Enhanced Cutting Performance of 50Cr15MoV Martensitic Stainless Steel Through Controlled Residual Austenite Stability

Abstract

1. Introduction

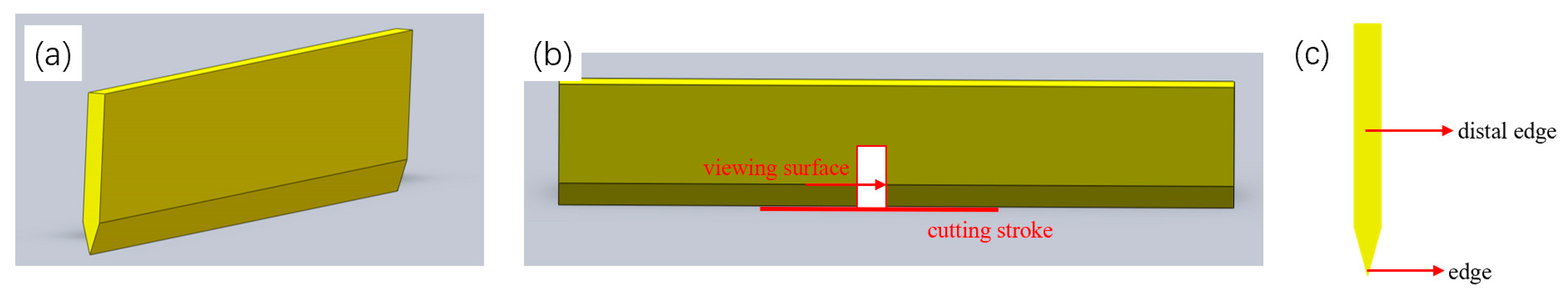

2. Materials and Methods

3. Results and Analyses

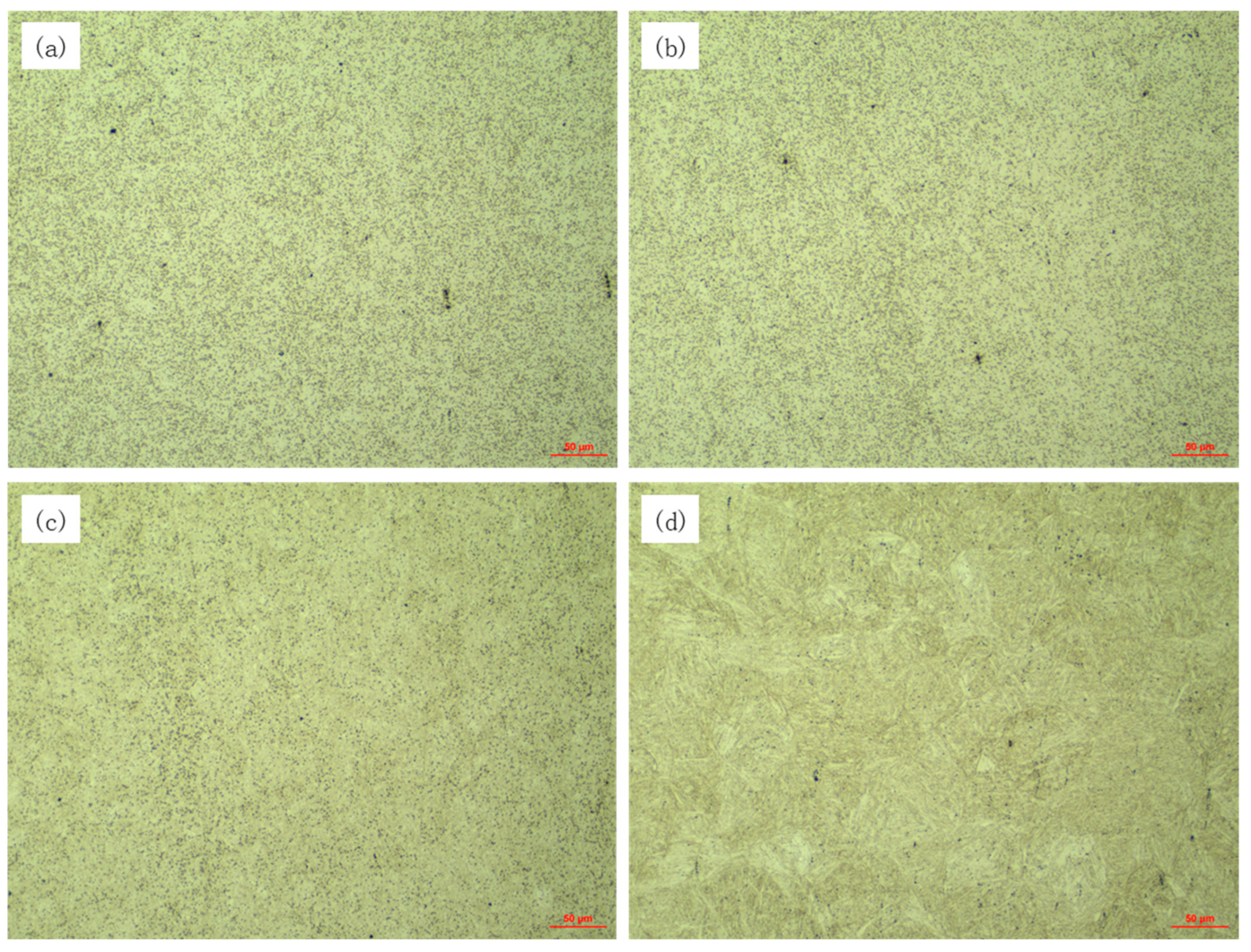

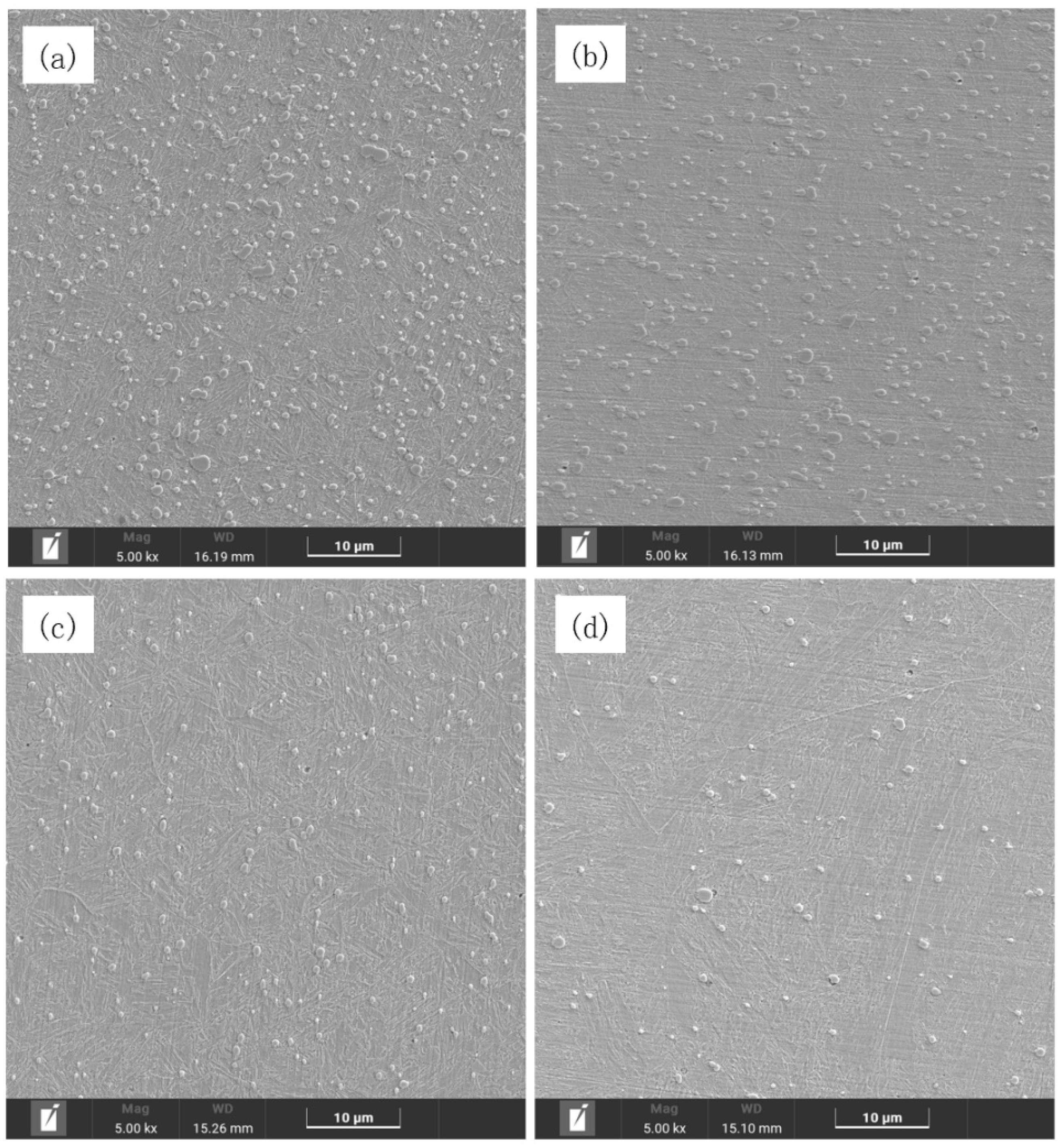

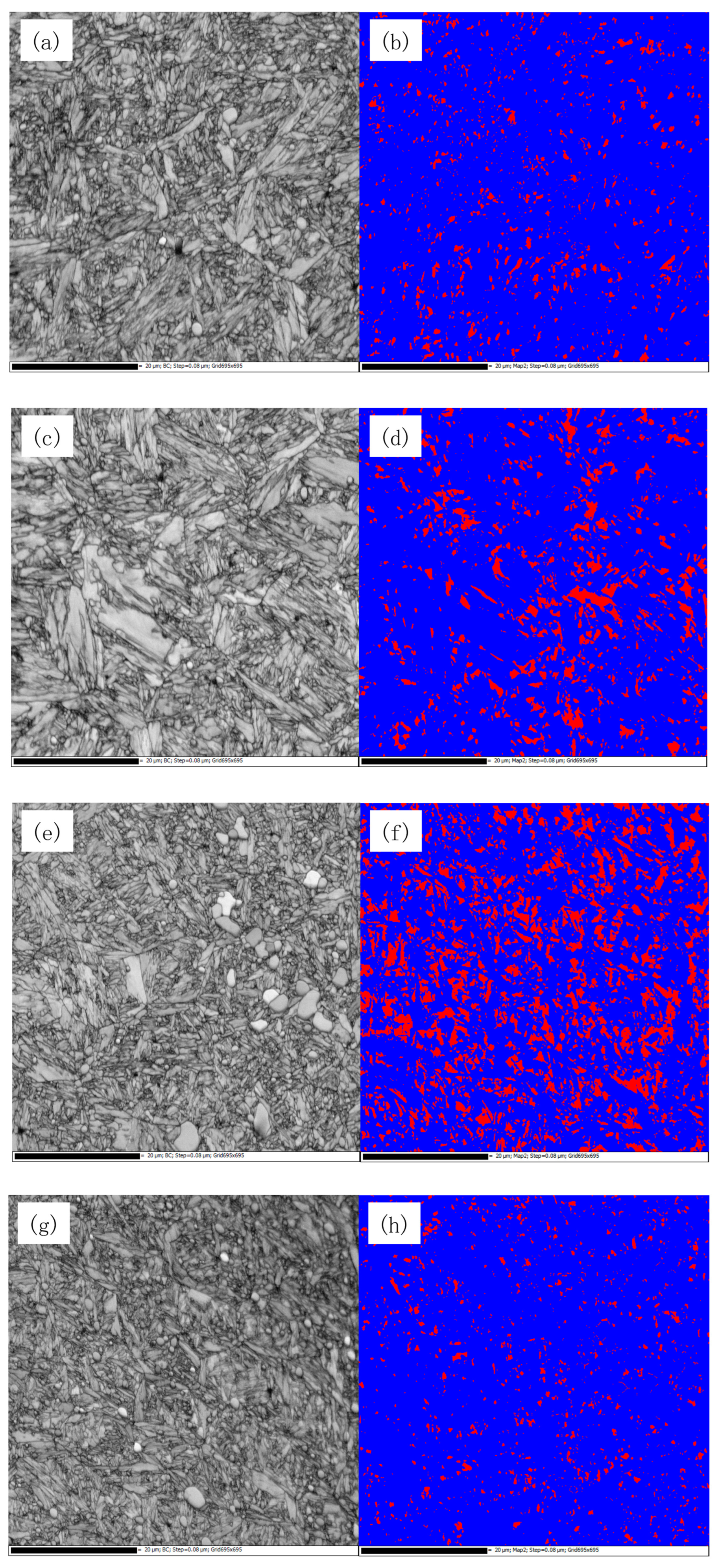

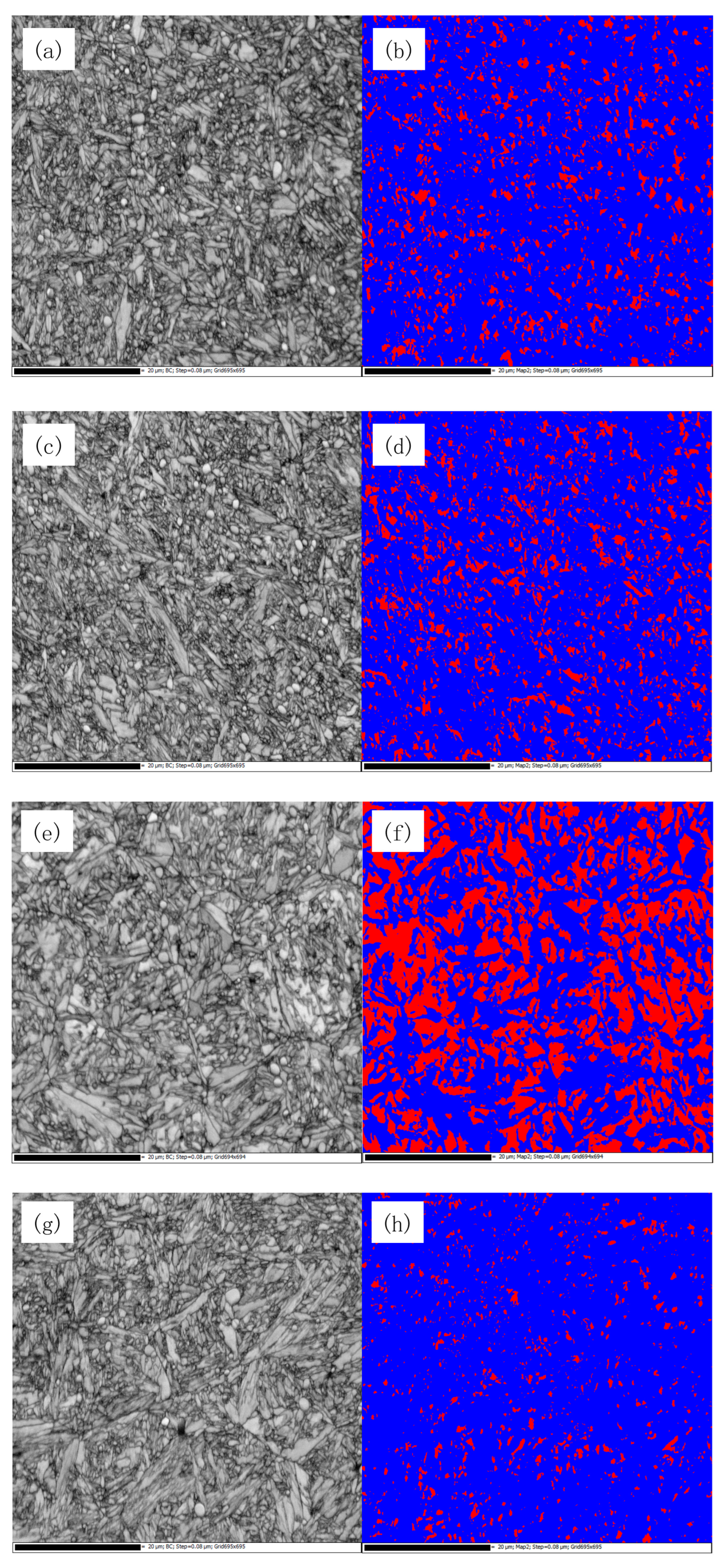

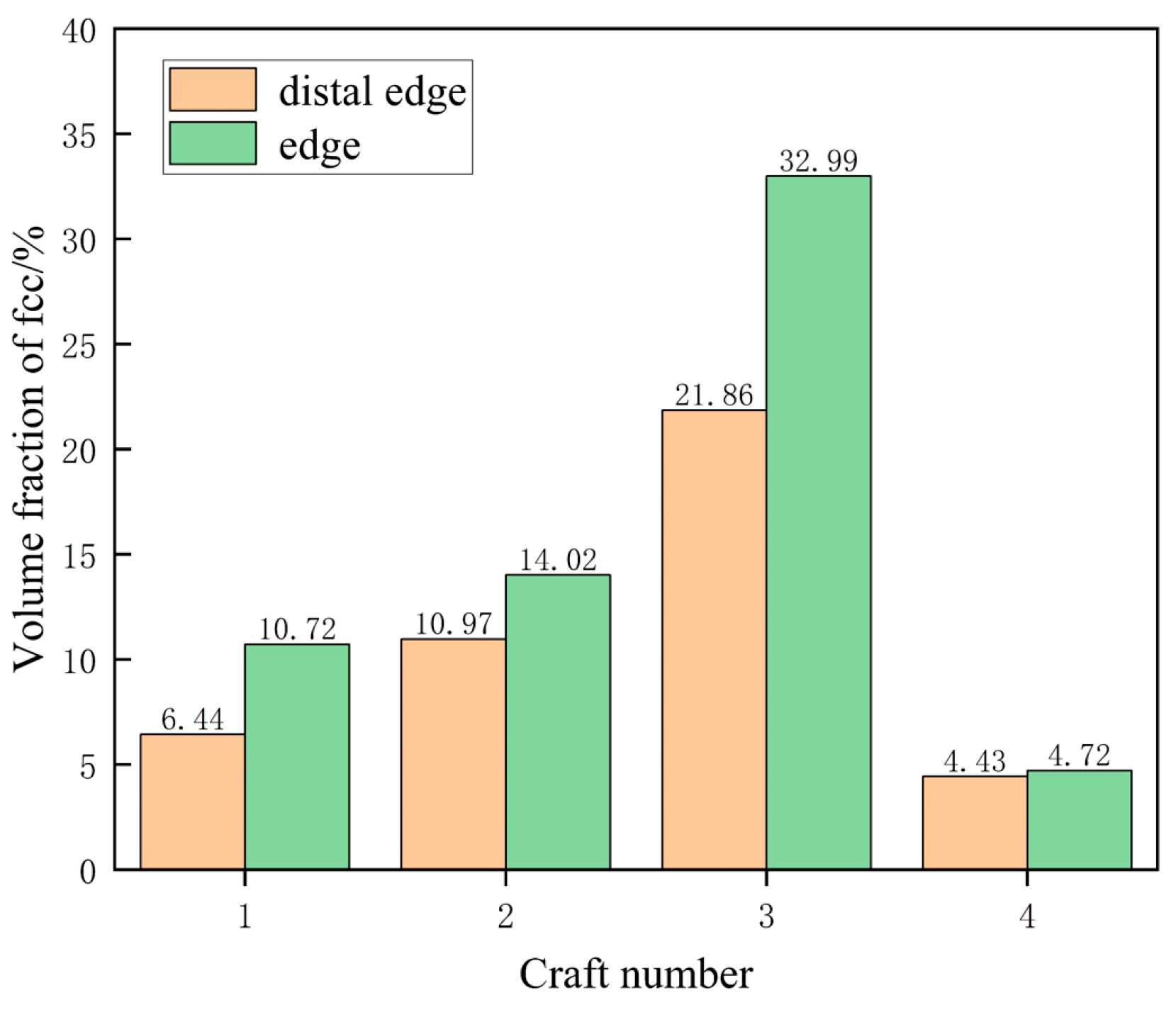

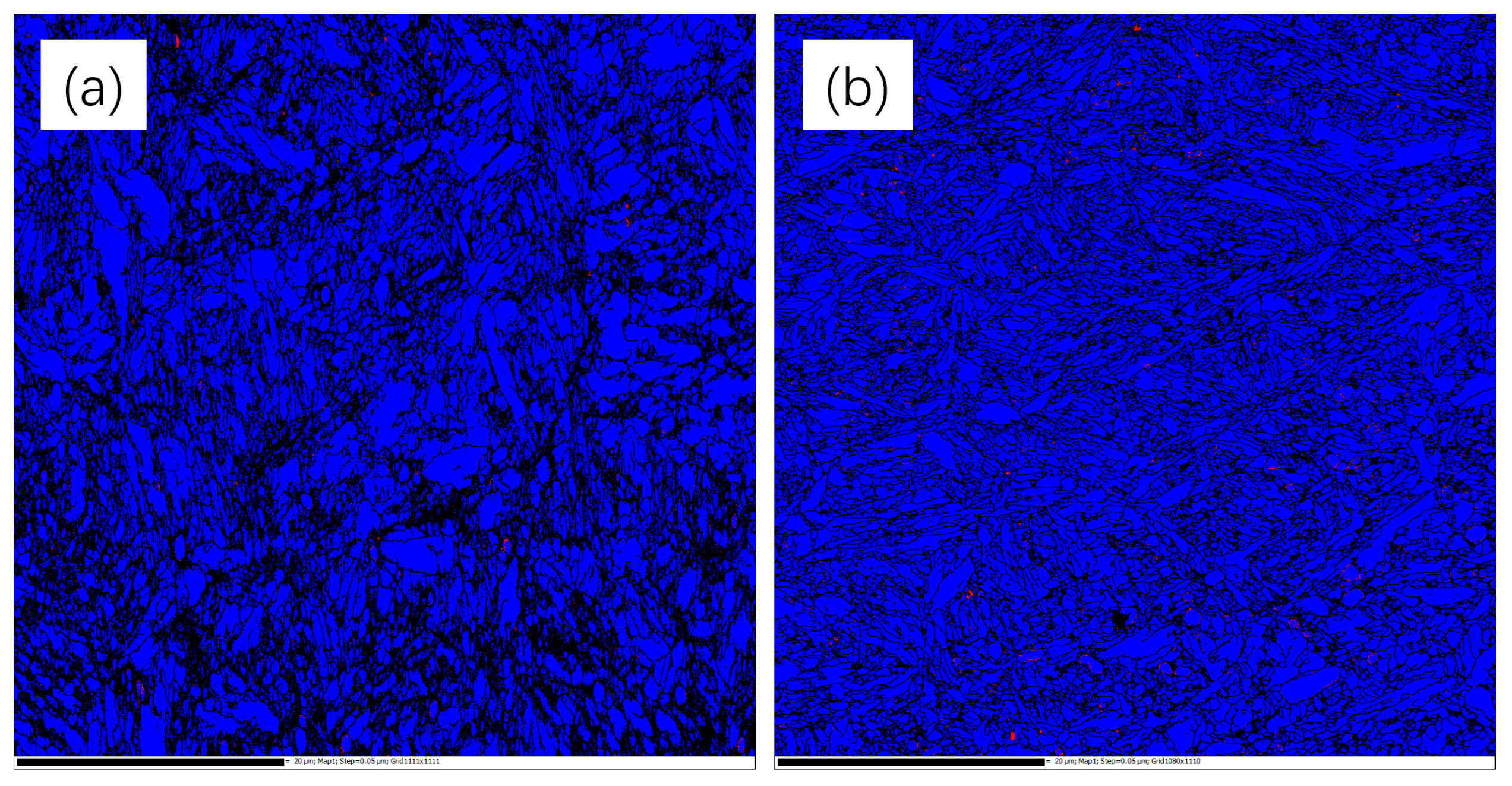

3.1. Microstructure

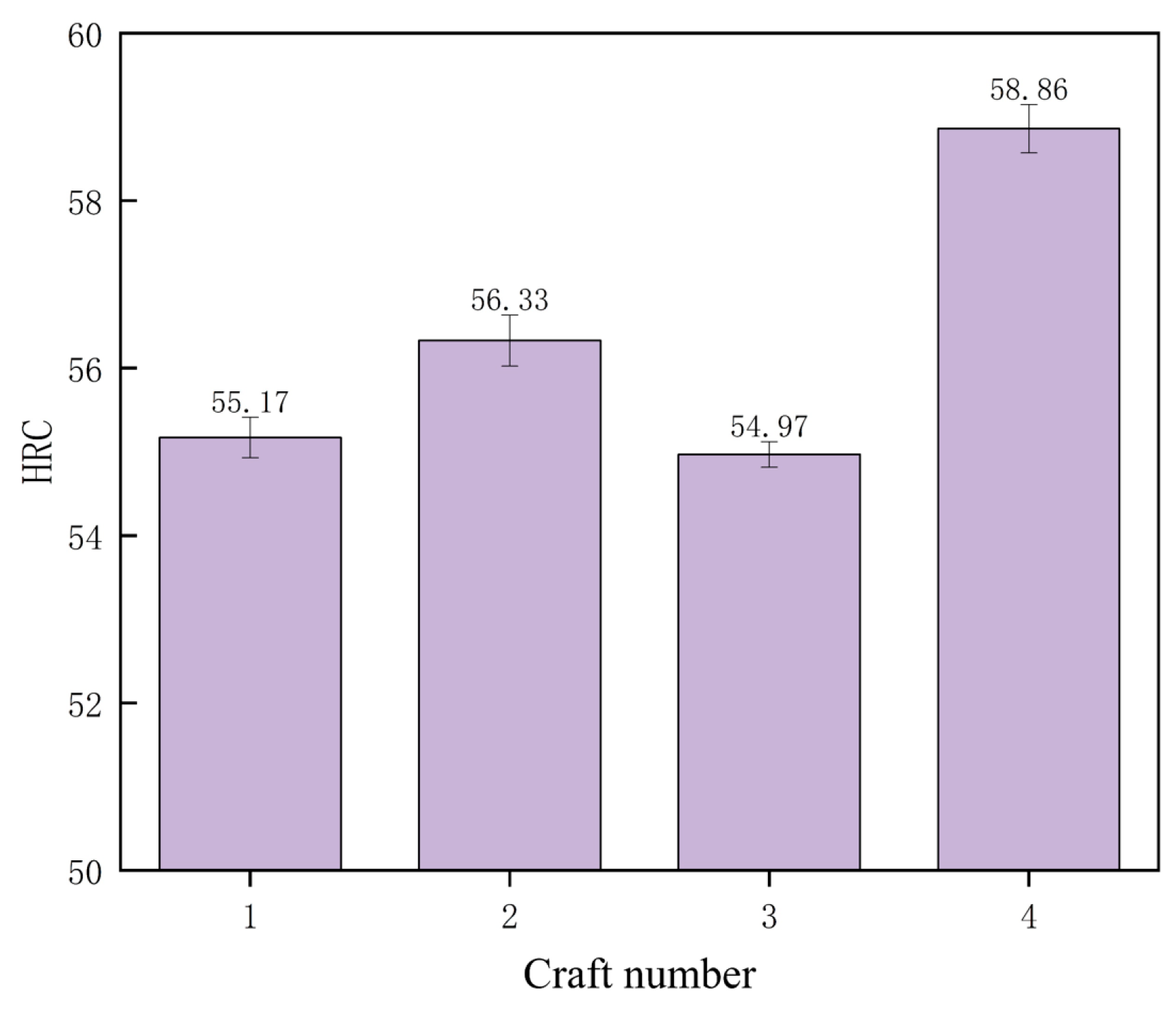

3.2. Knife Performance Comparison

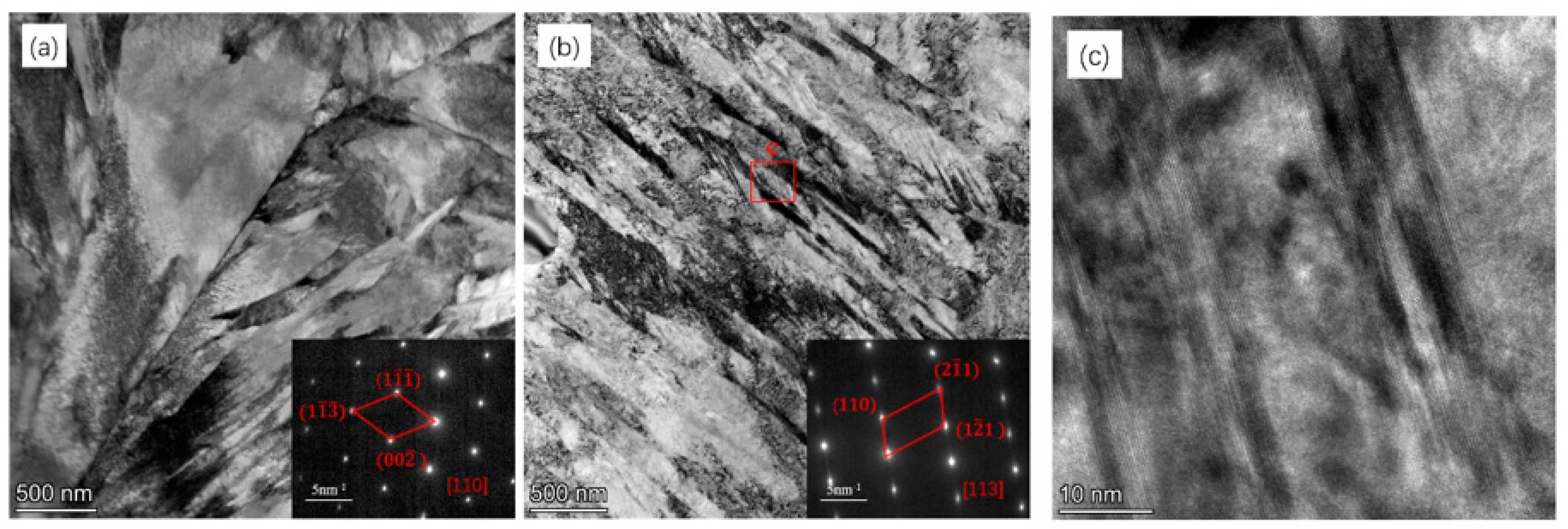

3.3. Microstructure Stability Analysis

4. Conclusions

- (1)

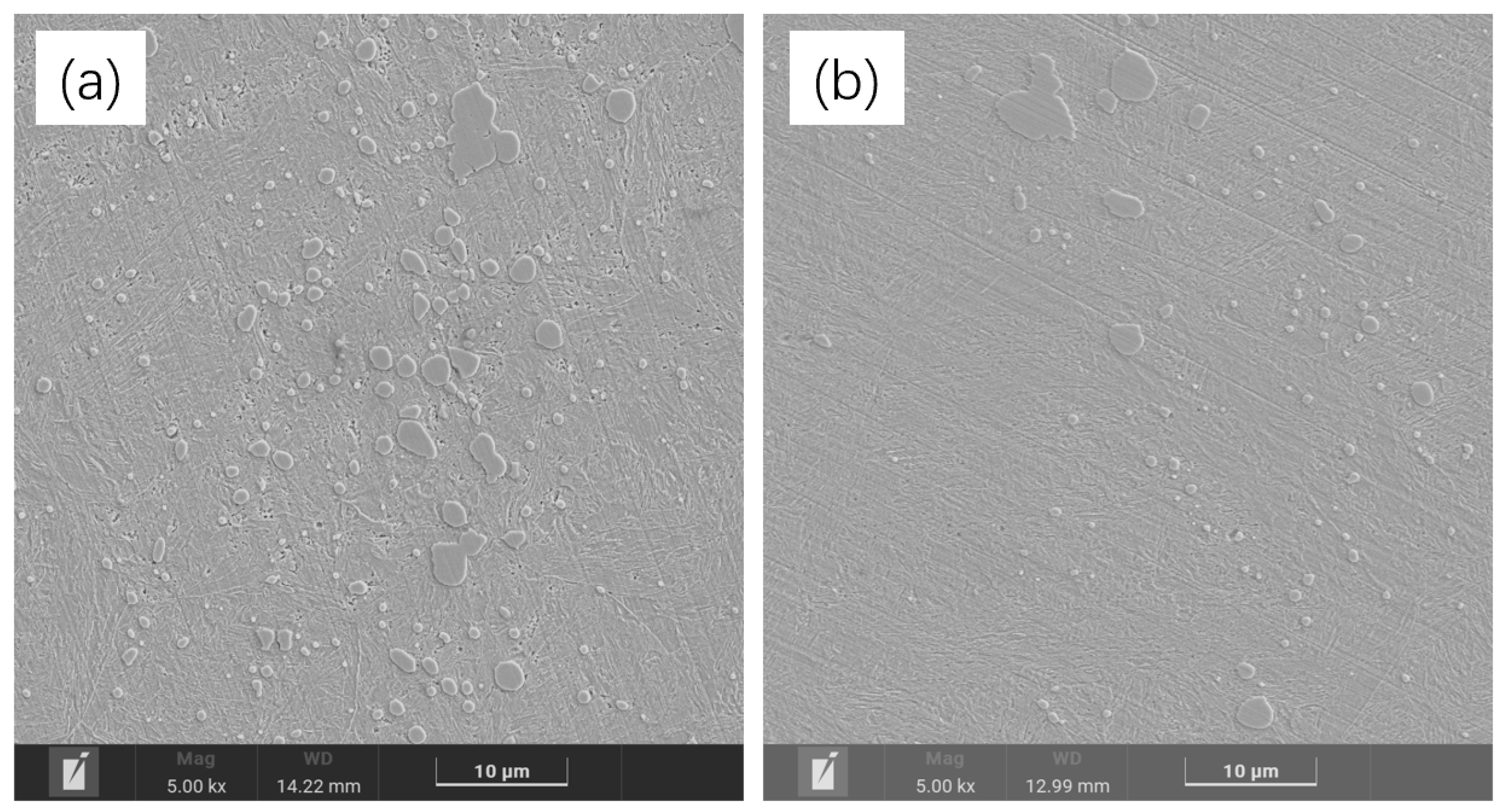

- The microstructure of 50Cr15MoV after different processes including different quenching temperatures, tempering, and cryogenic treatment is composed of plate martensite, undissolved carbide, and residual austenite. When the quenching temperature increased from 1020 °C to 1080 °C, the content of undissolved carbide decreased from 9.21% to 3.31%, and the volume fraction of residual austenite increased from 4.43% to 21.84%. Under the same quenching and tempering conditions, the addition of the cryogenic process reduced the residual austenite in steel by 17.43%, and the martensitic lath became smaller, and a large number of fault substructures appeared.

- (2)

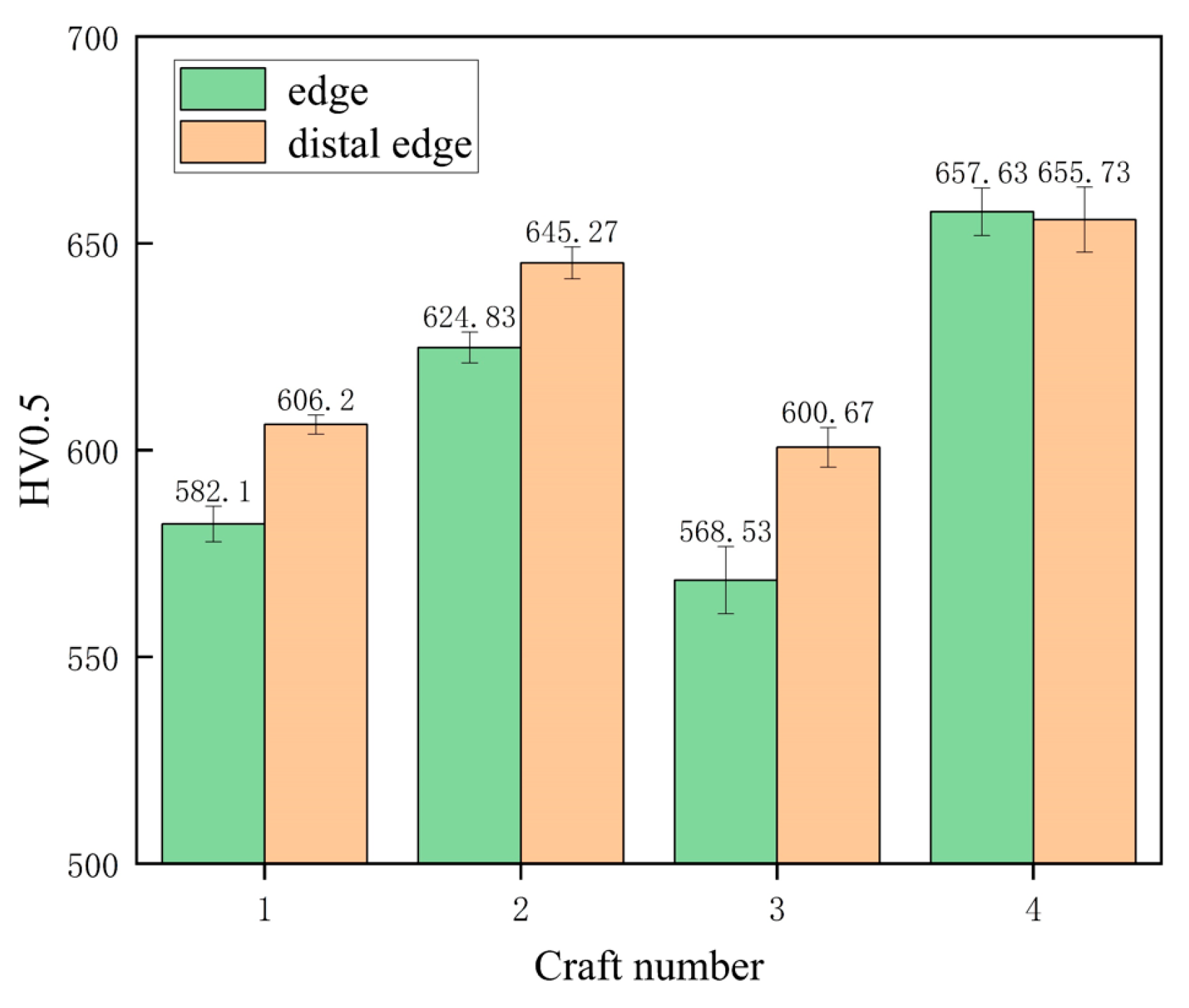

- As the quenching temperature increased from 1020 °C to 1080 °C, the hardness of 50Cr15MoV increased from 55.17 HRC to 56.33 HRC and then decreased to 54.97 HRC, reaching the maximum value of 56.33 HRC when the quenching temperature was 1050 °C. The hardness of the material increased by 3.89 HRC after cryogenic treatment.

- (3)

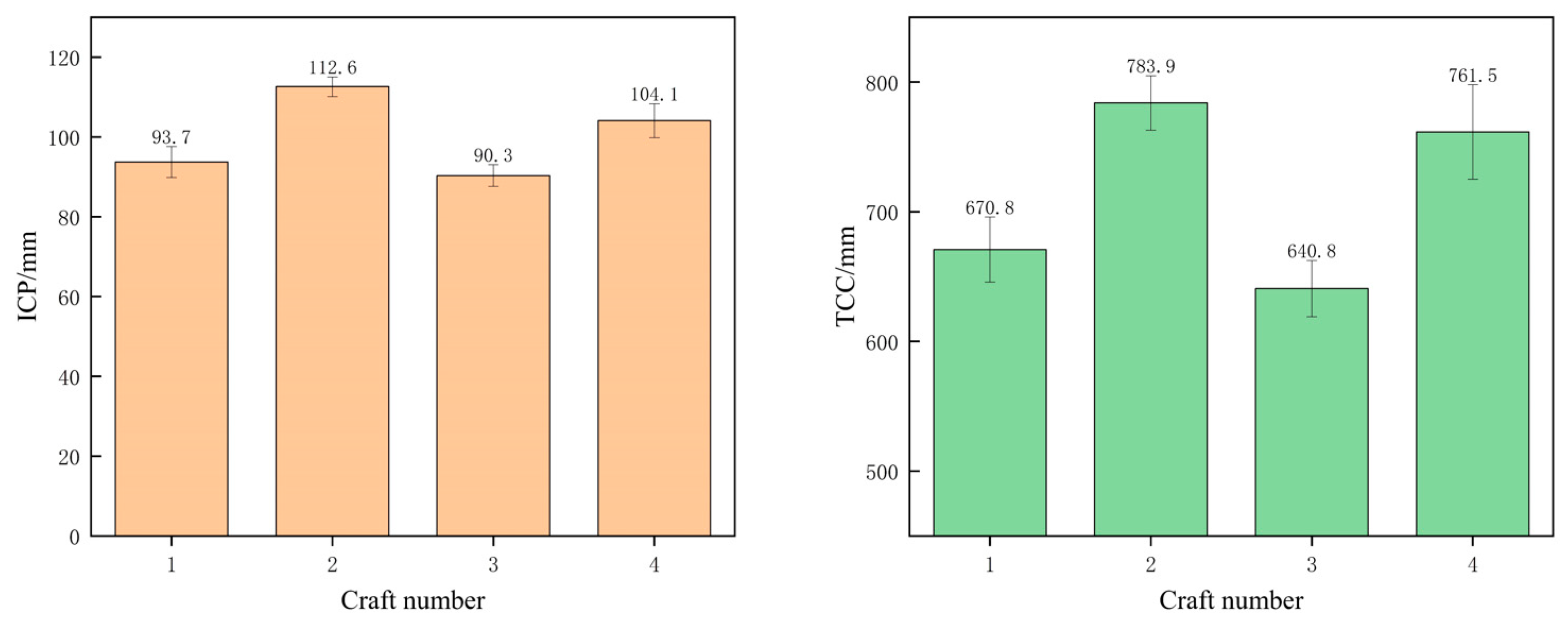

- When the quenching temperature increased from 1020 °C to 1080 °C, the sharpness performance of 50Cr15MoV first increased and then reduced; when the quenching temperature is 1050 °C, the sharp performance of the knife is the best, the ICP was 112.6 mm and TCC was 783.9 mm. The ICP of the knife after cryogenic treatment increased by 15.3% and TCC increased by 18.8%.

- (4)

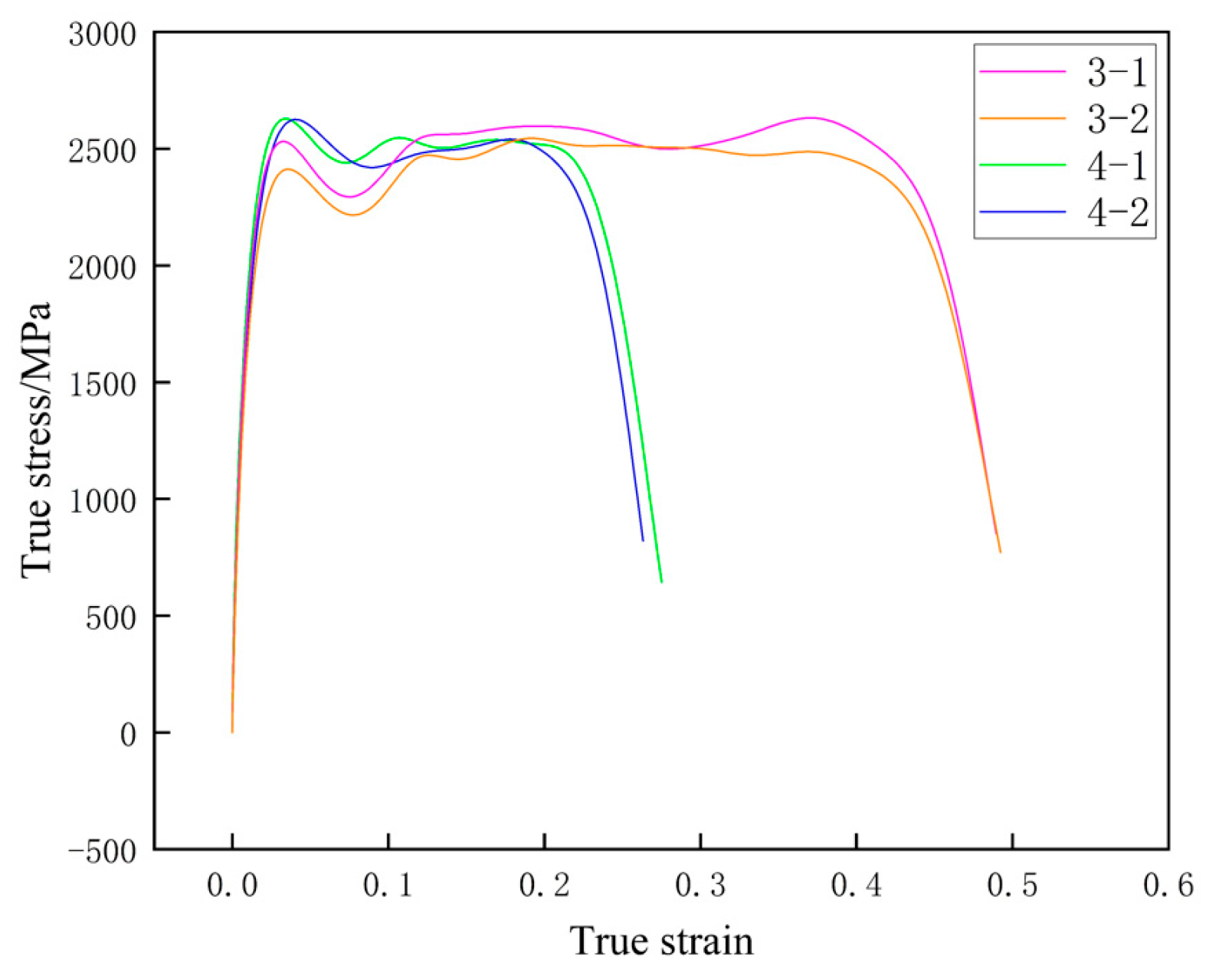

- After processing, a large number of lamination-fault substructures are formed, which can improve the strength of the material and reduce the strain. The residual austenite in the material was unstable, and no residual austenite was found at the high deformation rate of 5000 s−1.

Author Contributions

Funding

Data Availability Statement

Conflicts of Interest

References

- Gregory, G.; Hamby, R. Sharp edge cutting technology—A review of hand held and machine knives/blades and their sharp edge retention. Surf. Eng. 2000, 16, 373–378. [Google Scholar] [CrossRef]

- Wu, D.; Qu, S.; Zhang, Q.; Zhou, H. Enhanced wear resistance of blades made of martensitic steels: A study of diverse α′-matrix/carbide microstructures. Mater. Charact. 2023, 201, 112939. [Google Scholar] [CrossRef]

- Claudon, L.; Marsot, J. Effect of knife sharpness on upper limb biomechanical stresses—A laboratory study. Int. J. Ind. Ergon. 2006, 36, 239–246. [Google Scholar] [CrossRef]

- Bush, R.; Gill, J.; Teakell, J. Heat Treatment Optimization and Fabrication of a 440C Stainless Steel Knife. J. Miner. Met. Mater. Soc. 2016, 68, 3167–3173. [Google Scholar] [CrossRef]

- Verhoeven, J.D.; Pendray, A.H.; Clark, H.F. Wear tests of steel knife blades. Wear 2008, 265, 1093–1099. [Google Scholar] [CrossRef]

- Kurt, A.; Kose, E.; Sahinbaskan, T. The Effects of Blade Angle on Blade Stresses During Cutting of Different Kinds of Paper Materials. J. Mech. Eng. 2009, 55, 633–640. [Google Scholar]

- McCarthy, C.T.; Hussey, M.; Gilchrist, M.D. On the sharpness of straight edge blades in cutting soft solids: Part I–indentation experiments. Eng. Fract. Mech. 2007, 74, 2205–2224. [Google Scholar] [CrossRef]

- Roscioli, G.; Taheri-Mousavi, S.M.; Tasan, C.C. How hair deforms steel. Science 2020, 369, 689–694. [Google Scholar] [CrossRef] [PubMed]

- Roscioli, G.; Repka, M.; Pedrazzini, S.; Tasan, C.C. Chemo-mechanical effects on the cutting-induced mixed-mode II-III fracture of martensitic stainless steels: An in-situ investigation. Acta Mater. 2022, 231, 117803. [Google Scholar] [CrossRef]

- Chiu, L.H.; Liao, H.C.; Lin, S.C.; Pan, Y.T.; Liou, H.Y. Carbide distribution effect on wear behavior of cold work tool steels. Adv. Mater. Res. 2012, 567, 240–243. [Google Scholar] [CrossRef]

- Ciulica, L.G.; Rus, F. Experimental regarding the determination of the optimum cutting angle using a single edged knife. Bulletin of the Transilvania University of Brasov. For. Wood Ind. Agric. Food Eng. 2012, 5, 135. [Google Scholar]

- Reilly, G.A.; McCormack, B.A.O.; Taylor, D. Cutting sharpness measurement: A critical review. J. Mater. Process. Technol. 2014, 153, 261–267. [Google Scholar] [CrossRef]

- McCarthy, C.T.; Annaidh, A.N.; Gilchrist, M.D. On the sharpness of straight edge blades in cutting soft solids: Part II–Analysis of blade geometry. Eng. Fract. Mech. 2010, 77, 437–451. [Google Scholar] [CrossRef]

- Wu, D.; Qu, S.; Zhang, Q.; Zhou, H. A quantitative model that correlates sharpness retention and abrasive wear of knife blades. Wear 2023, 518, 204634. [Google Scholar] [CrossRef]

- Zhang, W.X.; Chen, Y.Z.; Cong, Y.B.; Liu, Y.H. On the austenite stability of cryogenic Ni steels: Microstructural effects: A review. J. Mater. Sci. 2021, 56, 12539–12558. [Google Scholar] [CrossRef]

- Weng, Z.; Gu, K.; Zheng, J.; Cui, C.; Zhang, M.; Wang, J. Cryogenically martensitic transformation and its effects on tempering behaviors of bearing steel. Materials Characterization 2022, 190, 112066. [Google Scholar] [CrossRef]

- Wong, A. Modelling the stability and transformation kinetics of retained austenite in steels. Mater. Sci. Technol. 2022, 38, 676–688. [Google Scholar] [CrossRef]

- Zhu, Z.; Liu, J.; Gong, B.; Zhao, J.; Yang, M.; Chen, L. Analyzing the effect of the mechanical stability of residual austenite on the wear performance. Tribol. Int. 2024, 192, 109326. [Google Scholar] [CrossRef]

- Han, Y. Study on Carbide Precipitation Behavior at Grain Boundary of 5Cr15MoV Martensitic Stainless Steel; University of Science and Technology Liaoning: Anshan, China, 2020. [Google Scholar]

- Hao, X.-X. Study on Microstructure and Properties of 5Cr15MoV Martensitic Stainless Steel Containing Copper; University of Science and Technology of China: Hefei, China, 2021. [Google Scholar]

- Yang, Y.D.; Zhao, H.S.; Liu, T.S. Microstructure and properties of new high-carbon martensitic stainless steels. J. Iron Steel Res. 2020, 32, 135–142. [Google Scholar]

- Tian, C.; Dong, J.; Wang, J.; Zhang, H.; Feng, T.; Liu, X. Effect of Quenching Temperature on microstructure and properties of 5Cr15MoV Steel during Air-cooled quenching. Heat Treat. Met. 2012, 47, 211–216. [Google Scholar]

- Bin, Q. Effect of Heat Treatment on microstructure and properties of 5Cr15MoV cold rolled annealed sheet of Martensitic Stainless steel. Spec. Steel 2011, 32, 66–68. [Google Scholar]

- Chen, J.; Zhang, Q.; Deng, J.; Yuan, S.; Zhou, H.; Wu, D. Evolution law of carbides in tempering process of Martensitic stainless steel and its influence on corrosion resistance. Heat Treat. Met. 2023, 48, 38–43. [Google Scholar]

- Deng, B.; Hou, Z.Y.; Wang, G.D.; Yi, H.L. Toughness Improvement in a Novel Martensitic Stainless Steel Achieved by Quenching–Tempering and Partitioning. Met. Mater Trans A 2021, 52, 4852–4864. [Google Scholar] [CrossRef]

- ISO 8442-5; Materials and Articles in Contact with Foodstuffs—Cutlery and Table Holloware—Part 5: Specification for Sharpness and Edge Retention Test of Cutlery. ISO: Geneva, Switzerland, 2004.

- Samek, L.; De Moor, E.; Penning, J.; De Cooman, B.C. Influence of alloying elements on the kinetics of strain-induced martensitic nucleation in low-alloy, multiphase high-strength steels. Met. Mater Trans A 2006, 37, 109–124. [Google Scholar] [CrossRef]

- Zhou, C.; Ye, Q.-B.; Zhao, T.; Hu, J.; Gao, X.-H.; Wang, Z.-D. Strengthening and toughening mechanisms in Ni-alloyed steel: Enhancing the integral stability of retained austenite. Mater. Sci. Eng. A 2022, 852, 143703. [Google Scholar] [CrossRef]

- Li, Y.; Zhong, S.; Luo, H.; Xu, C.; Jia, X. Intermediate stacking fault and twinning induced cooperative strain evolution of dual phase in lean duplex stainless steels with excellent cryogenic strength-ductility combinations. Mater. Sci. Eng. A 2022, 831, 142347. [Google Scholar] [CrossRef]

- Moallemi, M.; Kim, S.-J.; Zarei-Hanzaki, A.; Farabi, E. Strain hardening analysis and deformation micromechanisms in high strength-high ductility metastable duplex stainless steels: Role of sustained stacking faults in the work hardening. Mater. Charact. 2023, 197, 112662. [Google Scholar] [CrossRef]

- Yang, Z.; Liu, Z.; Liang, J.; Yang, Z.; Sheng, G. Elucidating the role of secondary cryogenic treatment on mechanical properties of a martensitic ultra-high strength stainless steel. Mater. Charact. 2021, 178, 111277. [Google Scholar] [CrossRef]

- Zheng, C.; Fan, J.; Gong, X.; Yang, C.; Liu, T. Study on Dynamic constitutive Relationship of fine crystal 93W-4.9Ni-2.1Fe alloy. Rare Met. Mater. Eng. 2013, 42, 2043–2047. [Google Scholar]

- Chun, R.; Pengwan, C.; Ling, L.; Zhang, W. Experimental study on dynamic mechanical behavior of TC18 titanium alloy at medium and high strain rates. J. Ordnance Eng. 2017, 38, 1723–1728. [Google Scholar]

- Yang, Y.; Yang, S.; Liu, W. Effect of microstructure on adiabatic shear sensitivity of Fe50Mn30Co10Cr10 high entropy alloy. Min. Metall. Eng. 2019, 39, 119–122. [Google Scholar]

- Yan, N.; Li, Z.; Xu, Y.; Meyers, M.A. Shear localization in metallic materials at high strain rates. Prog. Mater. Sci. 2021, 119, 100755. [Google Scholar] [CrossRef]

| C | Si | Mn | p | S | Cr | N | Mo | V | Fe |

|---|---|---|---|---|---|---|---|---|---|

| 0.482 | 0.436 | 0.411 | 0.018 | 0.003 | 14.72 | 0.036 | 0.552 | 0.121 | Bal. |

| Craft Number | Quenching Temperature/°C | Quenching | Cryogenic Treatment | Tempering |

|---|---|---|---|---|

| 1 | 1020 | Heat retention 20 min and oil quenching | - | 180 °C × 3 h and air cooling |

| 2 | 1050 | - | ||

| 3 | 1080 | - | ||

| 4 | 1080 | Liquid nitrogen for 1 h |

Disclaimer/Publisher’s Note: The statements, opinions and data contained in all publications are solely those of the individual author(s) and contributor(s) and not of MDPI and/or the editor(s). MDPI and/or the editor(s) disclaim responsibility for any injury to people or property resulting from any ideas, methods, instructions or products referred to in the content. |

© 2025 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (https://creativecommons.org/licenses/by/4.0/).

Share and Cite

Guo, F.; Peng, Z.; Lu, G.; Liu, W.; Li, G.; Zhang, P.; Shang, C. Enhanced Cutting Performance of 50Cr15MoV Martensitic Stainless Steel Through Controlled Residual Austenite Stability. Metals 2025, 15, 95. https://doi.org/10.3390/met15010095

Guo F, Peng Z, Lu G, Liu W, Li G, Zhang P, Shang C. Enhanced Cutting Performance of 50Cr15MoV Martensitic Stainless Steel Through Controlled Residual Austenite Stability. Metals. 2025; 15(1):95. https://doi.org/10.3390/met15010095

Chicago/Turabian StyleGuo, Fujian, Zhimin Peng, Guangyi Lu, Wenle Liu, Guoqing Li, Pan Zhang, and Chengjia Shang. 2025. "Enhanced Cutting Performance of 50Cr15MoV Martensitic Stainless Steel Through Controlled Residual Austenite Stability" Metals 15, no. 1: 95. https://doi.org/10.3390/met15010095

APA StyleGuo, F., Peng, Z., Lu, G., Liu, W., Li, G., Zhang, P., & Shang, C. (2025). Enhanced Cutting Performance of 50Cr15MoV Martensitic Stainless Steel Through Controlled Residual Austenite Stability. Metals, 15(1), 95. https://doi.org/10.3390/met15010095