Hybrid Reinforced Magnesium Matrix Composites (Mg/Sic/GNPs): Drilling Investigation

Abstract

:1. Introduction

2. Experimental Procedure

2.1. Composite MaterialSynthesis

2.2. Experimental Design

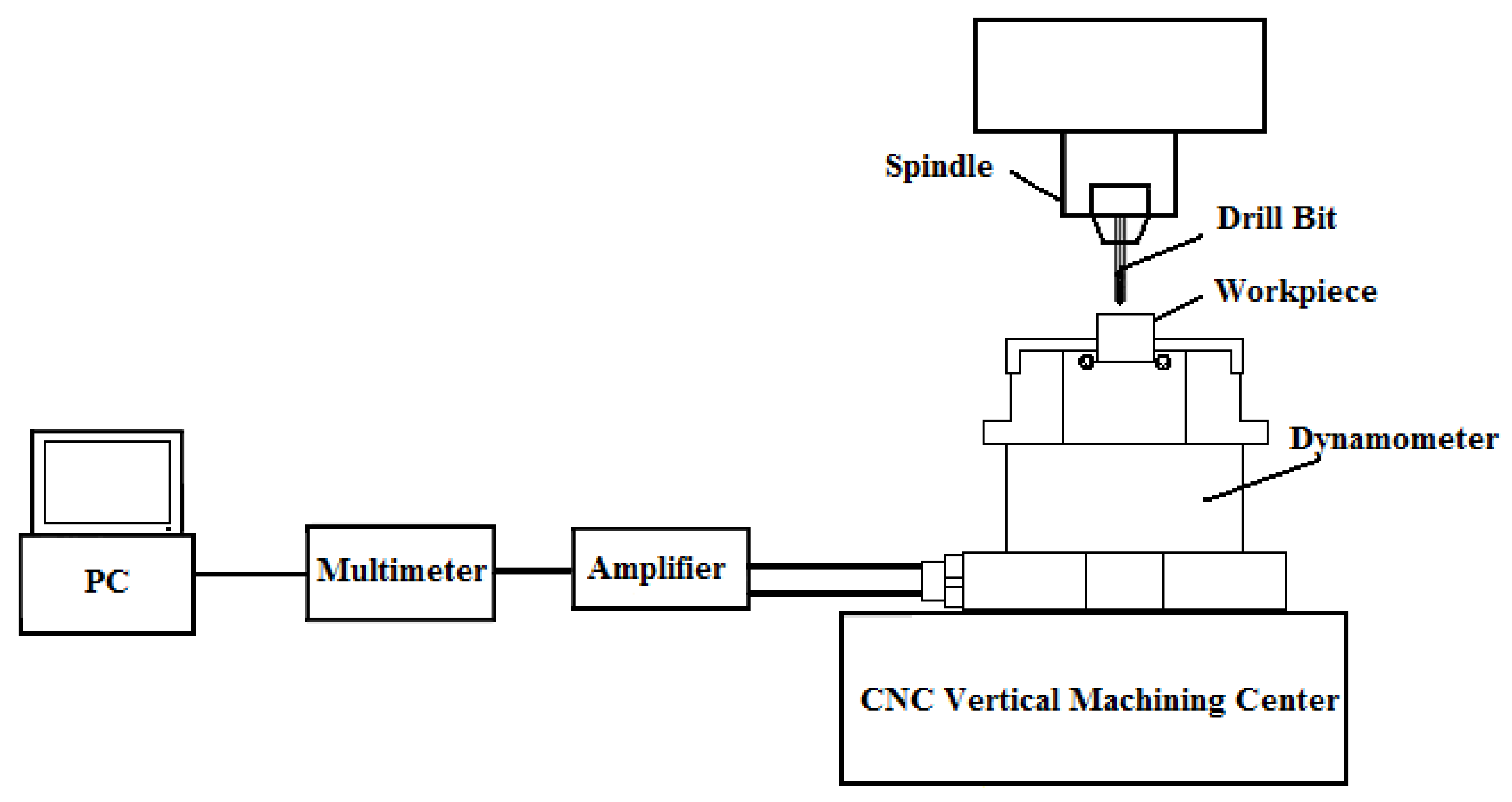

2.3. Measurement of Cutting Thrust Force

2.4. Surface Roughness (Ra) Measurement

3. Experimental Results and Discussion

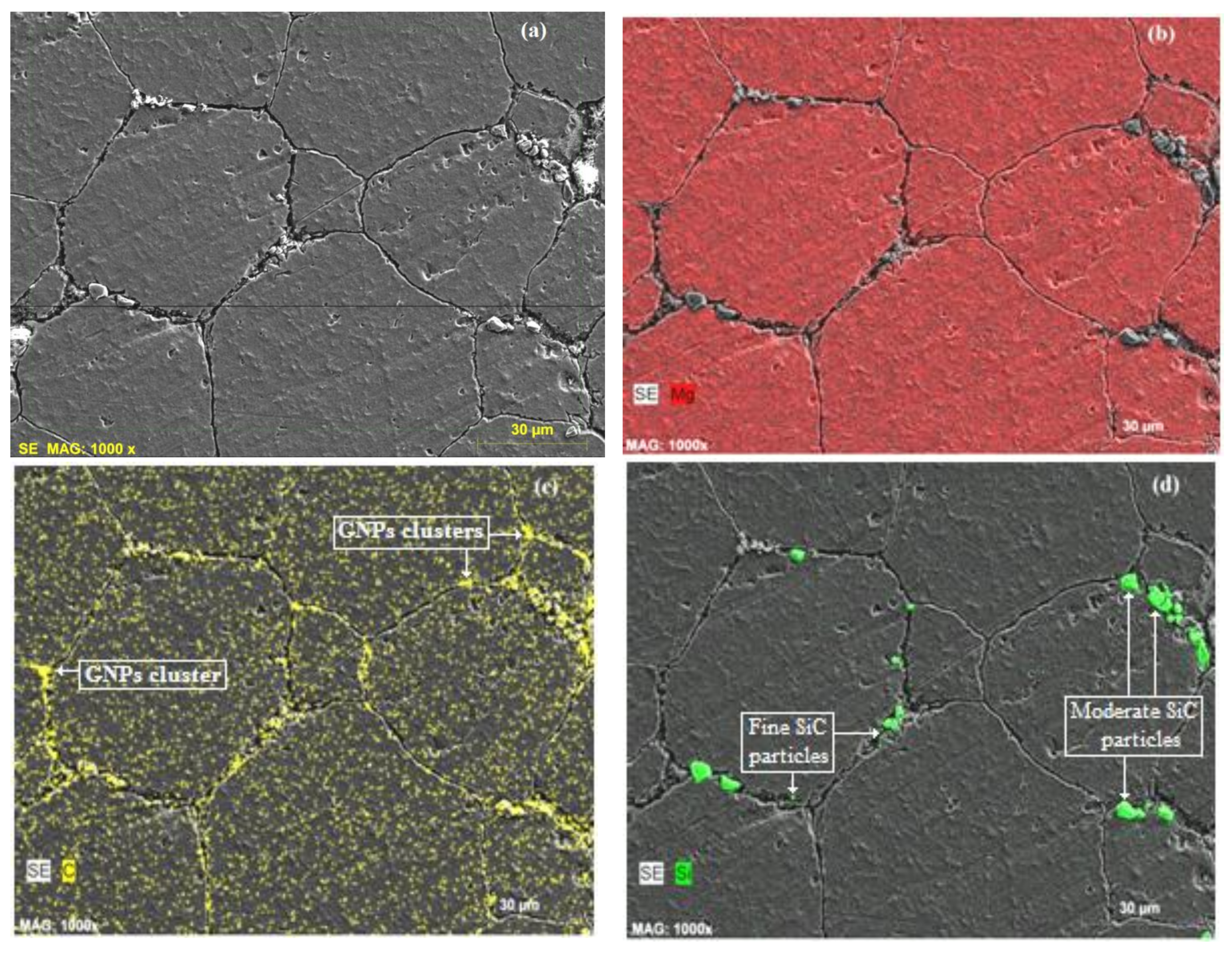

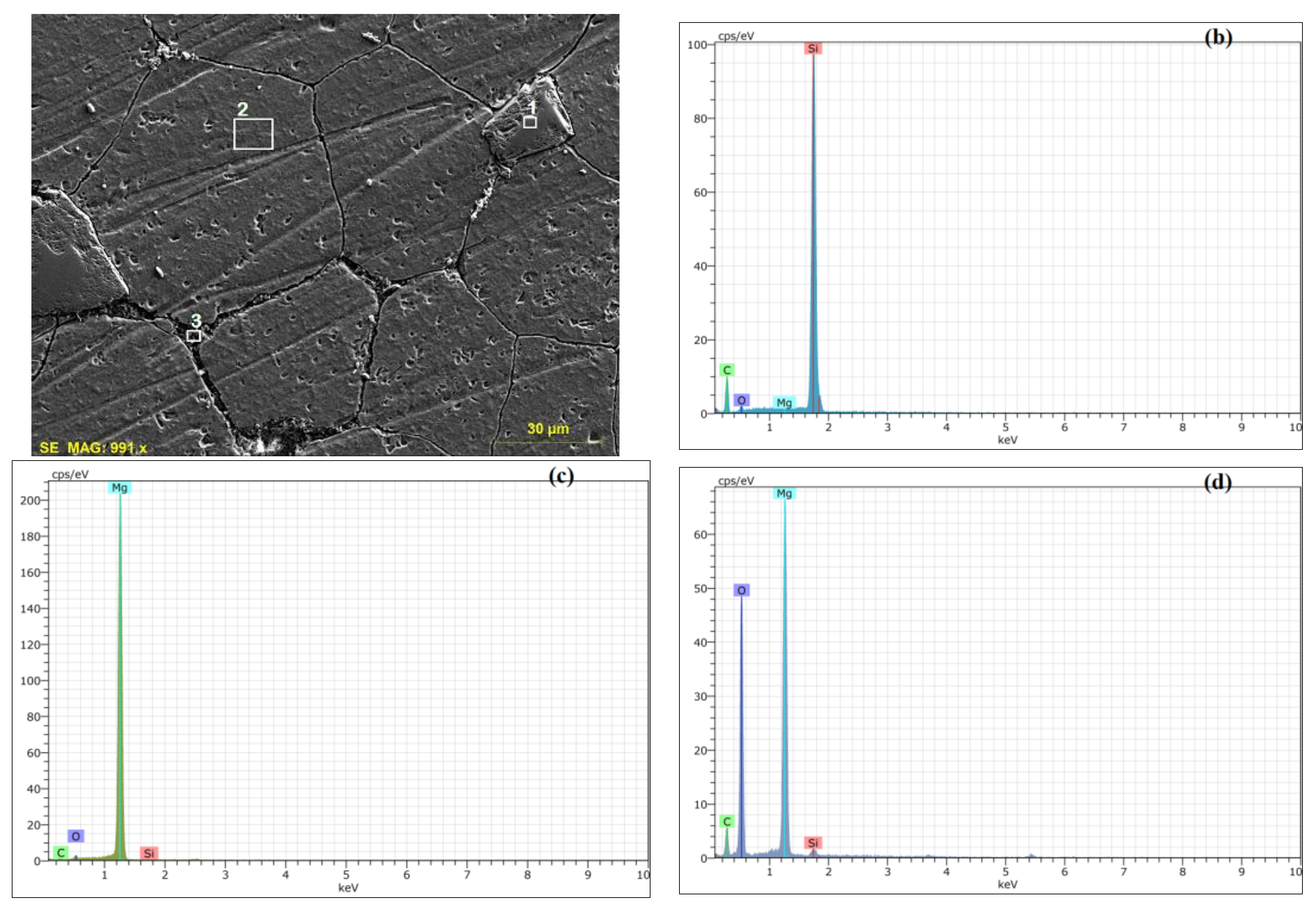

3.1. Microstructural Characterization

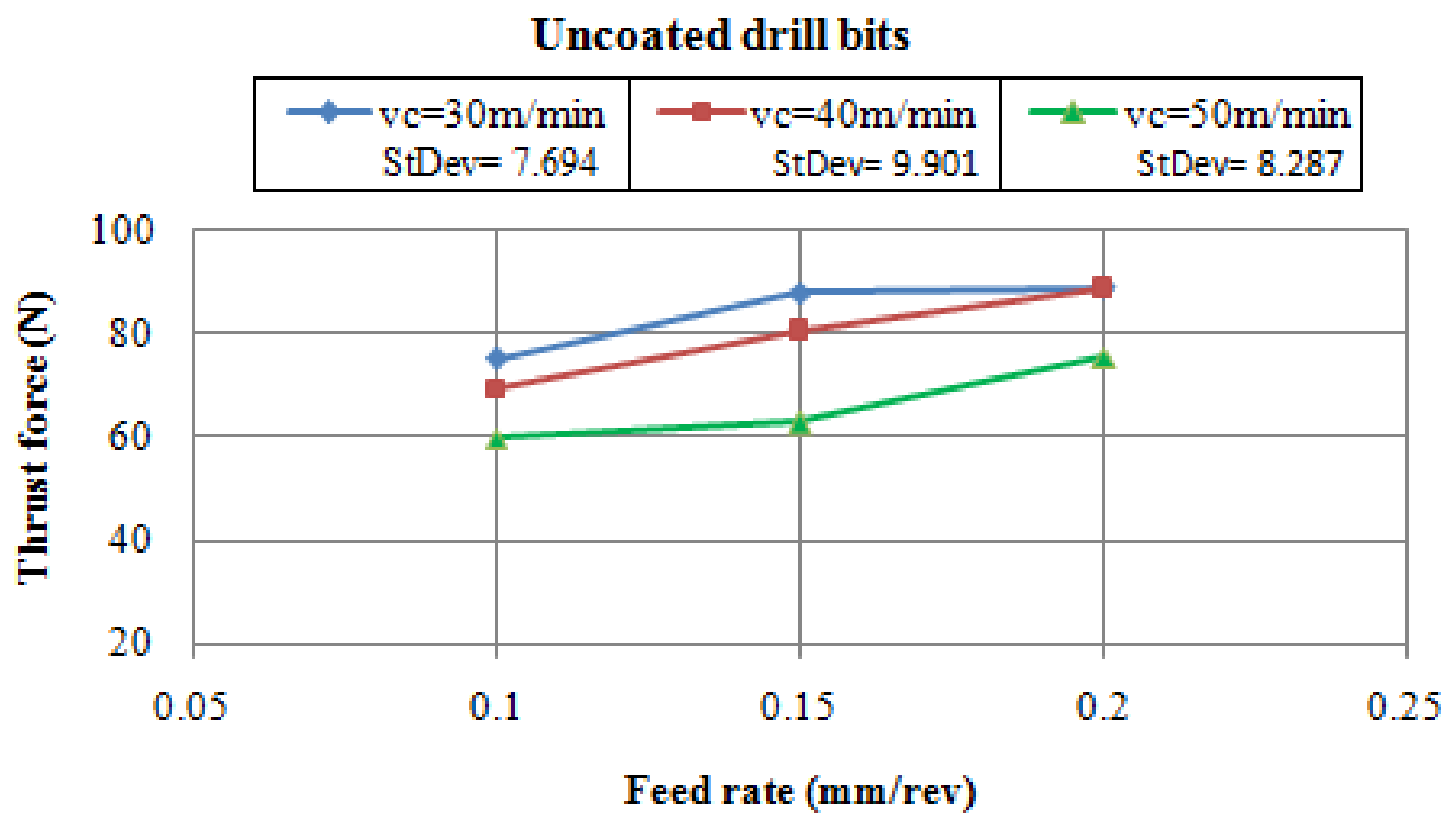

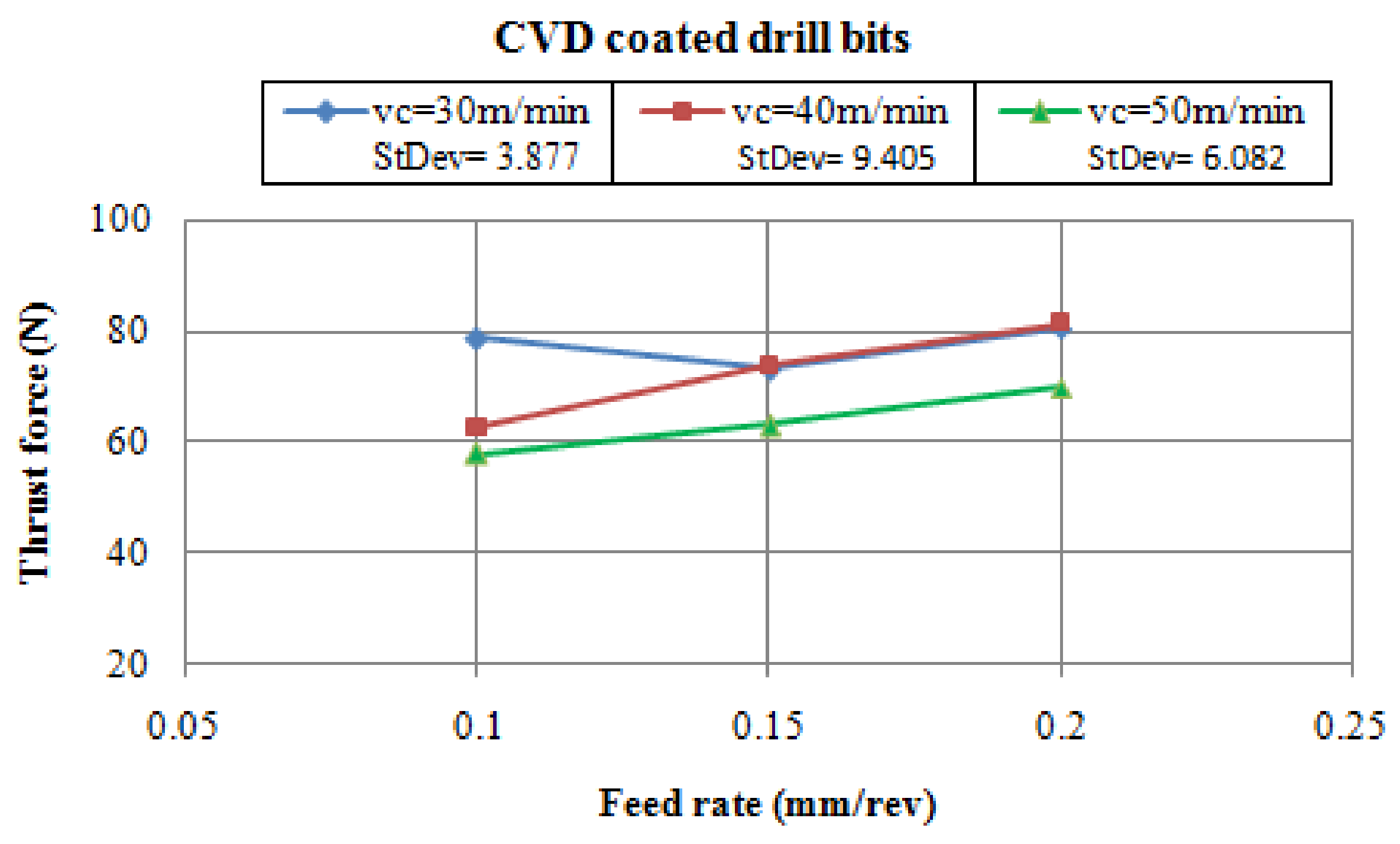

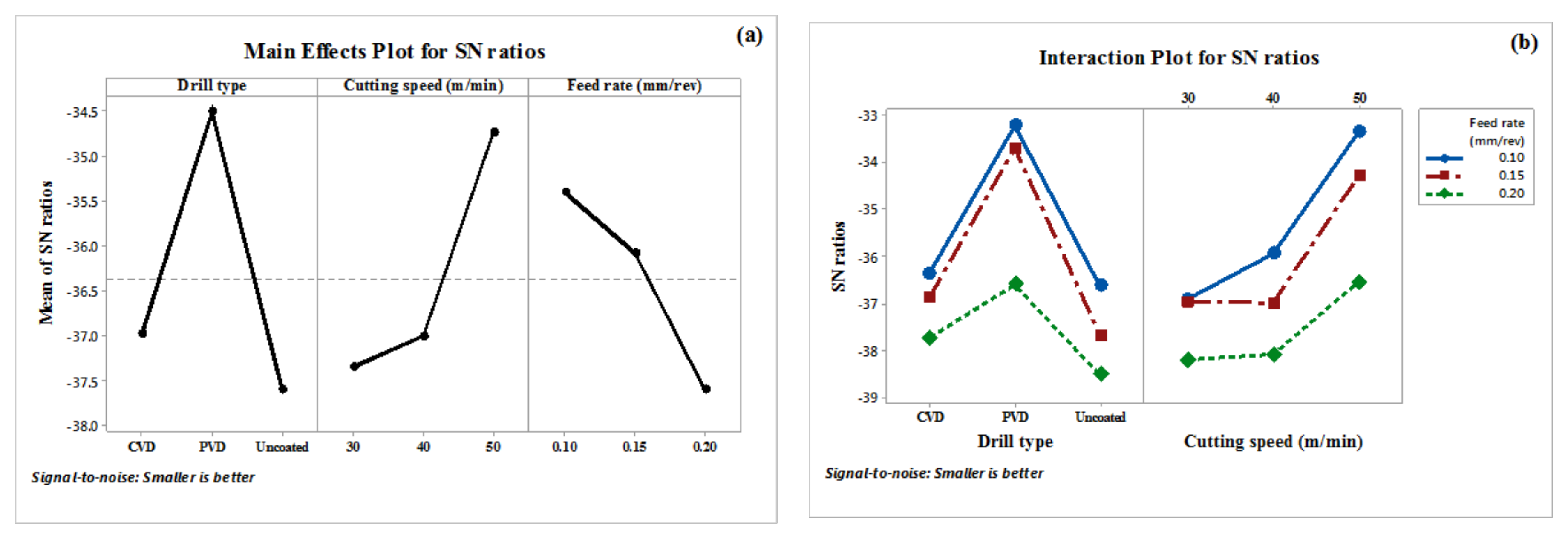

3.2. Thrust Force

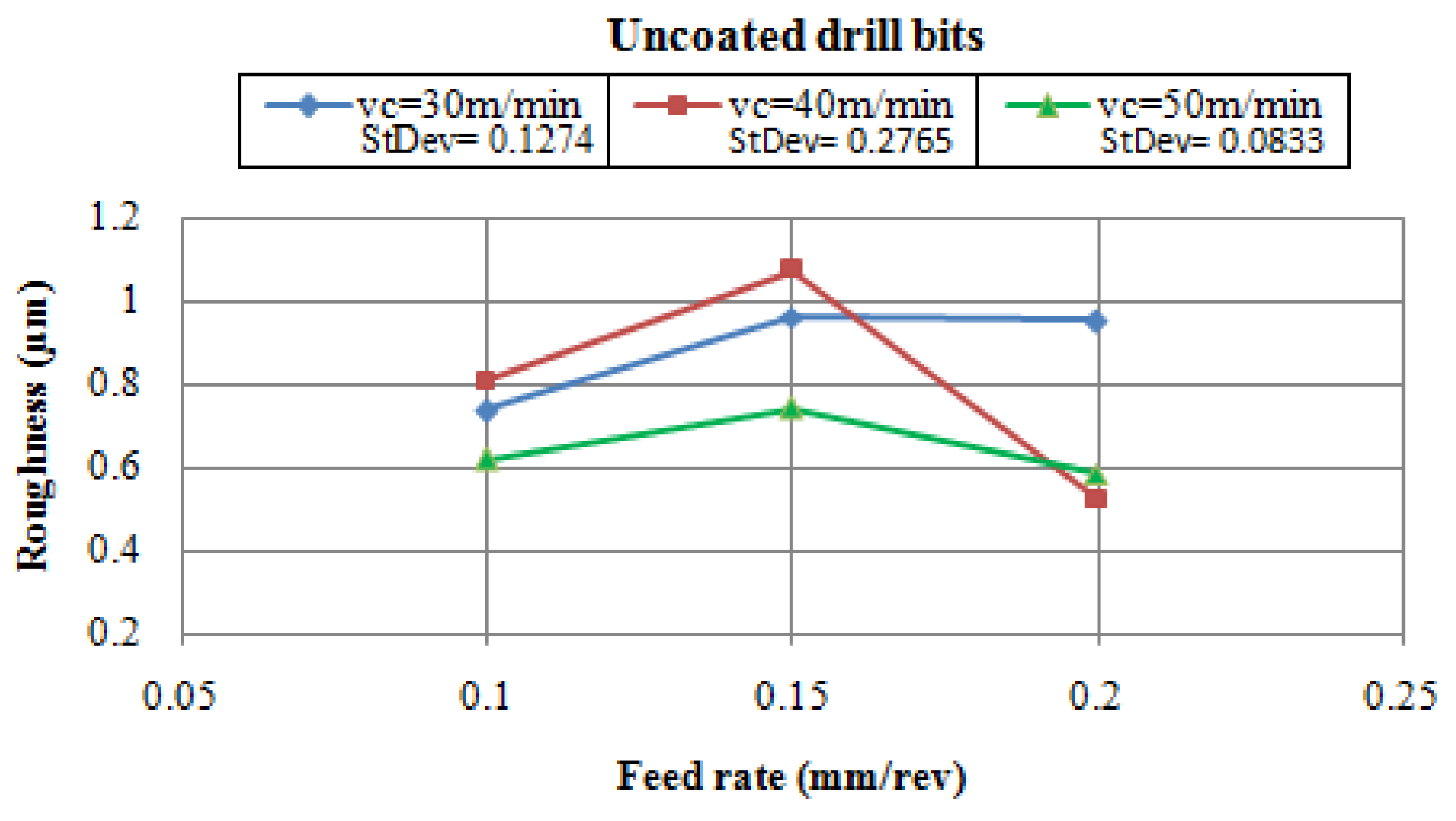

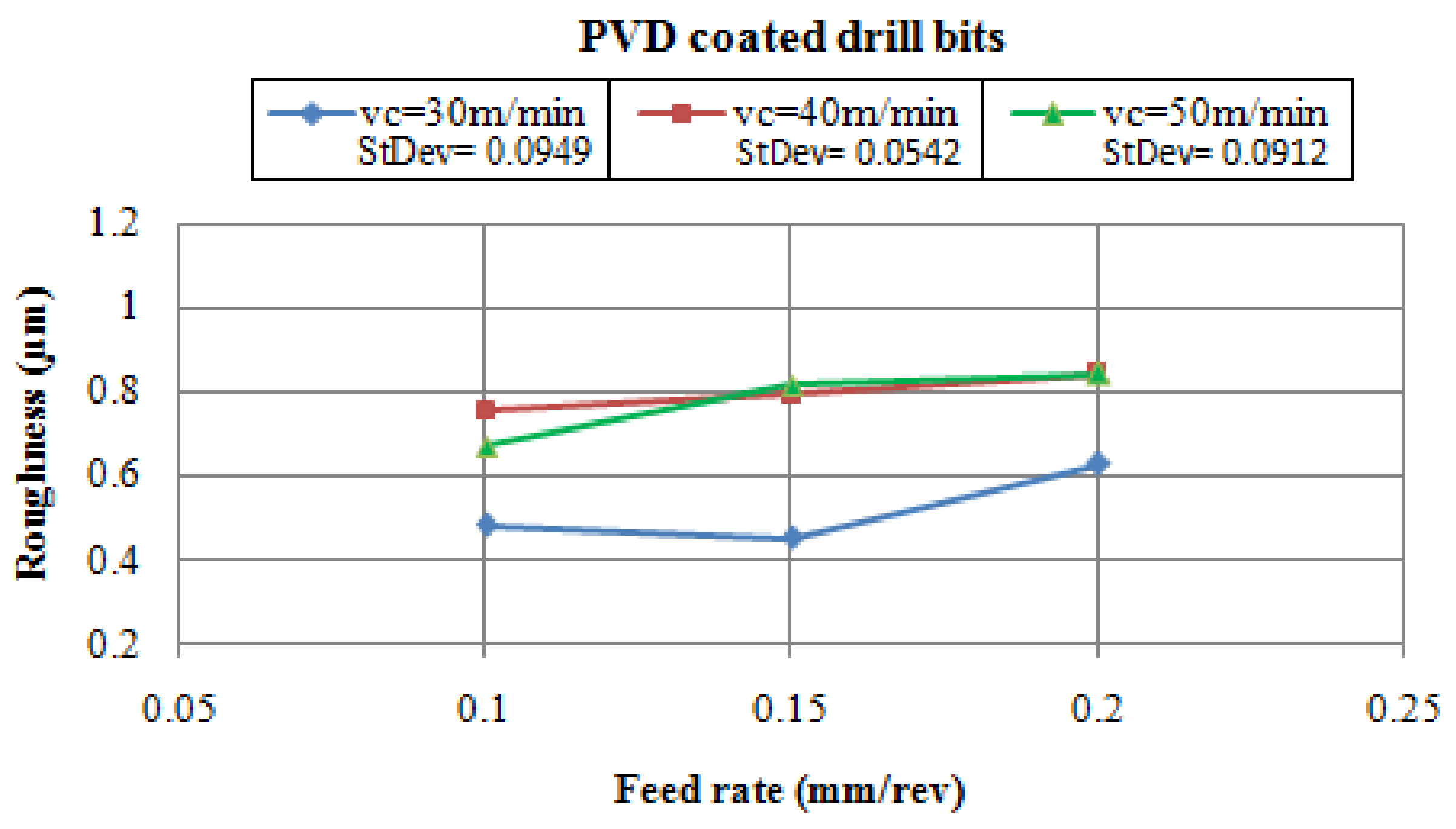

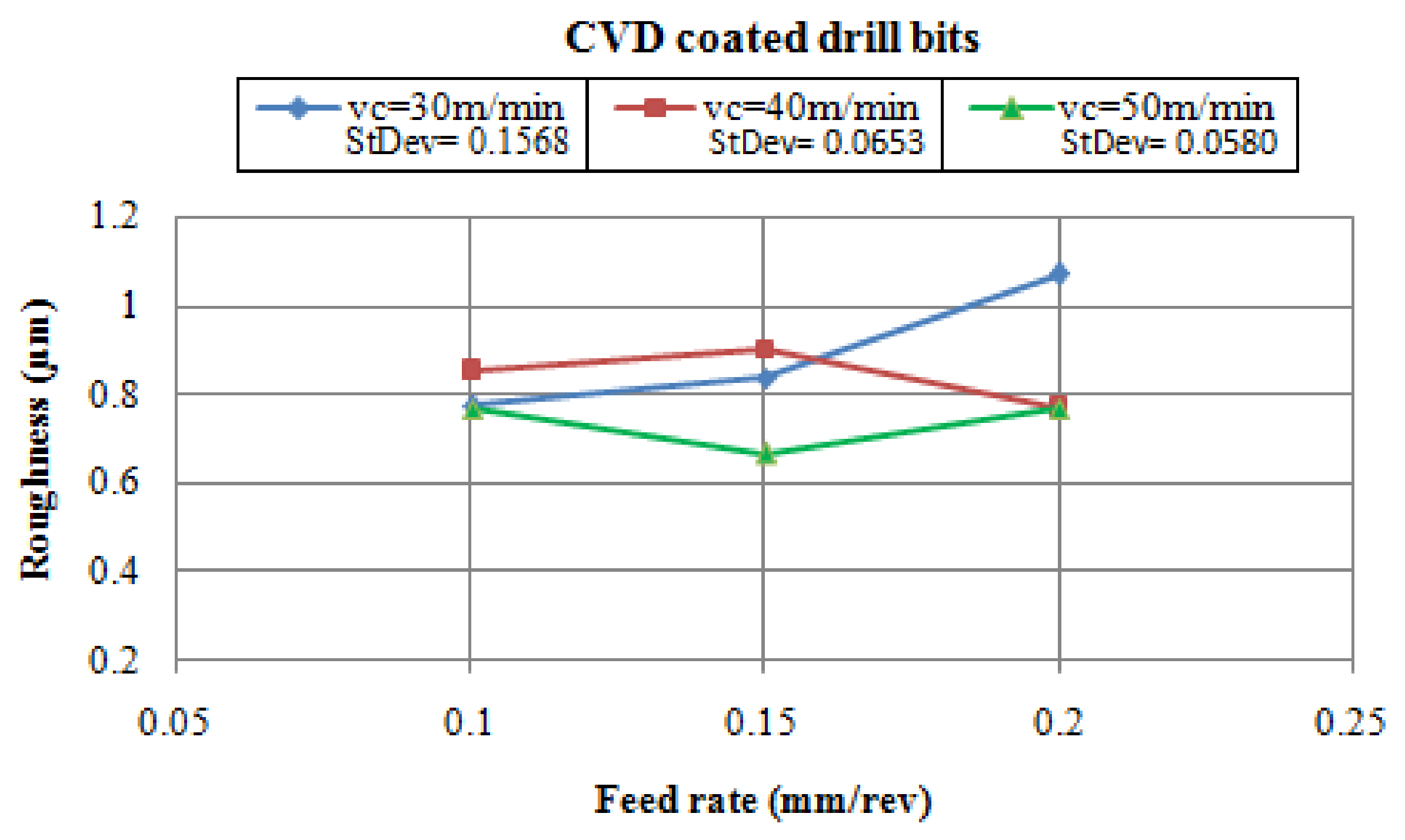

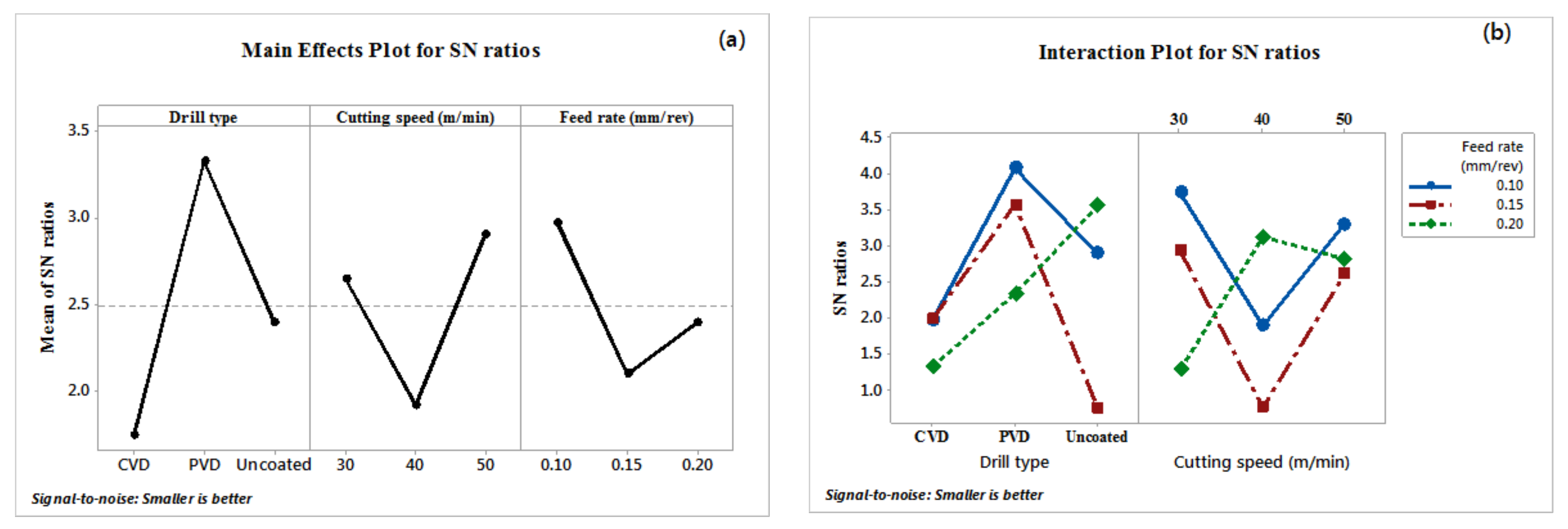

3.3. Surface Roughness (Ra)

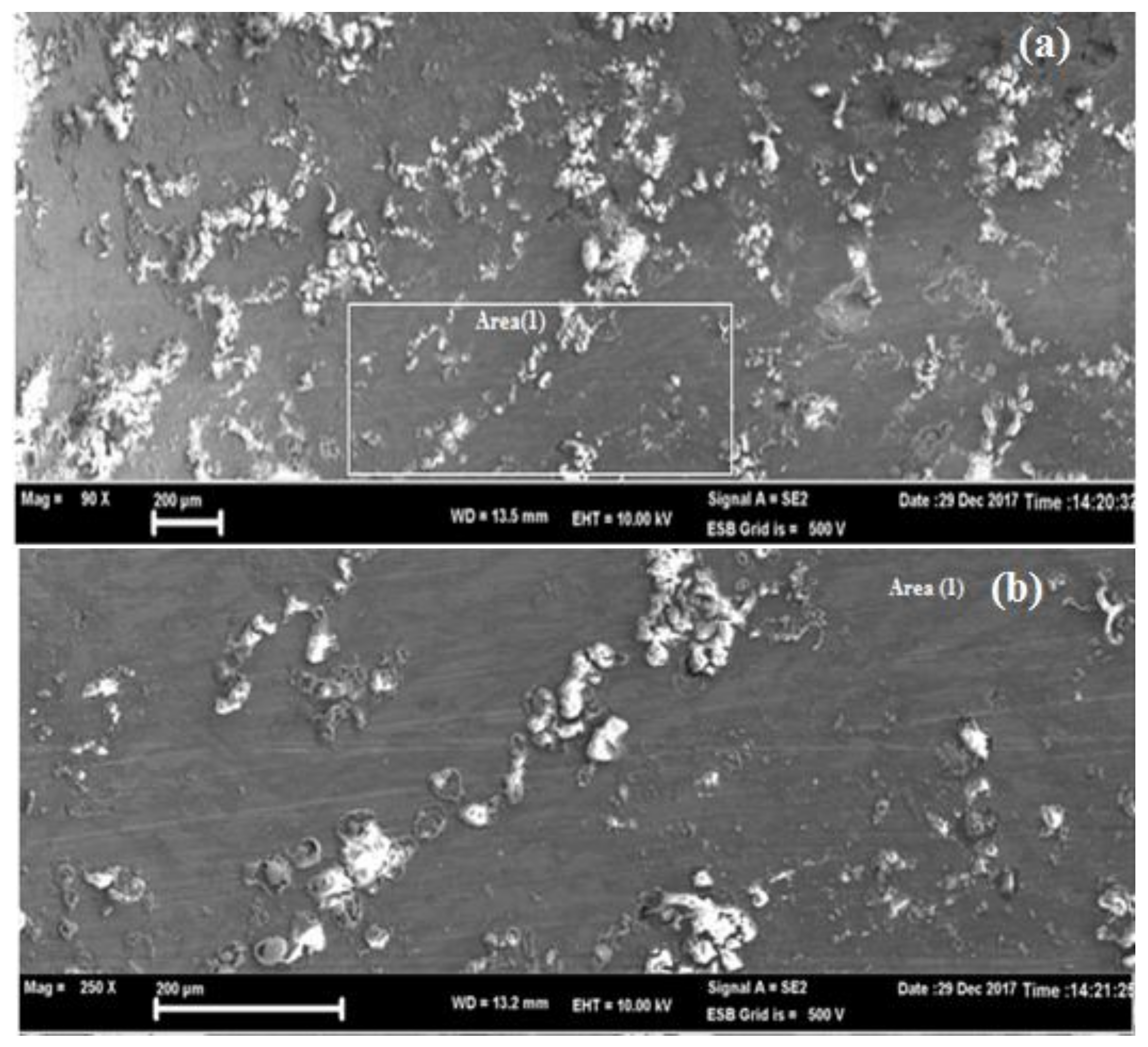

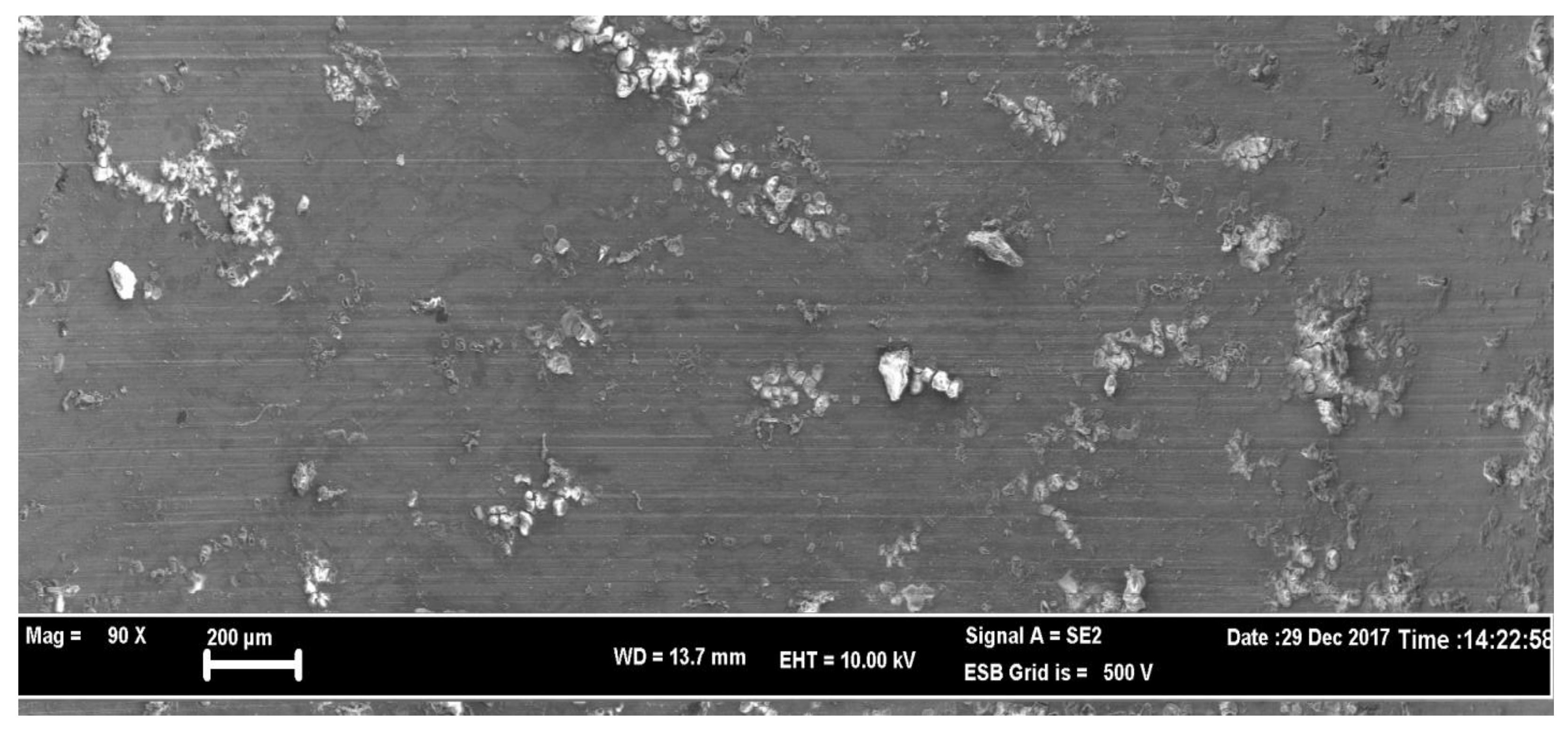

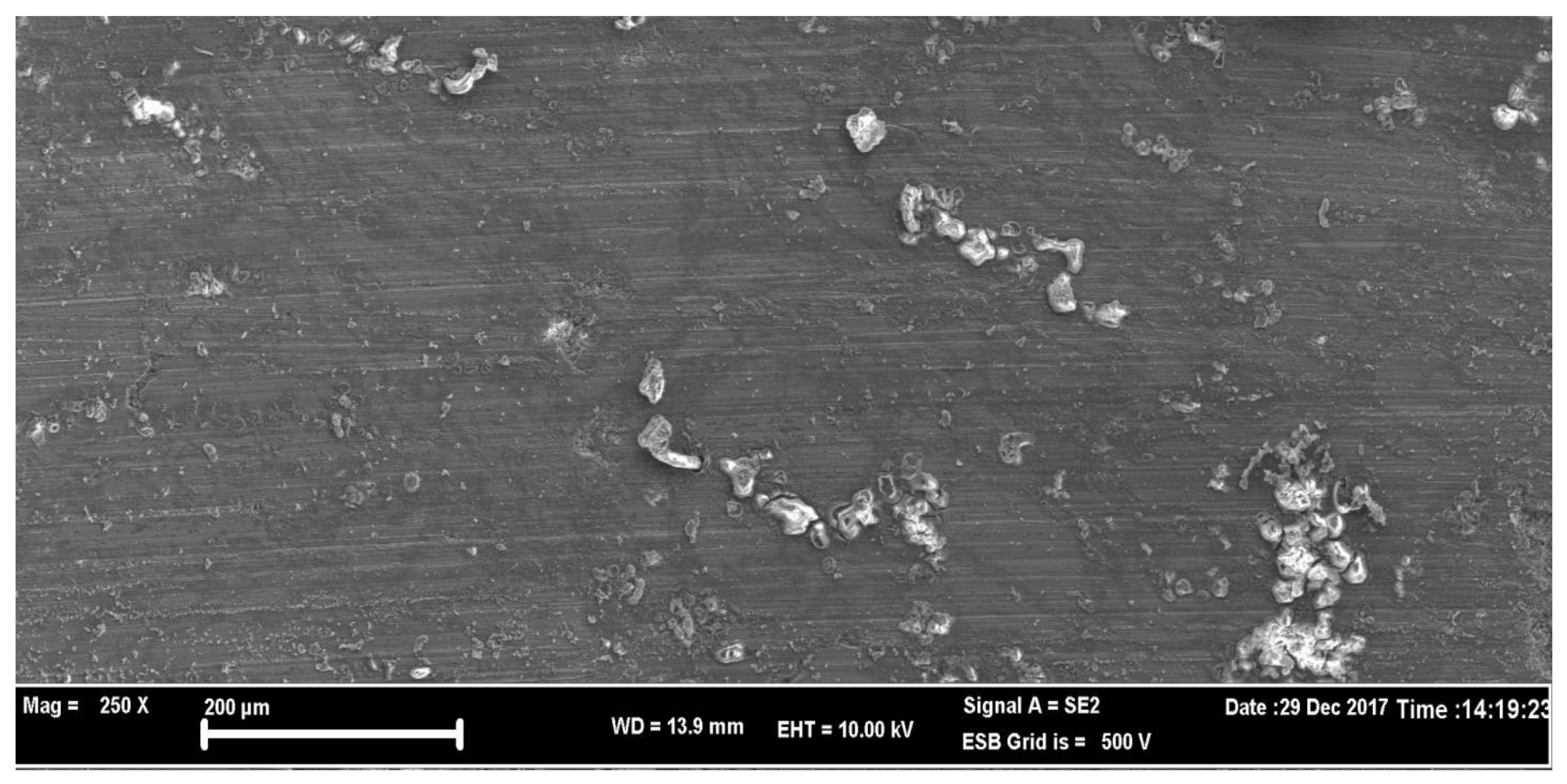

3.4. Drilled Surfaces SEM Investigation

4. Conclusions

- The uniform distribution of GNPs and SiC reinforcements inside the grains of magnesium matrix was confirmed via SEM.

- Thrust force and surface roughness in the drilling of hybrid Mg MMC Mg/10 wt %SiC/0.25 wt %GNPs are highly dependent on the feed rate, cutting speed, and type of drill bits. In addition, they are dependent on the matrix material and reinforced elements composition, interface, and properties.

- The thrust force is increased by increasing the feed rate, while the thrust force decreases with the increase of the cutting speed. The highest thrust forces were reached at lower cutting speed when using uncoated drill bits. However, with the PVD-coated drill bits, the lowest thrust force was reached at the cutting speed of 50 m/min with the three levels of feed rates.

- Taguchi statistical analysis shows that the most significant parameters that affect the thrust force are the type of drill, followed by the cutting speed and the feed rate. The optimal parameters combination to reach the minimum value of thrust force are the PVD coated drill bit, the cutting speed of 50 m/min, and feed rate of 0.10 mm/rev.

- The surface roughness (Ra) values of drilled surfaces are lower during the usage of coated drill bits. This is due to the hard coating over the drill bit surfaces, which reduced the BUE formation during drilling. The higher value is obtained during the use of uncoated drill bits at a cutting speed of 40 m/min and a 0.15 mm/rev feed rate. The results specify that lower feed rates are preferred in the drilling of hybrid Mg/SiC/GNPs MMC. The increase in the feed rate increases the thrust force and this affects the surface finish.

- Taguchi statistical analysis shows the most significant parameters that affect the surface roughness (Ra) are the type of drill, followed by the cutting speed and then the feed rate.

- The surfaces produced by using the uncoated drill bits is poor in quality, with fine grooves affecting the surface finish, and the performance of the coated drill bits is better compared to the uncoated drill bits at the different feed rates and cutting speeds were used in this investigation study.

- The hole drilled surface is smoother and flatter with some amount of BUE when using the PVD- and the CVD-coated drill bits, this is because of the hard coating layer (TiN and AlTiN) which reduces the BUE phenomenon.

Acknowledgments

Author Contributions

Conflicts of Interest

References

- Li, X.P.; Lu, L. Study of the reinforcement percentage of Mg-Al-SiC MMC in relation to the mechanical properties and machinability. In Materials Science Forum; Trans Tech Publications Ltd.: Zurich-Uetikon, Switzerland, 2003; Volume 437, pp. 185–188. [Google Scholar] [CrossRef]

- Rajmohan, T.; Palanikumar, K.; Kathirvel, M. Optimization of machining parameters in drilling hybrid aluminium metal matrix composites. Trans. Nonferrous Met. Soc. China 2012, 22, 1286–1297. [Google Scholar] [CrossRef]

- Sahin, Y.; Sur, G. The effect of Al2O3, Ti(C, N) based CVD coatings on tool wear in machining metal matrix composites. Surf. Coat. Technol. 2004, 179, 349–355. [Google Scholar] [CrossRef]

- Jiang, Q.C.; Li, X.L.; Wang, H.Y. Fabrication of TiC particulate reinforced magnesium matrix composites. Scr. Mater. 2003, 48, 713–717. [Google Scholar] [CrossRef]

- Rashad, M.; Pan, F.; Tang, A.; Asif, M.; Hussain, S.; Gou, J.; Mao, J. Improved strength and ductility of magnesium and graphenenanoplatelets using semi powder metallurgy method. J. Ind. Eng. Chem. 2015, 23, 243–250. [Google Scholar] [CrossRef]

- Weinert, K.; Lange, M. Machining of magnesium matrix composites. Adv. Eng. Mater. 2001, 3, 975–979. [Google Scholar] [CrossRef]

- Morin, E.; Masounave, J.; Laufer, E.E. Effect of drill wear on cutting forces in the drilling of metal-matrix composites. Wear 1995, 184, 11–16. [Google Scholar] [CrossRef]

- Gupta, M.; Wong, W.L.E. Magnesium-based nano composites: Lightweight materials of the future. Mater. Charact. 2015, 105, 30–46. [Google Scholar] [CrossRef]

- Rashad, M.; Pan, F.; Asif, M. Magnesium matrix composites reinforced with Graphene Nanoplatelets. In Graphene Materials: Fundamentals and Emerging Applications; John Wiley & Sons: Hoboken, NJ, USA, 2015; pp. 151–189. [Google Scholar]

- Rashad, M.; Pan, F.; Tang, A.; Asif, M.; She, J.; Gou, J.; Mao, J.; Hu, H. Development of magnesium graphenenanoplatelets composite. J. Compos. Mater. 2015, 49, 285–293. [Google Scholar] [CrossRef]

- Rashad, M.; Pan, F.; Tang, A.; Lu, Y.; Asif, M.; Hussain, S.; She, J.; Gou, J.; Mao, J. Effect of graphenenanoplatelets addition on strength and ductility of magnesium-titanium alloys. J.Magnes. Alloy. 2013, 1, 242–248. [Google Scholar] [CrossRef]

- Saravananakumar, M.; Natarajan, N.; Krishnaraj, V. Study of cutting forces in machining of magnesium composite by response surface methodology. Carbon Sci. Technol. 2015, 7, 36–58. [Google Scholar]

- Raj, A.M.; Das, S.L.; Palanikumarr, K. Influence of drill geometry on surface roughness in drilling of Al/SiC/Gr hybrid metal matrix composite. Indian J. Sci. Technol. 2013, 6, 5002–5007. [Google Scholar]

- Anthony, X.M.; Kumar, A.J.P. Machinability of hybrid metal matrix composite-A review. Procedia Eng. 2017, 174, 1110–1118. [Google Scholar]

- Palanikumar, K.; Muniaraj, A. Experimental investigation and analysis of thrust force in drilling cast hybrid metal matrix(Al-SiC-graphite) composites. Measurement 2014, 53, 240–250. [Google Scholar] [CrossRef]

- Sekhar, R.; Singh, T.P. Mechanisms in turning of metal matrix composites: A review. J. Mater. Res. Technol. 2015, 4, 197–207. [Google Scholar] [CrossRef]

- Nicholls, C.J.; Boswell, B.; Davies, I.J.; Islam, M.N. Review of machining metal matrix composites. Inter. J. Adv. Manuf. Technol. 2017, 90, 2429–2441. [Google Scholar] [CrossRef]

- Teng, X.; Huo, D.; Wong, E.; Meenashisundaram, G.; Gupta, M. Micro-machinability of nanoparticle-reinforced Mg-based MMCs: An experimental investigation. Inter. J. Adv. Manuf. Technol. 2016, 87, 2165–2178. [Google Scholar] [CrossRef]

- Pedersen, W.; Ramulu, M. Facing SiCp/Mg metal matrix composites with carbide tools. J. Mater. Process. Technol. 2006, 172, 417–423. [Google Scholar] [CrossRef]

| Drill Bit Type | Code | Bit Material | Coating Material | Coating Thickness (µm) | Point Angle | Helix Angle |

|---|---|---|---|---|---|---|

| Uncoated | DNGCUS-C06M0500 | Tungsten carbide W/C | - | - | 135° | 28° |

| PVD coated | DNGCUS-C06M0500/PVD | Tungsten carbide W/C | TiN | 3.0 | 135° | 28° |

| CVD coated | DNGCUS-C06M0500/CVD | Tungsten carbide W/C | AlTiN | 5.0 | 135° | 28° |

| Level | Cutting Speed Levels | Feed Rate Levels | Drill Bits Types |

|---|---|---|---|

| 1 | V1 = 30 m/min | f1 = 0.10 mm/rev | Uncoated Tungsten carbide |

| 2 | V2 = 40 m/min | f2 = 0.15 mm/rev | PVD-coated Tungsten carbide |

| 3 | V3 = 50 m/min | f3 = 0.20 mm/rev | CVD-coated Tungsten carbide |

| Exp. No. | Drill Type | Cutting Speed (m/min) | Feed Rate (mm/rev) |

|---|---|---|---|

| 1 | Uncoated | 30 | 0.10 |

| 2 | Uncoated | 30 | 0.15 |

| 3 | Uncoated | 30 | 0.20 |

| 4 | Uncoated | 40 | 0.10 |

| 5 | Uncoated | 40 | 0.15 |

| 6 | Uncoated | 40 | 0.20 |

| 7 | Uncoated | 50 | 0.10 |

| 8 | Uncoated | 50 | 0.15 |

| 9 | Uncoated | 50 | 0.20 |

| 10 | PVD | 30 | 0.10 |

| 11 | PVD | 30 | 0.15 |

| 12 | PVD | 30 | 0.20 |

| 13 | PVD | 40 | 0.10 |

| 14 | PVD | 40 | 0.15 |

| 15 | PVD | 40 | 0.20 |

| 16 | PVD | 50 | 0.10 |

| 17 | PVD | 50 | 0.15 |

| 18 | PVD | 50 | 0.20 |

| 19 | CVD | 30 | 0.10 |

| 20 | CVD | 30 | 0.15 |

| 21 | CVD | 30 | 0.20 |

| 22 | CVD | 40 | 0.10 |

| 23 | CVD | 40 | 0.15 |

| 24 | CVD | 40 | 0.20 |

| 25 | CVD | 50 | 0.10 |

| 26 | CVD | 50 | 0.15 |

| 27 | CVD | 50 | 0.20 |

| Levels | Drill Bit | Cutting Speed (m/min) | Feed Rate (mm/rev) |

|---|---|---|---|

| 1 | −36.98 | −37.36 | −35.41 |

| 2 | −34.51 | −37.01 | −36.08 |

| 3 | −37.60 | −34.74 | −37.61 |

| Delta | 3.09 | 2.62 | 2.21 |

| Rank | 1 | 2 | 3 |

| Levels | Drill Bit | Cutting Speed (m/min) | Feed Rate (mm/rev) |

|---|---|---|---|

| 1 | 1.758 | 2.651 | 2.978 |

| 2 | 3.327 | 1.929 | 2.105 |

| 3 | 2.404 | 2.909 | 2.406 |

| Delta | 1.569 | 0.980 | 0.874 |

| Rank | 1 | 2 | 3 |

© 2018 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (http://creativecommons.org/licenses/by/4.0/).

Share and Cite

Abdulgadir, M.M.; Demir, B.; Turan, M.E. Hybrid Reinforced Magnesium Matrix Composites (Mg/Sic/GNPs): Drilling Investigation. Metals 2018, 8, 215. https://doi.org/10.3390/met8040215

Abdulgadir MM, Demir B, Turan ME. Hybrid Reinforced Magnesium Matrix Composites (Mg/Sic/GNPs): Drilling Investigation. Metals. 2018; 8(4):215. https://doi.org/10.3390/met8040215

Chicago/Turabian StyleAbdulgadir, Mustafa M., Bilge Demir, and Muhammet Emre Turan. 2018. "Hybrid Reinforced Magnesium Matrix Composites (Mg/Sic/GNPs): Drilling Investigation" Metals 8, no. 4: 215. https://doi.org/10.3390/met8040215

APA StyleAbdulgadir, M. M., Demir, B., & Turan, M. E. (2018). Hybrid Reinforced Magnesium Matrix Composites (Mg/Sic/GNPs): Drilling Investigation. Metals, 8(4), 215. https://doi.org/10.3390/met8040215