Cold Agglomeration of Ultrafine Oxidized Dust (UOD) from Ferromanganese and Silicomanganese Industrial Process

Abstract

:1. Introduction

2. Materials and Methods

2.1. Raw Materials

- Portland cement (Tudela Veguín III/A 42.5 N/SR). (Chemical composition: 6% C3A; 18% C3A + C4AF; 3.9% CaCO3; 43.4% slag; 1.52% SO3; and 0.23% unsolvable residue)

- Calcium aluminate refractory cement SECAR 71 Kerneos Inc. (Madrid, 28020, Spain) (Chemical composition: >68.1% Al2O3; <31% CaO; <0.8% SiO2; and <0.4% Fe2O3).

2.2. Test for the Determination of the Optimal Mixture

- 15% Portland cement

- 500 g UOD

- Water: 25% of the cement–UOD mixture

- 10% Refractory cement

- 500 g UOD

- Water: 22% of the cement–UOD mixture

2.3. Test for the Determination of the Briquettes’ Degradability Using Portland and Refractory Cement

3. Results and Discussion

4. Conclusions

Acknowledgments

Author Contributions

Conflicts of Interest

References and Notes

- O’Hara, K.D. Cave Art and Climate Change, 1st ed.; Archway Publishing: Bloomington, IN, USA, 2014; p. 64. [Google Scholar]

- Freestone, I.C.; Stapleton, C.P. Composition, technology and production of coloured glasses from Roman mosaic vessels. In Glass of the Roman World, 1st ed.; Bayley, J., Freestone, I., Jackson, C., Eds.; Oxbow Books: Oxford, UK, 2015; pp. 61–66. [Google Scholar]

- Duncan, R.D. Hydrogen to Tin: Elements of Faith. Faith Facts and Learning Lessons from the Periodic Table, 1st ed.; Master Books Inc.: Green Forest, AR, USA, 2008; p. 54. [Google Scholar]

- Olsen, S.E.; Tangstad, M.; Lindstad, T. Production of Manganese Ferroalloys, 1st ed.; SINTEF and Tapir Academic Press: Trondheim, Norway, 2007; pp. 11–69. [Google Scholar]

- Sancho, J.P.; Verdeja, L.F.; Ballester, A. Metalurgia Extractiva: Procesos de Obtención, 1st ed.; Editorial Síntesis: Madrid, Spain, 2008; Volume II, pp. 15–161. [Google Scholar]

- Kemmitt, R.D.W.; Peacock, R.D. The Chemistry of Manganese, Technetium and Rhenium: Pergamon Texts in Inorganic Chemistry, 1st ed.; Pergamon Press: Oxford, UK, 1973. [Google Scholar]

- Pero-Sanz, J.A. Aceros: Metalurgia Física, Selección y Diseño, 1st ed.; CIE-Dossat: Madrid, Spain, 2000. [Google Scholar]

- Ballester, A.; Verdeja, L.F.; Sancho, J. Metalurgia Extractiva: Volumen I. Fundamentos, 1st ed.; Editorial Síntesis: Madrid, Spain, 2008; pp. 289–290. [Google Scholar]

- Rodero, J.I.; Sancho-Gorostiaga, J.; Ordiales, M.; Fernández-González, D.; Mochón, J.; Ruiz-Bustinza, I.; Fuentes, A.; Verdeja, L.F. Blast furnace and metallurgical coke’s reactivity and its determination by termal gravimetric analysis. Ironmak. Steelmak. 2015, 42, 618–625. [Google Scholar] [CrossRef]

- Hansan, H. Understanding the Elements of the Periodic Table, 1st ed.; The Rosen Publishing Group Inc.: New York, NY, USA, 2008; pp. 19–20. [Google Scholar]

- Han, H.; Duan, D.; Yuan, P. Binders and bounding mechanism for RHF briquette made from blast furnace dust. ISIJ Int. 2014, 54, 1781–1789. [Google Scholar] [CrossRef]

- Kemppainen, A.; Iljana, M.; Heikkinen, E.; Paananen, T.; Mattila, O.; Fabritius, T. Reduction behavior of cold-bonded briquettes under simulated blast furnace conditions. ISIJ Int. 2014, 54, 1539–1545. [Google Scholar] [CrossRef]

- Bizhanov, A.; Kurunov, I.; Podgorodetskyi, G.; Dashevskyi, V.; Pavlov, A. Extruded briquettes-new charge component for the manganese ferroalloys production. ISIJ Int. 2014, 54, 2206–2214. [Google Scholar] [CrossRef]

- Bye, G.C. Portland Cement: Composition, Production and Properties, 2nd ed.; Thomas Telford: London, UK, 1999. [Google Scholar]

- Ahmed, Y.M.Z.; Mohamed, F.M. Recycling of manganese secondary raw material via cold-bond pelletizing process. Metall. Ital. 2005, 10, 33–38. [Google Scholar]

- Kurunov, I.F.; Bizhanov, A.M.; Tikhonov, D.N.; Mansurova, N.R. Metallurgical properties of brex. Metallurgist 2012, 56, 430–437. [Google Scholar] [CrossRef]

- Singh, M.; Björkman, B. Strength of cement-bonded briquettes. Miner. Metall. Proc. 2006, 23, 203–213. [Google Scholar]

- American Society for Testing Materials. Standard Test Method for Determination of Abrasion Resistance of Iron Ore Pellets and Sinter by the Tumbler Test; ASTM E279-97, 2010.

- Instrucción de Hormigón Estructural (EHE-08). Available online: http://dadun.unav.edu/bitstream/10171/17515/1/RE_Vol%2030_08.pdf (accessed on 24 August 2016).

- Verdeja, L.F.; Sancho, J.P.; Ballester, A.; González, R. Refractory and Ceramic Materials, 1st ed.; Editorial Síntesis: Madrid, Spain, 2014; pp. 235–237. [Google Scholar]

| 5% | 10% | 15% | ||||||

|---|---|---|---|---|---|---|---|---|

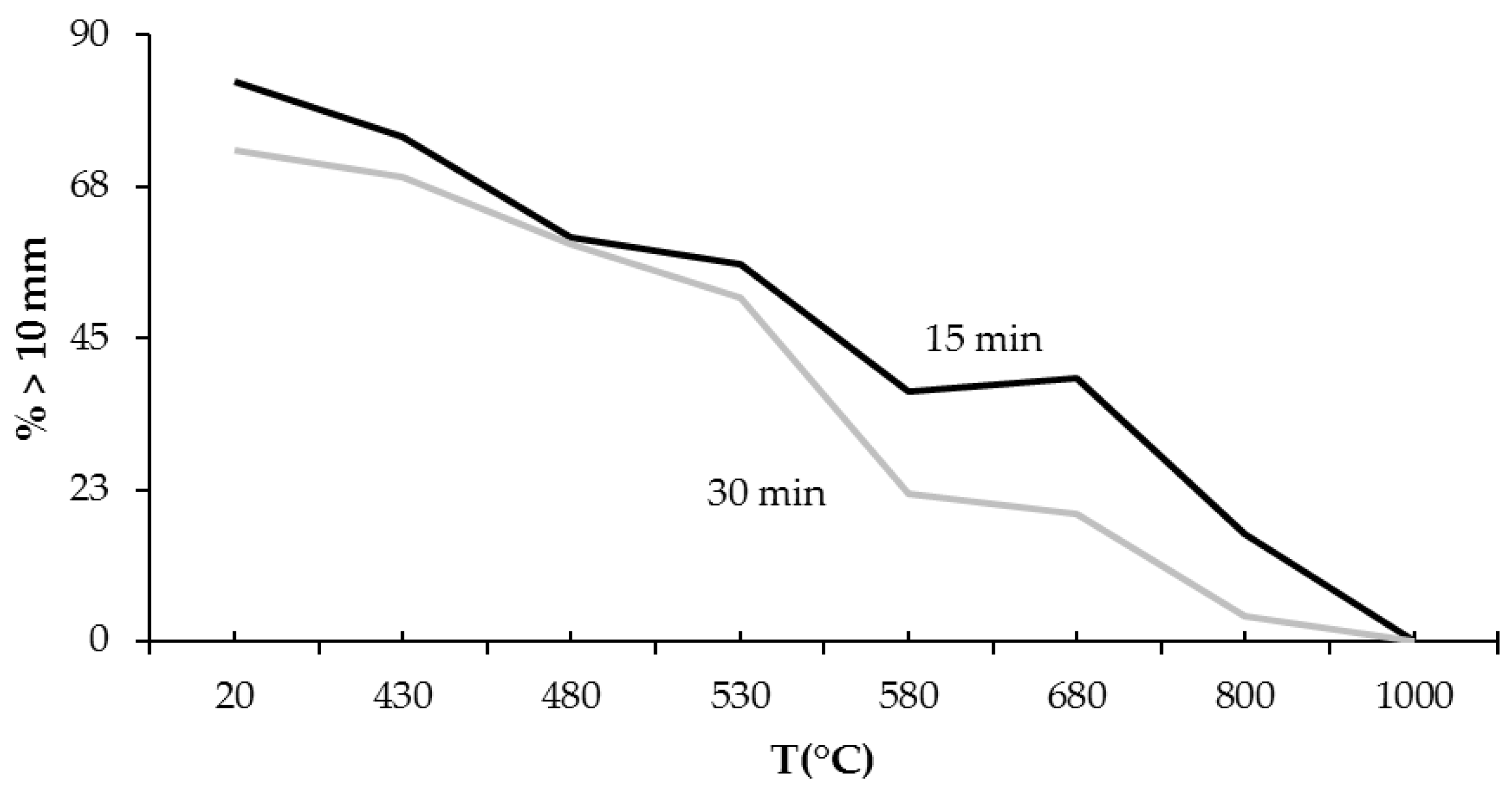

| t (min) | % >10 mm | T (°C) | t (min) | % >10 mm | T (°C) | t (min) | % >10 mm | T (°C) |

| 15 | 0 | 25 | 15 | 73.6 | 25 | 15 | 75.0 | 25 |

| 15 | 0 | 450 | 15 | 47.0 | 450 | 15 | 65.0 | 450 |

| 15 | 0 | 515 | 15 | 16.0 | 515 | 15 | 38.0 | 515 |

| 15 | 0 | 650 | 15 | 20.0 | 650 | 15 | 36.0 | 650 |

| 15 | 0 | 780 | 15 | 3.6 | 780 | 15 | 13.0 | 780 |

| 5% | 10% | 15% | ||||||

|---|---|---|---|---|---|---|---|---|

| t (min) | % > 10 mm | T (°C) | t (min) | % > 10 mm | T (°C) | t (min) | % > 10 mm | T (°C) |

| 15 | 41.8 | 25 | 15 | 55.1 | 25 | 15 | 73.6 | 25 |

| 15 | 21.6 | 450 | 15 | 32.4 | 450 | 15 | 25 | 450 |

| 15 | 13.4 | 515 | 15 | 30 | 515 | 15 | 21 | 515 |

| 15 | 11.3 | 650 | 15 | 50 | 650 | 15 | 52 | 650 |

| 15 | 8 | 780 | 15 | 80 | 780 | 15 | 72 | 780 |

© 2016 by the authors; licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC-BY) license (http://creativecommons.org/licenses/by/4.0/).

Share and Cite

Ordiales, M.; Iglesias, J.; Fernández-González, D.; Sancho-Gorostiaga, J.; Fuentes, A.; Verdeja, L.F. Cold Agglomeration of Ultrafine Oxidized Dust (UOD) from Ferromanganese and Silicomanganese Industrial Process. Metals 2016, 6, 203. https://doi.org/10.3390/met6090203

Ordiales M, Iglesias J, Fernández-González D, Sancho-Gorostiaga J, Fuentes A, Verdeja LF. Cold Agglomeration of Ultrafine Oxidized Dust (UOD) from Ferromanganese and Silicomanganese Industrial Process. Metals. 2016; 6(9):203. https://doi.org/10.3390/met6090203

Chicago/Turabian StyleOrdiales, María, Juan Iglesias, Daniel Fernández-González, José Sancho-Gorostiaga, Alberto Fuentes, and Luis Felipe Verdeja. 2016. "Cold Agglomeration of Ultrafine Oxidized Dust (UOD) from Ferromanganese and Silicomanganese Industrial Process" Metals 6, no. 9: 203. https://doi.org/10.3390/met6090203

APA StyleOrdiales, M., Iglesias, J., Fernández-González, D., Sancho-Gorostiaga, J., Fuentes, A., & Verdeja, L. F. (2016). Cold Agglomeration of Ultrafine Oxidized Dust (UOD) from Ferromanganese and Silicomanganese Industrial Process. Metals, 6(9), 203. https://doi.org/10.3390/met6090203