Microstructural Evolution of P92 Steel with Different Creep Life Consumptions After Long-Term Service

Abstract

1. Introduction

2. Experimental Details

2.1. Experiment Material

2.2. Experiment Procedure

3. Results

3.1. The Microstructure Observed Under the OM

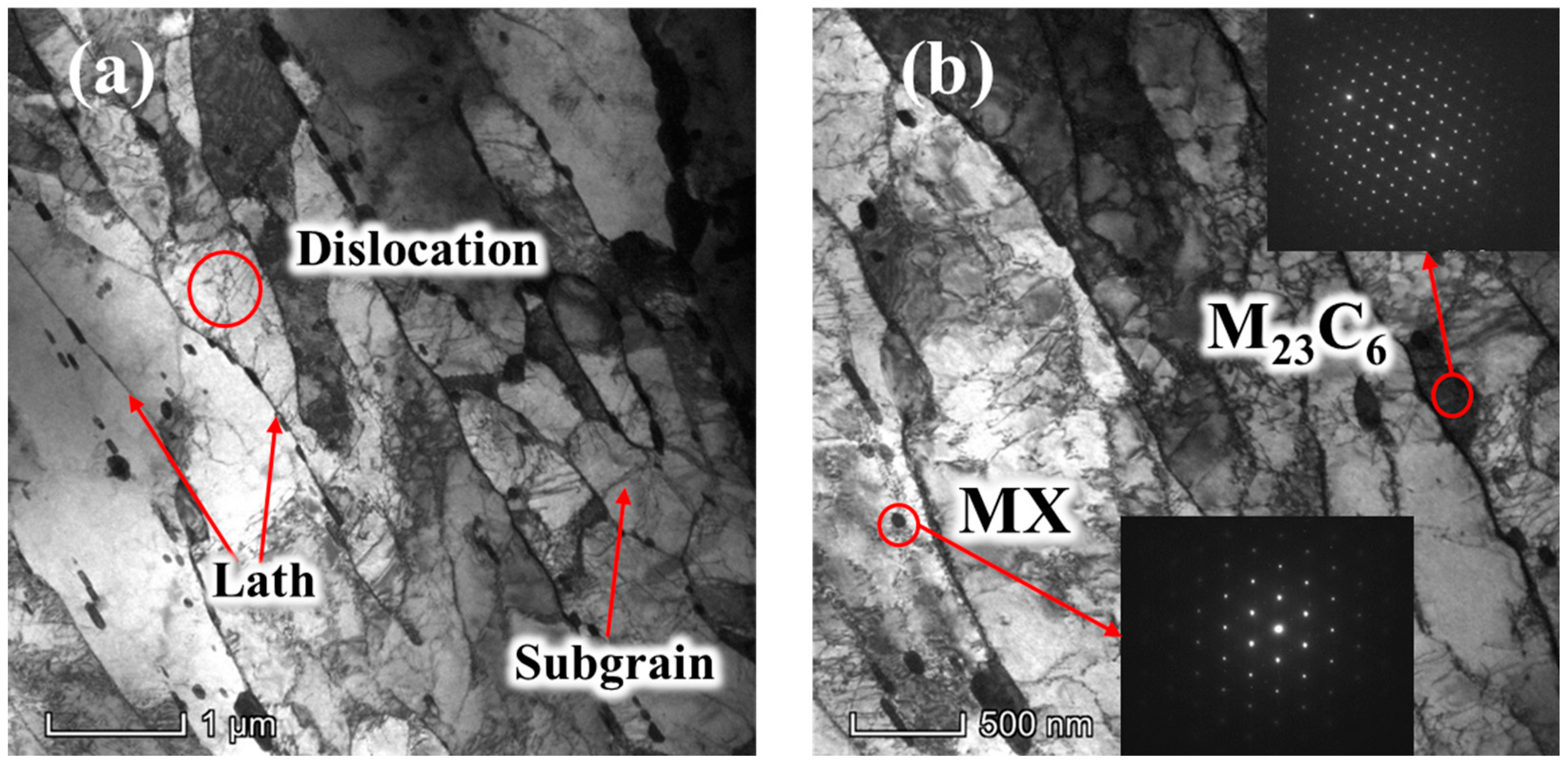

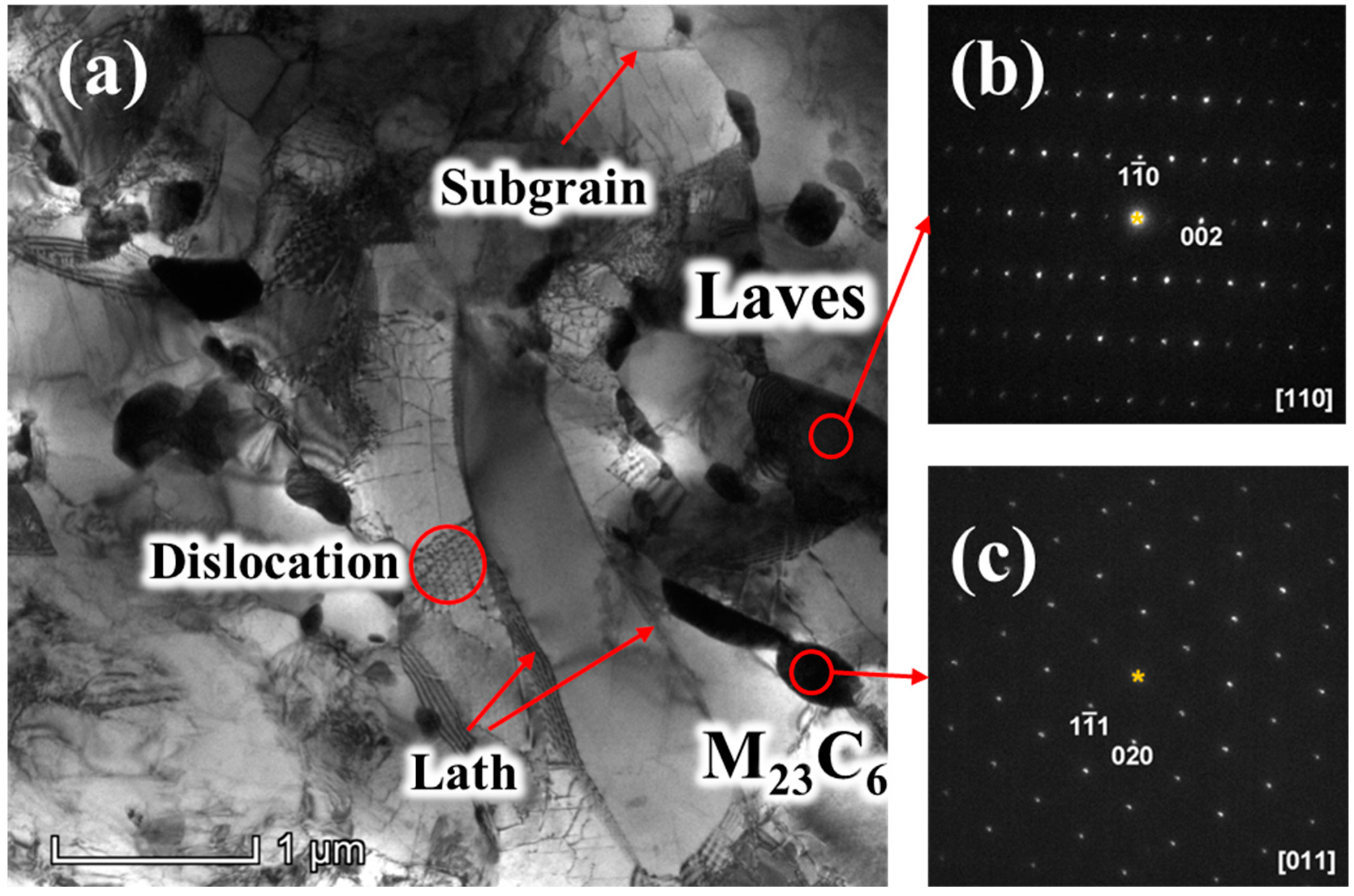

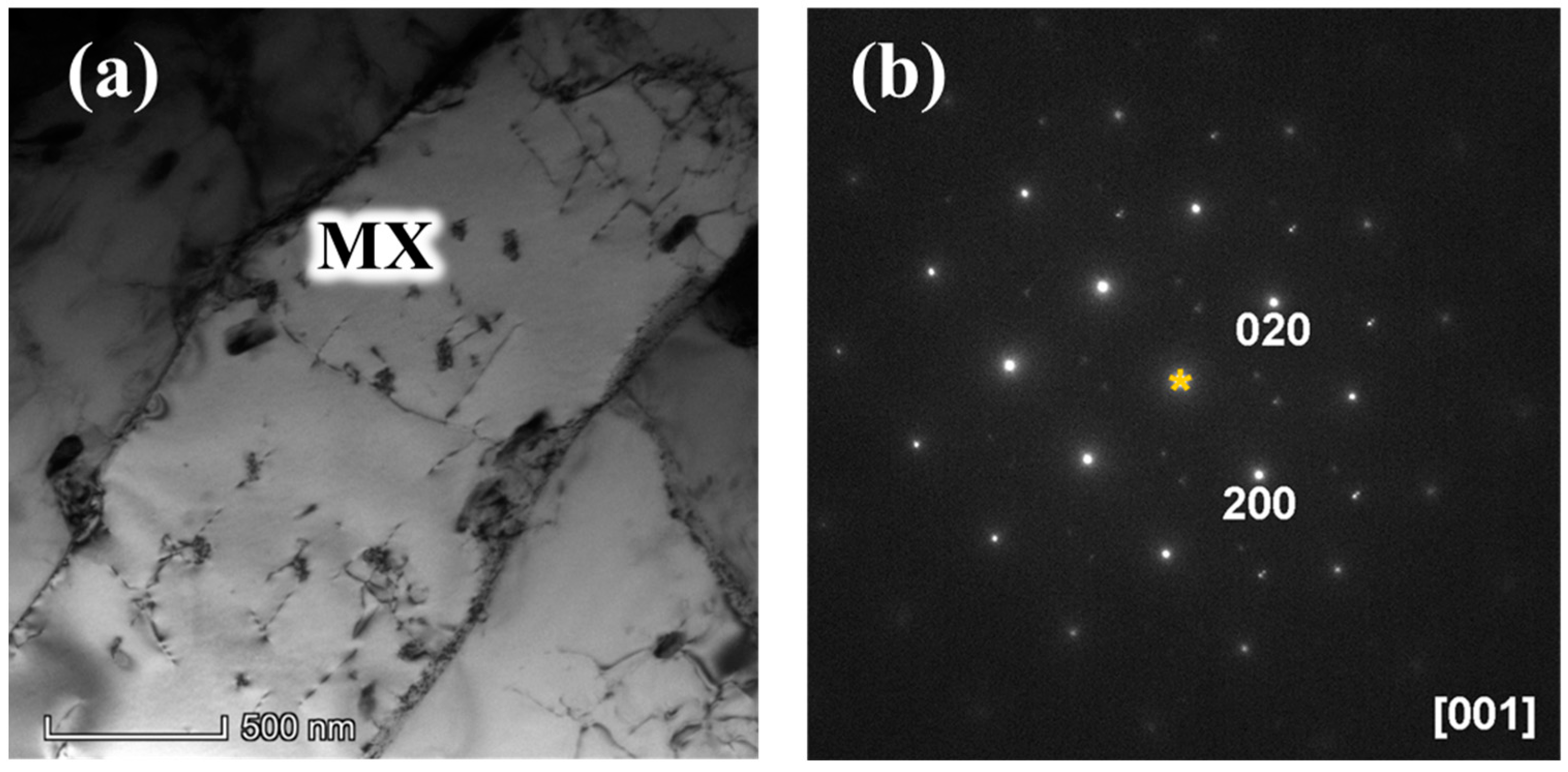

3.2. The Microstructure Observed Under the TEM

4. Discussion

5. Conclusions

- (1)

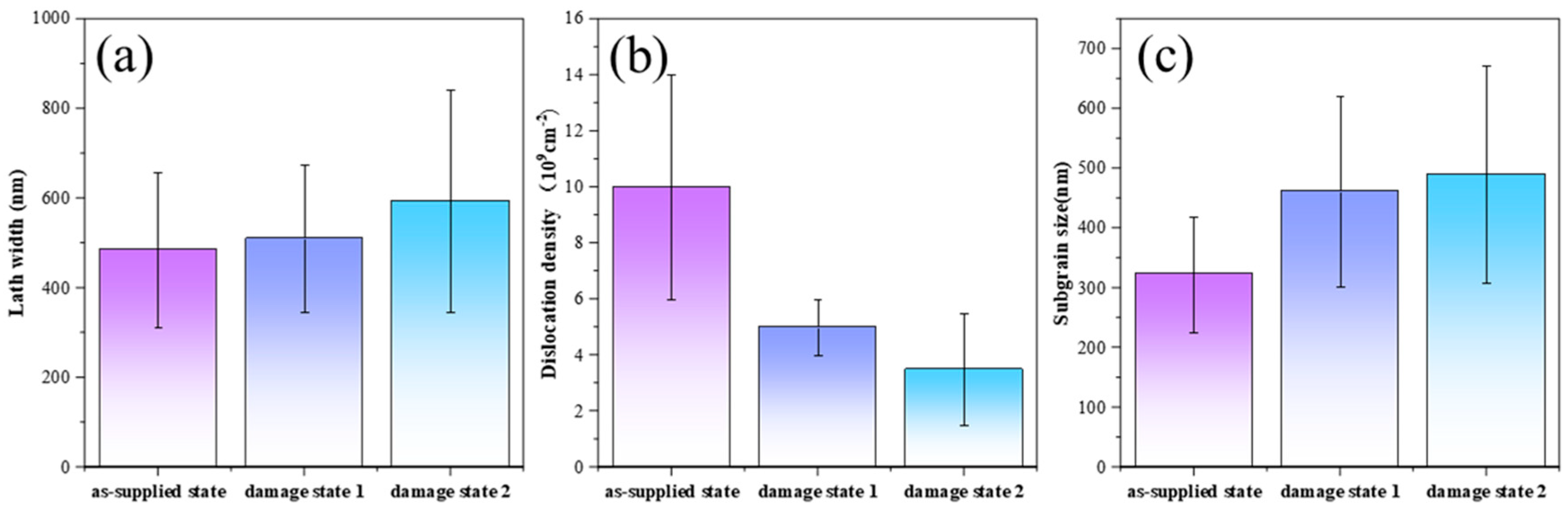

- P92 steel retains a martensitic lath structure even after extended service, but with increasing creep life consumption, the width of the martensitic laths and the subgrain size gradually increase and the dislocation density decreases.

- (2)

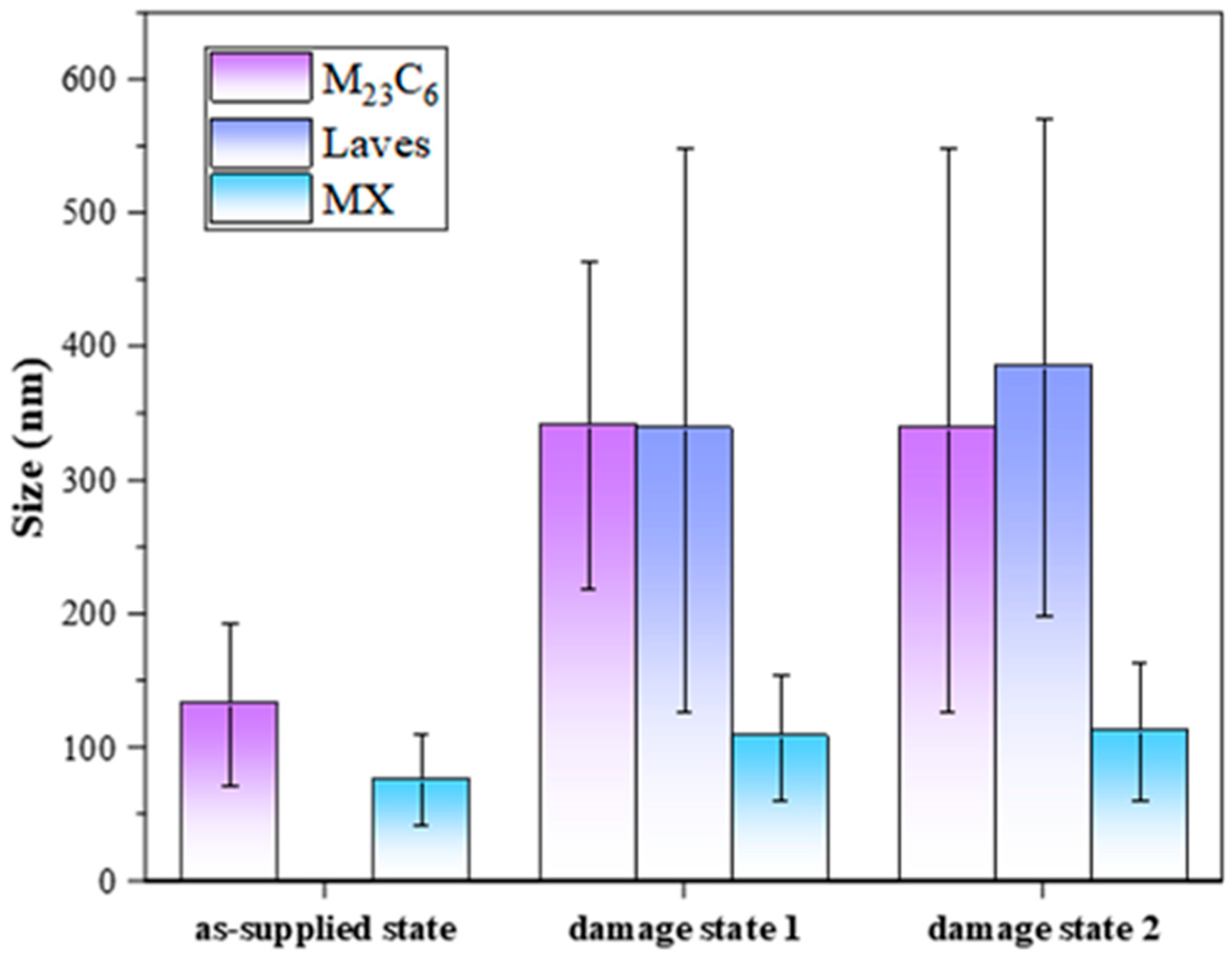

- In the as-supplied state, P92 steel precipitates mainly consist of M23C6 and MX phases. With increased creep life consumption, Laves and Z phases precipitate sequentially. The size of M23C6 and Laves phases gradually increases, while the MX phase shows little change.

- (3)

- At 605 °C and 80.28 MPa, after 100,000 h of service, P92 steel exhibits precipitation of the Z phase. The precipitation of the Z phase consumes the MX phase, and at this stage, the Z phase is relatively small and coexists with the MX phase.

Author Contributions

Funding

Data Availability Statement

Conflicts of Interest

References

- Fan, H.; Zhang, Z.; Dong, J.; Xu, W. China’s R&D of Advanced Ultra-Supercritical Coal-Fired Power Generation for Addressing Climate Change. Therm. Sci. Eng. Prog. 2018, 5, 364–371. [Google Scholar] [CrossRef]

- Masuyama, F. Advances in Physical Metallurgy and Processing of Steels. History of Power Plants and Progress in Heat Resistant Steels. ISIJ Int. 2001, 41, 612–625. [Google Scholar] [CrossRef]

- Zhang, Z.; Wang, X.; Li, Z.; Xia, X.; Chen, Y.; Zhang, T.; Zhang, H.; Yang, Z.; Zhang, X.; Gong, J. Machine Learning-Assisted Probabilistic Creep Life Assessment for High-Temperature Superheater Outlet Header Considering Material Uncertainty. Int. J. Press. Vessels Pip. 2024, 209, 105211. [Google Scholar] [CrossRef]

- Li, Y.; Hu, L.; Yan, J.; Ji, X.; Wang, W. Effect of Structural Induced Stress on Creep of P92 Steel Pipe to Elbow Welds. Metals 2022, 12, 1792. [Google Scholar] [CrossRef]

- Langdon, T.G. Identifiying Creep Mechanisms at Low Stresses. Mater. Sci. Eng. A 2000, 283, 266–273. [Google Scholar] [CrossRef]

- Ashby, M.F. Boundary Defects, and Atomistic Aspects of Boundary Sliding and Diffusional Creep. Surf. Sci. 1972, 31, 498–542. [Google Scholar] [CrossRef]

- Gifkins, R.C. Grain-Boundary Sliding and Its Accommodation during Creep and Superplasticity. Metall. Trans. A 1976, 7, 1225–1232. [Google Scholar] [CrossRef]

- Cocks, A.C.F.; Ashby, M.F. On Creep Fracture by Void Growth. Prog. Mater. Sci. 1982, 27, 189–244. [Google Scholar] [CrossRef]

- Zhao, J.; Gong, J.; Saboo, A.; Dunand, D.C.; Olson, G.B. Dislocation-Based Modeling of Long-Term Creep Behaviors of Grade 91 Steels. Acta Mater. 2018, 149, 19–28. [Google Scholar] [CrossRef]

- Xiao, B.; Xu, L.; Zhao, L.; Jing, H.; Han, Y. Deformation-Mechanism-Based Creep Model and Damage Mechanism of G115 Steel over a Wide Stress Range. Mater. Sci. Eng. A 2019, 743, 280–293. [Google Scholar] [CrossRef]

- Abe, F. Precipitate Design for Creep Strengthening of 9% Cr Tempered Martensitic Steel for Ultra-Supercritical Power Plants. Sci. Technol. Adv. Mater. 2008, 9, 013002. [Google Scholar] [CrossRef] [PubMed]

- Hald, J.; Korcakova, L. Precipitate Stability in Creep Resistant Ferritic Steels-Experimental Investigations and Modelling. ISIJ Int. 2003, 43, 420–427. [Google Scholar] [CrossRef]

- Jin, X.; Zhu, B.; Li, Y.; Zhao, Y.; Xue, F.; Zhang, G. Effect of the Microstructure Evolution on the High-Temperature Strength of P92 Heat-Resistant Steel for Different Service Times. Int. J. Press. Vessels Pip. 2020, 186, 104131. [Google Scholar] [CrossRef]

- Maruyama, K.; Sawada, K.; Koike, J. Advances in Physical Metallurgy and Processing of Steels. Strengthening Mechanisms of Creep Resistant Tempered Martensitic Steel. ISIJ Int. 2001, 41, 641–653. [Google Scholar] [CrossRef]

- Zeng, Y.; Jia, J.; Cai, W.; Dong, S.; Wang, Z. Effect of Long-Term Service on the Precipitates in P92 Steel. Int. J. Miner. Metall. Mater. 2018, 25, 913–921. [Google Scholar] [CrossRef]

- Lombardi, P.; Cipolla, L.; Folgarait, P.; Bonora, N.; Esposito, L. New Time-Independent Formulation for Creep Damage in Polycrystalline Metals and Its Specialisation to High Alloy Steel for High-Temperature Applications. Mater. Sci. Eng. A 2009, 510–511, 214–218. [Google Scholar] [CrossRef]

- Shang, C.G.; Wang, M.L.; Zhou, Z.C.; Yagi, K.; Lu, Y.H. The Microstructure Evolution and Its Effect on Creep Behaviors in P92 Steel under Different Stresses. Mater. Charact. 2023, 198, 112744. [Google Scholar] [CrossRef]

- Zieliński, A.; Golański, G.; Sroka, M. Assessment of Microstructure Stability and Mechanical Properties of X10CrWMoVNb9-2 (P92) Steel after Long-Term Thermal Ageing for High-Temperature Applications. Met. Mater. 2016, 54, 61–70. [Google Scholar] [CrossRef]

- Yong, L.; Jiaqing, W.; Junjian, L.; Yue, W.; Wen, F. Microstructure and Mechanical Property Changes of P92 Steel for Main Steam Pipe in Ultra-Supercritical Power Plant After Long-Term Service at High Temperature. J. Mater. Eng. Perform. 2024, 33, 4911–4919. [Google Scholar] [CrossRef]

- Liu, C.; Peng, Z.F.; Peng, F.F.; Chen, F.; Liu, S. Phase Parameter Changes of Specific Positions of P92 Steel Specimens during Creep Rupture Test at 625 °C. J. Mater. Eng. 2020, 48, 98–104. [Google Scholar]

- Yang, M.; Long, S.; Liang, Y. Study on the Key Role of Hierarchical Microstructure for Strength and Plasticity in a Lath Martensitic Steel. IOP Conf. Ser. Mater. Sci. Eng. 2018, 324, 012043. [Google Scholar] [CrossRef]

- Zhang, Y.; He, H.; Wang, H.; Chen, G.; An, X.; Wang, Y. Evolution of Microstructure and Mechanical Properties of 9Cr Ferrite/Martensite Steels with Different Si Content after Long-Term Aging at 550 °C. J. Alloys Compd. 2021, 873, 159817. [Google Scholar] [CrossRef]

- Xu, Y.; Nie, Y.; Wang, M.; Li, W.; Jin, X. The Effect of Microstructure Evolution on the Mechanical Properties of Martensite Ferritic Steel during Long-Term Aging. Acta Mater. 2017, 131, 110–122. [Google Scholar] [CrossRef]

- Morsdorf, L.; Jeannin, O.; Barbier, D.; Mitsuhara, M.; Raabe, D.; Tasan, C.C. Multiple Mechanisms of Lath Martensite Plasticity. Acta Mater. 2016, 121, 202–214. [Google Scholar] [CrossRef]

- Polcik, P. Modellierung Des Verformungsverhaltens Der Warmfesten 9–12%-Chromstähle Im Temperaturbereich von 550–650 °C.; Shaker: Nordrhein-Westfalen, Germany, 1999. [Google Scholar]

- Hald, J. Microstructure and Long-Term Creep Properties of 9–12% Cr Steels. Int. J. Press. Vessels Pip. 2008, 85, 30–37. [Google Scholar] [CrossRef]

- Zhao, Y.; Liu, K.; Zhang, H.; Tian, X.; Jiang, Q.; Murugadoss, V.; Hou, H. Dislocation Motion in Plastic Deformation of Nano Polycrystalline Metal Materials: A Phase Field Crystal Method Study. Adv. Compos. Hybrid Mater. 2022, 5, 2546–2556. [Google Scholar] [CrossRef]

- Ghassemi-Armaki, H.; Chen, R.P.; Maruyama, K.; Yoshizawa, M.; Igarashi, M. Static Recovery of Tempered Lath Martensite Microstructures during Long-Term Aging in 9–12% Cr Heat Resistant Steels. Mater. Lett. 2009, 63, 2423–2425. [Google Scholar] [CrossRef]

- Wang, X.; Xu, Q.; Yu, S.; Hu, L.; Liu, H.; Ren, Y. Laves-Phase Evolution during Aging in 9Cr-1.8W-0.5Mo-VNb Steel for USC Power Plants. Mater. Chem. Phys. 2015, 163, 219–228. [Google Scholar] [CrossRef]

- Xinmei, L.; Zhang, Z.; Zou, Y.; Baoshuai, D.; Wei, Y.; Yin, Z. Microstructure of P92 Steel for Main Steam Pipeline of Ultra Supercritical Units after 50,000 h Service. IOP Conf. Ser. Earth Environ. Sci. 2019, 358, 042021. [Google Scholar] [CrossRef]

- Jin, X.; Zhou, L.; Xi, Y.; Fu, Y.; Zhu, B.; Li, Y.; Zhao, Y.; Xia, X. Comparative Study on Microstructure and Properties of P92 Steel After Long-term Service. Proc. CSEE 2023, 43, 8378–8388. [Google Scholar] [CrossRef]

- Jin, X.; Zhu, B.Y.; Xia, X.X.; Li, Y.F.; Liu, X.B.; Zhang, Y.W.; Xu, C.L.; Yin, J.; Jia, W.Q. Study on the Microstructure Evolution and Effect on Mechanical Properties of P92 Steel during Long Term Service. Materialia 2024, 35, 102124. [Google Scholar] [CrossRef]

- Yin, S.; Yang, L.; Liu, Y.; Yang, R.; Wang, Y.; Zhao, F. Stabilities of the Precipitates in CLAM Steel during 30,000 h Thermal Aging. J. Nucl. Mater. 2022, 567, 153805. [Google Scholar] [CrossRef]

- Prat, O.; Garcia, J.; Rojas, D.; Sauthoff, G.; Inden, G. The Role of Laves Phase on Microstructure Evolution and Creep Strength of Novel 9%Cr Heat Resistant Steels. Intermetallics 2013, 32, 362–372. [Google Scholar] [CrossRef]

- Xinjun, J.; Zhiqiang, S.; Chunpo, T.; Yao, X.; Long, Z.; Shaohua, Y.; Zhongbing, C. Analysis on the Microstructure and Properties of P92 Steel after Long-Term Service at High Temperature. J. Phys. Conf. Ser. 2020, 1653, 012009. [Google Scholar] [CrossRef]

- Komazaki, S.; Kishi, S.; Shoji, T.; Chiba, H.; Suzuki, K. Thermal Aging Embrittlement of Tungsten-Alloyed 9%Cr Ferritic Steels and Electrochemical Evaluation. J. Soc. Mater. Sci. Jpn. 2003, 52, 42–49. [Google Scholar] [CrossRef]

- Guo, X.; Gong, J.; Jiang, Y.; Rong, D. The Influence of Long-Term Aging on Microstructures and Static Mechanical Properties of P92 Steel at Room Temperature. Mater. Sci. Eng. A 2013, 564, 199–205. [Google Scholar] [CrossRef]

- Cipolla, L.; Danielsen, H.K.; Venditti, D.; Di Nunzio, P.E.; Hald, J.; Somers, M.A.J. Conversion of MX Nitrides to Z-Phase in a Martensitic 12% Cr Steel. Acta Mater. 2010, 58, 669–679. [Google Scholar] [CrossRef]

- Yoshizawa, M.; Igarashi, M.; Moriguchi, K.; Iseda, A.; Armaki, H.G.; Maruyama, K. Effect of Precipitates on Long-Term Creep Deformation Properties of P92 and P122 Type Advanced Ferritic Steels for USC Power Plants. Mater. Sci. Eng. A 2009, 510–511, 162–168. [Google Scholar] [CrossRef]

- Sawada, K.; Kushima, H.; Kimura, K. Z-Phase Formation during Creep and Aging in 9–12% Cr Heat Resistant Steels. ISIJ Int. 2006, 46, 769–775. [Google Scholar] [CrossRef]

| Element | C | Si | Mn | P | S | Cr | Ni | Mo | Cu | V | Ti | Nb | Al | B | W | Zr | N |

|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|

| State 1 | 0.096 | 0.42 | 0.47 | 0.011 | 0.001 | 8.69 | 0.25 | 0.37 | 0.16 | 0.21 | <0.005 | 0.058 | 0.03 | 0.0025 | 1.77 | <0.01 | 0.039 |

| State 2 | 0.095 | 0.29 | 0.47 | 0.013 | 0.014 | 8.88 | 0.37 | 0.38 | 0.16 | 0.18 | <0.005 | 0.057 | 0.0053 | 0.0055 | 1.68 | <0.005 | 0.048 |

Disclaimer/Publisher’s Note: The statements, opinions and data contained in all publications are solely those of the individual author(s) and contributor(s) and not of MDPI and/or the editor(s). MDPI and/or the editor(s) disclaim responsibility for any injury to people or property resulting from any ideas, methods, instructions or products referred to in the content. |

© 2024 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (https://creativecommons.org/licenses/by/4.0/).

Share and Cite

Zhang, Z.; Yang, Z.; Tang, L. Microstructural Evolution of P92 Steel with Different Creep Life Consumptions After Long-Term Service. Metals 2024, 14, 1191. https://doi.org/10.3390/met14101191

Zhang Z, Yang Z, Tang L. Microstructural Evolution of P92 Steel with Different Creep Life Consumptions After Long-Term Service. Metals. 2024; 14(10):1191. https://doi.org/10.3390/met14101191

Chicago/Turabian StyleZhang, Zhen, Zheyi Yang, and Liying Tang. 2024. "Microstructural Evolution of P92 Steel with Different Creep Life Consumptions After Long-Term Service" Metals 14, no. 10: 1191. https://doi.org/10.3390/met14101191

APA StyleZhang, Z., Yang, Z., & Tang, L. (2024). Microstructural Evolution of P92 Steel with Different Creep Life Consumptions After Long-Term Service. Metals, 14(10), 1191. https://doi.org/10.3390/met14101191