Nanoscale Twinned Ti-44Al-4Nb-1.5Mo-0.007Y Alloy Promoted by High Temperature Compression with High Strain Rate

Abstract

1. Introduction

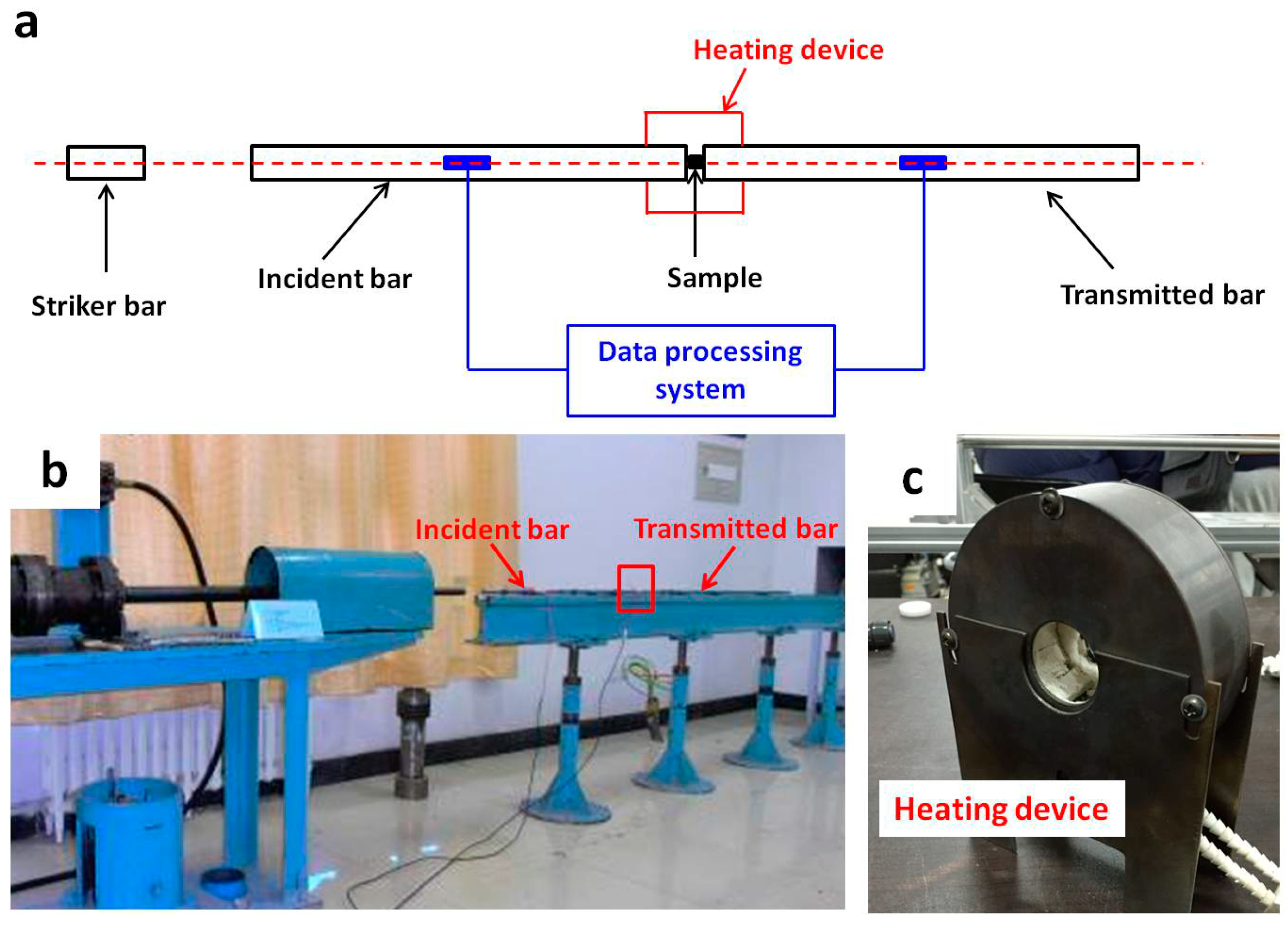

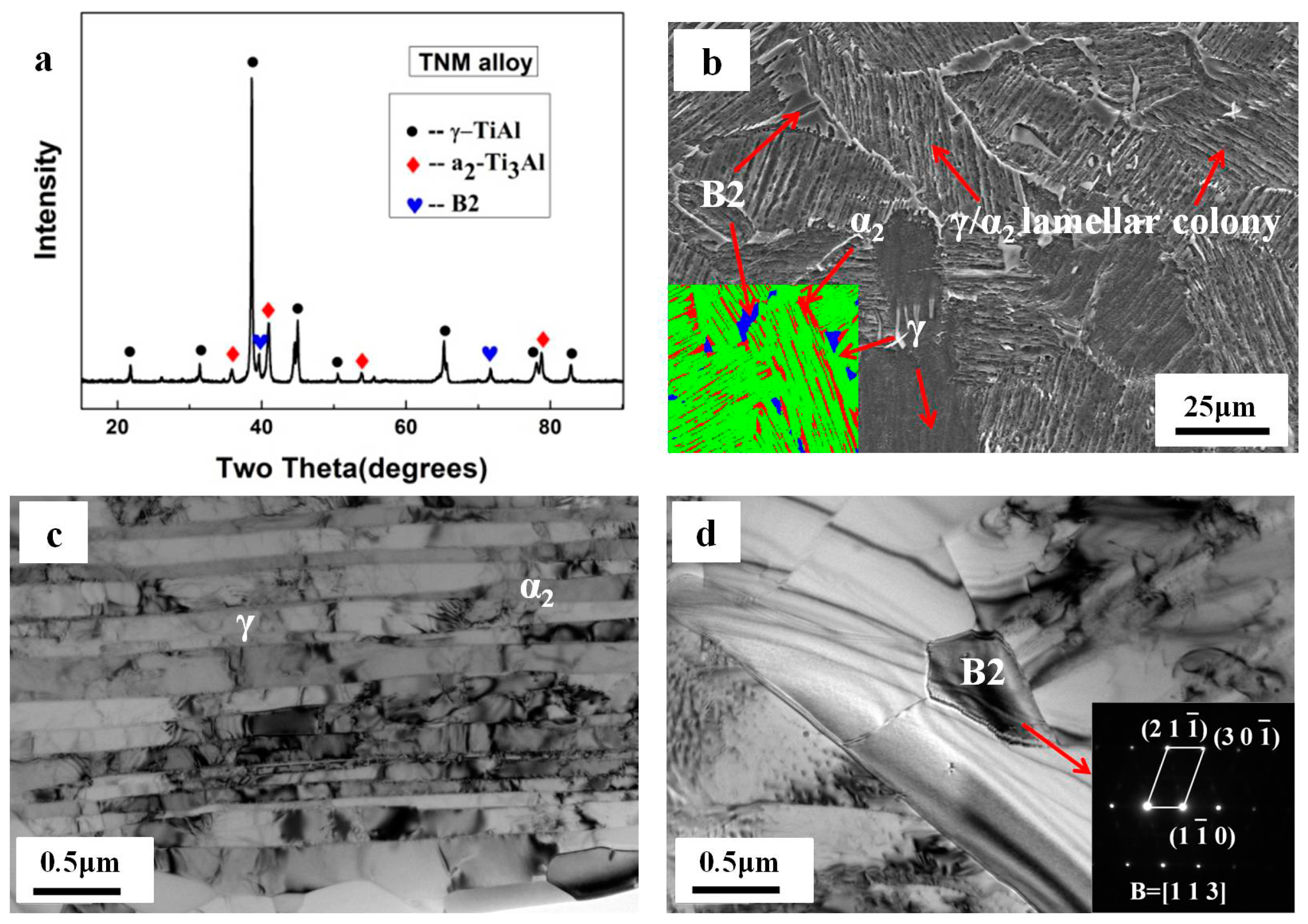

2. Materials and Methods

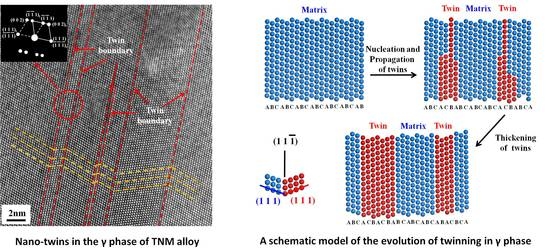

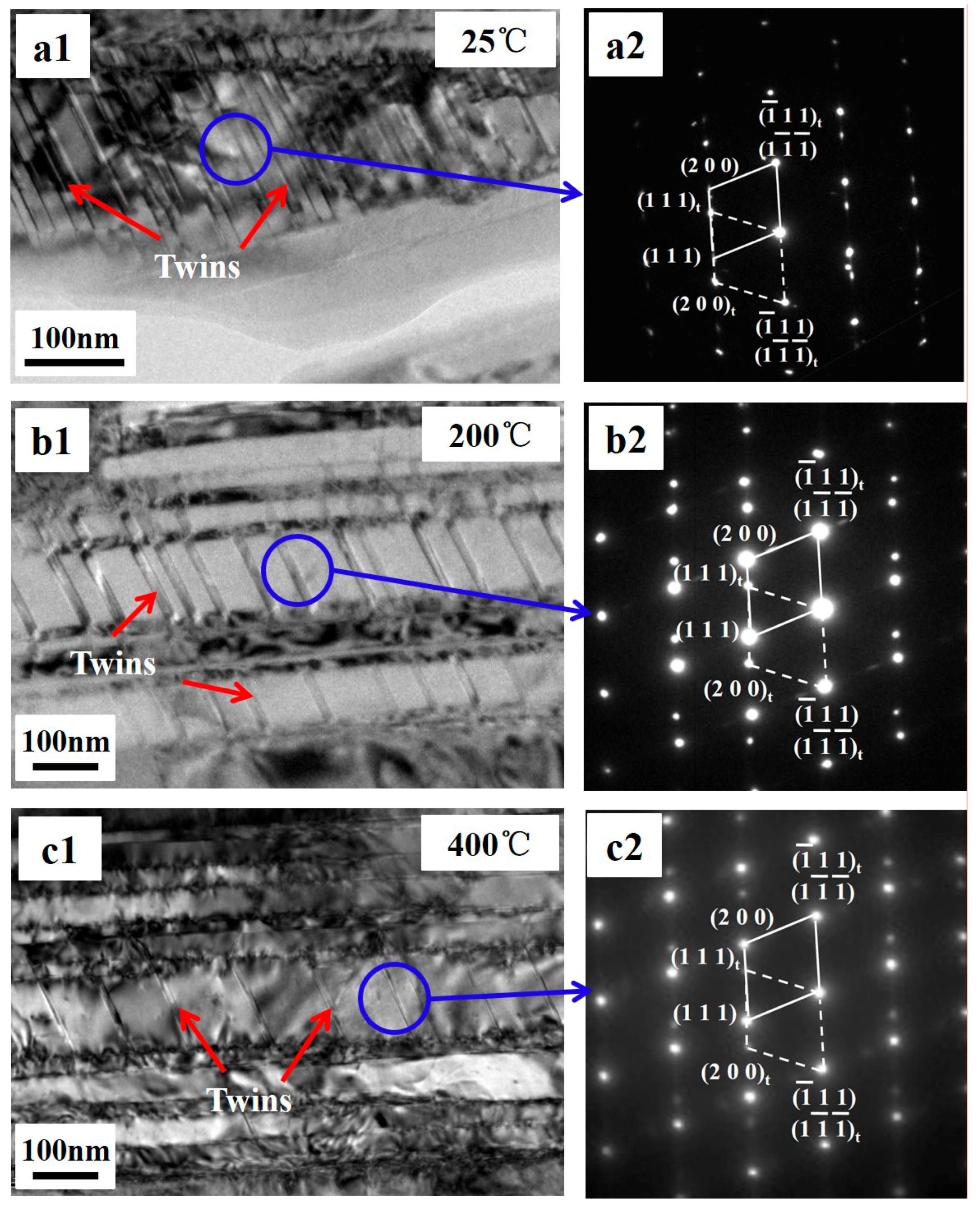

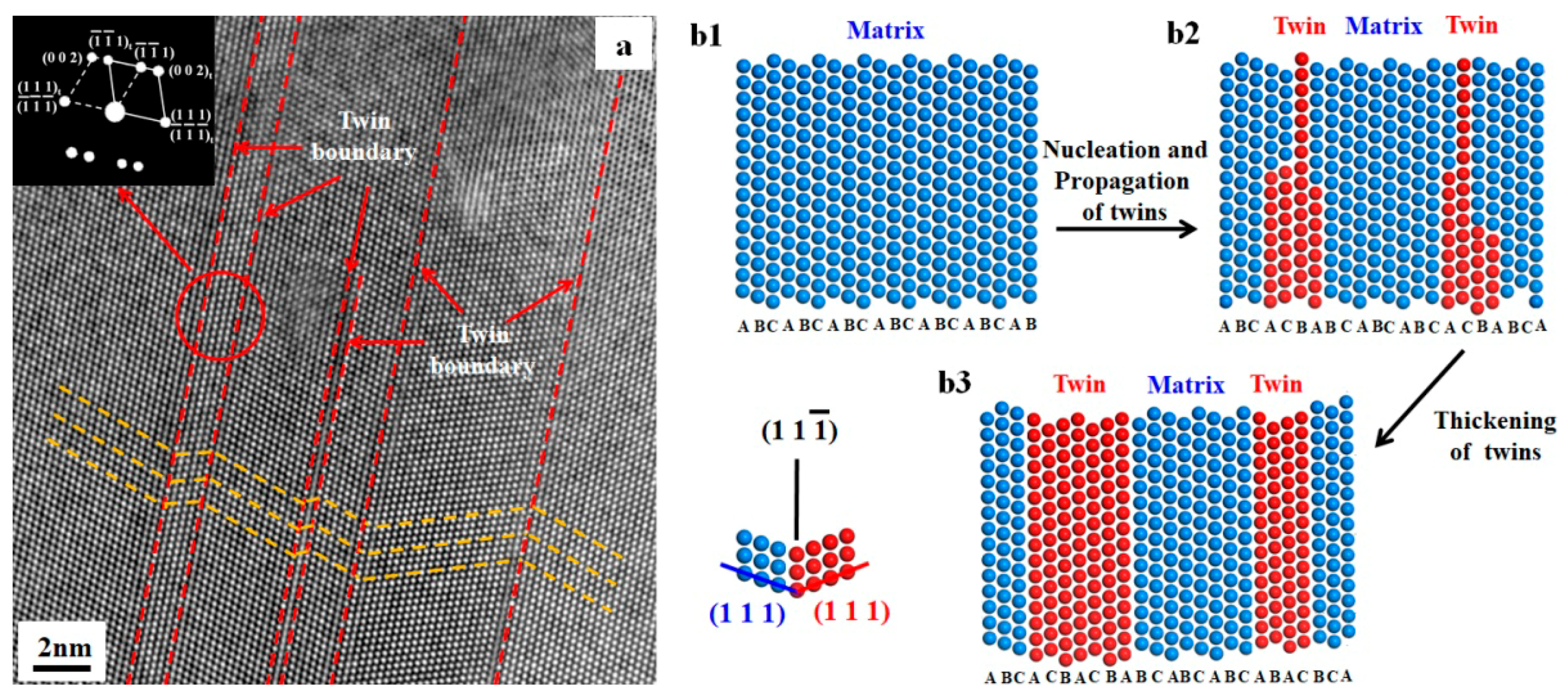

3. Results

4. Discussion

5. Conclusions

Author Contributions

Funding

Conflicts of Interest

References

- Wei, D.X.; Koizumi, Y.; Nagasako, M.; Chiba, A. Refinement of lamellar structures in Ti-Al alloy. Acta Mater. 2017, 125, 81–97. [Google Scholar] [CrossRef]

- Bartels, A.; Clemens, H.; Dehm, G.; Lach, E.; Schillinger, W. Strain Rate Dependence of the Deformation Mechanisms in a Fully Lamellar γ-TiAl-Based Alloy. Zeitschrift für Metallkunde 2002, 93, 180–185. [Google Scholar] [CrossRef]

- Erdely, P.; Staron, P.; Maawad, E. Effect of hot rolling and primary annealing on the microstructure and texture of a β-stabilised γ-TiAl based alloy. Acta Mater. 2017, 126, 145–153. [Google Scholar] [CrossRef]

- Wang, Q.; Ding, H.S.; Zhang, H. Influence of Mn addition on the microstructure and mechanical properties of a directionally solidified γ-TiAl alloy. Mater. Charact. 2018, 137, 133–141. [Google Scholar] [CrossRef]

- Vajpai, S.K.; Ameyama, K. A novel powder metallurgy processing approach to prepare fine-grained Ti-rich TiAl-based alloys from pre-alloyed powders. Intermetallics 2013, 42, 146–155. [Google Scholar] [CrossRef]

- Draper, S.L.; Krause, D.; Lerch, B. Development and evaluation of TiAl sheet structures for hypersonic applications. Mater. Sci. Eng. A 2007, 464, 330–342. [Google Scholar] [CrossRef]

- Clemens, H.; Kestler, H. Processing and Applications of Intermetallic γ-TiAl-Based Alloys. Adv. Eng. Mater. 2000, 2, 551–570. [Google Scholar] [CrossRef]

- Clemens, H.; Mayer, S. Design, Processing, Microstructure, Properties, and Applications of Advanced Intermetallic TiAl Alloys. Adv. Eng. Mater. 2013, 15, 191–215. [Google Scholar] [CrossRef]

- Liang, X.; Liu, Y.; Li, H.; Gan, Z. An investigation on microstructural and mechanical properties of powder metallurgical TiAl alloy during hot pack-rolling. Mater. Sci. Eng. A 2014, 619, 265–273. [Google Scholar] [CrossRef]

- Monchoux, J.P.; Luo, J.S.; Voisin, T. Deformation modes and size effect in near-γ TiAl alloys. Mater. Sci. Eng. A 2017, 679, 123–132. [Google Scholar] [CrossRef]

- Cheng, L.; Li, J.S.; Xue, X.Y. Superplastic deformation mechanisms of high Nb containing TiAl alloy with (α2 + γ) microstructure. Intermetallics 2016, 75, 62–71. [Google Scholar] [CrossRef]

- Cao, G.H.; Russell, A.M.; Oertel, C.-G. Microstructural evolution of TiAl-based alloys deformed by high-pressure torsion. Acta Mater. 2015, 98, 103–112. [Google Scholar] [CrossRef]

- Chen, G.L.; Zhang, L.C. Deformation mechanism at large strains in a high-Nb-containing TiAL at room temperature. Mater. Sci. Eng. A 2002, 329, 163–170. [Google Scholar] [CrossRef]

- Rackel, M.W.; Stark, A.; Gabrisch, H. Orthorhombic phase formation in a Nb-rich γ-TiAl based alloy—An in situ synchrotron radiation investigation. Acta Mater. 2016, 121, 343–351. [Google Scholar] [CrossRef]

- Jiang, H.T.; Tian, S.W.; Guo, W.Q. Hot deformation behavior and deformation mechanism of two TiAl-Mo alloys during hot compression. Mater. Sci. Eng. A 2018, 719, 104–111. [Google Scholar] [CrossRef]

- Jiang, H.T.; Zeng, S.W.; Zhao, A.M. Hot deformation behavior of β phase containing γ-TiAl alloy. Mater. Sci. Eng. A 2016, 661, 160–167. [Google Scholar] [CrossRef]

- Niu, H.Z.; Chen, Y.Y.; Xiao, S.L. High temperature deformation behaviors of Ti-45Al-2Nb-1.5V-1Mo-Y alloy. Intermetallics 2011, 19, 1767–1774. [Google Scholar] [CrossRef]

- Wang, G.; Xu, L.; Tian, Y.X. Flow behavior and microstructure evolution of a P/M TiAl alloy during high temperature deformation. Mater. Sci. Eng. A 2011, 528, 6754–6763. [Google Scholar] [CrossRef]

- Kothari, K.; Radhakrishnan, R.; Wereley, N.M. Advances in gamma titanium aluminides and their manufacturing techniques. Prog. Aerosp. Sci. 2012, 55, 1–16. [Google Scholar] [CrossRef]

- Hao, Y.J.; Liu, J.X.; Li, J.C. Investigation on dynamic properties and failure mechanisms of Ti–47Al–2Cr–2Nb alloy under uniaxial dynamic compression at a temperature range of 288 K–773 K. J. Alloys Compd. 2015, 649, 122–127. [Google Scholar]

- Maloy, S.A.; Gray, G.T., III. High strain rate deformation of Ti–48Al–2Nb–2Cr. Acta Mater. 1996, 44, 1741–1756. [Google Scholar] [CrossRef]

- Zan, X.; Wang, Y.; Xia, Y.M. Strain rate effect on the tensile behavior of Duplex Ti–46.5Al–2Nb–2Cr intermetallics at elevated temperatures. Mater. Sci. Eng. A 2008, 498, 296–301. [Google Scholar] [CrossRef]

- Wang, L.; Wang, Y.C.; Zhilyaev, A.P.; Korznikov, A.V.; Li, S.K.; Korznikova, E.; Langdon, T.G. Dynamic compressive behavior of ultrafine-grained pure Ti at elevated temperatures after processing by ECAP. J. Mater. Sci. 2014, 49, 6640–6647. [Google Scholar] [CrossRef]

- Chen, G.; Peng, Y.B.; Zheng, G. Polysynthetic twinned TiAl single crystals for high-temperature applications. Nat. Mater. 2016, 15, 876–882. [Google Scholar] [CrossRef] [PubMed]

- Dumitraschkewitz, P.; Clemens, H.; Mayer, S.; Holec, D. Impact of Alloying on Stacking Fault Energies in γ-TiAl. Appl. Sci. 2017, 7, 1193. [Google Scholar] [CrossRef]

© 2018 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (http://creativecommons.org/licenses/by/4.0/).

Share and Cite

Guo, W.; Jiang, H.; Tian, S.; Zhang, G. Nanoscale Twinned Ti-44Al-4Nb-1.5Mo-0.007Y Alloy Promoted by High Temperature Compression with High Strain Rate. Metals 2018, 8, 619. https://doi.org/10.3390/met8080619

Guo W, Jiang H, Tian S, Zhang G. Nanoscale Twinned Ti-44Al-4Nb-1.5Mo-0.007Y Alloy Promoted by High Temperature Compression with High Strain Rate. Metals. 2018; 8(8):619. https://doi.org/10.3390/met8080619

Chicago/Turabian StyleGuo, Wenqi, Haitao Jiang, Shiwei Tian, and Guihua Zhang. 2018. "Nanoscale Twinned Ti-44Al-4Nb-1.5Mo-0.007Y Alloy Promoted by High Temperature Compression with High Strain Rate" Metals 8, no. 8: 619. https://doi.org/10.3390/met8080619

APA StyleGuo, W., Jiang, H., Tian, S., & Zhang, G. (2018). Nanoscale Twinned Ti-44Al-4Nb-1.5Mo-0.007Y Alloy Promoted by High Temperature Compression with High Strain Rate. Metals, 8(8), 619. https://doi.org/10.3390/met8080619