Laser Surface Texturing of Cutting Tools for Improving the Machining of Ti6Al4V: A Review

Abstract

1. Introduction

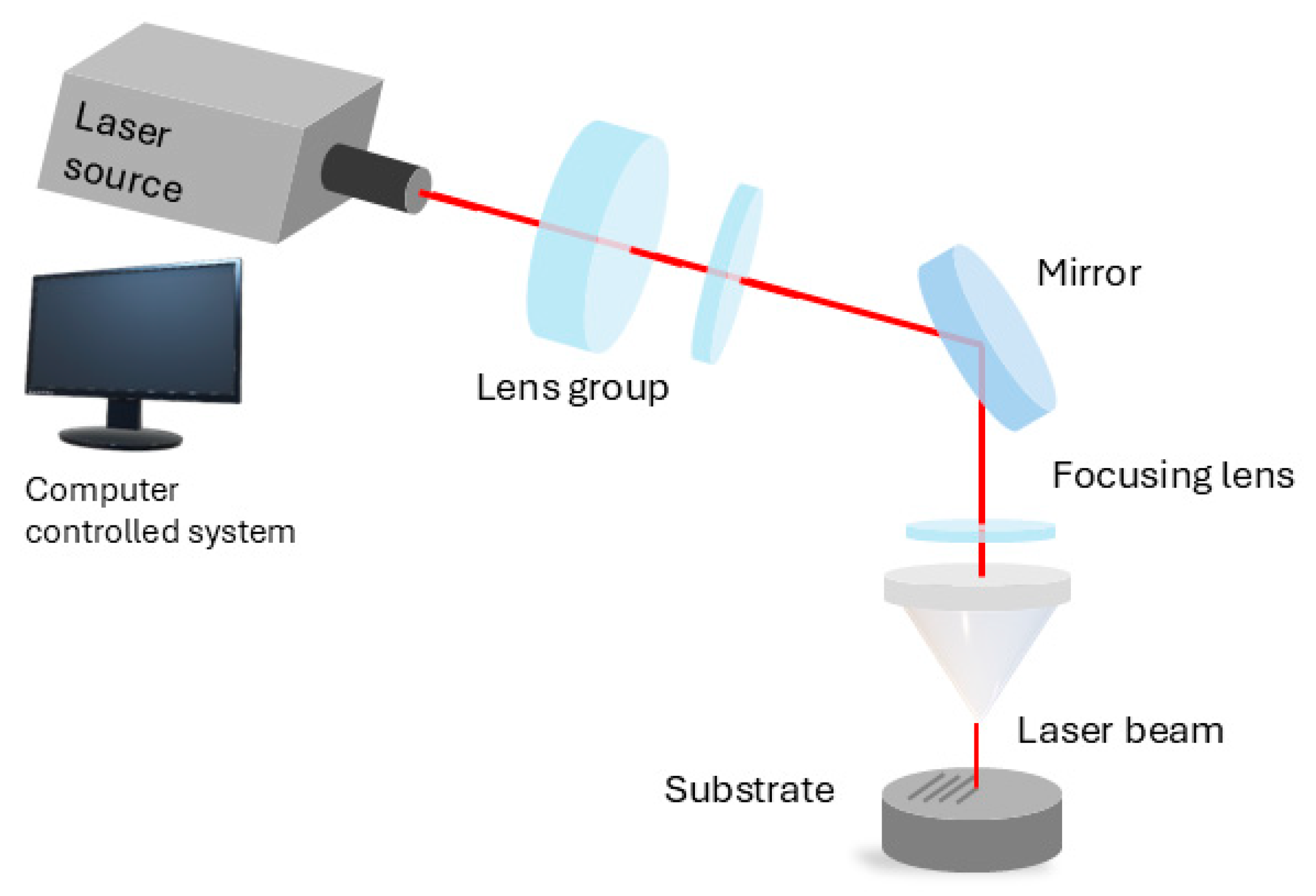

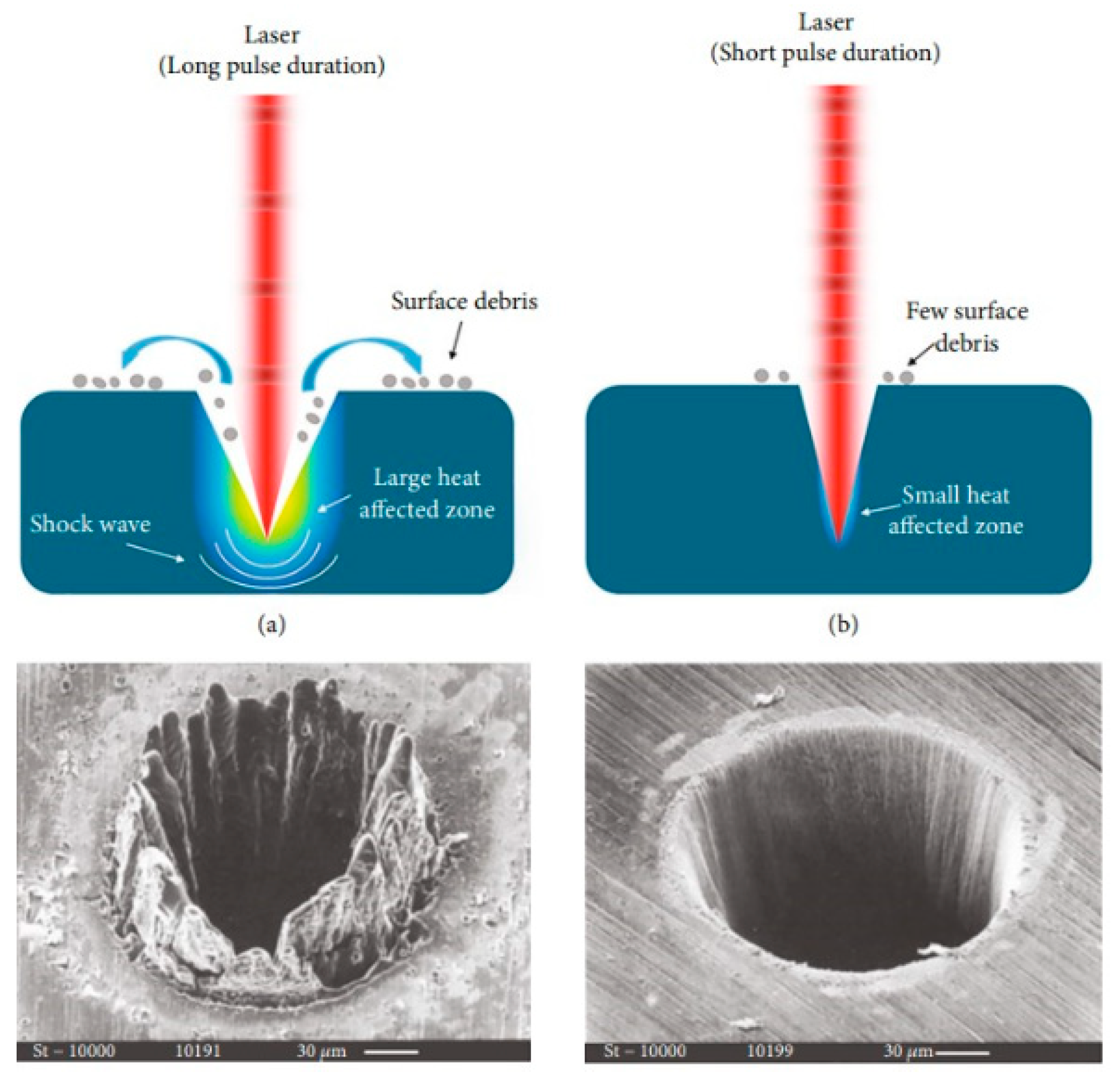

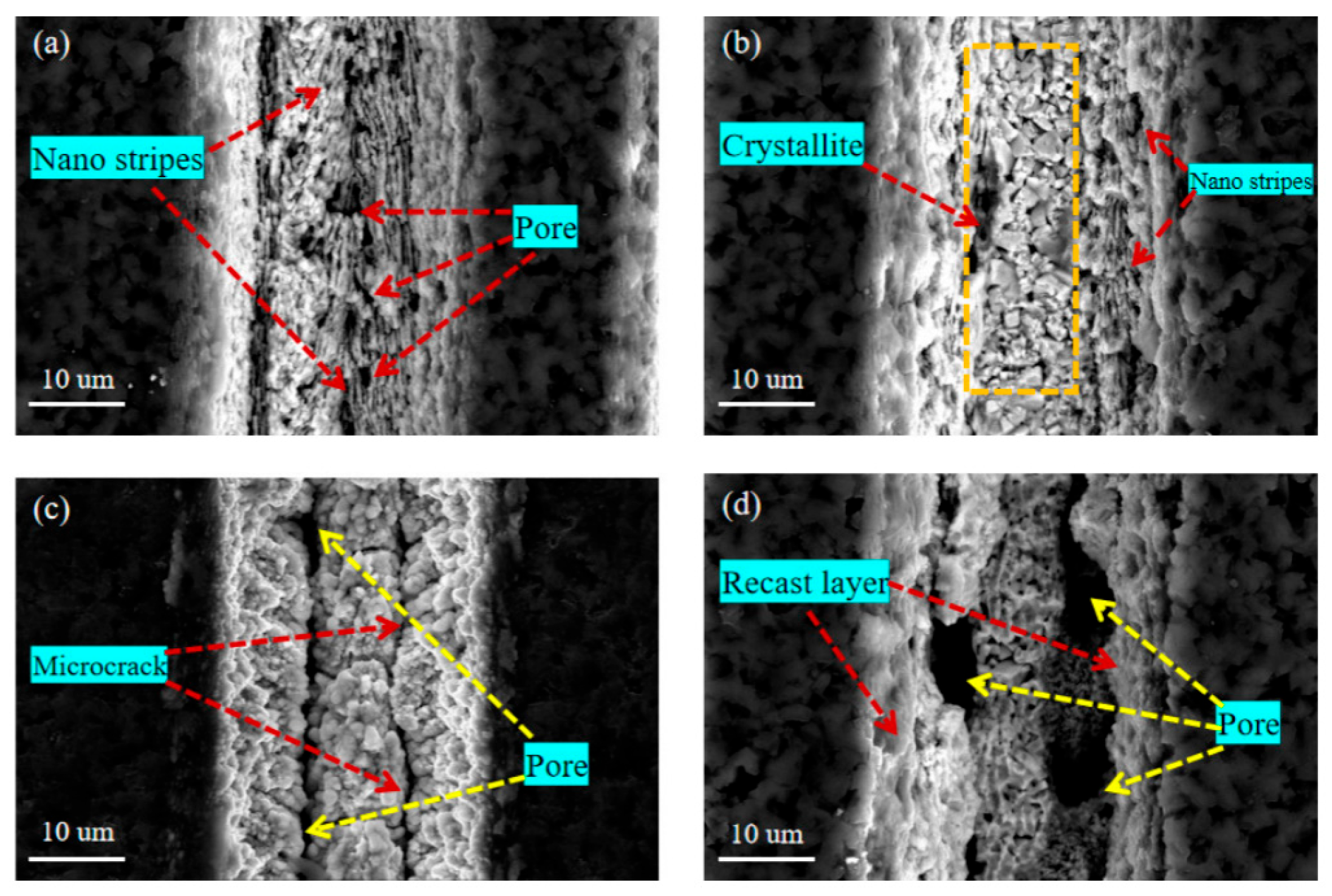

2. Fundamentals of Laser Surface Texturing

- -

- LST by laser interference: Two or more overlapping laser beams are used. The interference of these beams produces a periodic intensity distribution, which ablates the surface, forming textures that enhance tribological properties, reduce friction and improve wear resistance [36].

- -

- LST by laser shock: High-intensity laser pulses generate shock waves on a material’s surface. These shock waves enhance properties like hardness, fatigue strength and wear resistance. This method is particularly effective for improving the durability of materials used in demanding applications, as it increases surface compressive stresses [37].

- -

- LST by direct ablation: Short, high-intensity laser pulses are used to remove material from a surface in a controlled manner. This ablation process evaporates or sublimates tiny surface areas, allowing for custom-designed textures that can enhance properties such as friction reduction, wear resistance and hydrophobicity [31,35].

3. Recent Studies on LST in Cutting-Tool Texturing for Titanium Machining

4. Laser Surface Texturing for Titanium Machining

4.1. Effect of Laser Power

4.2. Effect of the Number of Passes

4.3. Effect of Other Laser Processing Parameters

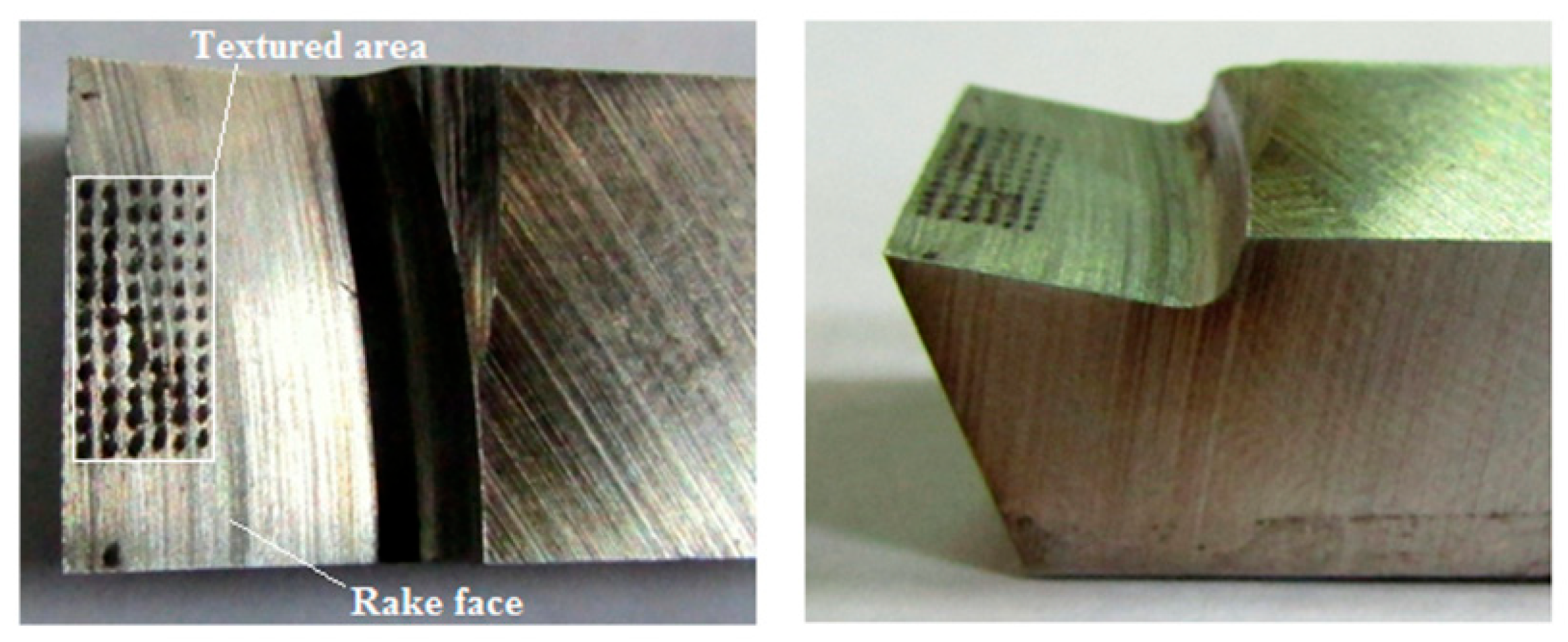

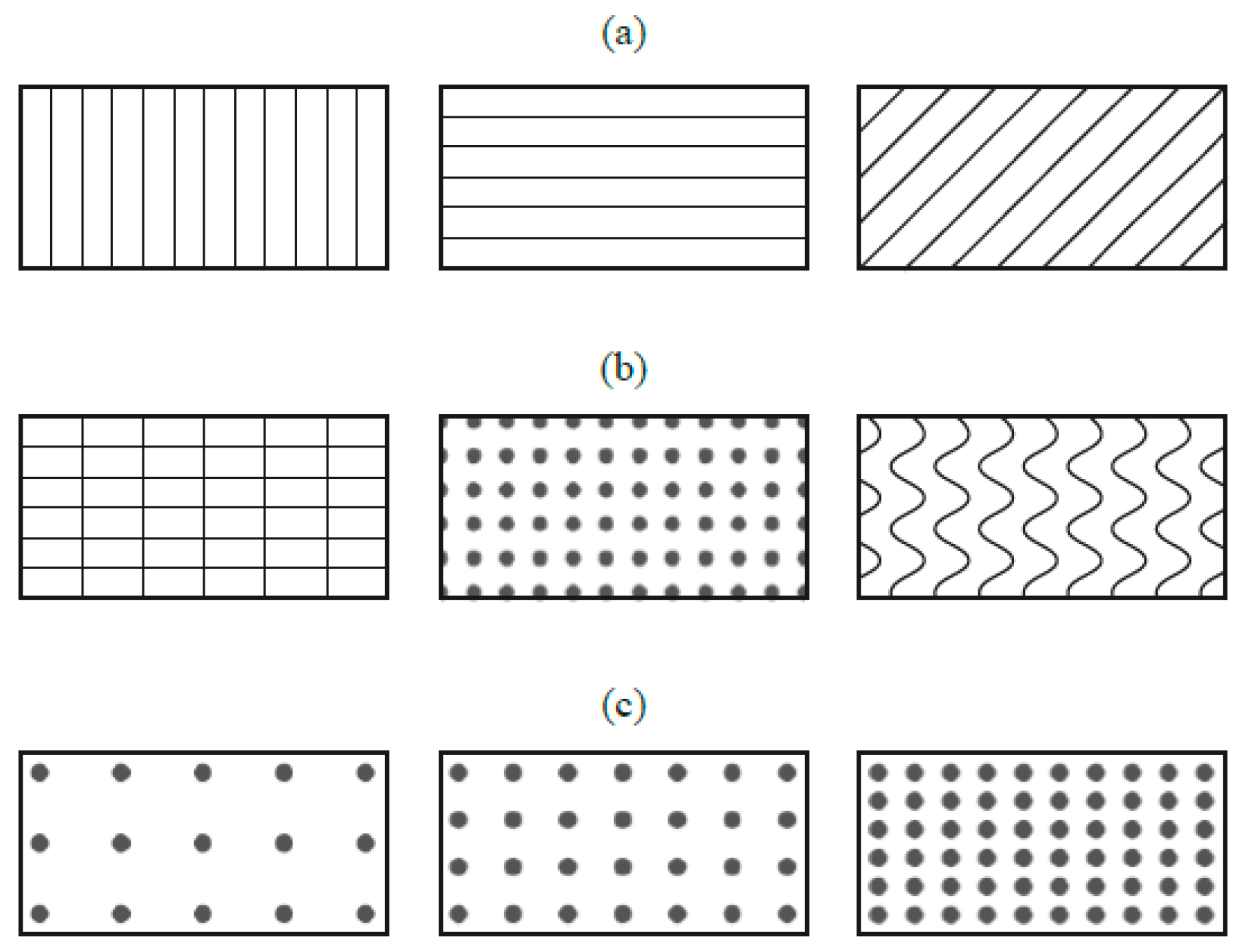

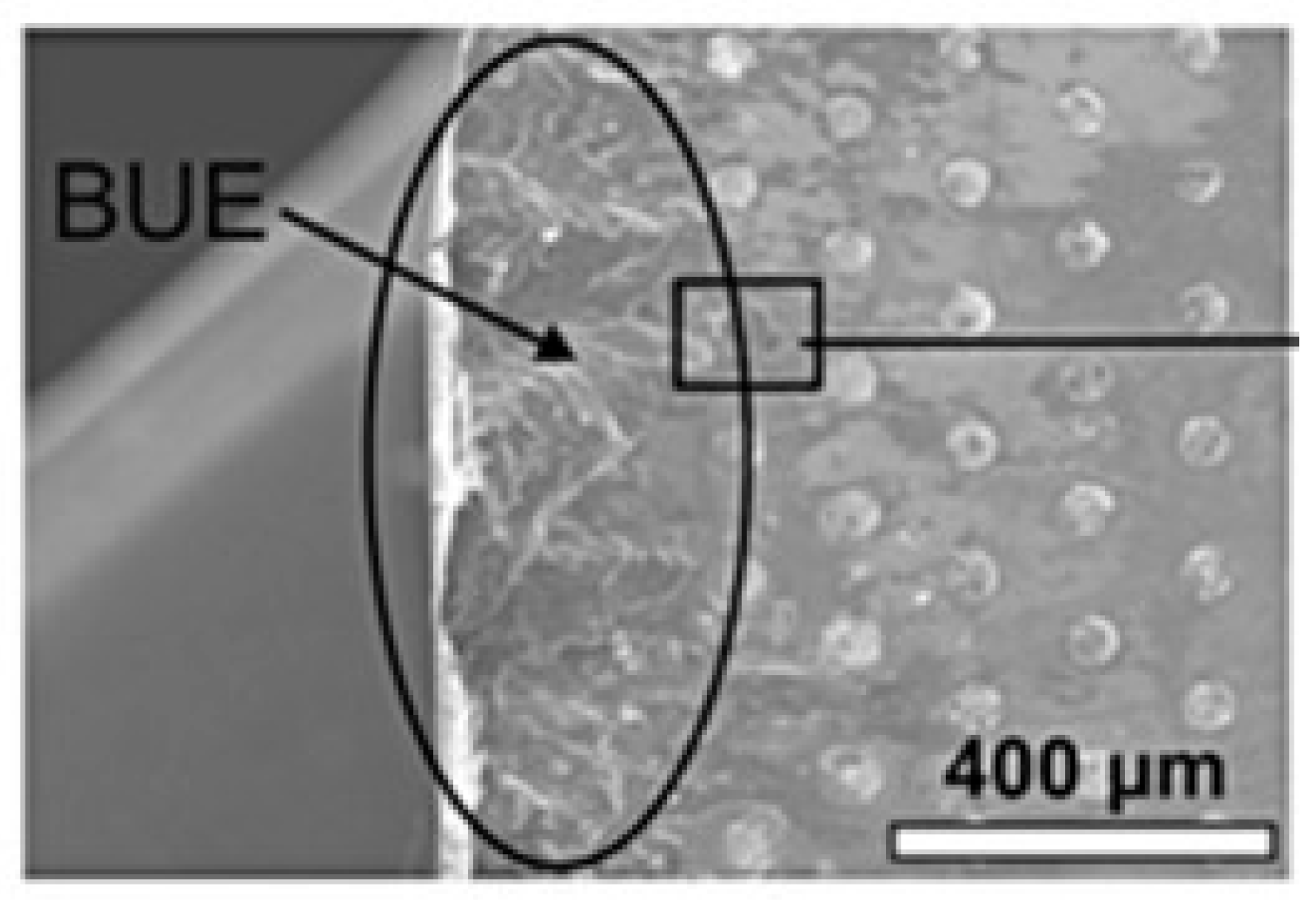

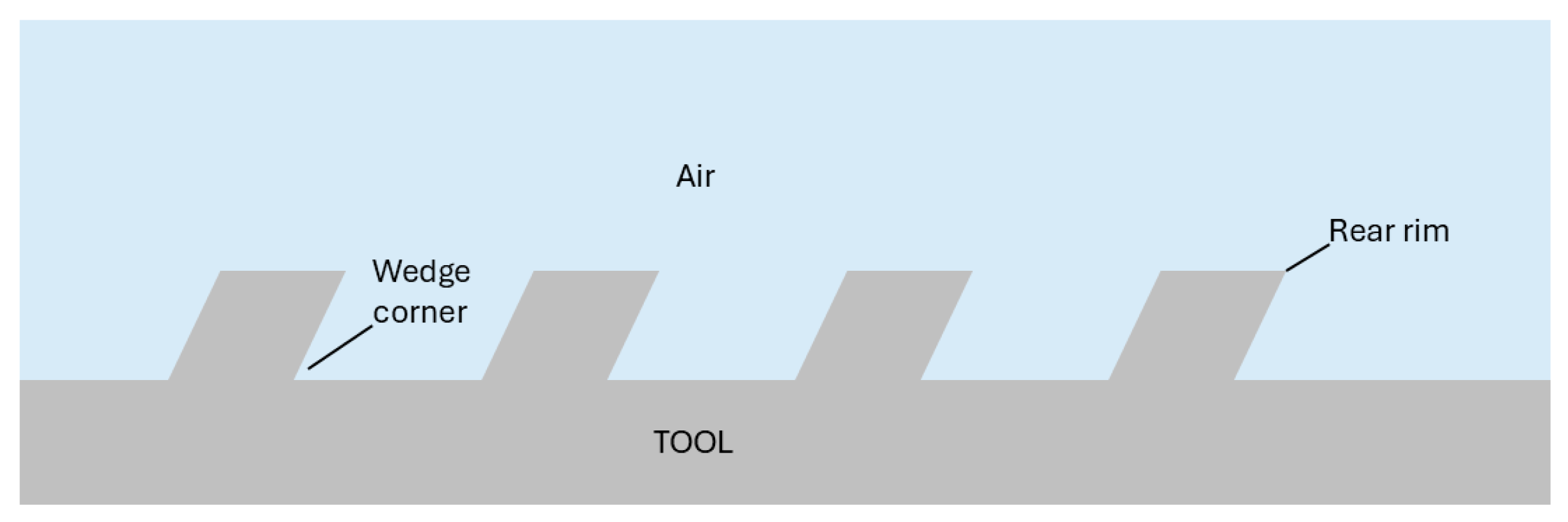

4.4. Effect of Texture Orientation and Geometry

5. Conclusions

5.1. Sustainable LST Technics

- Optimization strategies to reduce power consumption;

- Integration with renewable energy sources to power laser setups;

- The development of alternative green technologies with similar precision.

5.2. Future Opportunities and Challenges

Author Contributions

Funding

Data Availability Statement

Conflicts of Interest

References

- Cui, C.; Hu, B.; Zhao, L.; Liu, S. Titanium Alloy Production Technology, Market Prospects and Industry Development. Mater. Des. 2010, 32, 1684–1691. [Google Scholar] [CrossRef]

- Nouari, M.; Makich, H. Experimental Investigation on the Effect of the Material Microstructure on Tool Wear When Machining Hard Titanium Alloys: Ti-6Al-4V and Ti-555. Int. J. Refract. Met. Hard Mater. 2013, 41, 259–269. [Google Scholar] [CrossRef]

- Bai, J.; Bai, Q.; Tong, Z. Experimental and Multiscale Numerical Investigation of Wear Mechanism and Cutting Performance of Polycrystalline Diamond Tools in Micro-End Milling of Titanium Alloy Ti-6Al-4V. Int. J. Refract. Met. Hard Mater. 2018, 74, 40–51. [Google Scholar] [CrossRef]

- Yang, D.; Liu, Z. Surface Topography Analysis and Cutting Parameters Optimization for Peripheral Milling Titanium Alloy Ti-6Al-4V. Int. J. Refract. Met. Hard Mater. 2015, 51, 192–200. [Google Scholar] [CrossRef]

- Pramanik, A.; Littlefair, G. Machining of Titanium Alloy (Ti-6Al-4V)-Theory to Application. Mach. Sci. Technol. 2015, 19, 1–49. [Google Scholar] [CrossRef]

- Sun, X.; Wang, X.; Hu, Y.; Duan, J.A. The Effect of Micro-Texture on Wear Resistance of WC/Co-Based Tools during Cutting Ti-6Al-4V. Appl. Phys. A Mater. Sci. Process 2021, 127, 453. [Google Scholar] [CrossRef]

- Ulas, H.B.; Bilgin, M.; Sezer, H.K.; Ozkan, M.T. Performance of Coated and Uncoated Carbide/Cermet Cutting Tools during Turning. Mater./Mater. Test. 2018, 60, 893–901. [Google Scholar] [CrossRef]

- Li, B.; Zhang, T.; Zhang, S. Deep Cryogenic Treatment of Carbide Tool and Its Cutting Performances in Hard Milling of AISI H13 Steel. Procedia CIRP 2018, 71, 35–40. [Google Scholar] [CrossRef]

- Matsuoka, H.; Kubo, A.; Ono, H.; Ryu, T.; Qiu, H.; Nakae, T. Influence of Water-Miscible Cutting Fluids on Tool Wear Behavior of Different Coated HSS Tools in Hobbing. Mech. Eng. Res. 2018, 8, p10. [Google Scholar] [CrossRef]

- Zheng, K.; Yang, F.; Zhang, N.; Liu, Q.; Jiang, F. Study on the Cutting Performance of Micro Textured Tools on Cutting Ti-6Al-4V Titanium Alloy. Micromachines 2020, 11, 137. [Google Scholar] [CrossRef]

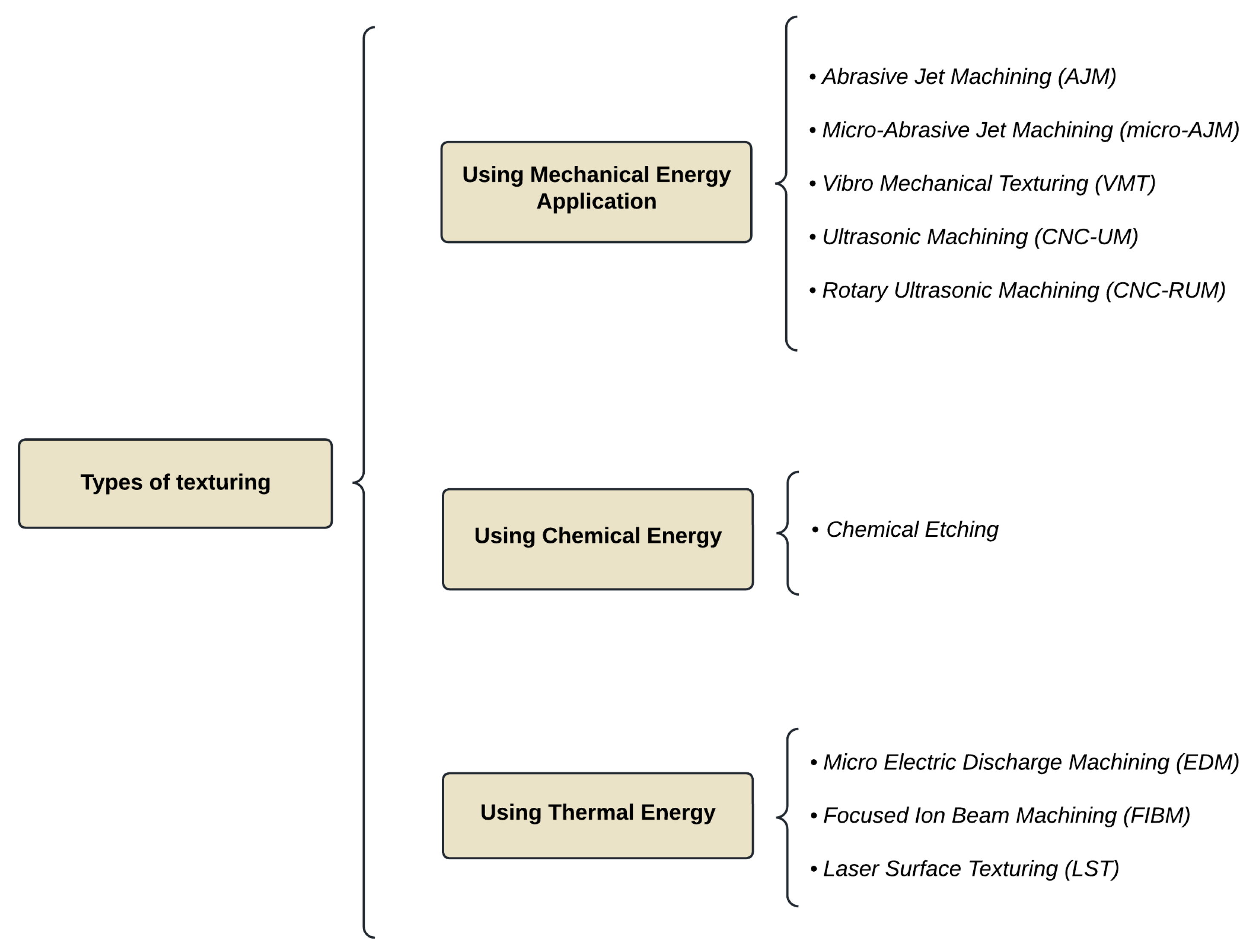

- Vishnoi, M.; Kumar, P.; Murtaza, Q. Surface Texturing Techniques to Enhance Tribological Performance: A Review. Surf. Interfaces 2021, 27, 101463. [Google Scholar] [CrossRef]

- Coblas, D.G.; Fatu, A.; Maoui, A.; Hajjam, M. Manufacturing Textured Surfaces: State of Art and Recent Developments. Proc. Inst. Mech. Eng. Part J J. Eng. Tribol. 2015, 229, 3–29. [Google Scholar] [CrossRef]

- Shivakoti, I.; Kibria, G.; Cep, R.; Pradhan, B.B.; Sharma, A. Laser Surface Texturing for Biomedical Applications: A Review. Coatings 2021, 11, 124. [Google Scholar] [CrossRef]

- Liu, M.; Zhou, R.; Chen, Z.; Yan, H.; Cui, J.; Liu, W.; Pan, J.H.; Hong, M. Tunable Hierarchical Nanostructures Onmicro-Conical Arrays of Laser Textured TC4 Substrate by Hydrothermal Treatment for Enhanced Anti-Icing Property. Coatings 2020, 10, 450. [Google Scholar] [CrossRef]

- Cholkar, A.; Chatterjee, S.; Richards, C.; McCarthy, É.; Perumal, G.; Regan, F.; Kinahan, D.; Brabazon, D. Biofouling and Corrosion Protection of Aluminum Alloys Through Ultrafast Laser Surface Texturing for Marine Applications. Adv. Mater. Interfaces 2024, 11, 2300835. [Google Scholar] [CrossRef]

- Tanvir Ahmmed, K.M.; Grambow, C.; Kietzig, A.M. Fabrication of Micro/Nano Structures on Metals by Femtosecond Laser Micromachining. Micromachines 2014, 5, 1219–1253. [Google Scholar] [CrossRef]

- Li, M.T.; Liu, M.; Sun, H.B. Surface Nanostructuring via Femtosecond Lasers. Phys. Chem. Chem. Phys. 2019, 21, 24262–24268. [Google Scholar] [CrossRef]

- Wang, H.; Deng, D.; Zhai, Z.; Yao, Y. Laser-Processed Functional Surface Structures for Multi-Functional Applications-a Review. J. Manuf. Process 2024, 116, 247–283. [Google Scholar] [CrossRef]

- Kumar, V.; Verma, R.; Kango, S.; Sharma, V.S. Recent Progresses and Applications in Laser-Based Surface Texturing Systems. Mater. Today Commun. 2021, 26, 101736. [Google Scholar] [CrossRef]

- Jia, X.; Zhang, Y.; Dong, X.; Wang, Z. Enhanced Lipophilicity and Wear Resistance of 20CrMnTi Induced by Laser Surface Texturing. Opt. Laser Technol. 2024, 170, 110329. [Google Scholar] [CrossRef]

- Bagade, V.U.; Duraiselvam, M.; Sarangi, N.; Parthiban, K. Laser Surface Texturing to Enhance CuNiIn Anti-Fretting Coating Adhesion on Ti6Al4V Alloy for Aerospace Application. Lasers Manuf. Mater. Process. 2020, 7, 141–153. [Google Scholar] [CrossRef]

- Rezayat, M.; Besharatloo, H.; Mateo, A. Investigating the Effect of Nanosecond Laser Surface Texturing on Microstructure and Mechanical Properties of AISI 301LN. Metals 2023, 13, 2021. [Google Scholar] [CrossRef]

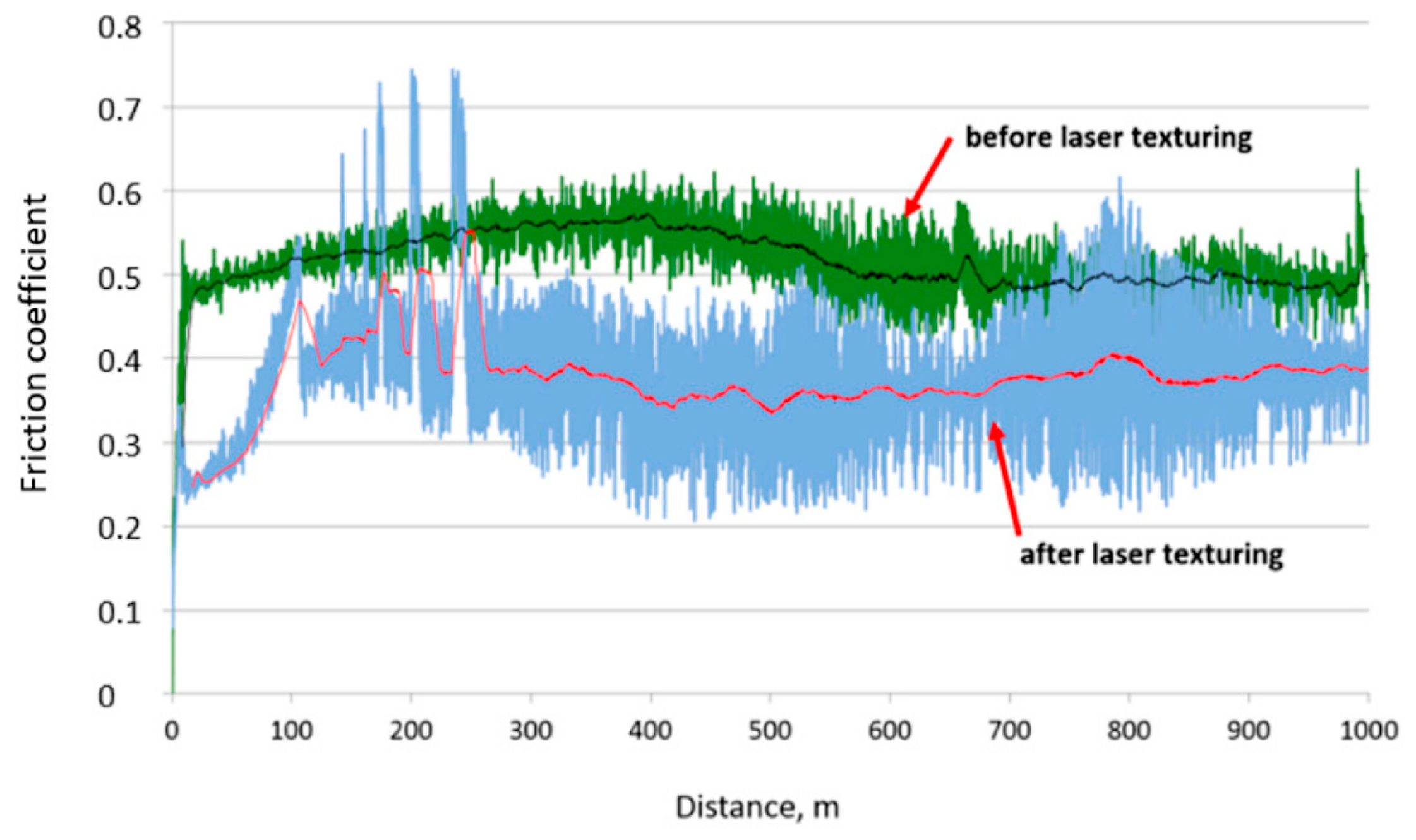

- Salguero, J.; Del Sol, I.; Dominguez, G.; Batista, M.; Vazquez-Martinez, J.M. Tribological Wear Effects of Laser Texture Design on AISI 630 Stainless Steel under Lubricated Conditions. Metals 2022, 12, 543. [Google Scholar] [CrossRef]

- Salguero, J.; Del Sol, I.; Vazquez-Martinez, J.M.; Schertzer, M.J.; Iglesias, P. Effect of Laser Parameters on the Tribological Behavior of Ti6Al4V Titanium Microtextures under Lubricated Conditions. Wear 2019, 426–427, 1272–1279. [Google Scholar] [CrossRef]

- Long, R.; Sun, Y.; Zhang, Y.; Shang, Q.; Ramteke, S.M.; Marian, M. Influence of Micro-Texture Radial Depth Variations on the Tribological and Vibration Characteristics of Rolling Bearings under Starved Lubrication. Tribol. Int. 2024, 194, 109545. [Google Scholar] [CrossRef]

- Narayana, T.; Saleem, S.S. Synergetic Effect of Oleophilic Textured Surfaces and MoS2 on the Tribological Properties of Ti-6Al-4V Alloy under Dry and Lubricated Sliding Conditions. Surf. Topogr. 2024, 12, 015008. [Google Scholar] [CrossRef]

- Shabir, S.; Sharma, M.D. Tribological Behaviour of Laser Textured Ti3AlV 2.5V Alloy under Simulated Body Fluid. Tribol. Int. 2024, 200, 110076. [Google Scholar] [CrossRef]

- Baby, A.K.; Rajendrakumar, P.K.; Lawrence, K.D. Comparative Study on the Tribological Performance and Wear Behaviour of Hypereutectic Al–Si Cylinder Liner Surfaces Textured Using Micro-Drilling and Mechanical Indentation-Based Approaches. Wear 2024, 540–541, 205240. [Google Scholar] [CrossRef]

- Gaikwad, A.; Vázquez-Martínez, J.M.; Salguero, J.; Iglesias, P. Tribological Properties of Ti6Al4V Titanium Textured Surfaces Created by Laser: Effect of Dimple Density. Lubricants 2022, 10, 138. [Google Scholar] [CrossRef]

- Kang, Z.; Fu, Y.; Kim, D.M.; Joe, H.E.; Fu, X.; Gabor, T.; Park, H.W.; Jun, M.B.-G. From Macro to Micro, Evolution of Surface Structures on Cutting Tools: A Review. JMST Adv. 2019, 1, 89–106. [Google Scholar] [CrossRef]

- Arslan, A.; Masjuki, H.H.; Kalam, M.A.; Varman, M.; Mufti, R.A.; Mosarof, M.H.; Khuong, L.S.; Quazi, M.M. Surface Texture Manufacturing Techniques and Tribological Effect of Surface Texturing on Cutting Tool Performance: A Review. Crit. Rev. Solid State Mater. Sci. 2016, 41, 447–481. [Google Scholar] [CrossRef]

- Tong, X.; Han, P.; Yang, S. Coating and Micro-Texture Techniques for Cutting Tools. J. Mater. Sci. 2022, 57, 17052–17104. [Google Scholar] [CrossRef]

- Rodríguez García, G. Caracterización de La Interacción Láser-Materia En El Texturizado Láser Femtosegundo de Material de Herramientas de Corte. Master’s Thesis, University of Cádiz, Cádiz, Spain, 2023. [Google Scholar]

- Puértolas Ráfales, J.A. Tecnología de Superficies En Materiales; Editorial Síntesis, S.A.: Madrid, Spain, 2010. [Google Scholar]

- Mao, B.; Siddaiah, A.; Liao, Y.; Menezes, P.L. Laser Surface Texturing and Related Techniques for Enhancing Tribological Performance of Engineering Materials: A Review. J. Manuf. Process 2020, 53, 153–173. [Google Scholar] [CrossRef]

- Fang, S.; Llanes, L.; Klein, S.; Gachot, C.; Rosenkranz, A.; Bähre, D.; Mücklich, F. Frictional Performance Assessment of Cemented Carbide Surfaces Textured by Laser. IOP Conf. Ser. Mater. Sci. Eng. 2017, 258, 012006. [Google Scholar] [CrossRef]

- Mao, B.; Siddaiah, A.; Menezes, P.L.; Liao, Y. Surface Texturing by Indirect Laser Shock Surface Patterning for Manipulated Friction Coefficient. J. Mater. Process Technol. 2018, 257, 227–233. [Google Scholar] [CrossRef]

- Harilal, S.S.; Freeman, J.R.; Diwakar, P.K.; Hassanein, A.; Harilal, S.S.; Freeman, J.R.; Diwakar, Á.P.K.; Hassanein, Á.A.; Musazzi, S.; Perini, U. Laser-Induced Breakdown Spectroscopy; Springer Series in Optical Sciences; Springer: Berlin/Heidelberg, Germany, 2014; Volume 182. [Google Scholar] [CrossRef]

- Hazzan, K.E.; Pacella, M.; See, T.L. Laser Processing of Hard and Ultra-Hard Materials for Micro-Machining and Surface Engineering Applications. Micromachines 2021, 12, 895. [Google Scholar] [CrossRef]

- Orlandini, A.; Baraldo, S.; Porta, M.; Valente, A. Ablation Threshold Estimation for Femtosecond Pulsed Laser Machining of AISI 316L. Procedia CIRP 2022, 107, 617–622. [Google Scholar] [CrossRef]

- Ranjan, P.; Hiremath, S.S. Role of Textured Tool in Improving Machining Performance: A Review. J. Manuf. Process 2019, 43, 47–73. [Google Scholar] [CrossRef]

- Nagarajan, B.; Han, J.; Huang, S.; Qian, J.; Vleugels, J.; Castagne, S. Femtosecond Laser Processing of Cemented Carbide for Selective Removal of Cobalt. Procedia CIRP 2022, 113, 576–581. [Google Scholar] [CrossRef]

- Kim, M.; Osone, S.; Kim, T.; Higashi, H.; Seto, T. Synthesis of Nanoparticles by Laser Ablation: A Review. KONA Powder Part. J. 2017, 34, 80–90. [Google Scholar] [CrossRef]

- Alsaigh, R.A. Enhancement of Surface Properties Using Ultrashort-Pulsed-Laser Texturing: A Review. Crystals 2024, 14, 353. [Google Scholar] [CrossRef]

- Mishra, S.; Yadava, V. Laser Beam MicroMachining (LBMM)—A Review. Opt. Lasers Eng. 2015, 73, 89–122. [Google Scholar] [CrossRef]

- Lureau, F.; Matras, G.; Chalus, O.; Derycke, C.; Morbieu, T.; Radier, C.; Casagrande, O.; Laux, S.; Ricaud, S.; Rey, G.; et al. High-Energy Hybrid Femtosecond Laser System Demonstrating 2 × 10 PW Capability. High Power Laser Sci. Eng. 2020, 8, e43. [Google Scholar] [CrossRef]

- Aizawa, T.; Inohara, T.; Aizawa, T.; Inohara, T. Pico- and Femtosecond Laser Micromachining for Surface Texturing. In Micromachining; IntechOpen: London, UK, 2019. [Google Scholar] [CrossRef]

- Li, X.; Guan, Y. Theoretical Fundamentals of Short Pulse Laser–Metal Interaction: A Review. Nanotechnol. Precis. Eng. 2020, 3, 105–125. [Google Scholar] [CrossRef]

- Kang, Z.; Fu, Y.; Fu, X.; Jun, M.B.G. Performance of Volcano-Like Laser Textured Cutting Tools: An Experimental and Simulative Investigation. Lubricants 2018, 6, 98. [Google Scholar] [CrossRef]

- Baumann, R.; Bouraoui, Y.; Teicher, U.; Selbmann, E.; Ihlenfeldt, S.; Lasagni, A.F. Tailored Laser Structuring of Tungsten Carbide Cutting Tools for Improving Their Tribological Performance in Turning Aluminum Alloy Al6061 T6. Materials 2023, 16, 1205. [Google Scholar] [CrossRef]

- Teicher, U.; Baumann, R.; Bouraoui, Y.; Achour, A.B.; Lasagni, A.F.; Ihlenfeldt, S. Laser Structuring with DLIP Technology of Tungsten Carbide with Different Binder Content. Procedia CIRP 2022, 111, 601–604. [Google Scholar] [CrossRef]

- Özel, T.; Biermann, D.; Enomoto, T.; Mativenga, P. Structured and Textured Cutting Tool Surfaces for Machining Applications. CIRP Ann. 2021, 70, 495–518. [Google Scholar] [CrossRef]

- Niketh, S.; Samuel, G.L. Surface Texturing for Tribology Enhancement and Its Application on Drill Tool for the Sustainable Machining of Titanium Alloy. J. Clean. Prod. 2017, 167, 253–270. [Google Scholar] [CrossRef]

- Pradhan, S.; Indraneel, S.; Bathe, R.N. Investigation of Machinability Criteria of Ti Gr-2 Using a New Design Micro-Texture Cutting Inserts with Graphene Based Solid Lubrication. Sadhana—Acad. Proc. Eng. Sci. 2022, 47, 175. [Google Scholar] [CrossRef]

- Zhou, Y.; Fu, Y.; Yang, J. Effect of Volcano-like Textured Coated Tools on Machining of Ti6Al4V: An Experimental and Simulative Investigation. Int. J. Adv. Manuf. Technol. 2022, 120, 7785–7802. [Google Scholar] [CrossRef]

- Mishra, S.K.; Ghosh, S.; Aravindan, S. Physical Characterization and Wear Behavior of Laser Processed and PVD Coated WC/Co in Dry Sliding and Dry Turning Processes. Wear 2019, 428–429, 93–110. [Google Scholar] [CrossRef]

- Wu, X.; Zhan, J.; Mei, S.; Riveiro, A.; Wu, X.; Zhan, J.; Mei, S. Optimization of Micro-Texturing Process Parameters of TiAlN Coated Cutting Tools by Femtosecond Laser. Materials 2022, 15, 6519. [Google Scholar] [CrossRef]

- Wan, Q.; Zhong, W.; Hu, X.; Yang, S. Inhibitory Effect of Laser Surface Texturing in Dry Cutting of Titanium Alloy on Cemented Carbide Tool Wear. Int. J. Precis. Eng. Manuf. 2024, 25, 539–553. [Google Scholar] [CrossRef]

- Ajay Kumar, G.V.; Ramaa, A.; Shilpa, M. Comparative Study of Dry Machining Performance Using Hybrid Textured Cutting Insert. Mater. Manuf. Process. 2024, 39, 1775–1783. [Google Scholar] [CrossRef]

- Vázquez, J.M.; Salguero, J.; Del Sol, I. Texturing Design of WC-Co through Laser Parameter Selection to Improve Lubricant Retention Ability of Cutting Tools. Int. J. Refract. Met. Hard Mater. 2022, 107, 105880. [Google Scholar] [CrossRef]

- Palanivel, R.; Dinaharan, I.; Laubscher, R.F.; Alswat, H.M. Influence of Micro-Textured Polycrystalline Diamond Tools on the Machining Performance of Titanium Alloy Ti-6Al-4V in Dry Turning. Int. J. Adv. Manuf. Technol. 2024, 132, 4297–4313. [Google Scholar] [CrossRef]

- Zhou, C.; Guo, X.; Zhang, K.; Cheng, L.; Wu, Y. The Coupling Effect of Micro-Groove Textures and Nanofluids on Cutting Performance of Uncoated Cemented Carbide Tools in Milling Ti-6Al-4V. J. Mater. Process Technol. 2019, 271, 36–45. [Google Scholar] [CrossRef]

- Fouathiya, A.; Meziani, S.; Sahli, M.; Barrière, T. Experimental Investigation of Microtextured Cutting Tool Performance in Titanium Alloy via Turning. J. Manuf. Process 2021, 69, 33–46. [Google Scholar] [CrossRef]

- Yang, S.; Guo, Y.; Xiao, Z.; Wang, D. Study on Cutting Performance of Micro-Textured Ball-End Milling Cutter with Multiple Distribution Density under the Action of Cutting Edge. J. Mech. Sci. Technol. 2024, 38, 1753–1764. [Google Scholar] [CrossRef]

- Zhang, N.; Yang, F.; Liu, G. Cutting Performance of Micro-Textured WC/Co Tools in the Dry Cutting of Ti-6Al-4V Alloy. Int. J. Adv. Manuf. Technol. 2020, 107, 3967–3979. [Google Scholar] [CrossRef]

- Mari, D.; Sarin, V.; Miguel, L.; Nebel, C.E. Nebel Comprehensive Hard Materials, 1st ed.; Elsevier: Amsterdam, The Netherlands, 2014; ISBN 9780080965277. [Google Scholar]

- Kurlov, A.S.; Gusev, A.I. Tungsten Carbides: Structure, Properties and Application in Hardmetals; Springer Series in Materials Science; Springer: Cham, Switzerland, 2013; Volume 184. [Google Scholar] [CrossRef]

- Upadhyaya, G.S. Nature and Properties of Refractory Carbides; Nova Biomedical: Waltham, MA, USA, 1996; Volume 545. [Google Scholar]

- Konyashin, I. Approaching the 100th Anniversary of the Hardmetal Invention: From First WC-Co Samples towards Modern Advanced Hardmetal Grades. Int. J. Refract. Met. Hard Mater. 2023, 111, 106113. [Google Scholar] [CrossRef]

- UNE-EN ISO 4499-2:2021; Metal Duro. Determinación Metalográfica. UNE: Madrid, Spain, 2021. Available online: https://www.une.org/encuentra-tu-norma/busca-tu-norma/norma?c=N0066225 (accessed on 15 October 2024).

- Khan, A.; Khan, M.A.Z.; Shah, K.; Khan, A.; Khan, M.; Imran, S.H.; Sheikh, M.A.; Li, L. Laser Micro Processing of Carbide Tool Insert. In Proceedings of the ASME 2014 International Manufacturing Science and Engineering Conference, MSEC 2014 Collocated with the JSME 2014 International Conference on Materials and Processing and the 42nd North American Manufacturing Research Conference, Detroit, MI, USA, 9–13 June 2014; Volume 1. [Google Scholar] [CrossRef]

- Romano, V. Ablation of Carbide Materials with Femtosecond Pulses. Appl. Surf. Sci. 2003, 205, 80–85. [Google Scholar] [CrossRef]

- Lei, P.; Zhang, P.; Song, S.; Liu, Z.; Yan, H.; Sun, T.; Lu, Q.; Chen, Y.; Gromov, V.; Shi, H. Research Status of Laser Surface Texturing on Tribological and Wetting Properties of Materials: A Review. Optik 2024, 298, 171581. [Google Scholar] [CrossRef]

- Bañon, F.; Martin, S.; Vazquez-Martinez, J.M.; Salguero, J.; Trujillo, F.J. Predictive Models Based on RSM and ANN for Roughness and Wettability Achieved by Laser Texturing of S275 Carbon Steel Alloy. Opt. Laser Technol. 2024, 168, 109963. [Google Scholar] [CrossRef]

- Yang, Q.; Zhou, W.; Wang, L.; Ren, X.; Wang, Y.; Lou, D.; Chen, L.; Cheng, J.; Zheng, Z.; Liu, D. Wettability Control on YW2 Cemented Carbide Surface by Femtosecond Laser Irradiation. Phys. Status Solidi (A) Appl. Mater. Sci. 2021, 218, 2000709. [Google Scholar] [CrossRef]

- Sun, X.; Liu, J.; Yu, Z.; Xu, J.; Li, Y.; Yang, S. Experimental Research on Micro-Cutting of Titanium Alloy with Surface Textured Tool. In Proceedings of the 2021 IEEE International Conference on Manipulation, Manufacturing and Measurement on the Nanoscale, 3M-NANO 2021—Proceedings, Xi’an, China, 2–6 August 2021; pp. 349–354. [Google Scholar] [CrossRef]

- Sasi, R.; Kanmani Subbu, S.; Palani, I.A. Performance of Laser Surface Textured High Speed Steel Cutting Tool in Machining of Al7075-T6 Aerospace Alloy. Surf. Coat. Technol. 2017, 313, 337–346. [Google Scholar] [CrossRef]

- Ding, Y.; Yang, L.; Cheng, B.; Wang, X.; Wang, Y.; Xie, H. Investigations on Femtosecond Laser-Modified Microgroove-Textured Cemented Carbide YT15 Turning Tool with Promotion in Cutting Performance. Int. J. Adv. Manuf. Technol. 2018, 96, 4367–4379. [Google Scholar] [CrossRef]

- Roushan, A. Chetan Influence of Laser Parameters on the Machining Performance of Textured Cutting Tools. Opt. Laser Technol. 2023, 165, 109569. [Google Scholar] [CrossRef]

- Sristi, N.A.; Zaman, P.B. A Review of Textured Cutting Tools’ Impact on Machining Performance from a Tribological Perspective. Int. J. Adv. Manuf. Technol. 2024, 133, 4023–4057. [Google Scholar] [CrossRef]

- Wu, Z.; Deng, J.; Chen, Y.; Xing, Y.; Zhao, J. Performance of the Self-Lubricating Textured Tools in Dry Cutting of Ti-6Al-4V. Int. J. Adv. Manuf. Technol. 2012, 62, 943–951. [Google Scholar] [CrossRef]

- Chen, J.; Liu, D.; Jin, T.; Qi, Y. A Novel Bionic Micro-Textured Tool with the Function of Directional Cutting-Fluid Transport for Cutting Titanium Alloy. J. Mater. Process Technol. 2023, 311, 117816. [Google Scholar] [CrossRef]

- Arulkirubakaran, D.; Senthilkumar, V.; Kumawat, V. Effect of Micro-Textured Tools on Machining of Ti-6Al-4V Alloy: An Experimental and Numerical Approach. Int. J. Refract. Met. Hard Mater. 2016, 54, 165–177. [Google Scholar] [CrossRef]

- Machado, A.R.; da Silva, L.R.R.; de Souza, F.C.R.; Davis, R.; Pereira, L.C.; Sales, W.F.; de Rossi, W.; Ezugwu, E.O. State of the Art of Tool Texturing in Machining. J. Mater. Process Technol. 2021, 293, 117096. [Google Scholar] [CrossRef]

- Wu, Z.; Bao, H.; Liu, L.; Xing, Y.; Huang, P.; Zhao, G. Numerical Investigation of the Performance of Micro-Textured Cutting Tools in Cutting of Ti-6Al-4V Alloys. Int. J. Adv. Manuf. Technol. 2020, 108, 463–474. [Google Scholar] [CrossRef]

- Jahaziel, R.B.; Krishnaraj, V.; Geetha Priyadarshini, B. Investigation on Influence of Micro-Textured Tool in Machining of Ti-6Al-4V Alloy. J. Mech. Sci. Technol. 2022, 36, 1987–1995. [Google Scholar] [CrossRef]

- Kumar Mishra, S.; Ghosh, S.; Aravindan, S. Machining Performance Evaluation of Ti6Al4V Alloy with Laser Textured Tools under MQL and Nano-MQL Environments. J. Manuf. Process 2020, 53, 174–189. [Google Scholar] [CrossRef]

- Pakula, D.; Staszuk, M.; Dziekońska, M.; Kožmín, P.; Čermák, A. Laser Micro-Texturing of Sintered Tool Materials Surface. Materials 2019, 12, 3152. [Google Scholar] [CrossRef]

- Siju, A.S.; Waigaonkar, S.D. Effects of Rake Surface Texture Geometries on the Performance of Single-Point Cutting Tools in Hard Turning of Titanium Alloy. J. Manuf. Process 2021, 69, 235–252. [Google Scholar] [CrossRef]

- Fernández-Lucio, P.; Villarón-Osorno, I.; Pereira Neto, O.; Ukar, E.; López de Lacalle, L.N.; Gil del Val, A. Effects of Laser-Textured on Rake Face in Turning PCD Tools for Ti6Al4V. J. Mater. Res. Technol. 2021, 15, 177–188. [Google Scholar] [CrossRef]

| Authors | Tool Material | Studied Process | Ti Alloy | Laser Parameters | Texture Geometry | Cooling |

|---|---|---|---|---|---|---|

| Wan et al., 2024 [58] | WC | Turning | Ti6Al4V | St = 2, 3, 4, 5 N Lp = 40, 42.5, 45, 47.5 W Ss = 1200, 1300, 1400, 1500 mm/s | Dimples | Dry |

| Narayana et al., 2024 [26] | WC-Co | Tribology study | Ti6Al4V | Ss = 200 mm/s Lp = 8 W f = 23 kHz LBd = 20 μm | Triangular, square and circular | Dry and lubricated (PAO-4 and MoS2) |

| Ajay Kumar et al., 2024 [59] | AISI H13 | Turning | Ti6Al4V | Not described | Dimples and grooves (hybrid textures) | Dry |

| Vázquez et al., 2022 [60] | WC-Co | Tribology study | Not defined | Ss = 50, 100, 150 mm/s Ed = 5.89/11.79/17.68/35.37 | Grooves | Lubricated (Acculube LB5000) |

| Mishra et al., 2019 [56] | PVD-coated (AlTiN and AlCrN) WC-Co | Sliding and turning | Ti6Al4V | Wl = 1064 nm Spot size = 2 mm | Microholes | Dry |

| Salguero et al., 2022 [24] | WC-Co | Tribology study | Ti6Al4V | f = 20, 50, 80 kHz Ed = 17.68/7.07/4.42 J/cm2 Wl = 1070 nm | Grooves | Lubricated |

| Palanivel et al., 2024 [61] | PCD | Turning | Ti6Al4V | Not described | Concentric circular pattern, square pattern, cross pattern and diagonal pattern | Dry |

| Zhou et al., 2019 [62] | PCD | Turning | Ti6Al4V | St = 8 f = 25 kHz Ss = 200 mm/s | Grooves | Lubricated |

| Fouathiya et al., 2021 [63] | WC-Co | Turning | Ti6Al4V; Ti-555 | Ss = 3.3 m/s f = 100 kHz 120 fs | Parallel, perpendicular, cross and tank grooves | Lubricated |

| Yang et al., 2024 [64] | Hybrid textured tool (HTT) | Milling | Titanium | Lp = 40 W Ss = 50, 100, 150 mm/s | Dimples | Not described |

| Zhang et al., 2020 [65] | WC-Co | Tribology study | Ti6Al4V | Ss = 100 mm/s f = 20 kHz; 10 ns, 200 | Line and sinusoidal grooves | Dry |

| Sun et al., 2021 [6] | WC-Co | Turning | Ti6Al4V | Ss = 100 μm/s; 120 ns; f = 1 kHz | Grooves | Lubricated |

| Pradhan et al., 2022 [54] | CVD | Turning | Ti Gr-2 | f = 10 kHz; 100 fs Lp = 500 mW | Grooves | Lubricated |

| Zhou et al., 2022 [55] | Cemented carbide tool | Turning | Ti6Al4V | Lp = 60 W Wl = 1080 nm St = 1 | Dimples | Lubricated |

Disclaimer/Publisher’s Note: The statements, opinions and data contained in all publications are solely those of the individual author(s) and contributor(s) and not of MDPI and/or the editor(s). MDPI and/or the editor(s) disclaim responsibility for any injury to people or property resulting from any ideas, methods, instructions or products referred to in the content. |

© 2024 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (https://creativecommons.org/licenses/by/4.0/).

Share and Cite

Garcia-Fernandez, J.; Salguero, J.; Batista, M.; Vazquez-Martinez, J.M.; Del Sol, I. Laser Surface Texturing of Cutting Tools for Improving the Machining of Ti6Al4V: A Review. Metals 2024, 14, 1422. https://doi.org/10.3390/met14121422

Garcia-Fernandez J, Salguero J, Batista M, Vazquez-Martinez JM, Del Sol I. Laser Surface Texturing of Cutting Tools for Improving the Machining of Ti6Al4V: A Review. Metals. 2024; 14(12):1422. https://doi.org/10.3390/met14121422

Chicago/Turabian StyleGarcia-Fernandez, Javier, Jorge Salguero, Moises Batista, Juan Manuel Vazquez-Martinez, and Irene Del Sol. 2024. "Laser Surface Texturing of Cutting Tools for Improving the Machining of Ti6Al4V: A Review" Metals 14, no. 12: 1422. https://doi.org/10.3390/met14121422

APA StyleGarcia-Fernandez, J., Salguero, J., Batista, M., Vazquez-Martinez, J. M., & Del Sol, I. (2024). Laser Surface Texturing of Cutting Tools for Improving the Machining of Ti6Al4V: A Review. Metals, 14(12), 1422. https://doi.org/10.3390/met14121422