Selective Laser Melting of Ti-45Nb Alloy

Abstract

:1. Introduction

2. Experimental Section

2.1. Powder Fabrication

2.2. Parameter Selection

2.3. Sample Characterization

| v [mm/s] | PL [W] | hatching [%] | EV [J/mm3] | rel. density [%] |

|---|---|---|---|---|

| 35 | 150 | 25 | 137 | 97.7 ± 1.3 |

| 35 | 250 | 25 | 172 | 99.4 ± 0.5 |

| 35 | 250 | 50 | 257 | 99.5 ± 0.2 |

3. Results and Discussion

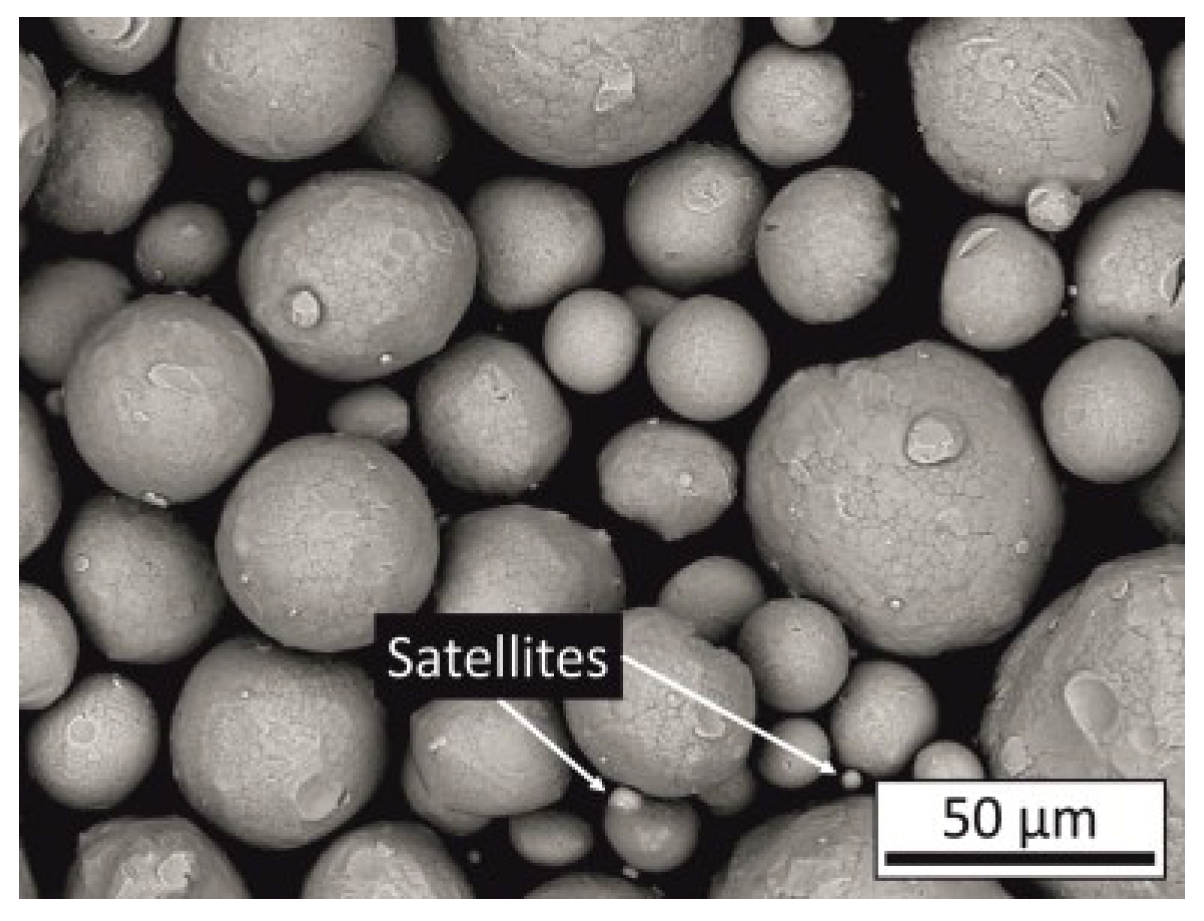

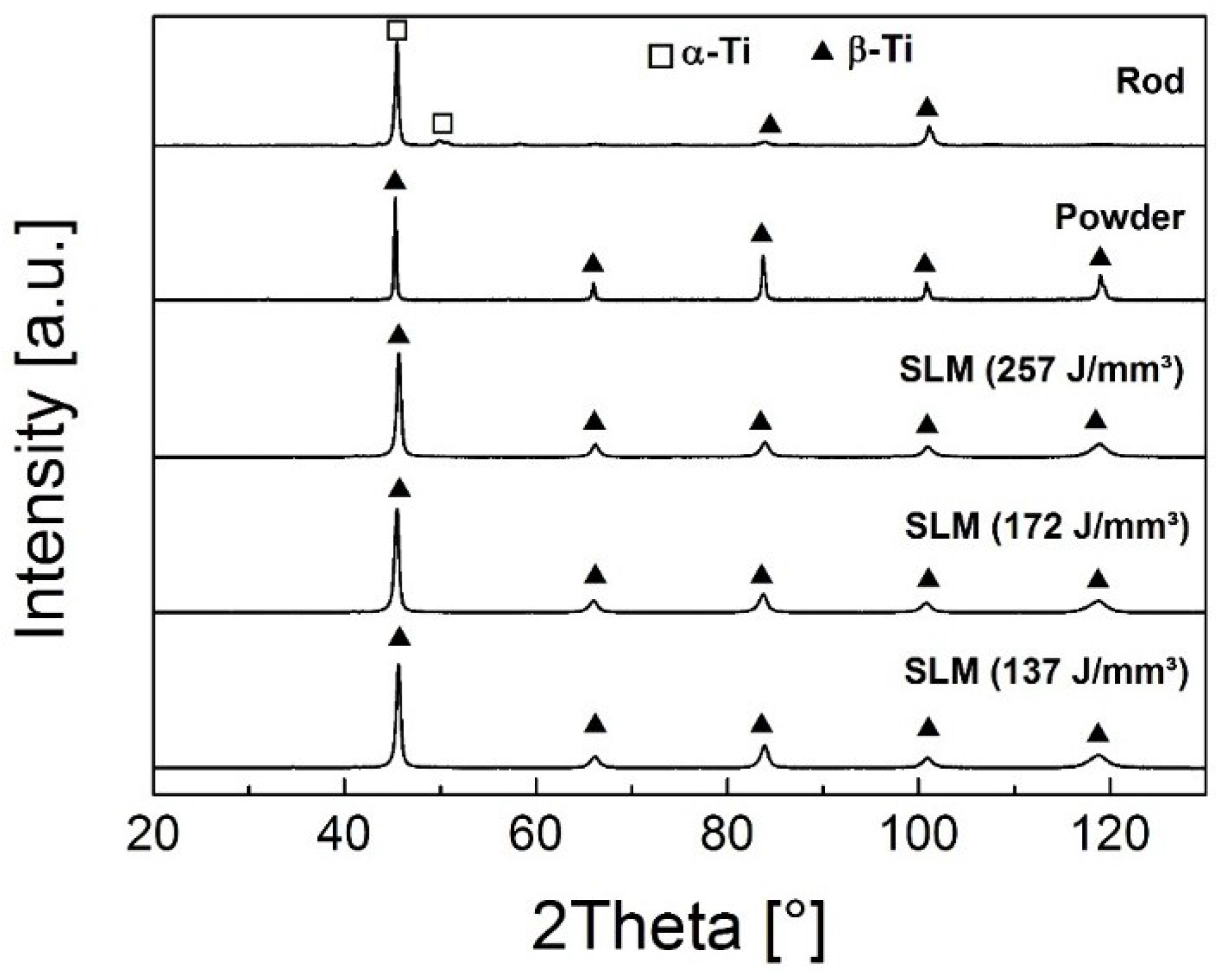

3.1. Ti-45Nb GAP Starting Material

3.2. Bulk SLM Samples

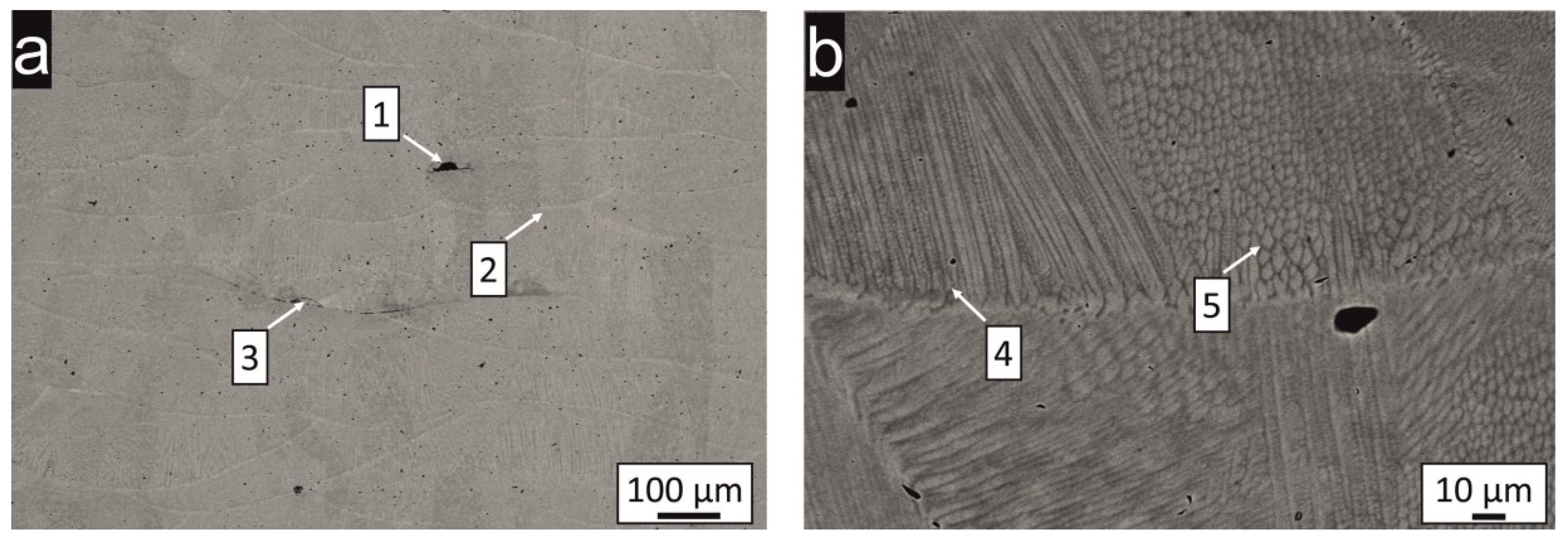

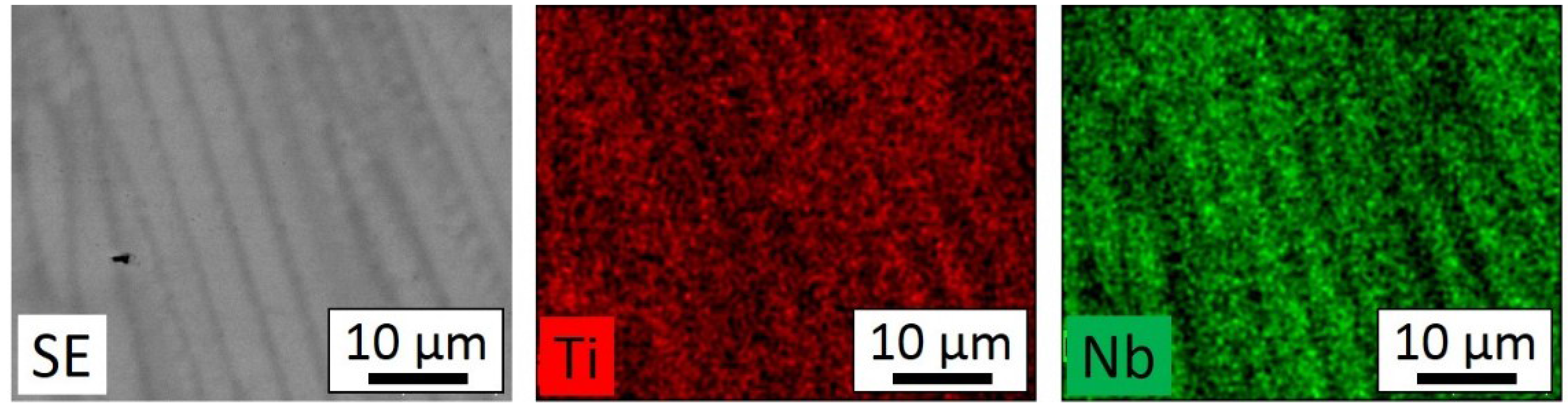

3.2.1. Microstructure

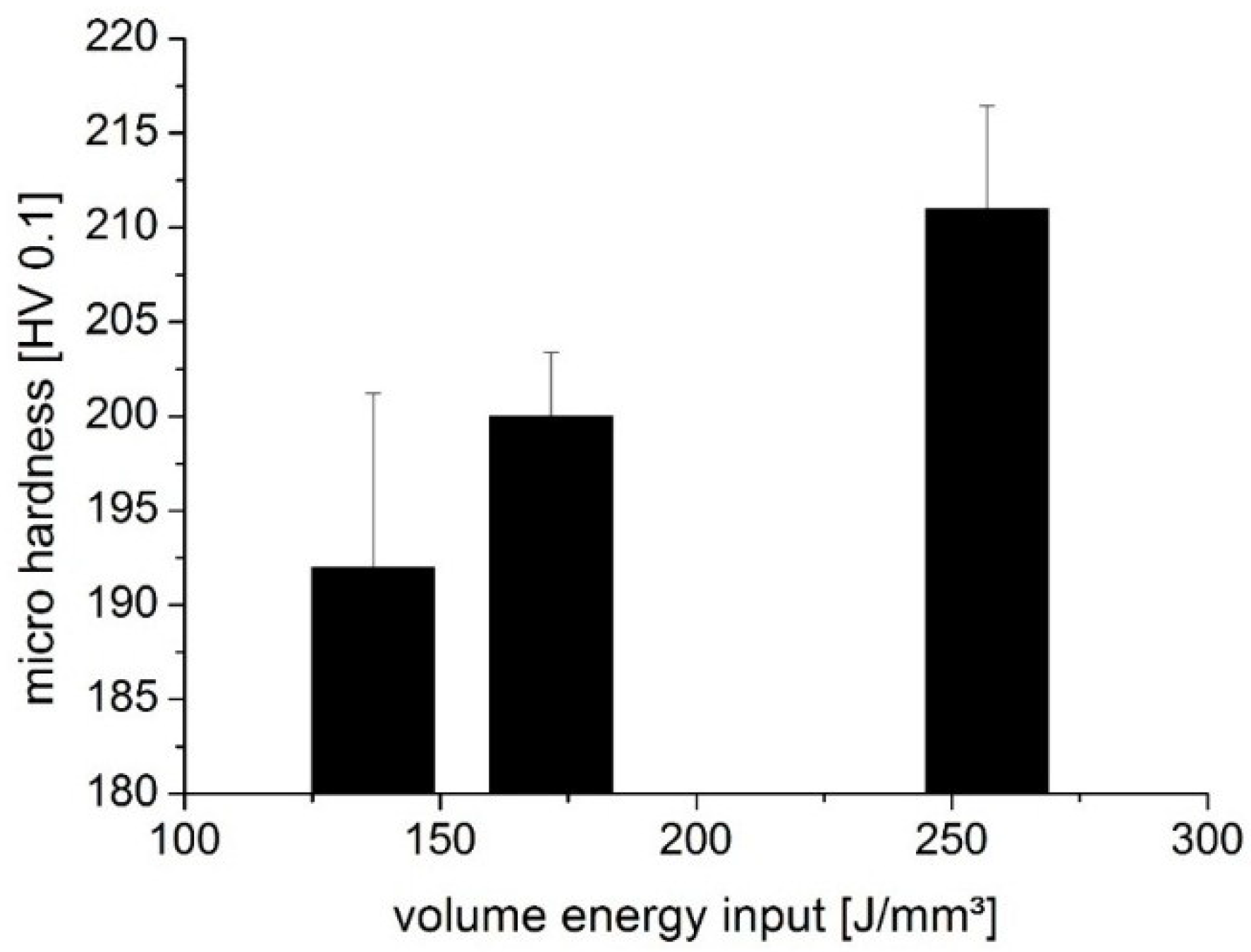

3.2.2. Micro Hardness

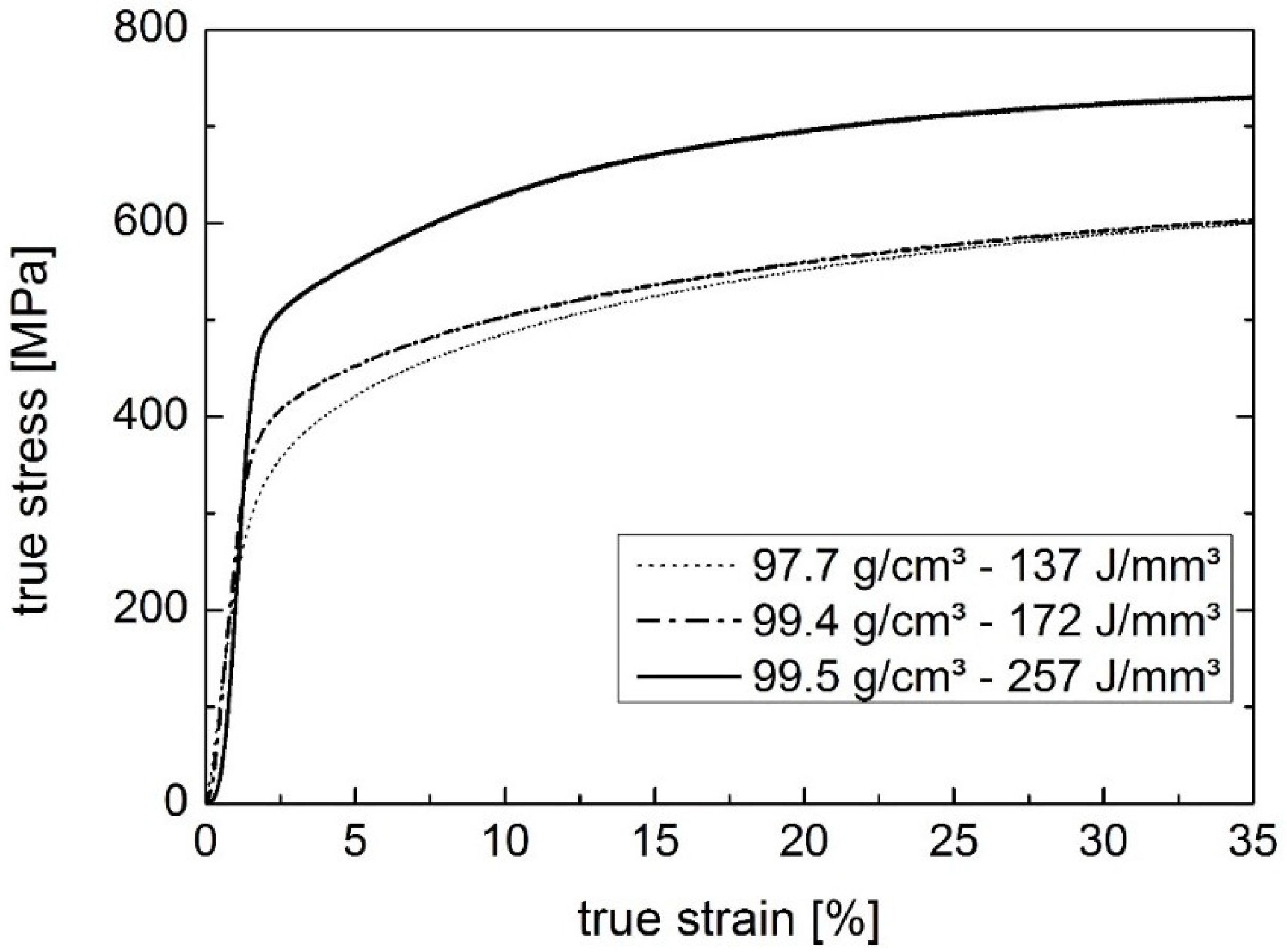

3.2.3. Compression Tests

4. Conclusions

Author Contributions

Conflicts of Interest

References

- Epple, M. Biomaterialien und Biomineralisation. Eine Einführung für Naturwissenschaftler, Mediziner und Ingenieure; Springer: Wiesbaden, Germany, 2003. [Google Scholar]

- Calin, M.; Helth, A.; Gutierrez Moreno, J.J.; Bönisch, M.; Brackmann, V.; Giebeler, L.; Gemming, T.; Lekka, C.E.; Gebert, A.; Schnettler, R.; et al. Elastic softening of β-type Ti–Nb alloys by indium (In) additions. J. Mechan. Behav. Biomed. Mater. 2014, 39, 162–174. [Google Scholar]

- Niinomi, M.; Nakai, M.; Hieda, J. Development of new metallic alloys for biomedical applications. Acta Biomater. 2012, 8, 3888–3903. [Google Scholar] [CrossRef]

- Haase, K.; Rouhi, G. Prediction of stress shielding around an orthopedic screw: Using stress and strain energy density as mechanical stimuli. Computers Biol. Med. 2013, 43, 1748–1757. [Google Scholar] [CrossRef]

- Zhuravleva, K.; Bönisch, M.; Scudino, S.; Calin, M.; Schultz, L.; Eckert, J.; Gebert, A. Phase transformations in ball-milled Ti–40Nb and Ti–45Nb powders upon quenching from the β-phase region. Powder Technol. 2014, 253, 166–171. [Google Scholar] [CrossRef]

- Hanada, S.; Matsumoto, H.; Watanabe, S. Mechanical compatibility of titanium implants in hard tissues. Int. Congress Ser. 2005, 1284, 239–247. [Google Scholar] [CrossRef]

- Peters, M.; Leyens, C. Titan und Titanlegierungen; Wiley-VCH Verlag GmbH: Weinheim, Germany, 2002. [Google Scholar]

- ATI 45Nb™ Alloy, Technical Data Sheet. Available online: https://www.atimetals.com/Documents/ti-45nb_tds_en_v1.pdf (accessed on 24 April 2015).

- Gostin, P.F.; Helth, A.; Voss, A.; Sueptitz, R.; Calin, M.; Eckert, J.; Gebert, A. Surface treatment, corrosion behavior, and apatite-forming ability of Ti-45Nb implant alloy. J. Biomed. Mater. Res. 2013, 101B, 269–278. [Google Scholar] [CrossRef]

- Chen, Y.; Li, J.; Tang, B.; Kou, H.; Zhang, F.; Chang, H.; Zhou, L. Grain boundary character distribution and texture evolution in cold-drawn Ti–45Nb wires. Mater. Lett. 2013, 98, 254–257. [Google Scholar] [CrossRef]

- Handtrack, D. Herstellung, Gefüge und Eigenschaften Nanokristalliner und Dispersionsverfestigter Titanwerkstoff; Shaker: Aachen, Germany, 2008. [Google Scholar]

- Prashanth, K.G.; Shakur Shahabi, H.; Attar, H.; Srivastava, V.C.; Ellendt, N.; Uhlenwinkel, V.; Eckert, J.; Scudino, S. Production of high strength Al85Nd8Ni5Co2 alloy by selective laser melting. Addit. Manuf. 2015, 6, 1–5. [Google Scholar] [CrossRef]

- Kruth, J.-P.; Froyen, L.; van Vaerenbergh, J.; Mercelis, P.; Rombouts, M.; Lauwers, B. Selective laser melting of iron-based powder. J. Mater. Process. Technol. 2004, 149, 616–622. [Google Scholar] [CrossRef]

- Zhang, B.; Dembinski, L.; Coddet, C. The study of the laser parameters and environment variables effect on mechanical properties of high compact parts elaborated by selective laser melting 316l powder. Mater. Sci. Eng. A 2013, 584, 21–31. [Google Scholar] [CrossRef]

- Prashanth, K.G.; Scudino, S.; Klauss, H.J.; Surreddi, K.B.; Löber, L.; Wang, Z.; Chaubey, A.K.; Kühn, U.; Eckert, J. Microstructure and mechanical properties of Al–12Si produced by selective laser melting: Effect of heat treatment. Mater. Sci. Eng. A 2014, 590, 153–160. [Google Scholar] [CrossRef]

- Löber, L.; Schimansky, F.P.; Kühn, U.; Pyczak, F.; Eckert, J. Selective laser melting of a beta-solidifying TNM-B1 titanium aluminide alloy. J. Mater. Process. Technol. 2014, 214, 1852–1860. [Google Scholar] [CrossRef]

- Yadroitsev, I.; Smurov, I. Selective laser melting technology: From the single laser melted track stability to 3D parts of complex shape. Phys. Procedia 2010, 5, 551–560. [Google Scholar] [CrossRef]

- Biamino, S.; Penna, A.; Ackelid, U.; Sabbadini, S.; Tassa, O.; Fino, P.; Pavese, M.; Gennaro, P.; Badini, C. Electron beam melting of Ti–48Tl–2Tr–2Tb alloy: Microstructure and mechanical properties investigation. Intermetallics 2011, 19, 776–781. [Google Scholar]

- Ardila, L.C.; Garciandia, F.; González-Díaz, J.B.; Álvarez, P.; Echeverria, A.; Petite, M.M.; Deffley, R.; Ochoa, J. Effect of IN718 recycled powder reuse on properties of parts manufactured by means of selective laser melting. Phys. Procedia 2014, 56, 99–107. [Google Scholar] [CrossRef]

- Yadroitsev, I.; Krakhmalev, P.; Yadroitsava, I.; Johansson, S.; Smurov, I. Energy input effect on morphology and microstructure of selective laser melting single track from metallic powder. J. Mater. Process. Technol. 2013, 213, 606–613. [Google Scholar] [CrossRef]

- Thijs, L.; Kempen, K.; Kruth, J.-P.; van Humbeeck, J. Fine-structured aluminium products with controllable texture by selective laser melting of pre-alloyed AlSi10Mg powder. Acta Mater. 2013, 61, 1809–1819. [Google Scholar] [CrossRef]

- Su, X.; Yang, Y. Research on track overlapping during selective laser melting of powders. J. Mater. Process. Technol. 2012, 212, 2074–2079. [Google Scholar] [CrossRef]

- Kanagarajah, P.; Brenne, F.; Niendorf, T.; Maier, H.J. Inconel 939 processed by selective laser melting: Effect of microstructure and temperature on the mechanical properties under static and cyclic loading. Mater. Sci. Eng. A 2013, 588, 188–195. [Google Scholar]

- Ma, P.; Prashanth, K.; Scudino, S.; Jia, Y.; Wang, H.; Zou, C.; Wei, Z.; Eckert, J. Influence of annealing on mechanical properties of Al-20Si processed by selective laser melting. Metals 2014, 4, 28–36. [Google Scholar] [CrossRef]

- Kruth, J.-P.; Badrossamay, M.; Yasa, E.; Deckers, J.; Thijs, L.; van Humbeeck, J. Part and material properties in selective laser melting of metals. In Proceedings of the 16th International Symposium on Electromachining, Shanghai, China, 19–23 April 2010.

- Attar, H.; Prashanth, K.G.; Chaubey, A.K.; Calin, M.; Zhang, L.C.; Scudino, S.; Eckert, J. Comparison of wear properties of commercially pure titanium prepared by selective laser melting and casting processes. Mater. Lett. 2015, 142, 38–41. [Google Scholar] [CrossRef]

- Attar, H.; Calin, M.; Zhang, L.C.; Scudino, S.; Eckert, J. Manufacture by selective laser melting and mechanical behavior of commercially pure titanium. Mater. Sci. Eng. A 2014, 593, 170–177. [Google Scholar] [CrossRef]

- Ozaki, T.; Matsumoto, H.; Watanabe, S.; Hanada, S. Beta Ti alloys with low Young’s modulus. Mater. Trans. 2004, 45, 2776–2779. [Google Scholar] [CrossRef]

- Hon, Y.-H.; Wang, J.-Y.; Pan, Y.-N. Composition/phase structure and properties of Titanium-Niobium alloys. Mater. Trans. 2003, 44, 2384–2390. [Google Scholar] [CrossRef]

© 2015 by the authors; licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution license (http://creativecommons.org/licenses/by/4.0/).

Share and Cite

Schwab, H.; Prashanth, K.G.; Löber, L.; Kühn, U.; Eckert, J. Selective Laser Melting of Ti-45Nb Alloy. Metals 2015, 5, 686-694. https://doi.org/10.3390/met5020686

Schwab H, Prashanth KG, Löber L, Kühn U, Eckert J. Selective Laser Melting of Ti-45Nb Alloy. Metals. 2015; 5(2):686-694. https://doi.org/10.3390/met5020686

Chicago/Turabian StyleSchwab, Holger, Konda Gokuldoss Prashanth, Lukas Löber, Uta Kühn, and Jürgen Eckert. 2015. "Selective Laser Melting of Ti-45Nb Alloy" Metals 5, no. 2: 686-694. https://doi.org/10.3390/met5020686

APA StyleSchwab, H., Prashanth, K. G., Löber, L., Kühn, U., & Eckert, J. (2015). Selective Laser Melting of Ti-45Nb Alloy. Metals, 5(2), 686-694. https://doi.org/10.3390/met5020686