Structural Changes in Copper Slags During Slow Cooling

Abstract

1. Introduction

2. Materials and Methods

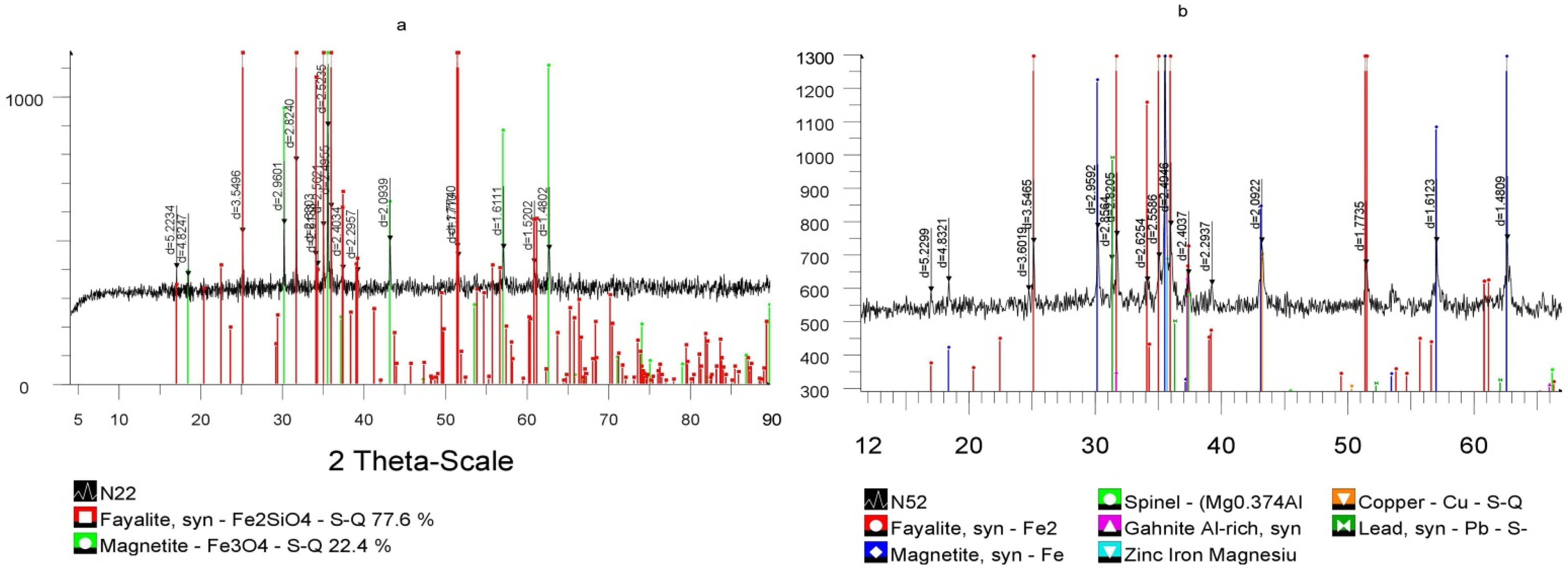

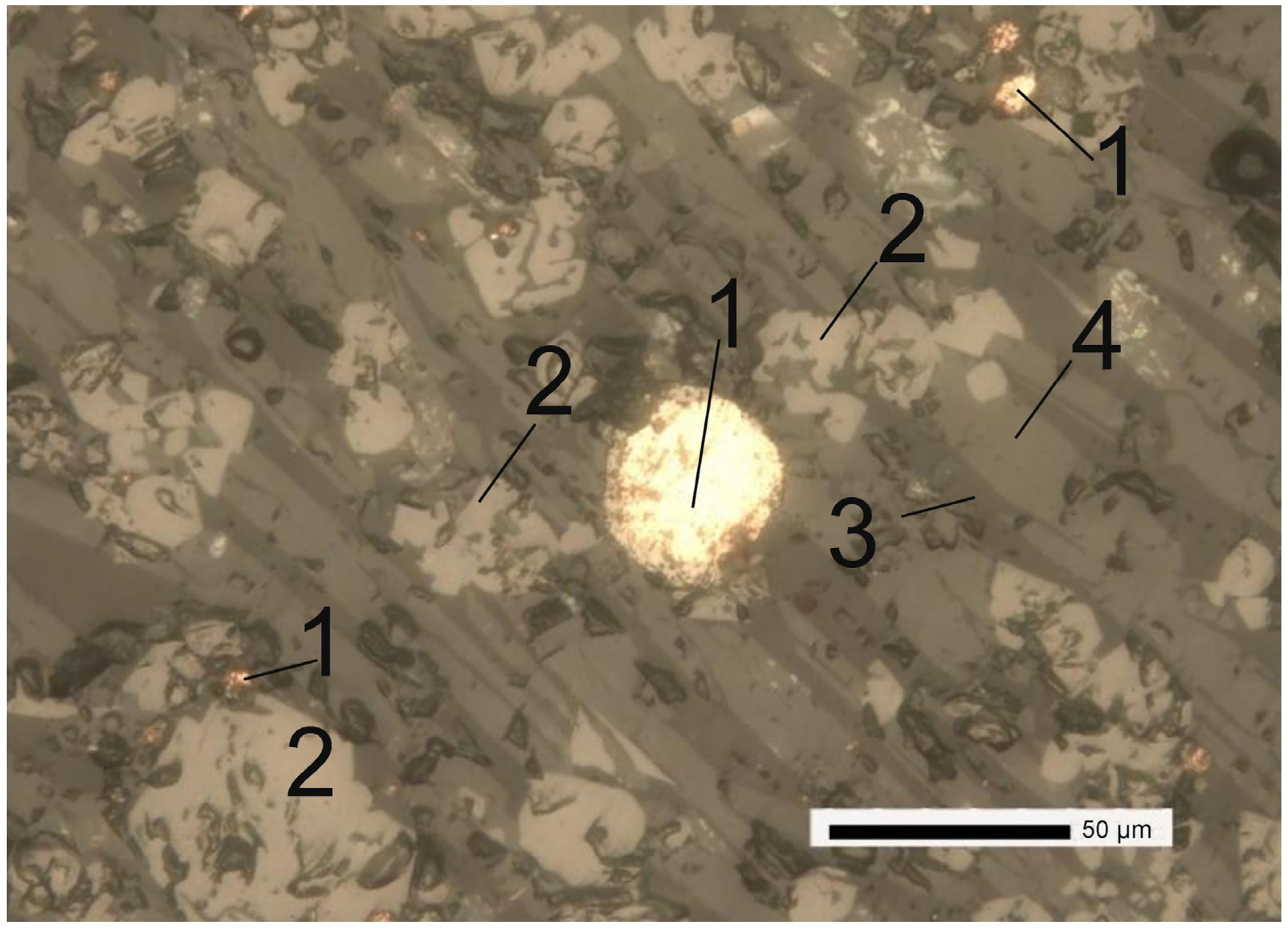

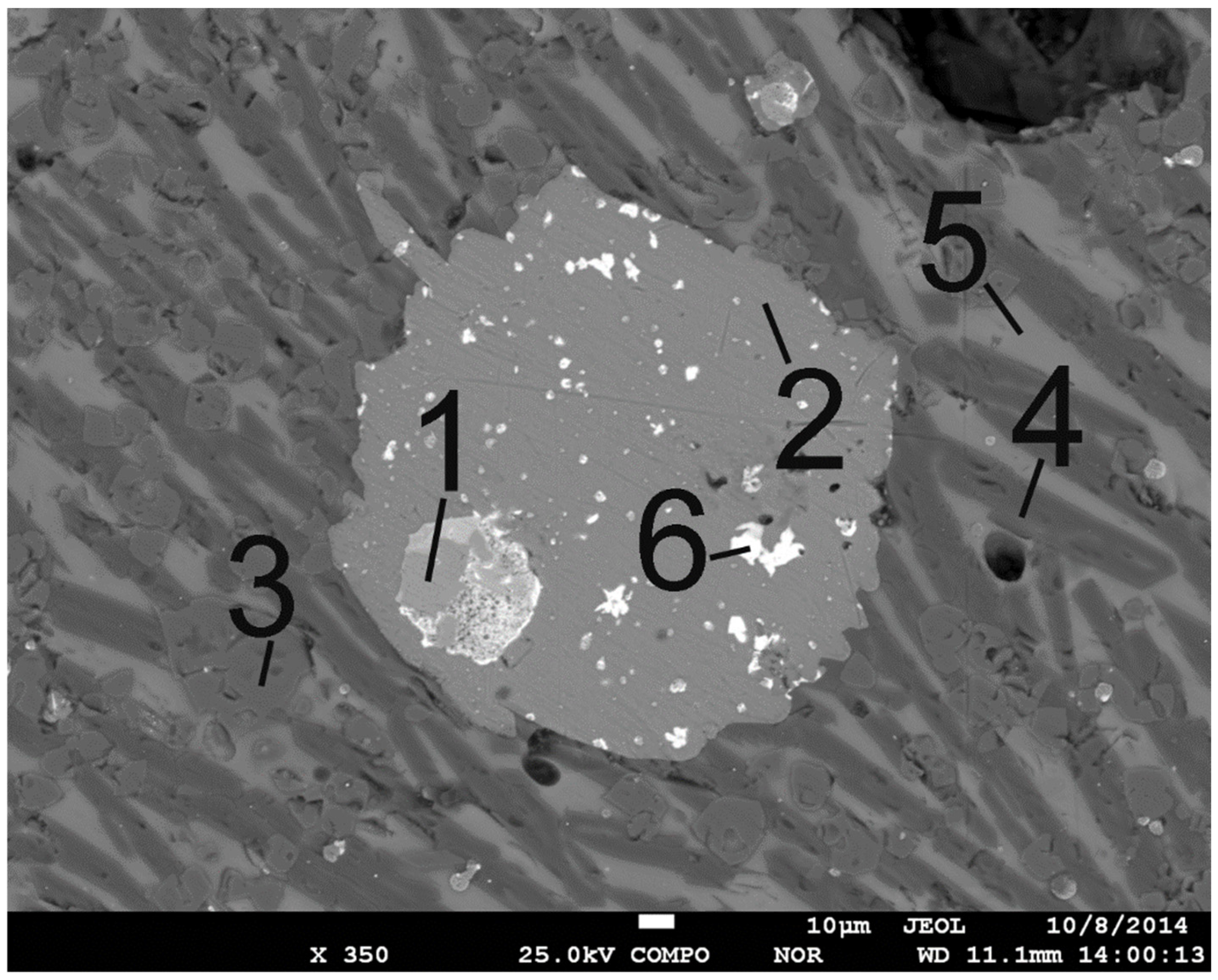

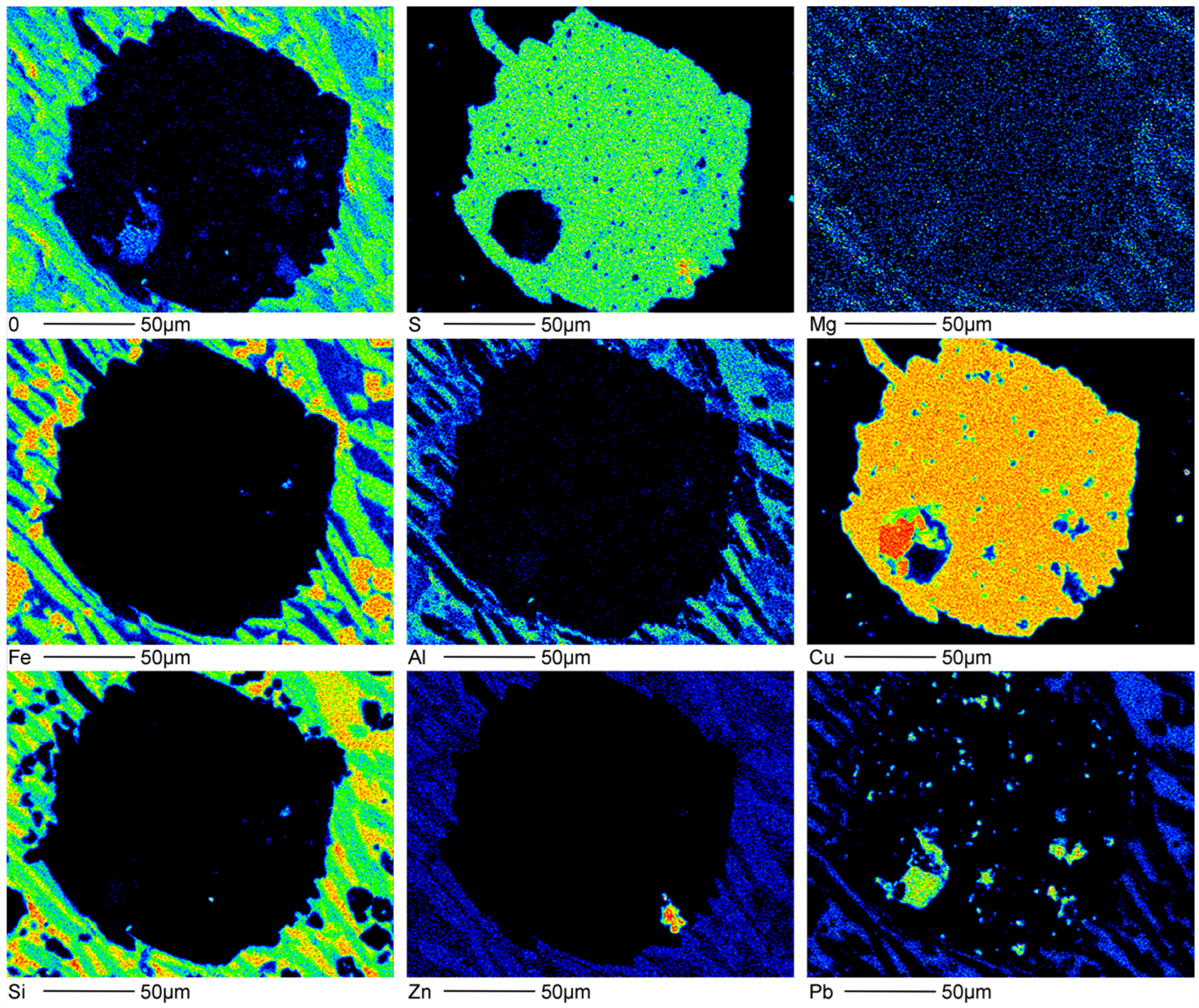

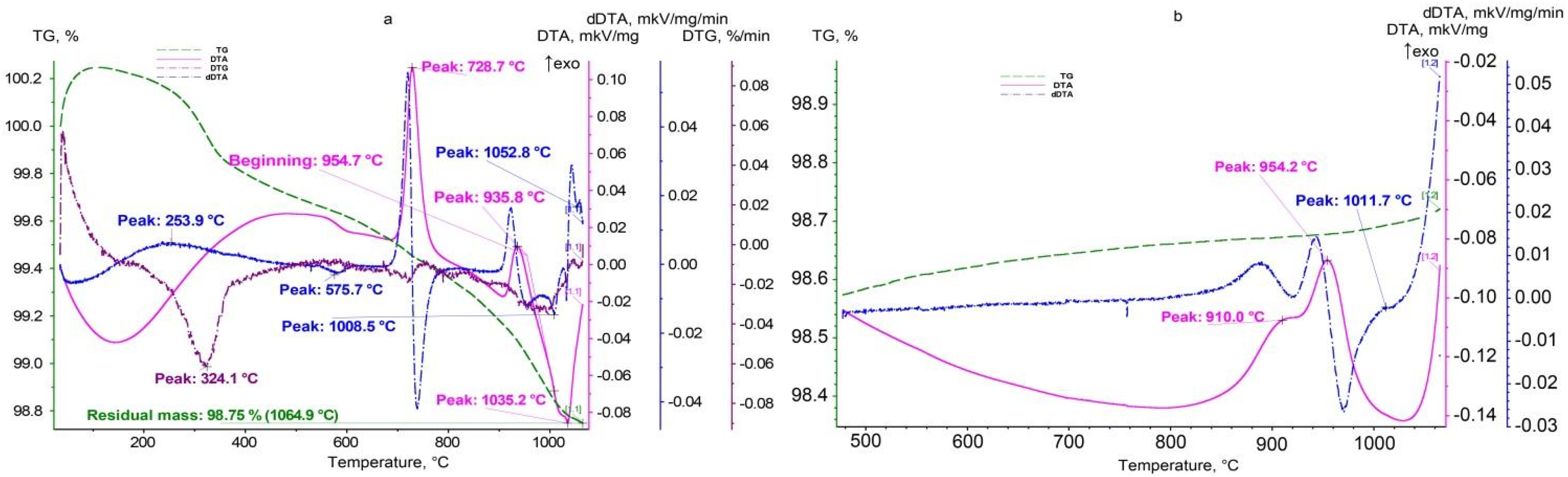

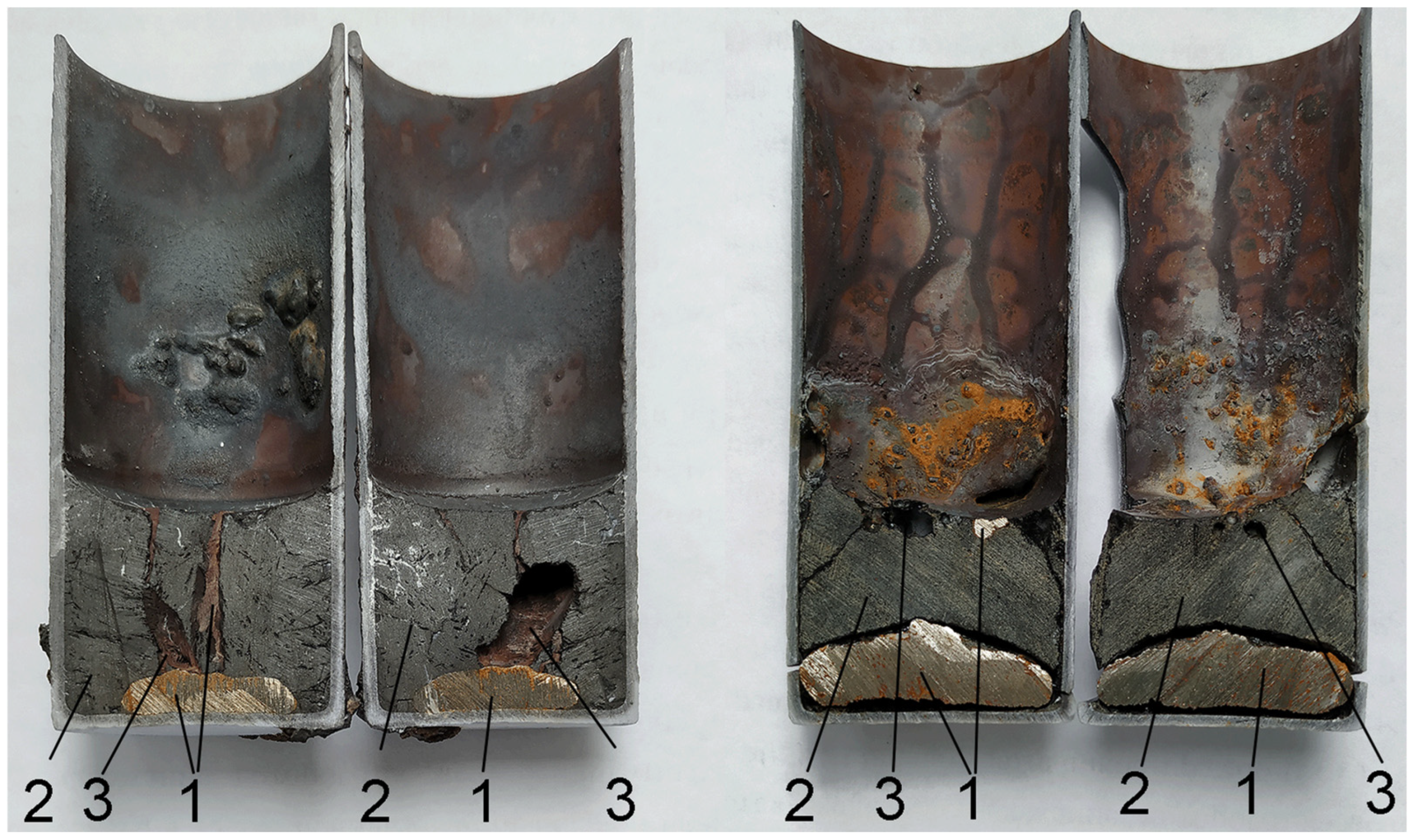

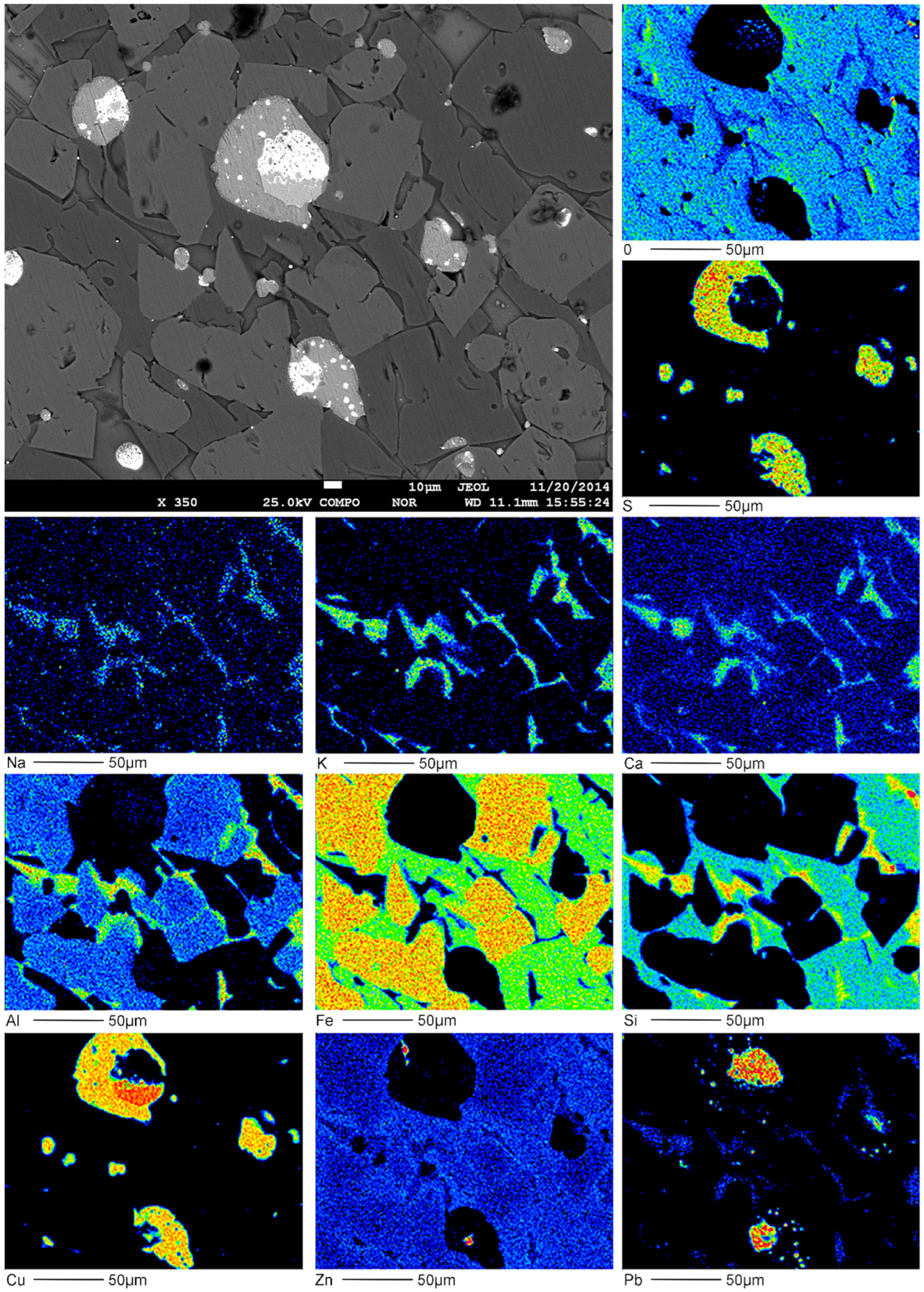

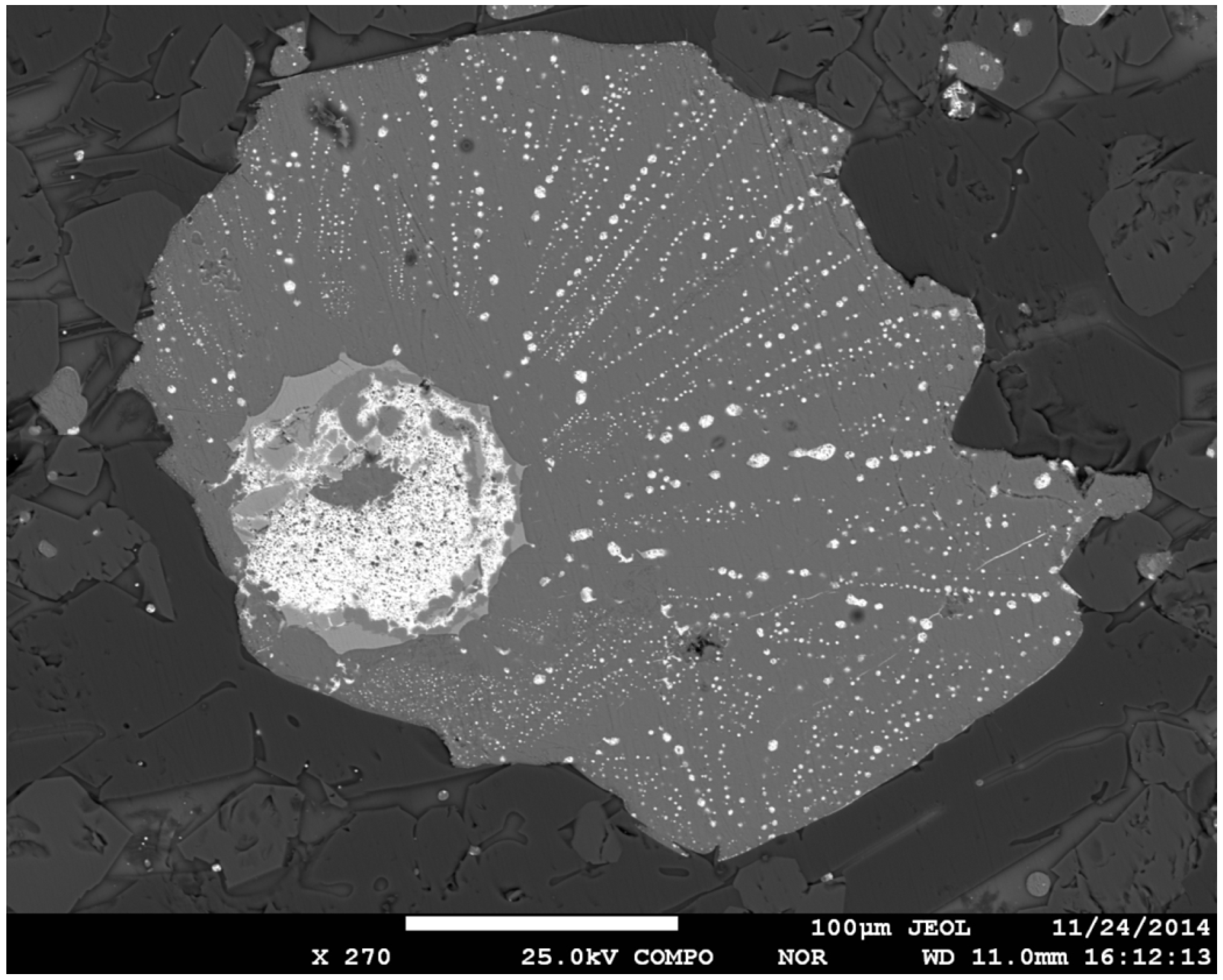

3. Results and Discussion

4. Conclusions

Author Contributions

Funding

Data Availability Statement

Acknowledgments

Conflicts of Interest

References

- Kenzhaliyev, B.; Kvyatkovskiy, S.; Dyussebekova, M.; Semenova, A.; Nurhadiyanto, D. Analysis of Existing Technologies for Depletion of Dump Slags of Autogenous Melting. Kompleks. Ispolz. Miner. Syra Complex Use Miner. Resour. 2022, 323, 23–29. [Google Scholar] [CrossRef]

- Argyn, A.; Zoldasbay, E.; Dosmukhamedov, N. Improving the quality of converting products by the joint smelting of high-sulfur copper concentrate with copper-lead matte. Kompleks. Ispolz. Miner. Syra Complex Use Miner. Resour. 2024, 328, 50–58. [Google Scholar] [CrossRef]

- Zoldasbay, E.; Argyn, A.; Dosmukhamedov, N. Analysis of the thermal regime of converting of copper-lead matte with high-sulfur copper concentrate. Kompleks. Ispolz. Miner. Syra Complex Use Miner. Resour. 2024, 329, 82–91. [Google Scholar] [CrossRef]

- Yakubov, M.; Yoqubov, M.; Kholikulov, D.; Maksudhodjaeva, M. Depletion of converter slags to waste in the Vanyukov furnace during pyrometallurgical copper production at JSC Almalyk MMC. Kompleks. Ispolz. Miner. Syra Complex Use Miner. Resour. 2024, 331, 60–68. [Google Scholar] [CrossRef]

- Gao, X.; Chen, Z.; Shi, J.; Taskinen, P.; Jokilaakso, A. Effect of cooling rate and slag modification on the copper matte in smelting slag. Min. Metall. Explor. 2020, 37, 1593–1601. [Google Scholar] [CrossRef]

- Tshiongo, N.; Mbaya, R.K.; Maweja, K.; Tshabalala, L.C. Effect of cooling rate on base metals recovery from copper matte smelting slags. Int. J. Mater. Metall. Eng. 2010, 4, 649–653. [Google Scholar] [CrossRef]

- Zhang, H.; Li, B.; Wei, Y.; Wang, H. The settling behavior of matte particles in copper slag and the new technology of copper slag cleaning. J. Mater. Res. Technol. 2021, 15, 6216–6230. [Google Scholar] [CrossRef]

- Gazaleeva, G.I.; Mamonov, S.V.; Sladkov, M.M.; Kutepov, A.V. Increasing of metallurgical results during the processing of copper slags of Ural mining and metallurgical company. Tsvetnye Met. 2016, 3, 18–22. [Google Scholar] [CrossRef]

- Askarova, N.M.; Samadov, A.U. Innovative approach to preparation of dump slags of copper production for further processing. Univers. Tekhnicheskie Nauk. 2020, 11, 45–47. [Google Scholar] [CrossRef]

- Mamonov, S.V.; Gazaleeva, G.I.; Dresviankina, T.P.; Volkova, S.V.; Vasil’ev, I.D. Improvement of technological indices of copper smelters slags processing on the basis of their slow cooling and ultra-fine grinding. Izv. Vyss. Uchebnykh Zaved. Gorn. Zhurnal Miner. Min. Eng. 2018, 2, 83–90. [Google Scholar] [CrossRef]

- Mamonov, S.V.; Gazaleeva, G.I.; Dresvyankina, T.P.; Volkova, S.V. Copper smeltery final dump slag processing technology improvement. Obogashchenie Rud 2018, 1, 38–42. [Google Scholar] [CrossRef]

- McKerrow, G.C.; Pelletier, A.; Newman, C.J. Process for Controlled Slow Cooling of Non-Ferrous Smelting Slags. U.S. Patent No. 4,046,323, 6 September 1977. [Google Scholar]

- Tsunazawa, Y.; Liu, C.; Toi, R.; Okura, T.; Tokoro, C. Crystal formation and growth by slow cooling for recovery of magnetite particles from copper smelting slag. Miner. Process. Extr. Metall. 2019, 128, 248–255. [Google Scholar] [CrossRef]

- Guo, Z.; Zhu, D.; Pan, J.; Wu, T.; Zhang, F. Improving beneficiation of copper and iron from copper slag by modifying the molten copper slag. Metals 2016, 6, 86. [Google Scholar] [CrossRef]

- Mihajlović, A.; Kamberović, Ž.; Korać, M.; Gavrilovski, M.; Jovanović, N. The effect of primary copper slag cooling rate on the copper valorization in the flotation process. Metall. Mater. Eng. 2015, 21, 127–141. [Google Scholar] [CrossRef] [PubMed]

- Xue, P.; Li, G.; Qin, Q. Recovery of Copper from Slow Cooled Ausmelt Furnace Slag by Floatation. In Characterization of Minerals, Metals, and Materials 2015; Carpenter, J.S., Bai, C., Escobedo, J.P., Hwang, J.-Y., Ikhmayies, S., Li, B., Li, J., Monteiro, S.N., Peng, Z., Zhang, M., Eds.; The Minerals, Metals & Materials Society: Pittsburgh, PA, USA, 2016; pp. 621–628. [Google Scholar] [CrossRef]

- Cao, S.; Liu, Z.; Lu, X.; Zhang, L.; Li, Q.; Xia, L. The Phase Transition and Element Distribution of Copper Smelting Slag in the Cooling—Sulfidation Process. Metall. Mater. Trans. B 2023, 54, 969–979. [Google Scholar] [CrossRef]

- Rahimi, E.; Mohaghegh, N. The Effect of Bed Thickness and Cooling Time on the Rate of Copper Slag Cooling, Case Study: Khatoonabad Copper Smelter Plant. Organ. Comm. Honor. Chair 2018, 1, 1073. [Google Scholar] [CrossRef]

- Fernández-Caliani, J.C.; Ríos, G.; Martínez, J.; Jiménez, F. Occurrence and speciation of copper in slags obtained during the pyrometallurgical processing of chalcopyrite concentrates at the Huelva smelter (Spain). J. Min. Metall. Sect. B Metall. 2012, 2, 161–171. [Google Scholar] [CrossRef]

- Coursol, P.; Valencia, N.C.; Macrey, P.; Bell, S.; Davis, B. Minimization of copper losses in copper smelting slag during electric furnace treatment. JOM 2012, 64, 1305–1313. [Google Scholar] [CrossRef]

- Das, B.; Michra, B.K.; Angadi, S.; Pradhan, S.K.; Prakash, S.; Mohanty, J.K. Characterization and recovery of copper values from discarded slag. Waste Manag. Res. 2010, 28, 561–567. [Google Scholar] [CrossRef] [PubMed]

| Element, Compound | Cu | Pb | Zn | Ni | Fe | SiO2 | CaO | MgO | Al2O3 | S |

|---|---|---|---|---|---|---|---|---|---|---|

| Content,% | 4.97 | 5.3 | 3.3 | 0.05 | 41.3 | 20.1 | 0.30 | 0.58 | 4.2 | 1.08 |

Disclaimer/Publisher’s Note: The statements, opinions and data contained in all publications are solely those of the individual author(s) and contributor(s) and not of MDPI and/or the editor(s). MDPI and/or the editor(s) disclaim responsibility for any injury to people or property resulting from any ideas, methods, instructions or products referred to in the content. |

© 2024 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (https://creativecommons.org/licenses/by/4.0/).

Share and Cite

Sukurov, B.; Kvyatkovskiy, S.; Kozhakhmetov, S.; Semenova, A.; Dyussebekova, M.; Kvyatkovskaya, M. Structural Changes in Copper Slags During Slow Cooling. Metals 2024, 14, 1187. https://doi.org/10.3390/met14101187

Sukurov B, Kvyatkovskiy S, Kozhakhmetov S, Semenova A, Dyussebekova M, Kvyatkovskaya M. Structural Changes in Copper Slags During Slow Cooling. Metals. 2024; 14(10):1187. https://doi.org/10.3390/met14101187

Chicago/Turabian StyleSukurov, Bulat, Sergey Kvyatkovskiy, Sultanbek Kozhakhmetov, Anastassiya Semenova, Maral Dyussebekova, and Marina Kvyatkovskaya. 2024. "Structural Changes in Copper Slags During Slow Cooling" Metals 14, no. 10: 1187. https://doi.org/10.3390/met14101187

APA StyleSukurov, B., Kvyatkovskiy, S., Kozhakhmetov, S., Semenova, A., Dyussebekova, M., & Kvyatkovskaya, M. (2024). Structural Changes in Copper Slags During Slow Cooling. Metals, 14(10), 1187. https://doi.org/10.3390/met14101187