Atomistic Study of the Interaction Nature of H-Dislocation and the Validity of Elasticity in Bcc Iron

Abstract

1. Introduction

2. Atomistic Simulations

2.1. Interatomic Potential

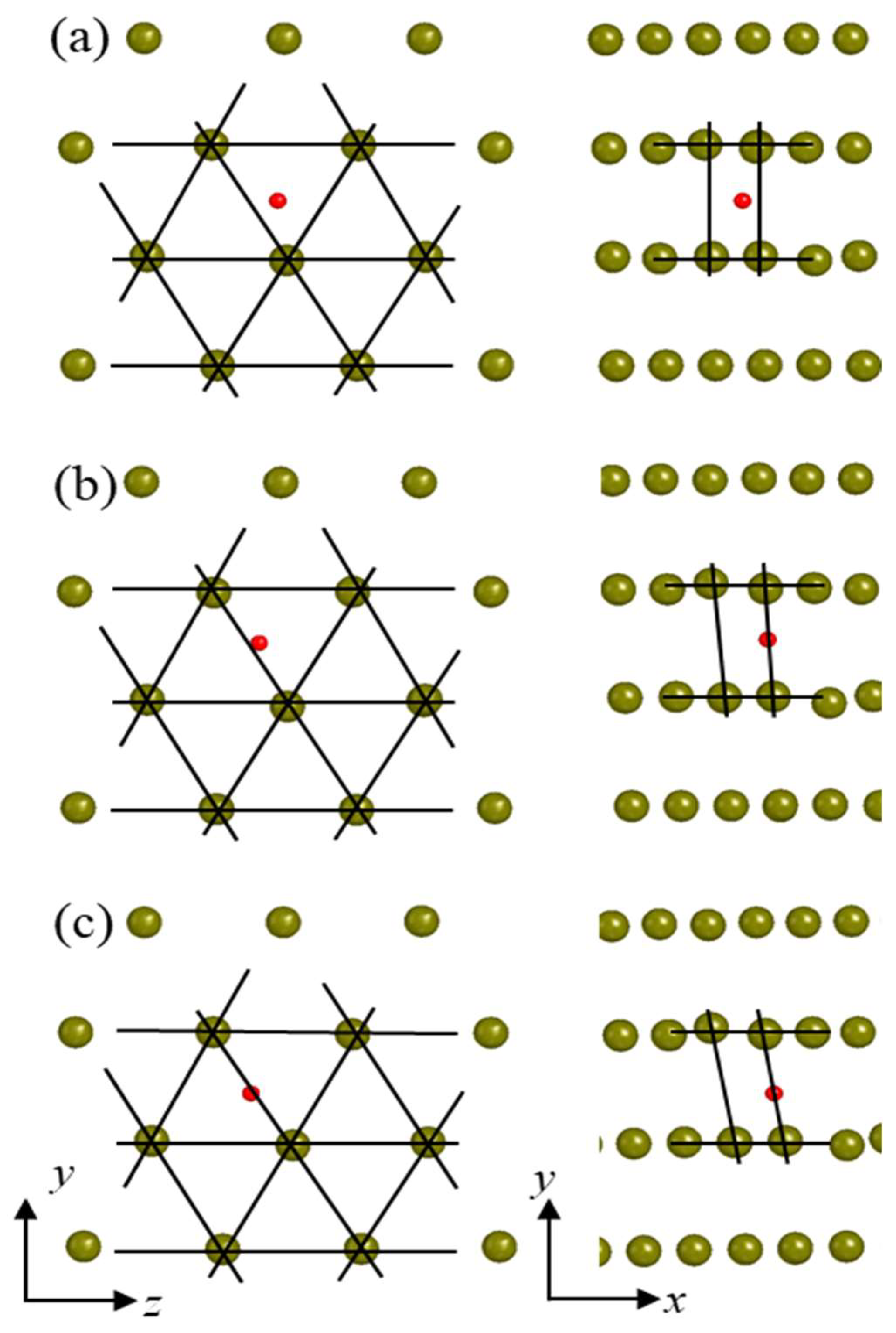

2.2. Details of Atomistic Simulation

3. Results

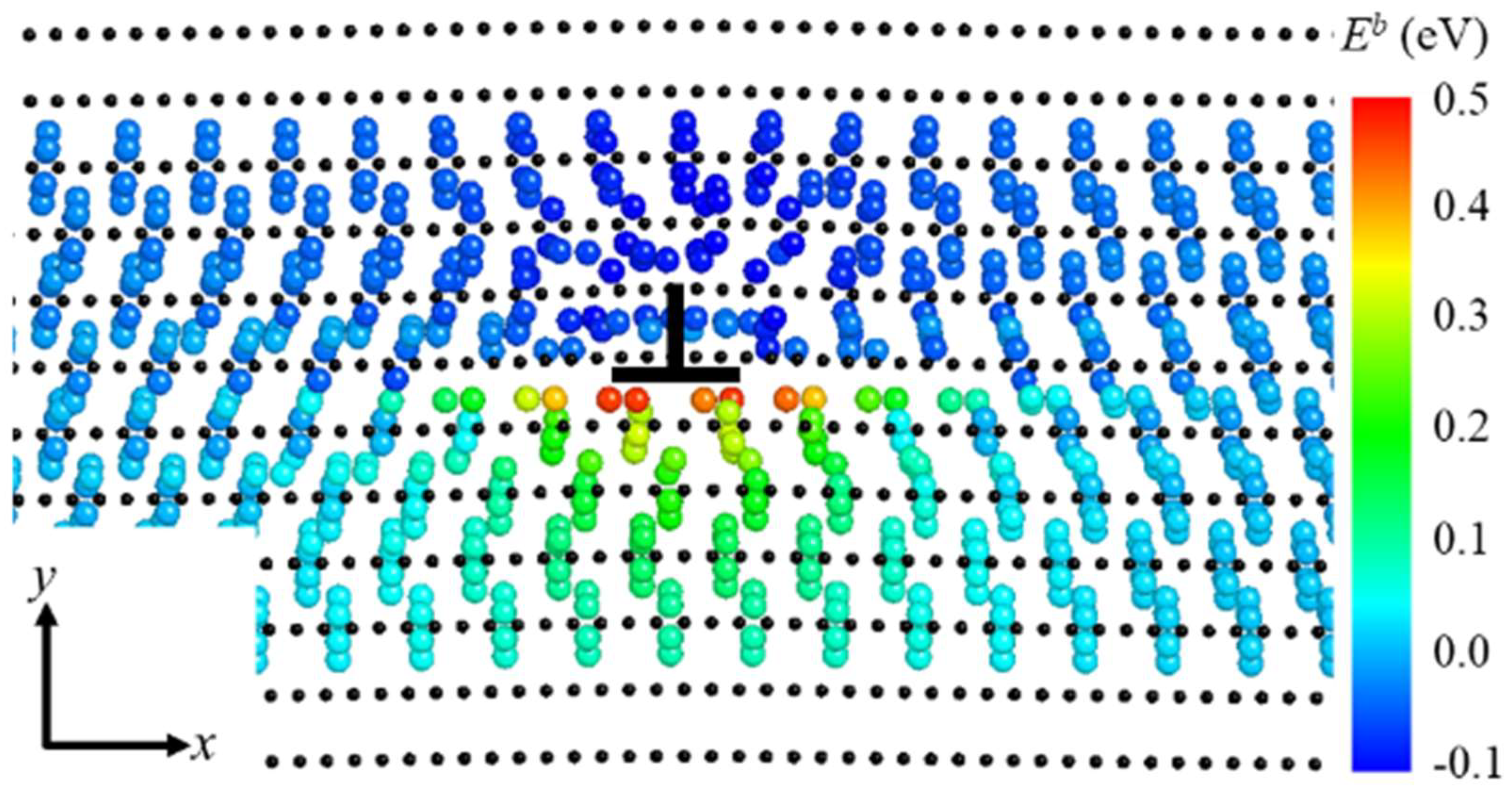

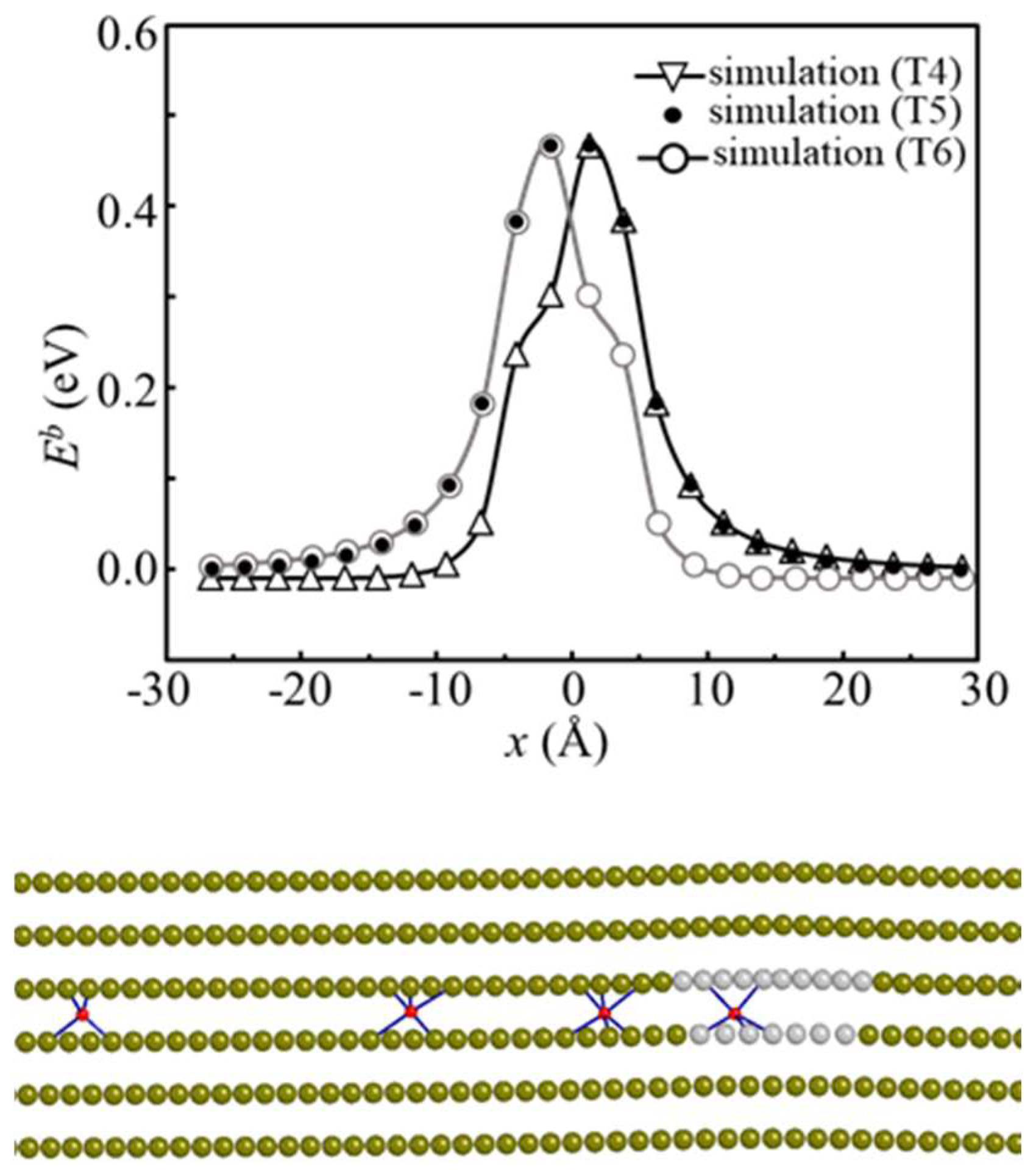

3.1. Atomistic Binding Energy

3.2. Results of Atomistic Simulations

4. Discussion

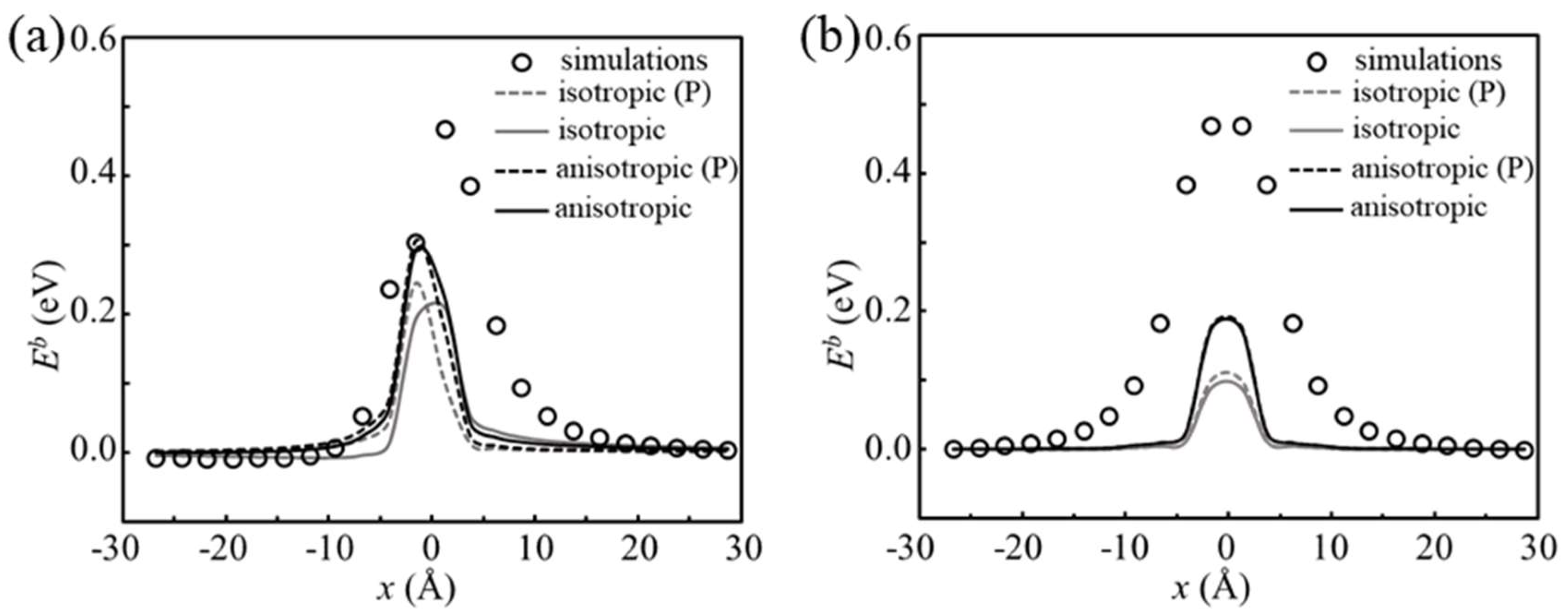

4.1. H Interaction with Dislocation

4.2. Comparison with Atomistic Simulations

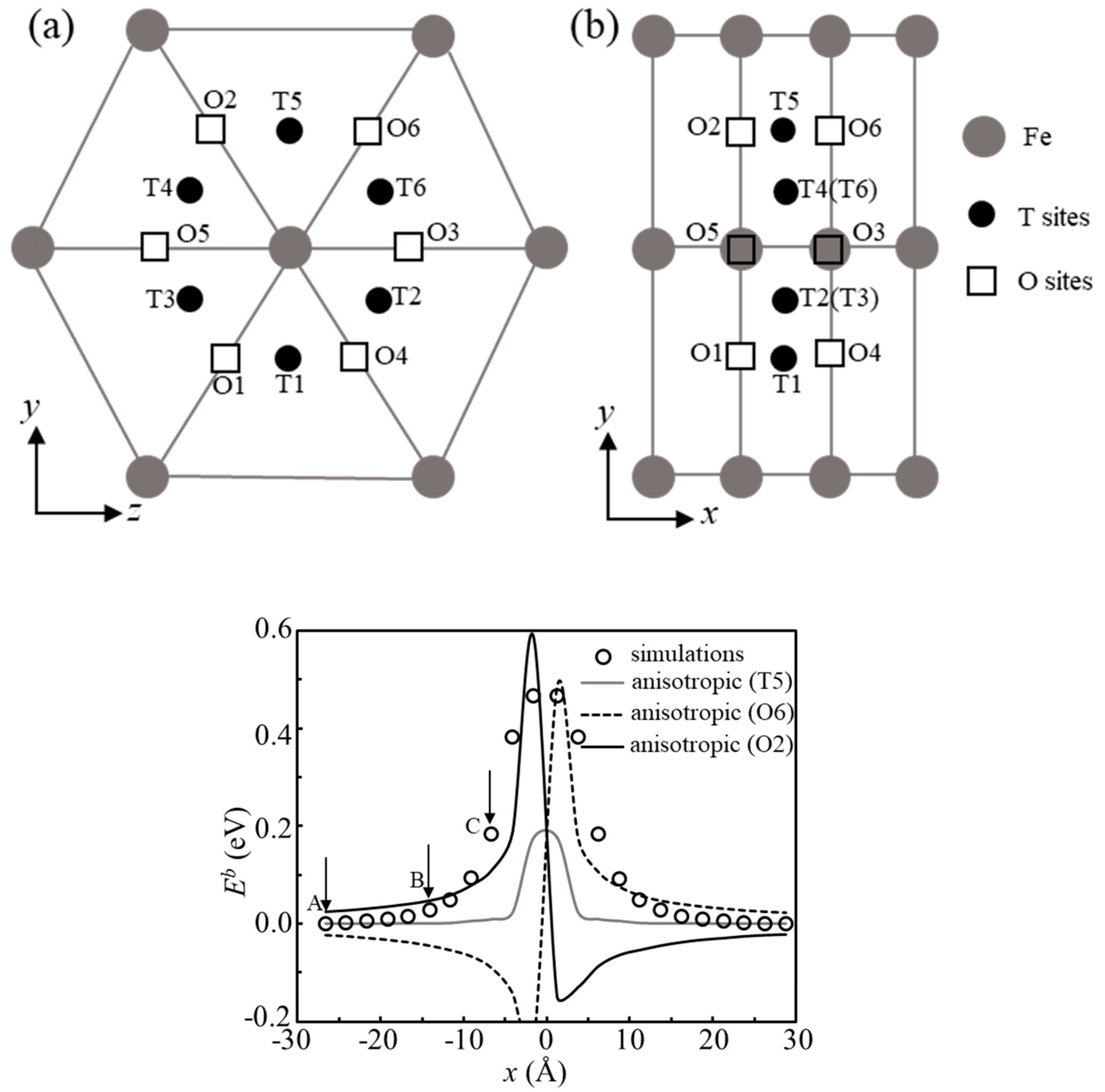

4.3. Influences of Octahedral Sites

- The first stage where |x| > 19 Å, and elasticity assuming H at T5 sites accurately describes the binding energy, while O sites overestimate (O6) or underestimate (O2) the energies;

- The second stage (9 Å < |x| < 19 Å), where atomistic results are in the middle of the results at T5 sites and at O6 sites (x < 0) or O2 sites (x > 0);

- The third stage (|x| < 9 Å), where elastic calculations underestimate the binding energies.

5. Conclusions

Author Contributions

Funding

Data Availability Statement

Conflicts of Interest

References

- Song, J.; Curtin, W.A. Atomic mechanism and prediction of hydrogen embrittlement in iron. Nat. Mater. 2013, 12, 145–151. [Google Scholar] [CrossRef]

- Robertson, I.M.; Sofronis, P.; Nagao, A.; Martin, M.L.; Wang, S. Hydrogen Embrittlement Understood. Met. Mater. Trans. B 2015, 46, 1085–1103. [Google Scholar] [CrossRef]

- Zheng, Y.Y.; Yu, P.; Zhang, K.Y.; Zhang, L. Coupling effect of grain boundary and hydrogen segregation on dislocation nucleation in bi-crystal nickel. Int. J. Hydrogen Energy 2020, 45, 20021–20031. [Google Scholar] [CrossRef]

- Dwivedi, S.K.; Vishwakarma, M. Hydrogen embrittlement in different materials: A review. Int. J. Hydrogen Energy 2018, 43, 21603–21616. [Google Scholar] [CrossRef]

- Deng, Y.; Hajilou, T.; Wan, D.; Kheradmand, N.; Barnoush, A. In-situ micro-cantilever bending test in environmental scanning electron microscope: Real time observation of hydrogen enhanced cracking. Scr. Mater. 2017, 127, 19–23. [Google Scholar] [CrossRef]

- Neeraj, T.; Srinivasan, R.; Li, J. Hydrogen embrittlement of ferritic steels: Observations on deformation microstructure, nanoscale dimples and failure by nanovoiding. Acta Mater. 2012, 60, 5160–5171. [Google Scholar] [CrossRef]

- Barnoush, A.; Kheradmand, N.; Hajilou, T. Correlation between the hydrogen chemical potential and pop-in load during in situ electrochemical nanoindentation. Scr. Mater. 2015, 108, 76–79. [Google Scholar] [CrossRef]

- Barnoush, A.; Asgari, M.; Johnsen, R. Resolving the hydrogen effect on dislocation nucleation and mobility by electrochemical nanoindentation. Scr. Mater. 2012, 66, 414–417. [Google Scholar] [CrossRef]

- Zhao, Y.; Lu, G. QM/MM study of dislocation-hydrogen/helium interactions in α-Fe. Modell. Simul. Mater. Sci. Eng. 2011, 19, 065004. [Google Scholar] [CrossRef]

- Tang, Y.Z.; El-Awady, J.A. Atomistic simulations of the interactions of hydrogen with dislocations in fcc metals. Phys. Rev. B 2012, 86, 174102. [Google Scholar] [CrossRef]

- Ramasubramaniam, A.; Itakura, M.; Carter, E.A. Interatomic potentials for hydrogen in a-iron based on density functional theory. Phys. Rev. B 2009, 79, 174101. [Google Scholar] [CrossRef]

- Lu, T.; Xu, Y.-P.; Pan, X.-D.; Zhou, H.-S.; Ding, F.; Yang, Z.S.; Niu, G.-J.; Luo, G.-N.; Li, X.-C.; Gao, F. Atomistic study of hydrogen behavior around dislocations in α iron. J. Nucl. Mater. 2018, 510, 219–228. [Google Scholar] [CrossRef]

- Kimizuka, H.; Ogata, S. Slow diffusion of hydrogen at a screw dislocation core in α-iron. Phys. Rev. B 2011, 84, 024116. [Google Scholar] [CrossRef]

- Nowak, C.; Zhou, X.W. An interplay between a hydrogen atmosphere and dislocation characteristics in BCC Fe from time-averaged molecular dynamics. Phys. Chem. Chem. Phys. 2023, 25, 8369–8375. [Google Scholar] [CrossRef]

- Zheng, Z.L.; Yi, M.; Wang, S. Abnormal trapping of hydrogen in the elastic stress field of dislocations in body-centered cubic iron. Int. J. Hydrogen Energy 2022, 47, 39255–39264. [Google Scholar] [CrossRef]

- Simpson, E.L.; Paxton, A.T. Effect of applied strain on the interaction between hydrogen atoms and 1/2 <111> screw dislocations in α-iron. Int. J. Hydrogen Energy 2020, 45, 20069–20079. [Google Scholar]

- Nag, S.H.; Varvenne, C.; Curtin, W.A. Solute-strengthening in elastically anisotropic fcc alloys. Model. Simul. Mater. Sci. Eng. 2020, 28, 025007. [Google Scholar] [CrossRef]

- Rao, S.I.; Woodward, C.; Akdim, B. Solid solution softening and hardening in binary BCC alloys. Acta Mater. 2023, 243, 118440. [Google Scholar] [CrossRef]

- Cottrell, A.H.; Jaswon, M.A. Distribution of solute atoms round a slow dislocation. Proc. Proc. R. Soc. A 1949, 199, 104–114. [Google Scholar]

- Mavrikakis, N.; Detlefs, C.; Cook, P.K.; Kutsal, M.; Campos, A.P.C.; Gauvin, M.; Calvillo, P.R.; Saikaly, W.; Hubert, R.; Poulsen, H.F.; et al. A multi-scale study of the interaction of Sn solutes with dislocations during static recovery in α-Fe. Acta Mater. 2019, 174, 92–104. [Google Scholar] [CrossRef]

- Cochardt, A.W.; Schoek, G.; Wiedersich, H. Interaction between dislocations and interstitial atoms in body-centered cubic metals. Acta Metall. 1955, 6, 533–537. [Google Scholar] [CrossRef]

- Koguchi, H.; Hirasawa, Y. Stress and Displacement Fields Around Misfit Dislocation in Anisotropic Dissimilar Materials with Interface Stress and Interface Elasticity. J. Appl. Mech. Aug. 2015, 82, 081005. [Google Scholar] [CrossRef]

- Cai, W.; Sills, R.B.; Barnett, D.M.; Nix, W.D. Modeling a distribution of point defects as misfitting inclusions in stressed solids. J. Mech. Phy. Solids 2014, 66, 154–171. [Google Scholar] [CrossRef]

- Varvenne, C.; Leyson, G.P.M.; Ghazisaeidi, M.; Curtin, W.A. Solute strengthening in random alloys. Acta Mater. 2017, 124, 660–683. [Google Scholar] [CrossRef]

- Siddique, A.B.; Khraishi, T.A. Multi-scale modeling of solute atom strengthening using 3D discrete dislocation dynamics. J. Mater. Sci. 2022, 57, 10613–10626. [Google Scholar] [CrossRef]

- Fellinger, M.R.; Hector, L.G., Jr.; Trinkle, D.R. Solutes that reduce yield strength anisotropies in magnesium from first principles. Phys. Rev. Mater. 2022, 6, 013607. [Google Scholar] [CrossRef]

- Wang, P.; Song, Z.C.; Li, Q.Q.; Wang, H.T. Atomistic simulation for the interaction between dislocation and solute atoms, clusters, and associated physical insights. J. Appl. Phys. 2020, 128, 024301. [Google Scholar] [CrossRef]

- Nöhring, W.G.; Curtin, W.A. Dislocation cross-slip in fcc solid solution alloys. Acta Mater. 2017, 128, 135–148. [Google Scholar] [CrossRef]

- Clouet, E.; Garruchet, S.; Nguyen, H.; Perez, M.; Becquart, C.S. Dislocation interaction with C in a-Fe: A comparison between atomic simulations and elasticity theory. Acta Mater. 2008, 56, 3450–3460. [Google Scholar] [CrossRef]

- Zheng, Z.Q.; Chen, J.W.; Zhu, Y.X.; Zhao, L.; Huang, M.S.; Liang, S.; Li, Z.H. An atomistically-informed phase-field model for quantifying the effect of hydrogen on the evolution of dislocations in FCC metals. Int. J. Plast. 2021, 138, 102937. [Google Scholar] [CrossRef]

- Maresca, F. Screw dislocation structure and mobility in body centered cubic Fe predicted by a Gaussian Approximation Potential. Comp. Mater. Sci. 2018, 1, 7. [Google Scholar] [CrossRef]

- Zheng, Z.Q.; Liang, S.; Zhu, Y.X.; Huang, M.S.; Li, Z.H. Studying hydrogen effect on the core structure and mobility of dislocation in nickel by atomistically-informed generalized Peierls–Nabarro model. Mech. Mater. 2020, 140, 103221. [Google Scholar] [CrossRef]

- Borges, P.P.P.O.; Clouet, E.; Ventelon, L. Ab initio investigation of the screw dislocation-hydrogen interaction in bcc tungsten and iron. Acta Mater. 2022, 234, 118048. [Google Scholar] [CrossRef]

- Tsuru, T.; Suzudo, T. First-principles calculations of interaction between solutes and dislocations in tungsten. Nucl. Mater. Energy 2018, 16, 221–225. [Google Scholar] [CrossRef]

- Taketomi, S.; Matsumoto, R.; Miyazaki, N. Atomistic study of hydrogen distribution and diffusion around a {112} <111> edge dislocation in alpha iron. Acta Mater. 2008, 56, 3761–3769. [Google Scholar]

- Aubry, S.; Fitzgerald, S.P.; Arsenlis, A. Methods to compute dislocation line tension energy and force in anisotropic elasticity. Model. Simul. Mater. Sci. Eng. 2014, 22, 015001. [Google Scholar] [CrossRef]

- Bakaev, A.; Terentyev, D.; Chang, Z.; Posselt, M.; Olsson, P.; Zhurkin, E.E. Effect of isotropic stress on dislocation bias factor in bcc iron: An atomistic study. Philos. Mag. 2018, 98, 54–74. [Google Scholar] [CrossRef]

- Ohsawa, K.; Eguchi, K.; Watanabe, H.; Yamaguchi, M.; Yagi, M. Configuration and binding energy of multiple hydrogen atoms trapped in monovacancy in bcc transition metals. Phys. Rev. B 2012, 85, 094102. [Google Scholar] [CrossRef]

- Ramunni, V.P.; Pascuet, M.I.; Castin, N.; Rivas, A.M.F. The influence of grain size on the hydrogen diffusion in bcc Fe. Comp. Mater. Sci. 2021, 188, 110146. [Google Scholar] [CrossRef]

- Vitek, V.; Mrovec, M.; Bassani, J.L. Influence of non-glide stresses on plastic flow: From atomistic to continuum modeling. Mater. Sci. Eng. A 2004, 365, 31–37. [Google Scholar] [CrossRef]

- Katzarov, I.H.; Drenchev, L.B.; Pashov, D.L.; Zarrouk, T.N.A.T.; Al-lahham, O.; Paxton, A.T. Dynamic strain aging and the role of the Cottrell atmosphere. Phys. Rev. Mater. 2022, 6, 063603. [Google Scholar] [CrossRef]

Disclaimer/Publisher’s Note: The statements, opinions and data contained in all publications are solely those of the individual author(s) and contributor(s) and not of MDPI and/or the editor(s). MDPI and/or the editor(s) disclaim responsibility for any injury to people or property resulting from any ideas, methods, instructions or products referred to in the content. |

© 2023 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (https://creativecommons.org/licenses/by/4.0/).

Share and Cite

Zheng, Y.; Yu, P.; Zhang, L. Atomistic Study of the Interaction Nature of H-Dislocation and the Validity of Elasticity in Bcc Iron. Metals 2023, 13, 1267. https://doi.org/10.3390/met13071267

Zheng Y, Yu P, Zhang L. Atomistic Study of the Interaction Nature of H-Dislocation and the Validity of Elasticity in Bcc Iron. Metals. 2023; 13(7):1267. https://doi.org/10.3390/met13071267

Chicago/Turabian StyleZheng, Yuanyuan, Ping Yu, and Lin Zhang. 2023. "Atomistic Study of the Interaction Nature of H-Dislocation and the Validity of Elasticity in Bcc Iron" Metals 13, no. 7: 1267. https://doi.org/10.3390/met13071267

APA StyleZheng, Y., Yu, P., & Zhang, L. (2023). Atomistic Study of the Interaction Nature of H-Dislocation and the Validity of Elasticity in Bcc Iron. Metals, 13(7), 1267. https://doi.org/10.3390/met13071267