Enhanced Mechanical Properties of MgZnCa Bulk Metallic Glass Composites with Ti-Particle Dispersion

Abstract

:1. Introduction

2. Experimental

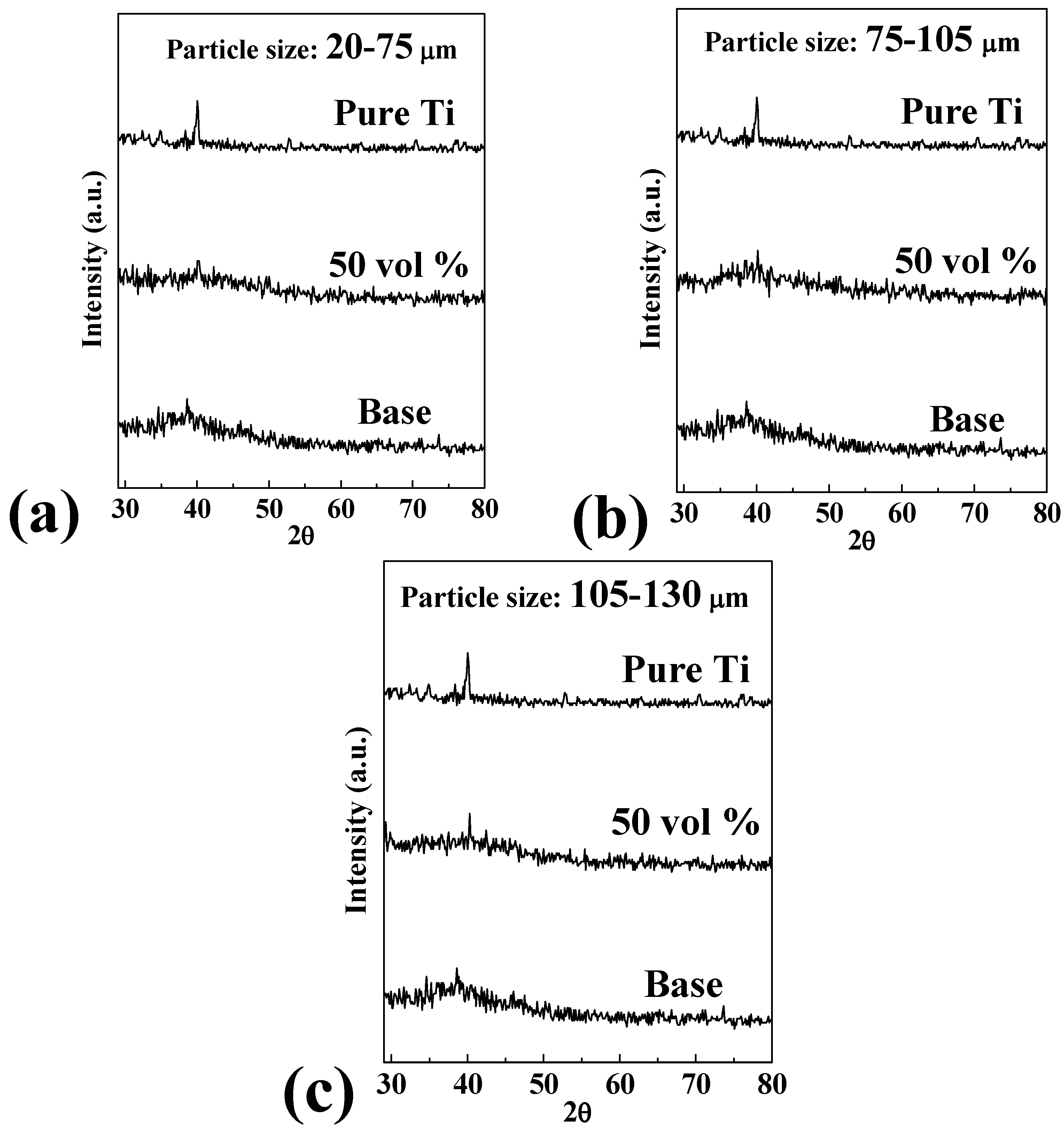

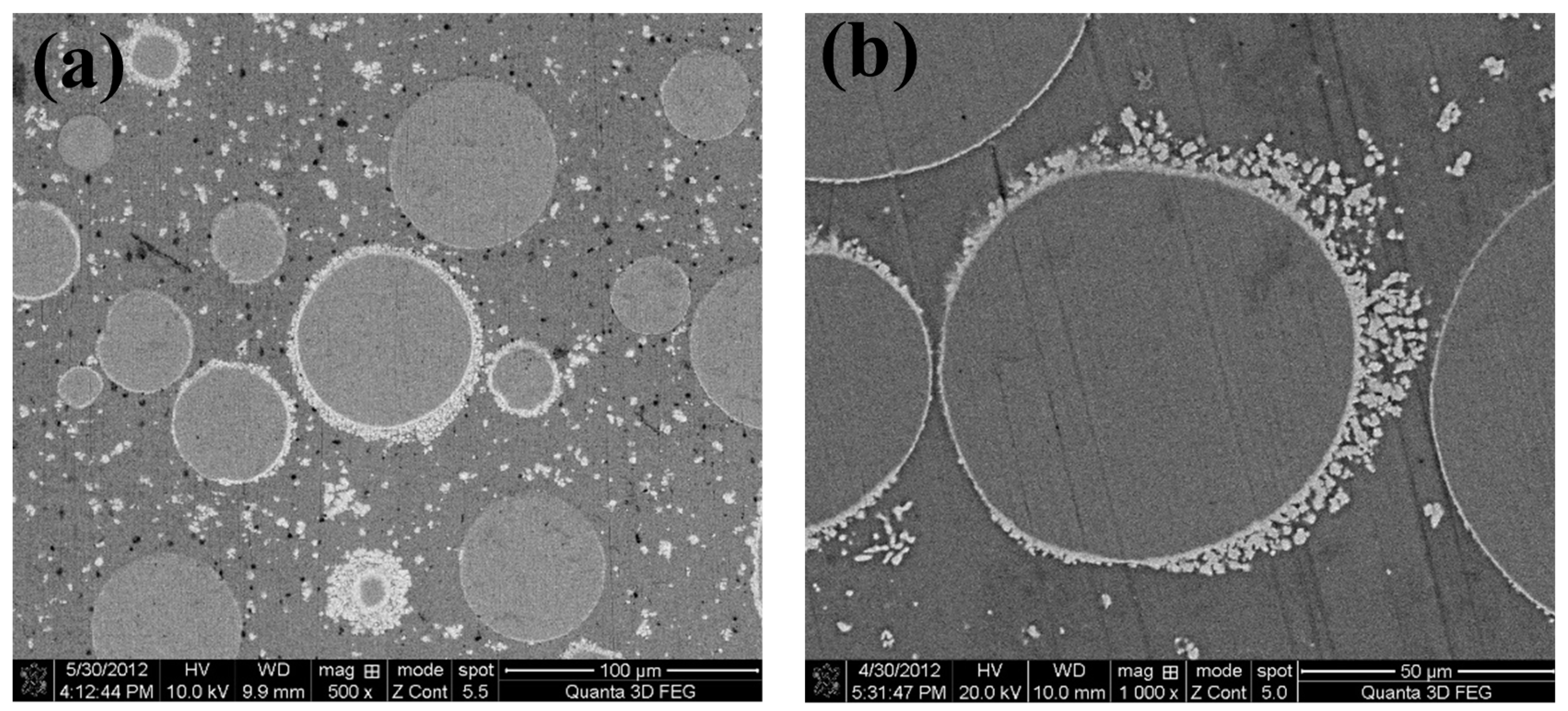

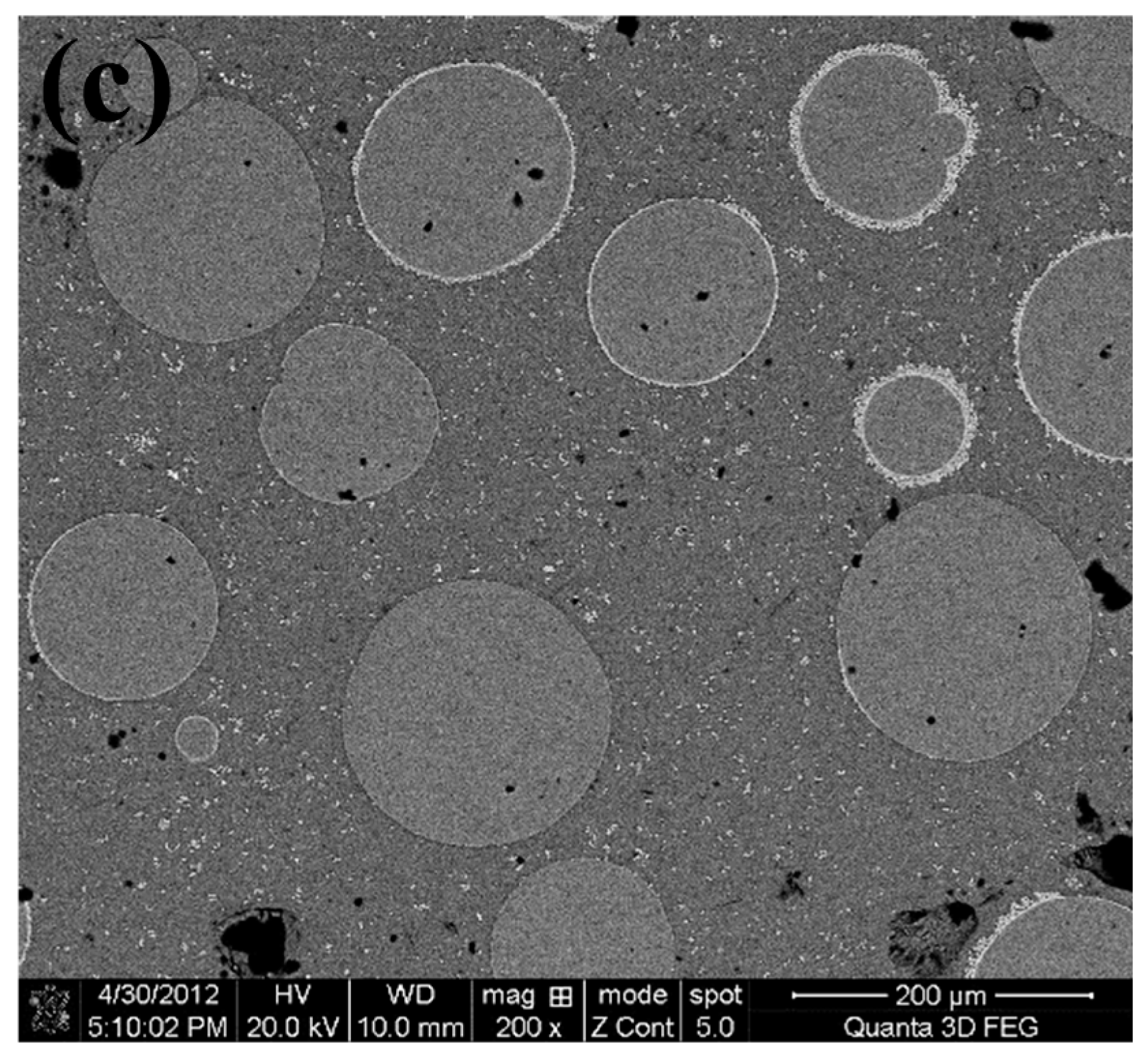

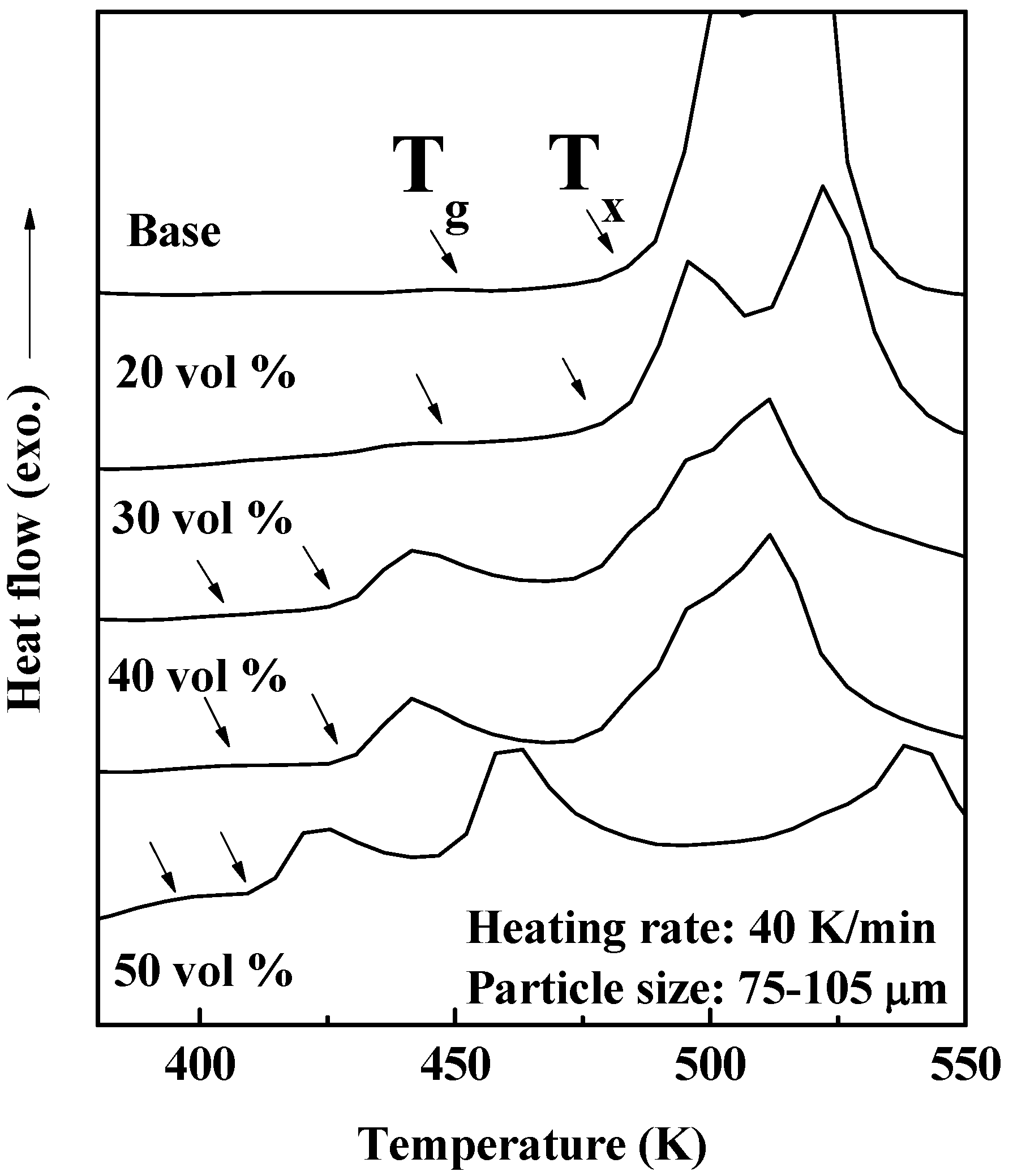

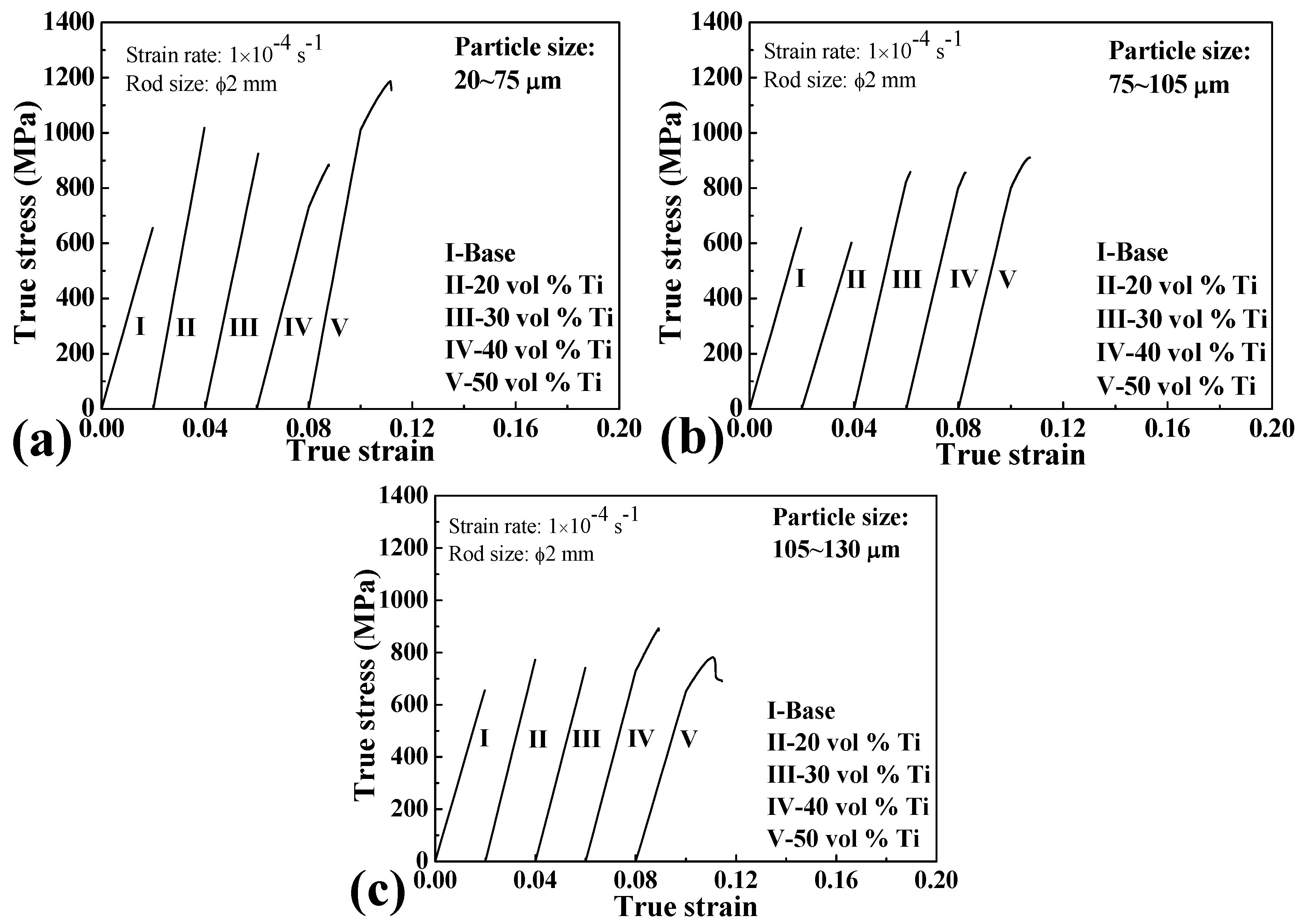

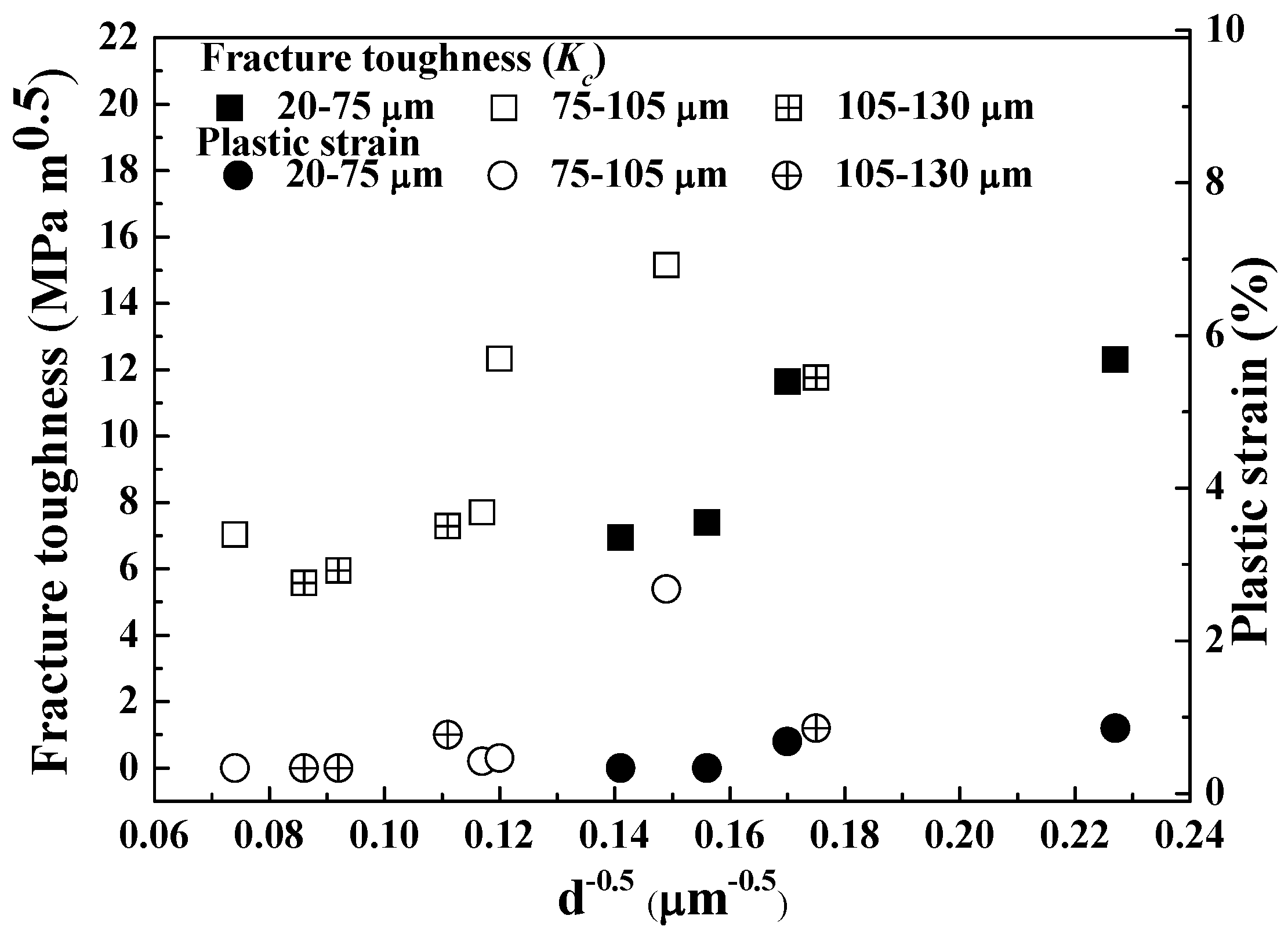

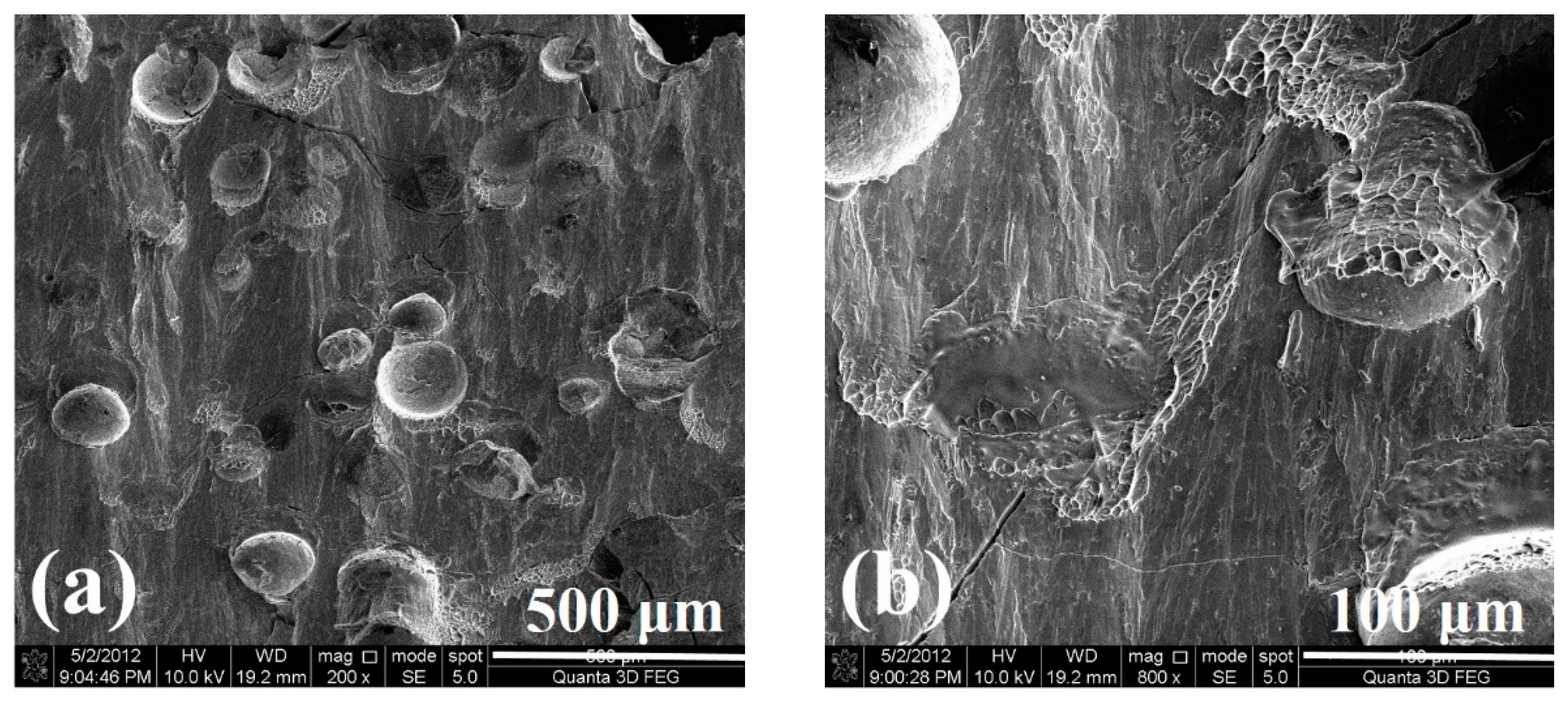

3. Result and Discussion

4. Conclusions

Acknowledgments

Author Contributions

Conflicts of Interest

References

- Mordin, M.; Frankel, V.H. Basic Biomechanics of the Musculoskeletal System, 4th ed.; Lippincott Williams & Willkin: Philadelphia, PA, USA, 2012. [Google Scholar]

- Zberg, B.; Uggowitzer, P.J.; Loffler, J.F. MgZnCa glasses without clinically observable hydrogen evolution for biodegradable implants. Nat. Mater. 2009, 8, 887–891. [Google Scholar] [CrossRef] [PubMed]

- Gu, X.N.; Zheng, Y.F.; Zhong, S.P.; Xi, T.F.; Wang, J.Q.; Wang, W.H. Corrosion of, and cellular response to Mg-Zn-Ca bulk metallic glasses. Biomaterials 2010, 31, 1093–1103. [Google Scholar] [CrossRef] [PubMed]

- Li, Q.F.; Weng, H.R.; Suo, Z.Y.; Ren, Y.L.; Yuan, X.G.; Qiu, K.Q. Microstructure and mechanical properties of bulk Mg-Zn-Ca amorphous alloy and amorphous matrix composites. Mater. Sci. Eng. A 2008, 487, 301–308. [Google Scholar] [CrossRef]

- Zhao, Y.Y.; Ma, E.; Xu, J. Reliability of compressive fracture strength of Mg-Zn-Ca bilk metallic glass: Flaw sensitivity and Weibull statistics. Scr. Mater. 2009, 58, 496–499. [Google Scholar] [CrossRef]

- Zberg, B.; Arata, E.R.; Uggowitzer, P.J.; Loffler, J.F. Tensile properties of glassy MgZnCa wires and reliability analysis using Weibull statistics. Acta Mater. 2009, 57, 3223–3231. [Google Scholar] [CrossRef]

- Jang, J.S.C.; Li, T.H.; Jian, S.R.; Huang, J.C.; Nieh, T.G. Effects of characteristics of Mo dispersions on the plasticity of Mg-based bulk metallic glass composites. Intermetallics 2011, 19, 738–743. [Google Scholar] [CrossRef]

- Hsieh, P.J.; Yang, L.C.; Su, H.C.; Lu, C.C.; Jang, J.S.C. Improvement of mechanical properties in MgCuYNdAg bulk metallic glasses with adding Mo particles. J. Alloy. Compd. 2010, 504, 98–101. [Google Scholar] [CrossRef]

- Jang, J.S.C.; Chang, Y.S.; Li, T.H.; Hsieh, P.J.; Huang, J.C.; Tsao, C.Y. Plasticity enhancement of Mg58Cu28.5Gd11Ag2.5 based bulk metallic glass composites dispersion strengthened by Ti particles. J. Alloy. Compd. 2010, 504, 102–105. [Google Scholar] [CrossRef]

- Kinaka, M.; Kato, H.; Hasegawa, M.; Inoue, A. High specific strength Mg-based metallic glass matrix composite highly ductilized by Ti dispersoid. Mater. Sci. Eng. A 2008, 494, 299–303. [Google Scholar] [CrossRef]

- Shanthi, M.; Gupta, M.; Jarfors, A.E.W.; Tan, M.J. Synthesis characterization and mechanical properties of nano alumina particulate reinforced magnesium based bulk metallic glass composites. Mater. Sci. Eng. A 2011, 528, 6045–6050. [Google Scholar] [CrossRef]

- Xu, Y.K.; Ma, H.; Xu, J.; Ma, E. Mg-based bulk metallic glass composites with plasticity and gigapascal strength. Acta Mater. 2005, 53, 1857–1866. [Google Scholar] [CrossRef]

- Jang, J.S.C.; Jian, S.R.; Li, T.H.; Huang, J.C.; Tsao, C.Y.; Liu, C.T. Structural and mechanical characterizations of ductile Fe particles-reinforced Mg-based bulk metallic glass composites. J. Alloy. Compd. 2009, 485, 290–294. [Google Scholar] [CrossRef]

- Jang, J.S.C.; Ciou, J.Y.; Li, T.H.; Huang, J.C.; Nieh, T.G. Dispersion toughening of Mg-based bulk metallic glass reinforced with porous Mo particles. Intermetallics 2010, 18, 451–458. [Google Scholar] [CrossRef]

- Jang, J.S.C.; Li, J.B.; Lee, S.L.; Chang, Y.S.; Jian, S.R.; Huang, J.C.; Nieh, T.G. Prominent plasticity of Mg-based bulk metallic glass composites by ex-situ spherical Ti particles. Intermetallics 2012, 30, 25–29. [Google Scholar] [CrossRef]

- Wang, J.F.; Huang, S.; Wei, Y.Y.; Guo, S.F.; Pan, F.S. Enhanced mechanical properties and corrosion resistance of a Mg-Zn-Ca bulk metallic glass composite by Fe particle addition. Mater. Lett. 2013, 91, 311–314. [Google Scholar] [CrossRef]

- Wang, J.F.; Huang, S.; Li, Y.; Wei, Y.Y.; Guo, S.F.; Pan, F.S. Ultrahigh strength MgZnCa eutectic alloy/Fe particle composites with excellent plasticity. Mater. Lett. 2014, 137, 139–142. [Google Scholar] [CrossRef]

- Xi, X.K.; Zhao, D.Q.; Pan, M.X.; Wang, W.H.; Wu, Y.; Lewandowski, J.J. Fracture of Brittle Metallic Glasses: Brittleness or Plasticity. Phys. Rev. Lett. 2005, 94. [Google Scholar] [CrossRef] [PubMed]

- Meyers, M.A.; Chawla, K.K. Mechanical Behavior of Materials; Cambridge University Press: Cambridge, UK, 2009. [Google Scholar]

| Particle Size (D) | vol % | Tg (K) | Tx (K) | Tl (K) | Trg | γ | γm | ΔTx |

|---|---|---|---|---|---|---|---|---|

| Base | 446 | 488 | 700 | 0.638 | 0.426 | 0.758 | 42 | |

| 20–75 μm | 20 | 400 | 430 | 675 | 0.593 | 0.400 | 0.681 | 30 |

| 30 | 400 | 429 | 671 | 0.597 | 0.400 | 0.683 | 29 | |

| 40 | 403 | 432 | 674 | 0.598 | 0.401 | 0.684 | 29 | |

| 50 | 395 | 418 | 676 | 0.585 | 0.391 | 0.654 | 23 | |

| 75–105 μm | 20 | 394 | 433 | 679 | 0.580 | 0.404 | 0.698 | 40 |

| 30 | 402 | 430 | 673 | 0.599 | 0.400 | 0.681 | 28 | |

| 40 | 404 | 429 | 672 | 0.601 | 0.399 | 0.677 | 25 | |

| 50 | 393 | 414 | 673 | 0.584 | 0.388 | 0.646 | 21 | |

| 105–130 μm | 20 | 408 | 435 | 671 | 0.609 | 0.403 | 0.688 | 27 |

| 30 | 405 | 431 | 681 | 0.595 | 0.396 | 0.670 | 25 | |

| 40 | 400 | 425 | 680 | 0.588 | 0.394 | 0.663 | 25 | |

| 50 | 400 | 425 | 682 | 0.587 | 0.392 | 0.658 | 24 | |

| Particle Size (D) | vol % | Inter-Particle Spacing (Edge to Edge, μm) | |

|---|---|---|---|

| Calculated | Measured | ||

| 20–75 μm (Average 48 μm) | 20 | 59 | 53 ± 11 |

| 30 | 40 | 42 ± 7 | |

| 40 | 28 | 36 ± 8 | |

| 50 | 18 | 19 ± 3 | |

| 75–105 μm (Average 90 μm) | 20 | 110 | 91 ± 21 |

| 30 | 74 | 74 ± 14 | |

| 40 | 52 | 68 ± 12 | |

| 50 | 37 | 34 ± 4 | |

| 105–130 μm (Average 120 μm) | 20 | 148 | 135 ± 26 |

| 30 | 99 | 117 ± 21 | |

| 40 | 68 | 83 ± 26 | |

| 50 | 50 | 65 ± 11 | |

© 2016 by the authors; licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC-BY) license (http://creativecommons.org/licenses/by/4.0/).

Share and Cite

Wong, P.C.; Lee, T.H.; Tsai, P.H.; Cheng, C.K.; Li, C.; Jang, J.S.-C.; Huang, J.C. Enhanced Mechanical Properties of MgZnCa Bulk Metallic Glass Composites with Ti-Particle Dispersion. Metals 2016, 6, 116. https://doi.org/10.3390/met6050116

Wong PC, Lee TH, Tsai PH, Cheng CK, Li C, Jang JS-C, Huang JC. Enhanced Mechanical Properties of MgZnCa Bulk Metallic Glass Composites with Ti-Particle Dispersion. Metals. 2016; 6(5):116. https://doi.org/10.3390/met6050116

Chicago/Turabian StyleWong, Pei Chun, Tsung Hsiung Lee, Pei Hua Tsai, Cheng Kung Cheng, Chuan Li, Jason Shian-Ching Jang, and J. C. Huang. 2016. "Enhanced Mechanical Properties of MgZnCa Bulk Metallic Glass Composites with Ti-Particle Dispersion" Metals 6, no. 5: 116. https://doi.org/10.3390/met6050116

APA StyleWong, P. C., Lee, T. H., Tsai, P. H., Cheng, C. K., Li, C., Jang, J. S.-C., & Huang, J. C. (2016). Enhanced Mechanical Properties of MgZnCa Bulk Metallic Glass Composites with Ti-Particle Dispersion. Metals, 6(5), 116. https://doi.org/10.3390/met6050116