1. Introduction

With the rapid advancement of modern industry, mechanical equipment is evolving toward higher power and heavier loads, while service environments continue to deteriorate. Components operating under high-temperature and high-pressure conditions are often subject to damage. Wear, corrosion, and fatigue are the three most common forms of component failure, leading to significant economic losses. The microstructure and properties of metallic materials are directly related to their failure mechanisms. To prevent the premature failure of components, various surface engineering techniques have been employed, including plasma spraying, chemical vapor deposition, and physical vapor deposition [

1,

2,

3,

4,

5,

6]. The application of these surface engineering techniques effectively mitigates component damage, enhances material utilization, and reduces economic losses.

Laser cladding is a surface modification technique that employs a high-energy density laser beam as a heat source to rapidly melt powders with specific properties onto the surface of a substrate, forming a protective or functional coating [

7,

8,

9]. The resulting cladding layer establishes a strong metallurgical bond with the substrate through the processes of melting and solidification. This bond exhibits a strength comparable to, or even exceeding, that of the base material—significantly superior to the mechanical bonding seen in conventional surface treatment methods such as thermal spraying and electroplating [

10,

11]. As a result, the coating demonstrates excellent adhesion and is resistant to delamination under harsh operating conditions. During the laser cladding process, the laser energy is highly concentrated and applied over a short duration, resulting in low heat input to the substrate. This minimizes the risk of thermal deformation and grain coarsening, which are common issues associated with high-temperature processing. Laser cladding is particularly well-suited for the repair and localized strengthening of precision components. By precisely adjusting key processing parameters, such as the laser power, scanning speed, and powder feeding rate, the original characteristics of the powder materials can be largely preserved [

12,

13]. Commonly used powders include self-fluxing alloy powders, ceramic particles, and various composite materials. The composition of the powders can be flexibly tailored to meet specific functional requirements, enabling the fabrication of customized coatings. The laser beam offers micrometer-level positioning accuracy, allowing for the precise treatment of localized areas and even the surface modification of complex geometries. When integrated with CNC systems and robotic arms, laser cladding can be fully automated, making it ideal for large-scale production and the thermal processing of intricate structural components [

14]. Furthermore, laser cladding can be combined with additive manufacturing technologies to enable integrated rapid prototyping and component repair [

15]. Compared to replacing an entire part, laser cladding allows for the direct restoration and reinforcement of worn or damaged surfaces. This process achieves a material utilization rate of over 95%, significantly reducing resource consumption and production costs. Additionally, the process offers strong controllability and a low scrap rate. Laser cladding has been widely adopted in industries such as aerospace, energy and power, mold manufacturing, automotive production, and petrochemicals. It is especially advantageous for the remanufacturing of high value-added components [

16]. With ongoing advancements in laser technology, powder preparation, and intelligent control systems, the applications of laser cladding are expected to continue to expand, driving further innovation and evolution within the manufacturing sector.

In recent years, biomimetic engineering has introduced innovative solutions to improve material performance by imitating the unique structures, functions, and behaviors of living organisms. For example, the radial ribs on shell surfaces play a crucial role in enhancing wear resistance. These ribs help shells disperse and absorb energy when subjected to sediment and water flow impacts, thereby reducing direct damage. The diverse structural characteristics of shells allow them to maintain their integrity and functionality in complex natural environments over long periods. They also improve impact toughness, making shells more resistant to breaking or deformation under external forces, which further enhances their wear resistance. Inspired by these natural structures, biomimetic designs based on shell radial ribs have been applied to various materials [

17,

18].

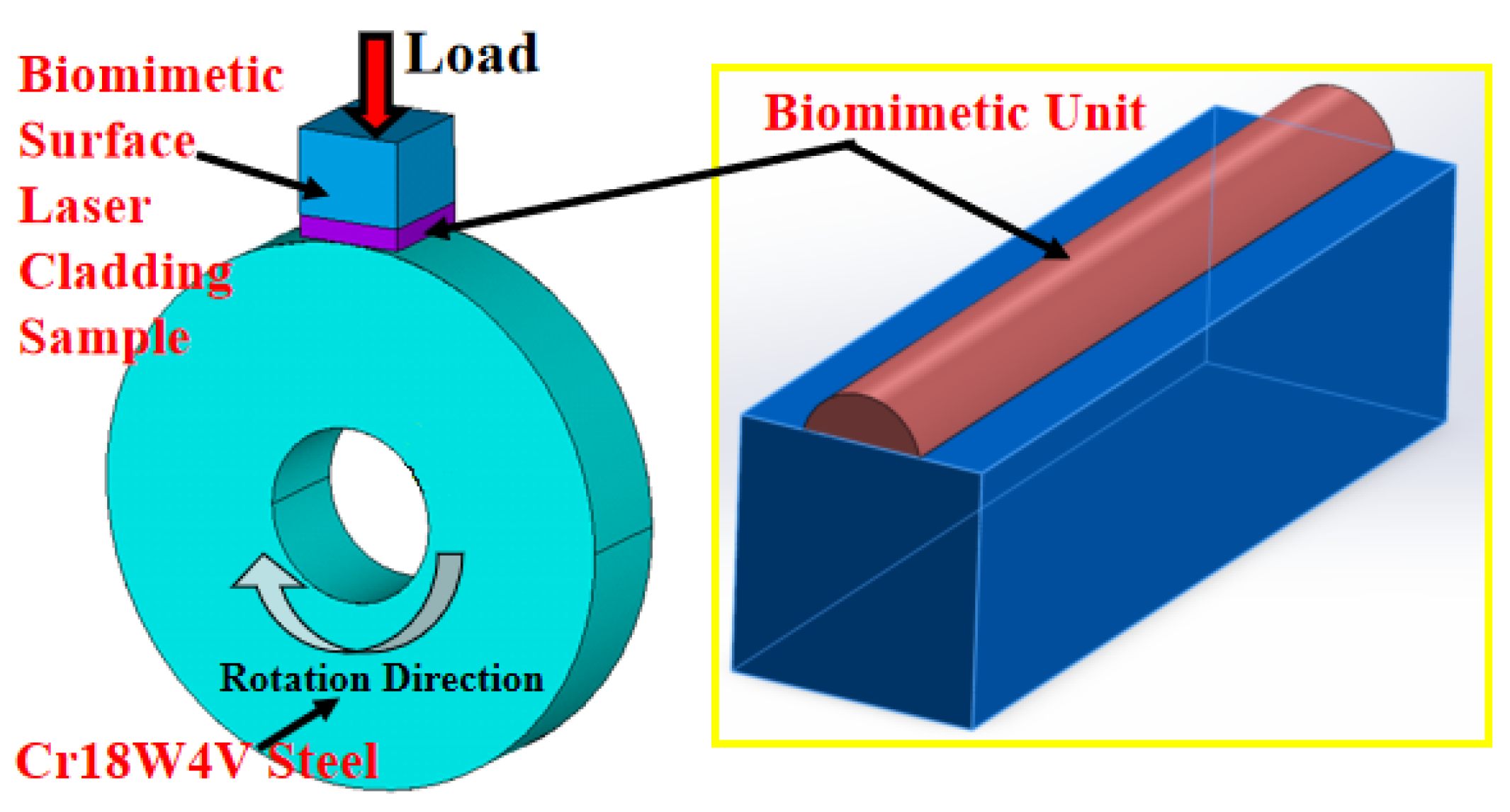

20CrMnTi steel is a widely used structural steel with excellent mechanical and processing properties, commonly employed in the automotive and tractor industries. It is particularly valued in the production of critical components such as gears, shafts, and pistons. However, under harsh working conditions, severe surface wear can compromise its performance, making it difficult to meet operational demands. In this paper, a composite powder composed of Ni60 alloy powder and tungsten carbide (WC) was used. Using laser cladding technology, a biomimetic unit was fabricated on the surface of 20CrMnTi steel to enhance its wear resistance and reliability. Size measurements, microstructure observations, hardness tests, and surface roughness analyses of the biomimetic unit were conducted to investigate the effect of different WC contents on its wear performance. This research aims to provide new insights and methods for advancing surface engineering technology for metallic materials.

2. Materials and Methods

2.1. Material and Laser Cladding

In this experiment, 20CrMnTi steel was used as the substrate. The particle size of Ni60 alloy powder was 320 mesh, while the WC powder had a particle size range of 60–200 mesh. The chemical composition of 20CrMnTi steel, Ni60 alloy powder, and WC is shown in

Table 1. Both the Ni60 alloy powder and WC powder had spherical shapes. The laser processing parameters were kept constant, with the WC content being the only variable.

Table 2 presents the laser processing parameters (Guangzhou Xingrui Laser Technology Co., Ltd., Guangdong, China), powder ratios, and sample numbers for each specimen. The laser cladding test was performed using a 3 kW high-power fiber laser. The laser processing method employed was coaxial powder feeding. Argon (Ar) gas was used as a protective atmosphere at a flow rate of 20 L/min to prevent material oxidation.

The reason for choosing WC instead of TiC or SiC as ceramic particles to be added to Ni60 alloy powder is as follows.

TiC was not chosen as the ceramic reinforcement for the Ni60 alloy powder for several reasons. Firstly, the self-fluxing elements present in Ni60 alloy significantly reduce the surface tension of the melt pool, thereby improving the wettability of the WC particles. The contact angle between liquid Ni60 alloy and WC is lower than that between Ni60 and TiC, indicating that WC has superior wettability. In contrast, TiC exhibits relatively poor wettability with Ni60 alloy, which results in the agglomeration and suspension of the TiC particles in the melt pool. Secondly, during the laser cladding process, some of the WC particles melt, releasing W and C atoms that react with elements such as Ni and Fe to form a variety of tough carbides. However, when TiC reacts with elements in the Ni60 alloy, brittle intermetallic compounds such as Ni3Ti are formed. These brittle phases weaken the metallurgical bond between the coating and the substrate, reducing the overall bonding strength. Thirdly, the reaction between WC and the Ni60 alloy leads to the formation of W2C, a carbide known for its good toughness, which helps mitigate coating embrittlement. In contrast, the interfacial reactions between TiC and Ni60 alloy tend to form brittle phases such as Ni3Ti and NiTi. These brittle compounds increase the likelihood of premature coating failure due to crack initiation and propagation.

SiC was not chosen as the reinforcing ceramic phase in Ni60 alloy powder for several key reasons. Firstly, although the melting point of SiC is comparable to that of WC, WC has a higher melting point than Ni60 alloy, enabling it to remain largely undissolved during the rapid melting and solidification process of laser cladding. This allows the WC particles to act as hard phases within the coating, significantly enhancing the wear resistance. In contrast, SiC tends to decompose in the nickel-based melt pool, leading to the formation of brittle phases such as Ni3Si. Additionally, free carbon released during SiC decomposition may react with nickel to form Ni3C, which contributes to reduced coating hardness and increased brittleness. Secondly, the thermal expansion mismatch between the ceramic particles and the metal matrix plays a critical role in coating reliability. WC and Ni60 alloy have relatively similar coefficients of thermal expansion, which minimizes interfacial thermal stress during cooling and reduces the risk of particle detachment or cracking. However, the thermal expansion mismatch between SiC and Ni60 alloy is significantly greater. This mismatch generates considerable thermal stress at the interface during cooling, leading to the formation of microcracks around SiC particles and even coating delamination, which severely compromises the bonding strength and structural integrity of the coating. Thirdly, the wettability of the ceramic particles by the molten matrix is crucial for achieving uniform dispersion and strong interfacial bonding. Liquid Ni60 alloy exhibits good wettability toward WC particles, allowing them to be evenly distributed in the melt pool via convection and facilitating metallurgical bonding with the substrate. In contrast, the wettability of SiC by liquid Ni60 alloy is relatively poor, making SiC particles more likely to agglomerate or float to the melt pool surface. As a result, SiC cannot be uniformly dispersed in the coating, leading to nonhomogeneous microstructures and compromised coating performance.

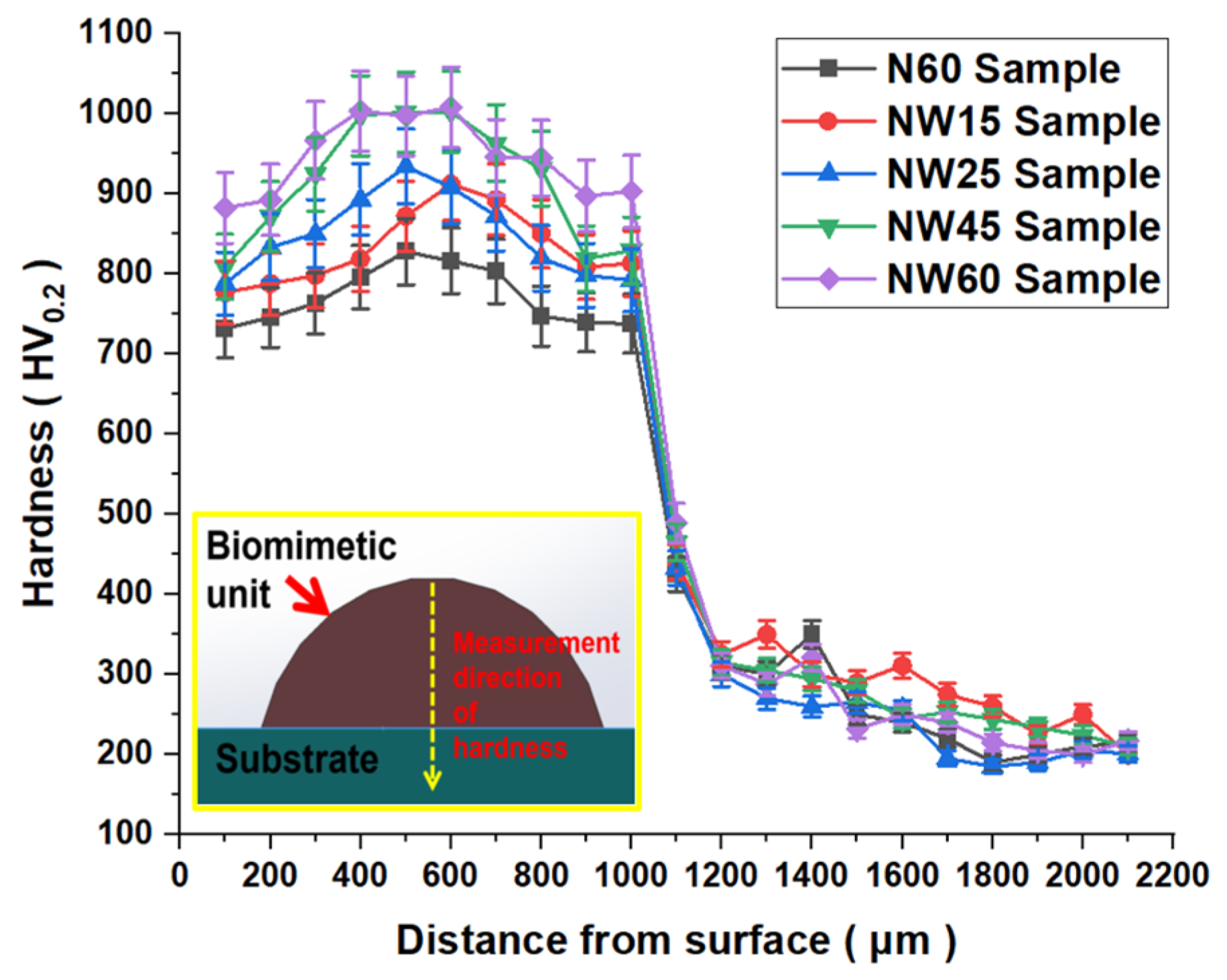

2.4. Hardness Measurement

Hardness profiling was performed using a Vickers hardness tester (Mitutoyo, Kawasaki, Kanagawa Prefecture, Japan). Measurements were taken along the depth direction using a pyramidal diamond indenter under a 200 gf load, with a dwell time of 10 s. A calibrated depth-step motor ensured precise indent spacing at 100 μm intervals along the cross-sectional gradient. To enhance measurement reliability, three measurements were taken at each depth station within a 50 μm lateral spacing. The reported hardness value represents the arithmetic mean of three valid impressions. To ensure accurate hardness measurements, approximately ten exploratory indentations and readings were typically performed. If significant discrepancies were observed between any two measurements, additional measurements were taken. This method increased the number of random samples, thereby minimizing measurement error and enhancing the reliability of the hardness data. In the hardness measurement of the biomimetic unit, the depth direction referred to the vertical axis extending from the surface of the biomimetic unit into the substrate. Hardness values were measured point by point along this direction to analyze the variation in hardness across the cross-section of the biomimetic unit.

Prior to performing hardness measurements and microstructural observations, the biomimetic unit must undergo meticulous sample preparation. This process involved four main steps: “wire cutting”, “embedding and fixing”, “grinding and polishing”, and “etching”. The objective of these steps was to obtain a flat, scratch-free, and clean cross-section suitable for precise testing. The detailed procedures are as follows.

Wire Cutting: The sample was cut using a slow wire cutting method (cutting speed ≤ 5 mm/min) along a direction perpendicular to the laser scanning path. A specialized cutting fluid was used throughout the process to thoroughly cool the cutting area, minimizing thermal damage and ensuring a smooth surface. After cutting, the surface was cleaned with anhydrous ethanol to remove oil residues and metal debris.

Embedding and Fixing: The cut surface of the biomimetic unit was placed face-down into the mold of the embedding machine. Phenolic resin particles were used to fill the mold. The embedding process was carried out at a temperature of 150 °C and a pressure of 15 MPa, which was maintained for 15 min. After the sample had cooled, it was demolded to obtain the embedded specimen.

Grinding and Polishing: This step included rough grinding, fine grinding, and fine polishing. Its purpose was to remove the damaged surface layer caused by cutting and embedding, ultimately producing a flat, mirror-like cross-section free of scratches. Rough grinding used diamond grinding discs with particle sizes ranging from 180 # to 600 #. The embedded sample was held by hand, placed on a diamond grinding disc, and pressed evenly downward. Grinding must be performed in a single direction to avoid random scratches that can result from circular motion. Before replacing each type of diamond grinding disc, it was necessary to rinse the sample with clean water and to clean the embedded sample with ultrasonic waves for 5 min to prevent secondary scratches caused by residual coarse particles. The surface of the sample was observed under a microscope until the wire cutting marks on the surface of the sample were completely removed and a bright metallic luster appeared. Diamond sandpaper with a particle size of 800–2000 # was used for fine grinding. Every time the sandpaper was replaced, the grinding direction of the sample needed to be rotated 90 ° to facilitate the removal of scratches left by the previous grinding. In the polishing step, diamond suspension with a particle size of 5 μm and a polishing cloth were used. The speed of the polishing machine was 200 rpm. The polishing time was 10 min. The sample was gently pressed until the surface had a mirror-like state. There were no visible scratches. Then, the sample could be subjected to hardness testing.

Etching: If microstructural observation is to be conducted using scanning electron microscopy (SEM), the sample must undergo an etching process. This involved using cotton swabs soaked in aqua regia to gently wipe the polished surface of the sample. The etching duration was 30 s. After etching, the polished surface should be immediately rinsed with clean water, followed by dehydration using anhydrous ethanol. Finally, the sample was dried using cold air.

4. Conclusions

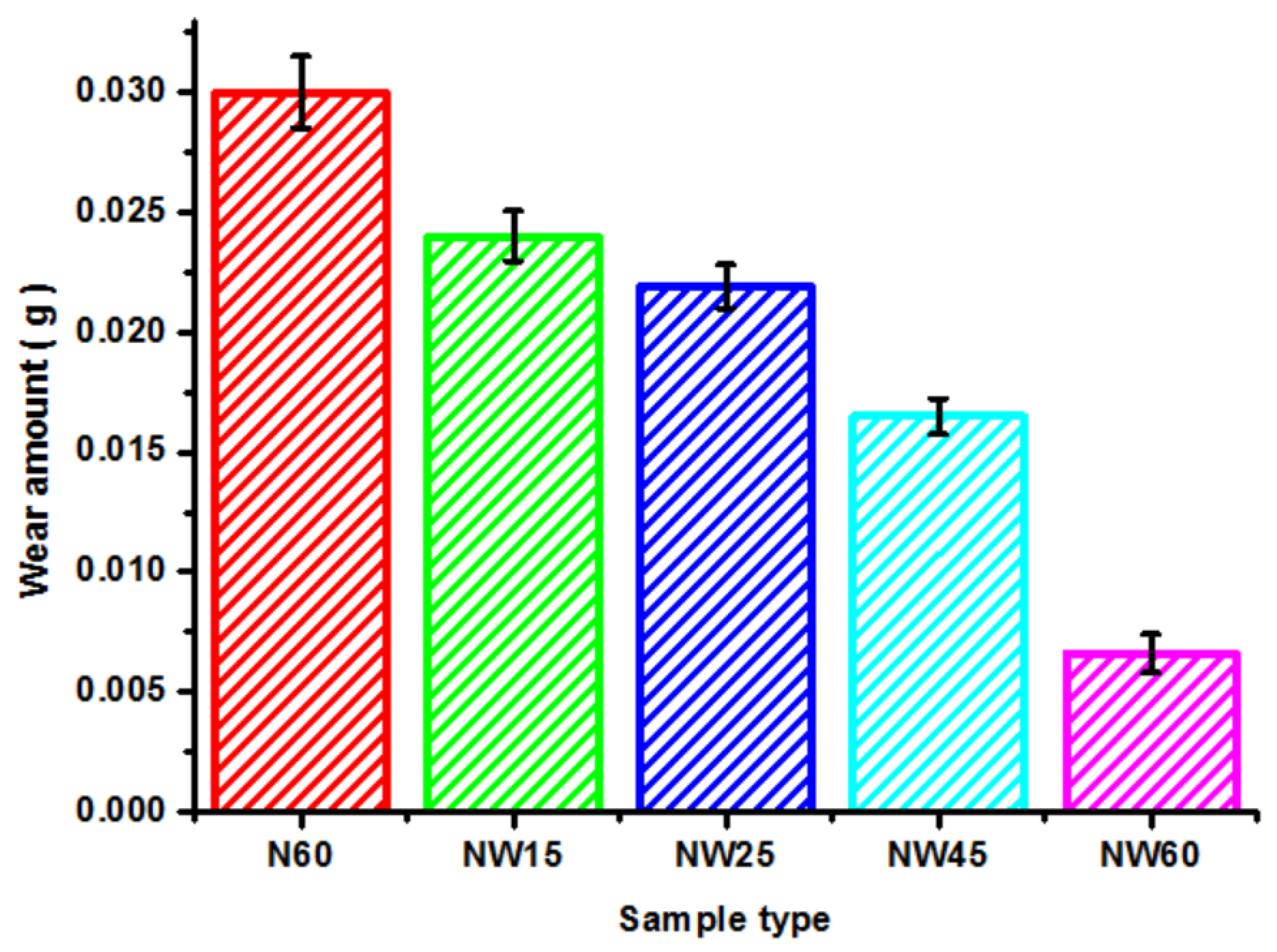

In this paper, laser cladding was used to prepare biomimetic units on 20CrMnTi steel, inspired by the radial ribs of the shell surface morphology, aiming to improve its wear performance. The influence of the WC content on the microstructure, hardness, surface roughness, and wear performance of biomimetic units was studied. The following main conclusions were drawn:

The WC content significantly affected the width and height of the biomimetic units. When the WC content reached 25% and 45%, the width of the biomimetic unit stabilized at 4595.82 μm and 4580.25 μm, respectively. The presence of unmelted WC as a second phase increased the viscosity of the liquid metal, thereby limiting the lateral expansion of the molten pool. At a high WC content, the accumulated unmelted WC formed a hard barrier, hindering the flow of liquid metal and limiting the overall growth of biomimetic units.

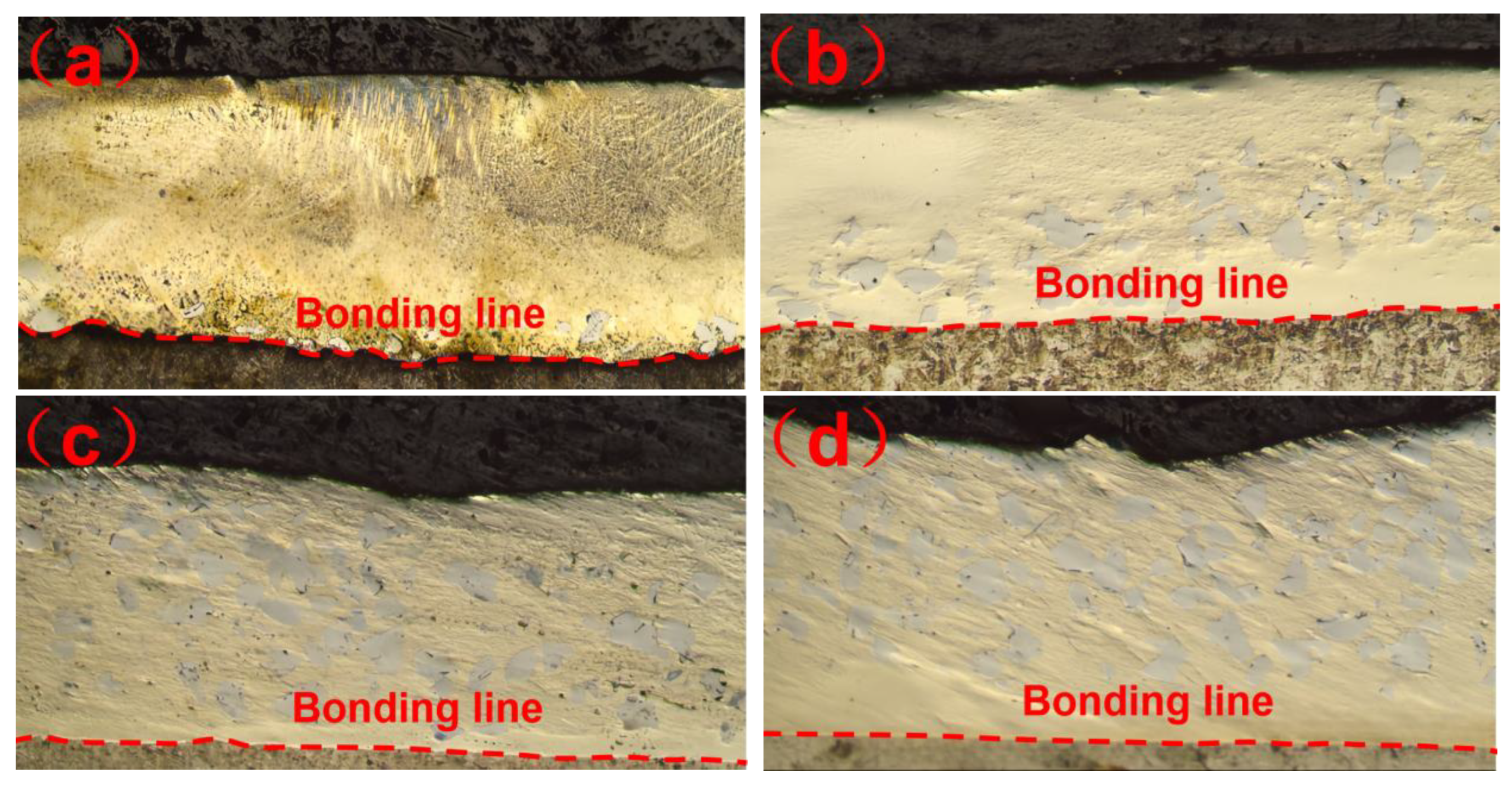

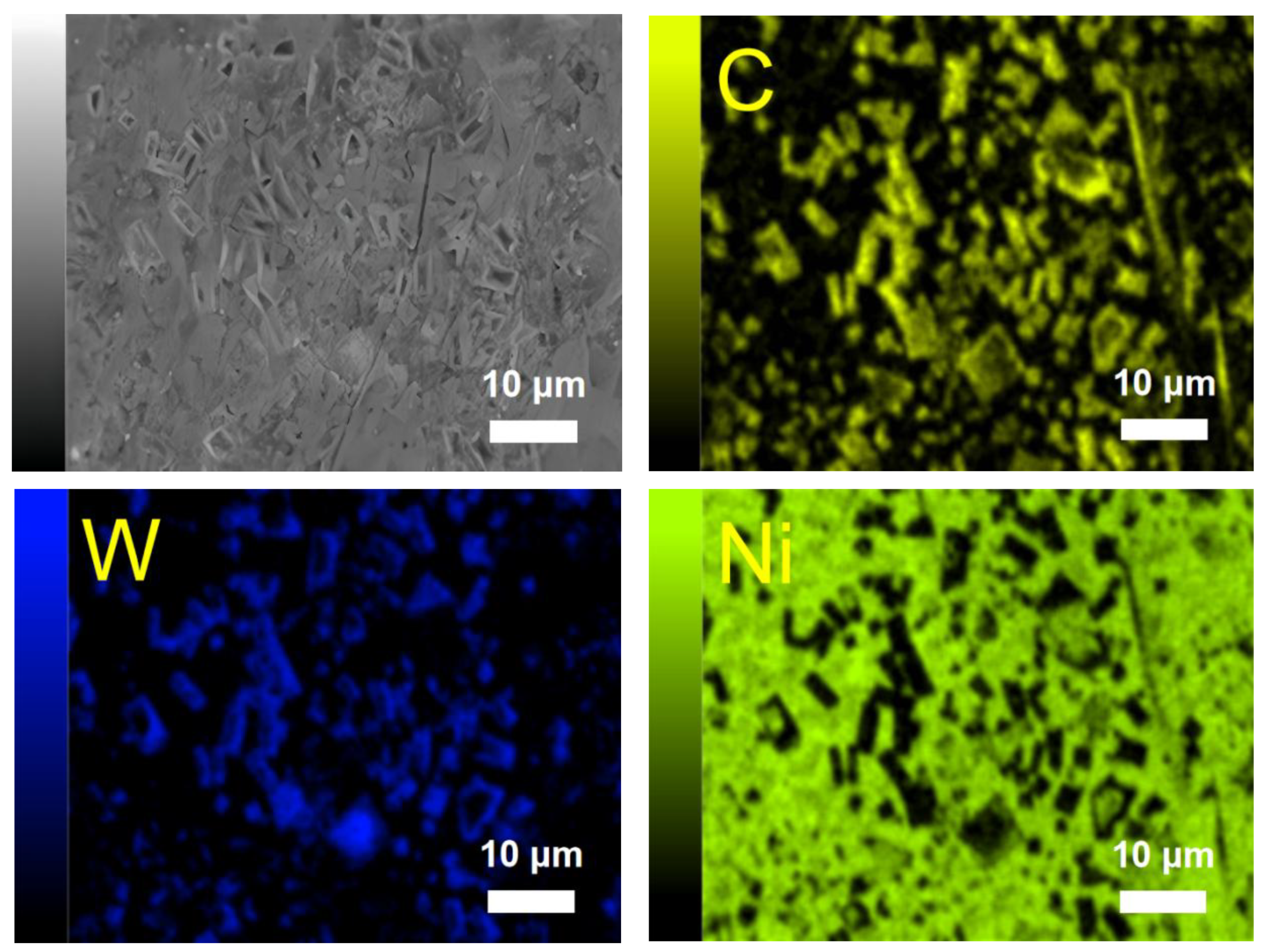

The microstructure of the upper and middle parts of the biomimetic unit was composed of equiaxed crystals and dendritic crystals, respectively. At a low WC content, coarse equiaxed grains and dendrites were formed. As the WC content increased, unmelted WC particles began to disperse throughout the entire melt pool. The WC particles acted as heterogeneous nucleation sites, promoting non-uniform nucleation and refining the grain size of the biomimetic units.

As the WC content increased, the hardness value continued to increase. When the WC content was 15%, the hardness range of the biomimetic unit was 777 HV0.2 to 912 HV0.2. When the WC content was 60%, the hardness range was 882 HV0.2 to 1008 HV0.2. The maximum hardness of each sample was observed in the subsurface layer of the biomimetic unit, and the hardness decreased sharply with increasing depth.

At a low WC content, the WC particles had little effect on the surface roughness. With the increase in the WC content, the viscosity of the melt pool increased, resulting in uneven cooling and solidification, thus increasing the surface roughness of the biomimetic unit.

The wear mechanism of the N60 biomimetic unit was abrasive wear and oxidative wear. Adding WC to the nickel-based alloy powder changed the wear mechanism of the biomimetic units, namely, to adhesive wear, abrasive wear, and oxidative wear. As the WC content increased, the friction coefficient of the biomimetic unit initially showed a downward trend, followed by an upward trend. As the WC content increased, the hardness of the biomimetic unit increased, leading to a gradual reduction in wear. WC, as a hard phase, enhanced the strength and wear performance of biomimetic units.

Author Contributions

Methodology, B.C. and Y.L.; software, Z.S.; validation, Y.T.; data curation, Z.S. and Y.T.; writing—original draft, B.C.; writing—review and editing, Y.L. and B.C.; supervision, Z.S.; project administration, Y.L.; funding acquisition, Y.T. All authors have read and agreed to the published version of the manuscript.

Funding

This work was supported by the Natural Science Foundation of Jilin Province (Key Project of Free Exploration (Stable Support Project)) (No. YDZJ202401392ZYTS).

Data Availability Statement

The raw data supporting the conclusions of this article will be made available by the authors on request.

Conflicts of Interest

The authors declare no conflicts of interest.

References

- Reddy, G.; Madhu, S.; Prasad, C.D.; Kumar, B.K.P.; Sollapur, S.B. Investigation of hot corrosion behavior of plasma sprayed cermet composite coatings on titanium and special steel alloys. Surf. Coat. Technol. 2025, 499, 131883. [Google Scholar] [CrossRef]

- Alam, M.S.; Das, A.K. Surface morphological studies on hot corrosion behaviour of pre-oxidized plasma sprayed WC-CoCr coating on AISI316L steel in Na2SO4/NaCl molten salt environment. Phys. Scr. 2025, 100, 15943. [Google Scholar] [CrossRef]

- Mallick, R.; Kumar, R.; Panda, A.; Sahoo, A.K. A Novel Application of MgO Nano-cutting Fluid in Hardened AISI D2 Steel Machining Using a Chemical Vapor Deposition-Coated Carbide Tool. J. Mater. Eng. Perform. 2025, 34, 330–355. [Google Scholar] [CrossRef]

- Meysami, A.; Najafabadi, R.A.; Yosefnejad, T. Enhancing Wear Behavior and Hardness of D5 Cold Work Tool Steel through TiCrN Multilayer Nanocoating via Physical Vapor Deposition. Surf. Eng. Appl. Electrochem. 2024, 60, 58–68. [Google Scholar] [CrossRef]

- Locks, E.; He, Q.X.; Depaiva, J.M.; Guimaraes, M. Investigating the Impact of Physical Vapour Deposition (PVD)-Coated Cutting Tools on Stress Corrosion Cracking Susceptibility in Turning Super Duplex Stainless Steel. Coatings 2024, 14, 290. [Google Scholar] [CrossRef]

- Aktas, C.G.; Fountas, K.; Atapek, S.H.; Polat, S. Investigation of the Nitriding Effect on the Adhesion and Wear Behavior of CrN-, AlTiN-, and CrN/AlTiN-Coated X45CrMoV5-3-1 Tool Steel Formed Via Cathodic Arc Physical Vapor Deposition. Lubricants 2024, 12, 170. [Google Scholar] [CrossRef]

- Rafiei, J.; Ghasemi, A.R. Experimental Study of Stainless-Steel Nanoparticles Coating on Carbon Steel Using the Laser Cladding Approach. Mech. Compos. Mater. 2025, 60, 1183–1194. [Google Scholar] [CrossRef]

- Chen, X.; Wang, J.L.; Ke, D.W.; Wen, K. Numerical simulation and structure properties of laser clad 316 L stainless steel coating. Appl. Phys. A Mater. Sci. Process. 2025, 131, 111. [Google Scholar] [CrossRef]

- Zu, H.Y.; Liu, Y.P.; Chen, S.H.; Jin, X.; Ye, W.D. Forming Process Prediction Model and Application of Laser Cladding for Remanufactured Screw Pump Rotors. Materials 2025, 18, 1673. [Google Scholar] [CrossRef]

- Hu, K.X.; Huang, Q.Y.; Wang, L.; Zhou, Y.; Li, W.D. Optimization of multi-track, multi-layer laser cladding process parameters using Gaussian process regression and improved multi-objective particle swarm optimization. Int. J. Adv. Manuf. Technol. 2025, 137, 3503–3523. [Google Scholar] [CrossRef]

- Lu, D.; Cui, X.C.; Zhang, J.W. Microstructure and properties of high entropy alloy coating obtained by laser cladding. Sci. Rep. 2025, 15, 7357. [Google Scholar] [CrossRef] [PubMed]

- Liu, Z.B.; Han, C.H.; Cao, X.J.; Guo, J.; Li, H.X.; Lin, Y.J.; Yang, J. Microstructure and wear behavior of AISI 316L austenitic stainless steel coating fabricated by laser cladding and plasma nitriding. Mater. Lett. 2025, 383, 137951. [Google Scholar] [CrossRef]

- Wang, J.Y.; Cui, X.F.; Zhao, Y.; Zhang, Y.; Jin, G.; Feng, C.C. Microstructure and corrosion performance of Fe-based composite layer doped modification with Ti6Al4V fabricated by underwater wet laser cladding. Mater. Today Commun. 2025, 44, 111875. [Google Scholar] [CrossRef]

- Gan, R.; Liu, Z.D.; Kong, Y.; Chang, Y.R.; Shen, Y.; Li, J.X.; Ning, H.Q. Preparation and properties of Cu/Cu-Sn alloy cladding layers on titanium alloy by laser cladding. J. Alloy. Compd. 2025, 1020, 179547. [Google Scholar] [CrossRef]

- Xu, Y.H.; Wang, D.Z.; Wu, S.J.; Lu, H.X.; Yao, R.; Yang, J.; Jiang, F.; Takao, A. Research progress on defect formation mechanism and process optimization of laser cladding high entropy alloy coatings. Opt. Laser Technol. 2025, 187, 112819. [Google Scholar] [CrossRef]

- Hou, J.X.; Jin, X.W.; Xu, J.W.; Ding, K.J.; Liu, F.H.; Li, Z.X. Investigation on the influence of particle size on the microstructure and properties of laser-cladded CuSn12 coatings. J. Laser Appl. 2025, 37, 022017. [Google Scholar] [CrossRef]

- Sui, Q.; Zhou, H.; Yang, L.; Zhang, H.F.; Peng, L.; Zhang, P. Couple of biomimetic surfaces with different morphologies for remanufacturing nonuniform wear rail surface. Opt. Laser Technol. 2018, 99, 333–341. [Google Scholar] [CrossRef]

- Cong, D.L.; Li, Z.S.; He, Q.B.; Chen, D.J.; Chen, H.B. Effect of unit size on thermal fatigue behavior of hot work steel repaired by a biomimetic laser remelting process. Opt. Laser Technol. 2018, 98, 205–213. [Google Scholar] [CrossRef]

- Chuang, H.; Fan, W.; Liu, Z.C.; Kong, D.J. Effect of laser scanning speed on microstructure and corrosive-wear performance of Ni-60%WC coating in Wusu mine water. Ind. Lubr. Tribol. 2023, 75, 698–705. [Google Scholar] [CrossRef]

- Cao, Q.Z.; Fan, L.; Chen, H.Y.; Hou, Y.; Dong, L.H.; Ni, Z.W. Wear behavior of laser cladded WC-reinforced Ni-based coatings under low temperature. Tribol. Int. 2022, 176, 107939. [Google Scholar] [CrossRef]

- Wei, Y.C.; Feng, A.X.; Chen, C.L.; Shang, D.Z.; Pan, X.M.; Xue, J.J. Effects of Laser Remelting on Microstructure, Wear Resistance, and Impact Resistance of Laser-Clad Inconel625-Ni/WC Composite Coating on Cr12MoV Stee. Coatings 2023, 13, 1039. [Google Scholar] [CrossRef]

- Cao, Q.Z.; Fan, L.; Chen, H.Y.; Hou, Y.; Dong, L.H.; Ni, Z.W. Wear and corrosion mechanisms of Ni-WC coatings modified with different Y2O3 by laser cladding on AISI 4145H steel. Sci. Eng. Compos. Mater. 2022, 29, 364–377. [Google Scholar] [CrossRef]

- Wang, X.G.; Qi, J.J.; Zhang, H.; Zhao, N.; Shao, Z.B.; Wang, S.Y. Study on Wear and Corrosion Resistance of Ni60/WC Coating by Laser Cladding on Reciprocating Pump Plunger: Comparison with Flame-Sprayed Plungers. Materials 2024, 17, 5183. [Google Scholar] [CrossRef] [PubMed]

- Zhang, X.S.; Wang, Q.Y.; Deng, Y.H.; Chai, H.; Hu, S.Y. Effect of microstructure and micromechanics on wear/wear-corrosion mechanism of laser-repaired Ni-WC coating. Eng. Fail. Anal. 2024, 162, 108837. [Google Scholar] [CrossRef]

- Li, Y.F.; Shi, Y.; Tang, S.F.; Wu, J.X.; Zhang, W.Z.; Wang, J.S. Effect of nano-WC on wear and impact resistance of Ni-based multi-layer coating by laser cladding. Int. J. Adv. Manuf. Technol. 2023, 128, 4253–4268. [Google Scholar] [CrossRef]

- Li, C.G.; Zhang, Q.S.; Wang, F.F.; Deng, P.R.; Lu, Q.H. Microstructure and wear behaviors of WC-Ni coatings fabricated by laser cladding under high frequency micro-vibration. Appl. Surf. Sci. 2019, 485, 513–519. [Google Scholar] [CrossRef]

- Feng, M.J.; Ma, Y.H.; Tian, Y.T.; Cao, H.T. Microstructure and Wear Resistance of Ti6Al4V Titanium Alloy Laser-Clad Ni60/WC Composite Coating. Materials 2024, 17, 264. [Google Scholar] [CrossRef]

- Weng, Z.K.; Wang, A.H.; Wu, X.H.; Wang, Y.Y.; Yang, Z.X. Wear resistance of diode laser-clad Ni/WC composite coatings at different temperatures. Surf. Coat. Technol. 2016, 304, 283–292. [Google Scholar] [CrossRef]

- Liu, Y.; Xu, T.H.; Liu, Y.; Gao, Y.L.; Di, C. Wear and heat shock resistance of Ni-WC coating on mould copper plate fabricated by laser. J. Mater. Res. Technol-JMRT 2020, 9, 8283–8288. [Google Scholar] [CrossRef]

- Yang, H.S.; Li, W.; Liu, Y.C.; Li, F.X.; Yi, J.H.; Eckert, J. The Microstructure and Properties of Ni60/60% WC Wear-Resistant Coatings Prepared by Laser-Directed Energy Deposition. Micromachines 2024, 15, 1071. [Google Scholar] [CrossRef]

- Tao, L.; Yang, Y.; Zhu, W.L.; Sun, J.; Wu, J.L. Stress Distribution in Wear Analysis of Nano-Y2O3 Dispersion Strengthened Ni-Based μm-WC Composite Material Laser Coating. Materials 2024, 17, 121. [Google Scholar] [CrossRef]

- Liu, Y.; Xu, T.H.; Li, G.H. Research on Wear and Corrosion Resistance of Ni60-WC Coating Fabricated by Laser on the Preheated Copper Alloy. Coatings 2022, 12, 1537. [Google Scholar] [CrossRef]

- Wu, X.Q.; Zhang, D.D.; Hu, Z. Microstructure and Wear Properties of Laser Cladding WC/Ni-Based Composite Layer on Al-Si Alloy. Materials 2021, 14, 5288. [Google Scholar] [CrossRef] [PubMed]

- Xu, J.S.; Zhang, X.C.; Xuan, F.Z.; Wang, Z.D.; Tu, S.T. Microstructure and Sliding Wear Resistance of Laser Cladded WC/Ni Composite Coatings with Different Contents of WC Particle. J. Mater. Eng. Perform. 2012, 21, 1904–1911. [Google Scholar] [CrossRef]

- Guo, C.; Zhou, J.S.; Chen, J.M.; Zhao, J.R.; Yu, Y.J.; Zhou, H.D. High temperature wear resistance of laser cladding NiCrBSi and NiCrBSi/WC-Ni composite coatings. Wear 2011, 270, 492–498. [Google Scholar] [CrossRef]

- Bao, Y.C.; Deng, J.X.; Cao, S.H.; Wang, J.Y.; Zhang, Z.H.; Lu, Y. High temperature wear performance of in-situ forming textured Ni60/WC/h-BN composite coatings based on laser micro-cladding. J. Mater. Res. Technol-JMRT 2024, 33, 3470–3481. [Google Scholar] [CrossRef]

- Chen, C.L.; Feng, A.X.; Wei, Y.C.; Wang, Y.; Pan, X.M.; Song, X.Y. Effects of WC particles on microstructure and wear behavior of laser cladding Ni60 composite coatings. Opt. Laser Technol. 2023, 163, 109425. [Google Scholar] [CrossRef]

- Guo, C.; Chen, J.M.; Zhou, J.S.; Zhao, J.R.; Wang, L.Q. Effects of WC-Ni content on microstructure and wear resistance of laser cladding Ni-based alloys coating. Surf. Coat. Technol. 2012, 206, 2064–2071. [Google Scholar] [CrossRef]

- Zhao, T.; Cai, X.; Wang, S.X.; Zheng, S. Effect of CeO2 on microstructure and corrosive wear behavior of laser-cladded Ni/WC coating. Thin Solid Films 2000, 379, 128–132. [Google Scholar]

- Zhao, N.; Tao, L.; Guo, H.; Zhang, M.Q. Effect of Ultra-fine WC Particles on Microstructural Evolution and Wear Behavior of Ni-Based Nano-CeO2 Coatings Produced by Laser. Rare Metal Mat. Eng. 2018, 47, 20–25. [Google Scholar]

- Zhu, Y.Q.; Shen, S.K.; Yang, X.F.; Song, F.; Dong, W.L.; Wang, Z.Y.; Wu, M. Study on the friction and wear performance of laser cladding WC-TiC/Ni60 coating on the working face of shield bobbing cutter. Opt. Mater. 2024, 148, 114875. [Google Scholar] [CrossRef]

- Farahmand, P.; Kovacevic, R. Corrosion and wear behavior of laser cladded Ni-WC coatings. Surf. Coat. Technol. 2015, 276, 112–135. [Google Scholar] [CrossRef]

- Huang, S.W.; Samandi, M.; Brandt, A. Abrasive wear performance and microstructure of laser clad WC/Ni layers. Wear 2004, 256, 1095–1105. [Google Scholar] [CrossRef]

- Wang, J.; Zhang, X.Q.; Qiao, L.; Zhao, Y.; Ren, M.F.; Li, T.T.; Li, R.F. A Comprehensive Study on Microstructure and Wear Behavior of Nano-WC Reinforced Ni60 Laser Coating on 17-4PH Stainless Steel. Coatings 2024, 14, 484. [Google Scholar] [CrossRef]

| Disclaimer/Publisher’s Note: The statements, opinions and data contained in all publications are solely those of the individual author(s) and contributor(s) and not of MDPI and/or the editor(s). MDPI and/or the editor(s) disclaim responsibility for any injury to people or property resulting from any ideas, methods, instructions or products referred to in the content. |

© 2025 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (https://creativecommons.org/licenses/by/4.0/).