Wear Resistance of WC-10Co-4Cr Cemented Carbide Coatings Prepared by Atmospheric Plasma Spraying and Laser Cladding

Abstract

1. Introduction

2. Experimental Materials and Methods

2.1. Powder and Substrate

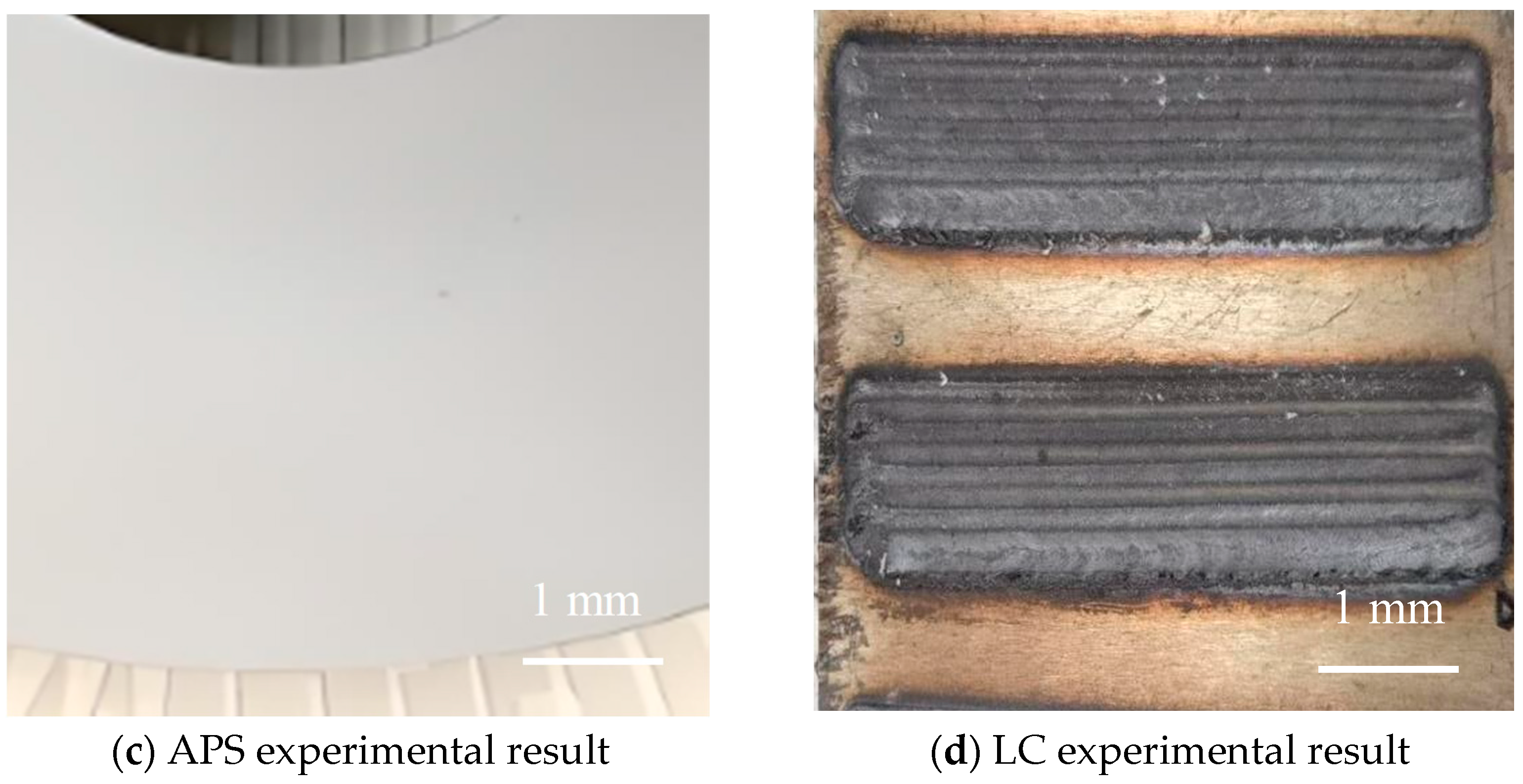

2.2. Coating Preparation

2.3. Characterization

3. Results and Discussion

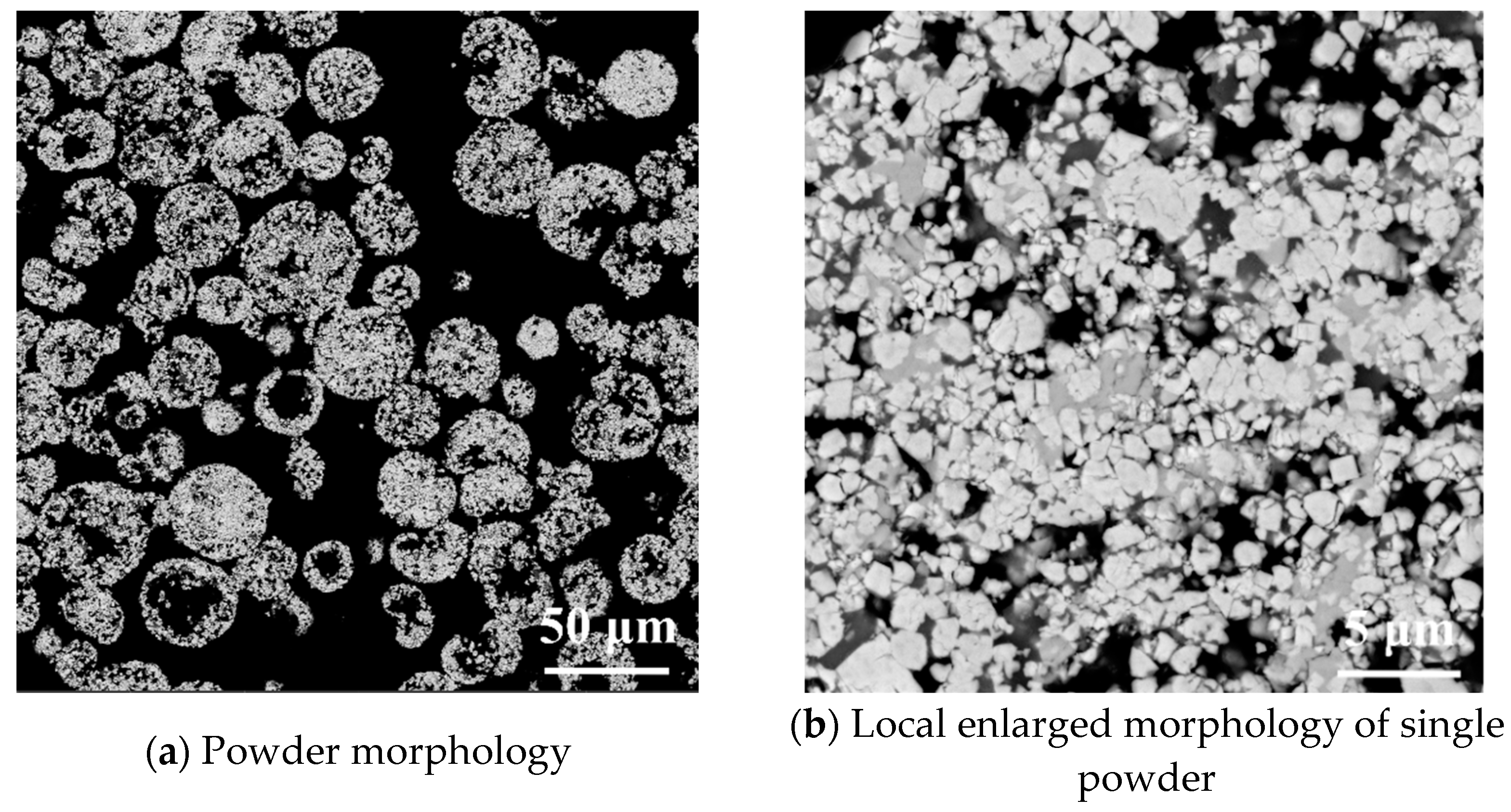

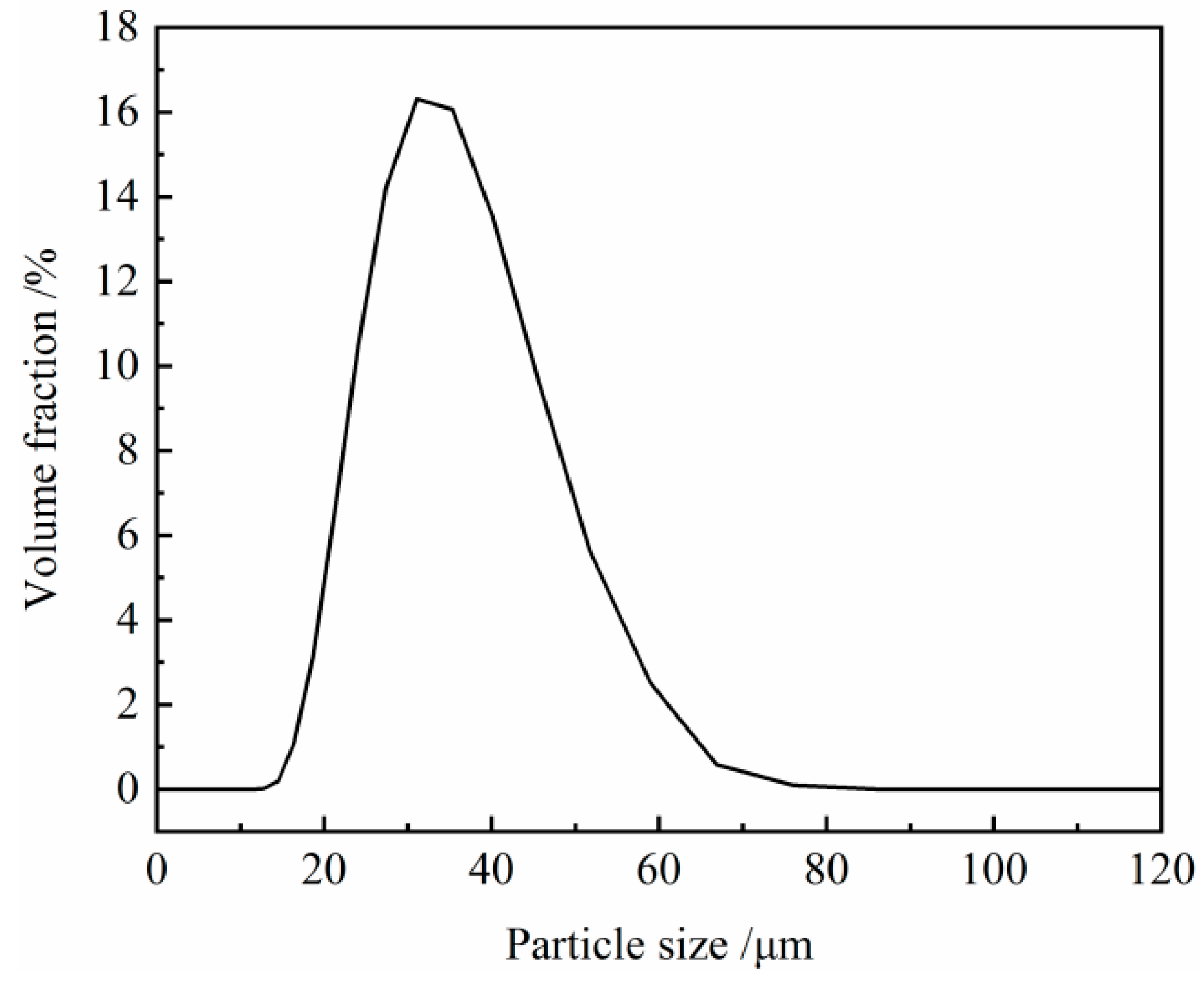

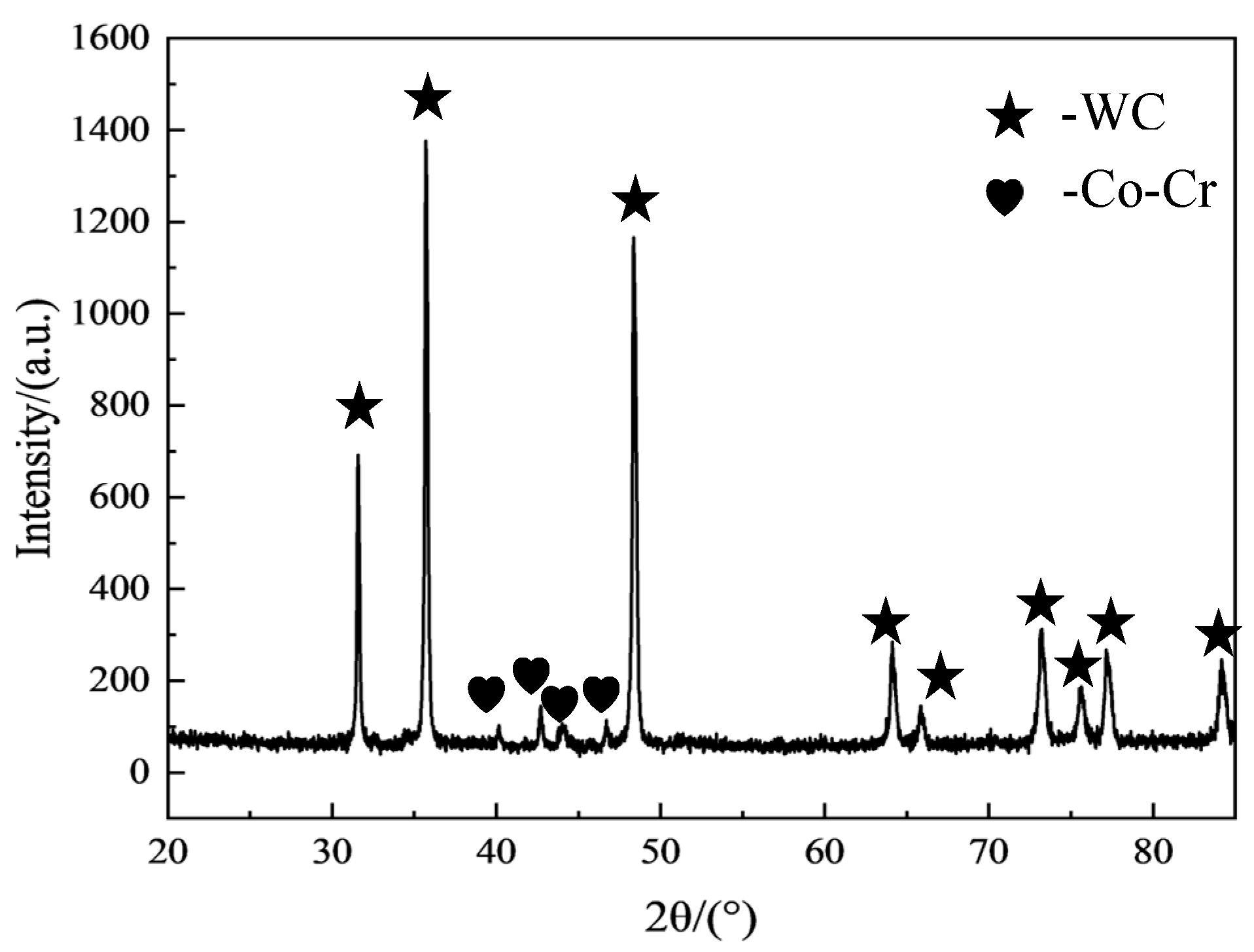

3.1. Powder Morphology and Performance Analysis

3.2. Microstructural and Phase Analysis of Coatings

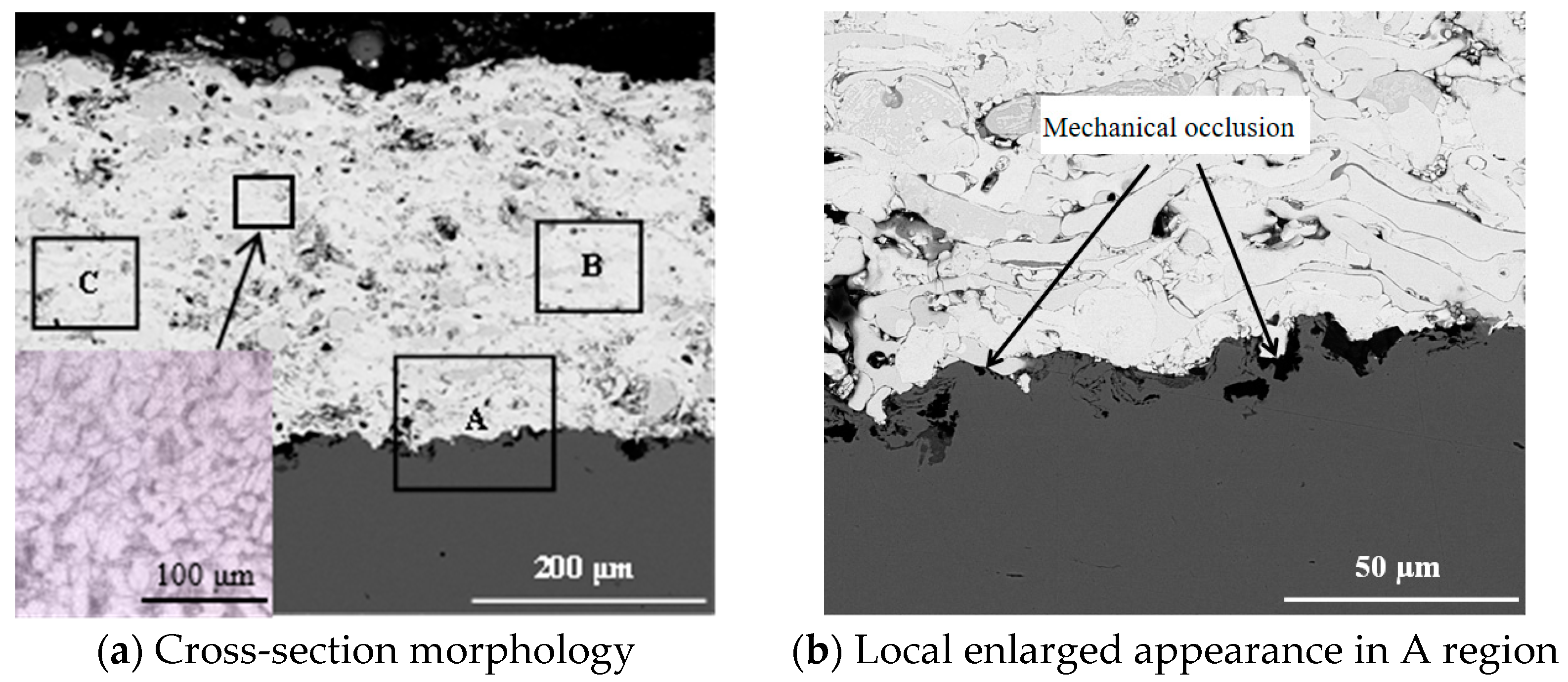

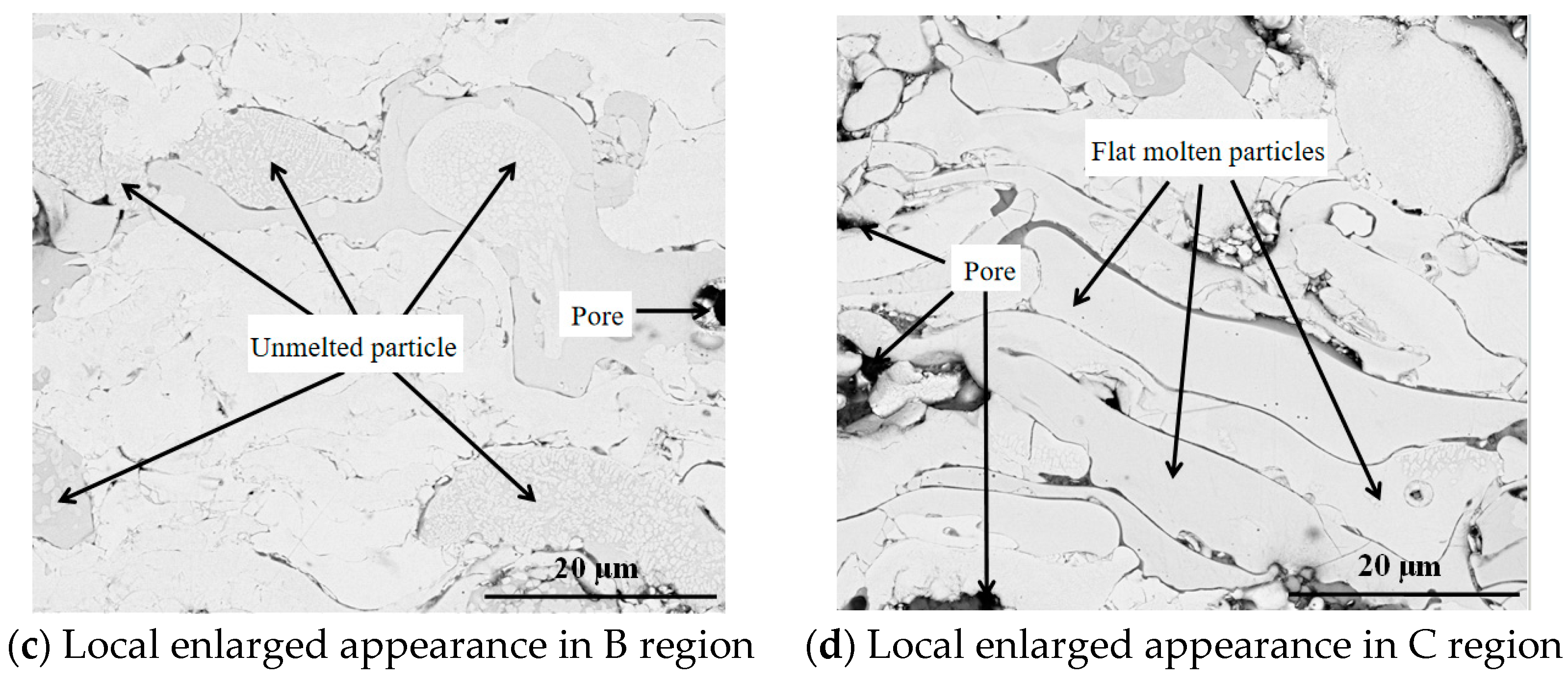

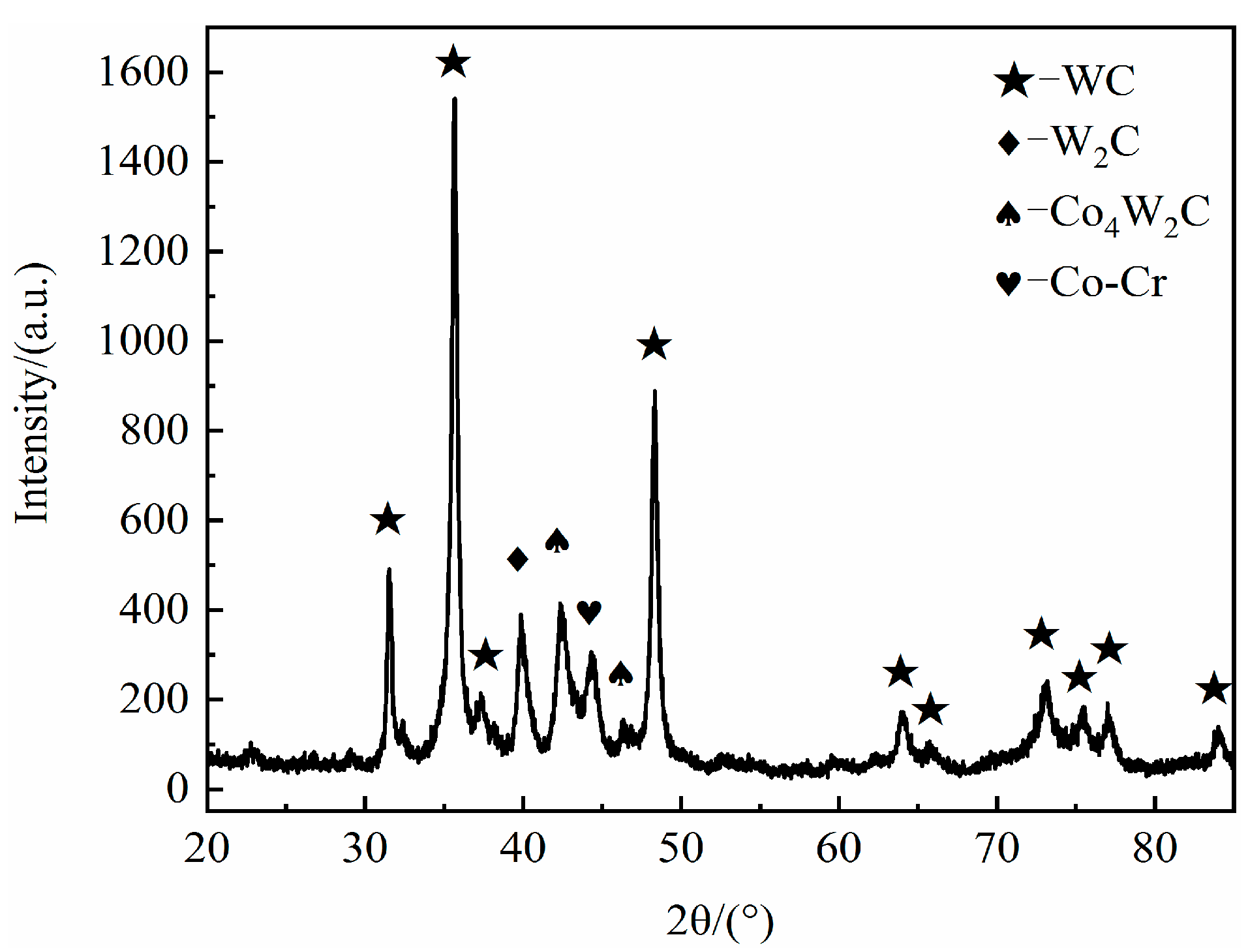

3.2.1. Microstructural and Phase Analysis of APS Coatings

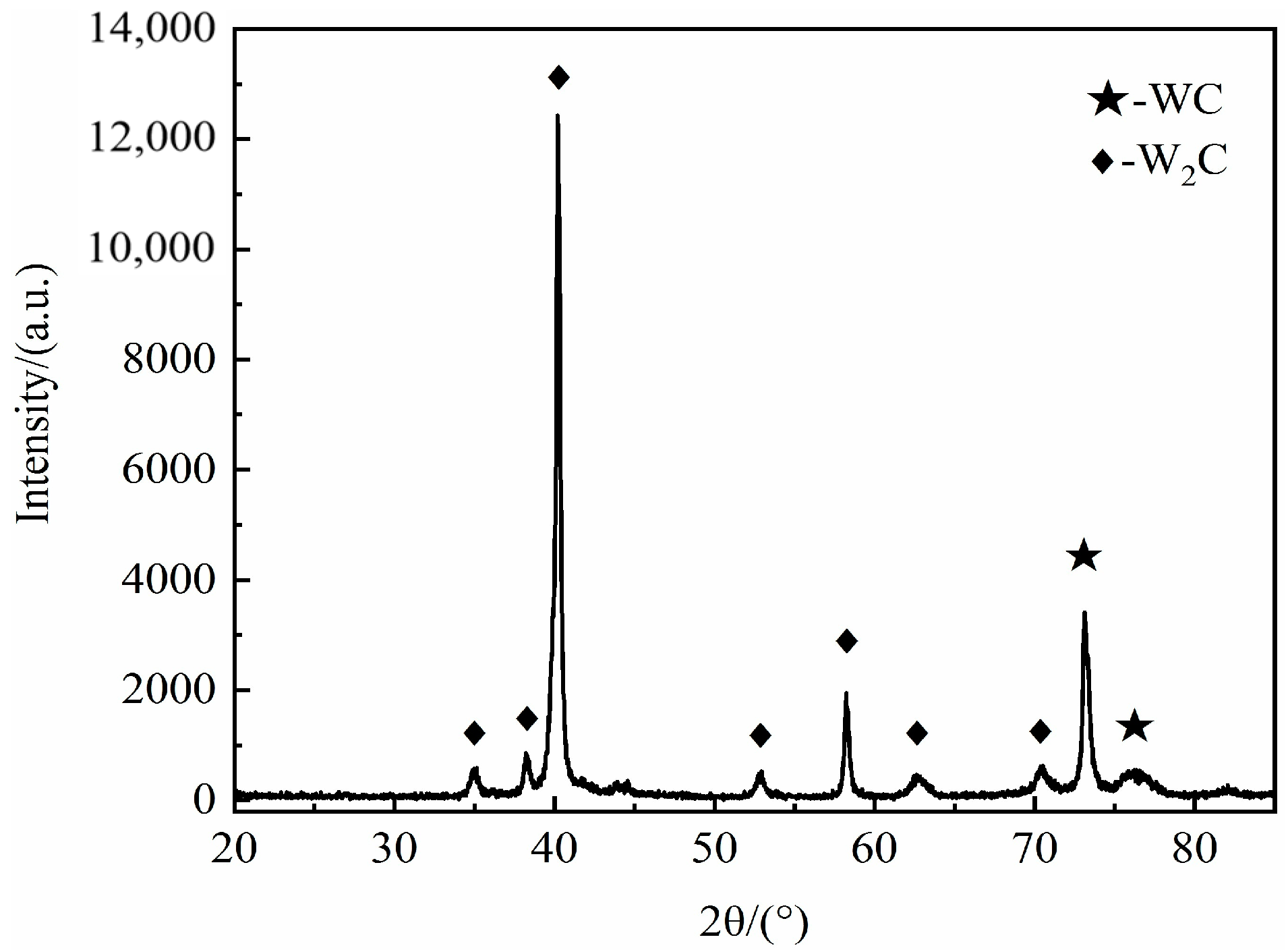

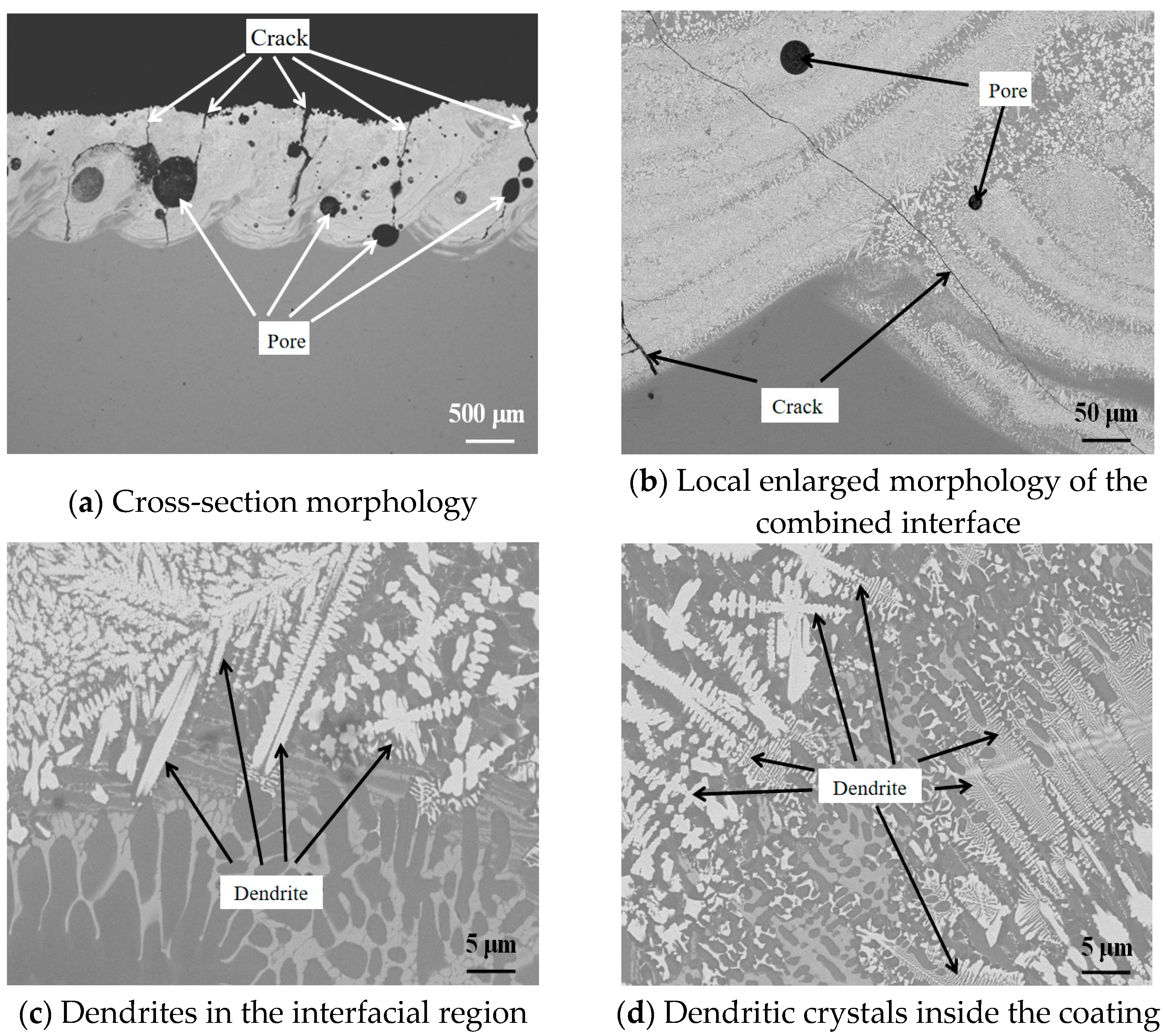

3.2.2. Microstructural and Phase Analysis of LC Coatings

3.3. Mechanical Properties Analysis of the Coatings

4. Conclusions

- In this study, WC-10Co-4Cr hard alloy coatings were successfully fabricated on the surfaces of 304 and 316 stainless steel substrates using APS and LC technologies. The LC coating displayed a dendritic structure with a metallurgical bonding interface, in-dicating the LC coating has a superior bonding effect with the substrate. The lower de-gree of WC phase decomposition compared to the APS coating contributes positively to the enhancement of coating strength.

- The average micro-Vickers hardness of the APS coating and the LC coating is 1341.7 HV and 1440.5 HV, respectively. The micro-Vickers hardness of the LC coating is 7% higher than that of the APS coating.

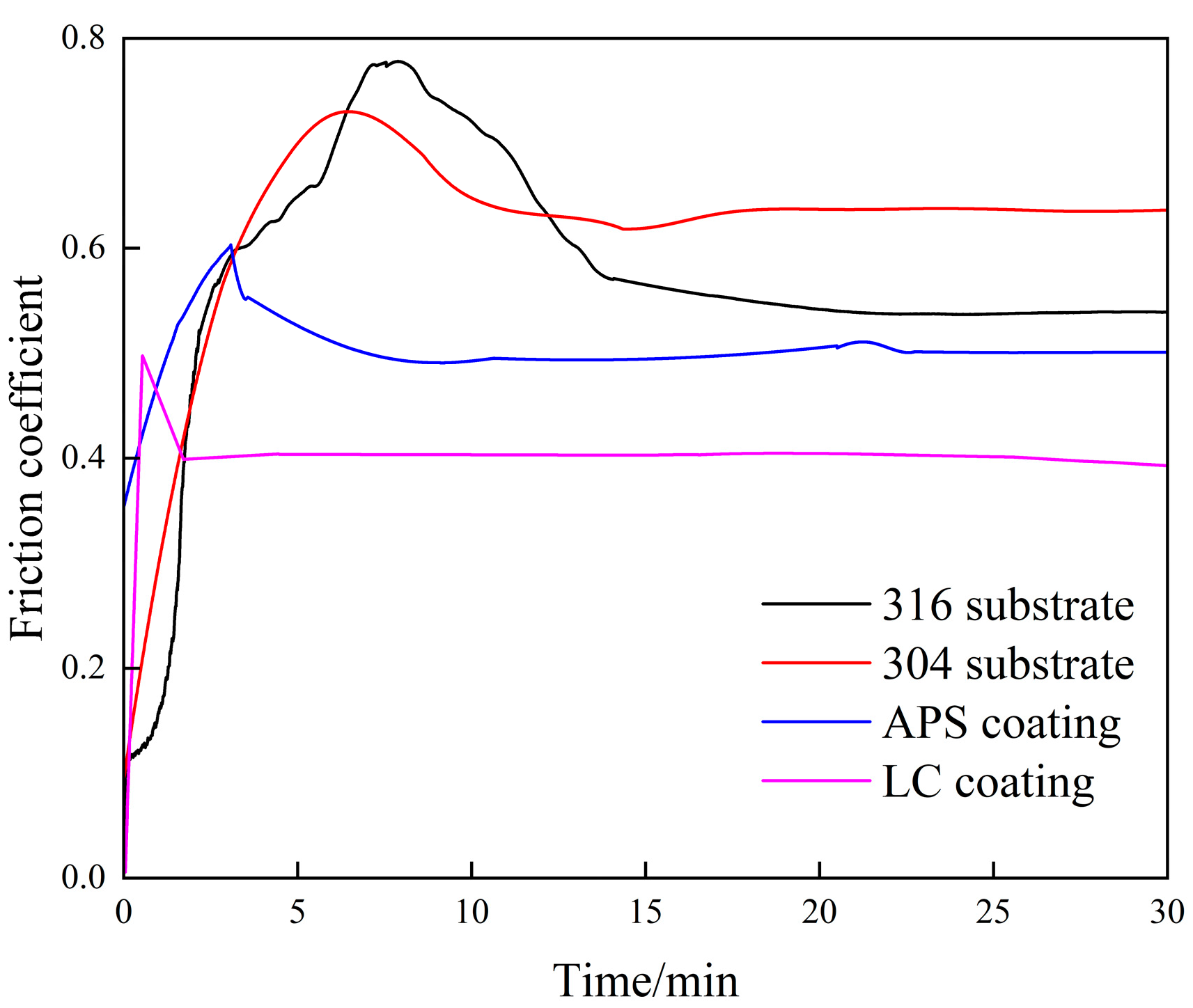

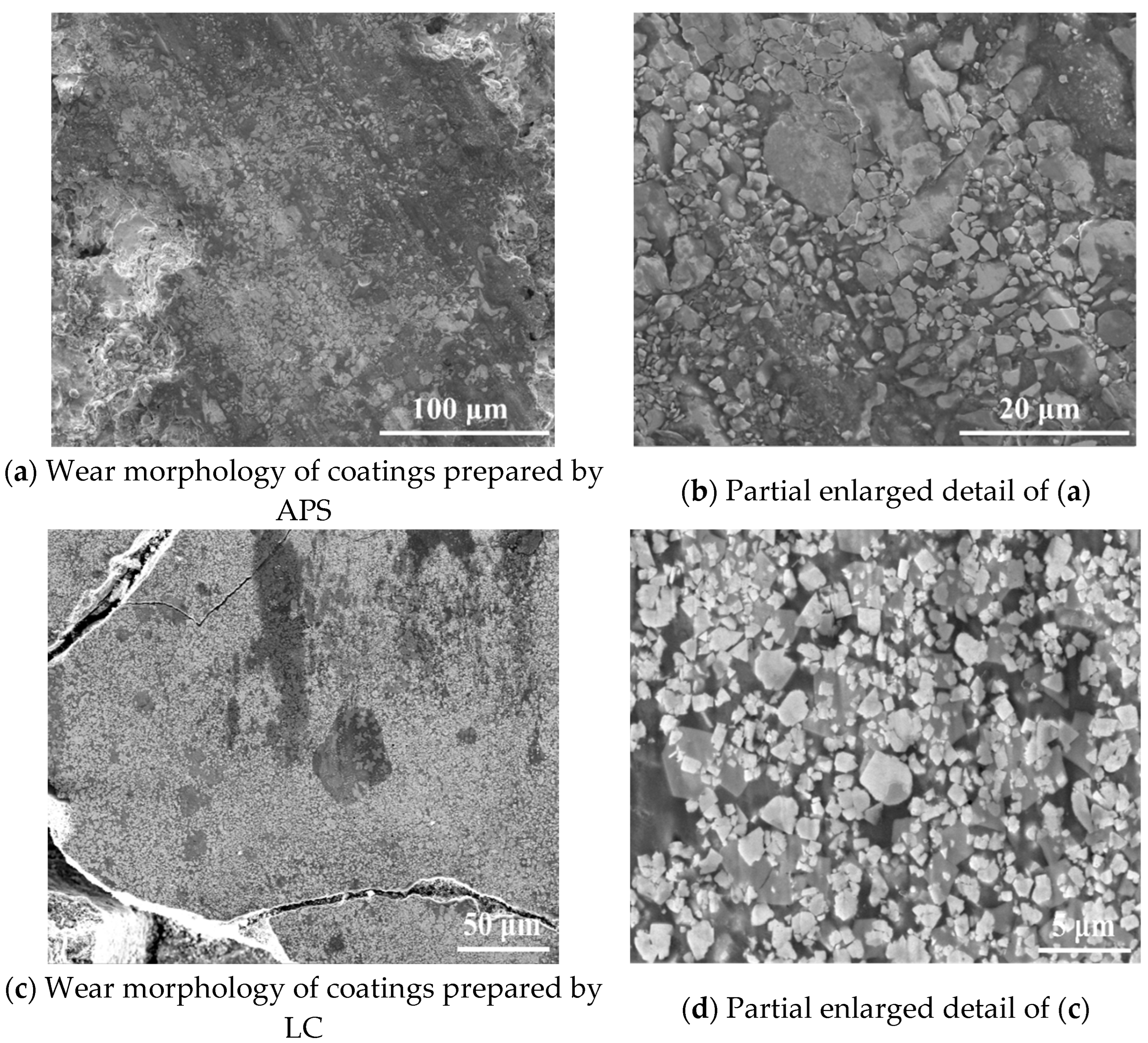

- During the wear test of the APS coating, the friction coefficient was approximately 0.45 and the mass loss was 0.005 g. A large number of wear particles and spalling pits appeared on the worn surface of the APS coating, exposing the underlying structure of the coating. In contrast, for the LC coating, the friction coefficient was approximately 0.4 and the mass loss was 0.002 g. The wear surface of the LC coating displayed nu-merous wear particles along with a few microcracks, demonstrating a uniform wear pattern without extensive spalling. These results indicate that the WC-10Co-4Cr coat-ing produced by LC exhibits superior mechanical properties, thereby meeting the re-quirements for more demanding service conditions.

Author Contributions

Funding

Data Availability Statement

Conflicts of Interest

References

- Yadav, S.; Zhang, Q.; Behera, A.; Haridas, R.S.; Agrawal, P.; Gong, J.; Mishra, R.S. Role of Binder Phase on the Microstructure and Mechanical Properties of a Mechanically Alloyed and Spark Plasma Sintered WC-FCC HEA Composites. J. Alloys Compd. 2021, 877, 160265. [Google Scholar] [CrossRef]

- Chang, L.; Wang, W.; Ma, D.; Xie, J. Deposition Effects and Interface Structure of HVOF-Sprayed Multimodal WC-CoCr Coatings. J. Mater. Res. 2023, 38, 4345–4356. [Google Scholar] [CrossRef]

- Suresh Babu, P.; Madhavi, Y.; Rama Krishna, L.; Srinivasa Rao, D.; Padmanabham, G. Thermally-Sprayed WC-Based Cermet Coatings for Corrosion Resistance Applications. JOM 2018, 70, 2636–2649. [Google Scholar] [CrossRef]

- Hu, Q.; Ji, D.; Shen, M.; Zhuang, H.; Yao, H.; Zhao, H.; Guo, H.; Zhang, Y. Three-Body Abrasive Wear Behavior of WC-10Cr3C2-12Ni Coating for Ball Mill Liner Application. Materials 2022, 15, 4569. [Google Scholar] [CrossRef]

- Wang, Q.; Zhong, Y.; Li, H.; Wang, S.; Liu, J.; Wang, Y.; Ramachandran, C.S. Effect of Cobalt and Chromium Content on Microstructure and Properties of WC-Co-Cr Coatings Prepared by High-Velocity Oxy-Fuel Spraying. Materials 2023, 16, 7003. [Google Scholar] [CrossRef]

- Matikainen, V.; Koivuluoto, H.; Vuoristo, P.; Schubert, J. Effect of Nozzle Geometry on the Microstructure and Properties of HVAF-Sprayed WC-10Co4Cr and Cr3C2-25NiCr Coatings. J. Therm. Spray Technol. 2018, 27, 680–694. [Google Scholar] [CrossRef]

- Liu, S.; Ma, X.; Zhen, X.; Wang, F.; Liu, Y.; Meng, Q. Effect of WC-10Co-4Cr Reinforcement Amount on Wear and Corrosion Resistance of Fe-Based Amorphous Coatings. J. Therm. Spray Technol. 2024, 33, 1601–1611. [Google Scholar] [CrossRef]

- Picas, J.A.; Punset, M.; Rupérez, E.; Menargues, S.; Martin, E.; Baile, M.T. Corrosion Mechanism of HVOF Thermal Sprayed WC-CoCr Coatings in Acidic Chloride Media. Surf. Coat. Technol. 2019, 371, 378–388. [Google Scholar] [CrossRef]

- Cui, S.; Miao, Q.; Xu, Y.; Li, B. Comparative Analysis of Tribological Behavior of Plasma- and High-Velocity Oxygen Fuel-Sprayed WC-10Co-4Cr Coatings | Emerald Insight. Ind. Lubr. Tribol. 2017, 69, 325–332. [Google Scholar] [CrossRef]

- Xi, H.; He, P.; Wang, H.; Liu, M.; Chen, S.; Xing, Z.; Ma, G.; Lv, Z. Microstructure and Mechanical Properties of Mo Coating Deposited by Supersonic Plasma Spraying. Int. J. Refract. Met. Hard Mater. 2020, 86, 105095. [Google Scholar] [CrossRef]

- Liang, X.; Zhuang, T.; Lan, L.; Huang, J.; Li, S.; Lei, Y.; Xu, B.; Wang, Y.; Shi, X.; Hu, Q. Study on Wear and Scour Performance of Ni6035WC/Wc-10Cr-4Cr Coating by HVAF. Coatings 2024, 14, 1148. [Google Scholar] [CrossRef]

- Yin, M.; Shao, Y.; Kang, X.; Long, J.; Zhang, X. Fretting Corrosion Behavior of WC-10Co-4Cr Coating on Inconel 690 Alloy by HVOF Thermal Spraying. Tribol. Int. 2023, 177, 107975. [Google Scholar] [CrossRef]

- Hong, S.; Wu, Y.; Zhang, J.; Zheng, Y.; Qin, Y.; Lin, J. Ultrasonic Cavitation Erosion of High-Velocity Oxygen-Fuel (HVOF) Sprayed near-Nanostructured WC–10Co–4Cr Coating in NaCl Solution. Ultrason. Sonochem. 2015, 26, 87–92. [Google Scholar] [CrossRef]

- Angelastro, A.; Campanelli, S.L.; Casalino, G.; Ludovico, A.D. Optimization of Ni-Based WC/Co/Cr Composite Coatings Produced by Multilayer Laser Cladding. Adv. Mater. Sci. Eng. 2013, 2013, 615464. [Google Scholar] [CrossRef]

- López-Baltazar, E.A.; Ruiz-Luna, H.; Baltazar-Hernández, V.H.; Ruiz-Mondragón, J.J.; Ibarra-Medina, J.; Alvarado-Orozco, J.M. Effect of the Average Energy on WC Grain Growth of WC-10Co-4Cr Composite by Laser Cladding. Metals 2019, 9, 1245. [Google Scholar] [CrossRef]

- Shi, J.; Ge, Y.; Kong, D. Microstructure, Dry Sliding Friction Performances and Wear Mechanism of Laser Cladded WC–10Co4Cr Coating with Different Al2O3 Mass Fractions. Surf. Coat. Technol. 2021, 406, 126749. [Google Scholar] [CrossRef]

- Jiangzheng, S.; Dejun, K. Effects on Al2O3 and La2O3 Additions on Electrochemical Performances of Laser-Cladded WC10Co4Cr Coatings. Int. J. Appl. Ceram. Technol. 2022, 19, 436–450. [Google Scholar] [CrossRef]

- Khanna, A.S.; Kumari, S.; Kanungo, S.; Gasser, A. Hard Coatings Based on Thermal Spray and Laser Cladding. Int. J. Refract. Met. Hard Mater. 2009, 27, 485–491. [Google Scholar] [CrossRef]

- Naghiyan Fesharaki, M.; Shoja-Razavi, R.; Mansouri, H.A.; Jamali, H. Microstructure Investigation of Inconel 625 Coating Obtained by Laser Cladding and TIG Cladding Methods. Surf. Coat. Technol. 2018, 353, 25–31. [Google Scholar] [CrossRef]

- Geng, Z.; Zhang, M.; Zhu, J.; Peng, Y.; Zhang, W.; Liu, F. Effect of Chromium Carbide Addition on the Microstructures and Properties in Dual Carbide Phases Reinforced Ni-Based Composite Coatings by Plasma Cladding. Materials 2023, 16, 4580. [Google Scholar] [CrossRef]

- Fernández, M.R.; García, A.; Cuetos, J.M.; González, R.; Noriega, A.; Cadenas, M. Effect of Actual WC Content on the Reciprocating Wear of a Laser Cladding NiCrBSi Alloy Reinforced with WC. Wear 2015, 324–325, 80–89. [Google Scholar] [CrossRef]

- Ding, X.; Cheng, X.; Yu, X.; Li, C.; Yuan, C.; Ding, Z. Structure and Cavitation Erosion Behavior of HVOF Sprayed Multi-Dimensional WC–10Co4Cr Coating. Trans. Nonferrous Met. Soc. China 2018, 28, 487–494. [Google Scholar] [CrossRef]

- Hou, G.; An, Y.; Liu, G.; Zhou, H.; Chen, J.; Chen, Z. Effect of Atmospheric Plasma Spraying Power on Microstructure and Properties of WC-(W,Cr)2C-Ni Coatings. J. Therm. Spray Technol. 2011, 20, 1150–1160. [Google Scholar] [CrossRef]

- Wang, Z.; Tan, M.; Wang, J.; Zeng, J.; Zhao, F.; Xiao, X.; Xu, S.; Liu, B.; Gong, L.; Sui, Q.; et al. Core-Shell Structural Iron Based Metal Matrix Composite Powder for Laser Cladding. J. Alloys Compd. 2021, 878, 160127. [Google Scholar] [CrossRef]

- Biswas, K.; Sahoo, C.K. The Performance Evaluation of WC/Co-Cr Coating for Developing Hard, Wear, and Corrosion Resistance Surface Using TIG Arc Source. Int. J. Refract. Met. Hard Mater. 2025, 128, 106983. [Google Scholar] [CrossRef]

- Murugan, K.; Ragupathy, A.; Balasubramanian, V.; Sridhar, K. Optimizing HVOF Spray Process Parameters to Attain Minimum Porosity and Maximum Hardness in WC–10Co–4Cr Coatings. Surf. Coat. Technol. 2014, 247, 90–102. [Google Scholar] [CrossRef]

- Prasad, R.V.; Rajesh, R.; Thirumalaikumarasamy, D.; Vignesh, S.; Sreesabari, S. Sensitivity Analysis and Optimisation of HVOF Process Inputs to Reduce Porosity and Maximise Hardness of WC-10Co-4Cr Coatings. Sādhanā 2021, 46, 149. [Google Scholar] [CrossRef]

- Vaz, R.F.; Silvello, A.; Albaladejo, V.; Sanchez, J.; Cano, I.G. Improving the Wear and Corrosion Resistance of Maraging Part Obtained by Cold Gas Spray Additive Manufacturing. Metals 2021, 11, 1092. [Google Scholar] [CrossRef]

- Ceviz, M.; Misirli, C.; Karabeyoglu, S.S. The Effect of Temperature on Wear Performance of High-Velocity Oxy-Fuel Sprayed WC-10Co-4Cr Coating on AA7075-T6 Substrate. J. Mater. Eng. Perform. 2022, 31, 128–138. [Google Scholar] [CrossRef]

| Element/wt.% | Cr | Co | W | C |

|---|---|---|---|---|

| WC-10Co-4Cr powder | 4.28 | 8.32 | 71.49 | 15.91 |

| Element/wt.% | C | Si | Mn | P | S | Ni | Cr | Mo |

|---|---|---|---|---|---|---|---|---|

| 304 stainless steel | ≤0.08 | ≤1.0 | ≤2.0 | ≤0.035 | ≤0.035 | 8.0~10.5 | 18.0~20.0 | - |

| 316 stainless steel | ≤0.08 | ≤1.0 | ≤2.0 | ≤0.035 | ≤0.035 | 10.0~14.0 | 16.0~18.0 | 2.0~3.0 |

| HV | AVG. | σ |

|---|---|---|

| APS | 1341.7 | 101.6 |

| LC | 1440.5 | 54.4 |

Disclaimer/Publisher’s Note: The statements, opinions and data contained in all publications are solely those of the individual author(s) and contributor(s) and not of MDPI and/or the editor(s). MDPI and/or the editor(s) disclaim responsibility for any injury to people or property resulting from any ideas, methods, instructions or products referred to in the content. |

© 2025 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (https://creativecommons.org/licenses/by/4.0/).

Share and Cite

Geng, Z.; Liu, F.; Wang, Y. Wear Resistance of WC-10Co-4Cr Cemented Carbide Coatings Prepared by Atmospheric Plasma Spraying and Laser Cladding. Metals 2025, 15, 309. https://doi.org/10.3390/met15030309

Geng Z, Liu F, Wang Y. Wear Resistance of WC-10Co-4Cr Cemented Carbide Coatings Prepared by Atmospheric Plasma Spraying and Laser Cladding. Metals. 2025; 15(3):309. https://doi.org/10.3390/met15030309

Chicago/Turabian StyleGeng, Zhanji, Feng Liu, and Yuping Wang. 2025. "Wear Resistance of WC-10Co-4Cr Cemented Carbide Coatings Prepared by Atmospheric Plasma Spraying and Laser Cladding" Metals 15, no. 3: 309. https://doi.org/10.3390/met15030309

APA StyleGeng, Z., Liu, F., & Wang, Y. (2025). Wear Resistance of WC-10Co-4Cr Cemented Carbide Coatings Prepared by Atmospheric Plasma Spraying and Laser Cladding. Metals, 15(3), 309. https://doi.org/10.3390/met15030309