Effects of Porosity on Mechanical Properties and Corrosion Resistances of PM-Fabricated Porous Ti-10Mo Alloy

Abstract

1. Introduction

2. Experiments and Methods

2.1. Materials and Sample Preparation by PM

2.2. Materials Characterization

2.3. Corrosion Testing

3. Results and Discussion

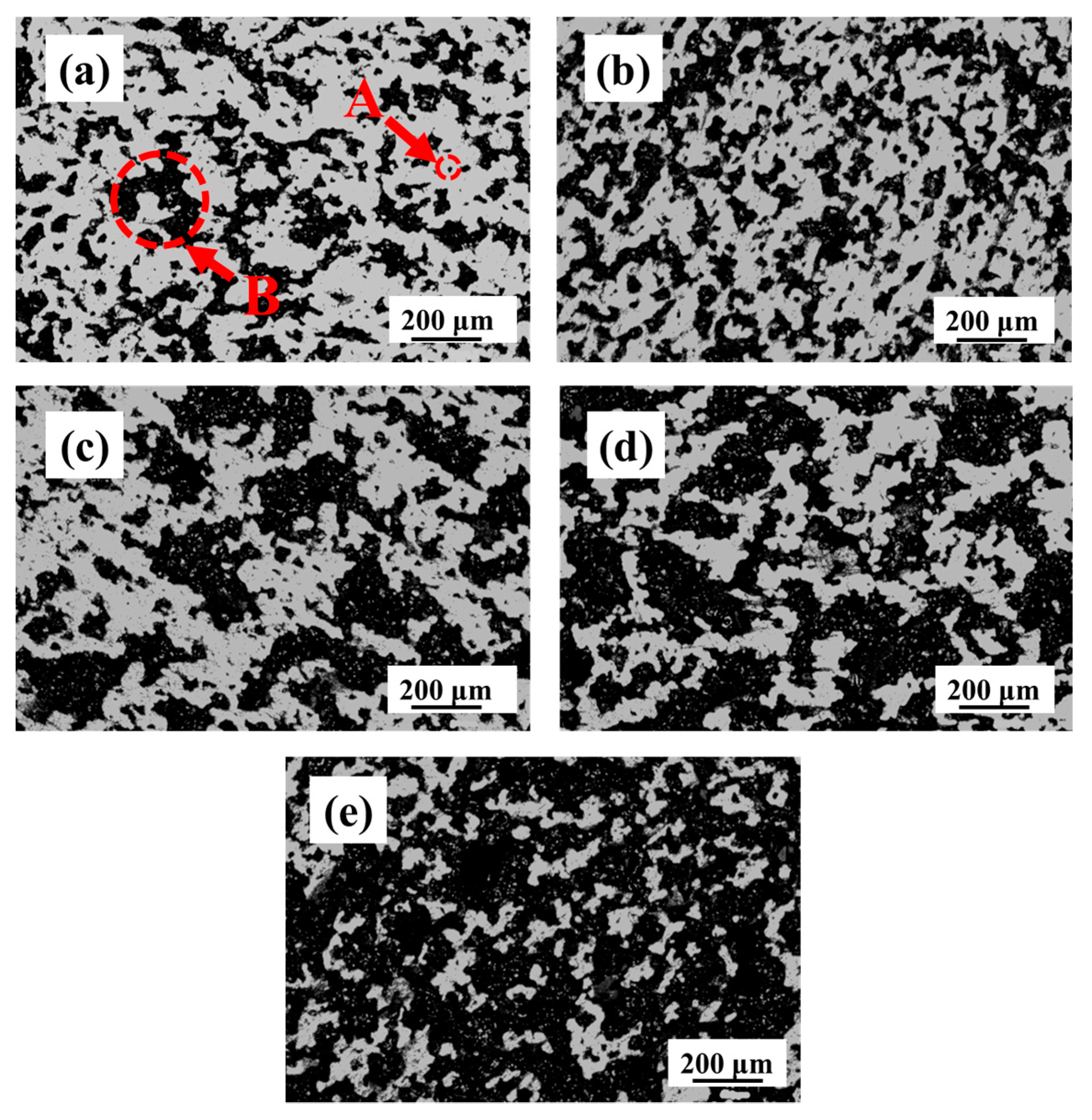

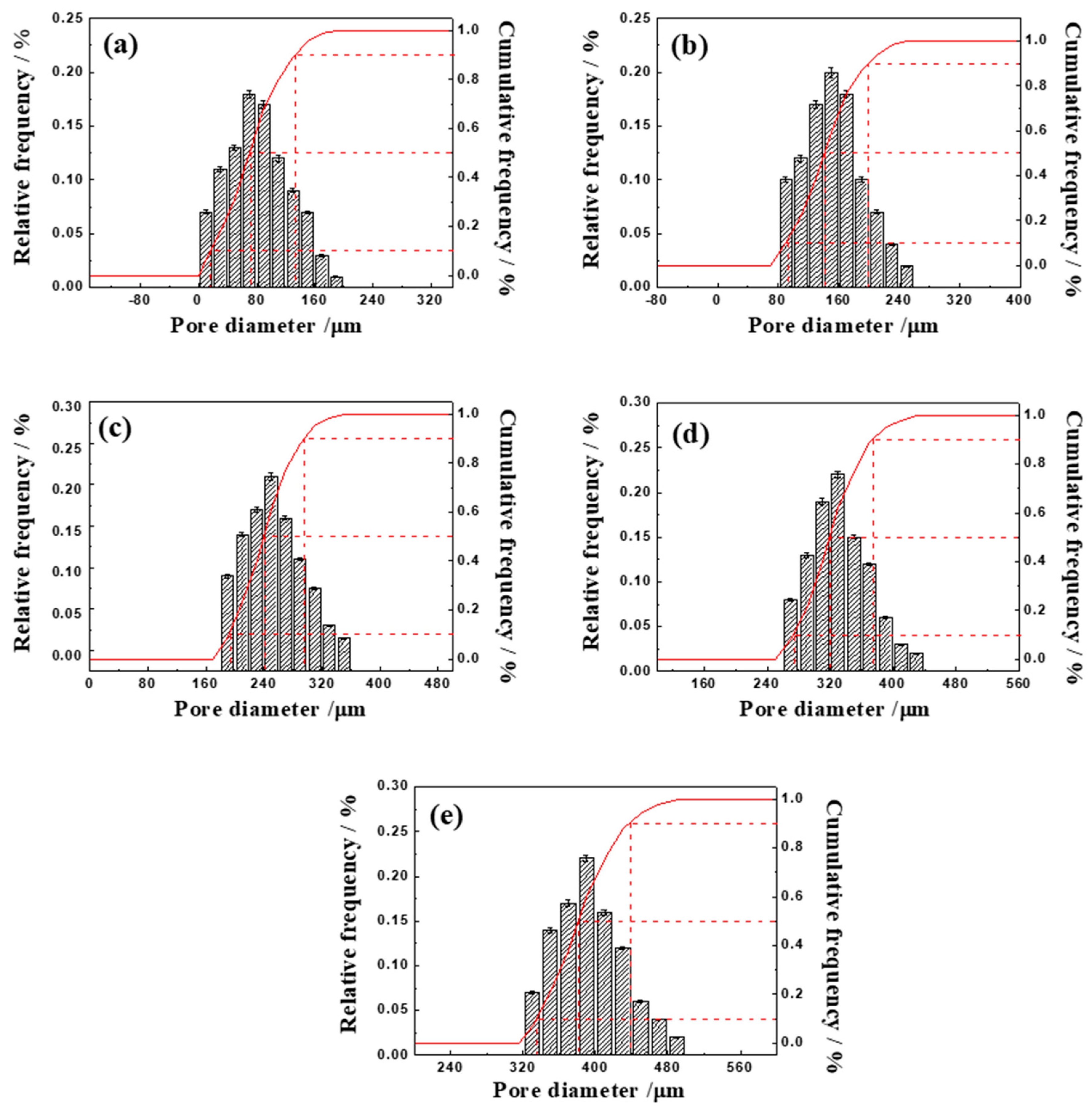

3.1. Pore Characteristics

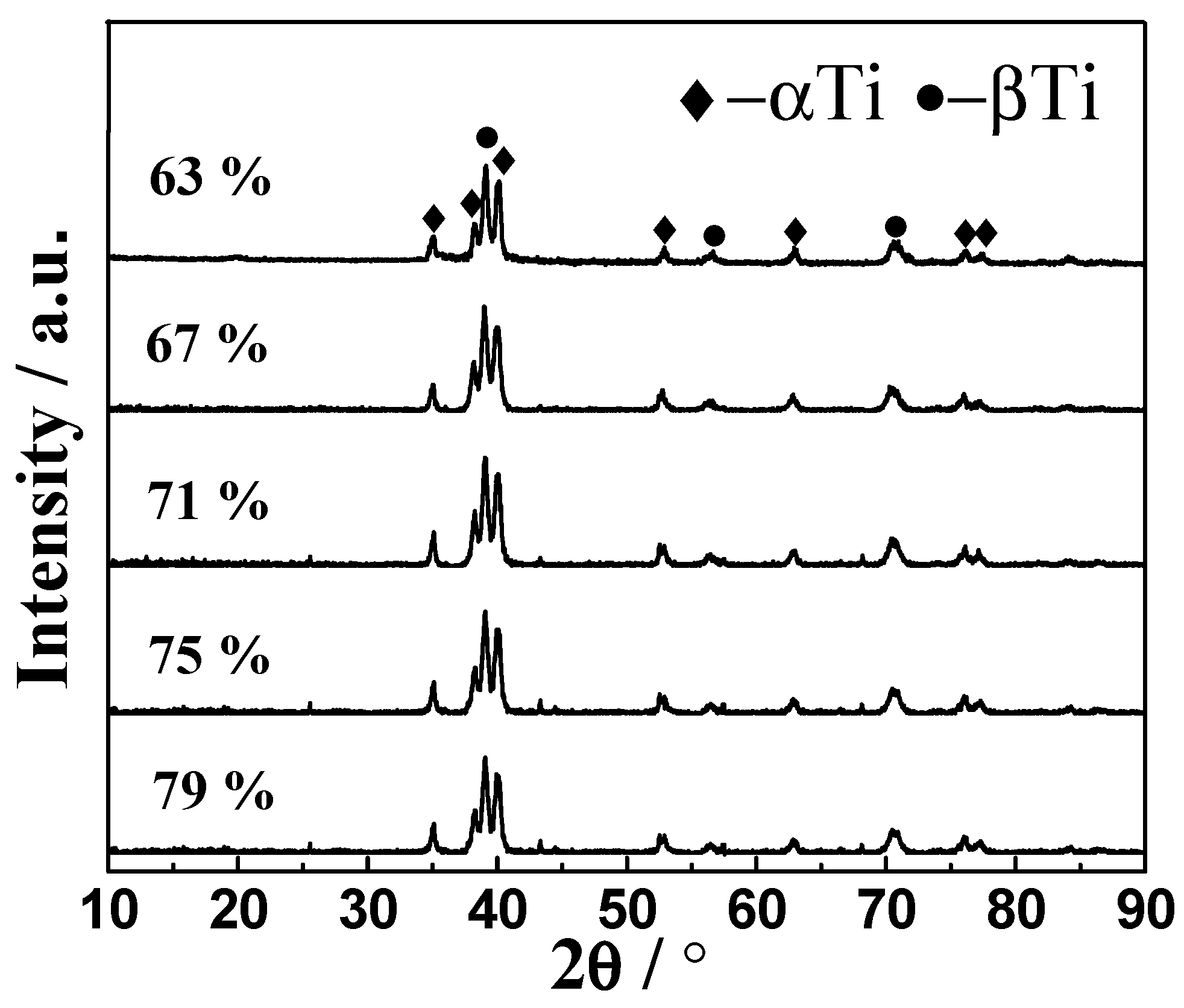

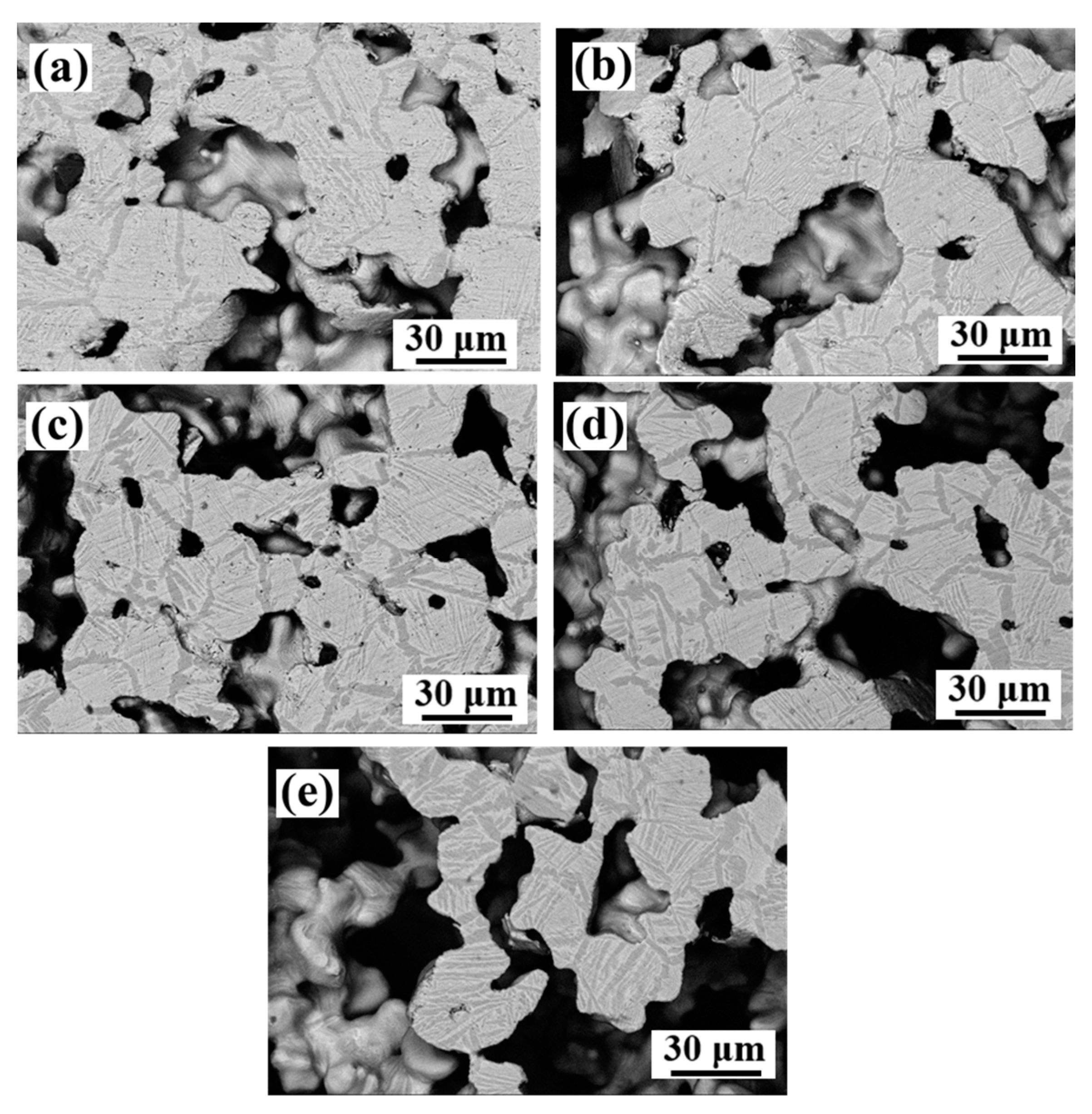

3.2. Microstructure Observation

3.3. Mechanical Properties

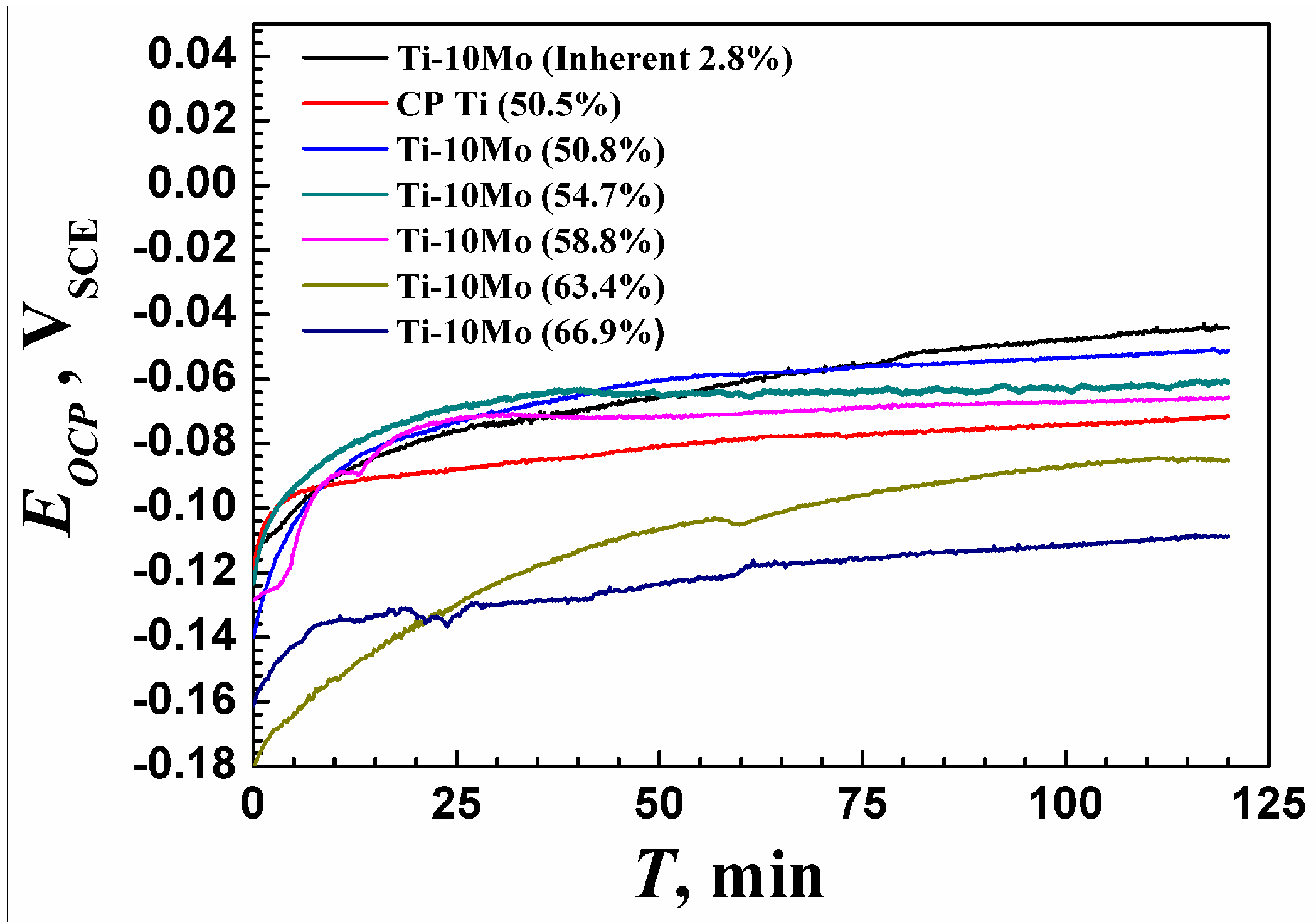

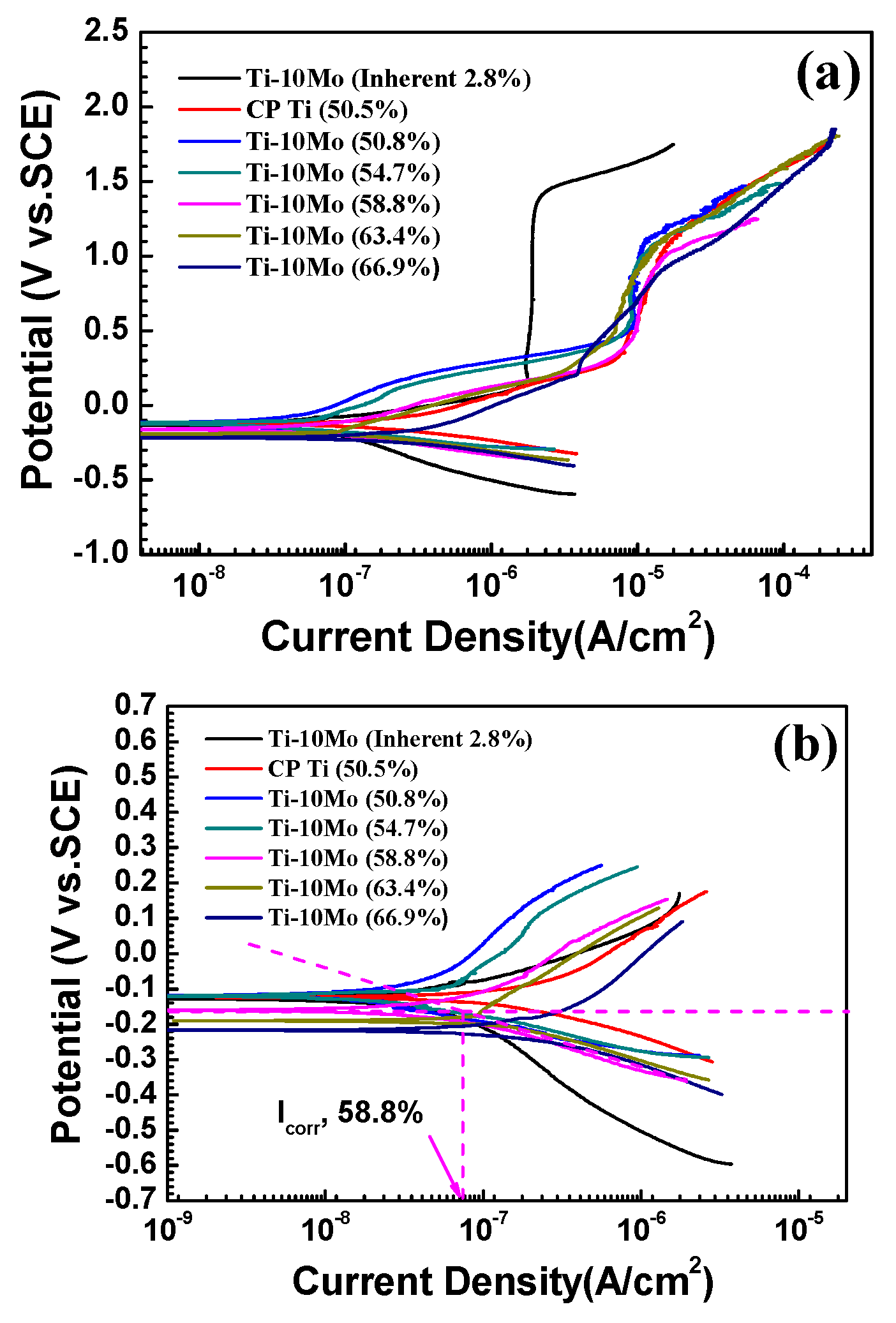

3.4. Electrochemical Behaviors

3.5. Relationship among Porosity, Mechanical Properties and Corrosion Resistance

4. Conclusions

- (1)

- Porous Ti-10Mo alloys can be fabricated by PM of adding NH4HCO3 with low-cost non-spherical elemental powders. With different contents added, the porosity can be controlled in the range of 50–67% with the average pores size of 70–381 μm.

- (2)

- The PM-fabricated porous Ti-10Mo alloy is characterized by typical Widmanstaten structure. With porosity increasing, their elastic modulus decreases exponentially in the range of 6.4–1.7 GPa, while yield compression strength decreases linearly in 248.2–76.9 MPa, respectively.

- (3)

- With rising of porosity, the corrosion potential of porous Ti-10Mo alloy in PBS shift to negative direction, while corrosion current density increases significantly. The corrosion rate of the Ti-10Mo increases exponentially with porosity increasing, and is much lower than that of CP Ti with similar porosity.

- (4)

- The association among porosity characteristics, mechanical properties, and corrosion resistance of Ti-10Mo by PM is formed, which can be used as a design reference for material selection for orthopedic applications.

Acknowledgments

Author Contributions

Conflicts of Interest

References

- Zhao, X.; Niinomi, M.; Nakai, M. Beta type Ti-Mo alloys with changeable Young’s modulus for spinal fixation applications. Acta Biomater. 2012, 8, 1990–1997. [Google Scholar] [CrossRef] [PubMed]

- Wang, X.J.; Xu, S.Q.; Zhou, S.W.; Xu, W.; Leary, M.; Choong, P.; Qian, M.; Brandt, M.; Xie, Y.M. Topological design and additive manufacturing of porous metals for bone scaffolds and orthopaedic implants: A review. Biomaterials 2016, 83, 127–141. [Google Scholar] [CrossRef] [PubMed]

- Ho, W.F.; Ju, C.P.; Lin, J.C. Structure and properties of cast binary Ti-Mo alloys. Biomaterials 1999, 20, 2115–2122. [Google Scholar] [CrossRef]

- Gonzalez, J.E.; Mirza-Rosca, J.C. Study of the corrosion behavior of titanium and some of its alloys for biomedical and dental implant applications. J. Electroanal. Chem. 1999, 471, 109–115. [Google Scholar] [CrossRef]

- Kumar, S.; Narayanan, T.S. Corrosion behaviour of Ti-15Mo alloy for dental implant applications. J. Dent. 2008, 36, 500–507. [Google Scholar] [CrossRef] [PubMed]

- Oliveira, N.T.; Guastaldi, A.C. Electrochemical stability and corrosion resistance of Ti-Mo alloys for biomedical applications. Acta Biomater. 2009, 5, 399–405. [Google Scholar] [CrossRef] [PubMed]

- Jablokov, V.R.; Nutt, M.J.; Richelsoph, M.E.; Freese, H.L. The application of Ti-15Mo beta titanium alloy in high strength structural orthopaedic applications. J. ASTM Int. 2005, 2, 1–8. [Google Scholar] [CrossRef]

- Li, Y.; Wong, C.; Xiong, J.; Hodgson, P.; Wen, C. Cytotoxicity of titanium and titanium alloying elements. J. Dent. Res. 2010, 89, 493–497. [Google Scholar] [CrossRef] [PubMed]

- Niinomi, M.; Akahori, T.; Yamaguchi, T.; Kasuga, T.; Fukui, H.; Suzuki, A. Aging characteristics and mechanical property of Ti-29Nb-13Ta-4.6Zr coated with calcium phosphate invert glass-ceramic for biomedical application. J. Jpn. Inst. Met. 2003, 67, 604–613. [Google Scholar] [CrossRef][Green Version]

- Cremasco, A.; Messias, A.D.; Esposito, A.R.; Rezende Duek, E.A.; Caram, R. Effects of alloying elements on the cytotoxic response of titanium alloys. Mater. Sci. Eng. C 2011, 31, 833–839. [Google Scholar] [CrossRef]

- Lee, E.B.; Han, M.K.; Kim, B.J.; Song, H.J.; Park, Y.J. Effect of molybdenum on the microstructure, mechanical properties and corrosion behavior of Ti alloys. Int. J. Mater. Res. 2014, 105, 847–853. [Google Scholar] [CrossRef]

- Yan, M.; Qian, M.; Kong, C.; Dargusch, M. Impacts of trace carbon on the microstructure of as-sintered biomedical Ti-15Mo alloy and reassessment of the maximum carbon limit. Acta Biomater. 2014, 10, 1014–1023. [Google Scholar] [CrossRef] [PubMed]

- Van den Dolder, J.; Farber, E.; Spauwen, P.H.M.; Jansen, J.A. Bone tissue reconstruction using titanium fiber mesh combined with rat bone marrow stromal cells. Biomaterials 2003, 24, 1745–1750. [Google Scholar] [CrossRef]

- Marin, E.; Fusi, S.; Pressacco, M.; Paussa, L.; Fedrizzi, L. Characterization of cellular solids in Ti6Al4V for or thopaedic implant applications: Trabecular titanium. J. Mech. Behav. Biomed. 2010, 3, 373–381. [Google Scholar] [CrossRef] [PubMed]

- Zardiackas, L.D.; Dillon, L.D.; Mitchell, D.W.; Nunnery, L.A.; Poggie, R. Structure, metallurgy, and mechanical properties of a porous tantalum foam. J. Biomed. Mater. Res. A 2011, 58, 180–187. [Google Scholar] [CrossRef]

- Larrañeta, E.; Lutton, R.E.M.; Woolfson, A.D.; Donnelly, R.F. Microneedle arrays as transdermal and intradermal drug delivery systems: Materials science, manufacture and commercial development. Mater. Sci. Eng. R 2016, 104, 1–32. [Google Scholar] [CrossRef]

- Gao, Z.; Li, Q.; He, F.; Huang, Y.; Wan, Y. Mechanical modulation and bioactive surface modification of porous Ti-10Mo alloy for bone implants. Mater Des. 2012, 42, 13–20. [Google Scholar] [CrossRef]

- Xie, F.X.; He, X.B.; Lu, X.; Cao, S.L.; Qu, X.H. Preparation and properties of porous Ti-10Mo alloy by selective laser sintering. Mater. Sci. Eng. C 2013, 33, 1085–1090. [Google Scholar] [CrossRef] [PubMed]

- Xie, F.X.; He, X.M.; Lv, Y.M.; Wu, M.P.; He, X.B.; Qu, X.H. Selective laser sintered porous Ti-(4–10)Mo alloys for biomedical applications: Structural characteristics, mechanical properties and corrosion behaviour. Corros. Sci. 2015, 95, 117–124. [Google Scholar] [CrossRef]

- Xie, F.X.; He, X.B.; Cao, S.L.; Lu, X.; Qu, X.H. Structural characterization and electrochemical behavior of a laser-sintered porous Ti-10Mo alloy. Corros. Sci. 2013, 67, 217–224. [Google Scholar] [CrossRef]

- Chou, X.M. Research on Titanium Alloy and Porous Titanium in Powder Metallurgy; Central South University: Changsha, China, 2007; pp. 27–28. [Google Scholar]

- Sidambe, A.T.; Figueroa, I.A.; Hamilton, H.G.C.; Todd, I. Metal injection moulding of CP-Ti components for biomedical applications. J. Mater. Process. Technol. 2012, 212, 1591–1597. [Google Scholar] [CrossRef]

- Xu, G.F.; Zhou, L.Q.; Li, X.; Duan, Y.L.; Tao, X.F. Existing forms and effects of trace impurities on mechanical properties of CP Ti. Mater. Sci. Eng. Powder Metall. 2016, 21, 672–677. [Google Scholar]

- Nyberg, E.; Miller, M.; Simmons, K.; Weil, K.S. Microstructure and mechanical properties of titanium components fabricated by a new powder injection molding technique. Mater. Sci. Eng. C 2005, 25, 336–342. [Google Scholar] [CrossRef]

- Wen, C.E.; Yamada, Y.; Shimojima, K.; Chino, Y.; Hosokawa, H.; Mabuchi, M. Novel titanium foam for bone tissue engineering. J. Mater. Res. 2002, 17, 2633–2639. [Google Scholar] [CrossRef]

- Kawai, N.; Niwa, S.; Sato, M.; Sato, Y.; Suwa, Y.; Ichihara, I. Bone formation by cells from femurs cultured among three-dimensionally arranged hydroxyapatite granules. J. Biomed. Mater. Res. A 1997, 37, 1–8. [Google Scholar] [CrossRef]

- Krishna, B.V.; Bose, S.; Bandyopadhyay, A. Low stiffness porous Ti structures for load-bearing implants. Acta Biomater. 2007, 3, 997–1006. [Google Scholar] [CrossRef] [PubMed]

- Heakal, E.T.; Ghoneim, A.A.; Mogoda, A.S.; Awad, K. Electrochemical behaviour of Ti-6Al-4V alloy and Ti in azide and halide solutions. Corros. Sci. 2011, 53, 2728–2737. [Google Scholar] [CrossRef]

- Levy, M.; Sklover, G.N. Anodic Polarization of titanium and titanium alloys in hydrochloric acid. J. Electrochem. Soc. 1969, 116, 323–328. [Google Scholar] [CrossRef]

- Assis, S.L.D.; Wolynec, S.; Costa, I. Corrosion characterization of titanium alloys by electrochemical techniques. Electrochim. Acta 2006, 51, 1815–1819. [Google Scholar] [CrossRef]

- McCafferty, E. Validation of corrosion rates measured by the Tafel extrapolation method. Corros. Sci. 2005, 47, 3202–3215. [Google Scholar] [CrossRef]

- Thieme, M.; Wieters, K.P.; Bergner, F.; Scharnweber, D.; Worch, H.; Ndop, J.; Kim, T.J.; Grill, W. Titanium Powder Sintering for Preparation of a Porous FGM Destined as a Skeletal Replacement Implant. Mater. Sci. Forum 1999, 308, 374–382. [Google Scholar] [CrossRef]

- Wen, C.E.; Mabuchi, M.; Yamada, Y.; Shimojima, K.; Chino, Y.; Asahina, T. Processing of biocompatible porous Ti and Mg. Scr. Mater. 2001, 45, 1147–1153. [Google Scholar] [CrossRef]

- Geetha, M.; Singh, A.K.; Asokamani, R.; Gogia, A.K. Ti based biomaterials, the ultimate choice for orthopaedic implants—A review. Prog. Mater. Sci. 2009, 54, 397–425. [Google Scholar] [CrossRef]

| Powder | Chemical Composition (wt. %) | |||||||||

|---|---|---|---|---|---|---|---|---|---|---|

| H | C | N | O | Si | Cl | Fe | Ni | Ti | Mo | |

| Ti | 0.02 | 0.02 | 0.04 | 0.25 | 0.02 | 0.05 | 0.06 | 0 | Bal. | 0 |

| Mo | 0.07 | 0.05 | 0.05 | 0.20 | 0.02 | 0.01 | 0.06 | 0.01 | 0 | Bal. |

| Alloys | Space-Holder Content (vol. %) | Total Porosity (Pt, %) | Connected Porosity (Pc, %) | d50 (μm) | d10/d90 (μm) |

|---|---|---|---|---|---|

| Ti-10Mo | 63 | 50.8 ± 1.1 | 46.1 ± 1.0 | 70.1 ± 1.6 | 14.2 ± 0.3/132.5 ± 2.3 |

| 67 | 54.7 ± 1.2 | 50.5 ± 1.2 | 140.9 ± 2.9 | 87.1 ± 1.9/199.2 ± 4.3 | |

| 71 | 58.8 ± 1.4 | 54.3 ± 1.4 | 241.3 ± 5.7 | 190.1 ± 3.7/296.5 ± 6.6 | |

| 75 | 63.4 ± 1.5 | 59.1 ± 1.4 | 321.6 ± 7.8 | 271.3 ± 5.4/374.5 ± 10.2 | |

| 79 | 66.9 ± 1.6 | 62.8 ± 1.7 | 381.4 ± 10.1 | 335.4 ± 7.8/438.7 ± 11.2 |

| Alloys | Porosity (%) | Ecorr (mV vs. SCE) | Icorr × 10−8 (A/cm2) | βc (mV Decade−1) |

|---|---|---|---|---|

| Ti-10Mo | Inherent 2.8 ± 0.2 | −131.1 ± 7.4 | 1.4 ± 0.5 | −205.1 ± 4.2 |

| 50.8 ± 1.1 | −119.1 ± 9.5 | 3.5 ± 0.2 | −121.4 ± 3.6 | |

| 54.7 ± 1.2 | −121.5 ± 8.7 | 5.4 ± 0.4 | −105.6 ± 1.4 | |

| 58.8 ± 1.4 | −155.1 ± 3.3 | 7.1 ± 0.5 | −102.4 ± 2.6 | |

| 63.4 ± 1.5 | −188.1 ± 3.8 | 9.8 ± 0.4 | −128.3 ± 2.9 | |

| 66.9 ± 1.6 | −210.1 ± 9.8 | 14.1 ± 0.4 | −148.6 ± 2.1 | |

| CP Ti | 50.5 ± 1.2 | −125.1 ± 5.1 | 8.9 ± 0.7 | −131.3 ± 1.2 |

| Alloys | Pore Characteristics | Mechanical Properties | Corrosion Properties | ||

|---|---|---|---|---|---|

| Porosity (%) | Average Pore Size (d50, μm) | Compression Yield Strength (MPa) | Elastic Modulus (GPa) | Corrosion Rate (g/m2·day) | |

| Ti-10Mo | Inherent 2.8 ± 0.2 | - | 908.1 ± 20.6 | 66.2 ± 3.2 | 1.6 ± 0.1 |

| 50.8 ± 1.1 | 70.1 ± 1.6 | 248.2 ± 15.9 | 6.4 ± 0.9 | 4.1 ± 0.2 | |

| 54.7 ± 1.2 | 140.9 ± 2.9 | 194.7 ± 15.1 | 5.1 ± 0.8 | 6.3 ± 0.3 | |

| 58.8 ± 1.4 | 241.3 ± 5.7 | 166.2 ± 13.5 | 3.9 ± 0.4 | 8.1 ± 0.3 | |

| 63.4 ± 1.5 | 321.6 ± 7.8 | 127.5 ± 12.7 | 2.9 ± 0.2 | 11.2 ± 0.5 | |

| 66.9 ± 1.6 | 381.4 ± 10.1 | 76.9 ± 11.9 | 1.7 ± 0.1 | 17.1 ± 0.9 | |

| CP Ti | 50.5 ± 1.0 | 68.8 ± 2.1 | 201.9 ± 14.8 | 6.1 ± 1.1 | 10.1 ± 1.8 |

© 2018 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (http://creativecommons.org/licenses/by/4.0/).

Share and Cite

Xu, W.; Lu, X.; Zhang, B.; Liu, C.; Lv, S.; Yang, S.; Qu, X. Effects of Porosity on Mechanical Properties and Corrosion Resistances of PM-Fabricated Porous Ti-10Mo Alloy. Metals 2018, 8, 188. https://doi.org/10.3390/met8030188

Xu W, Lu X, Zhang B, Liu C, Lv S, Yang S, Qu X. Effects of Porosity on Mechanical Properties and Corrosion Resistances of PM-Fabricated Porous Ti-10Mo Alloy. Metals. 2018; 8(3):188. https://doi.org/10.3390/met8030188

Chicago/Turabian StyleXu, Wei, Xin Lu, Bing Zhang, Chengcheng Liu, Shaomin Lv, Shidi Yang, and Xuanhui Qu. 2018. "Effects of Porosity on Mechanical Properties and Corrosion Resistances of PM-Fabricated Porous Ti-10Mo Alloy" Metals 8, no. 3: 188. https://doi.org/10.3390/met8030188

APA StyleXu, W., Lu, X., Zhang, B., Liu, C., Lv, S., Yang, S., & Qu, X. (2018). Effects of Porosity on Mechanical Properties and Corrosion Resistances of PM-Fabricated Porous Ti-10Mo Alloy. Metals, 8(3), 188. https://doi.org/10.3390/met8030188