The Influence of Different External Fields on Aging Kinetics of 2219 Aluminum Alloy

Abstract

:1. Introduction

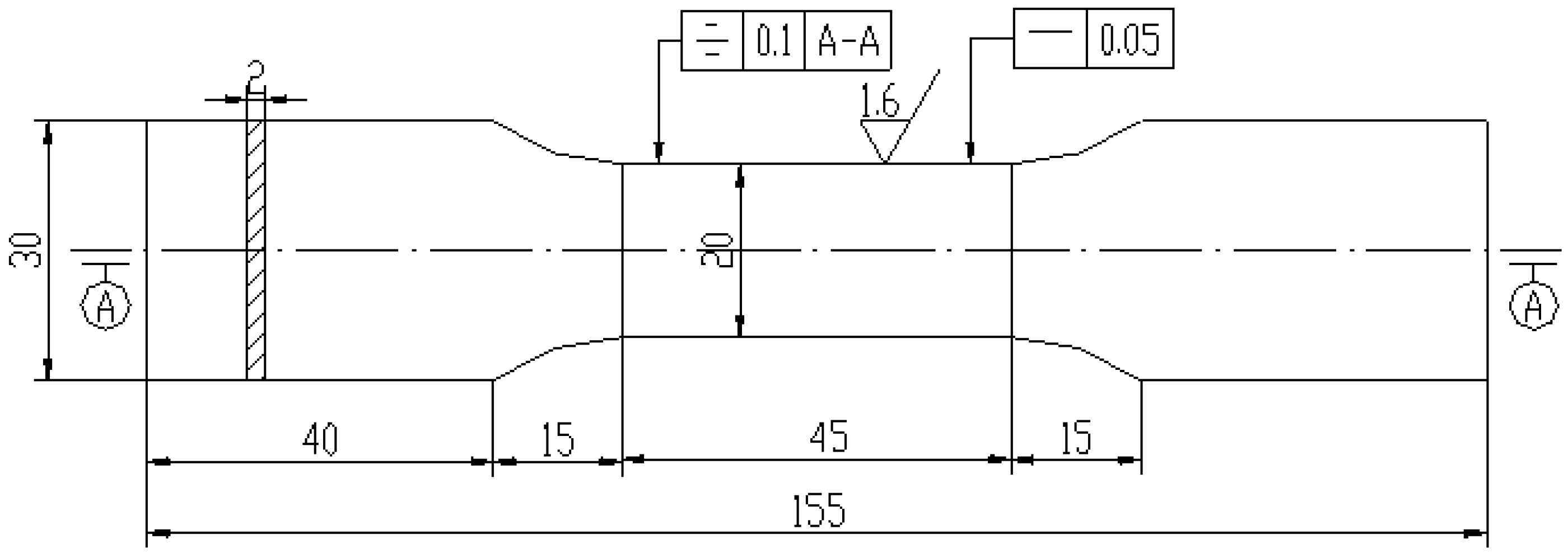

2. Materials and Methods

3. Results and Discussion

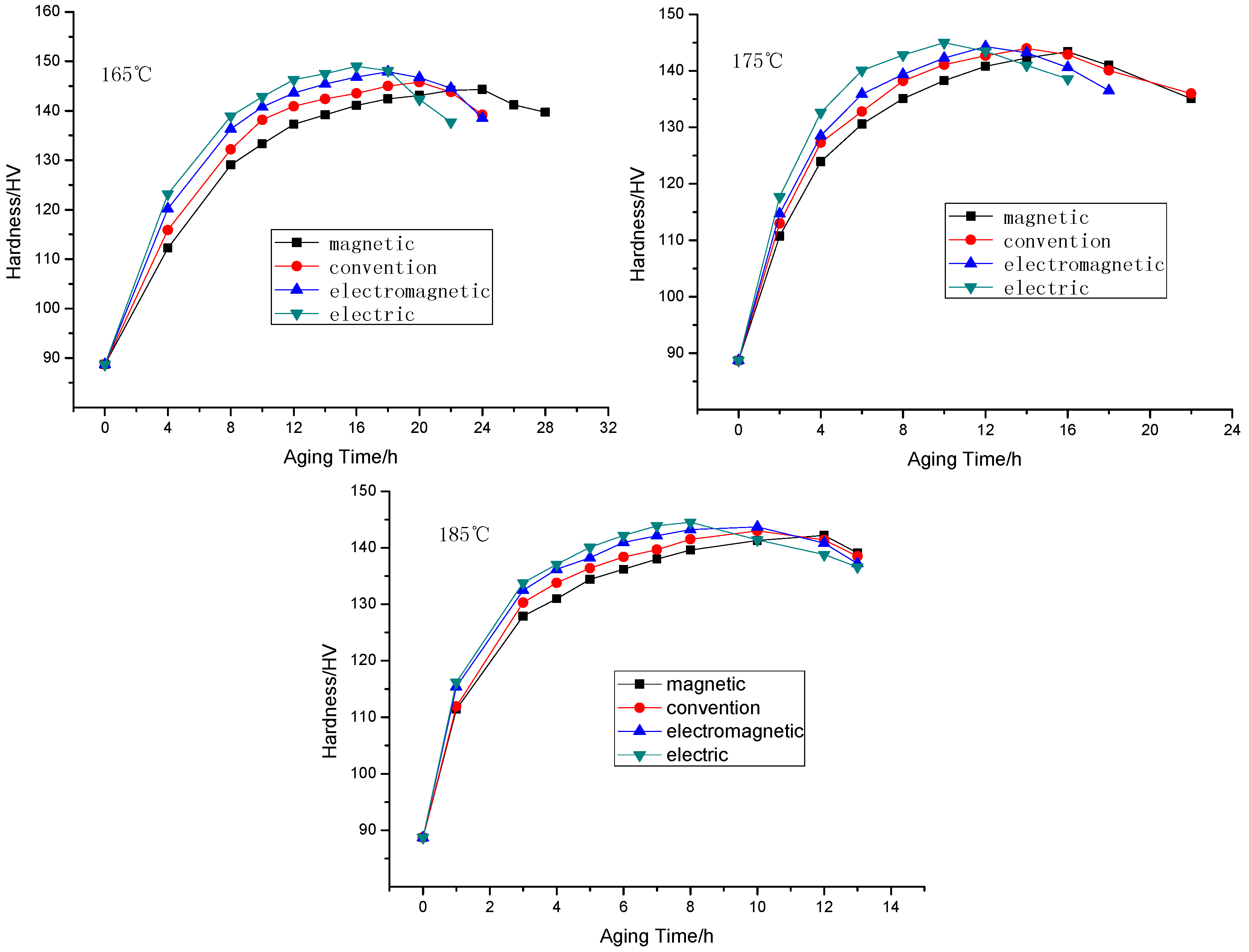

3.1. Effects of Different External Fields on the 2219 Aging Process

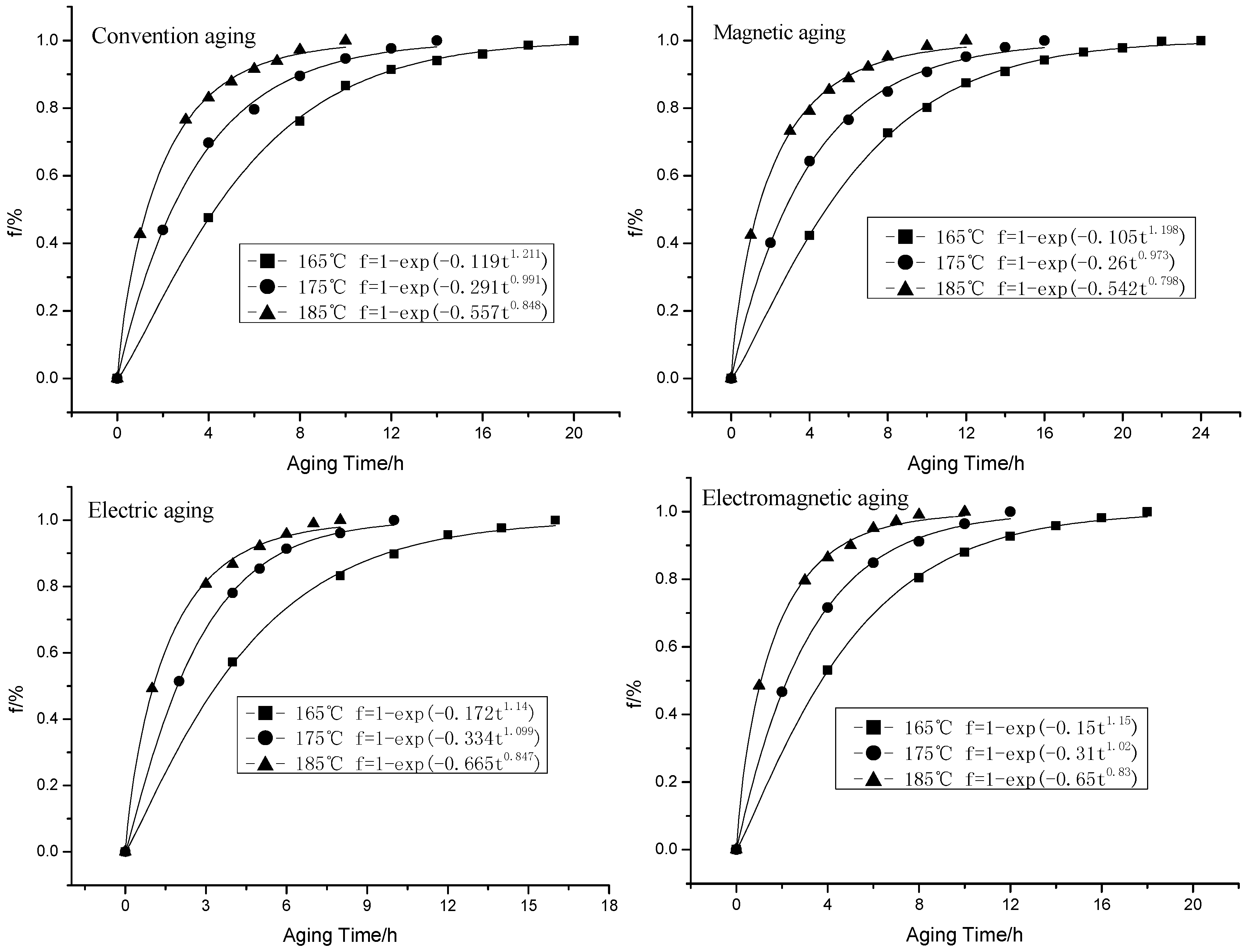

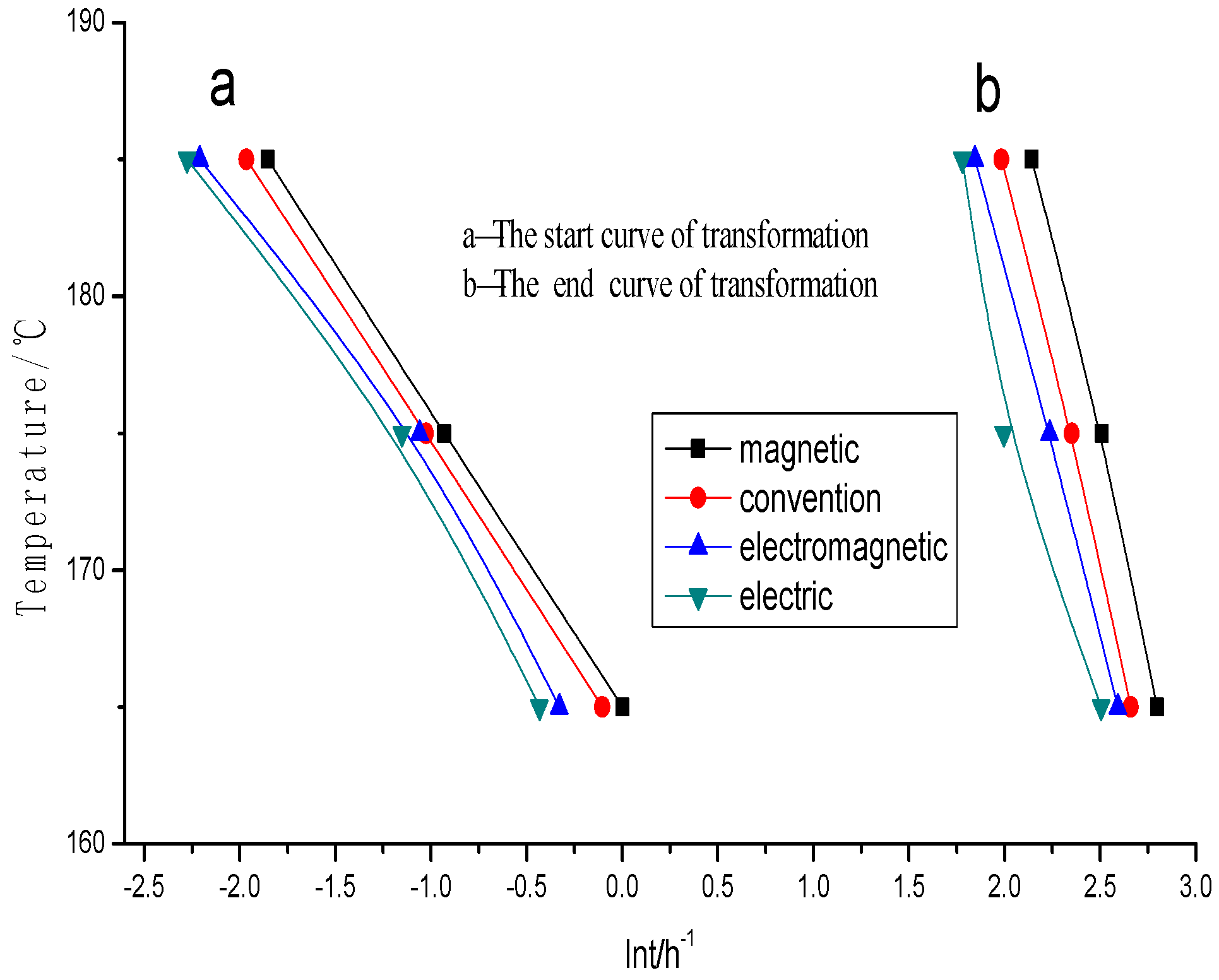

3.2. TTT Curve under the Effects of Different External Fields

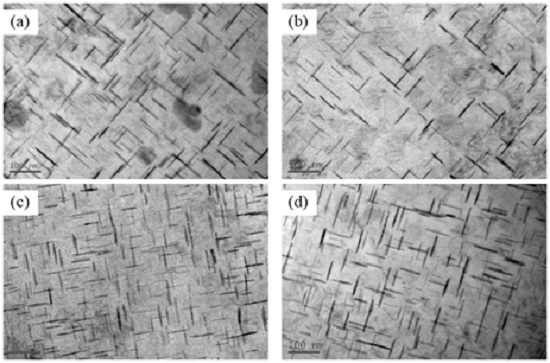

3.3. Effects of Different External Fields on the Microstructure

3.4. Effects of Different External Fields on the Mechanical Property

4. Conclusions

- (1)

- The introduction of external fields changes the aging precipitation process of 2219 aluminum alloy, extending the time for the alloy to reach peak aging, whereas the application of electric field and electromagnetic field brings the peak aging time forward and increases the peak hardness of the alloy.

- (2)

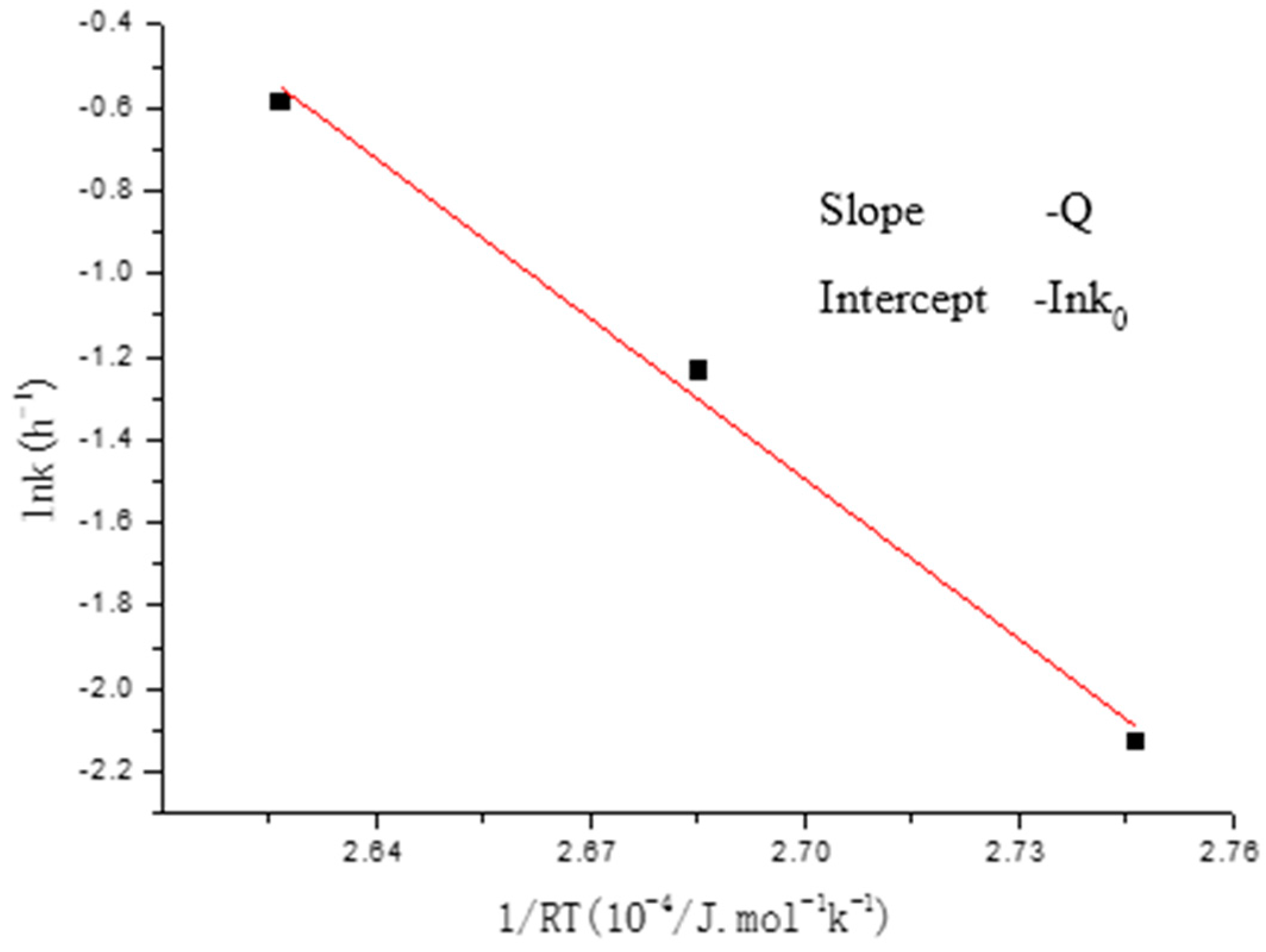

- Avrami empirical equation perfectly describes the aging kinetic behaviors of 2219 aluminum alloy, from which it can be known that the diffusion activation energy Q of current, electric field + magnetic field, conventional aging, and magnetic field gradually increases.

- (3)

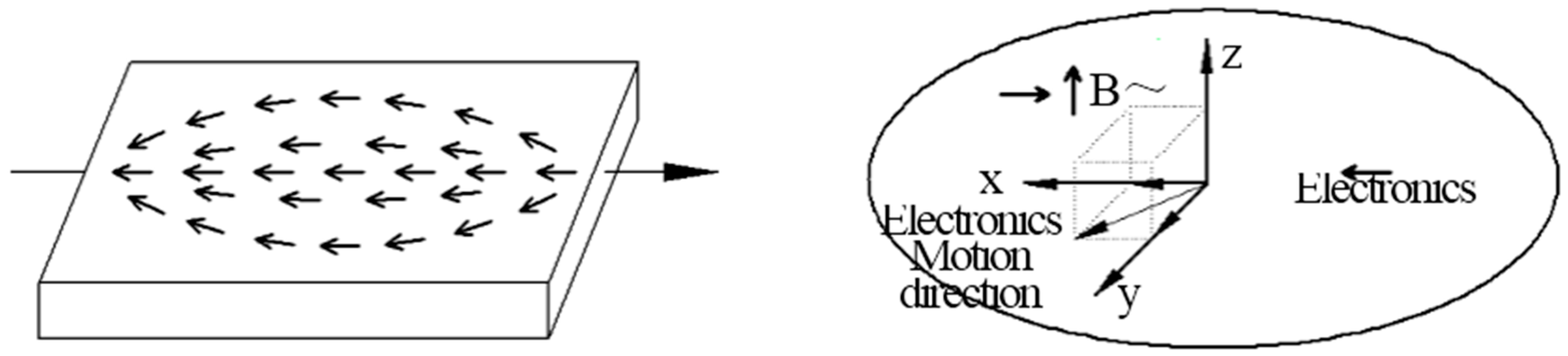

- During the aging process, the introduction of electric field magnifies the volume fraction, reduces the size, and increases the degree of diffusion of internal alloy precipitated phase; the introduction of magnetic field reduces the volume fraction of internal alloy precipitated phase; while the introduction of both electric field and magnetic field can not only guarantee that the mechanical property of the alloy does not decrease, but also make sure the stability of alloy performance.

Acknowledgments

Author Contributions

Conflicts of Interest

References

- Shimotomai, M.; Maruta, K.; Mine, K.; Matsui, M. Formation of aligned two-phase microstructures by applying a magnetic field during the austenite to ferrite transformation in steels. Acta Mater. 2003, 51, 2921–2932. [Google Scholar] [CrossRef]

- Yang, G.; Feng, G.H. Phenomenon of heat conduction in the magnetic field heat treatment for ferritie and pearlitie steels. J. Steel Iron Res. 2000, 12, 31–35. [Google Scholar]

- Wang, Z.; Zhong, Y.; Cao, G.; Wang, C.; Wang, J.; Ren, W.; Lei, Z.; Ren, Z. Influence of dc electric current on the hardness of thermally aged Cu-Cr-Zr alloy. J. Alloys Compd. 2009, 479, 303–306. [Google Scholar] [CrossRef]

- Wang, Z.-Q.; Zhong, Y.-B.; Rao, X.-J.; Wang, C.; Wang, J.; Zhang, Z.-G.; Ren, W.-L.; Ren, Z.-M. Electrical and mechanical properties of Cu-Cr-Zr alloy aged under imposed direct continuous current. Trans. Nonferrous Metals Soc. China 2012, 22, 1106–1111. [Google Scholar] [CrossRef]

- Zhan, L.; Jia, S.; Zhang, J. Influence of electrical impulse aging on microstructure and mechanical properties of 7075 aluminum alloy. Trans. Nonferrous Metals Soc. China 2014, 3, 600–605. [Google Scholar]

- Wang, H.; Yi, Y.; Huang, S. Influence of pre-deformation and subsequent ageing on the hardening behavior and microstructure of 2219 aluminum alloy forgings. J. Alloys Compd. 2016, 685, 941–948. [Google Scholar] [CrossRef]

- Owolabi, G.M.; Bolling, D.T.; Tiamiyu, A.A.; Abu, R.; Odeshi, A.G.; Whitworth, H.A. Shear strain localization in AA 2219-T8 aluminum alloy at high strain rates. Mater. Sci. Eng. A 2016, 655, 212–220. [Google Scholar] [CrossRef]

- Li, Q.; Wu, A.; Li, Y.; Wang, G.; Yan, D.; Liu, J. Influence of temperature cycles on the microstructures and mechanical properties of the partially melted zone in the fusion welded joints of 2219 aluminum alloy. Mater. Sci. Eng. A 2015, 623, 38–48. [Google Scholar] [CrossRef]

- Yang, Y.; Zhan, L.; Ma, Q.; Feng, J.; Li, X. Effect of pre-deformation on creep age forming of AA2219 plate: Springback, microstructures and mechanical properties. J. Mater. Process. Technol. 2016, 229, 697–702. [Google Scholar] [CrossRef]

- Chen, Y.; Liu, H.; Feng, J. Friction stir welding characteristics of different heat-treated-state 2219 aluminum alloy plates. Mater. Sci. Eng. A 2006, 420, 21–25. [Google Scholar] [CrossRef]

- Mazurina, I.; Sakai, T.; Miura, H.; Sitdikov, O.; Kaibyshev, R. Effect of deformation temperature on microstructure evolution in aluminum alloy 2219 during hot ECAP. Mater. Sci. Eng. A 2008, 486, 662–671. [Google Scholar] [CrossRef]

- Li, Y.; Yi, D. Dynamics of phase transfomation in Cu-Fe-Ag alloy. Trans. Metal Heat Treat. 2010, 5, 49–52. [Google Scholar]

- Zhang, J.; Zhan, L.; Jia, S. Effects of Electric Pulse Current on the Aging Kinetics of 2219 Aluminum Alloy. Adv. Mater. Sci. Eng. 2014, 2014, 1–8. [Google Scholar] [CrossRef]

- Ber, L.B. Accelerated artificial ageing regimes of commercial aluminium alloys. II: Al-Cu, Al-Zn-Mg-(Cu), Al-Mg-Si-(Cu) alloys. Mater. Sci. Eng. A 2000, 280, 91–96. [Google Scholar] [CrossRef]

- Zheng, Z. Fundamentals of Material Science, 1st ed.; Science Press: Beijing, China, 2007. [Google Scholar]

| Cu | Mg | Mn | Si | Fe | Ni | Zr | Ti | Al |

|---|---|---|---|---|---|---|---|---|

| 5.24 | 0.028 | 0.27 | 0.024 | 0.13 | 0.03 | 0.14 | 0.065 | Bal. |

| Temperature/°C | External Field | Tensile Strength/MPa | Yield Strength/MPa | Elongation/% |

|---|---|---|---|---|

| 175 °C | Convention | 376.9 | 262.41 | 18.37 |

| Magnetic | 375.81 | 257.38 | 16.05 | |

| Electric | 387.22 | 274.52 | 15.48 | |

| Electromagnetic | 387.5 | 270.35 | 15.2 |

© 2016 by the authors; licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC-BY) license (http://creativecommons.org/licenses/by/4.0/).

Share and Cite

Zhan, L.; Li, W.; Ma, Q.; Liu, L. The Influence of Different External Fields on Aging Kinetics of 2219 Aluminum Alloy. Metals 2016, 6, 201. https://doi.org/10.3390/met6090201

Zhan L, Li W, Ma Q, Liu L. The Influence of Different External Fields on Aging Kinetics of 2219 Aluminum Alloy. Metals. 2016; 6(9):201. https://doi.org/10.3390/met6090201

Chicago/Turabian StyleZhan, Lihua, Wenke Li, Qiangqiang Ma, and Lingfeng Liu. 2016. "The Influence of Different External Fields on Aging Kinetics of 2219 Aluminum Alloy" Metals 6, no. 9: 201. https://doi.org/10.3390/met6090201

APA StyleZhan, L., Li, W., Ma, Q., & Liu, L. (2016). The Influence of Different External Fields on Aging Kinetics of 2219 Aluminum Alloy. Metals, 6(9), 201. https://doi.org/10.3390/met6090201