.2 | +10 | 20 | No | No | PA |

| 11 | Bead-on-plate | 1.2 | +10 | 20 | No | No | PC |

| 12 | Bead-on-plate | 0.9 | +10 | 20 | No | No | PA |

| 13 | Bead-on-plate | 0.9 | +10 | 20 | No | No | PC |

© 2018 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (http://creativecommons.org/licenses/by/4.0/).

Share and Cite

Zhang, M.; Chen, S.; Zhang, Y.; Chen, G.; Bi, Z. Mechanisms for Improvement of Weld Appearance in Autogenous Fiber Laser Welding of Thick Stainless Steels. Metals 2018, 8, 625. https://doi.org/10.3390/met8080625

Zhang M, Chen S, Zhang Y, Chen G, Bi Z. Mechanisms for Improvement of Weld Appearance in Autogenous Fiber Laser Welding of Thick Stainless Steels. Metals. 2018; 8(8):625. https://doi.org/10.3390/met8080625

Chicago/Turabian StyleZhang, Mingjun, Shun Chen, Yingzhe Zhang, Genyu Chen, and Zhuming Bi. 2018. "Mechanisms for Improvement of Weld Appearance in Autogenous Fiber Laser Welding of Thick Stainless Steels" Metals 8, no. 8: 625. https://doi.org/10.3390/met8080625

APA StyleZhang, M., Chen, S., Zhang, Y., Chen, G., & Bi, Z. (2018). Mechanisms for Improvement of Weld Appearance in Autogenous Fiber Laser Welding of Thick Stainless Steels. Metals, 8(8), 625. https://doi.org/10.3390/met8080625