Microstructure and Tensile Property Tailoring of Al–5Mg (wt%) Alloy Combined with Continuous Rheo-Extrusion and Sc Modification

Abstract

1. Introduction

2. Materials and Methods

3. Results

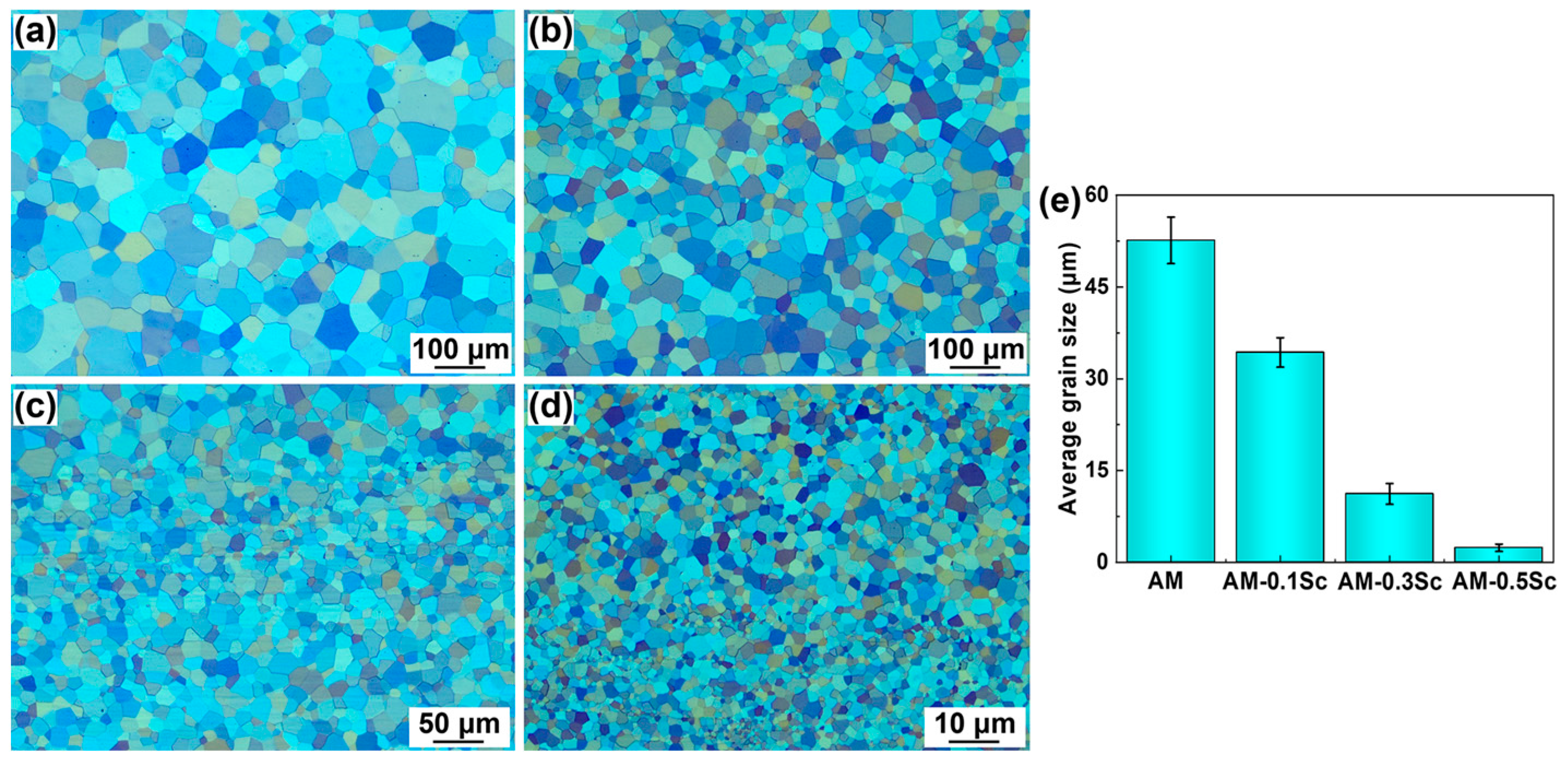

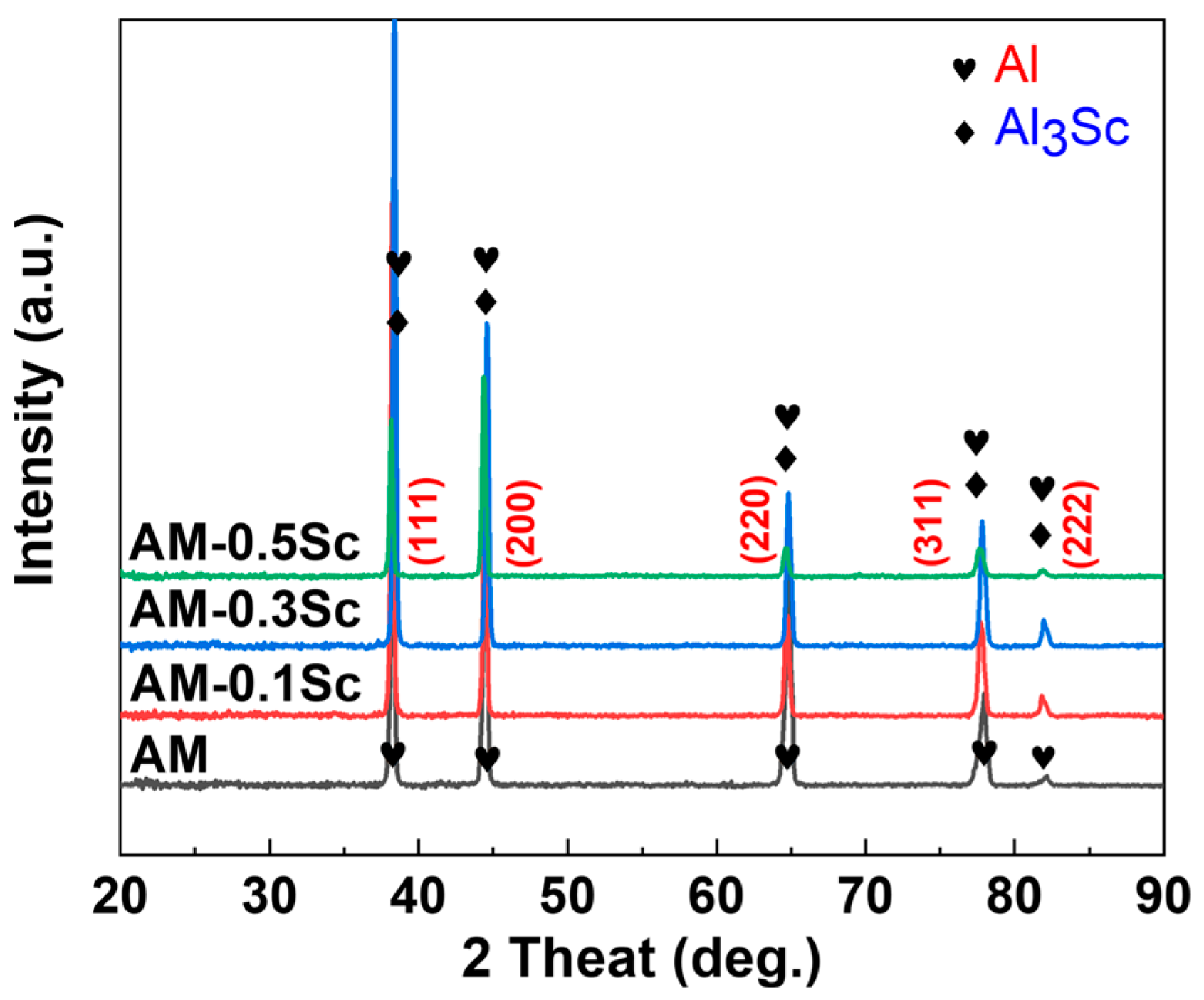

3.1. Microstructural Characterization

3.2. Mechancial Properties

4. Discussion

4.1. Grain Refinement Induced by Sc Modification During Solidification

4.2. Grain Refinement Induced by Al3Sc-Phase Particles During Recrystallization

4.3. Strengthening Mechanisms of the CREed AM Alloy with Sc Modification

5. Conclusions

Author Contributions

Funding

Data Availability Statement

Conflicts of Interest

References

- Zhang, H.T.; Zhang, Q.D.; Wang, F.Y.; Guo, C.; Yang, D.H.; Wang, Z.; Tang, X.C.; Li, Z.P.; Nagaumi, H. Influence of Mo on microstructure, mechanical properties and intergranular corrosion properties of Al–Mg–Mn alloys. J. Alloys Compd. 2024, 1007, 176284. [Google Scholar] [CrossRef]

- Nagaraja, S.; Anand, P.B.; Mariswamy, M.; Alkahtani, M.Q.; Islam, S.; Khan, M.A.; Khan, W.A.; Bhutto, J.K. Friction stir welding of dissimilar Al–Mg alloys for aerospace applications: Prospects and future potential. Rev. Adv. Mater. Sci. 2024, 63, 20240033. [Google Scholar] [CrossRef]

- Guo, W.; Zhuo, Y.C.; Zhao, Y.L.; Li, H.; Han, B.Y. Wetting behaviors of Al–Si–Cu–Mg–Zn brazing materials on 5083 aluminum alloy. Metals 2024, 14, 1183. [Google Scholar] [CrossRef]

- Tian, T.; Zha, M.; Jia, H.L.; Hua, Z.M.; Ma, P.K.; Wang, H.Y. The effect of high solid solution Mg contents (7–13 wt%) on the dynamic strain aging behavior of Al–Mg alloys. Mater. Sci. Eng. A 2023, 880, 145376. [Google Scholar] [CrossRef]

- Zha, M.; Zhang, H.M.; Meng, X.T.; Jia, H.L.; Jin, S.B.; Sha, G.; Wang, H.Y.; Li, Y.J.; Roven, H.J. Stabilizing a severely deformed Al–7Mg alloy with a multimodal grain structure via Mg solute segregation. J. Mater. Sci. Technol. 2021, 89, 141–149. [Google Scholar] [CrossRef]

- Raabe, D.; Tasan, C.C.; Olivetti, E.A. Strategies for improving the sustainability of structural metals. Nature 2019, 575, 64–74. [Google Scholar] [CrossRef]

- Liu, Z.B.; Sun, J.N.; Yan, Z.G.; Lin, Y.J.; Liu, M.P.; Roven, H.J.; Dahle, A.K. Enhanced ductility and strength in a cast Al–Mg alloy with high Mg content. Mater. Sci. Eng. A 2021, 806, 140806. [Google Scholar] [CrossRef]

- Jia, J.; Zhuang, W.; Li, J.; Cao, Q.; Liu, J. Effect of La on microstructure, mechanical properties and friction behavior of in situ synthesized TiB2/6061 composites. Metals 2024, 14, 1169. [Google Scholar] [CrossRef]

- Tian, N.; Liu, H.; Zhang, Z.S.; Liu, J.C.; Zhang, Y.Z.; Zhou, Y.R.; Zhao, G.; Qin, G.W. Portevin-Le Chatelier characterization of annealed Al–Mg alloy sheets with different Mg contents. Mater. Sci. Eng. A 2024, 893, 146118. [Google Scholar] [CrossRef]

- Zhou, D.S.; Zhang, X.Z.; Wang, H.; Li, Y.; Sun, B.H.; Zhang, D.L. Influence of Mg on tensile deformation behavior of high Mg-content Al–Mg alloys. Int. J. Plast. 2022, 157, 103405. [Google Scholar] [CrossRef]

- Jiang, J.Y.; Wang, H.L.; Tong, M.M.; Jiang, F.; Zhang, M.H. Effect of cryogenic environment on tensile property and microstructure evolution of an Al–Mg–Sc alloy. Mater. Charact. 2023, 195, 112550. [Google Scholar] [CrossRef]

- Mofarrehi, M.; Javidani, M.; Chen, X.G. Effect of Mn content on the hot deformation behavior and microstructure evolution of Al–Mg–Mn 5xxx alloys. Mater. Sci. Eng. A 2022, 845, 143217. [Google Scholar] [CrossRef]

- Borodianskiy, K.; Selivorstov, V.; Dotsenko, Y.; Zinigrad, M. Effect of additions of ceramic nanoparticles and gas-dynamic treatment on Al casting alloys. Metals 2015, 5, 2277–2288. [Google Scholar] [CrossRef]

- Borodianskiy, K. Effect of carbon nanotubes’ addition on mechanical properties and thermal conductivity of copper. J. Mater. Sci. 2019, 54, 13767–13774. [Google Scholar] [CrossRef]

- Ji, J.S.; Wang, L.L.; Lyu, F.; Gao, Z.N.; Zhan, X.H. Strength-ductility synergy of deposited Al–Mg–Sc alloy with a homogeneous phase distribution brought by heat treatment. Mater. Sci. Eng. A 2024, 913, 147034. [Google Scholar] [CrossRef]

- Zhang, H.M.; Zha, M.; Jia, H.L.; Tian, T.; Zhang, X.H.; Wang, C.; Ma, P.K.; Gao, D.; Wang, H.Y. Influences of the Al3Sc particle content on the evolution of bimodal grain structure and mechanical properties of Al–Mg–Sc alloys processed by hard-plate rolling. Mater. Sci. Eng. A 2021, 802, 140451. [Google Scholar] [CrossRef]

- Qiu, Y.C.; Yang, X.F.; Li, J.X.; Xiang, S.H.; Shi, J.; Xu, J.Y.; Sanders, R.E. The influence of Sc and Zr additions on microstructure and corrosion behavior of AA5182 alloy sheet. Corros. Sci. 2022, 199, 110181. [Google Scholar] [CrossRef]

- Zhou, S.A.; Zhang, Z.; Li, M.; Pan, D.J.; Su, H.L.; Du, X.D.; Li, P.; Wu, Y.C. Effect of Sc on microstructure and mechanical properties of as-cast Al–Mg alloys. Mater. Des. 2016, 90, 1077–1084. [Google Scholar] [CrossRef]

- Zhang, J.Y.; Gao, Y.H.; Yang, C.; Zhang, P.; Kuang, J.; Liu, G.; Sun, J. Microalloying Al alloys with Sc: A review. Rare Metals 2020, 39, 636–650. [Google Scholar] [CrossRef]

- Li, C.L.; Li, X.W.; Zhang, Y.A.; Wen, K.; Xiao, W.; Li, Y.N.; Yu, M.Y.; Gao, G.J.; Li, Z.H.; Xiong, B.Q. Effect of Sc content on microstructure characteristics and evolution of W phase in Al–Cu–Li alloys under as-cast and homogenization conditions. J. Mater. Res. Technol. 2023, 25, 7335–7352. [Google Scholar] [CrossRef]

- Yang, Z.; Tang, J.; Mo, X.D.; Chen, W.T.; Fu, D.F.; Zhang, H.; Teng, J.; Jiang, F.L. Microstructure, mechanical properties, and strengthening mechanisms of ultra-high strength Al–Zn–Mg–Cu alloy prepared by continuous extrusion forming process. Mat. Des. 2024, 242, 112985. [Google Scholar] [CrossRef]

- Lu, R.Q.; Zhang, L.; Zheng, S.W.; Fu, D.F.; Teng, J.; Chen, J.C.; Zhao, G.D.; Jiang, F.L.; Zhang, H. Microstructure, mechanical properties and deformation mechanisms of an Al-Mg alloy processed by the cyclical continuous expanded extrusion and drawing approach. Int. J. Min. Met. Mater. 2022, 29, 108–118. [Google Scholar] [CrossRef]

- Li, Q.L.; Huang, G.J.; Cao, Y.; Zhang, C.H.; He, J.; Jiang, H.A.; Lin, L.; Liu, Q. Microstructure refinement, strengthening and ductilization mechanisms in Al–Mg–Mn–Er–Zr alloy with high Mn content by friction stir processing. Mat. Charact. 2022, 189, 111939. [Google Scholar] [CrossRef]

- Liu, Y.; Liu, M.P.; Chen, X.F.; Cao, Y.; Roven, H.J.; Murashkin, M.; Valiev, R.Z.; Zhou, H. Effect of Mg on microstructure and mechanical properties of Al–Mg alloys produced by high pressure torsion. Scr. Mat. 2019, 159, 137–141. [Google Scholar] [CrossRef]

- Ciemiorek, M.; Chrominski, W.; Jasinski, C.; Lewandowska, M. Microstructural changes and formability of Al–Mg ultrafine-grained aluminum plates processed by multi-turn ECAP and upsetting. Mater. Sci. Eng. A 2022, 831, 142202. [Google Scholar] [CrossRef]

- Santos, I.C.D.; Mazzer, E.M.; Figueiredo, R.B.; Langdon, T.G.; Pereira, P.H.R. Evidence for two-stage hardening in an Al–Zn–Mg–Cu alloy processed by high-pressure torsion. J. Alloys Compd. 2023, 941, 168839. [Google Scholar] [CrossRef]

- Lee, S.W.; Yeh, J.W. Microstructural evolution and superplasticity of Al–5.8Mg–0.23Mn alloys processed by reciprocating extrusion. Metall. Mater. Trans. A 2005, 36, 2225–2234. [Google Scholar] [CrossRef]

- Yang, B.W.; Gao, M.Q.; Wang, Y.; Guan, R.G. Dynamic recrystallization behavior and mechanical properties response of rheo-extruded Al–Mg alloys with various Mg contents. Mater. Sci. Eng. A 2022, 849, 143450. [Google Scholar] [CrossRef]

- Yang, B.W.; Wang, Y.; Gao, M.Q.; Wang, C.F.; Guan, R.G. Microstructural evolution and strengthening mechanism of Al–Mg alloys with fine grains processed by accumulative continuous extrusion forming. J. Mater. Sci. Tech. 2022, 128, 195–204. [Google Scholar] [CrossRef]

- Kouhgard, M.; Daneshifar, M.H.; Jabbareh, M.A. Multipass friction stir welding of dissimilar Al–Si and Al–Mg cast aluminum alloys. Mater. Chem. Phys. 2024, 315, 128987. [Google Scholar] [CrossRef]

- Yan, K.; Chen, Z.W.; Lu, W.J.; Zhao, Y.N.; Le, W.; Naseem, S. Nucleation and growth of Al3Sc precipitates during isothermal aging of Al–0.55 wt% Sc alloy. Mat. Charact. 2021, 179, 111331. [Google Scholar] [CrossRef]

- Kishchik, M.S.; Mochugovskiy, A.G.; Cuda, M.; Kishchik, A.A.; Mikhaylovskaya, A.V. Particle stimulated nucleation effect for Al–Mg–Zr–Sc alloys with Ni addition during multidirectional forging. Metals 2023, 13, 1499. [Google Scholar] [CrossRef]

- Li, X.C.; Zhao, K.; Yang, L.Y.; Shi, S.Y.; Guo, E.Y.; Kang, H.J.; Hao, Z.G.; Chen, Z.N.; Wang, T.M. The role of TiB2 nanoparticles in reducing the microstructural sensitivity of as-cast Al–Mg–Mn alloy to cooling rate. Mater. Sci. Eng. A 2024, 894, 146157. [Google Scholar] [CrossRef]

- Zhu, Y.X.; Zhao, Y.; Chen, B. A study on Sc- and Zr-modified Al–Mg alloys processed by selective laser melting. Mater. Sci. Eng. A 2022, 833, 142516. [Google Scholar] [CrossRef]

- Dang, B.; Jian, Z.Y.; Xu, J.F. The effect of phosphorus on solidification behaviour of undercooled Al–70 wt.%Si alloys. Sci. Rep. 2020, 10, 18230. [Google Scholar] [CrossRef] [PubMed]

- Zheng, Q.J.; Zhang, L.L.; Jiang, H.X.; Zhao, J.Z.; He, J. Effect mechanisms of micro-alloying element La on microstructure and mechanical properties of hypoeutectic Al–Si alloys. J. Mater. Sci. Technol. 2020, 47, 142–151. [Google Scholar] [CrossRef]

- Luo, S.X.; Shi, Z.M.; Li, N.Y.; Lin, Y.M.; Liang, Y.H.; Zeng, Y.D. Crystallization inhibition and microstructure refinement of Al–5Fe alloys by addition of rare earth elements. J. Alloys Compd. 2019, 789, 90–99. [Google Scholar] [CrossRef]

- Saha, S.; Todorova, T.Z.; Zwanziger, J.W. Temperature dependent lattice misfit and coherency of Al3X (X = Sc, Zr, Ti and Nb) particles in an Al matrix. Acta. Mater. 2015, 89, 109–115. [Google Scholar] [CrossRef]

- Li, H.T.; Wang, Y.; Fan, Z. Mechanisms of enhanced heterogeneous nucleation during solidification in binary Al–Mg alloys. Acta. Mater. 2012, 60, 1528–1537. [Google Scholar] [CrossRef]

- Guan, R.G.; Tie, D.; Li, Z.; An, Y.N.; Wang, X.; Li, Q.; Chen, X.B. Microstructure evolution and mechanical property improvement of aluminum alloys with high magnesium content during continuous rheo-extrusion. Mater. Sci. Eng. A 2018, 738, 31–37. [Google Scholar] [CrossRef]

- Shen, Y.F.; Guan, R.G.; Zhao, Z.Y.; Misra, R.D.K. Ultrafine-grained Al–0.2Sc–0.1Zr alloy: The mechanistic contribution of nano-sized precipitates on grain refinement during the novel process of accumulative continuous extrusion. Acta. Mater. 2015, 100, 247–255. [Google Scholar] [CrossRef]

- Liu, F.Z.; Zhu, X.H.; Qin, J.; Zhou, W.; Ling, J.Q.; Dong, Q.P.; Yu, J.M.; Nagaumi, H. Effect of Mn/Cr ratio on precipitation behaviors of α-Al(FeMnCr)Si dispersoids and mechanical properties of Al–Mg–Si–Cu alloys. Mater. Sci. Eng. A 2022, 860, 144269. [Google Scholar] [CrossRef]

- Malopheyev, S.; Kulitskiy, V.; Kaibyshev, R. Deformation structures and strengthening mechanisms in an Al–Mg–Sc–Zr alloy. J. Alloys Compd. 2017, 698, 957–966. [Google Scholar] [CrossRef]

- Zhang, M.T.; Jiang, T.; Xie, Y.F.; Feng, X.N.; Su, Y.; Shen, Z.K.; Sun, Z.G.; Xu, Y.X.; Li, W.Y. Microstructure evolution and strengthening mechanisms of an additive friction stir deposited multi-layer Al–Mg–Sc–Zr alloy. J. Alloys Compd. 2024, 1004, 175783. [Google Scholar] [CrossRef]

- Ouyang, Y.; Liu, F.; Chen, H.; Tao, X.; Du, Y.; He, Y. The structural stability, elastic constants and electronic structure of Al–Sr intermetallics by first-principles calculations. Phys. B 2011, 406, 3681–3686. [Google Scholar] [CrossRef]

- Jang, D.H.; Park, Y.B.; Kim, W.J. Significant strengthening in superlight Al–Mg alloy with an exceptionally large amount of Mg (13 wt%) after cold rolling. Mater. Sci. Eng. A 2019, 744, 36–44. [Google Scholar] [CrossRef]

- Oguocha, I.N.A.; Tiamiyu, A.A.; Rezaei, M.; Odeshi, A.G.; Szpunar, J.A. Experimental investigation of the dynamic impact responses of as-cast and homogenized A535 aluminum alloy. Mater. Sci. Eng. A 2020, 771, 138536. [Google Scholar] [CrossRef]

| Alloy | Mg | Sc | Al |

|---|---|---|---|

| Al–5Mg (AM) | 4.94 | – | Bal. |

| Al–5Mg–0.1Sc (AM–0.1Sc) | 4.97 | 0.09 | Bal. |

| Al–5Mg–0.3Sc (AM–0.3Sc) | 4.92 | 0.31 | Bal. |

| Al–5Mg–0.5Sc (AM–0.5Sc) | 4.96 | 0.47 | Bal. |

| Alloy | UTS (MPa) | YS (MPa) | EL (%) | Hardness (HV) |

|---|---|---|---|---|

| AM | 257.6 ± 1.7 | 99.8 ± 2.1 | 52.8 ± 4.2 | 69.8 ± 0.7 |

| AM–0.1Sc | 331.3 ± 2.4 | 133.5 ± 1.2 | 41.8 ± 1.1 | 101.4 ± 1.5 |

| AM–0.3Sc | 389.2 ± 3.9 | 181.3 ± 3.2 | 32.0 ± 2.5 | 126.5 ± 1.9 |

| AM–0.5Sc | 456.4 ± 3.6 | 220.1 ± 2.8 | 24.8 ± 1.9 | 143.7 ± 2.2 |

| Symbol | Description | Values | Unit | Ref. |

|---|---|---|---|---|

| kSS | Constant | 13.8 | MPa/(wt%) | [43] |

| n | Constant | 1 | - | [43] |

| C | Mg solute content | 4.94/4.96 | wt% | This work |

| kHP | Hall–Petch coefficient | 0.14 | MPa·m−0.5 | [44] |

| d | Average grain size | 52.6/2.4 | μm | This work |

| G | Shear modulus | 28.9 | GPa | [45] |

| b | Burgers vector | 0.286 | nm | [23] |

| dsp | Average diameter | 20.5 | nm | This work |

| fv | Volume fraction | 0.065 | - | This work |

| α | Constant | 0.3 | - | [29] |

| M | Mean orientation factor | 3.06 | - | [29] |

| ρ | Dislocation density | 1.32 × 1013/9.47 × 1013 | m−2 | This work |

Disclaimer/Publisher’s Note: The statements, opinions and data contained in all publications are solely those of the individual author(s) and contributor(s) and not of MDPI and/or the editor(s). MDPI and/or the editor(s) disclaim responsibility for any injury to people or property resulting from any ideas, methods, instructions or products referred to in the content. |

© 2025 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (https://creativecommons.org/licenses/by/4.0/).

Share and Cite

Yang, B.; Liu, W.; Liu, X.; Yang, D.; Gao, M. Microstructure and Tensile Property Tailoring of Al–5Mg (wt%) Alloy Combined with Continuous Rheo-Extrusion and Sc Modification. Metals 2025, 15, 54. https://doi.org/10.3390/met15010054

Yang B, Liu W, Liu X, Yang D, Gao M. Microstructure and Tensile Property Tailoring of Al–5Mg (wt%) Alloy Combined with Continuous Rheo-Extrusion and Sc Modification. Metals. 2025; 15(1):54. https://doi.org/10.3390/met15010054

Chicago/Turabian StyleYang, Bowei, Wenyue Liu, Xin Liu, Dalong Yang, and Minqiang Gao. 2025. "Microstructure and Tensile Property Tailoring of Al–5Mg (wt%) Alloy Combined with Continuous Rheo-Extrusion and Sc Modification" Metals 15, no. 1: 54. https://doi.org/10.3390/met15010054

APA StyleYang, B., Liu, W., Liu, X., Yang, D., & Gao, M. (2025). Microstructure and Tensile Property Tailoring of Al–5Mg (wt%) Alloy Combined with Continuous Rheo-Extrusion and Sc Modification. Metals, 15(1), 54. https://doi.org/10.3390/met15010054