Precipitation and Grain Size Effects on the Tensile Strain-Hardening Exponents of an API X80 Steel Pipe after High-Frequency Hot-Induction Bending

Abstract

:1. Introduction

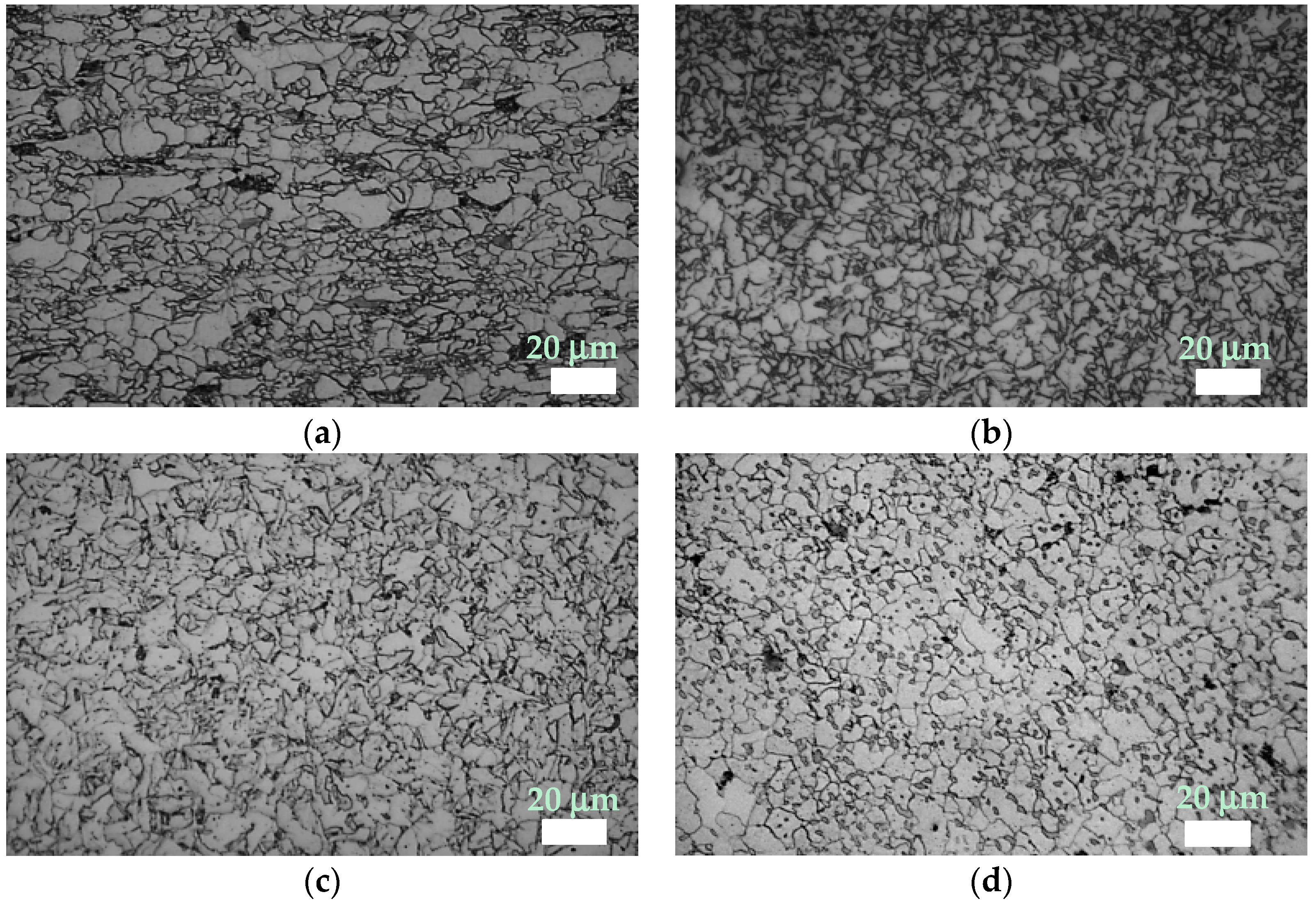

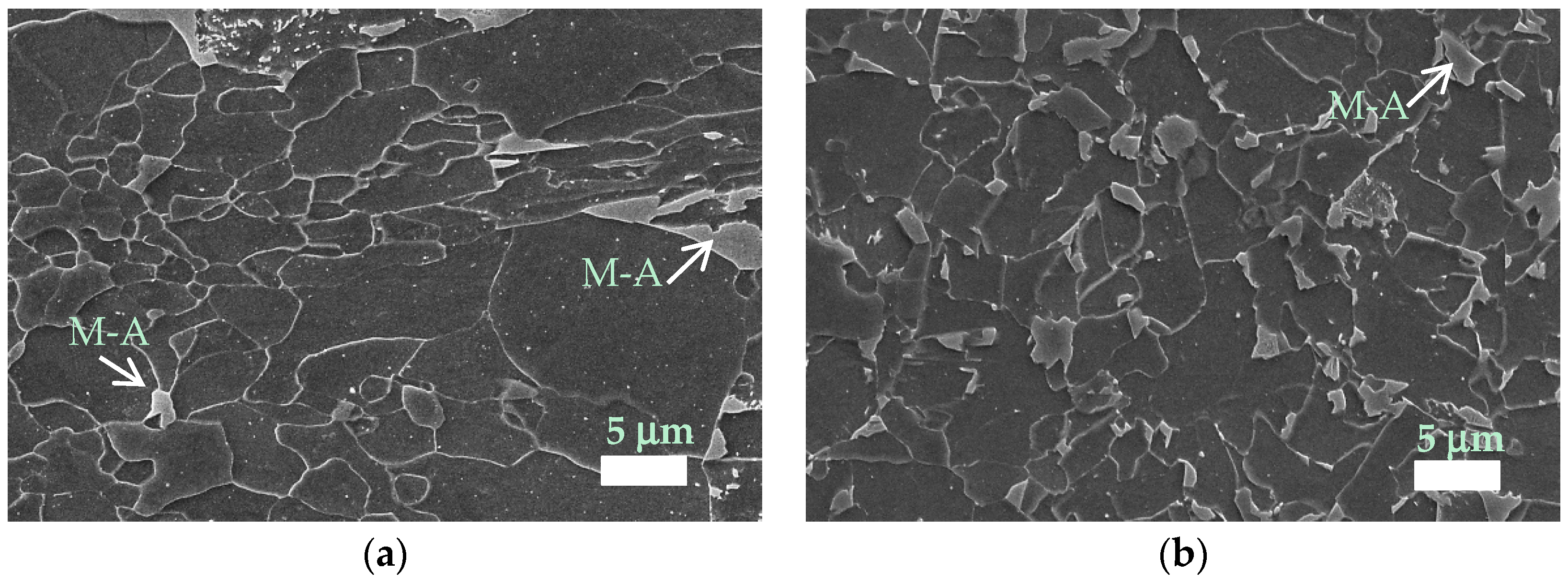

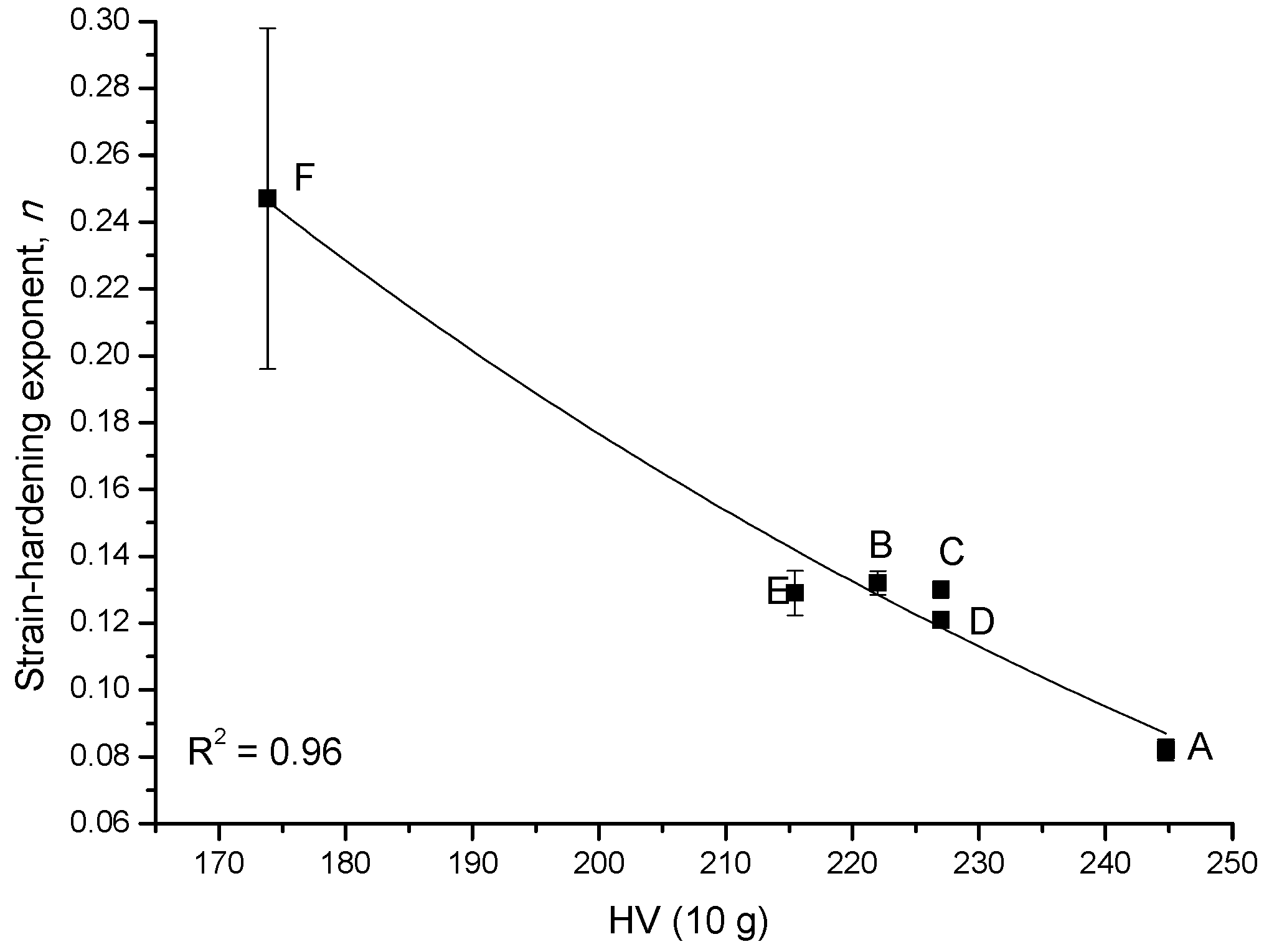

2. Experimental

2.1. Material

2.2. Heat Treatments

2.3. Characterization

2.4. Mechanical Tests

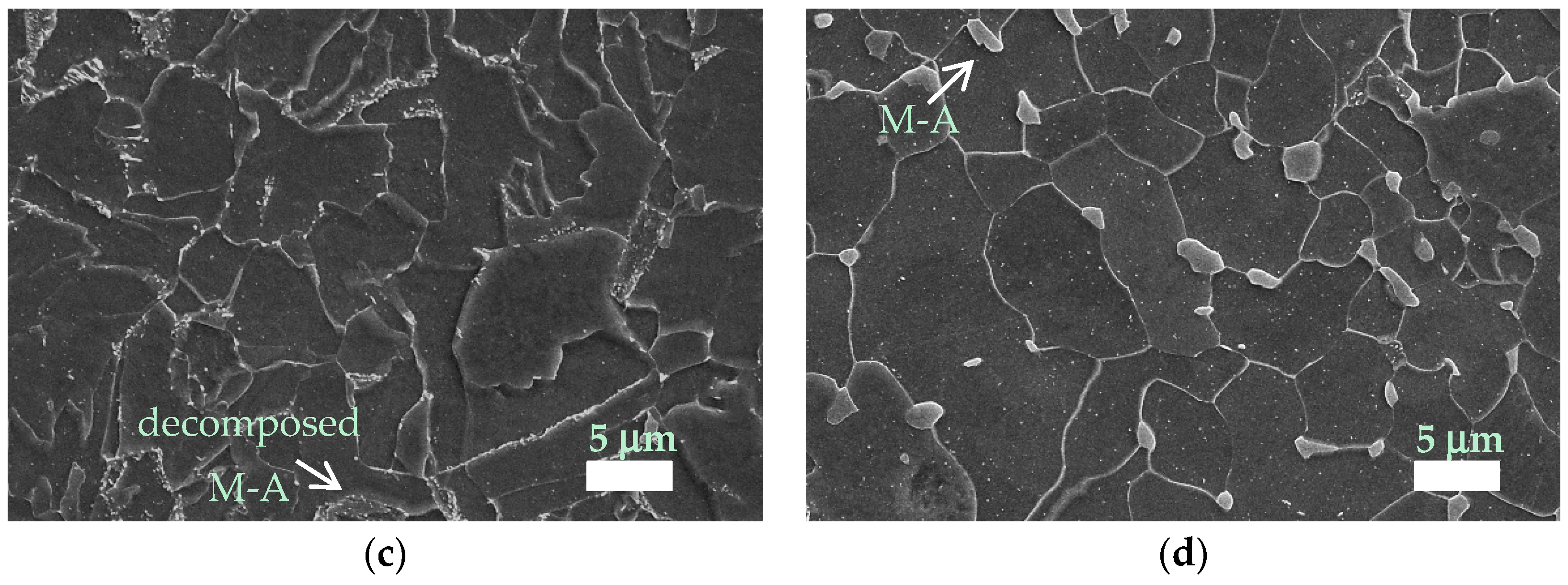

3. Results and Discussion

4. Conclusions and Final Considerations

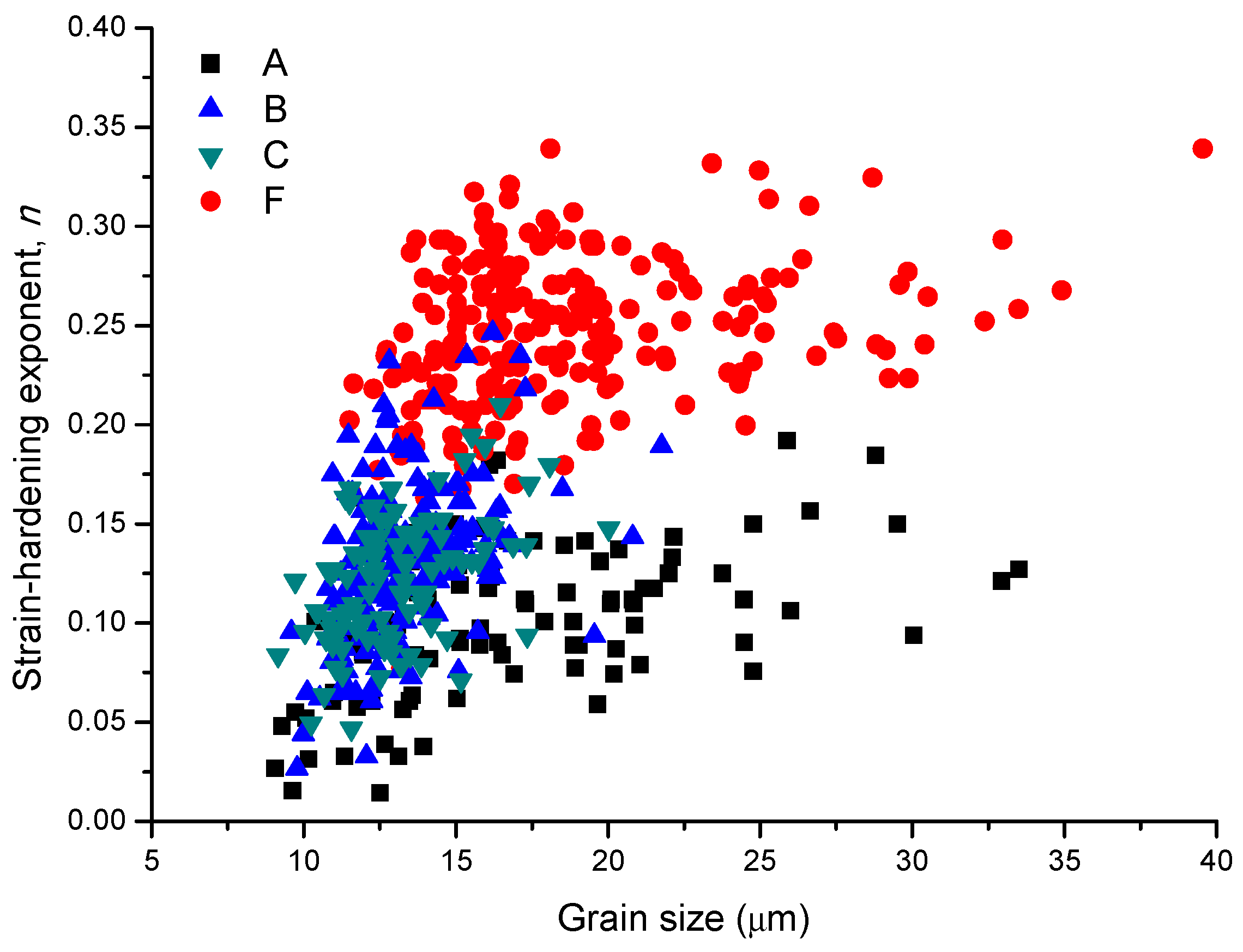

- The impact of precipitation hardening on the stable plastic behavior of the steel increased as the precipitation hardening became more intense. The effect of precipitation hardening on n become dominant, when compared with the effects of hardening mechanisms by dislocations and grain size.

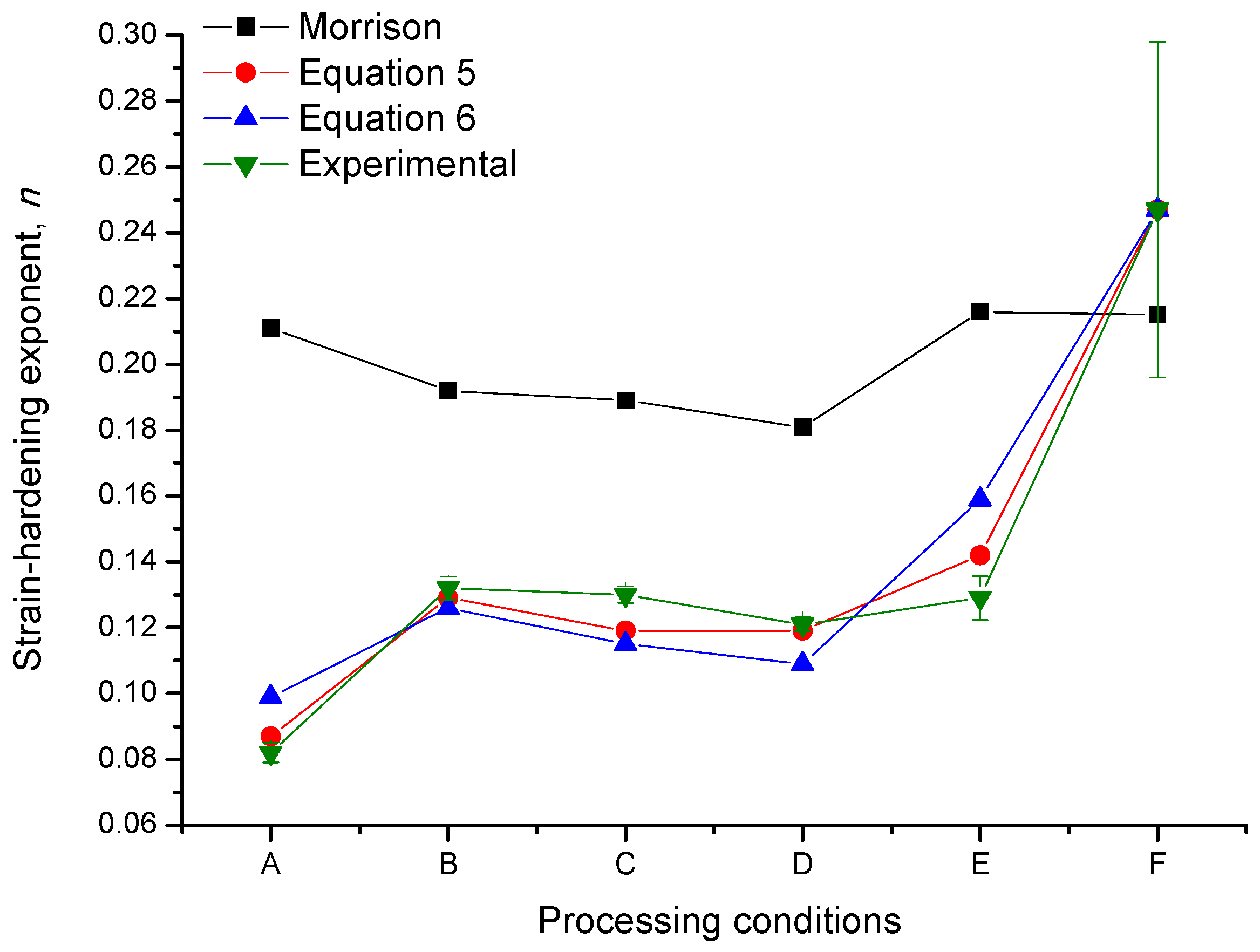

- The values of n could not be accurately estimated by the Morrison equation due to the different levels of precipitation shown—after different processing routes—by the pipeline microalloyed steel of this work.

- The values of n calculated from the modified equations agree well with the experimental results, revealing that the application of the microhardness of the material can be an alternative to estimate the capability to uniformly distribute the plastic deformation due to good correlations involving microhardness, processing conditions, and the hardening mechanisms.

Acknowledgments

Author Contributions

Conflicts of Interest

References

- Hosford, W.F. Mechanical Behavior of Materials, 2nd ed.; Cambridge University Press: Cambridge, UK, 2010; p. 163. [Google Scholar]

- Morrison, W.B. The effect of grain size on the stress-strain relationship in low carbon steel. Trans. ASM 1966, 59, 824–846. [Google Scholar]

- ASTM E112-96. Standard Test Methods for Determining Average Grain Size; American Society for Testing and Materials: West Conshohocken, PA, USA, 2004. [Google Scholar]

- Morales, E.V.; Silva, R.A.; Bott, I.S.; Paciornik, S. Strengthening mechanisms in a pipeline microalloyed steel with a complex microstructure. Mater. Sci. Eng. A 2013, 585, 253–260. [Google Scholar] [CrossRef]

- Ungar, T.; Dragomir, I.; Révész, Á.; Borbély, A. The contrast factors of dislocations in cubic crystal: The dislocation model of strain anisotropy in practice. J. Appl. Cryst. 1999, 32, 992–1002. [Google Scholar] [CrossRef]

- Ungár, T.; Gubicza, J.; Hanák, P.; Alexandrov, I. Densities and character of dislocations and size-distribution of subgrains in deformed metals by X-ray diffraction profile analysis. Mater. Sci. Eng. A 2001, 319–321, 274–278. [Google Scholar] [CrossRef]

- Silva, R.A. Correlation between the Induction Hot Bending Parameters for API X80 Pipe and the Resulting Mechanical and Microstructural Properties. Master’s Thesis, Pontifical Catholic University of Rio de Janeiro, Rio de Janeiro, Brazil, 21 October 2009; p. 207. (In Portuguese). [Google Scholar]

- Park, J.S.; Ha, Y.S.; Lee, S.J.; Lee, Y.K. Dissolution and precipitation kinetics of Nb(C,N) in austenite of a low-carbon Nb-microalloyed steel. Metall. Mater. Trans. A 2009, 40, 560–568. [Google Scholar] [CrossRef]

- Lu, J. Quantitative Microstructural Characterization of Microalloyed Steels. Ph.D. Thesis, University of Alberta, Edmonton, AB, Canada, November 2009; pp. 213–214. [Google Scholar]

- Garcia-Sanchez, R.; Bettmer, J.; Ebdon, L. Development of a new method for the separation of vanadium species and chloride interference removal using modified silica capillaries-DIN-ICP-MS. Microchem. J. 2004, 76, 161–171. [Google Scholar] [CrossRef]

- Karbasi, M.H.; Jahanparast, B.; Shamsipur, M.; Hassan, J. Simultaneous trace multielement determination by ICP-OES after solid phase extraction with modified octadecyl silica gel. J. Hazard. Mater. 2009, 170, 151–155. [Google Scholar] [CrossRef] [PubMed]

- Aydin, I.; Aydin, F.; Hamamci, C. Vanadium fractions determination in asphaltite combustion waste using sequential extraction with ICP-OES. Microchem. J. 2013, 108, 64–67. [Google Scholar] [CrossRef]

- ASTM E646-07. Standard Test Method for Tensile Strain-Hardening Exponents (n-Values) of Metallic Sheet Materials; American Society for Testing and Materials: West Conshohocken, PA, USA, 2007. [Google Scholar]

- API 5L. Specification for Line Pipe; American Petroleum Institute: Washington, WA, USA, 2004. [Google Scholar]

- ASTM A370. Standard Test Methods and Definitions for Mechanical Testing of Steel Products; American Society for Testing and Materials: West Conshohocken, PA, USA, 2003. [Google Scholar]

- Spindola, M.O.; Ribeiro, E.A.S.; Gonzalez, B.M.; Santos, D.B. Modeling of work hardening behaviour of high Mn and low C polycrystalline austenitic steel with TWIP effect. Rev. Mater. 2010, 15, 145–152. [Google Scholar]

- Lucas, J.P.; Gerberich, W.W. Low temperature and grain size effects on the cyclic strain hardening exponent of an HSLA steel. Scr. Metall. 1981, 15, 327–330. [Google Scholar] [CrossRef]

- Antoine, P.; Vandeputte, S.; Vogt, J.B. Empirical model predicting the value of the strain-hardening exponent of a Ti-IF steel grade. Mater. Sci. Eng. A 2006, 433, 55–63. [Google Scholar] [CrossRef]

- Gao, N.; Baker, T.N. Influence of AlN precipitation on thermodynamic parameters in C-Al-V-N microalloyed steel. ISIJ Int. 1997, 37, 596–604. [Google Scholar] [CrossRef]

- Hong, S.G.; Jun, H.J.; Kang, K.B.; Park, C.B. Evolution of precipitates in the Nb-Ti-V microalloyed HSLA steels during reheating. Scr. Mater. 2003, 48, 1201–1206. [Google Scholar] [CrossRef]

- Lee, W.-B.; Hong, S.-G.; Park, C.-G.; Park, S.-H. Carbide precipitation and high-temperature strength of hot-rolled high-strength, low-alloy steels containing Nb and Mo. Metall. Mater. Trans. A 2002, 33, 1689–1698. [Google Scholar] [CrossRef]

- Pickering, F.B. Physical Metallurgy and Design of Steels; Applied Science Publishers: London, UK, 1978. [Google Scholar]

- ASM Handbook. Metallography and Microstructures; ASM International: Materials Park, OH, USA, 1985; p. 116. [Google Scholar]

- Padilha, A.F. Materiais de Engenharia—Microestrutura e Propriedades; Hemus: Curitiba, Brazil, 2000; pp. 257–258. [Google Scholar]

- Lui, M.-W.; Le May, I. On the “Friedel Relation” in precipitation hardening. Scr. Metall. 1975, 9, 587–589. [Google Scholar] [CrossRef]

- Smallman, R.E.; Bishop, R.J. Modern Physical Metallurgy and Materials Engineering: Science, Process, Applications, 6th ed.; Butterworth-Heinemann: Oxford, UK, 1999; pp. 102–103. [Google Scholar]

- Morales, E.V.; Gallego, J.; Kestenbachz, H.-J. On coherent carbonitride precipitation in commercial microalloyed steels. Philos. Mag. Lett. 2003, 83, 79–87. [Google Scholar] [CrossRef]

- Morales, E.V.; Galeano Alvarez, N.J.; Morales, A.M.; Bott, I.S. Precipitation kinetics and their effects on age hardening in an Fe–Mn–Si–Ti martensitic alloy. Mater. Sci. Eng. A 2012, 534, 176–185. [Google Scholar] [CrossRef]

- Fultz, B.; Howe, J. Transmission Electron Microscopy and Diffractometry of Materials, 3rd ed.; Springer: Berlin/Heidelberg, Germany, 2008; p. 353. [Google Scholar]

| C | Mn | Si | P | S | Ni | Cr | Mo | Ti | Nb | V | N | Pcm |

|---|---|---|---|---|---|---|---|---|---|---|---|---|

| 0.05 | 1.74 | 0.21 | 0.018 | 0.002 | 0.011 | 0.147 | 0.177 | 0.014 | 0.069 | 0.022 | 0.005 | 0.17 |

| Samples | Description | Condition |

|---|---|---|

| A | Straight stretch | As-received |

| B | Intrados | Hot-bent |

| C | Extrados | Hot-bent |

| D | Extrados tempered at 600 °C | Hot-bent + as-tempered |

| E | Extrados tempered at 650 °C | Hot-bent + as-tempered |

| F | Straight stretch normalized at 900 °C | As-normalized |

| Samples | V (%) | Cr (%) | Cu (%) | Mo (%) | Ti (%) | Nb (%) |

|---|---|---|---|---|---|---|

| A | 41.7 | 35.0 | 66.1 | 83 | 100 | 99.9 |

| B | 25.9 | 28.1 | 66.8 | 82.7 | 100 | 99.9 |

| C | 12.7 | 19.2 | 65.2 | 80.4 | 99.9 | 99.8 |

| D | 29.5 | 22.3 | 66.3 | 81 | 100 | 99.8 |

| E | 30.5 | 21.9 | 67.5 | 81 | 100 | 99.9 |

| Samples | YS (MPa) | UTS (MPa) | HV (10 g) | d (μm) | V% (wt %) | fv VC0.75 (%) |

| A | 604 ± 20 | 679 ± 9.0 | 245 ± 22 | 5.35 ± 0.9 | 0.013 | 0.0150 |

| B | 477 ± 10 | 673 ± 1.5 | 222 ± 19 | 3.90 ± 0.4 | 0.016 | 0.0093 |

| C | 472 ± 16 | 658 ± 8.6 | 227 ± 17 | 3.70 ± 0.6 | 0.019 | 0.0046 |

| D | 558 ± 1.7 | 628 ± 1.7 | 227 ± 14 | 3.20 ± 0.6 | 0.016 | 0.0106 |

| E | 550 ± 19 | 594 ± 2.1 | 215 ± 13 | 5.80 ± 0.7 | 0.015 | 0.0110 |

| F | 239 ± 9.5 | 573 ± 4.0 | 174 ± 14 | 5.71 ± 0.8 | - | - |

| Samples | ρ (m−2) | n (Experimental) | n (Morrison) | Error (%) | n (Equation (5)) | Error (%) |

| A | 1.81 × 1014 | 0.082 ± 0.00301 | 0.211 | 158 | 0.087 | 6.6 |

| B | 4.26 × 1014 | 0.132 ± 0.00351 | 0.192 | 46 | 0.129 | 2.3 |

| C | 4.12 × 1014 | 0.130 ± 0.00252 | 0.189 | 45 | 0.119 | 8.3 |

| D | 2.94 × 1014 | 0.121 ± 0.00206 | 0.181 | 49 | 0.119 | 1.5 |

| E | 1.38 × 1014 | 0.129 ± 0.00667 | 0.216 | 68 | 0.142 | 10 |

| F | - | 0.247 ± 0.051 | 0.215 | 13 | 0.247 | 0.1 |

© 2018 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (http://creativecommons.org/licenses/by/4.0/).

Share and Cite

Silva, R.A.; Pinto, A.L.; Kuznetsov, A.; Bott, I.S. Precipitation and Grain Size Effects on the Tensile Strain-Hardening Exponents of an API X80 Steel Pipe after High-Frequency Hot-Induction Bending. Metals 2018, 8, 168. https://doi.org/10.3390/met8030168

Silva RA, Pinto AL, Kuznetsov A, Bott IS. Precipitation and Grain Size Effects on the Tensile Strain-Hardening Exponents of an API X80 Steel Pipe after High-Frequency Hot-Induction Bending. Metals. 2018; 8(3):168. https://doi.org/10.3390/met8030168

Chicago/Turabian StyleSilva, Rafael A., André L. Pinto, Alexei Kuznetsov, and Ivani S. Bott. 2018. "Precipitation and Grain Size Effects on the Tensile Strain-Hardening Exponents of an API X80 Steel Pipe after High-Frequency Hot-Induction Bending" Metals 8, no. 3: 168. https://doi.org/10.3390/met8030168

APA StyleSilva, R. A., Pinto, A. L., Kuznetsov, A., & Bott, I. S. (2018). Precipitation and Grain Size Effects on the Tensile Strain-Hardening Exponents of an API X80 Steel Pipe after High-Frequency Hot-Induction Bending. Metals, 8(3), 168. https://doi.org/10.3390/met8030168