Evolution of Stress Rupture Property for K439B Superalloy During Long-Term Thermal Exposure at 800 °C

Abstract

1. Introduction

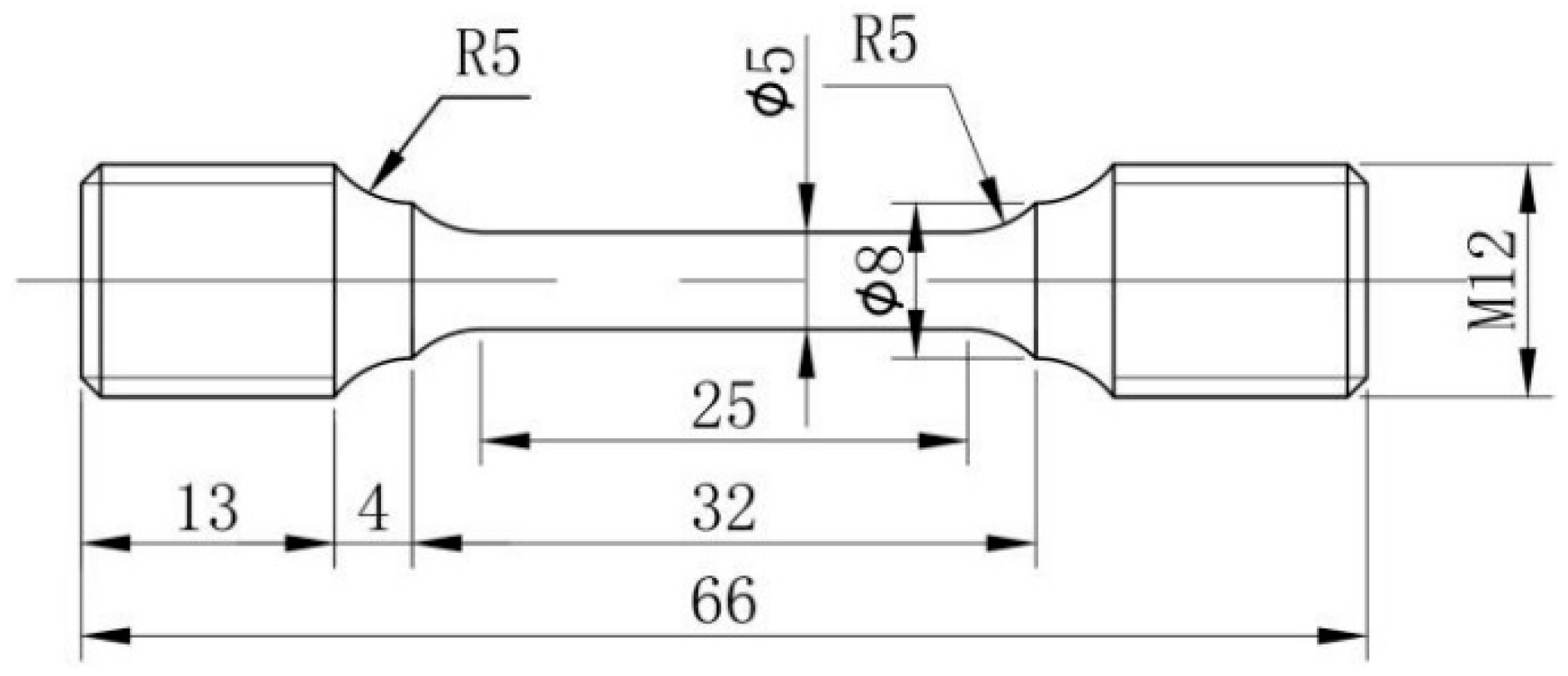

2. Materials and Methods

3. Results and Discussion

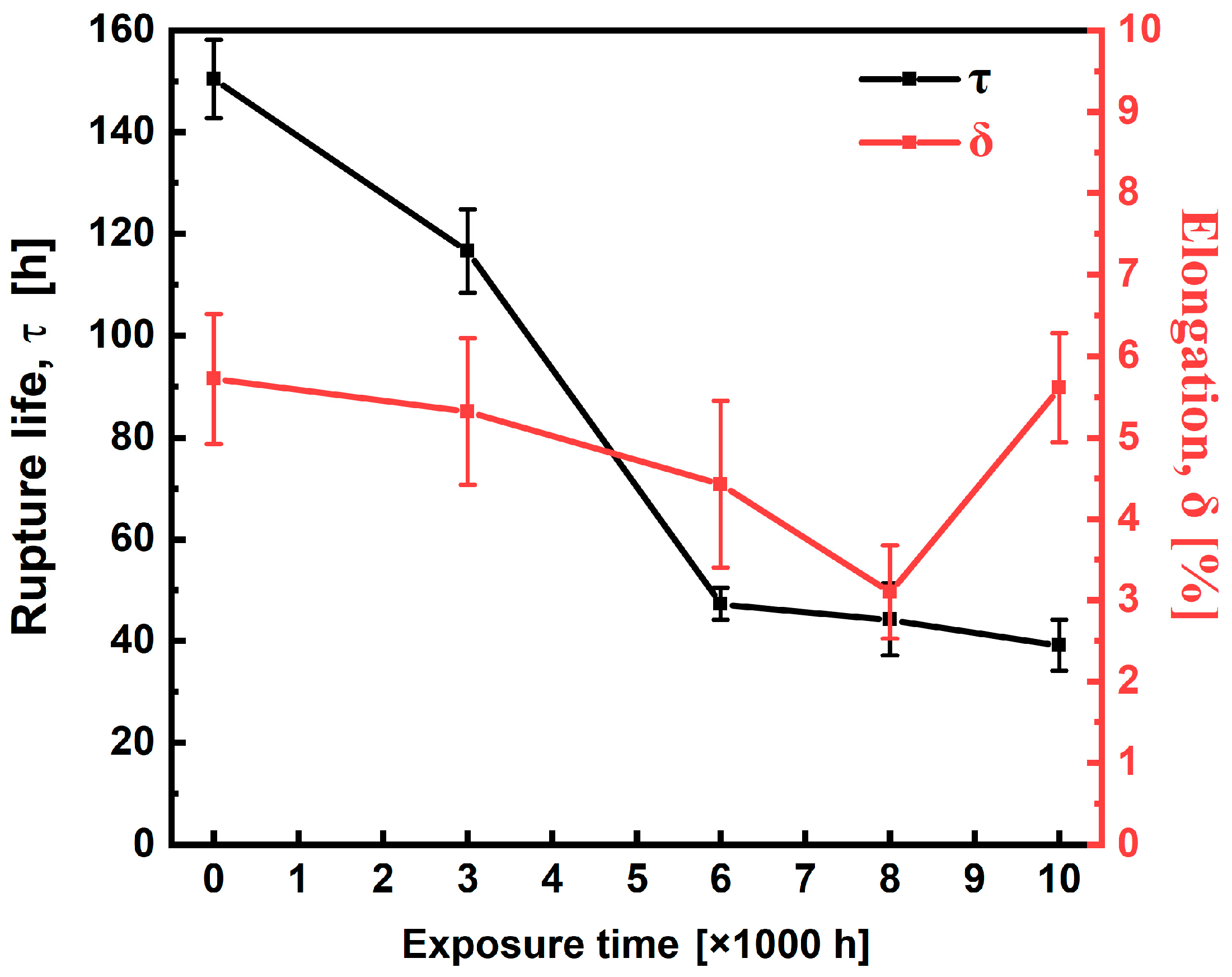

3.1. Stress Rupture Properties

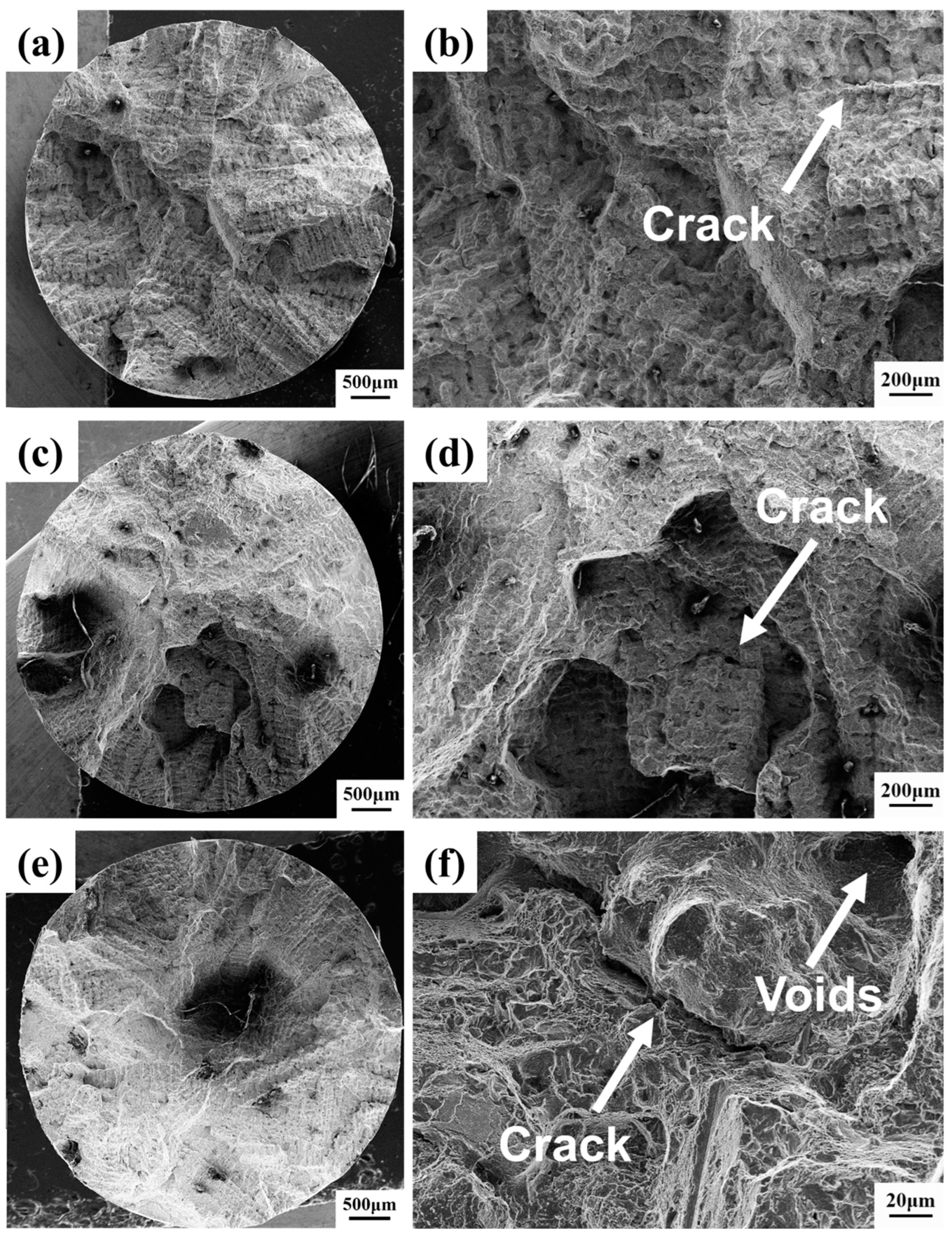

3.2. Fracture Morphology and Crack Features

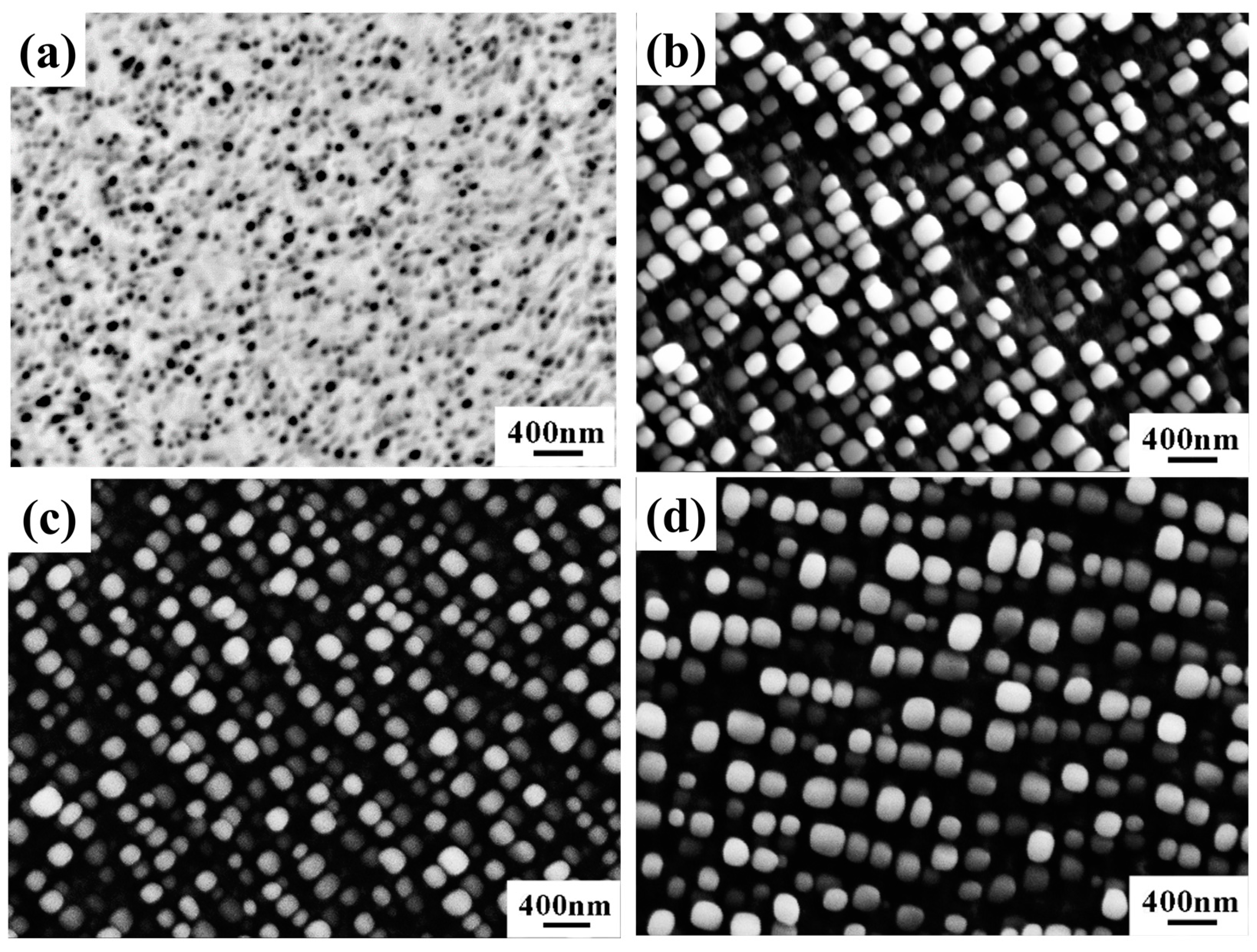

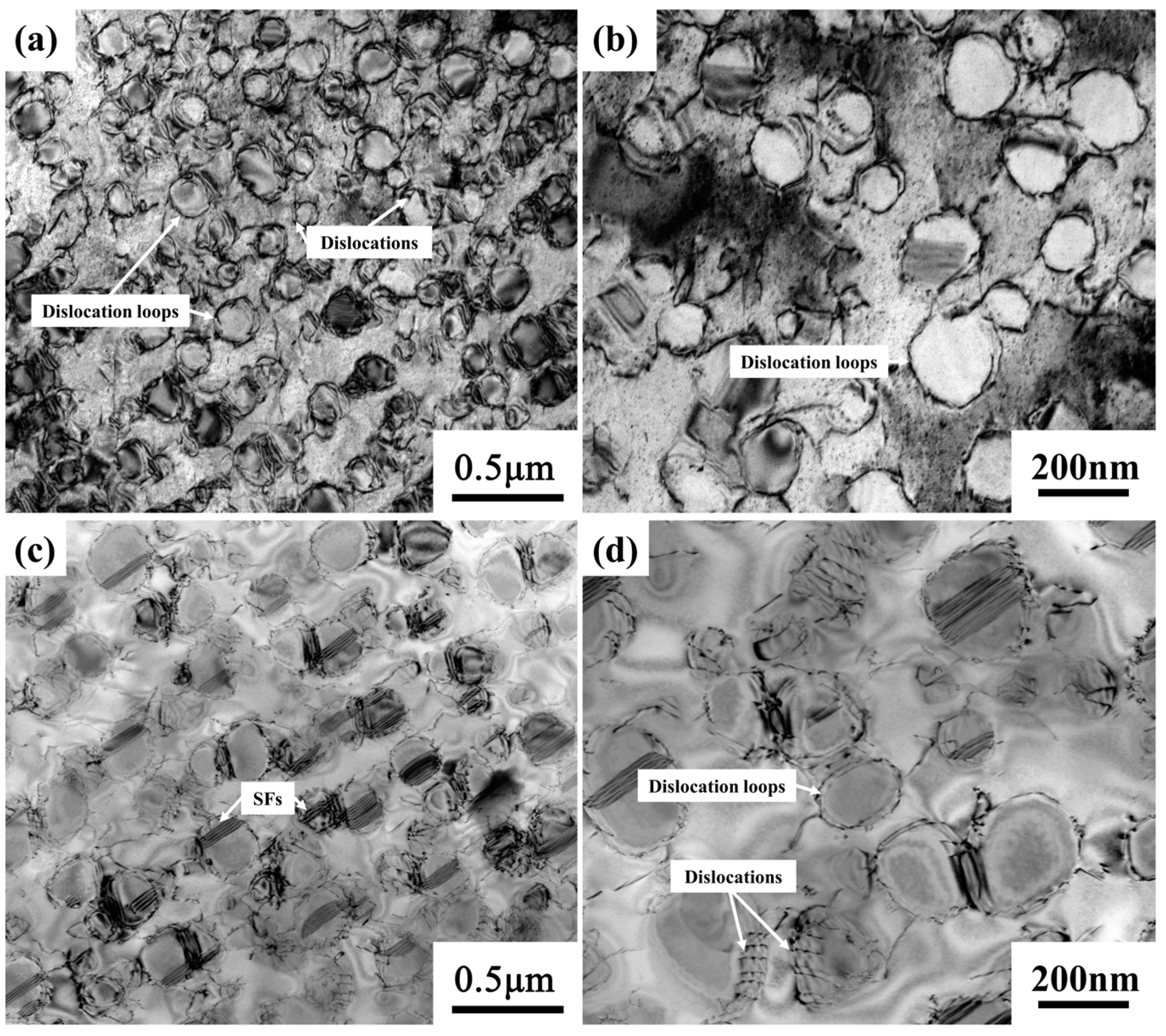

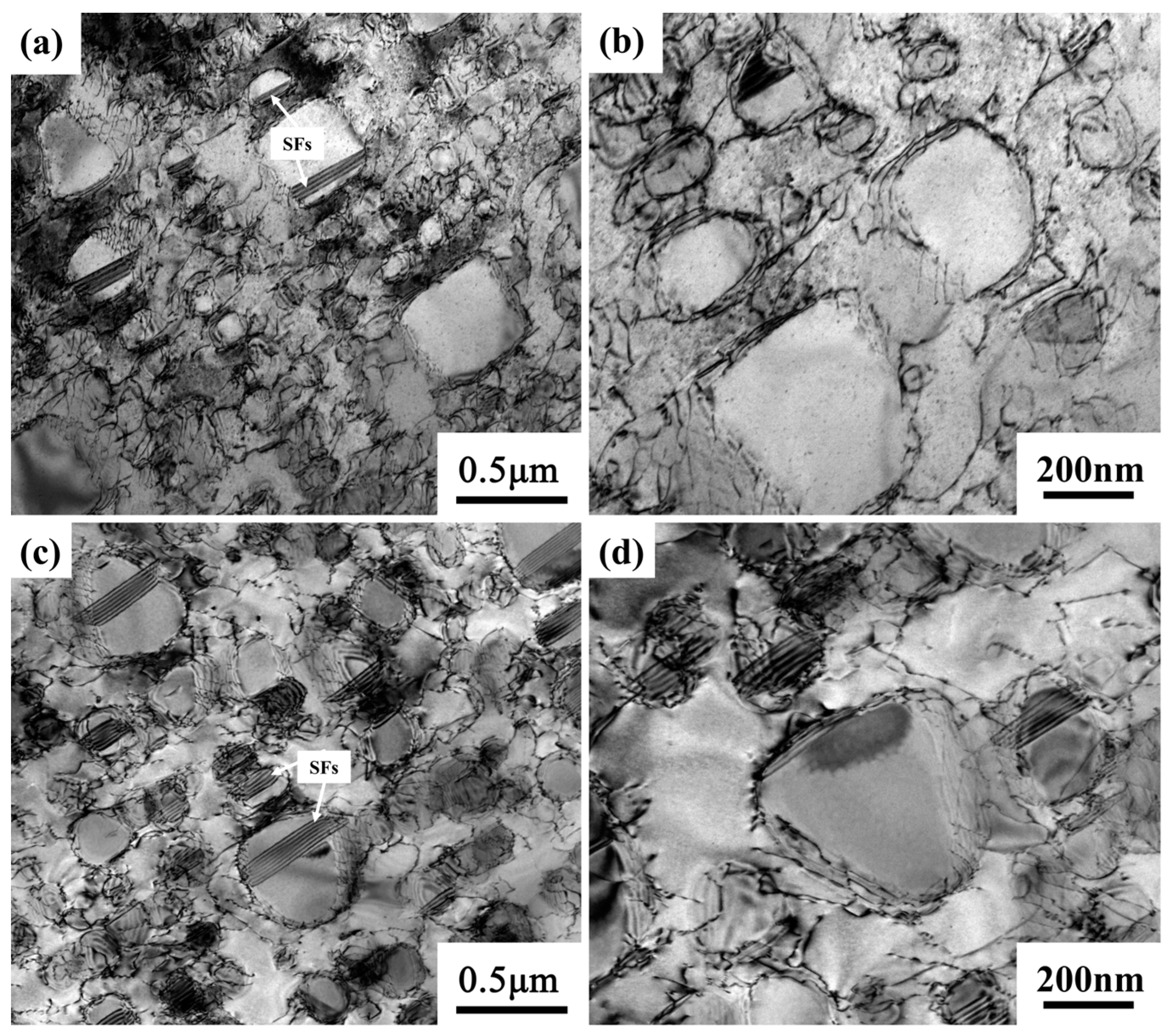

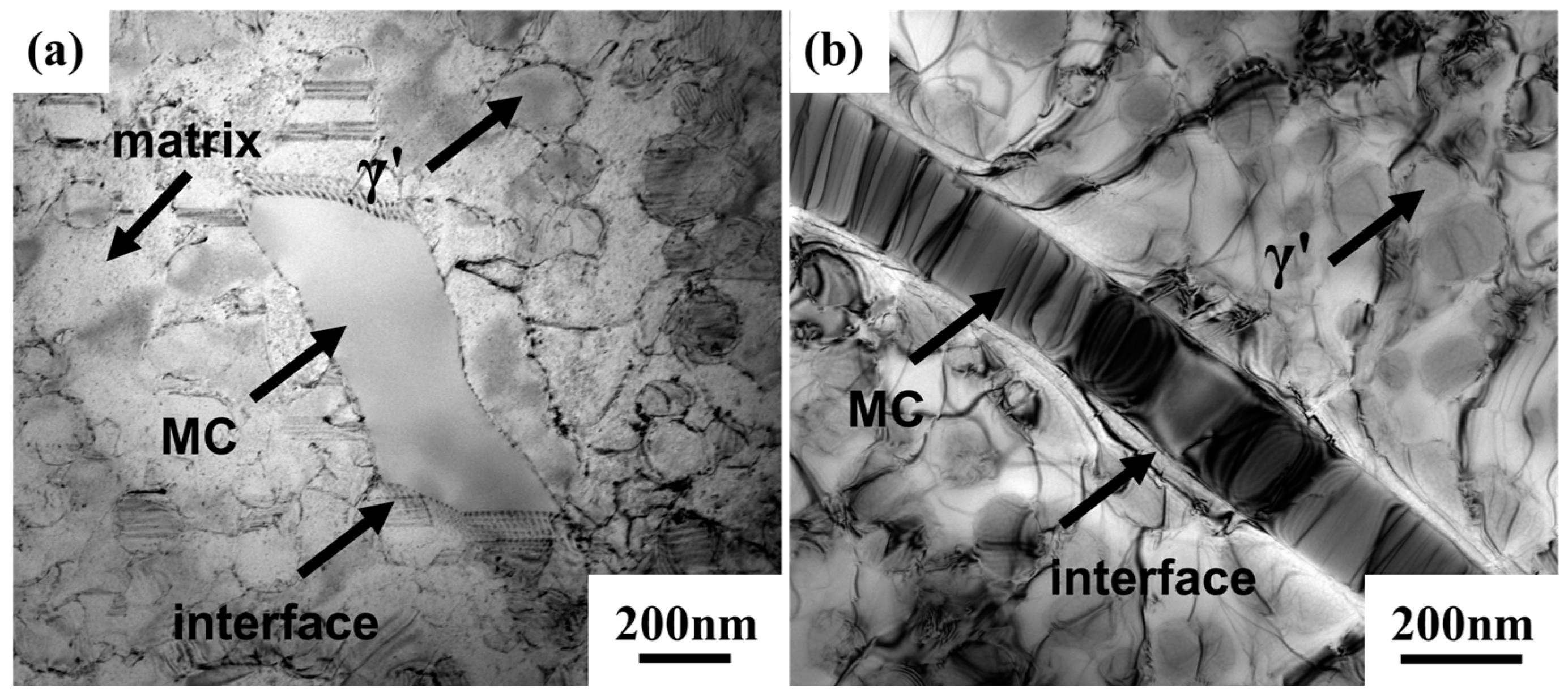

3.3. Analysis of Stress Rupture Degradation and Deformation Mechanisms

4. Conclusions

Author Contributions

Funding

Data Availability Statement

Conflicts of Interest

References

- Du, B.; Hu, Z.; Sheng, L.; Cui, C.; Yang, J.; Zheng, Y.; Sun, X. Tensile, creep behavior and microstructure evolution of an as-cast Ni-based K417G polycrystalline superalloy. J. Mater. Sci. Technol. 2018, 34, 1805–1816. [Google Scholar] [CrossRef]

- Li, D.; Cai, W.; Liu, Z.; Shen, X.; Wang, H.; Zhu, G.; Shu, D. Elemental mapping and quantitative characterization of dendrite structure in IN718 supperalloy based on micro beam X-ray fluorescence and EPMA. Vacuum 2022, 198, 110859. [Google Scholar] [CrossRef]

- Ye, R.; Li, H.; Ding, R.; Doel, T.J.A.; Bray, S.; Walpole, A.; Bowen, P. Microstructure and microhardness of dissimilar weldment of Ni-based superalloys IN718-IN713LC. Mater. Sci. Eng. A 2020, 774, 138894. [Google Scholar] [CrossRef]

- Mostafaei, A.; Ghiaasiaan, R.; Ho, I.T.; Strayer, S.; Chang, K.; Shamsaei, N.; Shao, S.; Paul, S.; Yeh, A.; Tin, S.; et al. Additive manufacturing of nickel-based superalloys: A state-of-the-art review on process-structure-defect-property relationship. Prog. Mater. Sci. 2023, 136, 101108. [Google Scholar] [CrossRef]

- Wang, Z.; Guan, K.; Gao, M.; Li, X.; Chen, X.; Zeng, X. The microstructure and mechanical properties of deposited-IN718 by selective laser melting. J. Alloys Compd. 2012, 513, 518–523. [Google Scholar] [CrossRef]

- Zhao, Y.; Guo, Q.; Ma, Z.; Yu, L. Comparative study on the microstructure evolution of selective laser melted and wrought IN718 superalloy during subsequent heat treatment process and its effect on mechanical properties. Mater. Sci. Eng. A 2020, 791, 139735. [Google Scholar] [CrossRef]

- Chen, J.; Ren, X.; Zhang, M.; Zhang, L.; Tang, X.; Xiao, C. Microstructure and typical properties of cast Ni-based superalloy K439B. Heat Treat. Met. 2023, 48, 100–104. [Google Scholar]

- Guo, X.; Zheng, W.; An, W.; Antonov, S.; Li, L.; Cormier, J.; Feng, Q. High temperature creep behavior of a cast polycrystalline nickel-based superalloy K465 under thermal cycling conditions. Materialia 2020, 14, 100913. [Google Scholar] [CrossRef]

- Kang, M.; Sridar, S.; Xiong, W.; Wang, J.; Yu, J.; Sun, B. Influence of long-term aging on microstructural stability and performance of DD6 superalloy. Mater. Sci. Technol. 2021, 37, 607–615. [Google Scholar] [CrossRef]

- Zhang, P.; Yuan, Y.; Yan, J.; Wang, J.; Song, X.; Yang, G. Morphological evolution of γ′ precipitates in superalloy M4706 during thermal aging. Mater. Lett. 2018, 211, 107–109. [Google Scholar] [CrossRef]

- Ou, M.; Ma, Y.; Hou, K.; Wang, M.; Ma, G.; Liu, K. Effect of grain boundary precipitates on the stress rupture properties of K4750 alloy after long-term aging at 750°C for 8000 h. J. Mater. Sci. Technol. 2021, 92, 11–20. [Google Scholar] [CrossRef]

- Cui, J.; Zhang, J.; Yao, J. Effect of Thermal Exposure on the Microstructure and Stress-Rupture Properties of a Directionally Solidified Superalloy. J. Mater. Eng. Perform. 2021, 30, 9200–9208. [Google Scholar] [CrossRef]

- Chen, J.; Huo, Q.; Chen, J.; Wu, Y.; Li, Q.; Xiao, C.; Hui, X. Tailoring the creep properties of second-generation Ni-based single crystal superalloys by composition optimization of Mo, W and Ti. Mater. Sci. Eng. A 2021, 799, 140163. [Google Scholar] [CrossRef]

- Zhang, L.; Chen, J.; Tang, X.; Xiao, C.; Zhang, M.; Yang, Q. Evolution of microstructures and mechanical properties of K439B superalloy during long-term aging at 800 °C. Acta Metall. Sin. 2023, 59, 1253–1264. [Google Scholar]

- Jahangiri, M.R.; Abedini, M. Effect of long time service exposure on microstructure and mechanical properties of gas turbine vanes made of IN939 alloy. Mater. Des. 2014, 64, 588–600. [Google Scholar] [CrossRef]

- Gao, L.; Qu, X.; Wu, Y.; Chen, J.; Xiao, C.; Hui, X. Evolution of carbides in K439B nickel-based cast superalloy during long-term aging at 800 °C. Mater. Rep. 2024, 38, 12–16. [Google Scholar]

- Liu, Z.; Li, C.; Dong, A.; Gu, J. Effect of initial microstructure on the properties of K439B nickel-based superalloy during prolonged aging at 800 °C. Intermetallics 2024, 172, 108364. [Google Scholar] [CrossRef]

- Azadi, M.; Marbout, A.; Safarloo, S.; Azadi, M.; Shariat, M.; Rizi, M.H. Effects of solutioning and ageing treatments on properties of Inconel-713C nickel-based superalloy under creep loading. Mater. Sci. Eng. A 2018, 711, 195–204. [Google Scholar] [CrossRef]

- Kvapilova, M.; Kral, P.; Dvorak, J.; Hutar, P.; Sklenicka, V. Evolution of high-temperature creep behaviour in cast GTD-111 nickel-based superalloy. Procedia Struct. Integr. 2024, 52, 89–98. [Google Scholar] [CrossRef]

- Aghaie-Khafri, M.; Hajjavady, M. The effect of thermal exposure on the properties of a Ni-base superalloy. Mater. Sci. Eng. A 2008, 487, 388–393. [Google Scholar] [CrossRef]

- Shi, Z.; Li, J.; Liu, S. Effect of long term aging on microstructure and stress rupture properties of a nickel based single crystal superalloy. Prog. Nat. Sci. Mater. Int. 2012, 22, 426–432. [Google Scholar] [CrossRef]

- Sun, F.; Gu, Y.; Yan, J.; Zhong, Z.; Yuyama, M. Phenomenological and microstructural analysis of intermediate temperatures creep in a Ni–Fe-based alloy for advanced ultra-supercritical fossil power plants. Acta Mater. 2016, 102, 70–78. [Google Scholar] [CrossRef]

- Lu, S.; Antonov, S.; Li, L.; Feng, Q. Two Steady-State Creep Stages in Co-Al-W-Base Single-Crystal Superalloys at 1273K/137 MPa. Metall. Mater. Trans. A 2018, 49, 4079–4089. [Google Scholar] [CrossRef]

- Rae, C.M.F.; Matan, N.; Reed, R.C. The role of stacking fault shear in the primary creep of [001]-oriented single crystal superalloys at 750°C and 750 MPa. Mater. Sci. Eng. A 2001, 300, 125–134. [Google Scholar] [CrossRef]

- Hu, X.; Qin, X.; Hou, J.; Zhou, L.; Ma, X. Microstructural characterization of the M23C6 carbide in a long-term aged Ni-based superalloy. Philos. Mag. Lett. 2017, 97, 43–49. [Google Scholar] [CrossRef]

- Lvov, G.; Levit, V.I.; Kaufman, M.J. Mechanism of primary MC carbide decomposition in Ni-base superalloys. Metall. Mater. Trans. A 2004, 35, 1669–1679. [Google Scholar] [CrossRef]

- Ge, H.; Liu, G.; Zheng, S.; Yang, Y.; Liu, K.; Ma, X. Dislocation climbing dominated decomposition and fracture of carbides in a Ni-based superalloy. Acta Mater. 2023, 246, 118669. [Google Scholar] [CrossRef]

Disclaimer/Publisher’s Note: The statements, opinions and data contained in all publications are solely those of the individual author(s) and contributor(s) and not of MDPI and/or the editor(s). MDPI and/or the editor(s) disclaim responsibility for any injury to people or property resulting from any ideas, methods, instructions or products referred to in the content. |

© 2024 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (https://creativecommons.org/licenses/by/4.0/).

Share and Cite

Wu, Y.; Qu, X.; Gao, L.; Song, C.; Dong, Z.; Chen, J.; Hui, X. Evolution of Stress Rupture Property for K439B Superalloy During Long-Term Thermal Exposure at 800 °C. Metals 2024, 14, 1461. https://doi.org/10.3390/met14121461

Wu Y, Qu X, Gao L, Song C, Dong Z, Chen J, Hui X. Evolution of Stress Rupture Property for K439B Superalloy During Long-Term Thermal Exposure at 800 °C. Metals. 2024; 14(12):1461. https://doi.org/10.3390/met14121461

Chicago/Turabian StyleWu, Yidong, Xinghai Qu, Lei Gao, Chaoqian Song, Zhao Dong, Jingyang Chen, and Xidong Hui. 2024. "Evolution of Stress Rupture Property for K439B Superalloy During Long-Term Thermal Exposure at 800 °C" Metals 14, no. 12: 1461. https://doi.org/10.3390/met14121461

APA StyleWu, Y., Qu, X., Gao, L., Song, C., Dong, Z., Chen, J., & Hui, X. (2024). Evolution of Stress Rupture Property for K439B Superalloy During Long-Term Thermal Exposure at 800 °C. Metals, 14(12), 1461. https://doi.org/10.3390/met14121461