Microstructure Evolution and Mechanical Properties of Pure Ti Alloy Sheet Fabricated by Double-Side Corrugated Rolling

Abstract

1. Introduction

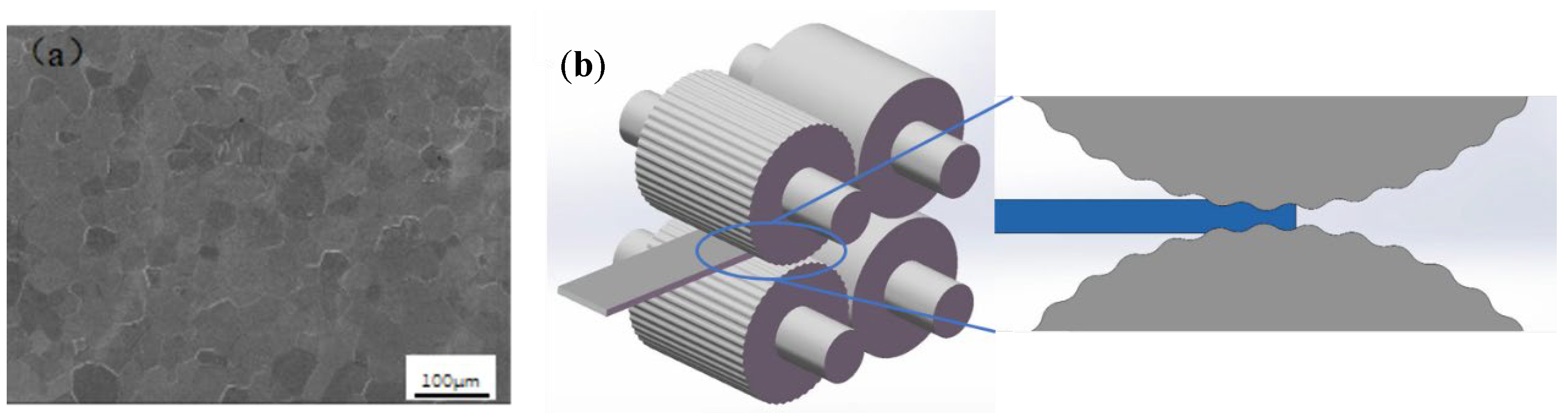

2. Experimental Procedure

3. Results

3.1. Microstructure of TA1 Plate Rolled at 400 °C

3.2. Microstructure of TA1 Plate Rolled at 700 °C

3.3. Mechanical Properties

4. Discussion

4.1. Rolled Texture and Annealed Texture at 400 °C

4.2. Rolled Texture and Annealed Texture at 700 °C

4.3. Effect of Texture Evolution on Properties of Alloys

5. Conclusions

- The recrystallization rate of the plates produced by the two rolling processes at different temperatures is small, and there are a lot of substructure and deformed grains.

- Compared with the FFR sheet, the texture weakening of the sheet rolled at 400 °C is insignificant. The textures of the sheet are the basal bimodal TD texture and mainly consist of B and E types with Euler angles (15°, 25°, 0°) and (15°, 30°, 30°).

- The tensile strength of the sheet rolled by DCFR at 400 °C was about 90 MPa higher than that of the sheet rolled by DCFR at 700 °C. The elongation in the rolling direction is almost 15%, and that in the transverse direction varies from 10% to 23% for the sheet rolled at different temperatures and rolling processes. The tensile test indicates that the alloy rolled by DCFR at 400 °C exhibits superior isotropy.

Author Contributions

Funding

Data Availability Statement

Acknowledgments

Conflicts of Interest

References

- Gan, X.; Li, S.; Xiao, S.; Yang, Y. Integrated high-performance and accurate shaping technology of low-cost powder metallurgy titanium alloys: A comprehensive review. Int. J. Miner. Metall. Mater. 2024, 31, 413–426. [Google Scholar] [CrossRef]

- Kim, K.T.; Eo, M.Y.; Nguyen, T.T.H.; Kim, S.M. General review of titanium toxicity. Int. J. Implant. Dent. 2019, 5, 10. [Google Scholar] [CrossRef] [PubMed]

- Sidambe, A. Biocompatibility of Advanced Manufactured Titanium Implants—A Review. Materials 2014, 7, 8168–8188. [Google Scholar] [CrossRef] [PubMed]

- Xu, C.; Zhu, W.-F. Comparison of microstructures and mechanical properties between forging and rolling processes for commercially pure titanium. Trans. Nonferrous Met. Soc. China 2012, 22, 1939–1946. [Google Scholar] [CrossRef]

- Li, K.; Yang, P. Interaction among deformation, recrystallization and phase transformation of TA2 pure titanium during hot compression. Trans. Nonferrous Met. Soc. China 2016, 26, 1863–1870. [Google Scholar] [CrossRef]

- Yin, Y.-F.; Xu, W.; Sun, Q.-Y.; Xiao, L.; Sun, J. Deformation and fracture behavior of commercially pure titanium with gradient nano-to-micron-grained surface layer. Trans. Nonferrous Met. Soc. China 2015, 25, 738–747. [Google Scholar] [CrossRef]

- Qarni, M.J.; Sivaswamy, G.; Rosochowski, A.; Boczkal, S. Effect of incremental equal channel angular pressing (I-ECAP) on the microstructural characteristics and mechanical behaviour of commercially pure titanium. Mater. Des. 2017, 122, 385–402. [Google Scholar] [CrossRef]

- Alvarez, K.; Nakajima, H. Metallic Scaffolds for Bone Regeneration. Materials 2009, 2, 790–832. [Google Scholar] [CrossRef]

- Yoo, M.H.; Wei, C.T. Slip Modes of Hexagonal-Close-Packed Metals. J. Appl. Phys. 1967, 38, 4317–4322. [Google Scholar] [CrossRef]

- Naka, S.; Kubin, L.P.; Perrier, C. The plasticity of titanium at low and medium temperatures. Philos. Mag. A 1991, 63, 1035–1043. [Google Scholar] [CrossRef]

- Biget, M.P.; Saada, G. Low-temperature plasticity of high-purity α-titanium single crystals. Philos. Mag. A 1989, 59, 747–757. [Google Scholar] [CrossRef]

- Naka, S.; Lasalmonie, A.; Costa, P.; Kubin, L.P. The low-temperature plastic deformation of α-titanium and the core structure of a-type screw dislocations. Philos. Mag. A 1988, 57, 717–740. [Google Scholar] [CrossRef]

- Wu, X.; Kalidindi, S.; Necker, C.; Salem, A. Prediction of crystallographic texture evolution and anisotropic stress–strain curves during large plastic strains in high purity α-titanium using a Taylor-type crystal plasticity model. Acta Mater. 2007, 55, 423–432. [Google Scholar] [CrossRef]

- Bozzolo, N.; Dewobroto, N.; Grosdidier, T.; Wagner, F. Texture evolution during grain growth in recrystallized commercially pure titanium. Mater. Sci. Eng. A 2005, 397, 346–355. [Google Scholar] [CrossRef]

- Chen, F.-K.; Chiu, K.-H. Stamping formability of pure titanium sheets. J. Mater. Process. Technol. 2005, 170, 181–186. [Google Scholar] [CrossRef]

- Ji, X.; Xu, J.; Zhang, H.; Du, J.; Zeng, W.; Wang, W. Plastic deformation mechanism of TA1 pure titanium plate using SEM-EBSD in-situ tensile testing. Mater. Sci. Eng. A 2024, 908, 146768. [Google Scholar]

- Liu, D.-K.; Huang, G.-S.; Gong, G.-L.; Wang, G.-G.; Pan, F.-S. Influence of different rolling routes on mechanical anisotropy and formability of commercially pure titanium sheet. Trans. Nonferrous Met. Soc. China 2017, 27, 1306–1312. [Google Scholar] [CrossRef]

- Wang, Z.; Song, H. Effect of electropulsing on anisotropy behaviour of cold-rolled commercially pure titanium sheet. Trans. Nonferrous Met. Soc. China 2009, 19, s409–s413. [Google Scholar] [CrossRef]

- Sahoo, S.K.; Sabat, R.K.; Sahni, S.; Suwas, S. Texture and microstructure evolution of commercially pure titanium during hot rolling: Role of strain-paths. Mater. Des. 2016, 91, 58–71. [Google Scholar] [CrossRef]

- Nasiri-Abarbekoh, H.; Ekrami, A.; Ziaei-Moayyed, A.A.; Shohani, M. Effects of rolling reduction on mechanical properties anisotropy of commercially pure titanium. Mater. Des. 2012, 34, 268–274. [Google Scholar] [CrossRef]

- Nasiri-Abarbekoh, H.; Ekrami, A.; Ziaei-Moayyed, A.A. Effects of thickness and texture on mechanical properties anisotropy of commercially pure titanium thin sheets. Mater. Des. 2013, 44, 528–534. [Google Scholar] [CrossRef]

- Li, S.; Liu, X.; Jia, Y.; Han, J.; Wang, T. Interface Characteristics and Bonding Performance of the Corrugated Mg/Al Clad Plate. Materials 2021, 14, 4412. [Google Scholar] [CrossRef] [PubMed]

- Wang, H.-Y.; Feng, T.-T.; Zhang, L.; Liu, C.-G.; Pan, Y.; Zha, M.; Nan, X.-L.; Wang, C.; Jiang, Q.-C. Achieving a weak basal texture in a Mg–6Al–3Sn alloy by wave-shaped die rolling. Mater. Des. 2015, 88, 157–161. [Google Scholar] [CrossRef]

- Sun, Z.; Wu, Y.; Xin, Y.; Peng, Y.; Feng, B.; Liu, Q. Varying the strong basal texture in a Mg-3Al-1Zn plate by a new wave-shaped interface rolling. Mater. Lett. 2018, 213, 151–153. [Google Scholar] [CrossRef]

- Gurao, N.P.; Kapoor, R.; Suwas, S. Deformation behaviour of commercially pure titanium at extreme strain rates. Acta Mater. 2011, 59, 3431–3446. [Google Scholar] [CrossRef]

- Qin, H.; Jonas, J.J. Variant selection during secondary and tertiary twinning in pure titanium. Acta Mater. 2014, 75, 198–211. [Google Scholar] [CrossRef]

- Wang, S.; Zhang, Y.; Schuman, C.; Lecomte, J.-S.; Zhao, X.; Zuo, L.; Philippe, M.-J.; Esling, C. Study of twinning/detwinning behaviors of Ti by interrupted in situ tensile tests. Acta Mater. 2015, 82, 424–436. [Google Scholar] [CrossRef]

- Gurao, N.P.; Sethuraman, S.; Suwas, S. Evolution of Texture and Microstructure in Commercially Pure Titanium with Change in Strain Path During Rolling. Metall. Mater. Trans. A 2012, 44, 1497–1507. [Google Scholar] [CrossRef]

- Lin, B.; Ma, P.-C.; Li, H.-R.; Deng, S.-X.; Zeng, G.-J.; Tang, J.-G.; Li, J.-F.; Li, X.-W. Anisotropy of Al-Li alloy plate and its heredity effect in mechanical property distribution of spun-dome. Trans. Nonferrous Met. Soc. China 2023, 33, 1318–1330. [Google Scholar] [CrossRef]

- Zhong, Y.; Yin, F.; Nagai, K. Role of deformation twin on texture evolution in cold-rolled commercial-purity Ti. J. Mater. Res. 2011, 23, 2954–2966. [Google Scholar] [CrossRef]

- Wang, T.; Liu, W.; Liu, Y.; Wang, Z.; Ignatov, A.V.; Huang, Q. Formation mechanism of dynamic multi-neutral points and cross shear zones in corrugated rolling of Cu/Al laminated composite. J. Mater. Process. Technol. 2021, 295, 117157. [Google Scholar] [CrossRef]

| Elements | Ti | Fe | C | N | H | O |

|---|---|---|---|---|---|---|

| at. % | 99.696 | 0.03 | 0.08 | 0.03 | 0.014 | 0.15 |

| σ0.2 (MPa) | σs (MPa) | δ (%) | |

|---|---|---|---|

| 400 DCFR-RD | 446.3 ± 13.4 | 458.5 ± 13.8 | 14.1 ± 0.4 |

| 400 DCFR-TD | 445.2 ± 13.4 | 455.2 ± 13.7 | 15.5 ± 0.5 |

| 400 FFR-RD | 442.4 ± 13.3 | 451.2 ± 13.5 | 25.6 ± 0.7 |

| 400 FFR-TD | 427.7 ± 12.8 | 436.5 ± 13.1 | 16.8 ± 0.5 |

| 700 DCFR-RD | 381.2 ± 11.4 | 389.4 ± 11.7 | 11.1 ± 0.3 |

| 700 DCFR-TD | 353.9 ± 10.6 | 360.6 ± 10.8 | 14.8 ± 0.4 |

| 700 FFR-RD | 396.2 ± 11.9 | 404.5 ± 12.1 | 25.5 ± 0.8 |

| 700 FFR-TD | 386.3 ± 11.6 | 393.6 ± 11.8 | 20.8 ± 0.6 |

| Original TA1 Sheet | 400 DCFR | 400 FFR | 700 DCFR | 700 FFR | |

|---|---|---|---|---|---|

| Vickers hardness/HV | 142.2 ± 4.1 | 165 ± 4.9 | 160 ± 4.8 | 155 ± 4.6 | 155 ± 4.5 |

| IPAσ0.2 | IPAδ | |

|---|---|---|

| 400 DCFR | 0.003 | 0.099 |

| 400 FFR | 0.033 | 0.344 |

| 700 DCFR | 0.072 | 0.333 |

| 700 FFR | 0.024 | 0.184 |

| Texture Type | |

|---|---|

| 400 DCFR-A | (8 °, 30 °, 0 °) |

| 400 DCFR-B | (25 °, 25 °, 0 °) and (10 °, 25 °, 30 °) |

| 400 DCFR-C | (20 °, 20 °, 0 °) and (30 °, 15 °, 30 °) |

| 400 DCFR-D | (30 °, 20 °, 0 °) and (15 °, 20 °, 30 °) |

| 400 FFR-E | (8 °, 30 °, 0 °) |

| 400 FFR-F | (10 °, 30 °, 0 °) and (15 °, 25 °, 30 °) |

Disclaimer/Publisher’s Note: The statements, opinions and data contained in all publications are solely those of the individual author(s) and contributor(s) and not of MDPI and/or the editor(s). MDPI and/or the editor(s) disclaim responsibility for any injury to people or property resulting from any ideas, methods, instructions or products referred to in the content. |

© 2024 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (https://creativecommons.org/licenses/by/4.0/).

Share and Cite

Du, Z.; Zhang, W.; Han, J. Microstructure Evolution and Mechanical Properties of Pure Ti Alloy Sheet Fabricated by Double-Side Corrugated Rolling. Metals 2024, 14, 1242. https://doi.org/10.3390/met14111242

Du Z, Zhang W, Han J. Microstructure Evolution and Mechanical Properties of Pure Ti Alloy Sheet Fabricated by Double-Side Corrugated Rolling. Metals. 2024; 14(11):1242. https://doi.org/10.3390/met14111242

Chicago/Turabian StyleDu, Zhihao, Wei Zhang, and Jianchao Han. 2024. "Microstructure Evolution and Mechanical Properties of Pure Ti Alloy Sheet Fabricated by Double-Side Corrugated Rolling" Metals 14, no. 11: 1242. https://doi.org/10.3390/met14111242

APA StyleDu, Z., Zhang, W., & Han, J. (2024). Microstructure Evolution and Mechanical Properties of Pure Ti Alloy Sheet Fabricated by Double-Side Corrugated Rolling. Metals, 14(11), 1242. https://doi.org/10.3390/met14111242