Microstructural Evolution and Tensile Properties of Nb-V-Ti-N Microalloyed Steel with Varying Nitrogen Contents

Abstract

1. Introduction

2. Materials and Methods

3. Results

3.1. Yeild Strength (YS)

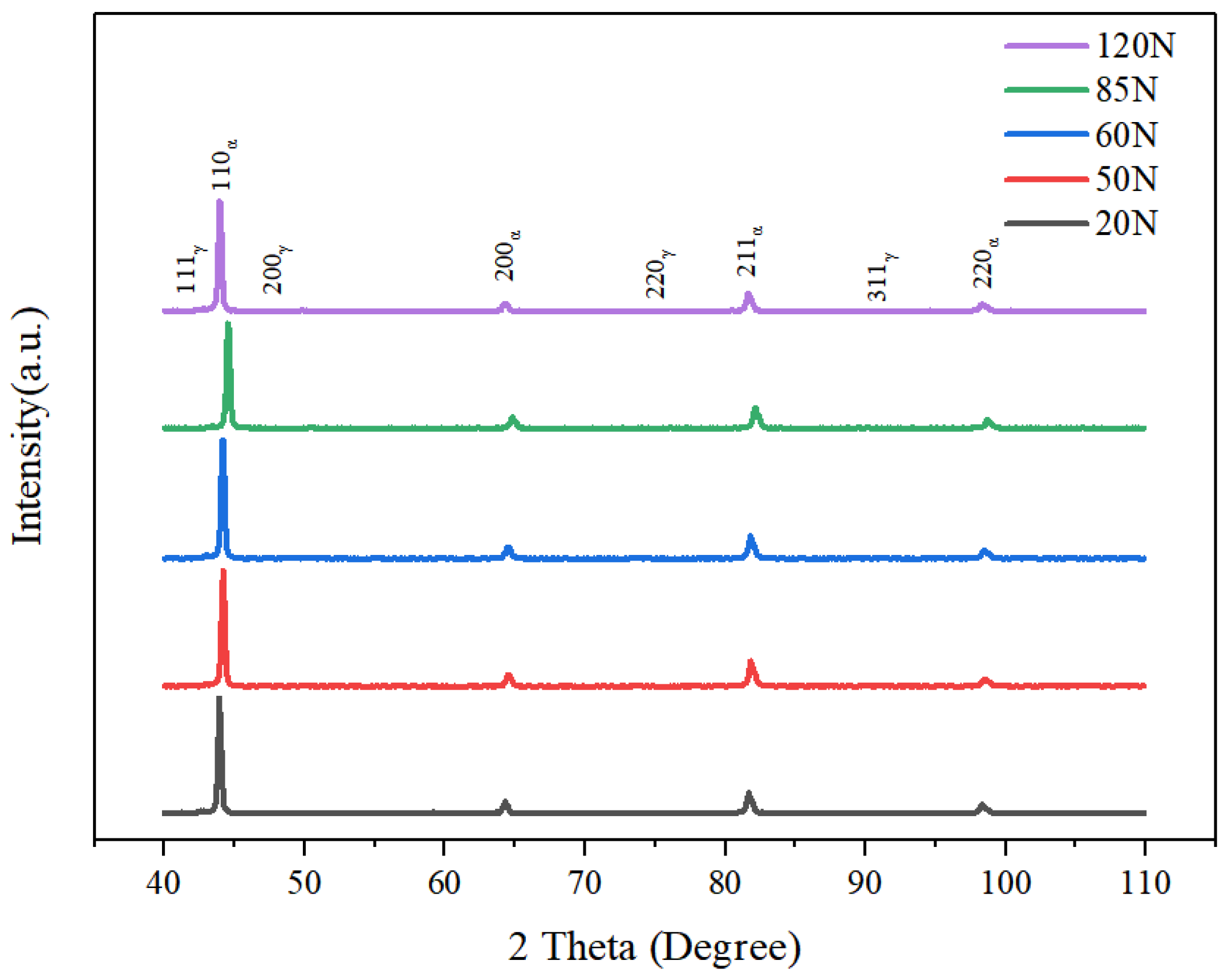

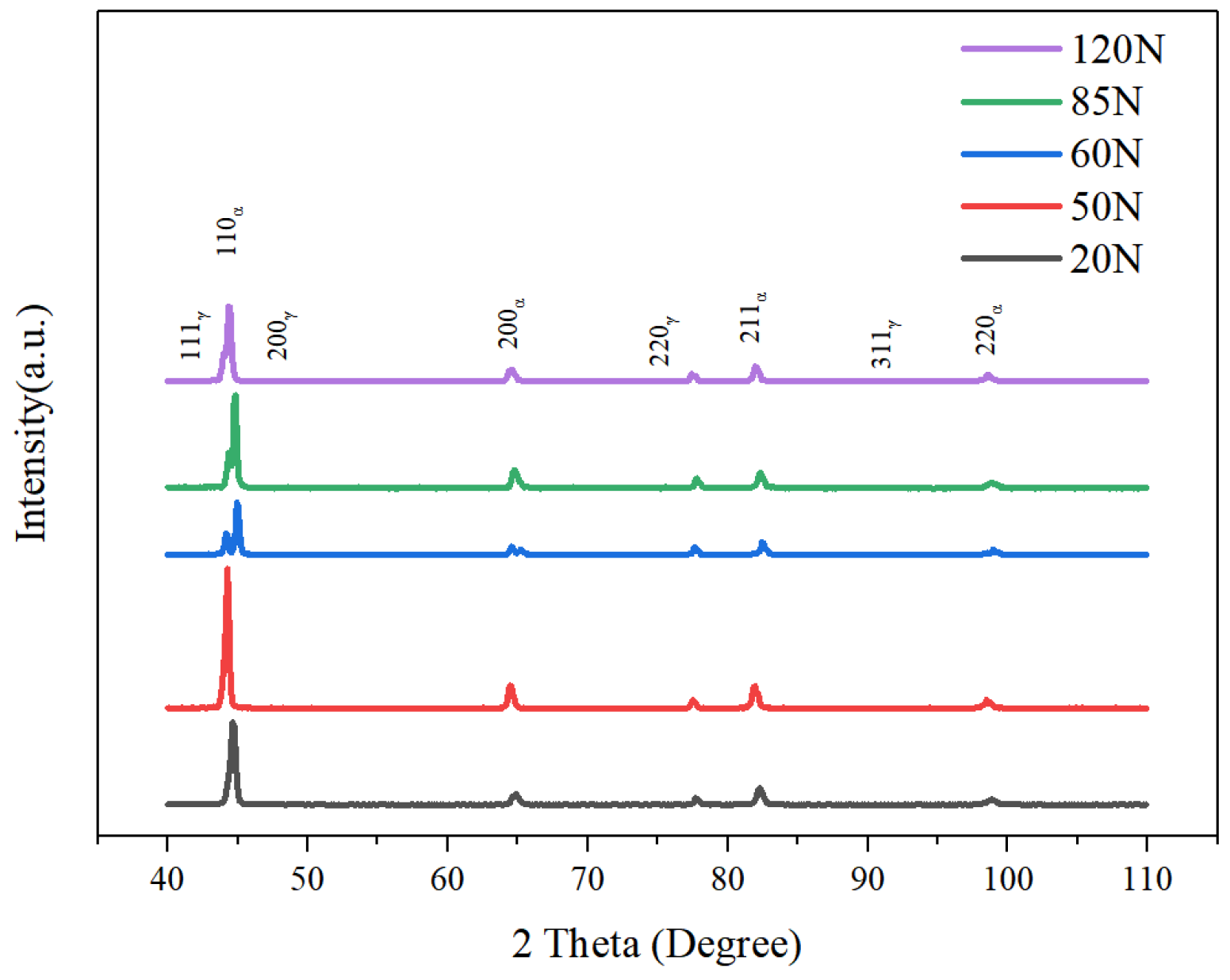

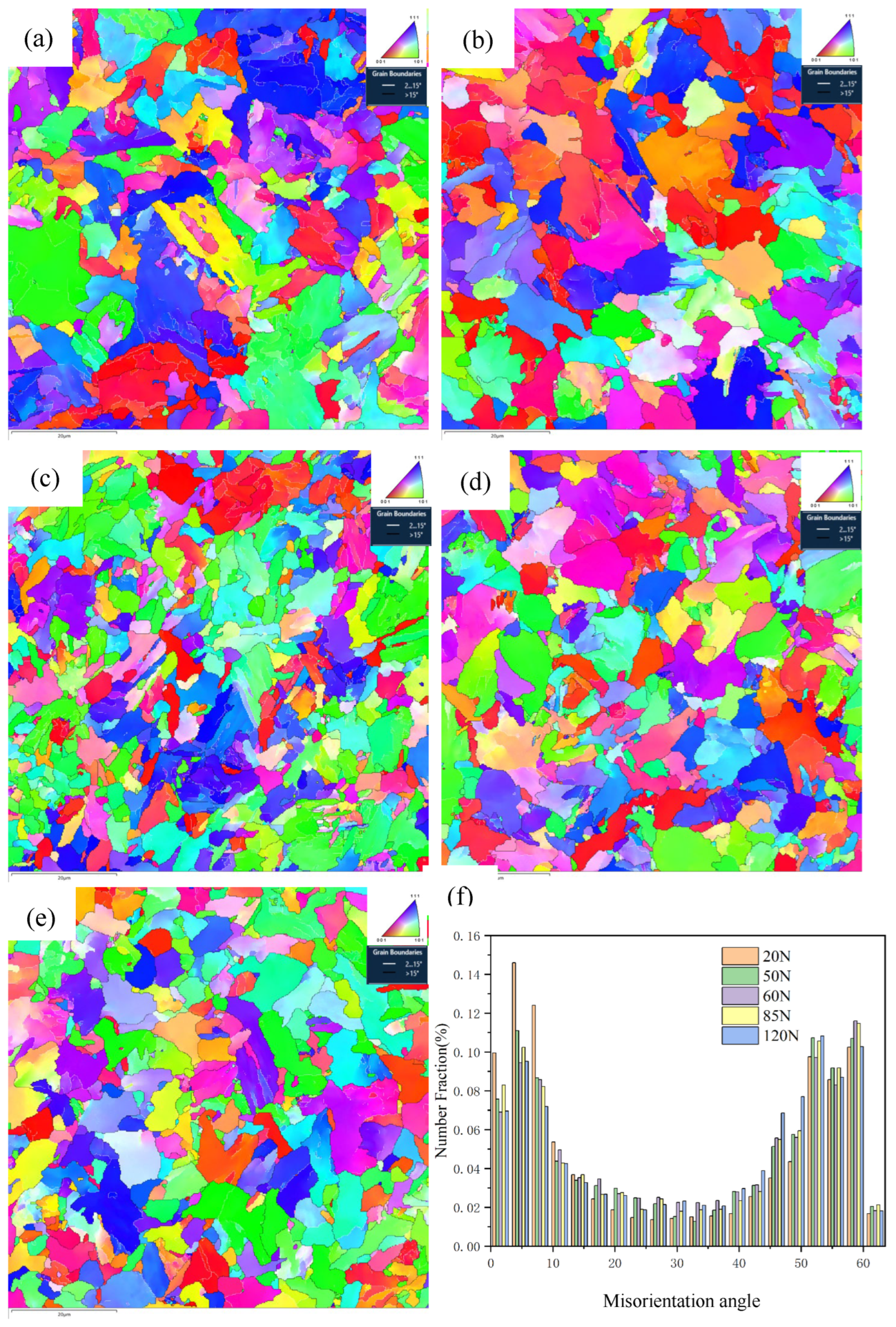

3.2. Microstructure Characterization

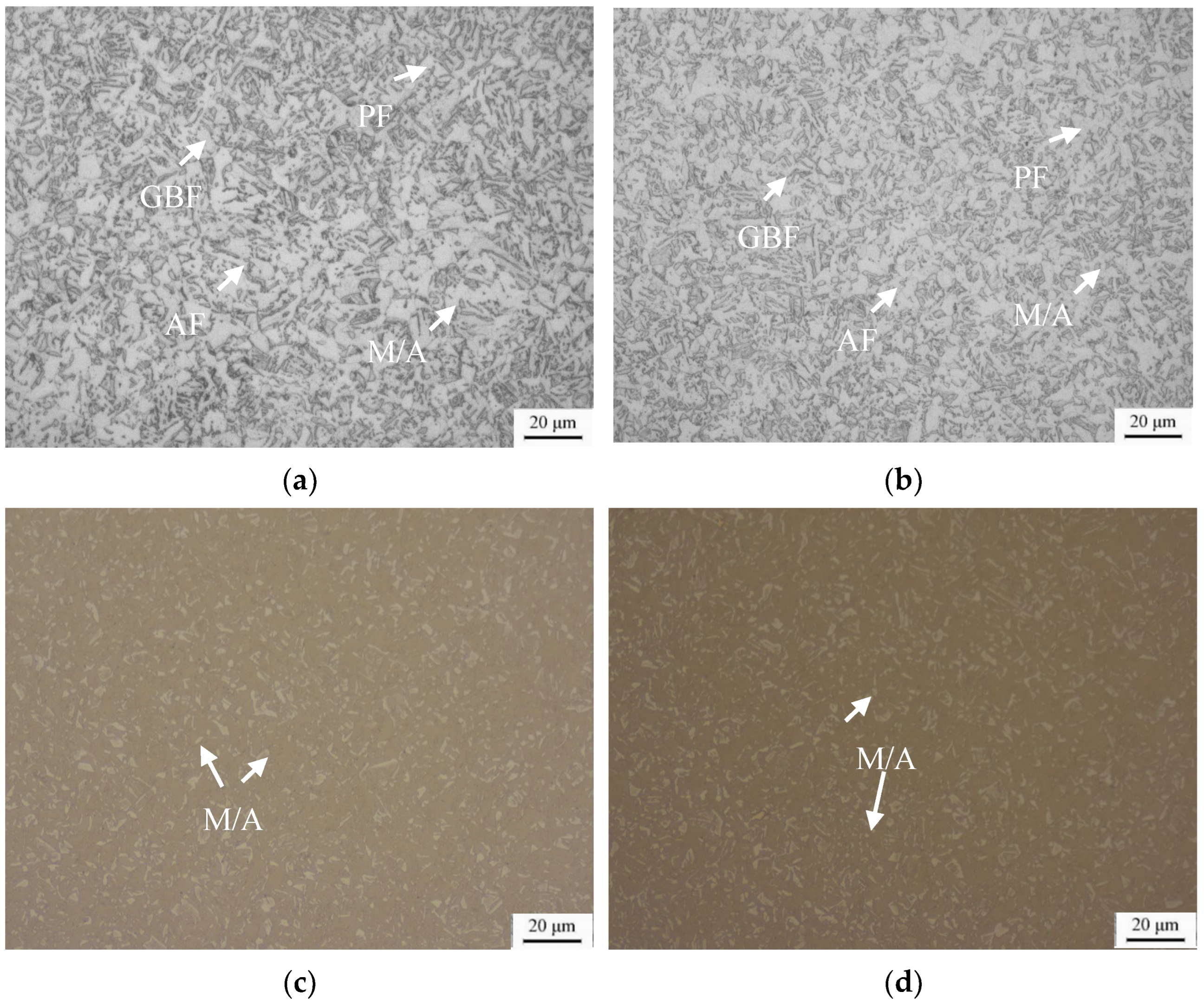

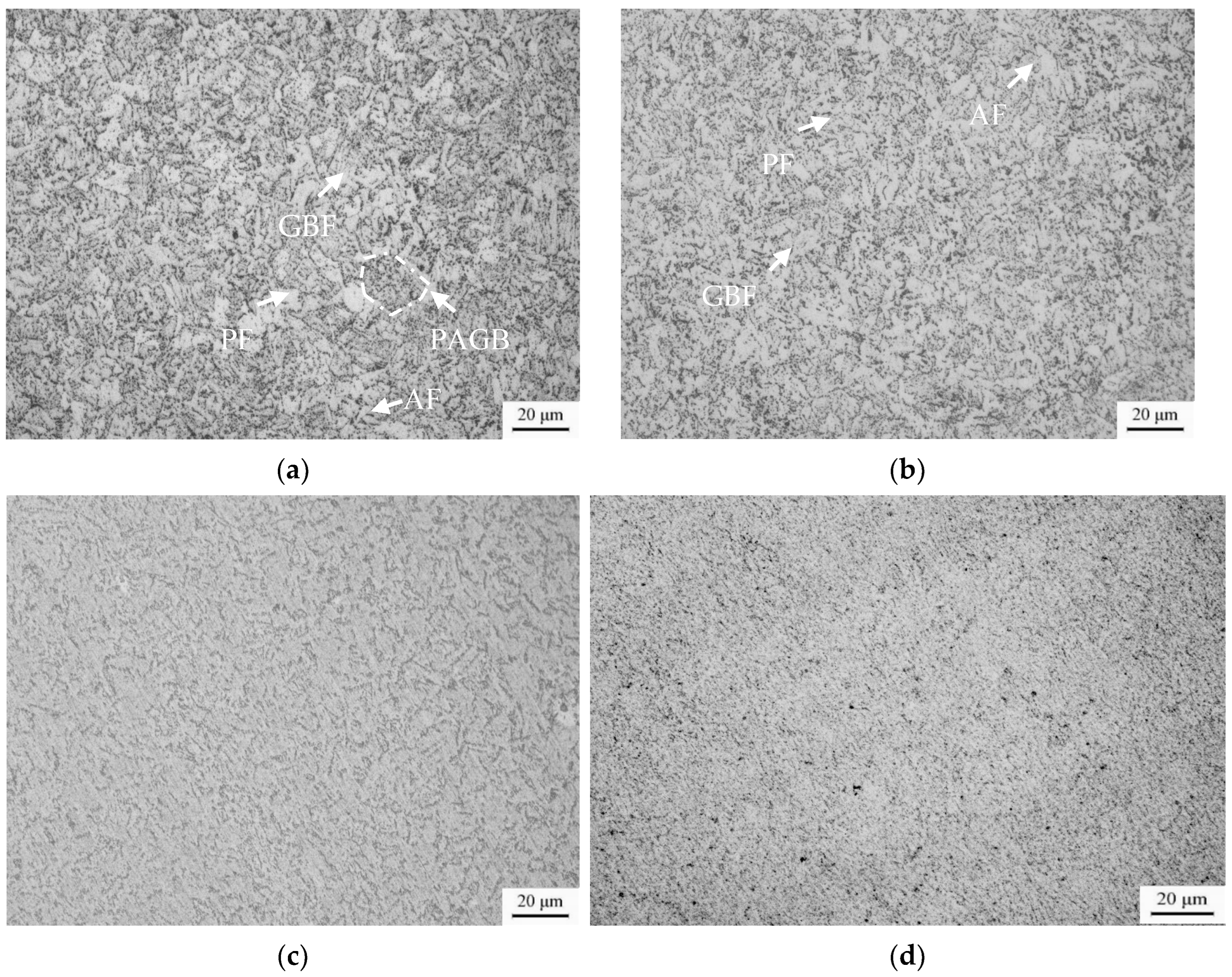

Microstructure of the Tested Steel After Quenching Treatment

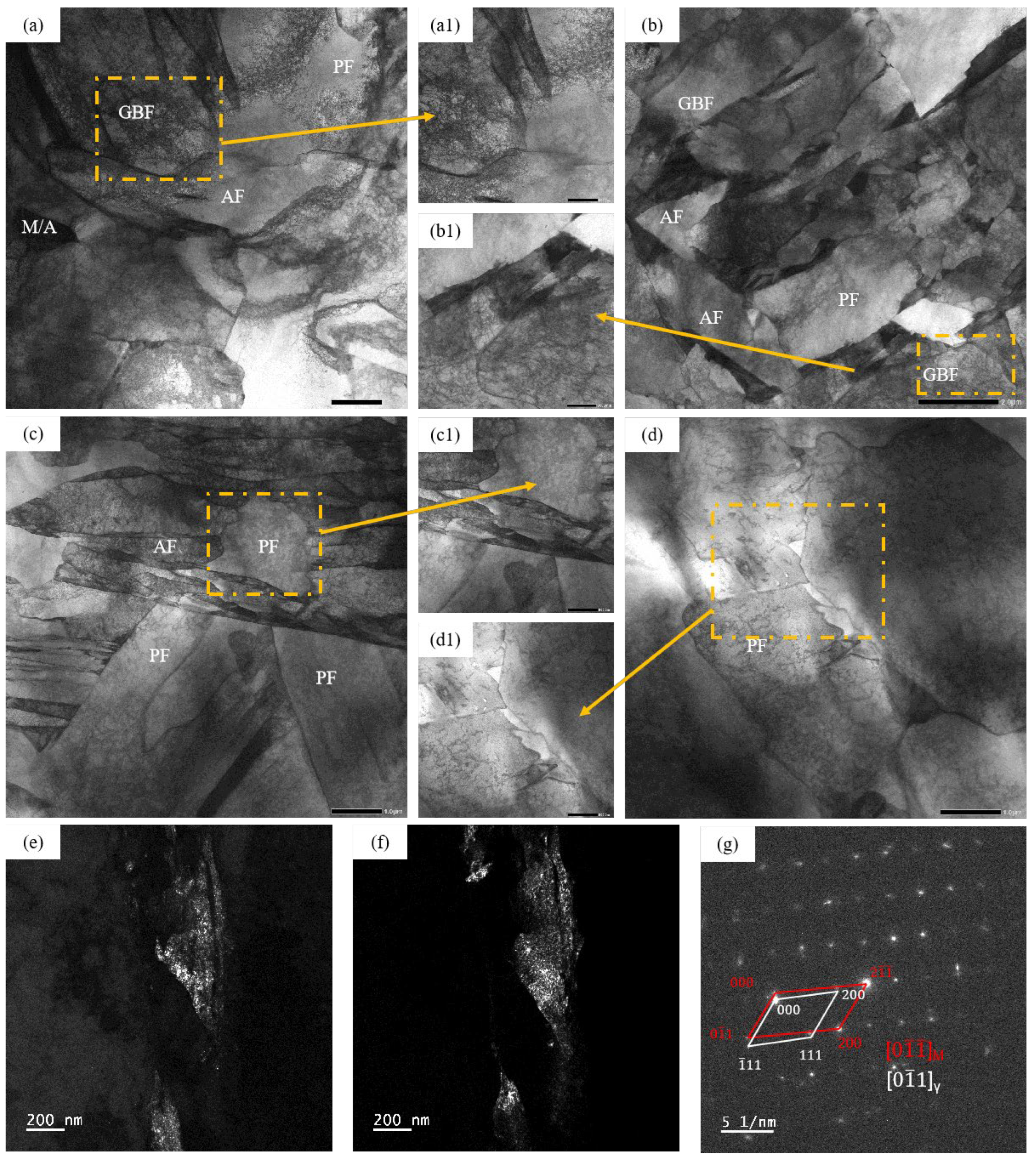

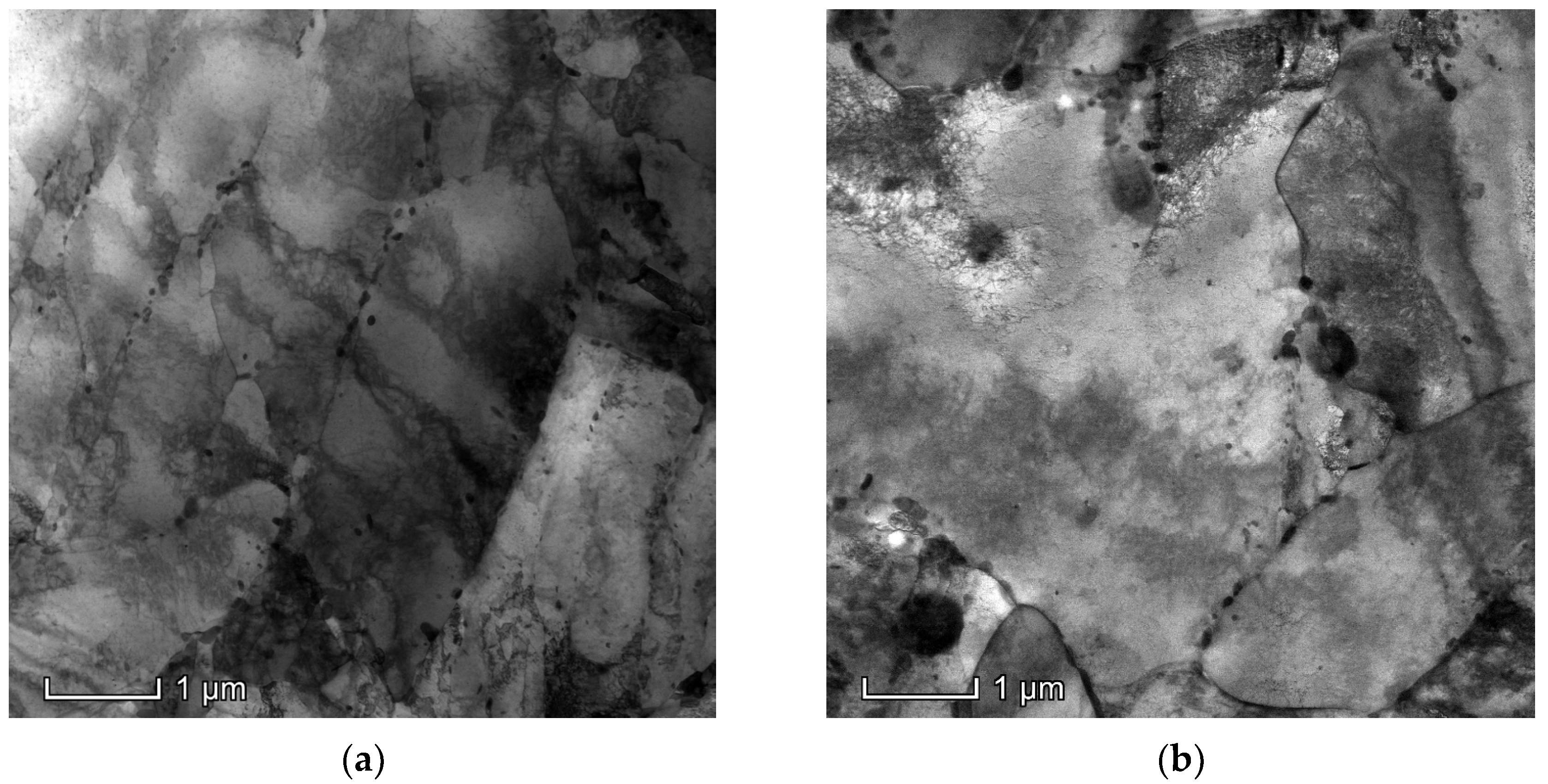

3.3. Microstructure of the Tested Steel After Quenching and Tempering Treatment

4. Discussion

4.1. Effect of Nitrogen Content on Microstructure Evolution

4.2. Effect of Nitrogen Content on the Yield Strength

- σt—yield strength;

- σ0—lattice strengthening;

- σs—solid solution strengthening;

- σg—fine grain strengthening;

- σρ—dislocation strengthening;

- σp—precipitation strengthening.

- σg—yield strength;

- σ0—other enhancements;

- KHP—correlation coefficient;

- D—grain size.

- σρ—dislocation strengthening;

- α—structural constant, taken as 0.15 [4];

- M—Taylor factor, taken as 2.73 [4];

- G—shear modulus, taken as 81.6 GPa [4];

- b—Burgers vector, taken as 0.248 nm;

- ρ—dislocation density.

5. Conclusions

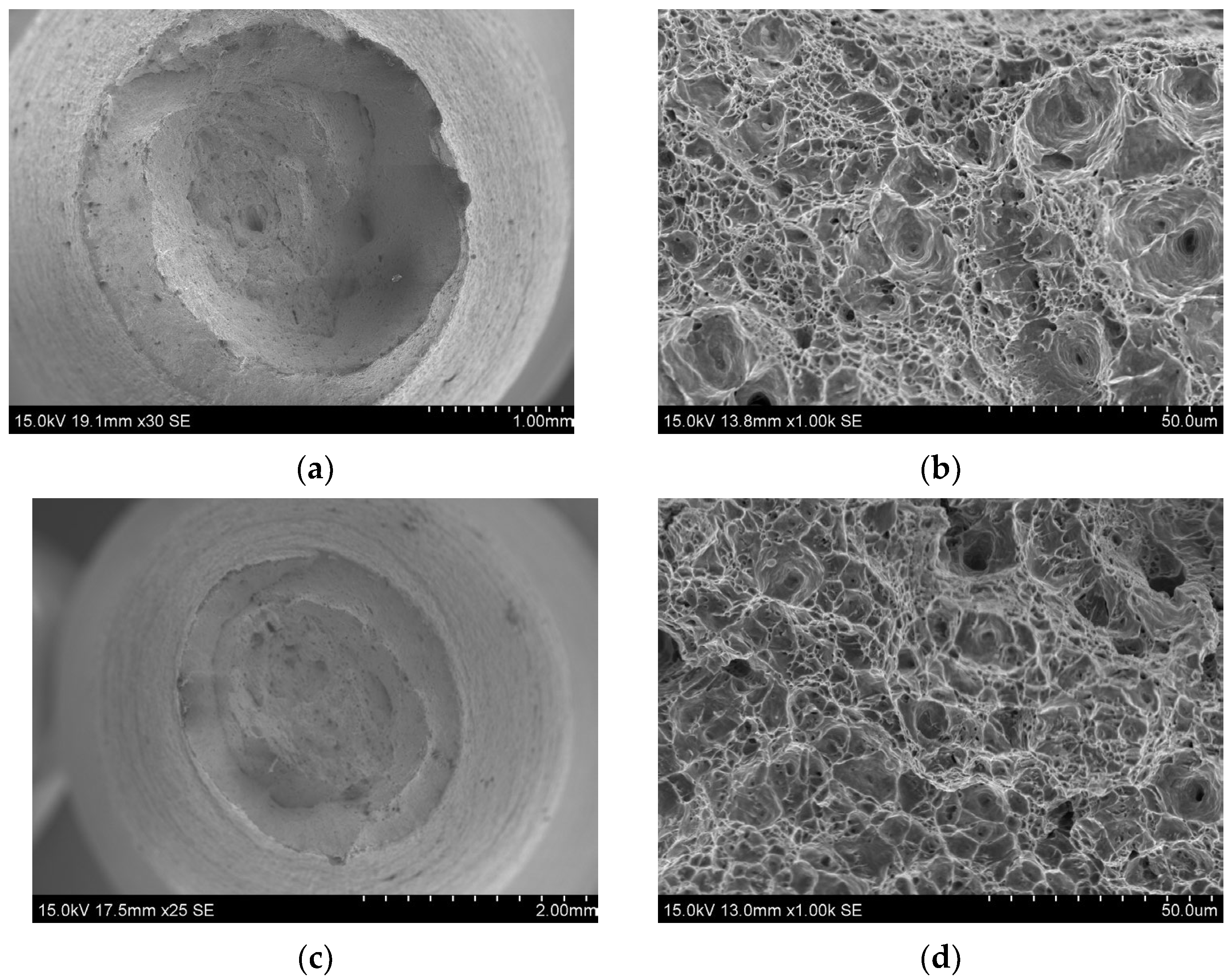

- The primary microstructure after quenching comprised granular bainitic ferrite (GBF), acicular ferrite (AF), polygonal ferrite (PF), and residual martensite/austenite (M/A) components. As the nitrogen content increased, the content of AF and M/A constituents gradually rose, while that of GBF correspondingly decreased. After tempering, the microstructure transformed into GBF, AF, and carbonitrides. The increase in nitrogen content led to a significant increase in the number of high-angle grain boundaries.

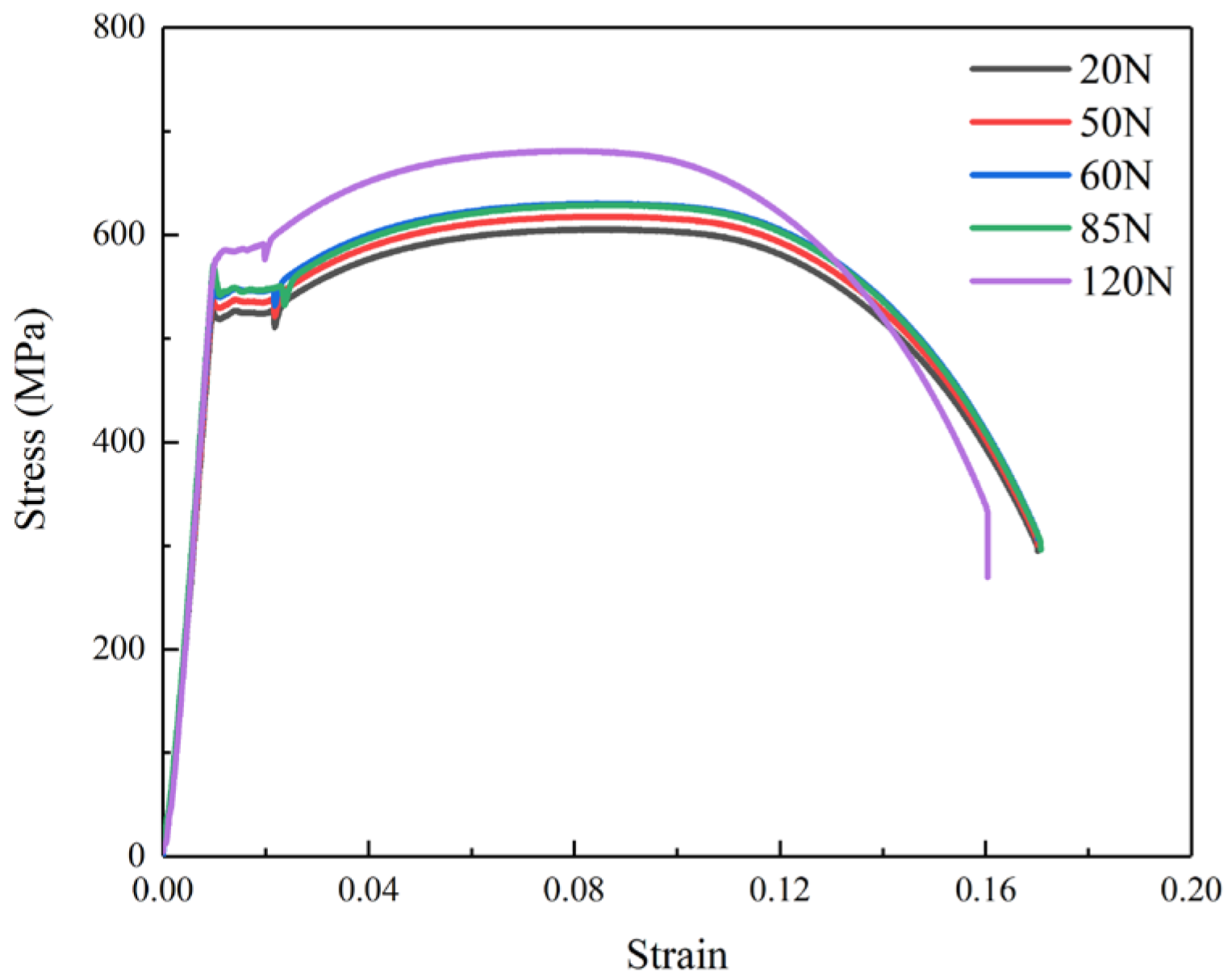

- With rising nitrogen content, the yield strength (YS) and ultimate tensile strength (UTS) of the steel gradually increased. Specifically, YS increased from 510 MPa to 576 MPa, and UTS from 605 MPa to 681 MPa, as nitrogen content varied from 20 ppm to 120 ppm. However, the elongation at break (TE) slightly decreased from 16.4% to 15.4%. The enhancement in yield strength can be attributed to multiple strengthening mechanisms, including fine grain strengthening, dislocation strengthening, and precipitation strengthening.

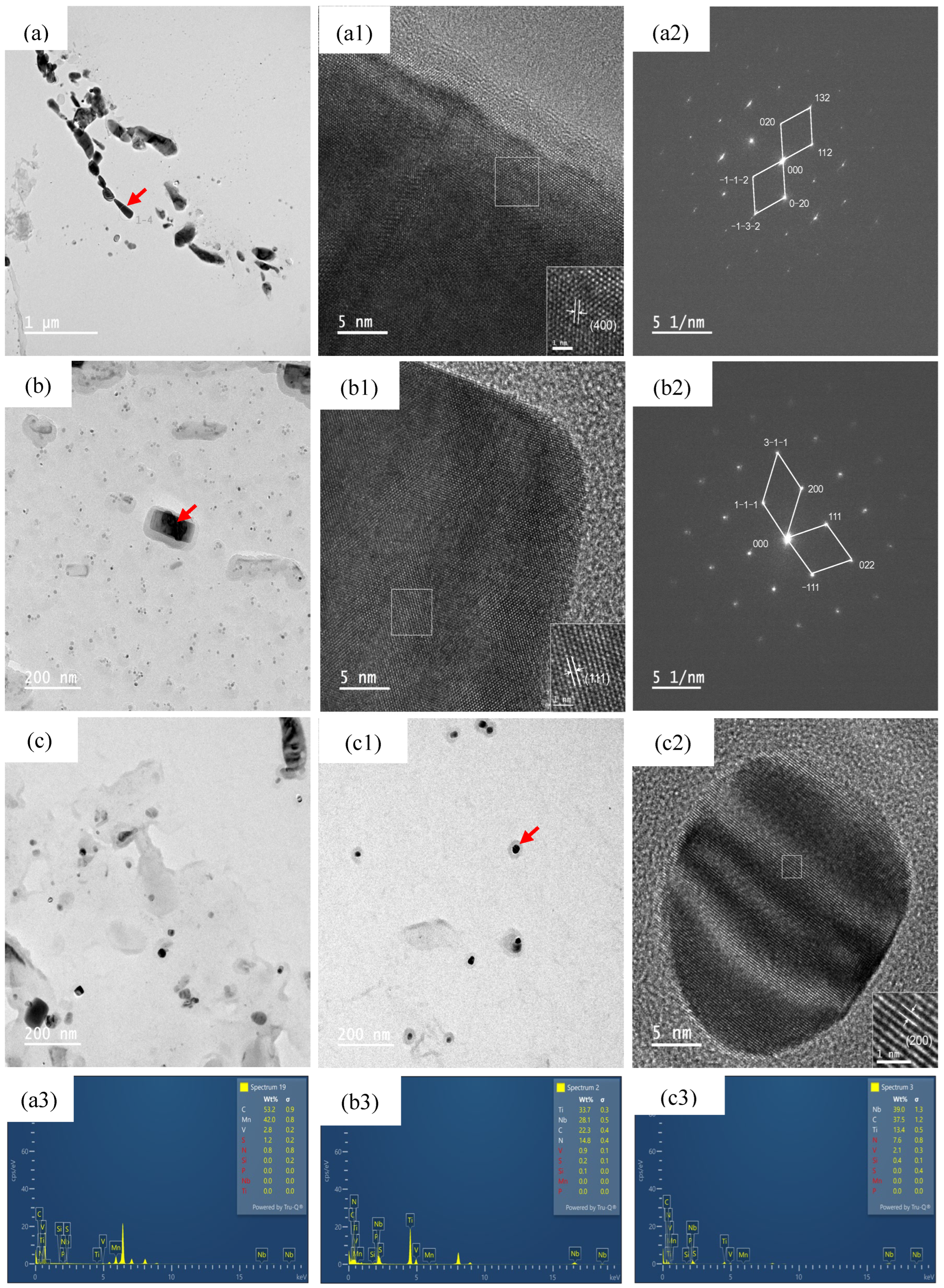

- Nitrogen addition led to the formation of a larger number of micro- and nano-scale precipitated particles, such as (Nb, V, Ti)(C, N), which refined the microstructure and served as nucleation sites for intragranular AF, enhancing the nucleation and growth of ferrite phases.

Author Contributions

Funding

Data Availability Statement

Conflicts of Interest

References

- Fang, B.; Hui, W.; Song, H.; Zhang, Y.; Zhao, X.; Xu, L. Hydrogen embrittlement of a V+Nb-microalloyed medium-carbon bolt steel subjected to different tempering temperatures. Int. J. Hydrog. Energy 2024, 81, 458–470. [Google Scholar] [CrossRef]

- Xu, G.; Gan, X.; Ma, G.; Luo, F.; Zou, H. The development of Ti-alloyed high strength microalloy steel. Mater. Des. 2010, 31, 2891–2896. [Google Scholar] [CrossRef]

- Korchynsky, M. Nitrogen Enhanced Ferritic Microalloyed Steels. In Proceedings of the High Nitrogen Steels International Conference, Jiuzhaigou, China, 29–31 August 2006; pp. 1–12. [Google Scholar]

- Zhang, S.; Liu, K.; Chen, H.; Xiao, X.; Qingfeng, W.; Fucheng, Z. Effect of increased N content on microstructure and tensile properties of low-C V-microalloyed steels. Mater. Sci. Eng. A 2016, 651, 951–960. [Google Scholar] [CrossRef]

- Staiger, M.P.; Jessop, B.; Hodgson, P.D.; Davies, C.H.J. Effect of nitrogen on formation of martensite-austenite constituent in low carbon steels. ISIJ Int. 1999, 39, 183–190. [Google Scholar] [CrossRef]

- Shi, Z.; Yang, C.; Wang, R.; Su, H.; Chai, F.; Chu, J.; Wang, Q. Effect of nitrogen on the microstructures and mechanical properties in simulated CGHAZ of vanadium microalloyed steel varied with different heat inputs. Mater. Sci. Eng. A 2016, 649, 270–281. [Google Scholar] [CrossRef]

- Chen, H.; Zhang, S.; Shi, G.; Gao, Y.; Qingfeng, W.; Fucheng, Z. Mechanism of increased N content in controlling the M-A constituent of low-carbon Mo-V-N steel. Mater. Lett. 2017, 189, 136–139. [Google Scholar] [CrossRef]

- Shi, G.; Luo, B.; Zhang, S.; Wang, Q.; Qingfeng, W. Microstructural evolution and mechanical properties of a low-carbon V–N–Ti steel processed with varied isothermal temperatures. Mater. Sci. Eng. A 2021, 801, 140396. [Google Scholar] [CrossRef]

- Rogachev, S.O.; Nikulin, S.A.; Khatkevich, V.M. Increasing the strength of low-carbon steel after overheating. Mater. Lett. 2024, 377, 137510. [Google Scholar] [CrossRef]

- Xiong, Z.; Liu, S.; Wang, X.; Kang, J. The contribution of intragranular acicular ferrite microstructural constituent on impact toughness and impeding crack initiation and propagation in the heat-affected zone (HAZ) of low-carbon steels. Mater. Sci. Eng. A 2015, 636, 117–123. [Google Scholar] [CrossRef]

- Choi, J.Y.; Ji, J.H.; Hwang, S.W.; Park, K.T. Effects of nitrogen content on TRIP of Fe–20Cr–5Mn–xN duplex stainless steel. Mater. Sci. Eng. A 2012, 534, 673–680. [Google Scholar] [CrossRef]

- Zajac, S.; Siwecki, T.; WB, H.; Lagneborg, R. Strengthening mechanisms in vanadium microalloyed steels intended for long products. ISIJ Int. 1998, 38, 1130–1139. [Google Scholar] [CrossRef]

- Zhao, B.; Zhao, T.; Li, G.; Lu, Q. Effect of Nitrogen on Transformation Behaviors and Microstructure of VN Microalloyed Steel. In HSLA Steels 2015 Microalloying 2015 & Offshore Engineering Steels 2015; Springer International Publishing: Cham, Switzerland, 2016; pp. 135–141. [Google Scholar]

- Zhang, L.; Kannengiesser, T. Austenite grain growth and microstructure control in simulated heat affected zones of microalloyed HSLA steel. Mater. Sci. Eng. A 2014, 613, 326–333. [Google Scholar] [CrossRef]

- Wu, K.M.; Yokomizo, T.; Enomoto, M. Three-dimensional Morphology and Growth Kinetics of Intragranular Ferrite Idiomorphs Formed in Association with Inclusions in an Fe-C-Mn Alloy. ISIJ Int. 2002, 42, 1144–1149. [Google Scholar] [CrossRef][Green Version]

- Park, K.-T.; Hwang, S.W.; Ji, J.H.; Lee, C.H. Inclusions nucleating intragranular polygonal ferrite and acicular ferrite in low alloyed carbon manganese steel welds. Met. Mater. Int. 2011, 17, 349–356. [Google Scholar] [CrossRef]

- Fan, H.; Shi, G.; Peng, T.; Wang, Q.; Wang, L.; Wang, Q.; Zhang, F. N-induced microstructure refinement and toughness improvement in thecoarse grain heat-affected zone of a low carbon Mo–V–Ti–B steel subjected to a high heat input welding thermal cycle. Mater. Sci. Eng. A 2021, 824, 141799. [Google Scholar] [CrossRef]

- Karmakar, A.; Kundu, S.; Roy, S.; Neogy, S.; Srivastava, D.; Chakrabarti, D. Effect of microalloying elements on austenite grain growth in Nb–Ti and Nb–V steels. Mater. Sci. Technol. 2014, 30, 653–664. [Google Scholar] [CrossRef]

- Zhang, J.; Xin, W.; Luo, G.; Wang, R.; Meng, Q.; Xian, S. Effect of welding heat input on microstructural evolution, precipitation behavior and resultant properties of the simulated CGHAZ in high-N V-alloyed steel. Mater. Charact. 2020, 162, 110201. [Google Scholar] [CrossRef]

- Hall, E. The Deformation and Ageing of Mild Steel: III Discussion of Results. Proc. Phys. Soc. Sect. B 1951, 64, 747–753. [Google Scholar] [CrossRef]

- Yakubtsov, I.; Poruks, P.; Boyd, J. Microstructure and mechanical properties of bainitic low carbon high strength plate steels. Mater. Sci. Eng. A 2008, 480, 109–116. [Google Scholar] [CrossRef]

- Kaijalainen, A.J.; Suikkanen, P.P.; Limnell, T.J.; Karjalainen, L.P.; Kömi, J.I.; Porter, D.A. Effect of austenite grain structure on the strength and toughness of direct-quenched martensite. J. Alloys Compd. 2013, 577, S642–S648. [Google Scholar] [CrossRef]

- Hughes, D. Microstructure evolution, slip patterns and flow stress. Mater. Sci. Eng. A 2001, 319–321, 46–54. [Google Scholar] [CrossRef]

- Wang, G.R.; Lau, T.W.; Weatherly, G.C.; North, T.H. Weld thermal cycles and precipitation effects in Ti-V-containing HSLA steels. Met. Mater. Trans. A 1989, 20, 2093–2100. [Google Scholar] [CrossRef]

| Steel | C | Mn | Si | S | P | Mo | Cr | V | Ti | Nb | Ni | B | N |

|---|---|---|---|---|---|---|---|---|---|---|---|---|---|

| 20 N | 0.09 | 1.19 | 0.23 | 0.002 | 0.002 | 0.14 | 0.13 | 0.043 | 0.012 | 0.027 | 0.15 | 0.0004 | 0.0018 |

| 50 N | 0.08 | 1.22 | 0.27 | 0.003 | 0.011 | 0.16 | 0.14 | 0.050 | 0.012 | 0.032 | 0.13 | 0.0003 | 0.0048 |

| 60 N | 0.09 | 1.26 | 0.23 | 0.003 | 0.009 | 0.16 | 0.14 | 0.050 | 0.014 | 0.030 | 0.13 | 0.0004 | 0.0059 |

| 85 N | 0.10 | 1.24 | 0.26 | 0.002 | 0.002 | 0.15 | 0.16 | 0.048 | 0.010 | 0.031 | 0.15 | 0.0004 | 0.0085 |

| 120 N | 0.10 | 1.24 | 0.26 | 0.002 | 0.002 | 0.15 | 0.16 | 0.048 | 0.010 | 0.031 | 0.15 | 0.0003 | 0.0120 |

| Steel | YS/MPa | UTS/MPa | TE |

|---|---|---|---|

| 20 N | 510 | 605 | 16.4 |

| 50 N | 521 | 617 | 16.4 |

| 60 N | 531 | 630 | 16.4 |

| 85 N | 532 | 629 | 16.5 |

| 120 N | 576 | 681 | 15.4 |

| Steel | fM/A (%) | f2° ≤ θ ≤ 15° (%) | MED2° ≤ θ ≤ 15° (μm) | Dp (nm) | fp (%) | ρ (×1014 m−2) |

|---|---|---|---|---|---|---|

| 20 | 12.6 | 44.3 | 5.15 | 9.15 | 0.68 × 10−4 | 2.79 |

| 50 | 13.2 | 33.7 | 4.87 | 9.60 | 0.80 × 10−4 | 2.84 |

| 60 | 13.6 | 31.8 | 4.53 | 9.65 | 0.86 × 10−4 | 2.78 |

| 85 | 15.3 | 31.3 | 4.42 | 10.38 | 1.01 × 10−4 | 2.48 |

| 120 | 16.2 | 29.8 | 3.34 | 13.69 | 1.65 × 10−4 | 2.54 |

| Steel | Ar3/°C | Ar1/°C |

|---|---|---|

| 20 N | 737 | 475 |

| 50 N | 760 | 485 |

| 60 N | 770 | 487 |

| 85 N | 772 | 461 |

| 120 N | 780 | 500 |

| Steel | YS/MPa | σg (MED) (MPa) | σρ (MPa) | σp (MPa) | σ0 + σs |

|---|---|---|---|---|---|

| 20 N | 510.89 | 265.60 | 138.5 | 29.62 | 77.17 |

| 50 N | 521.32 | 273.12 | 139.58 | 31.1 | 77.52 |

| 60 N | 531.74 | 283.19 | 138.11 | 32.23 | 78.21 |

| 85 N | 532.24 | 289.99 | 130.62 | 33.26 | 78.37 |

| 120 N | 576.37 | 328.80 | 131.97 | 35.2 | 80.40 |

Disclaimer/Publisher’s Note: The statements, opinions and data contained in all publications are solely those of the individual author(s) and contributor(s) and not of MDPI and/or the editor(s). MDPI and/or the editor(s) disclaim responsibility for any injury to people or property resulting from any ideas, methods, instructions or products referred to in the content. |

© 2025 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (https://creativecommons.org/licenses/by/4.0/).

Share and Cite

Liu, J.; Guo, K.; Ma, H.; He, J.; Wang, J.; Zhang, C.; Wang, T.; Wang, Q. Microstructural Evolution and Tensile Properties of Nb-V-Ti-N Microalloyed Steel with Varying Nitrogen Contents. Metals 2025, 15, 266. https://doi.org/10.3390/met15030266

Liu J, Guo K, Ma H, He J, Wang J, Zhang C, Wang T, Wang Q. Microstructural Evolution and Tensile Properties of Nb-V-Ti-N Microalloyed Steel with Varying Nitrogen Contents. Metals. 2025; 15(3):266. https://doi.org/10.3390/met15030266

Chicago/Turabian StyleLiu, Jiangcheng, Kai Guo, Haote Ma, Jiangli He, Junchao Wang, Chuanyou Zhang, Tiansheng Wang, and Qingfeng Wang. 2025. "Microstructural Evolution and Tensile Properties of Nb-V-Ti-N Microalloyed Steel with Varying Nitrogen Contents" Metals 15, no. 3: 266. https://doi.org/10.3390/met15030266

APA StyleLiu, J., Guo, K., Ma, H., He, J., Wang, J., Zhang, C., Wang, T., & Wang, Q. (2025). Microstructural Evolution and Tensile Properties of Nb-V-Ti-N Microalloyed Steel with Varying Nitrogen Contents. Metals, 15(3), 266. https://doi.org/10.3390/met15030266