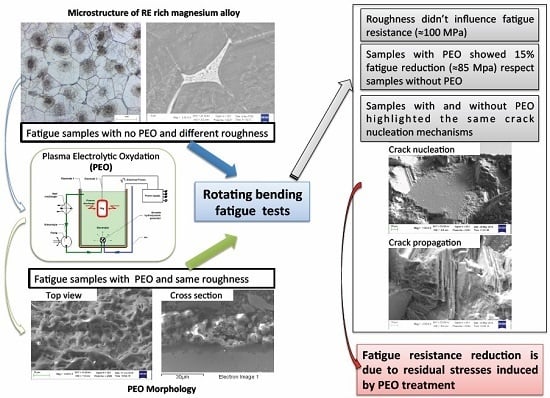

Fatigue Behavior of the Rare Earth Rich EV31A Mg Alloy: Influence of Plasma Electrolytic Oxidation

Abstract

:1. Introduction

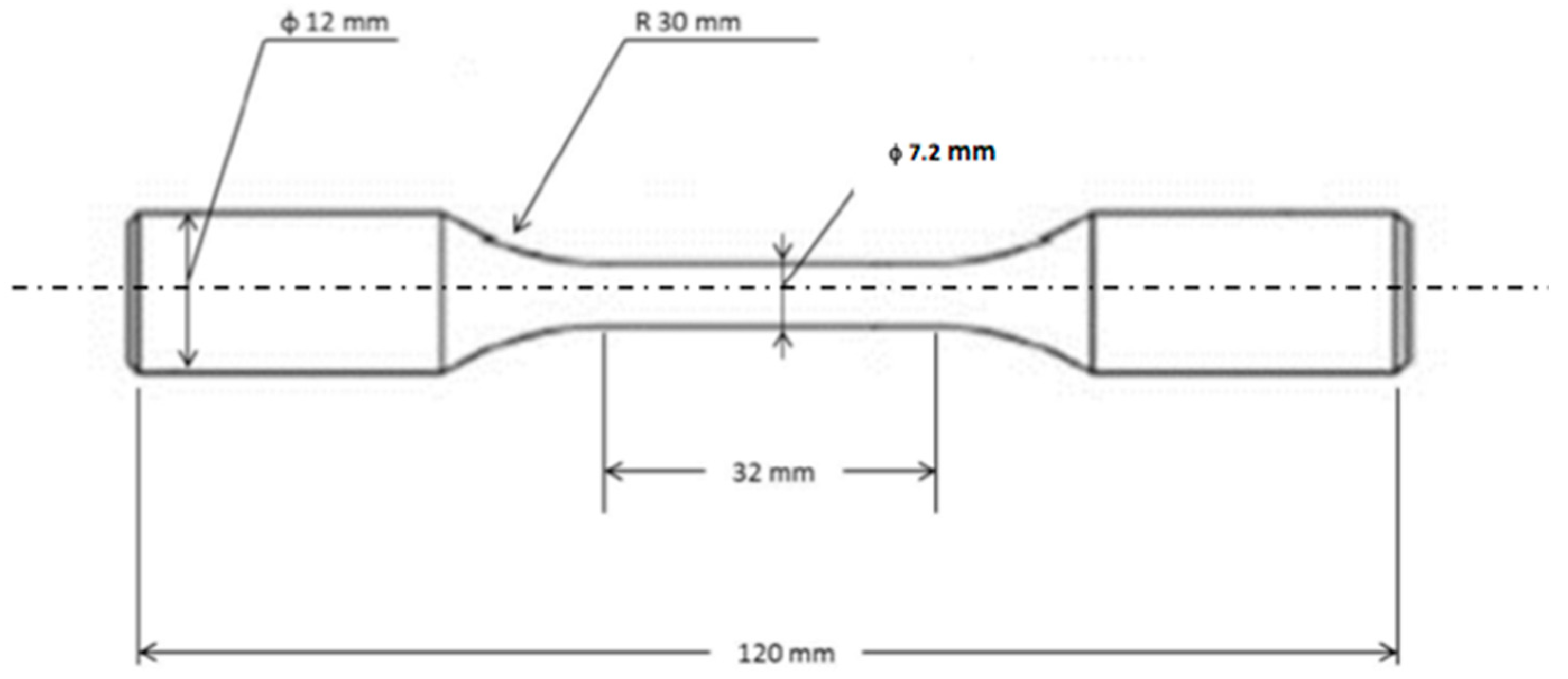

2. Materials and Methods

3. Results and Discussion

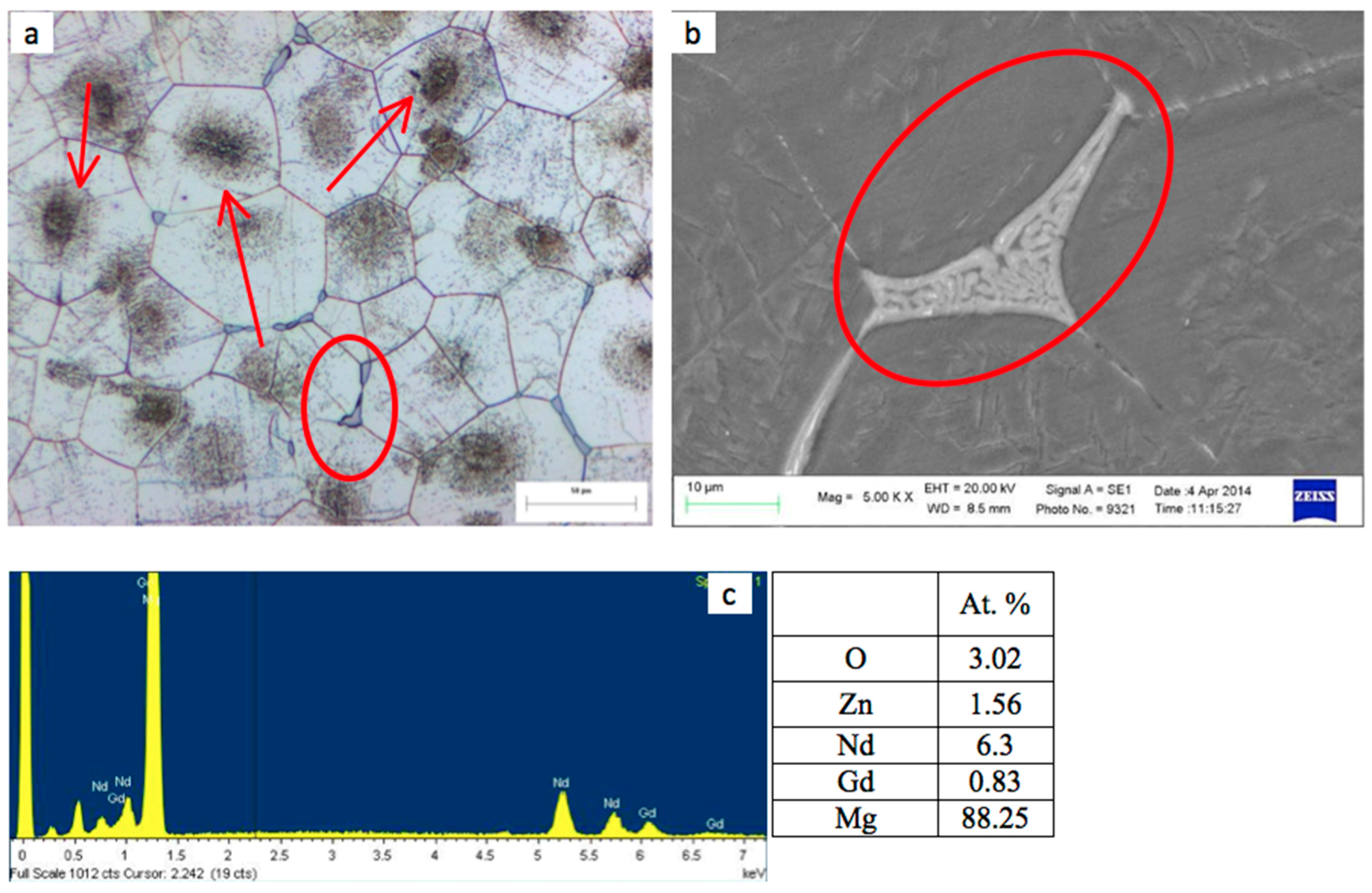

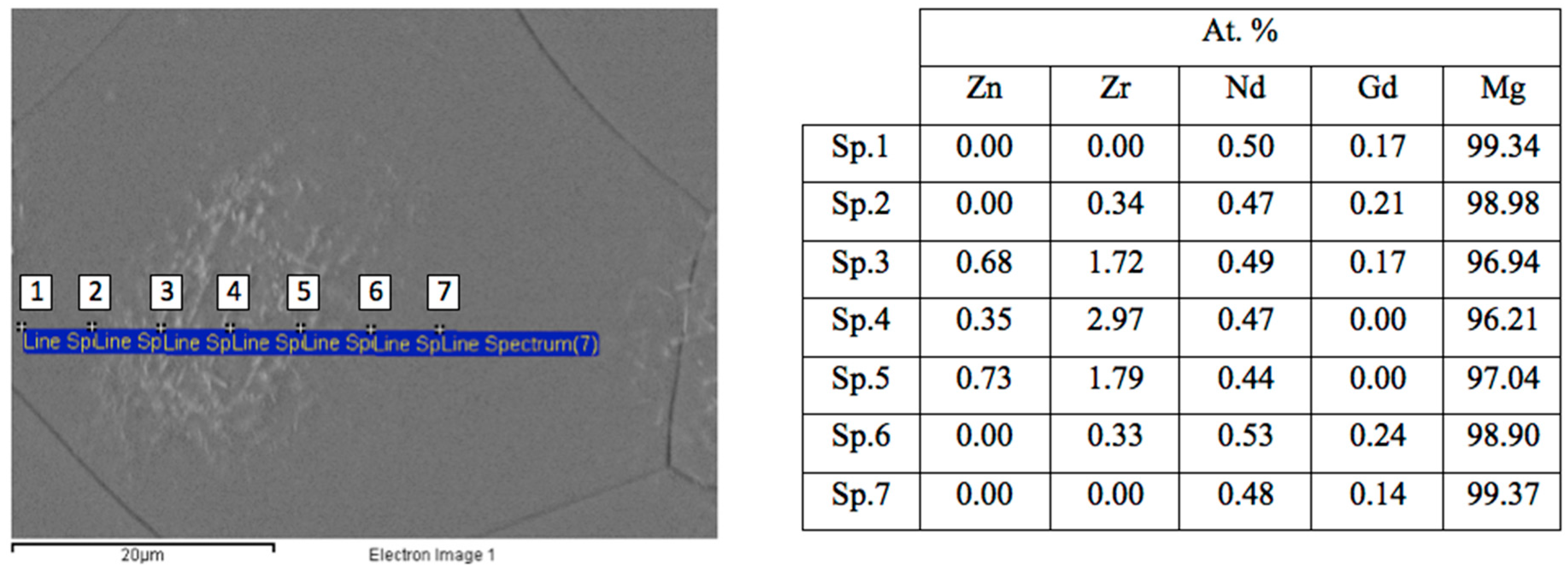

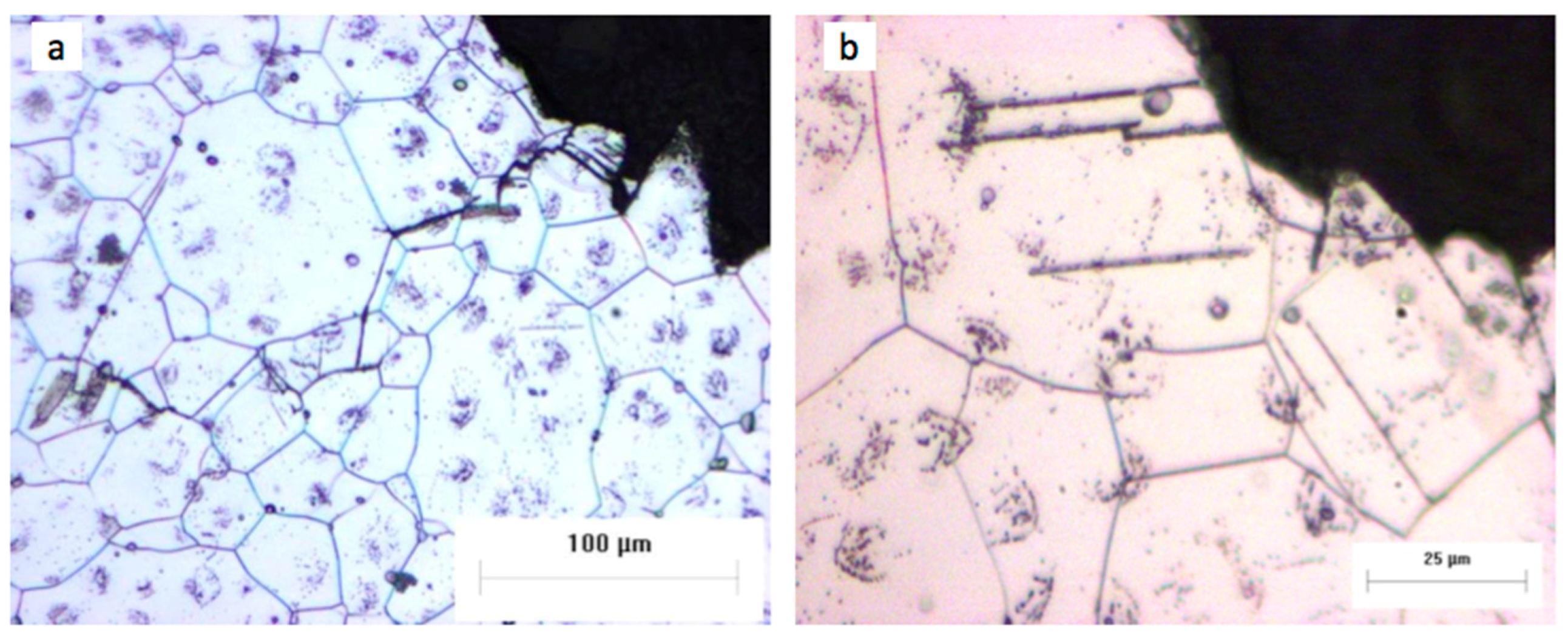

3.1. Microstructure of the Untreated Alloy

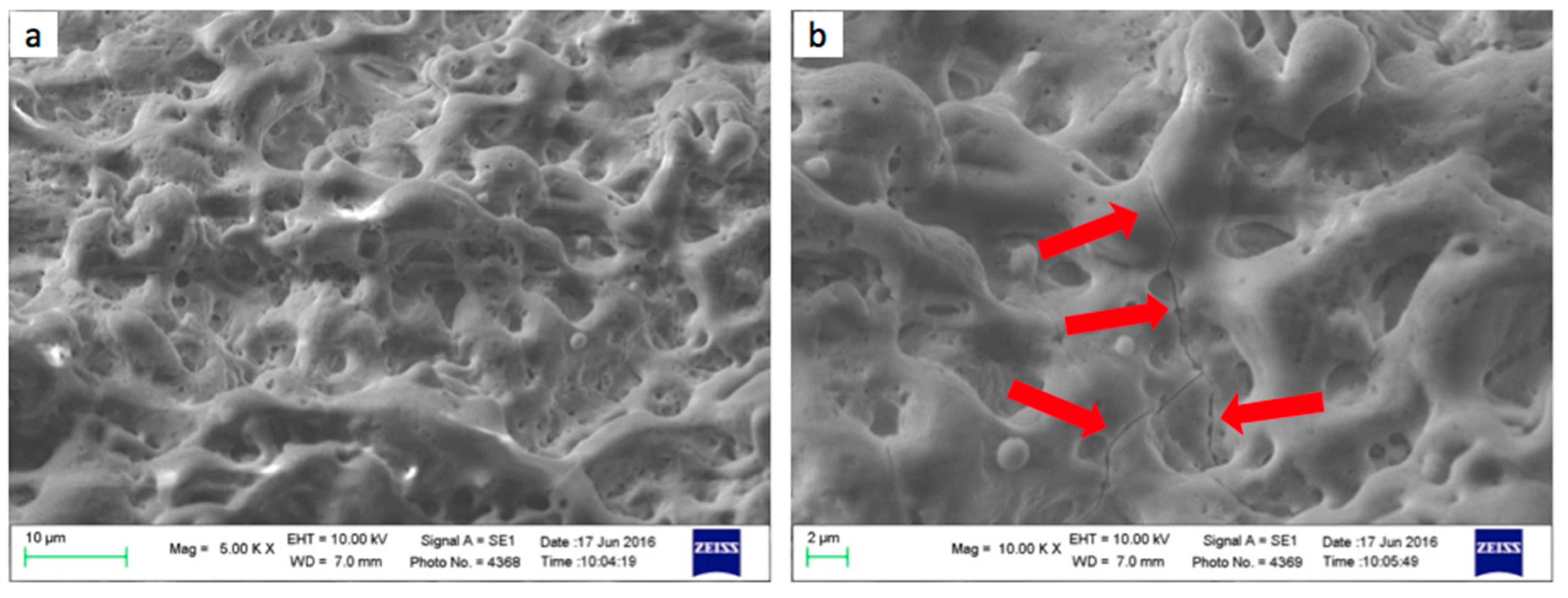

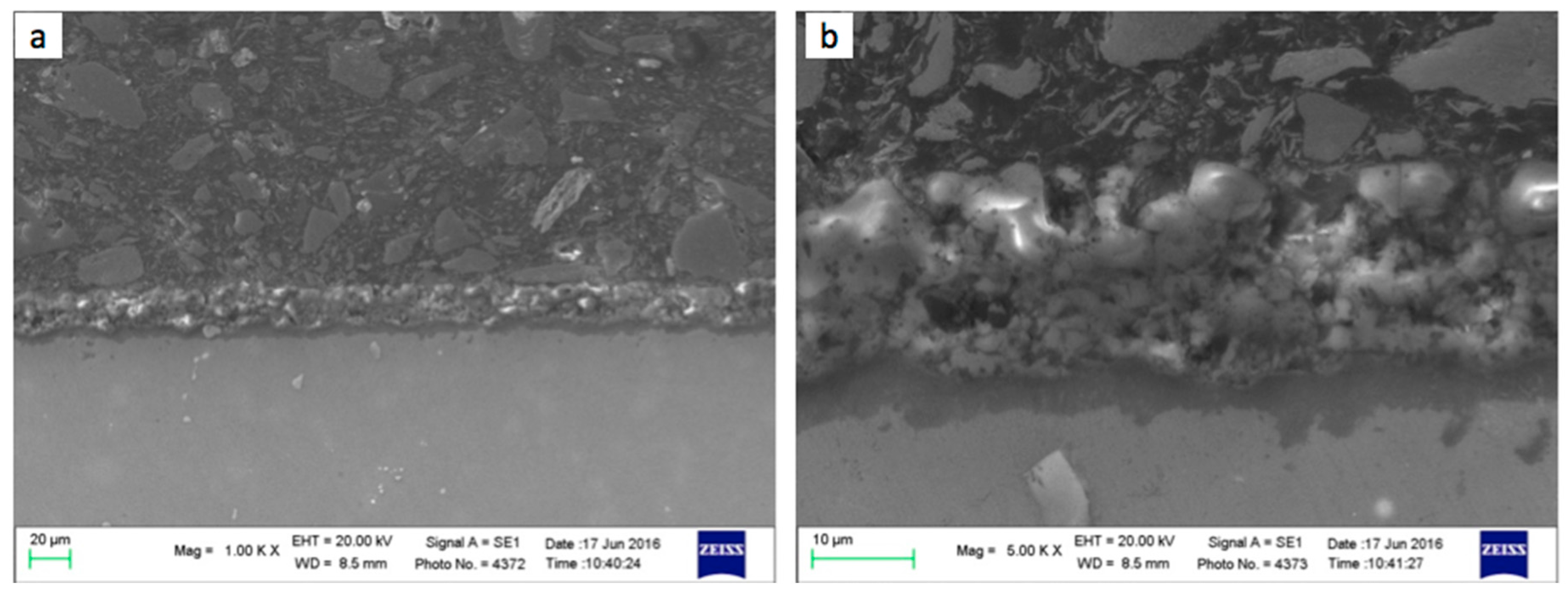

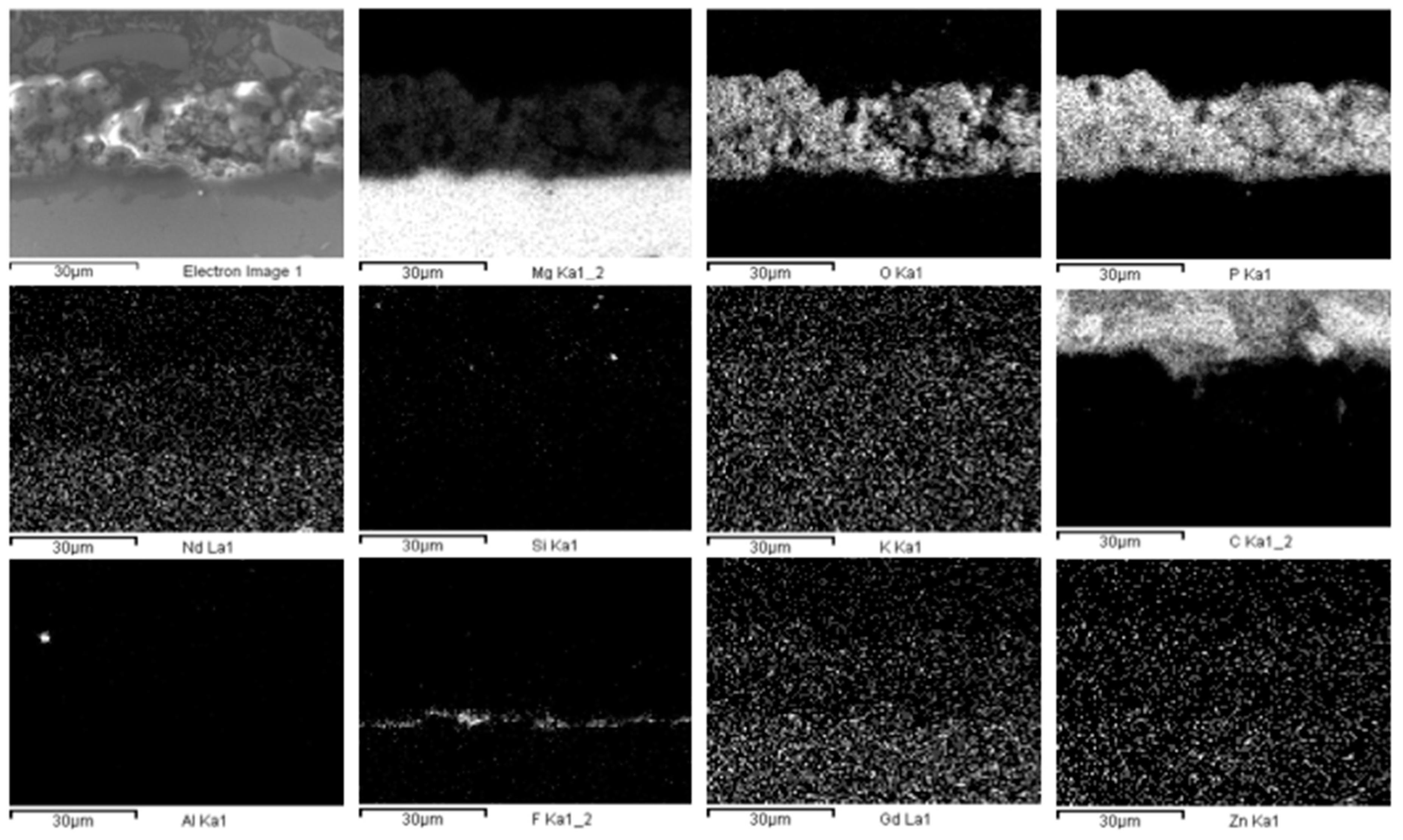

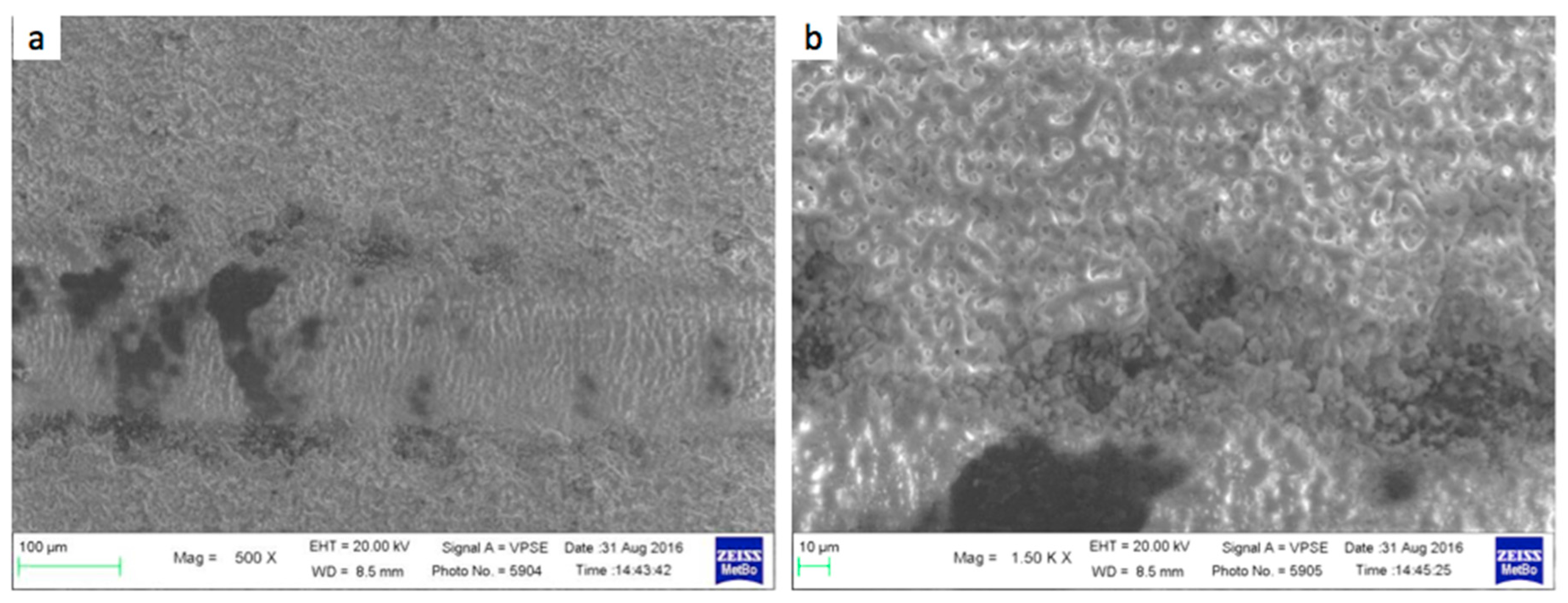

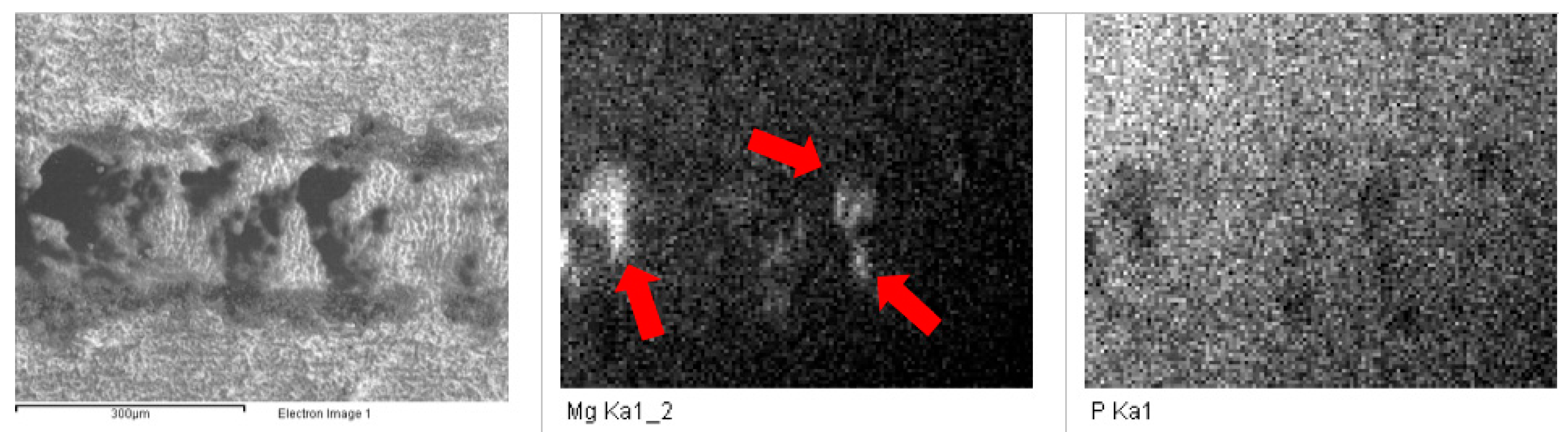

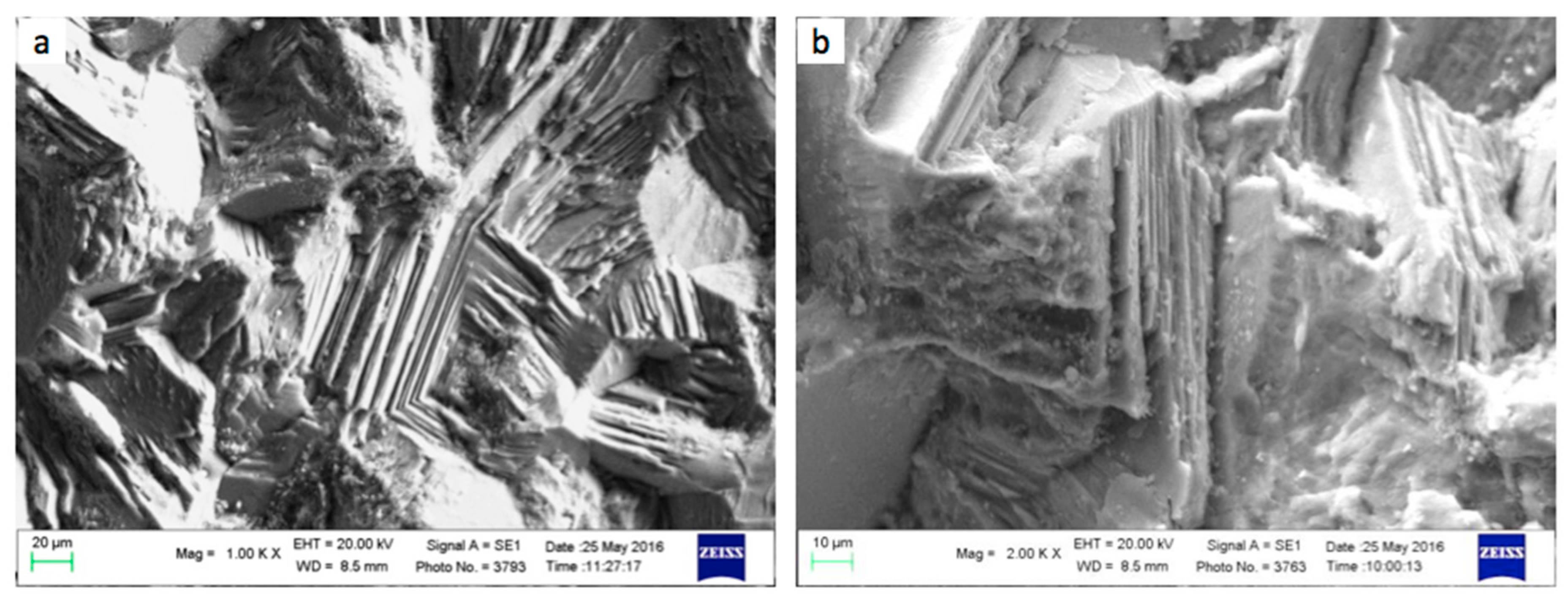

3.2. Microstructure of the PEO-Treated Alloy

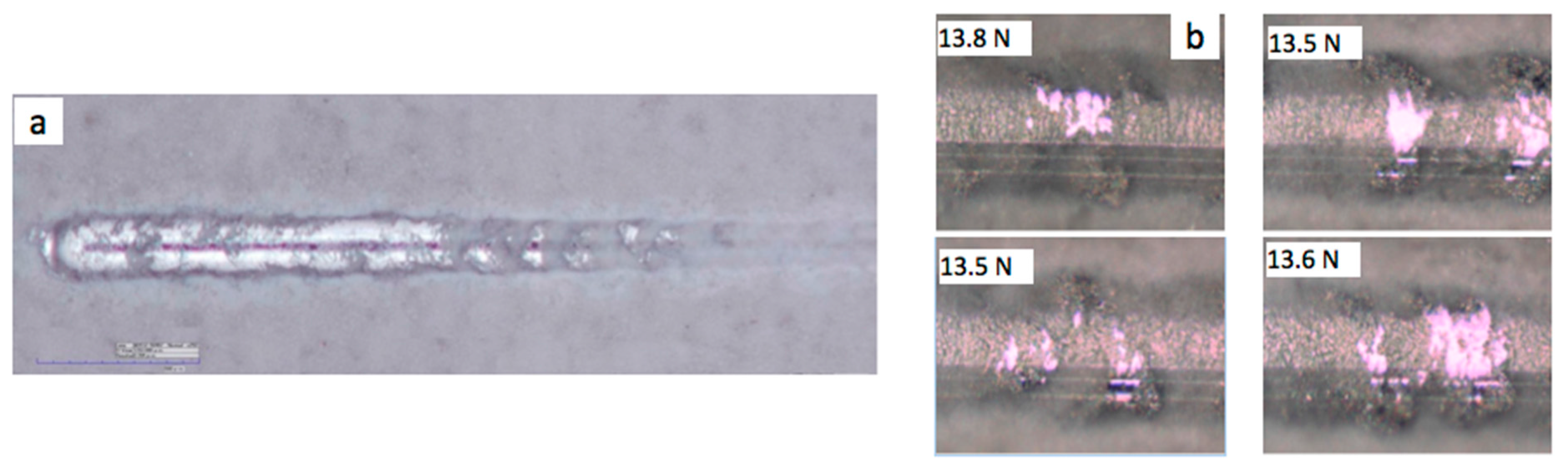

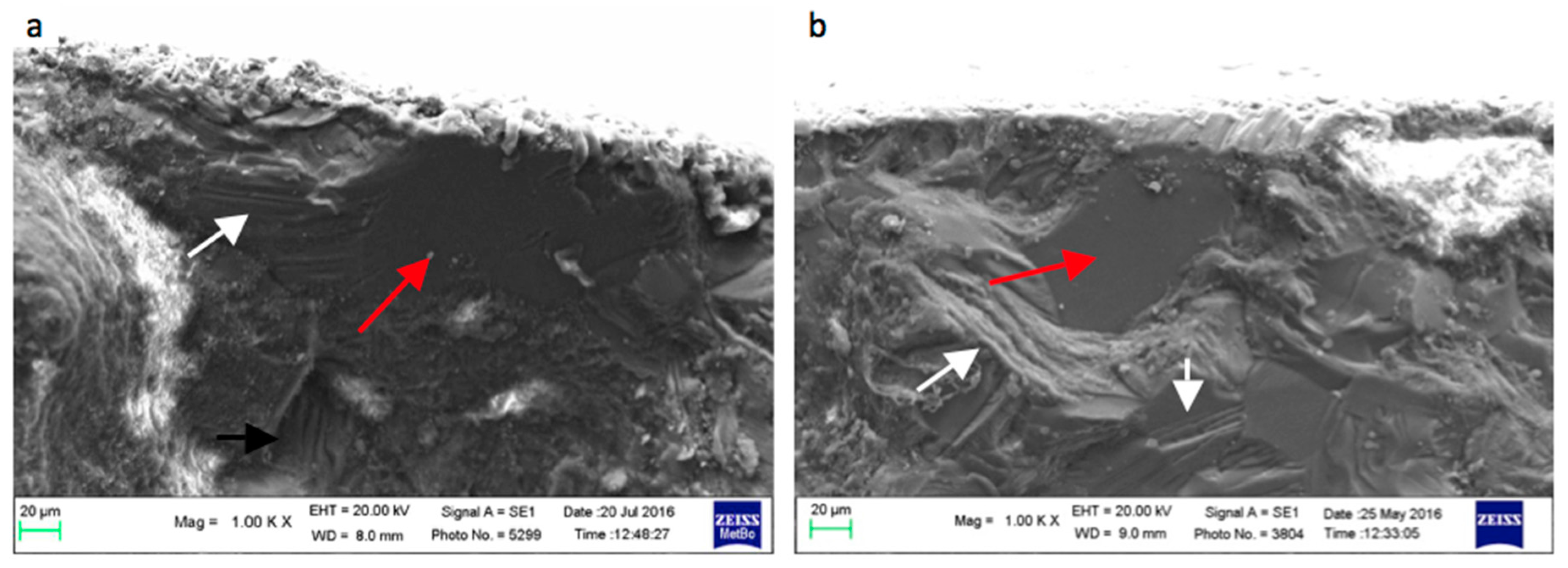

3.3. Adhesion of the Coating

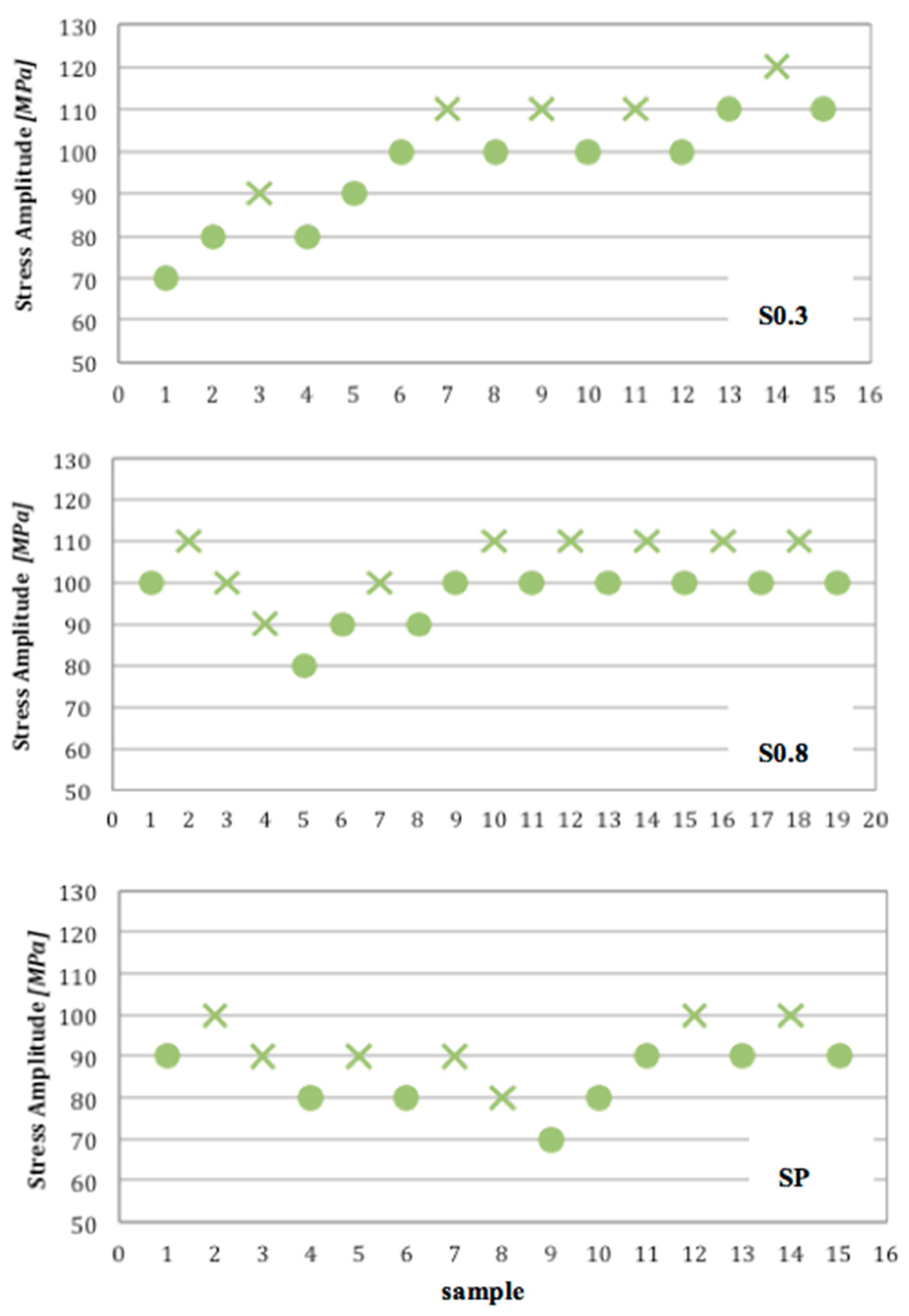

3.4. Fatigue Tests

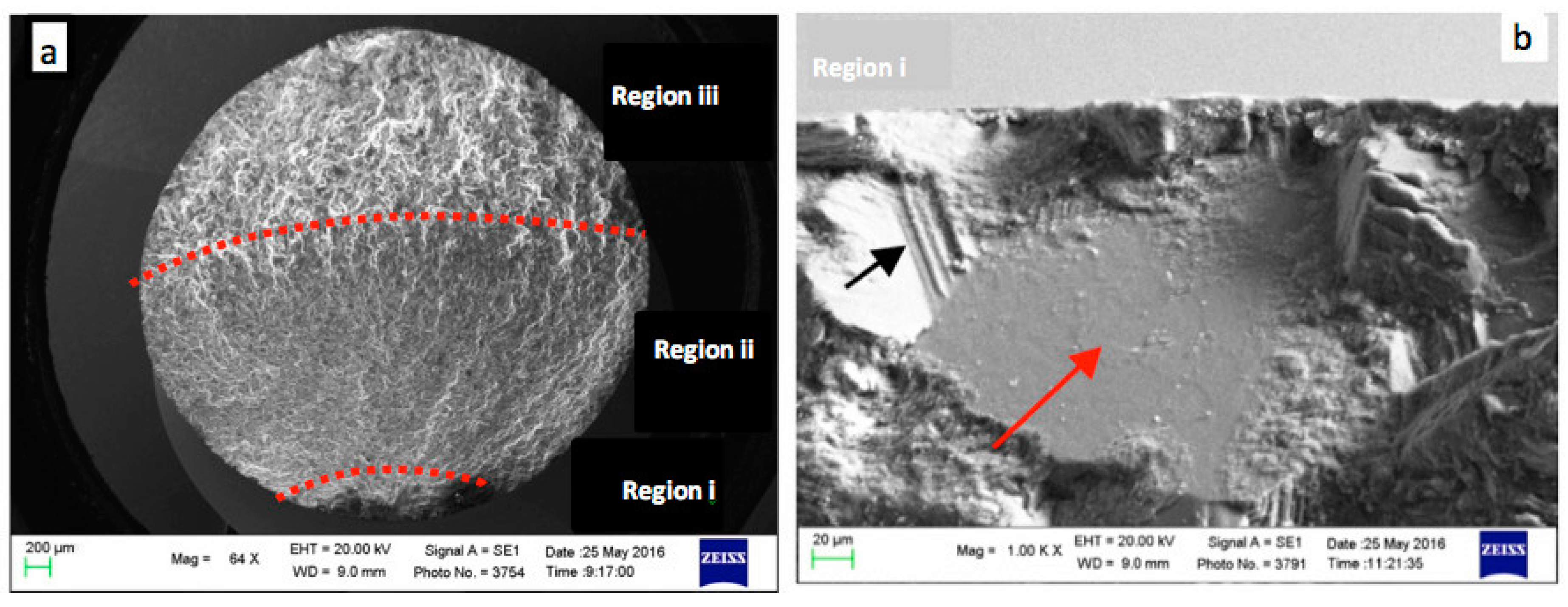

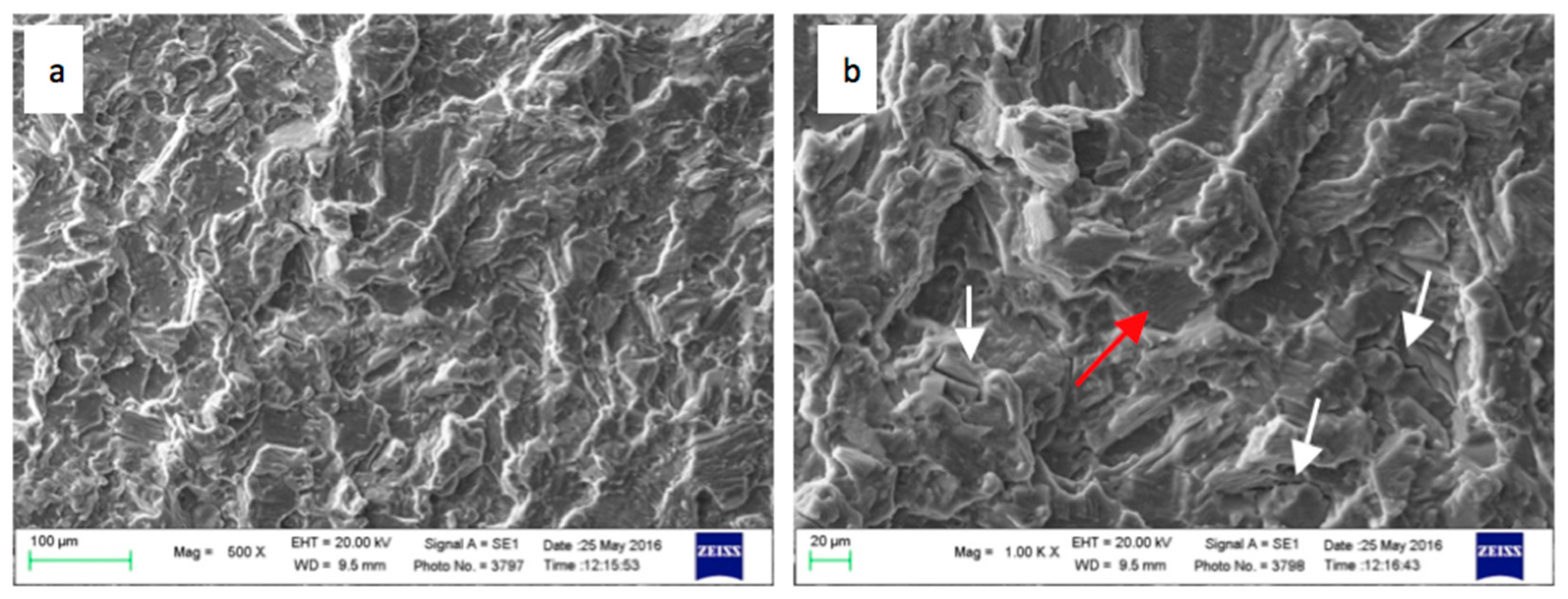

3.5. Fracture Surfaces Analysis

4. Conclusions

Acknowledgments

Author Contributions

Conflicts of Interest

References

- Li, Z.M.; Wang., Q.G.; Luo, A.A.; Peng, L.M.; Fu, P.H.; Wang, Y.X. Improved high cycle fatigue properties of a new magnesium alloy. Mater. Sci. Eng. A 2013, 582, 170–177. [Google Scholar] [CrossRef]

- Friedrich, H.; Schumann, S. Research for a “new age of magnesium” in the automotive industry. J. Mater. Process Technol. 2001, 117, 276–281. [Google Scholar] [CrossRef]

- Pantelakis, S.G.; Alexopoulos, N.D.; Chamos, A.N. Mechanical performance evaluation of cast magnesium alloys for automotive and aeronautical applications. J. Eng. Mater. Technol. 2007, 129, 422–430. [Google Scholar] [CrossRef]

- Mirza, F.A.; Chen, D.L.; Li, D.J.; Zeng, X.Q. Cyclic deformation behavior of a rare-earth containing extruded magnesium alloy: Effect of heat treatment. Metall. Mater. Trans. A 2014, 46, 1168–1187. [Google Scholar] [CrossRef]

- Li, Z.; Wang, Q.; Luo, A.A.; Fu, P.; Peng, L. Fatigue strength dependence on the ultimate tensile strength and hardness in magnesium alloys. Int. J. Fatigue 2015, 80, 468–476. [Google Scholar] [CrossRef]

- Li, Z.; Wang, Q.; Luo, A.A.; Fu, P.; Peng, L.; Wang, Y.; Wu, G. High cycle fatigue of cast Mg-3Nd-0.2Zn magnesium alloys. Metall. Mater. Trans. A 2013, 44, 5202–5215. [Google Scholar] [CrossRef]

- Peng, L.; Fu, P.; Li, Z.; Wang, Y.; Jiang, H. High cycle fatigue properties of cast Mg-xNd-0.2Zn-Zr alloys. J. Mater. Sci. 2014, 49, 7105–7115. [Google Scholar] [CrossRef]

- Li, H.; Lv, F.; Xiao, Z.; Liang, X.; Sang, F.; Li, P. Low-cycle fatigue behavior of a cast Mg–Y–Nd–Zr alloy by T6 heat treatment. Mater. Sci. Eng. A 2016, 676, 377–384. [Google Scholar] [CrossRef]

- Mirza, F.A.; Chen, D.L. Fatigue of rare-earth containing magnesium alloys: A review. Fatigue Fract. Eng. Mater. Struct. 2014, 37, 831–853. [Google Scholar] [CrossRef]

- Mokhtarishirazabad, M.; Boutorabi, S.M.A.; Azadi, M.; Nikravan, M. Effect of rare earth elements on high cycle fatigue behavior of AZ91 alloy. Mater. Sci. Eng. A 2013, 587, 179–184. [Google Scholar] [CrossRef]

- Pan, F.; Yang, M.; Chen, X. A review on casting magnesium alloys: Modification of commercial alloys and development of new alloys. J. Mater. Sci. Technol. 2016, 32, 1211–1221. [Google Scholar] [CrossRef]

- Peng, L.M.; Fu, P.H.; Li, Z.M.; Yue, H.Y.; Li, D.Y.; Wang, Y.X. High cycle fatigue behaviors of low pressure cast Mg-3Nd-0.2Zn-2Zr alloys. Mater. Sci. Eng. A 2014, 611, 170–176. [Google Scholar] [CrossRef]

- Wang, F.; Dong, J.; Jiang, Y.; Ding, W. Cyclic deformation and fatigue of extruded Mg-Gd-Y magnesium alloy. Mater. Sci. Eng. A 2013, 561, 403–410. [Google Scholar] [CrossRef]

- Stanford, N.; Barnett, M. Effect of composition on the texture and deformation behaviour of wrought Mg alloys. Scr. Mater. 2008, 58, 179–182. [Google Scholar] [CrossRef]

- Hadorn, J.P.; Hantzsche, K.; Yi, S.; Bohlen, J.; Letzig, D.; Agnew, S.R. Effects of solute and second-phase particles on the texture of Nd-containing Mg alloys. Metall. Mater. Trans. A 2012, 43, 1363–1375. [Google Scholar] [CrossRef]

- Mirza, F.A.; Chen, D.L.; Li, D.J.; Zeng, X.Q. Effect of rare earth elements on deformation behavior of an extruded Mg-10Gd-3Y-0.5Zr alloy during compression. Mater. Des. 2013, 46, 411–418. [Google Scholar] [CrossRef]

- Morales, E.D.; Ghali, E.; Hort, N.; Dietzel, W.; Kainer, K.U. Corrosion behaviour of magnesium alloys with RE additions in sodium chloride solutions. Mater. Sci. Forum 2003, 419, 867–872. [Google Scholar] [CrossRef]

- Wu, G.; Fan, Y.; Gao, H.; Zhai, C.; Zhu, Y.P. The effect of Ca and rare earth elements on the microstructure, mechanical properties and corrosion behavior of AZ91D. Mater. Sci. Eng. A 2005, 408, 255–263. [Google Scholar] [CrossRef]

- Smola, B.; Stulikova, I.; Von Buch, F.; Mordike, B.L. Structural aspects of high performance Mg alloys design. Mater. Sci. Eng. A 2002, 324, 113–117. [Google Scholar] [CrossRef]

- Xiao, W.; Shen, Y.; Wang, L.; Wu, Y.; Cao, Z.; Jia, S.; Wang, L. The influences of rare earth content on the microstructure and mechanical properties of Mg–7Zn–5Al alloy. Mater. Des. 2010, 31, 3542–3549. [Google Scholar] [CrossRef]

- Yerokhin, A.L.; Shatrov, A.; Samsonov, V.; Shashkov, P.; Leyland, A.; Matthews, A. Fatigue properties of Keronite coatings on a magnesium alloy. Surf. Coat. Technol. 2004, 182, 78–84. [Google Scholar] [CrossRef]

- Khan, S.A.; Miyashita, Y.; Mutoh, Y.; Koike, T. Effect of anodized layer thickness on fatigue behavior of magnesium alloy. Mater. Sci. Eng. A 2008, 474, 261–269. [Google Scholar] [CrossRef]

- Nemcova, A.; Skeldon, P.; Thompson, G.E.; Morse, S.; Cizek, J.; Pacal, B. Influence of plasma electrolytic oxidation on fatigue performance of AZ61 magnesium alloy. Corros. Sci. 2014, 82, 58–66. [Google Scholar] [CrossRef]

- Srinivasan, P.B.; Liang, J.; Blawert, C.; Dietzel, W. Dry sliding wear behaviour of magnesium oxide and zirconium oxide plasma electrolytic oxidation coated magnesium alloy. Appl. Surf. Sci. 2010, 256, 3265–3273. [Google Scholar] [CrossRef]

- Liu, C.; Liang, J.; Zhou, J.; Li, Q.; Peng, Z.; Wang, L. Characterization and corrosion behavior of plasma electrolytic oxidation coated AZ91-T6 magnesium alloy. Surf. Coat. Technol. 2016, 304, 179–187. [Google Scholar] [CrossRef]

- Durdu, S.; Usta, M. Characterization and mechanical properties of coatings on magnesium by micro arc oxidation. Appl. Surf. Sci. 2012, 261, 774–782. [Google Scholar] [CrossRef]

- Li, Z.; Wang, Q.; Luo, A.A.; Peng, L.; Zhang, P. Fatigue behavior and life prediction of cast magnesium alloys. Mater. Sci. Eng. A 2015, 647, 113–126. [Google Scholar] [CrossRef]

- Liu, W.; Jiang, L.; Cao, L.; Mei, J.; Wu, G.; Zhang, S.; Xiao, L.; Wang, S.; Ding, W. Fatigue behavior and plane-strain fracture toughness of sand-cast Mg-10Gd-3Y-0.5Zr magnesium alloy. Mater. Des. 2014, 59, 466–474. [Google Scholar] [CrossRef]

- Xu, D.K.; Liu, L.; Xu, Y.B.; Han, E.H. The fatigue behavior of I-phase containing as-cast Mg-Zn-Y-Zr alloy. Acta Mater. 2008, 56, 985–994. [Google Scholar] [CrossRef]

- Bhuiyan, M.S.; Mutoh, Y.; Murai, T.; Iwakami, S. Corrosion fatigue behavior of extruded magnesium alloy AZ61 under three different corrosive environments. Int. J. Fatigue 2008, 30, 1756–1765. [Google Scholar] [CrossRef]

- International Organization for Standardization. Metallic Materials—Rotating Bar Bending Fatigue Testing; International Organization for Standardization: Geneva, Switzerland, 2010. [Google Scholar]

- ASTM International. E112: Standard Test Methods for Determining Average Grain Size; ASTM International: West Conshohocken, PA, USA, 2012. [Google Scholar]

- Italian Organization for Standardization. Mechanical Testing of Metallic Materials Fatigue Testing at Room Temperature; Italian Organization for Standardization: Milano, Italy, 1985. [Google Scholar]

- Angelini, V.; Ceschini, L.; Morri, A.; Apelian, D. Influence of heat treatment on microstructure and mechanical properties of rare earth rich magnesium alloy. Int. J. Metalcast. 2016, 1–14. [Google Scholar] [CrossRef]

- Lyon, P. New magnesium alloy for aerospace and speciality applications. In Magnesium Technology; Luo, A.A., Ed.; TMS: Warrendale, PA, USA, 2004. [Google Scholar]

- Wang, Q.; Lu, Y.; Zeng, X.; Ding, W.; Zhu, Y.; Li, Q.; Lan, J. Study on the fluidity of AZ91+xRE magnesium alloy. Mater. Sci. Eng. A 1999, 271, 109–115. [Google Scholar]

- Duan, H.; Yan, C.; Wang, F. Effect of electrolyte additives on performance of plasma electrolytic oxidation films formed on magnesium alloy AZ91D. Electrochim. Acta 2007, 52, 3785–3793. [Google Scholar] [CrossRef]

- Arrabal, R.; Matykina, E.; Hashimoto, T.; Skeldon, P.; Thompson, G.E. Characterization of AC PEO coatings on magnesium alloys. Surf. Coat. Technol. 2009, 203, 2207–2220. [Google Scholar] [CrossRef]

- Ko, Y.G.; Namgung, S.; Shin, D.H. Correlation between KOH concentration and surface properties of AZ91 magnesium alloy coated by plasma electrolytic oxidation. Surf. Coat. Technol. 2010, 205, 2525–2531. [Google Scholar] [CrossRef]

- Blawert, C.; Srinivasan, P.B. Surface Engineering of Light Alloys, 1st ed.; Dong, H., Ed.; Woodhead Publishing: Sawston, UK, 2010; pp. 155–180. [Google Scholar]

- Bull, S.J.; Berasetegui, E.G. An overview of the potential of quantitative coating adhesion measurement by scratch testing. Tribol. Int. 2006, 39, 99–114. [Google Scholar] [CrossRef]

- Li, Z.; Fu, P.; Peng, L.; Becker, E.P.; Wu, G. Influence of solution temperature on fatigue behavior of AM-SC1 cast magnesium alloy. Mater. Sci. Eng. A 2013, 565, 250–257. [Google Scholar] [CrossRef]

- Yang, F.; Yin, S.M.; Li, S.X.; Zhang, Z.F. Crack initiation mechanism of extruded AZ31 magnesium alloy in the very high cycle fatigue regime. Mater. Sci. Eng. A 2008, 491, 131–136. [Google Scholar] [CrossRef]

- Wang, S.D.; Xu, D.K.; Wang, B.J.; Han, E.H.; Dong, C. Effect of corrosion attack on the fatigue behavior of an as-cast Mg-7%Gd-5%Y-1%Nd-0.5%Zr alloy. Mater. Des. 2015, 84, 185–193. [Google Scholar] [CrossRef]

- Liu, W.C.; Dong, J.; Zhang, P.; Korsunsky, A.M.; Song, X.; Ding, W.J. Improvement of fatigue properties by shot peening for Mg-10Gd-3Y alloys under different conditions. Mater. Sci. Eng. A 2011, 528, 5935–5944. [Google Scholar] [CrossRef]

- Mayer, H.; Papakyriacou, M.; Zettl, B.; Stanzl-Tschegg, S.E. Influence of porosity on the fatigue limit of die cast magnesium and aluminium alloys. Int. J. Fatigue 2003, 25, 245–256. [Google Scholar] [CrossRef]

- Tokaji, K.; Kamakura, M.; Ishiizumi, Y.; Hasegawa, N. Fatigue behaviour and fracture mechanism of a rolled AZ31 magnesium alloy. Int. J. Fatigue 2004, 26, 1217–1224. [Google Scholar] [CrossRef]

- Begum, S.; Chen, D.L.; Xu, S.; Luo, A.A. Effect of strain ratio and strain rate on low cycle fatigue behavior of AZ31 wrought magnesium alloy. Mater. Sci. Eng. A 2009, 517, 334–343. [Google Scholar] [CrossRef]

| Nd | Gd | Zr | Zn | Cu | Fe | Ni | Si | Mg |

|---|---|---|---|---|---|---|---|---|

| 2.8 | 1.5 | 0.53 | 0.25 | <0.008 | <0.003 | <0.001 | <0.01 | Balance |

| Sample Series | S0.3 | S0.8 | PEO |

|---|---|---|---|

| σD[50%] 1 [MPa] | 101 | 103 | 88 |

| SD 2 [MPa] | 12 | 17 | 13 |

| Alloy | Fatigue Strength [MPa] | Heat Treatment | Cycles |

|---|---|---|---|

| Mg-9 wt % Al-0.8 wt % Zn-0.2 wt % Mn [1] | 65 | Solution 415 °C for 8 h Aging 180 °C for 24 h | 107 |

| Mg-3 wt % Nd-0.2 wt % Zn-0.45 wt % Zr [1] | 87 | Solution 540 °C for 10 h Aging 200 °C for 14 h | 107 |

| Mg-3.5 wt % Y-2.4 wt % Nd-0.5 wt % Z [8] | 125 | Solution 525 °C for 4 h Aging 225 °C for 16 h | 104 |

| Mg-3 wt % Nd-0.2 wt % Zn-1 wt % Zr [12] | 84 | Solution 540 °C for 10 h Aging 200 °C for 14 h | 107 |

| Mg-1.7 wt % Nd-1.0 wt % other RE-0.5 wt % Zn-0.5 wt % Zr [42] | 98 | Solution 525 °C for 8 h Aging 215 °C for 4 h | 107 |

| Mg-2.9 wt % Al-1.0 wt % Zn-0.3 wt % Mn [43] | 89 | (no data reported) | 109 * |

| Mg-7 wt % Gd-5 wt % Y-1 wt % Nd-0.5 wt % Zr [44] | 105 | T6 (no data reported) | 106 |

| Mg-10 wt % Gd-3 wt % Y-0.5 wt % Zr [45] | 105 | Solution 500 °C for 6 h Aging 225 °C for 16 h | 107 |

| Mg-9 wt % Al-0.8 wt % Zn-0.2 wt % Mn [46] | 45 | (no data reported) | 109 * |

| Mg-6 wt % Al-0.3 wt % Mn [46] | 50 | (no data reported) | 109 * |

| Mg-4 wt % Al-0.4 wt % Mn-0.9 wt % Ce [46] | 42 | (no data reported) | 109 * |

| Mg-2.9 wt % Al-1.0 wt % Zn-0.3 wt % Mn [47] | 50 | As rolled condition | 107 |

© 2017 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (http://creativecommons.org/licenses/by/4.0/).

Share and Cite

Ceschini, L.; Morri, A.; Angelini, V.; Messieri, S. Fatigue Behavior of the Rare Earth Rich EV31A Mg Alloy: Influence of Plasma Electrolytic Oxidation. Metals 2017, 7, 212. https://doi.org/10.3390/met7060212

Ceschini L, Morri A, Angelini V, Messieri S. Fatigue Behavior of the Rare Earth Rich EV31A Mg Alloy: Influence of Plasma Electrolytic Oxidation. Metals. 2017; 7(6):212. https://doi.org/10.3390/met7060212

Chicago/Turabian StyleCeschini, Lorella, Alessandro Morri, Valerio Angelini, and Simone Messieri. 2017. "Fatigue Behavior of the Rare Earth Rich EV31A Mg Alloy: Influence of Plasma Electrolytic Oxidation" Metals 7, no. 6: 212. https://doi.org/10.3390/met7060212

APA StyleCeschini, L., Morri, A., Angelini, V., & Messieri, S. (2017). Fatigue Behavior of the Rare Earth Rich EV31A Mg Alloy: Influence of Plasma Electrolytic Oxidation. Metals, 7(6), 212. https://doi.org/10.3390/met7060212