The Effects of Nitrogen Gas on Microstructural and Mechanical Properties of TIG Welded S32205 Duplex Stainless Steel

Abstract

:1. Introduction

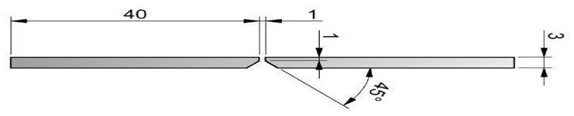

2. Materials and Methods

3. Results

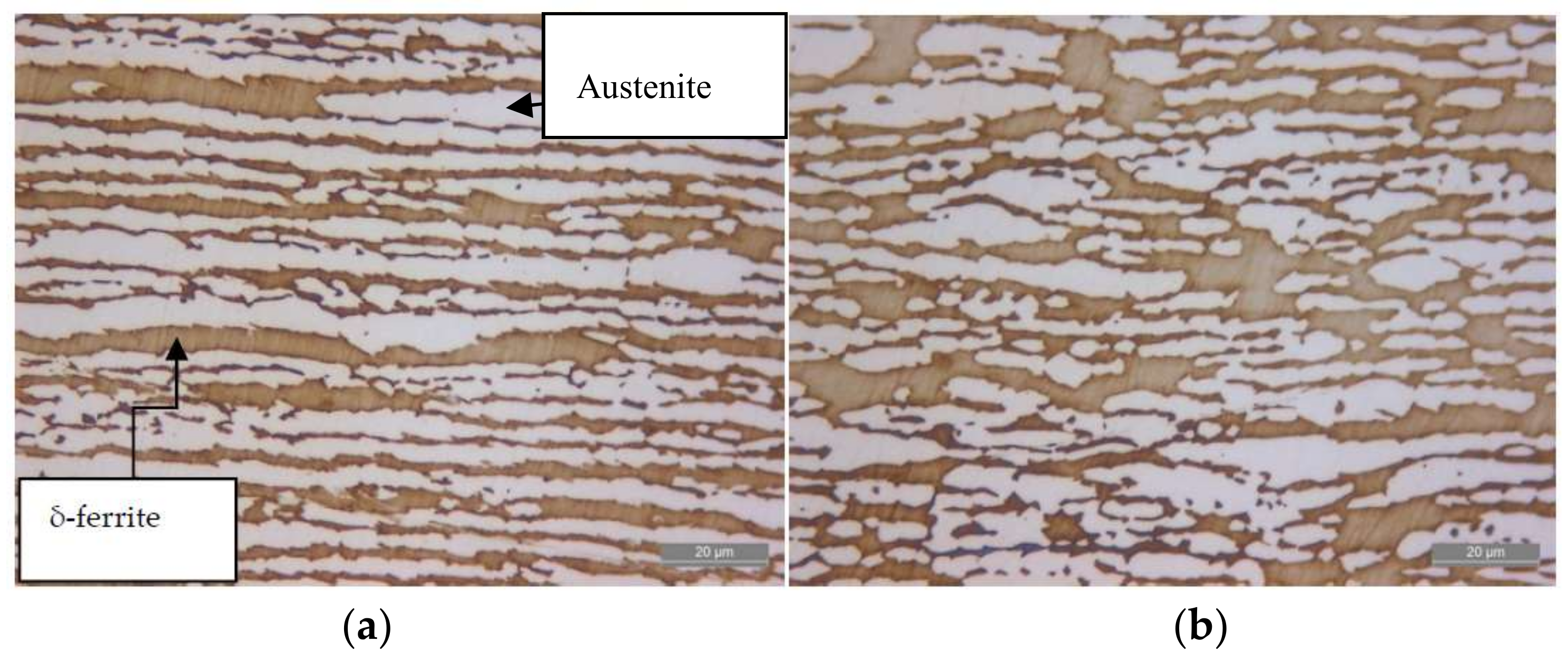

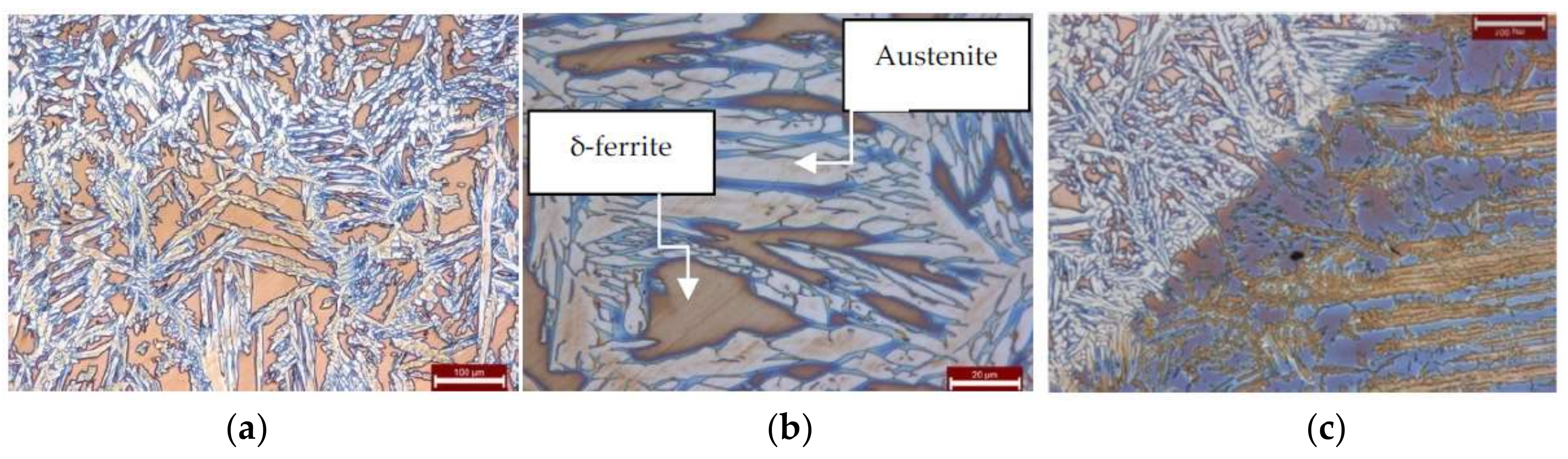

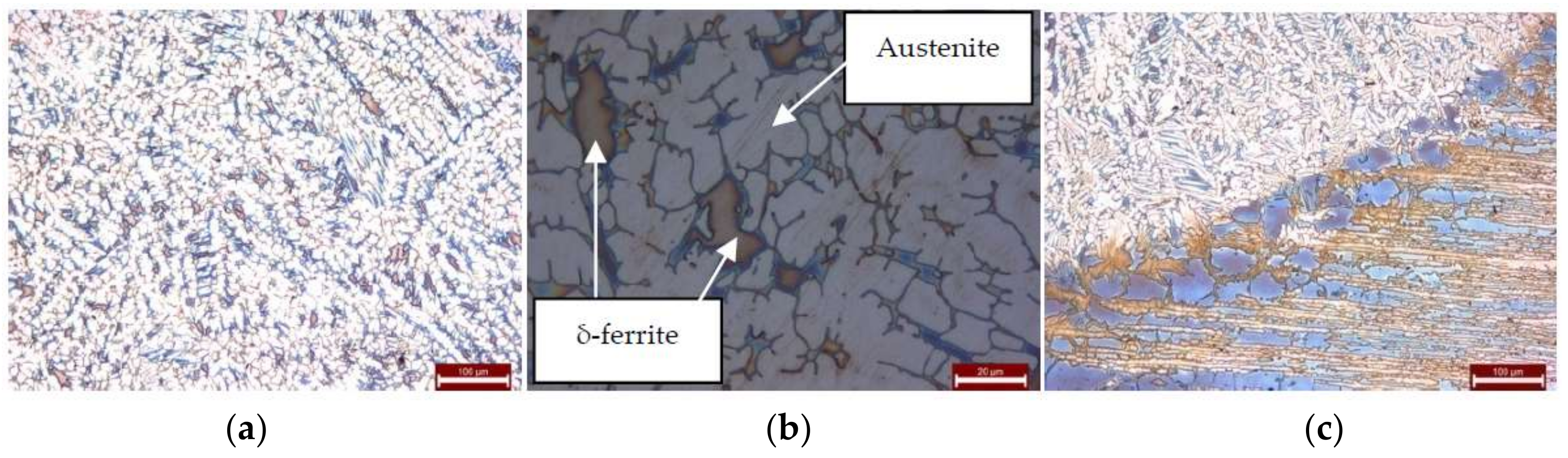

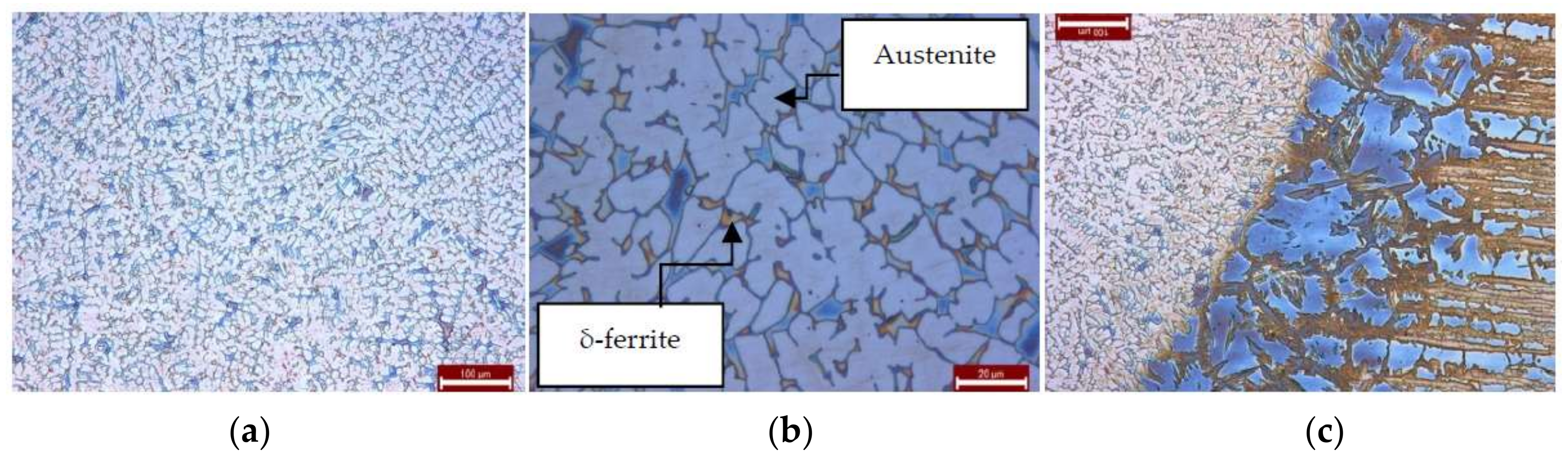

3.1. Microstructural Investigation of Base Metal

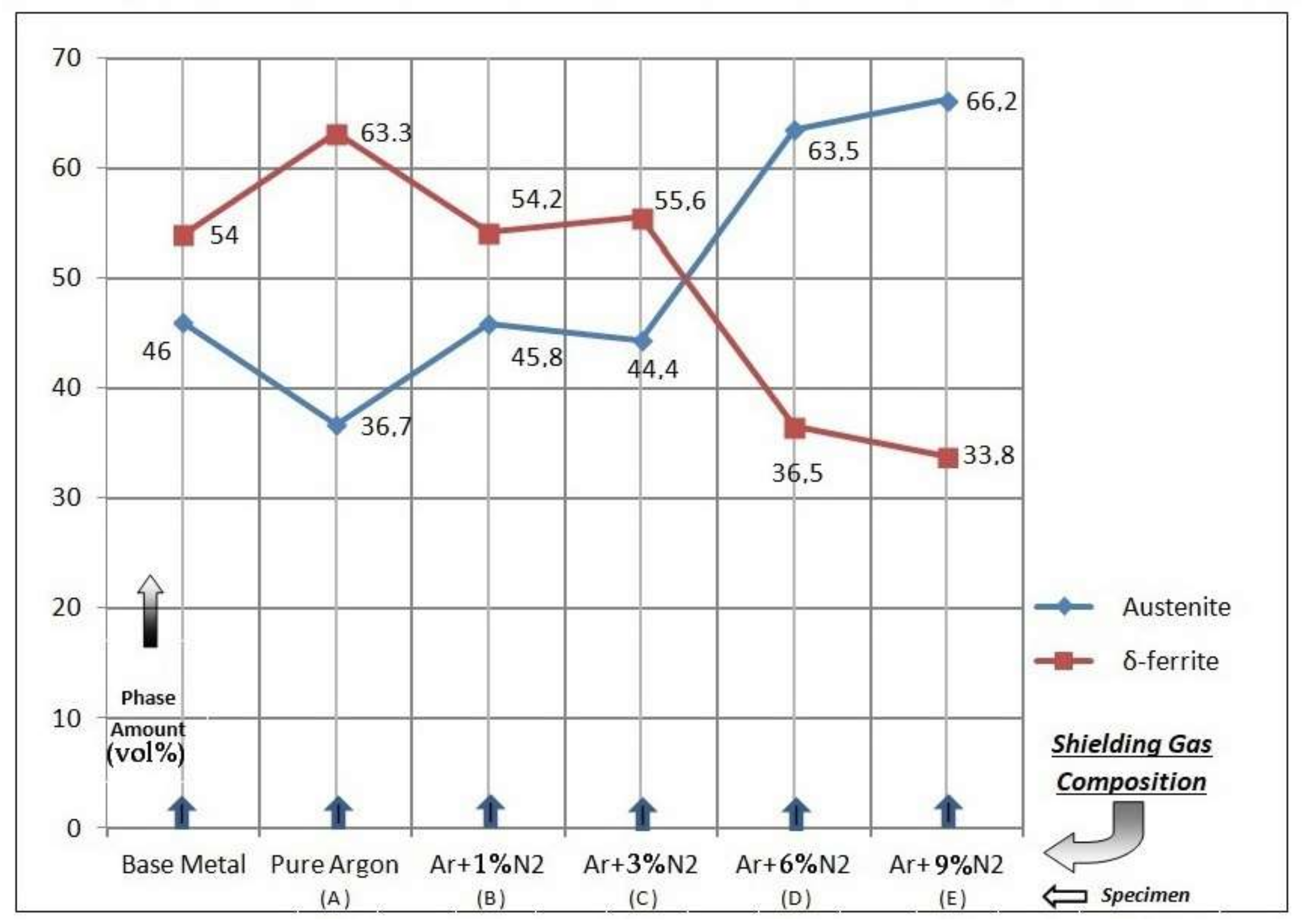

3.2. Determination of Phases by Microstructural and Magnetic Methods

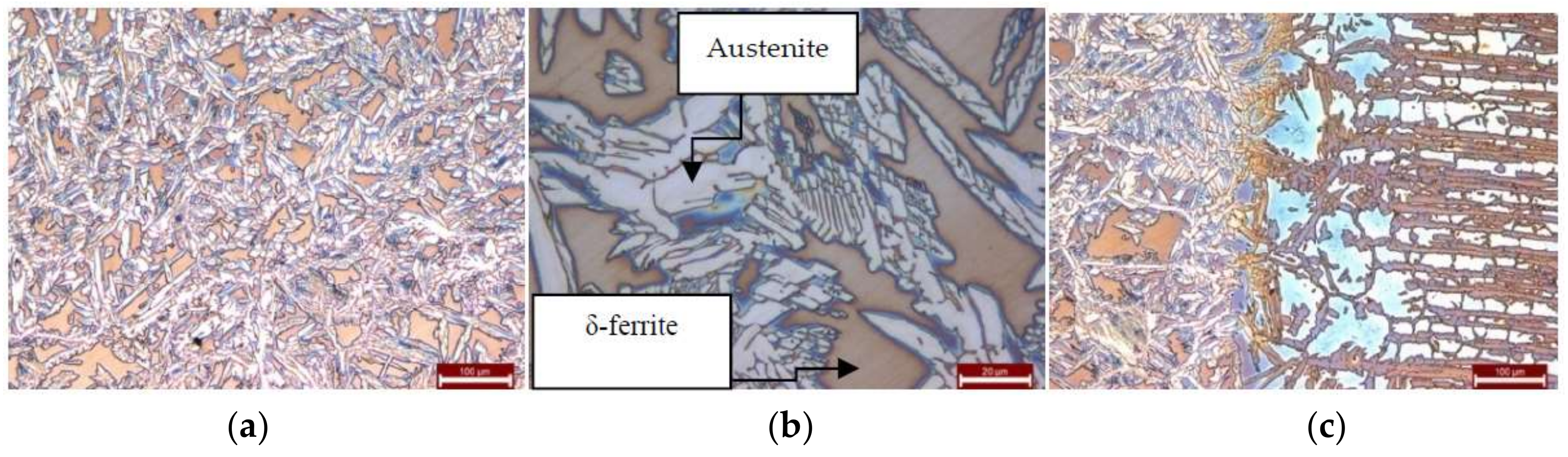

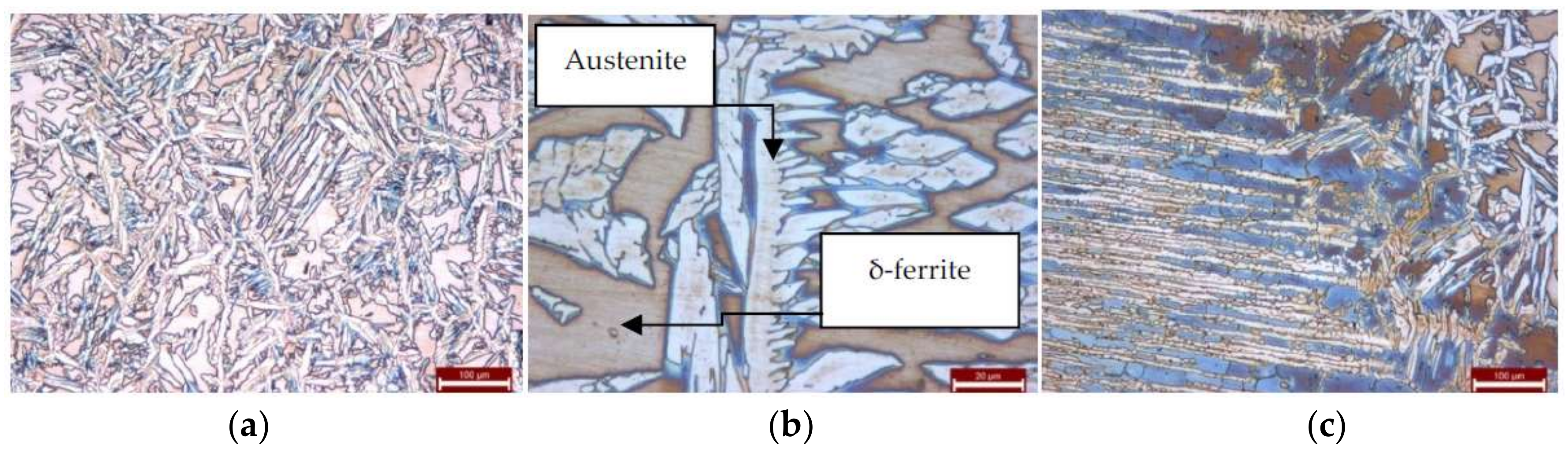

3.3. Microstructural Investigation of Weldments

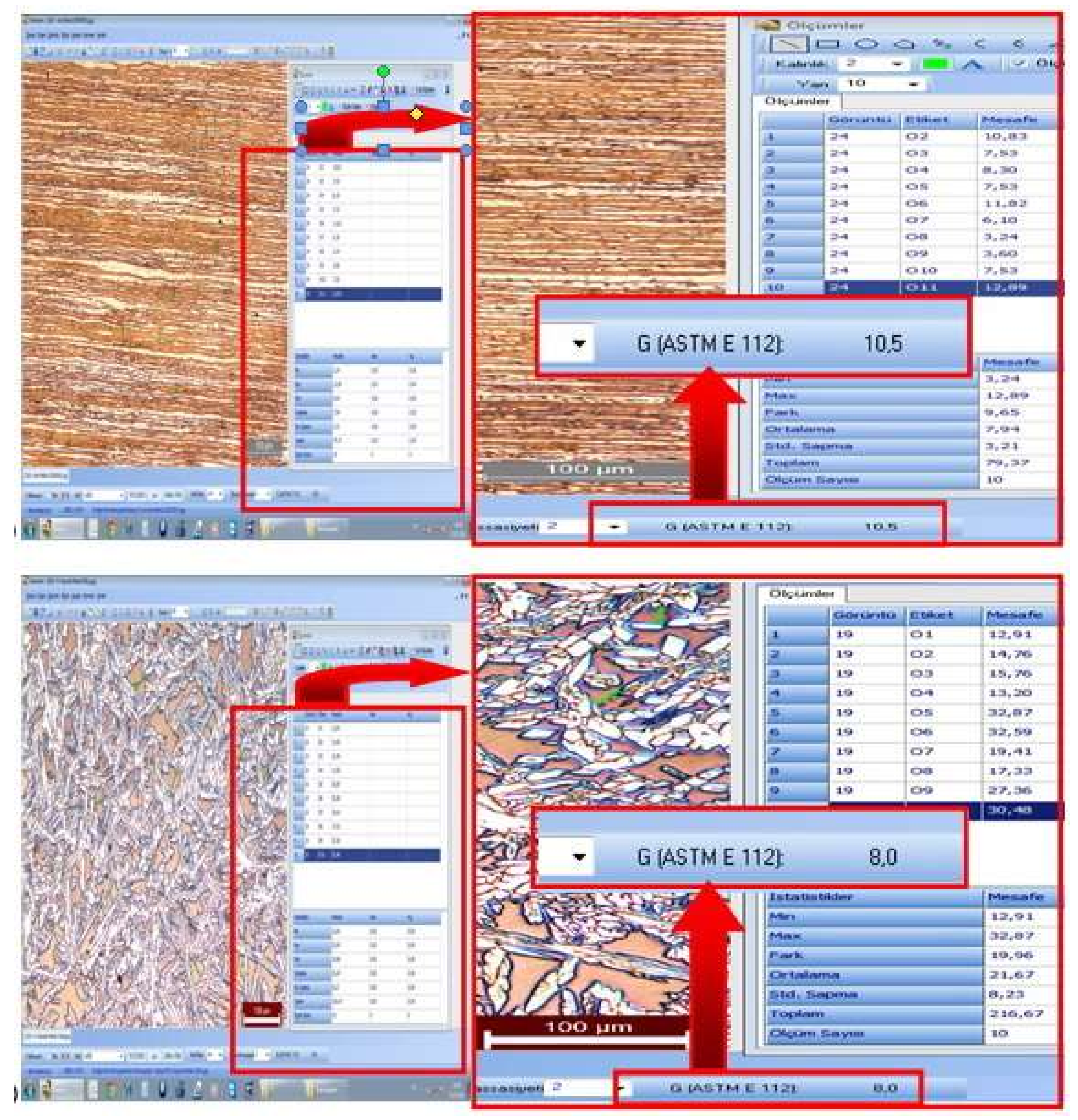

3.4. Determination of Grain-Sizes of Phases According to ASTM E 112 by Kameram Software

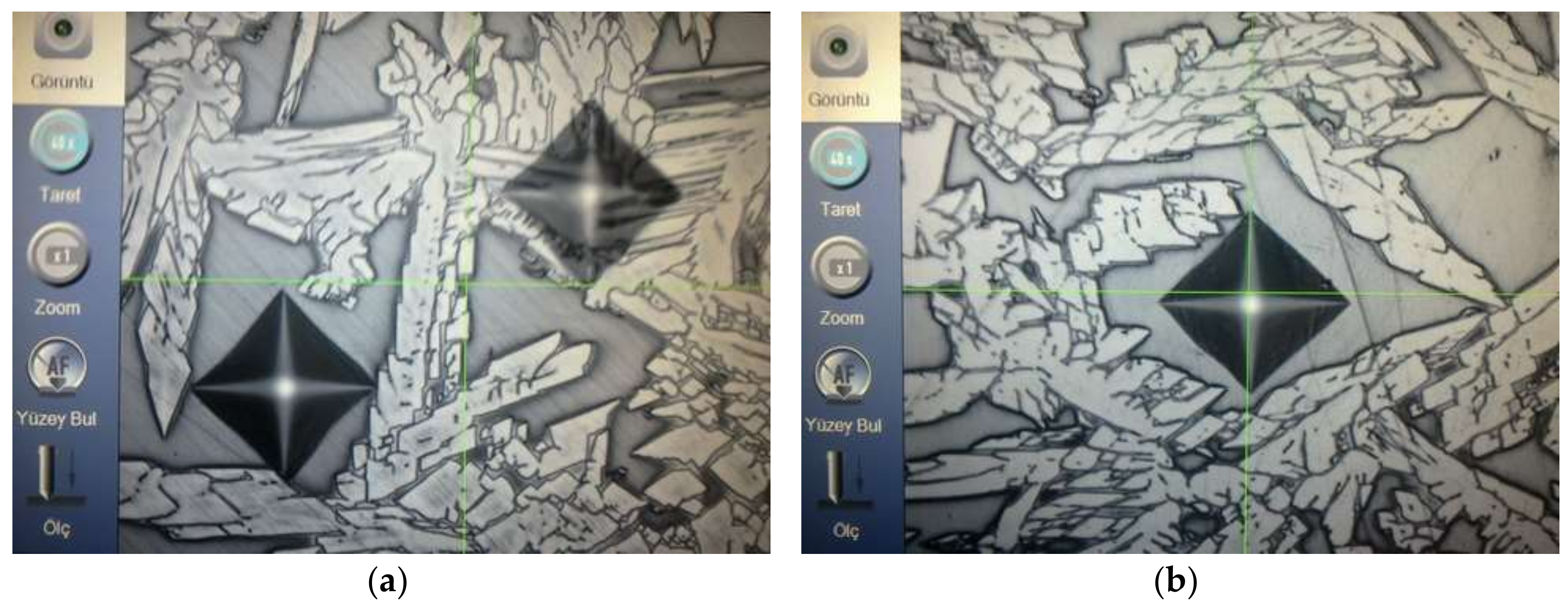

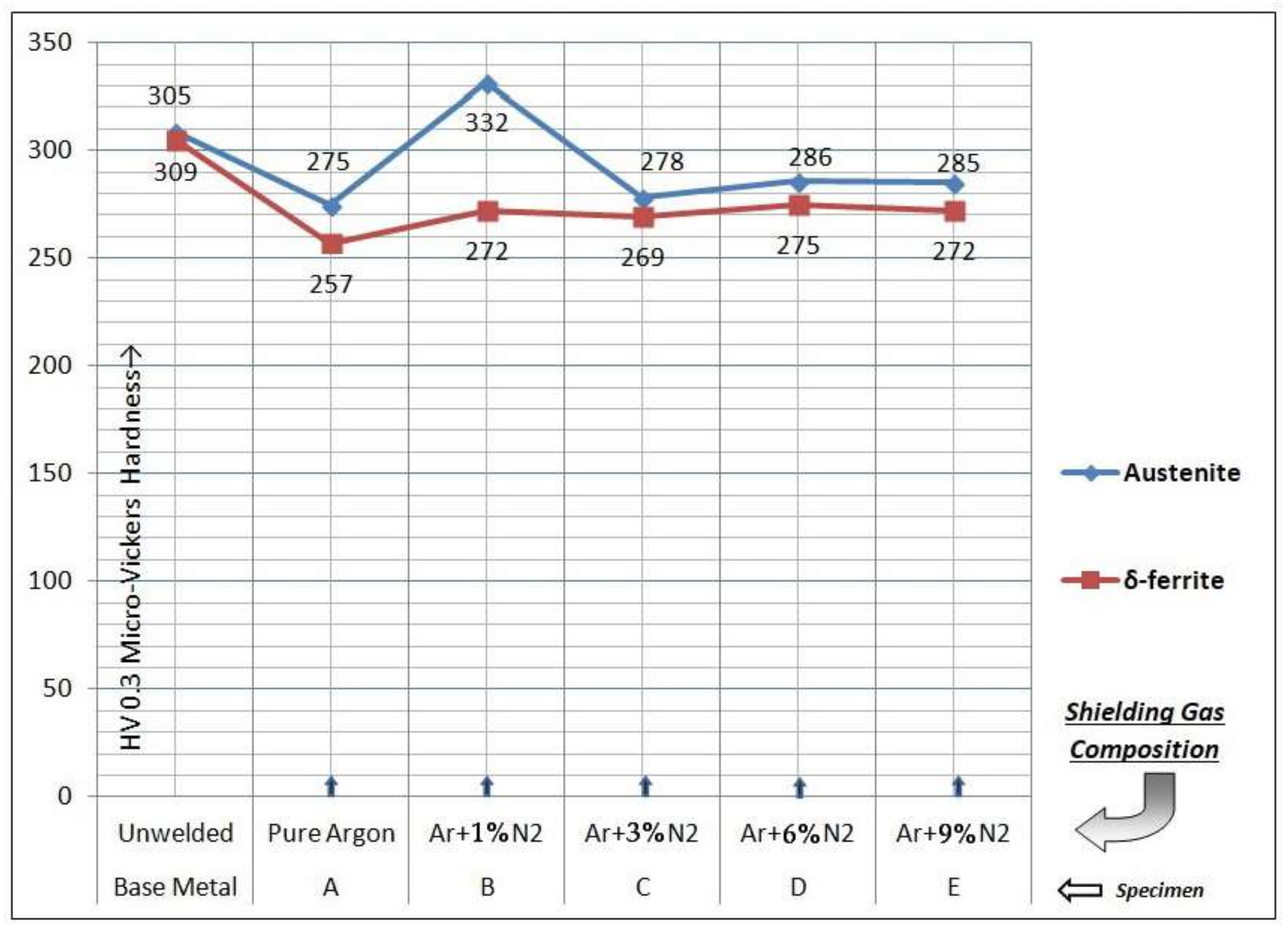

3.5. Micro-Hardness Profiles

4. Discussion

5. Conclusions

Acknowledgments

Author Contributions

Conflicts of Interest

References

- Gunn, N.R. Duplex Stainless Steels, Microstructures, Properties and Applications; Abington Publishing: Cambridge, UK, 2003. [Google Scholar]

- Lippold, J.; Kotecki, D. Welding Metallurgy and Weldability of Stainless Steels; Wiley Interscience Publications: Hoboken, NJ, USA, 2005. [Google Scholar]

- Liou, H.-Y.; Pan, Y.-T.; Hsieh, R.-I.; Tsai, W.-T. Effects of Alloying Elements on the Mechanical Properties and Corrosion Behaviors of 2205 Duplex Stainless Steels. J. Mater. Eng. Perform. 2001, 10, 231–241. [Google Scholar] [CrossRef]

- Iglesias, F.A.C.; Roman, J.M.R.; Prieto, J.M.R.; Cambronero, L.G.; Godino, F.J.I. Effect of nitrogen on sintered duplex stainless steels. Powder Metall. 2003, 46, 39–42. [Google Scholar] [CrossRef]

- Kou, S. Welding Metallurgy, 2nd ed.; Wiley Interscience Publications: Hoboken, NJ, USA, 2002. [Google Scholar]

- Sathirachinda, N.; Pettersson, R.; Wessman, S.; Pan, J. Study of nobility of chromium nitrides in isothermally aged duplex stainless steels by using SKPFM and SEM/EDS. Corros. Sci. 2010, 52, 179–186. [Google Scholar] [CrossRef]

- Muñoz, A.I.; Antón, J.G.; Guiñón, J.L.; Herranz, V.P. Effect of Nitrogen in Argon as a Shielding Gas on Tungsten Inert Gas Welds of Duplex Stainless Steels. Corrosion 2005, 61, 693–705. [Google Scholar] [CrossRef]

- Muthupandi, V.; Srinivasan, P.B.; Seshadri, S.K.; Sundaresan, S. Effect of nitrogen addition on formation of secondary austenite in duplex stainless steel weld metals and resultant properties. Sci. Technol. Weld. Join. 2004, 9, 47–52. [Google Scholar] [CrossRef]

- Udayakumara, T.; Rajaa, K.; Abhijit, A.T.; Sathiyab, P. Experimental investigation on mechanical and metallurgical properties of super duplex stainless steel joints using friction welding process. J. Manuf. Process. Elsevier 2013, 15, 558–571. [Google Scholar] [CrossRef]

- Yan, J.; Wang, J.; Lin, Y.; Gu, T.; Zeng, D.; Huang, R.; Ji, X.; Fan, H. Microstructure and Properties of SAE 2205 Stainless Steel After Salt Bath Nitrocarburizing at 450 °C. J. Mater. Eng. Perform. 2014, 23, 1157–1164. [Google Scholar] [CrossRef]

- Migiakis, K.; Papadimitriou, G.D. Effect of nitrogen and nickel on the microstructure and mechanical properties of plasma welded UNS S32760 super-duplex stainless steels. J. Mater. Sci. 2009, 44, 6372–6383. [Google Scholar] [CrossRef]

- Poonguzhali, A.; Pujar, M.G.; Mudali, U.K. Effect of Nitrogen and Sensitization on the Microstructure and Pitting Corrosion Behavior of AISI Type 316LN Stainless Steels. J. Mater. Eng. Perform. 2013, 22, 1170–1178. [Google Scholar] [CrossRef]

- Tseng, C.; Liou, H.; Tsa, W. Effect of Nitrogen Content on the Environmentally-Assisted Cracking Susceptibility of Duplex Stainless Steels. Metall. Mater. Trans. 2003, 34, 95–103. [Google Scholar] [CrossRef]

- Jang, M.; Moon, J.; Lee, T.H.; Park, S.J.; Nam Han, H. Effect of Nitrogen Partitioning on Yield Strength in Nitrogen-Alloyed Duplex Stainless Steel During Annealing. Miner. Met. Mater. Soc. 2014, 45, 1653–1658. [Google Scholar] [CrossRef]

- Lothongkum, G.; Wongpanya, P.; Morito, S.; Furuhara, T.; Maki, T. Effect of nitrogen on corrosion behavior of 28Cr-7Ni duplex and microduplex stainless steels in air-saturated 3.5 wt % NaCl solution. Corros. Sci. 2006, 48, 137–153. [Google Scholar]

- ASTM A923. Standart Test Methods for Detecting Detrimental Intermetallic Phase in Duplex Stainless Steels; ASM International: Almere, The Netherlands, 2008. [Google Scholar]

- ASM Handbook. Metallography and Microstructures of Stainless Steels and Maraging Steels; ASM International: Almere, The Netherlands, 2004. [Google Scholar]

- ASTM E562-11. Standard Test Method for Determining Volume Fraction by Systematic Manual Point Count; ASM International: Almere, The Netherlands, 2011. [Google Scholar]

- ASTM E1245-03. Standard Practice for Determining the Inclusion or Second Phase Constituent Content of Metals by Automatic Image Analysis; ASM International: Almere, The Netherlands, 2008. [Google Scholar]

- EN ISO 8249. Welding-Determination of Ferrite Number (FN) in Austenitic and Duplex Ferritic-Austenitic Cr-Ni Stainless Steel Weld Metals; European Standard: Brussels, Belgium, 2000. [Google Scholar]

- EN ISO 17655. Destructive Tests on Welds in Metallic Materials-Method for Taking Samples for Delta Ferrite Measurement; European Standard: Brussels, Belgium, 2003. [Google Scholar]

- AWS A4.2. Standard Procedures for Calibrating Magnetic Instruments to Measure the Delta Ferrite Content of Austenitic and Duplex Ferritic-Austenitic Stainless Steel Weld Metal; ASM International: Almere, The Netherlands, 2006. [Google Scholar]

- ASTM E112-12. Standard Test Methods for Determining Average Grain Size; ASM International: Almere, The Netherlands, 2012. [Google Scholar]

- Jımenez, J.A.; Carsı, M.; Ruan, O.A. Characterization of a duplex stainless steel. J. Mater. Sci. 2000, 35, 907–915. [Google Scholar] [CrossRef]

- Mariappan, R.; Kumaran, S.; Rao, T.S.; Chandrasekar, S.B. Microstructure and mechanical properties of duplex stainless steels sintered in different atmospheres. Powder Metall. 2011, 54, 236–241. [Google Scholar] [CrossRef]

- ASM Metals Handbook. Welding Brazing and Soldering; ASM International: Almere, The Netherlands, 1993. [Google Scholar]

| Material | C | Mn | P | S | Si | Cr | Ni | Mo | Fe | N | Others |

|---|---|---|---|---|---|---|---|---|---|---|---|

| 2205 duplex stainless steel composition | 0.031 | 0.832 | 0.024 | 0.004 | 0.423 | 24.957 | 6.638 | 3.511 | 62.10 | 0.306 | 1.174 |

| W22 9 3 NL, (ER 2209) TIG welding rods composition | 0.01 | 1.50 | 0.02 | 0.001 | 0.440 | 23.0 | 8.60 | 3.1 | 62.06 | 0.16 | 1.109 |

| Specimen | Welding Shielding Gas (by Volume) |

|---|---|

| Base Metal | Unwelded |

| A | Pure Argon |

| B | Ar + 1% N2 |

| C | Ar + 3% N2 |

| D | Ar + 6% N2 |

| E | Ar + 9% N2 |

| Shielding Gas | Shielding Gas Flow (L/min) | Welding Speed (mm/s) | Welding Current DC (−) Non-Pulsed (Amperes) | Welding Voltage (Volts) | |||

|---|---|---|---|---|---|---|---|

| Root Pass | Second (Final) Pass | Root Pass | Second (Final) Pass | Root Pass | Second (Final) Pass | ||

| 0%, 1%, 3%, 6%, 9% N2-remainders of argon gases | 6 L/min | 2.16 | 2.13 | 75A | 100A | 12V | 13V |

| Weldment preparation |  | ||||||

| Specimen | Welding Shielding Gas | Image Analysis by vol % Mean Values of 3 Individual Estimation (ASTM E562, ASTM E1245) | Magnetic % δ-Ferrite Analysis by 6 Individual Points and Mean Values in vol %. (Ferritetester-ISO 8249 ANSI/AWS A4.2-EN ISO 17655) | ||||||||

|---|---|---|---|---|---|---|---|---|---|---|---|

| δ-Ferrite/Std. Dev. | Austenite/Std. Dev. | 1 | 2 | 3 | 4 | 5 | 6 | Std. Dev. | Mean Value | ||

| Base metal | Unwelded | 54/0.577 | 46/0.816 | 53.8 | 53.6 | 55.5 | 55.9 | 56.1 | 56.7 | 1.275 | 55 |

| A | Pure Argon | 63.3/0.173 | 36.7/1.214 | 61.6 | 61.9 | 64.0 | 61.3 | 62.3 | 61.9 | 0.958 | 62 |

| B | Ar+1% N2 | 54.2/0.816 | 45.8/0.721 | 52.4 | 51.1 | 54.4 | 53.2 | 54.3 | 53.9 | 1.279 | 53 |

| C | Ar+3% N2 | 55.6/0.529 | 44.4/1.039 | 53.9 | 54.9 | 50.9 | 46.9 | 51.3 | 48.7 | 3.025 | 51 |

| D | Ar+6% N2 | 36.5/0.866 | 63.5/0.866 | 36.2 | 36.2 | 36.1 | 35.4 | 36.7 | 39.5 | 1.441 | 37 |

| E | Ar+9% N2 | 33.8/0.721 | 66.2/0.346 | 32.6 | 33.6 | 34.4 | 34.2 | 33.0 | 33.7 | 0.688 | 34 |

| Specimen | Status | Phase Ratios % | ASTM No. Grain Sizes of Phases-ASTM E 112 | ||||

|---|---|---|---|---|---|---|---|

| δ-Ferrite | Austenite | Austenite | μm | δ-Ferrite | μm | ||

| Base Metal | Unwelded | 55.0 | 45.0 | 10.5 | 8.14 | 10.5 | 7.94 |

| A | Pure Argon | 63.3 | 37.7 | 10.5 | 8.15 | 8.0 | 21.67 |

| B | Ar + 1% N2 | 54.2 | 46.8 | 8.5 | 15.60 | 7.0 | 26.70 |

| C | Ar + 3% N2 | 55.6 | 44.4 | 8.5 | 15.63 | 7.0 | 27.48 |

| D | Ar + 6% N2 | 36.5 | 64.5 | 9.5 | 12.70 | 10.5 | 8.35 |

| E | Ar + 9% N2 | 33.8 | 67.2 | 9.5 | 13.63 | 11.5 | 6.06 |

| Specimen | Micro-Vickers Hardness Values (HV0,3) | Image Analysis Test Results by Volume % (ASTM E562-ASTM E1245) | ||||||||

|---|---|---|---|---|---|---|---|---|---|---|

| Test No. | Austenite | Test No. | δ-Ferrite | Austenite. | Delta-Ferrite | |||||

| 1 | 2 | Standard Deviation | Mean Value | 1 | 2 | Standard Deviation | Mean Value | |||

| Base Metal (unwelded) | 305 | 305 | 0 | 305 | 309 | 309 | 0 | 309 | 54 | 46 |

| Pure argon | 273 | 277 | 2.828 | 275 | 261 | 253 | 5.657 | 257 | 63.3 | 36.7 |

| 1% N2 + Argon | 332 | 332 | 0 | 332 | 272 | 272 | 0 | 272 | 54.2 | 45.8 |

| 3% N2 + Argon | 278 | 278 | 0 | 278 | 269 | 269 | 0 | 269 | 55.6 | 44.4 |

| 6% N2 + Argon | 281 | 290 | 6.364 | 286 | 275 | 275 | 0 | 275 | 36.5 | 63.5 |

| 9% N2 + Argon | 285 | 285 | 0 | 285 | 272 | 272 | 0 | 272 | 33.8 | 66.2 |

© 2018 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (http://creativecommons.org/licenses/by/4.0/).

Share and Cite

Başyiğit, A.B.; Kurt, A. The Effects of Nitrogen Gas on Microstructural and Mechanical Properties of TIG Welded S32205 Duplex Stainless Steel. Metals 2018, 8, 226. https://doi.org/10.3390/met8040226

Başyiğit AB, Kurt A. The Effects of Nitrogen Gas on Microstructural and Mechanical Properties of TIG Welded S32205 Duplex Stainless Steel. Metals. 2018; 8(4):226. https://doi.org/10.3390/met8040226

Chicago/Turabian StyleBaşyiğit, Aziz Barış, and Adem Kurt. 2018. "The Effects of Nitrogen Gas on Microstructural and Mechanical Properties of TIG Welded S32205 Duplex Stainless Steel" Metals 8, no. 4: 226. https://doi.org/10.3390/met8040226

APA StyleBaşyiğit, A. B., & Kurt, A. (2018). The Effects of Nitrogen Gas on Microstructural and Mechanical Properties of TIG Welded S32205 Duplex Stainless Steel. Metals, 8(4), 226. https://doi.org/10.3390/met8040226