The Role of Si Element on the Precipitation Behavior of GH2907 Superalloys

Abstract

1. Introduction

2. Experimental Section

3. Results

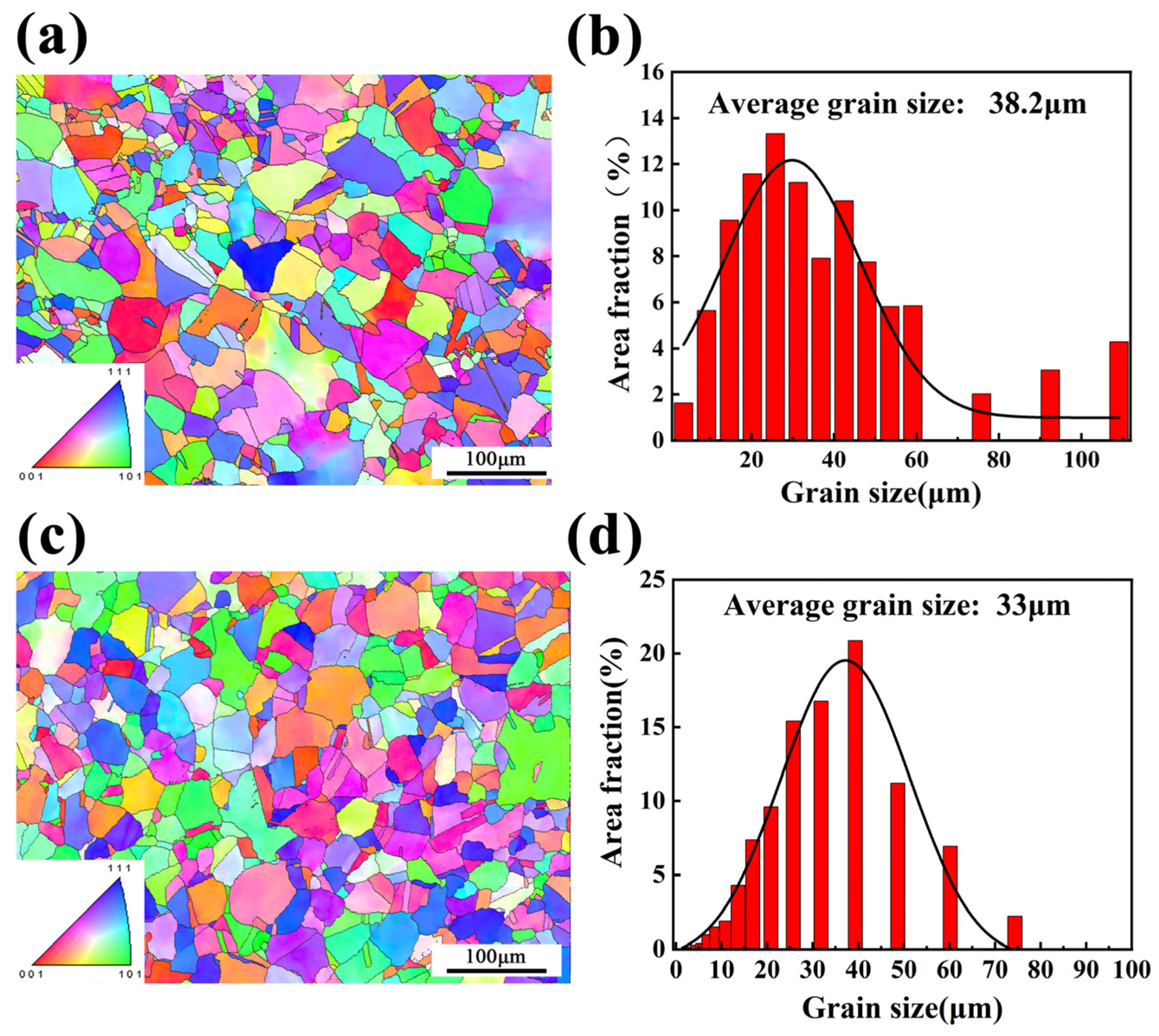

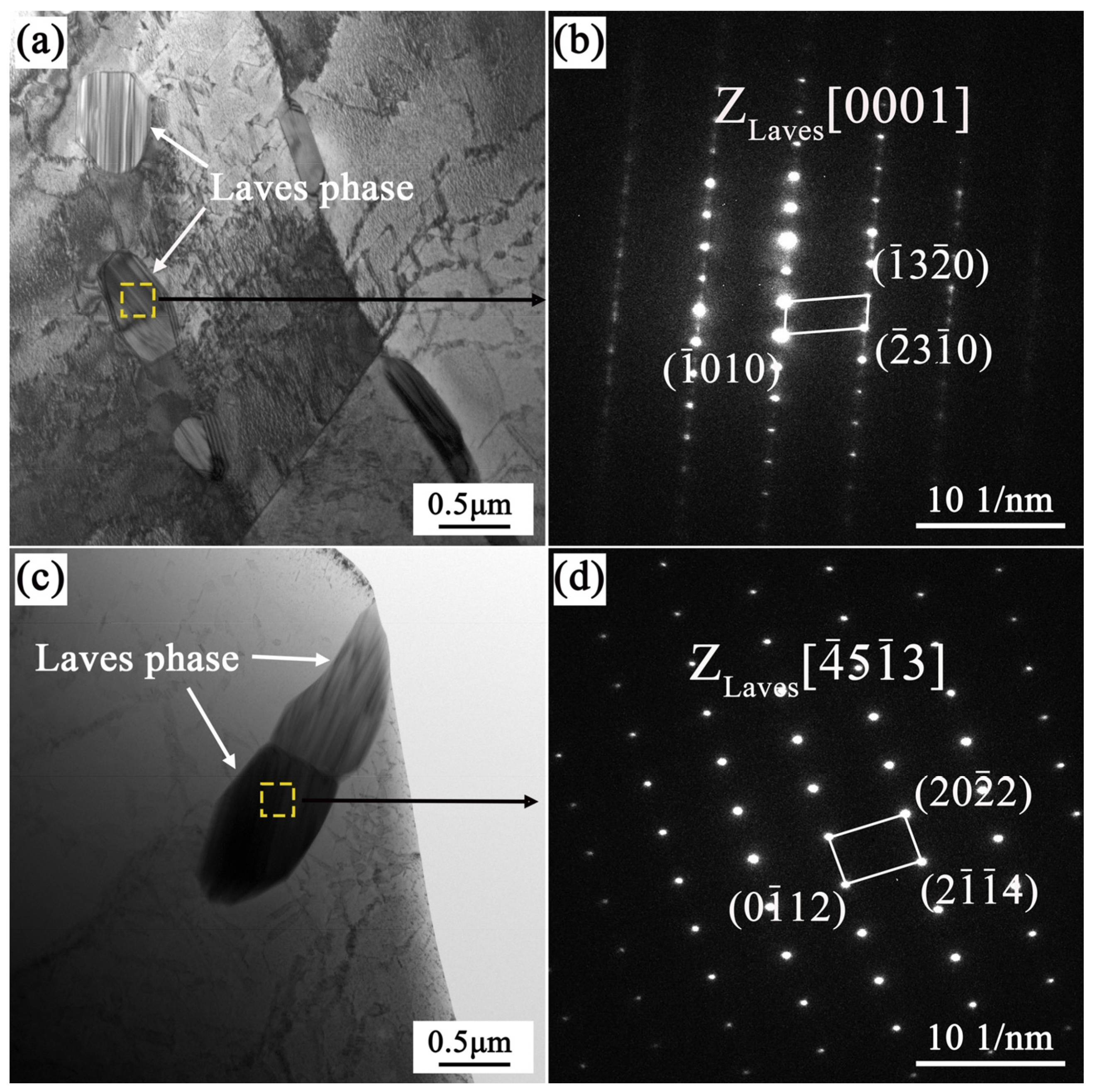

3.1. As-Forged Microstructures

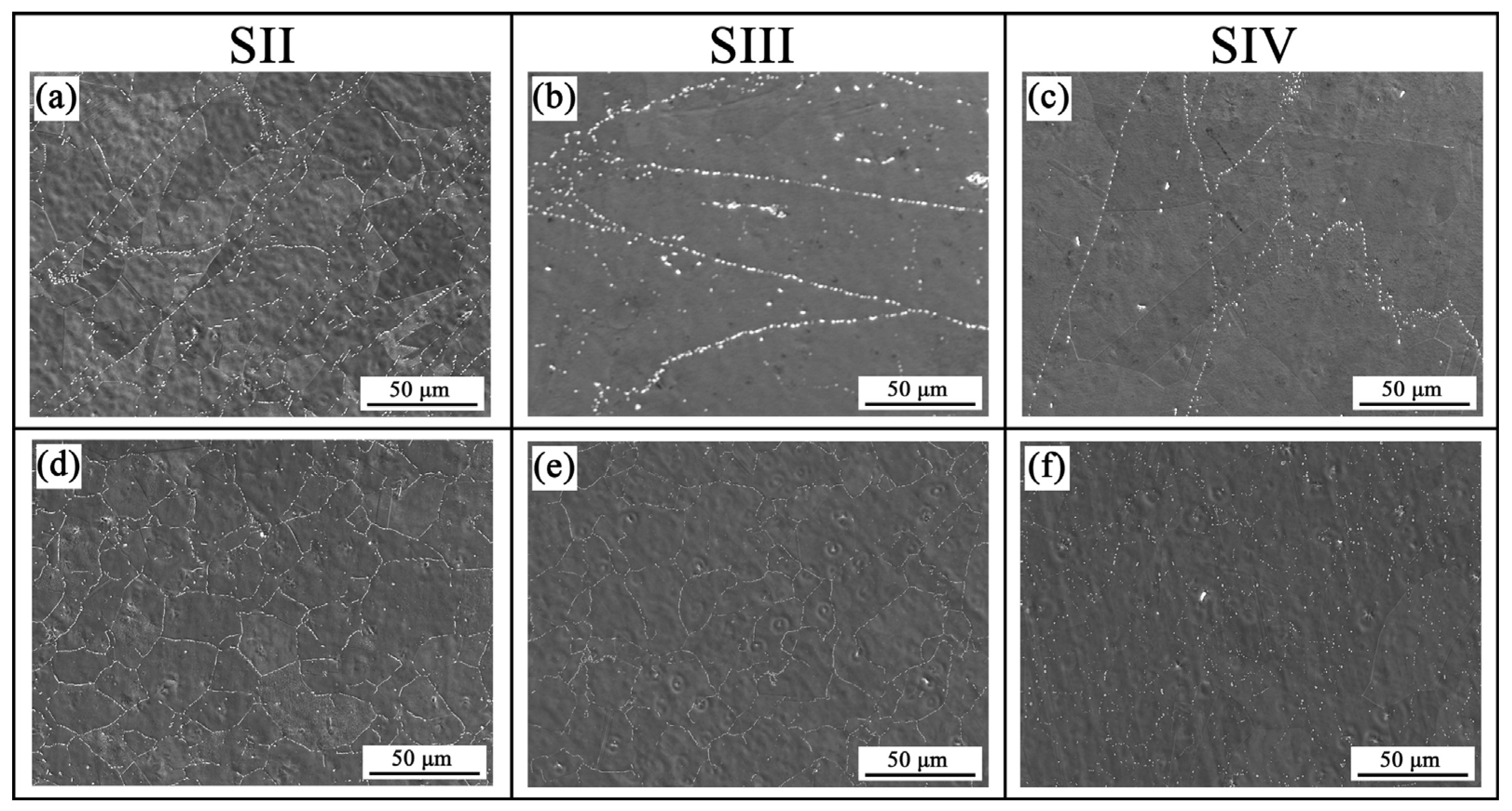

3.2. Microstructural Evolution During Various Heat Treatments

3.2.1. The Effects of Solution Treatment

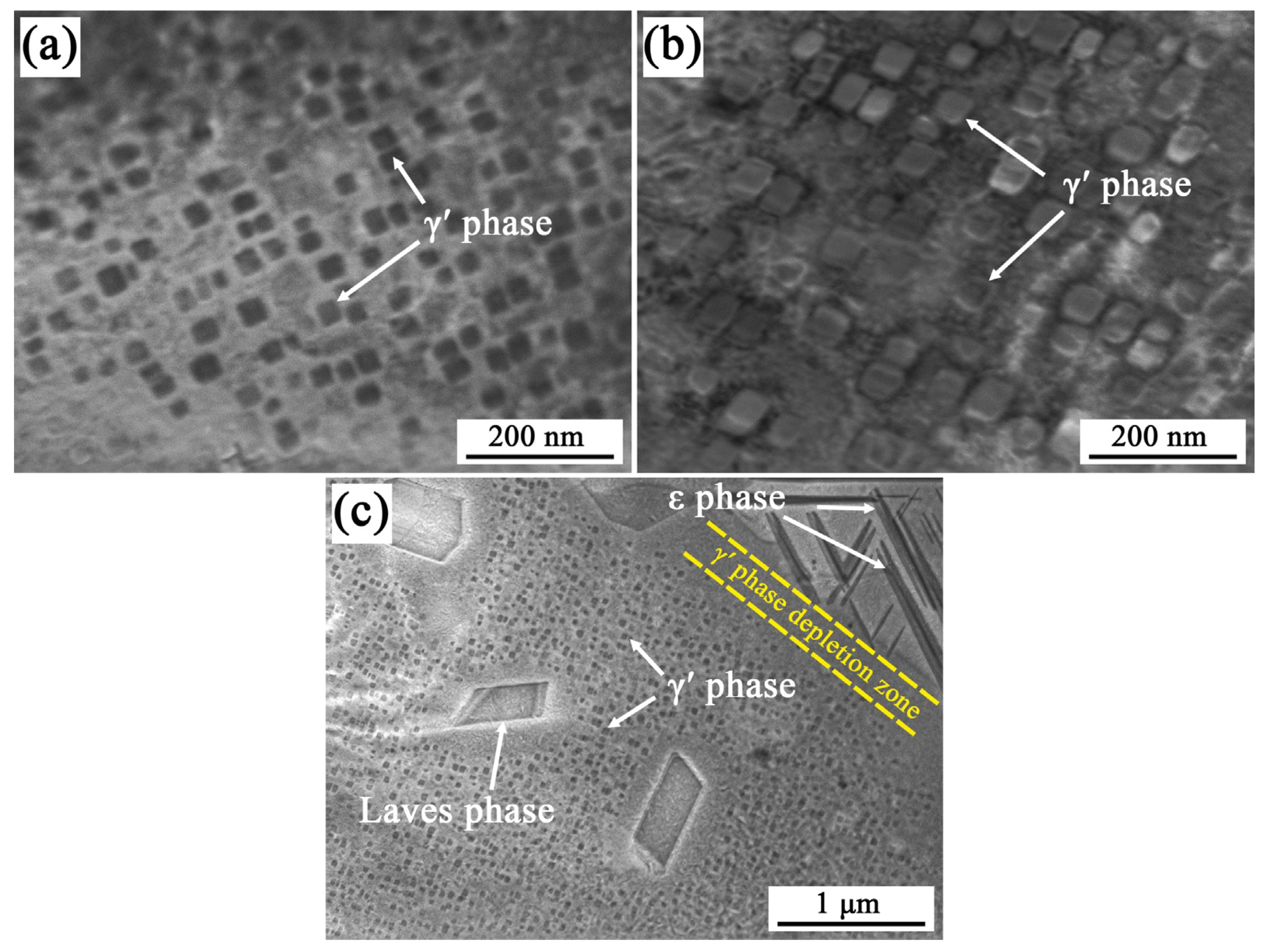

3.2.2. The Effects of Aging Treatment

3.3. Mechanical Properties

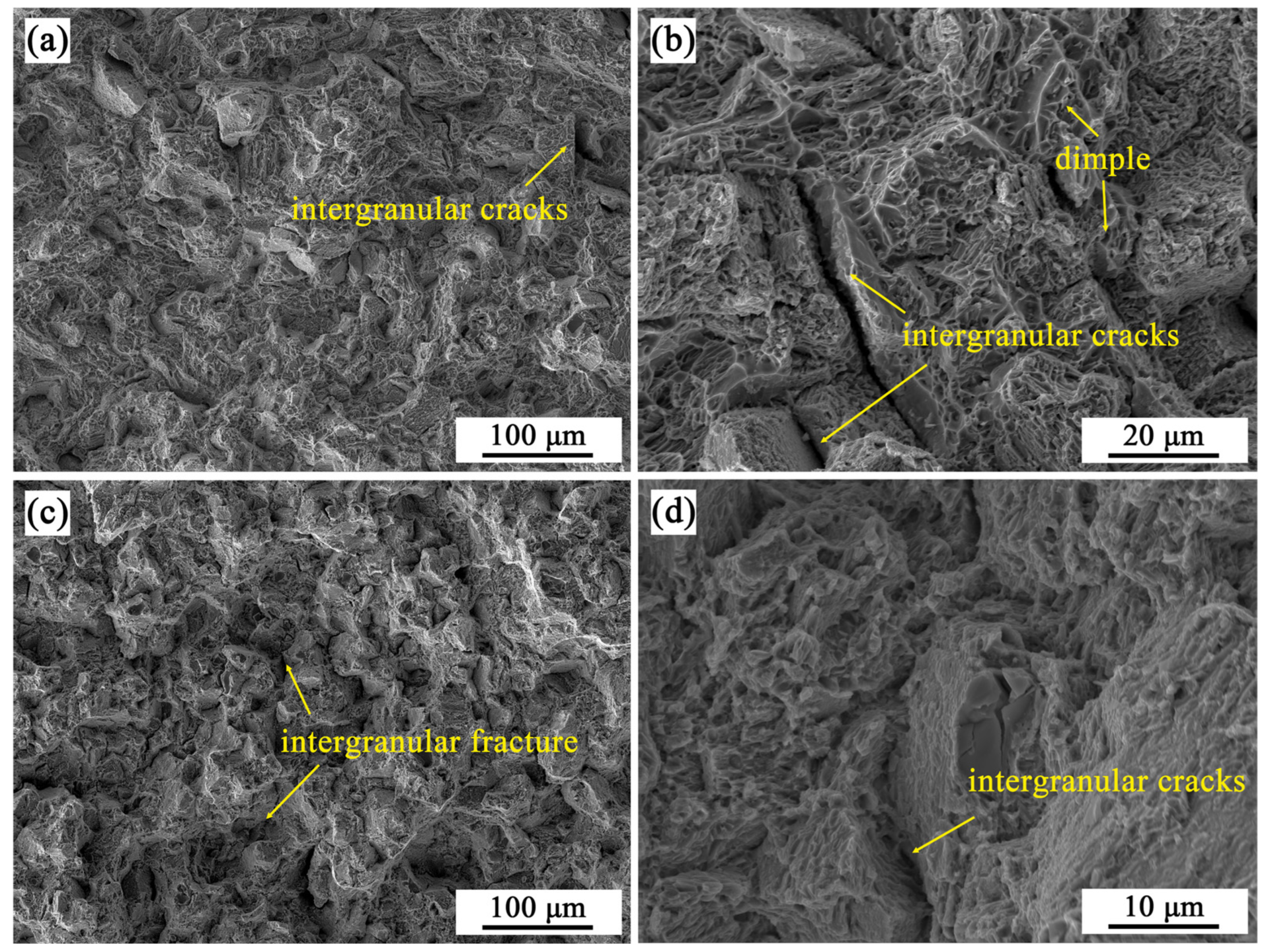

3.4. Fracture Analysis

4. Discussion

4.1. Precipitation Behavior

4.2. Effect of the Precipitation on the Mechanical Properties

5. Conclusions

- The Laves phase, which is used to control the grain size, continues to dissolve as the solution temperature increases. The precipitation of Laves phase decreased, and the lack of an effective grain growth inhibition mechanism resulted in a large number of grain growth.

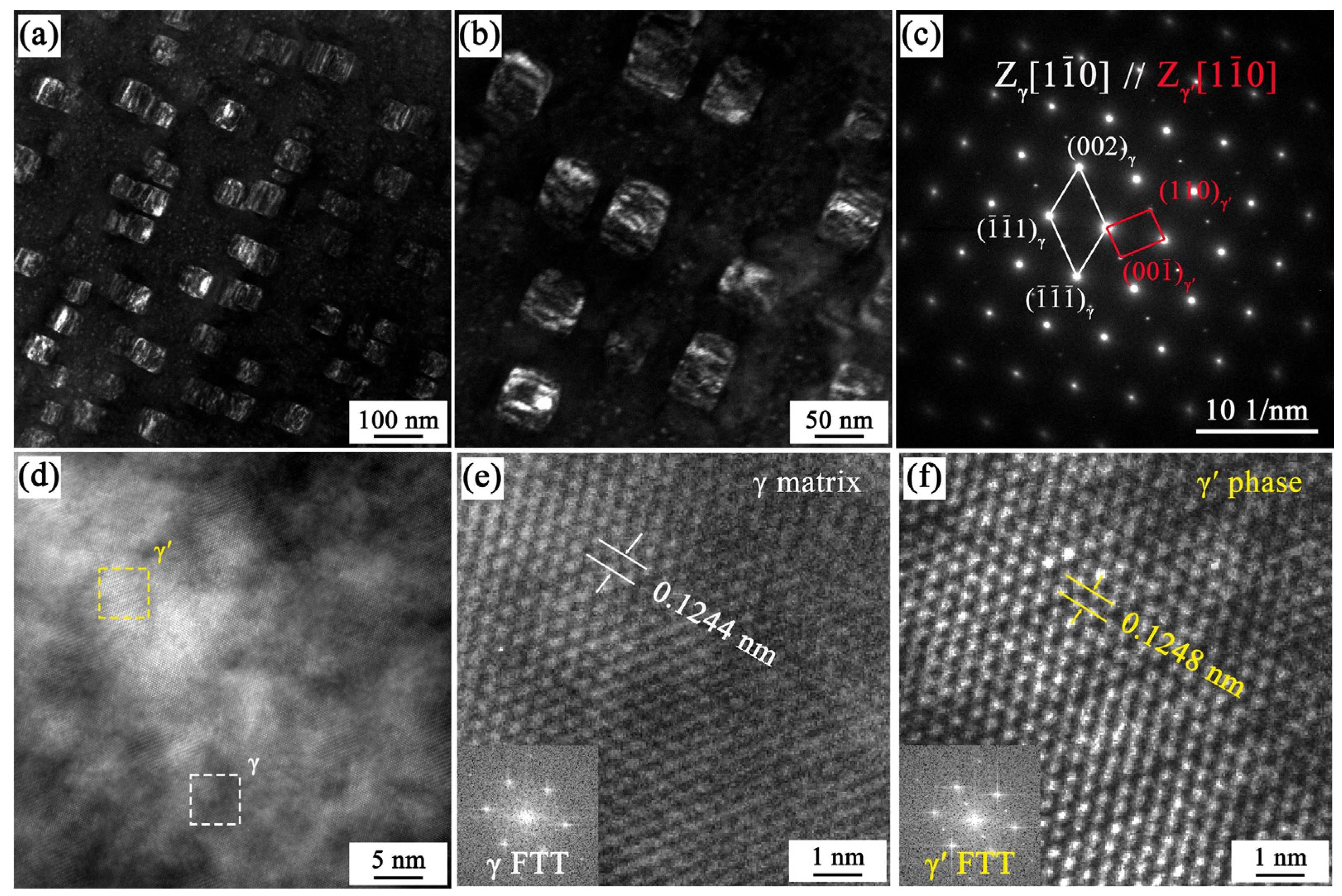

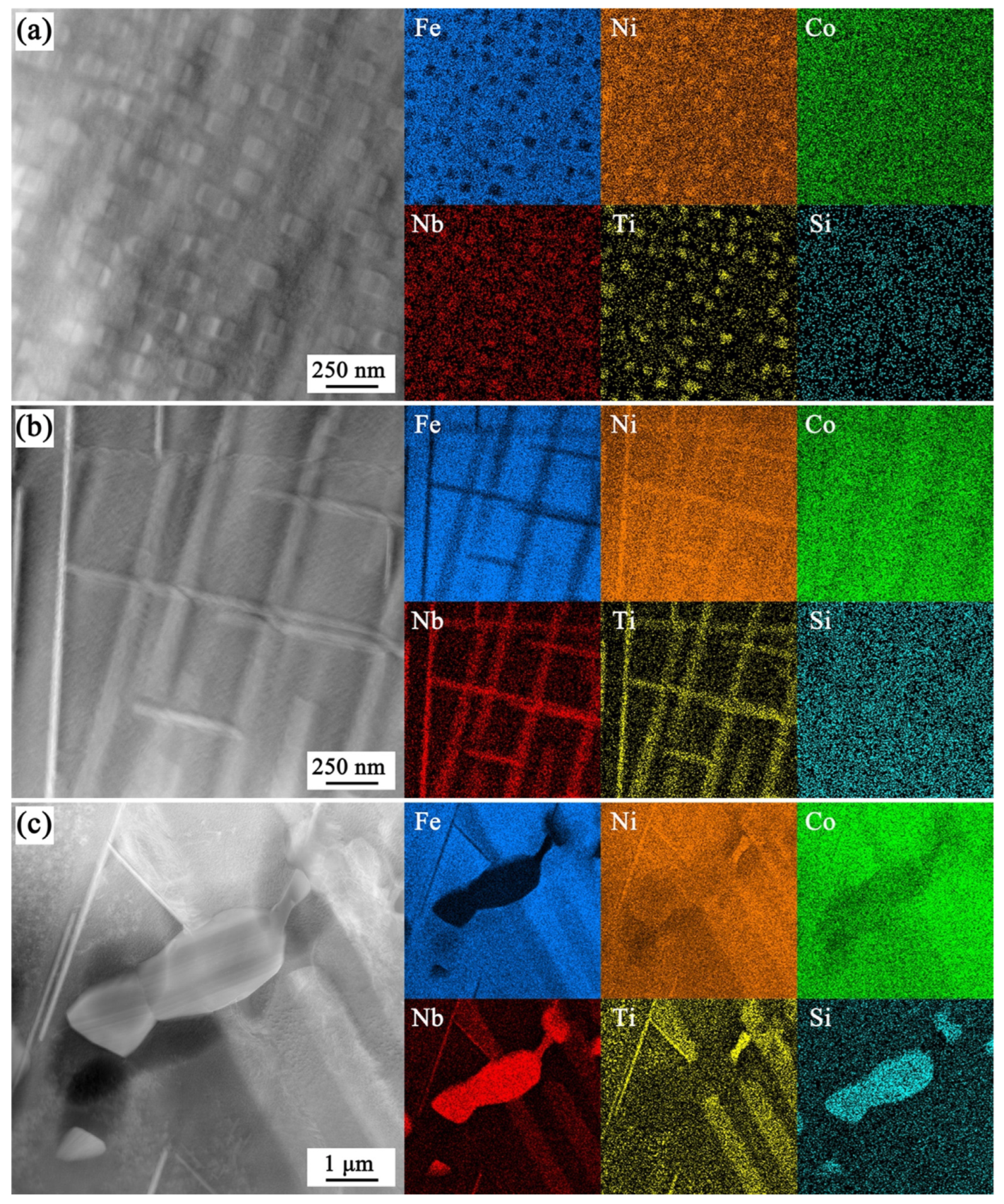

- After solid solution and double aging treatment, a large number of disc-shaped ε phases were precipitated in the GH2097 alloy crystal, which showed a Widmanstatten-type structure in the cross arrangement and was converted from the γ′ phase. The γ′ (Ni3TiNb) phase co-grid with the matrix grows, and the size of the γ′ phase increases with the increase in Si content.

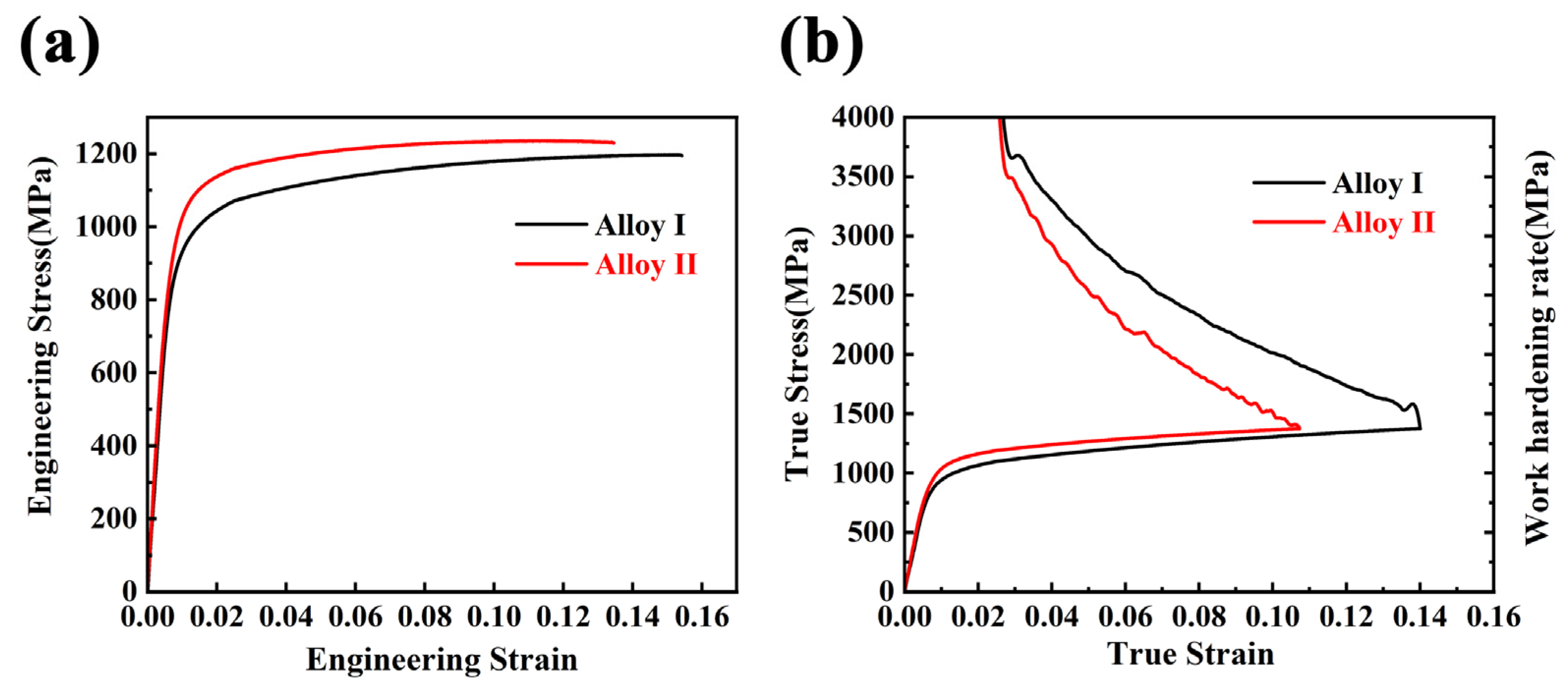

- The main strengthening mechanism of the high-temperature treated samples was the precipitation strengthening of γ′, which contributed 52% and 53% to the yield strength of Alloy I and Alloy II.

- Discontinuous precipitation of Laves or ε phases at grain or phase boundaries can induce stress concentration, promote crack initiation, and reduce toughness. Furthermore, the γ′ phase obstructs the dislocation movement through coherent precipitation and improves the yield strength of the alloy.

- The increase in Si content in the alloy significantly affects the formation of the precipitated phase during processing, and there are significant and complex differences in microstructure and physical metallurgy. The role of the Si element should be paid attention to in the microstructure control of the GH2907 superalloy.

Author Contributions

Funding

Data Availability Statement

Conflicts of Interest

References

- Moody, N.R.; Stoltz, R.E.; Perra, M.W. The effect of hydrogen on fracture toughness of the Fe-Ni-Co superalloy IN903. Met. Trans. 1987, 18, 1469–1482. [Google Scholar] [CrossRef]

- Guo, X.; Kusabiraki, K.; Saji, S. Intragranular precipitates in Incoloy Alloy 909. Scr. Mater. 2001, 44, 55–60. [Google Scholar] [CrossRef]

- Yan, F.; Wang, C.; Wang, Y.; Hu, X.; Wang, T.; Li, J.; Li, G. A study of the mechanism of laser welding defects in low thermal expansion superalloy GH909. Mater. Charact. 2013, 78, 21–30. [Google Scholar] [CrossRef]

- Hayes, R.W.; Smith, D.F.; Wanner, E.A.; Earthman, J.C. Effect of environment on the rupture behavior of alloys 909 and 718. Mater. Sci. Eng. A 1994, 177, 43–53. [Google Scholar] [CrossRef]

- Lagow, B.W. Materials selection in gas turbine engine design and the role of low thermal expansion materials. J. Manag. 2016, 68, 2770–2775. [Google Scholar] [CrossRef]

- Rae, C.M.F.; Reed, R.C. The precipitation of topologically close-packed phases in rhenium-containing superalloys. Acta Mater. 2001, 49, 4113–4125. [Google Scholar] [CrossRef]

- Sato, K.; Ohno, T. Development of low thermal expansion superalloy. J. Mater. Eng. Perform. 1993, 2, 511–516. [Google Scholar] [CrossRef]

- Joseph, J.; Annasamy, M.; Cizek, P.; Vahid, A.; Hodgson, P.D.; Barnett, M.R.; Fabijanic, D.M. Design of precipitation (γ′) strengthened Fe-rich medium entropy alloys. Scr. Mater. 2023, 235, 115630. [Google Scholar] [CrossRef]

- Yang, W.; Zong, H.; Yang, C.; Qu, P.; Su, H.; Dong, Y.; Zhang, J.; Liu, L. The effect of Fe addition on γ′ precipitates during thermal exposure in Ni-Co-based single crystal superalloys. J. Mater. Res. Technol. 2022, 20, 894–904. [Google Scholar] [CrossRef]

- Chen, Z.Q.; Brooks, J.W.; Loretto, M.H. Precipitation in Incoloy alloy 909. Mater. Sci. Technol. 1993, 9, 647–653. [Google Scholar] [CrossRef]

- Chen, Z. Identification of orthorhombic phase in incoloy alloy 909. Scr. Metall. Mater. 1992, 26, 1077–1082. [Google Scholar] [CrossRef]

- Guo, X.; Kusabiraki, K. Aging an Fe-Ni-Co-Nb-Ti-Si Superalloy under tensile stress. Int. J. Mater. Res. 2000, 91, 601–606. [Google Scholar] [CrossRef]

- Zhang, W.; Tan, Y.; Xin, X.; Sun, W.-r. Mechanism of notch sensitivity elimination via precipitating Laves phases at grain boundaries in a low expansion superalloy. J. Mater. Res. Technol. 2022, 18, 3094–3103. [Google Scholar] [CrossRef]

- Ruan, T.; Shen, J.; Li, B.; Zhao, Z.; Zhang, D. High-temperature strengthening mechanism and thermal stability of Laves phase in ferritic matrix. Mater. Sci. Eng. A 2022, 859, 144183. [Google Scholar] [CrossRef]

- Ma, P.; Jia, Y.; Prashanth, K.G.; Yu, Z.; Li, C.; Zhao, J.; Yang, S.; Huang, L. Effect of Si content on the microstructure and properties of Al–Si alloys fabricated using hot extrusion. J. Mater. Res. 2017, 32, 2210–2217. [Google Scholar] [CrossRef]

- Wanner, E.A.; DeAntonio, D.A.; Smith, D.F.; Smith, J.S. The current status of controlled thermal expansion superalloys. J. Met. 1991, 43, 38–43. [Google Scholar] [CrossRef]

- Kusabiraki, K.; Amada, E.; Ōoka, T.; Saji, S. Epsilon and Eta phases precipitated in an Fe-38Ni-13Co-4.7Nb-1.5Ti-0.4Si superalloy. Isij Int. 1997, 37, 80–86. [Google Scholar] [CrossRef]

- Dobrzański, L.A.; Labisz, K.; Jonda, E.; Klimpel, A. Comparison of the surface alloying of the 32CrMoV12-28 tool steel using TiC and WC powder. J. Mater. Process. Technol. 2007, 191, 321–325. [Google Scholar] [CrossRef]

- Marvel, C.J.; Behler, K.D.; LaSalvia, J.C.; Haber, R.A.; Harmer, M.P. Grain boundary segregation in Si-doped B-based ceramics and its effect on grain boundary cohesion. Acta Mater. 2022, 227, 117684. [Google Scholar] [CrossRef]

- Singh, V.K.; Sahoo, D.; Amirthalingam, M.; Karagadde, S.; Mishra, S.K. Dissolution of the Laves phase and δ-precipitate formation mechanism in additively manufactured Inconel 718 during post printing heat treatments. Addit. Manuf. 2024, 81, 104021. [Google Scholar] [CrossRef]

- Zhang, Z.; Liu, J.; Zhu, C.; Wang, X.; Zhou, Y.; Wang, J.; Li, J. Investigation of the formation mechanism between β-NiAl and C14-Laves phases in laser additive manufacturing of nickel-based superalloy. Intermetallics 2024, 168, 108272. [Google Scholar] [CrossRef]

- Murakumo, T.; Kobayashi, T.; Koizumi, Y.; Harada, H. Creep behaviour of Ni-base single-crystal superalloys with various γ′ volume fraction. Acta Mater. 2004, 52, 3737–3744. [Google Scholar] [CrossRef]

- Liu, W.B.; Liu, Z.; Luo, W.; Zuo, D.; Liu, H.Q.; Zhang, R.Q.; Wang, Q. Effect of Zr addition on coarse Laves phase stimulated nucleation of recrystallization in FeCrAl alloy. Mater. Sci. Eng. A 2022, 840, 142964. [Google Scholar] [CrossRef]

- Lv, P.; Liu, L.; Yang, Y.; Zhao, Y.; Zhang, J. Role of microstructural stability and superdislocation shearing on creep behavior of two low-cost Ni-based single crystal superalloys at 1100 °C/130 MPa. Mater. Sci. Eng. A 2023, 888, 145796. [Google Scholar] [CrossRef]

- Kishore, K.; Chandan, A.K.; Hung, P.T.; Kumar, S.; Ranjan, M.; Kawasaki, M.; Gubicza, J. Effect of Si on the evolution of plasticity mechanisms, grain refinement and hardness during high-pressure torsion of a non-equiatomic CoCrMnNi multi-principal element alloy. Int. J. Plast. 2023, 169, 103720. [Google Scholar] [CrossRef]

- Wu, Y.; Li, C.; Xia, X.; Liang, H.; Qi, Q.; Liu, Y. Precipitate coarsening and its effects on the hot deformation behavior of the recently developed γ’-strengthened superalloys. J. Mater. Sci. Technol. 2021, 67, 95–104. [Google Scholar] [CrossRef]

- Reed, R. The Superalloys Fundamentals and Applications; Cambridge University Press: Cambridge, UK, 2006; pp. 74–86. [Google Scholar]

- Peng, Z.; Tian, G.; Jiang, J.; Li, M.; Chen, Y.; Zou, J.; Dunne, F.P.E. Mechanistic behaviour and modelling of creep in powder metallurgy FGH96 nickel superalloy. Mater. Sci. Eng. A 2016, 676, 441–449. [Google Scholar] [CrossRef]

- Goodfellow, A.J. Strengthening mechanisms in polycrystalline nickel-based superalloys. Mater. Sci. Technol. 2018, 34, 1793–1808. [Google Scholar] [CrossRef]

- Kozar, R.W.; Suzuki, A.; Milligan, W.W.; Schirra, J.J.; Savage, M.F.; Pollock, T.M. Strengthening mechanisms in polycrystalline multimodal nickel-base superalloys. Metall. Mater. Trans. A 2009, 40, 1588–1603. [Google Scholar] [CrossRef]

- Roth, H.A.; Davis, C.L.; Thomson, R.C. Modeling solid solution strengthening in nickel alloys. Metall. Mater. Trans. A 1997, 28, 1329–1335. [Google Scholar] [CrossRef]

- Galindo-Nava, E.I.; Connor, L.D.; Rae, C.M.F. On the prediction of the yield stress of unimodal and multimodal γ′ Nickel-base superalloys. Acta Mater. 2015, 98, 377–390. [Google Scholar] [CrossRef]

- Xu, J.; Gruber, H.; Boyd, R.; Jiang, S.; Peng, R.L.; Moverare, J.J. On the strengthening and embrittlement mechanisms of an additively manufactured Nickel-base superalloy. Materialia 2020, 10, 100657. [Google Scholar] [CrossRef]

- Yang, B.; Shang, Z.; Ding, J.; Lopez, J.; Jarosinski, W.; Sun, T.; Richter, N.; Zhang, Y.; Wang, H.; Zhang, X. Investigation of strengthening mechanisms in an additively manufactured Haynes 230 alloy. Acta Mater. 2022, 222, 117404. [Google Scholar] [CrossRef]

- Kim, Y.-K.; Choe, J.; Lee, K.-A. Selective laser melted equiatomic CoCrFeMnNi high-entropy alloy: Microstructure, anisotropic mechanical response, and multiple strengthening mechanism. J. Alloys Compd. 2019, 805, 680–691. [Google Scholar] [CrossRef]

- Mughrabi, H. A two-parameter description of heterogeneous dislocation distributions in deformed metal crystals. Mater. Sci. Eng. 1987, 85, 15–31. [Google Scholar] [CrossRef]

- Jiang, S.; Shen, J.; Nagasaka, T.; Muroga, T.; Sagara, A.; Ohnuki, S.; Hokamoto, K.; Tanaka, S.; Inao, D.; Morizono, Y.; et al. Interfacial characterization of dissimilar-metals bonding between vanadium alloy and Hastelloy X alloy by explosive welding. J. Nucl. Mater. 2020, 539, 152322. [Google Scholar] [CrossRef]

- Rajendran, R.; Petley, V.; Rehmer, B. Dynamic elastic properties of aero-engine metallic isotropic materials. Proc. Inst. Mech. Eng. Part L J. Mater. Des. Appl. 2012, 227, 243–249. [Google Scholar] [CrossRef]

- Xu, J.; Lin, X.; Guo, P.; Yang, H.; Xue, L.; Huang, W. The microstructure evolution and strengthening mechanism of a γ′-strengthening superalloy prepared by induction-assisted laser solid forming. J. Alloys Compd. 2019, 780, 461–475. [Google Scholar] [CrossRef]

- Liu, X.; Hu, R.; Yang, C.; Luo, X.; Bai, J.; Ma, R. Microstructure evolution and strengthening mechanism of γ′-strengthening superalloy prepared by laser powder bed fusion. Mater. Sci. Eng. A 2023, 871, 144915. [Google Scholar] [CrossRef]

- Baik, S.-I.; Wang, S.-Y.; Liaw, P.K.; Dunand, D.C. Increasing the creep resistance of Fe-Ni-Al-Cr superalloys via Ti additions by optimizing the B2/L21 ratio in composite nano-precipitates. Acta Mater. 2018, 157, 142–154. [Google Scholar] [CrossRef]

- Lu, W.; Yan, K.; Luo, X.; Wang, Y.; Hou, L.; Li, P.; Huang, B.; Yang, Y. Superb strength and ductility balance of a Co-free medium-entropy alloy with dual heterogeneous structures. J. Mater. Sci. Technol. 2022, 98, 197–204. [Google Scholar] [CrossRef]

- Wang, J.-S. Dislocation nucleation and the intrinsic fracture behavior of L12 intermetallic alloys. Acta Mater. 1998, 46, 2663–2674. [Google Scholar] [CrossRef]

- Liu, X.; Liu, Y.; Zhou, Z.; Wang, K.; Zhan, Q.; Xiao, X. Grain refinement and crack inhibition of selective laser melted AA2024 aluminum alloy via inoculation with TiC–TiH2. Mater. Sci. Eng. A 2021, 813, 141171. [Google Scholar] [CrossRef]

- Lee, J.-U.; Kim, Y.-K.; Seo, S.-M.; Lee, K.-A. Effects of hot isostatic pressing treatment on the microstructure and tensile properties of Ni-based superalloy CM247LC manufactured by selective laser melting. Mater. Sci. Eng. A 2022, 841, 143083. [Google Scholar] [CrossRef]

| Fe | Si | Co | Nb | Ti | Ni | |

|---|---|---|---|---|---|---|

| Alloy I | 40.98 | 0.22 | 13.88 | 5.05 | 1.78 | Bal |

| Alloy II | 40.1 | 0.34 | 13.87 | 5.07 | 1.76 | Bal |

| Process | Heat Treatment |

|---|---|

| SI | As forged |

| SII | 980 °C, 1 h, AC |

| SIII | 990 °C, 1 h, AC |

| SIV | 1000 °C, 1 h, AC |

| SV | 980 °C, 1 h, AC + 770 °C, 12 h, FC (0.9 °C·min−1) to 621 °C, 8 h, AC |

| Alloy I | Alloy II | |

|---|---|---|

| Yield strength (MPa) | 890.3 ± 1 | 987.4 ± 1 |

| Ultimate tensile strength (MPa) | 1197.2 ± 4 | 1224.0 ± 11 |

| Uniform elongation (%) | 15.33 ± 0.04 | 11.12 ± 0.07 |

| Fracture elongation (%) | 15.42 ± 0.6 | 13.05 ± 0.4 |

Disclaimer/Publisher’s Note: The statements, opinions and data contained in all publications are solely those of the individual author(s) and contributor(s) and not of MDPI and/or the editor(s). MDPI and/or the editor(s) disclaim responsibility for any injury to people or property resulting from any ideas, methods, instructions or products referred to in the content. |

© 2025 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (https://creativecommons.org/licenses/by/4.0/).

Share and Cite

Li, M.; Wan, J.; Ding, Z.; Li, R. The Role of Si Element on the Precipitation Behavior of GH2907 Superalloys. Metals 2025, 15, 484. https://doi.org/10.3390/met15050484

Li M, Wan J, Ding Z, Li R. The Role of Si Element on the Precipitation Behavior of GH2907 Superalloys. Metals. 2025; 15(5):484. https://doi.org/10.3390/met15050484

Chicago/Turabian StyleLi, Mengxuan, Jianping Wan, Zuojun Ding, and Rengeng Li. 2025. "The Role of Si Element on the Precipitation Behavior of GH2907 Superalloys" Metals 15, no. 5: 484. https://doi.org/10.3390/met15050484

APA StyleLi, M., Wan, J., Ding, Z., & Li, R. (2025). The Role of Si Element on the Precipitation Behavior of GH2907 Superalloys. Metals, 15(5), 484. https://doi.org/10.3390/met15050484