Effect of Process Parameters on Friction Stir Welded Joints between Dissimilar Aluminum Alloys: A Review

Abstract

1. Introduction

- First, each process parameter is investigated in terms of influence on the joint performances;

- Then, the attention is focused on the tools used to predict or better investigate these effects such as finite element analyses, artificial neural networks, and statistical studies.

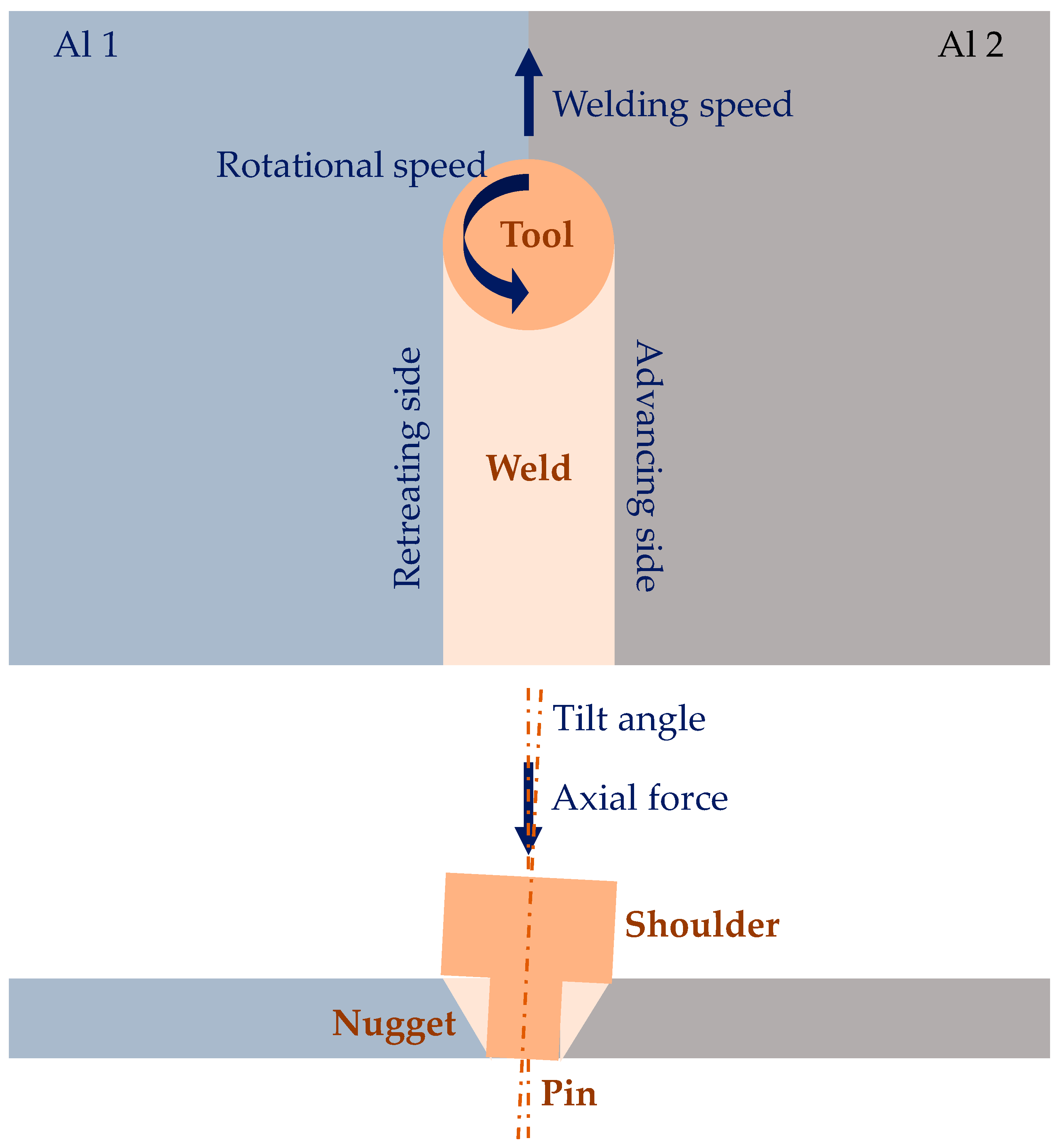

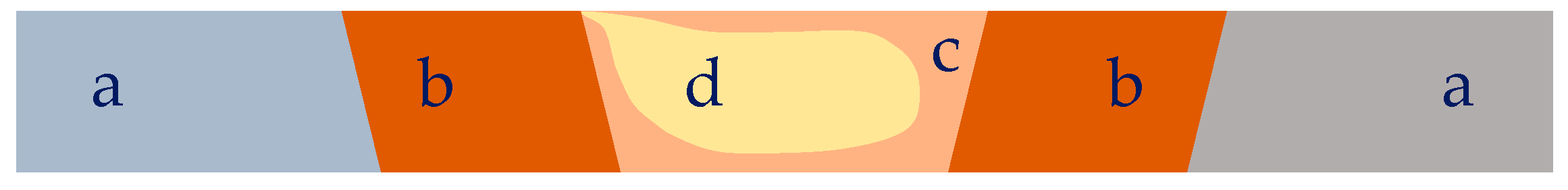

2. Effect of Process Parameters

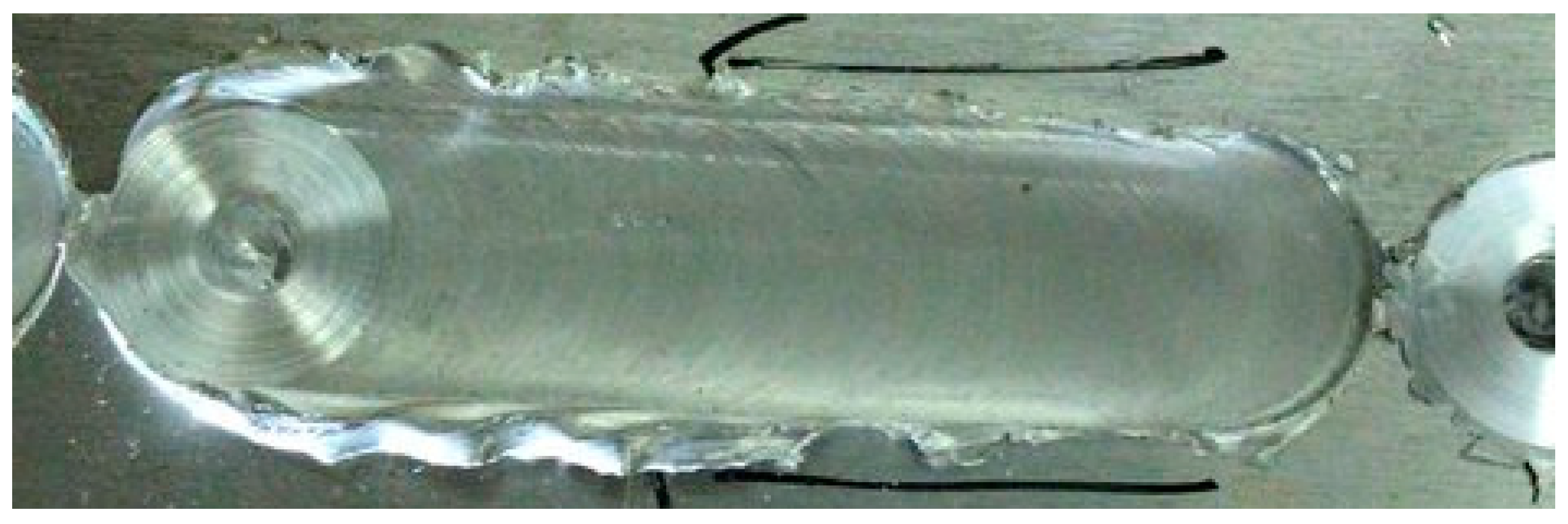

2.1. Tool Shoulder and Pin Geometry

2.2. Tool Tilt Angle

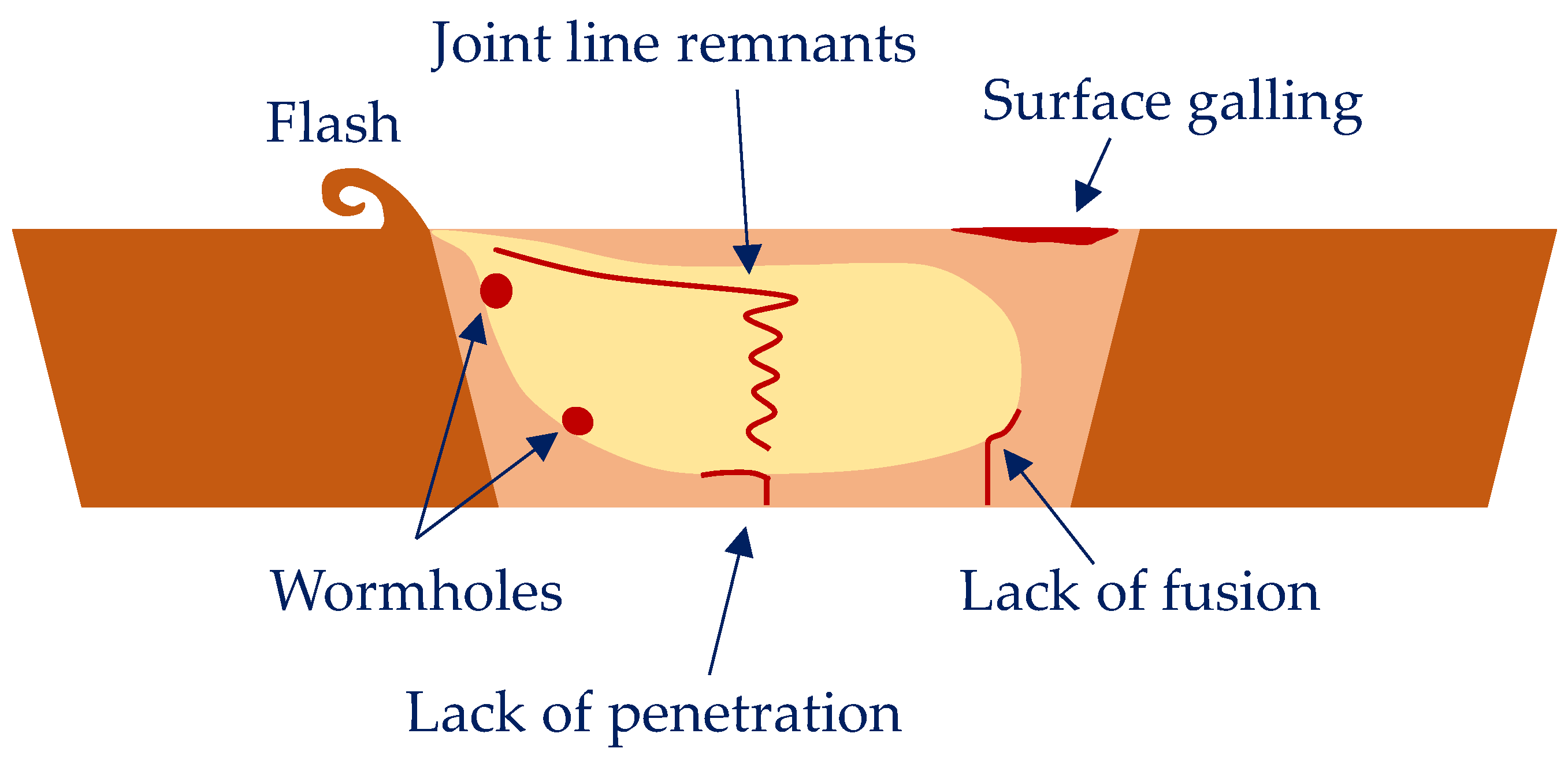

2.3. Tool Rotational Speed

- Heat generation: as the tool rotates, it generates frictional heat due to the contact between the tool and the workpiece, controlling heat generation or heat input as they relate to the material plastic flow [31]. Higher rotational speeds result in more heat generation, which can cause the material to soften and lead to better mixing and bonding between the two workpieces.

- Weld quality: an exceedingly low rotational speed can result in incomplete weld formation and poor bonding between the two workpieces. On the other hand, if the rotational speed is too high, it can lead to defects in the weld, such as poor surface (flash), voids, porosity, and tunneling or formation of wormholes because of the excessive heat input.

- Tool wear: higher rotational speeds can lead to more wear on the tool, which can reduce its lifespan.

- Welding force (i.e., required to push the tool through the workpiece): the rotational speed of the tool can also affect the force. Higher rotational speeds generally require higher forces to maintain the tool’s position and prevent it from slipping out of the joint.

2.4. Welding Speed

2.5. Position of Sheets

- Heat Input: the advancing side experiences higher heat input compared to the retreating side. As the tool moves forward, it generates more frictional heat, resulting in increased plastic deformation and temperature in the advancing side. This can lead to different thermal cycles and thermal gradients on the two sides of the joint.

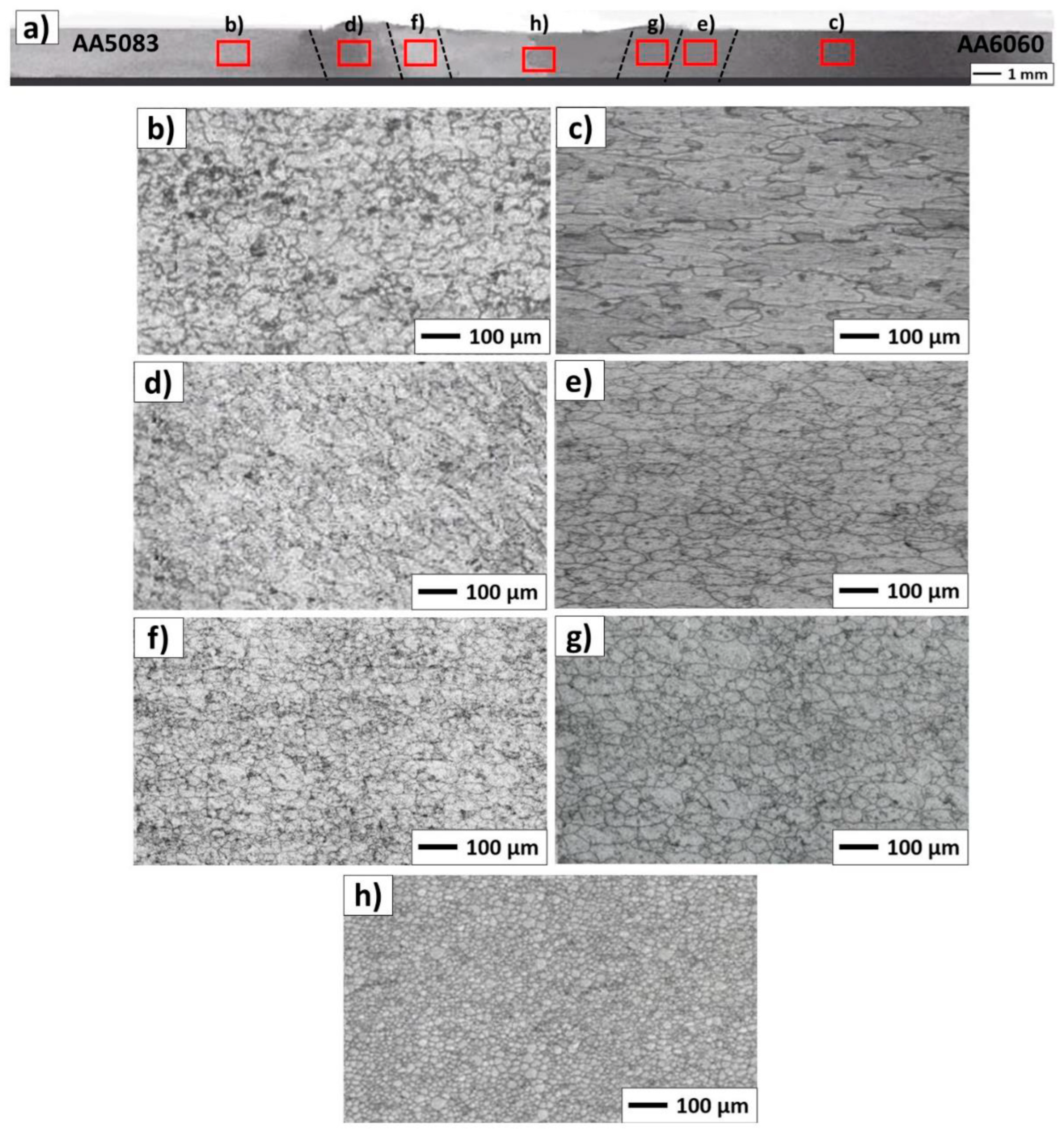

- Grain Structure: the different heat inputs on the advancing and retreating sides can result in variations in the grain structure of the weld. The advancing side generally experiences more severe deformation and recrystallization, leading to finer grain sizes compared to the retreating side. The grain structure affects the mechanical properties of the joint, such as strength and toughness.

- Composition Variation: dissimilar aluminum alloys may have different compositions and mechanical properties. The advancing side, experiencing higher heat and deformation, can lead to localized diffusion of alloying elements between the base materials. This diffusion can influence the composition and resulting properties of the joint.

- Residual Stresses: the differences in heat input and resulting microstructure can lead to variations in residual stresses along the joint. Residual stresses are important because they can affect the structural integrity and distortion of the welded components.

2.6. Axial Force

- Material Penetration: it ensures that the rotating tool penetrates the workpiece to the desired depth. It helps in achieving proper material mixing and bonding between the adjacent surfaces.

- Heat Generation: the downward pressure exerted by the axial force enhances the contact between the tool and the workpiece. This contact generates frictional heat due to the relative motion between the tool shoulder and the material. The heat softens the material, allowing it to deform and join.

- Plastic Deformation: as the rotating tool moves along the joint line, the force helps in deforming and stirring the material, facilitating metallurgical bonding. The plastic deformation allows the material to flow around the tool and form a solid-state weld.

- Quality of the Weld: proper application of force ensures that there is sufficient contact between the tool and the workpiece, promoting effective heat transfer and material flow. Insufficient axial force may result in inadequate mixing, incomplete bonding, or defects in the weld, while excessive force can lead to excessive material displacement or even tool breakage.

- Weld Strength and Integrity: by applying a suitable force, the material is effectively consolidated, leading to a sound weld joint with improved mechanical properties.

3. Design Tool

3.1. Statistical Approaches

3.2. Heuristic Techniques

3.2.1. Artificial Neural Networks

- Predictive Modeling: by training an ANN with input–output pairs of the FSW process parameters and the corresponding weld quality, the network can learn the complex relationships between these variables. Once trained, the ANN can predict the outcomes of FSW for new input parameters, allowing to estimate weld quality, defects, or other relevant properties.

- Optimization: by constructing an ANN-based surrogate model which approximates the relationship between process variables and a desired objective (i.e., joint strength, fatigue life), optimization algorithms can efficiently explore the parameter space and identify the combination of inputs that maximizes the objective. This can lead to improved weld quality and process efficiency.

- Fault Detection: by training an ANN with sensor data from the welding process, such as temperature, torque, or force measurements, the network can learn normal patterns and identify deviations that indicate potential faults or defects. This allows real-time monitoring of the welding process and early detection of issues, enabling timely corrective actions.

- Process Control: by employing ANN as part of control algorithms, the network can analyze sensor data in real time, make predictions, and adjust process parameters accordingly. This adaptive control approach can enhance the stability, accuracy, and repeatability of the FSW process, leading to improved weld quality.

- Material Characterization: by training an ANN with input data such as material composition, microstructural features, and mechanical properties, the network can learn the relationships between these parameters and welding outcomes. This can aid in understanding the ways in which different materials behave during FSW and enable the selection of suitable welding parameters for specific materials.

3.2.2. Genetic Algorithms

3.3. Finite Element Analysis

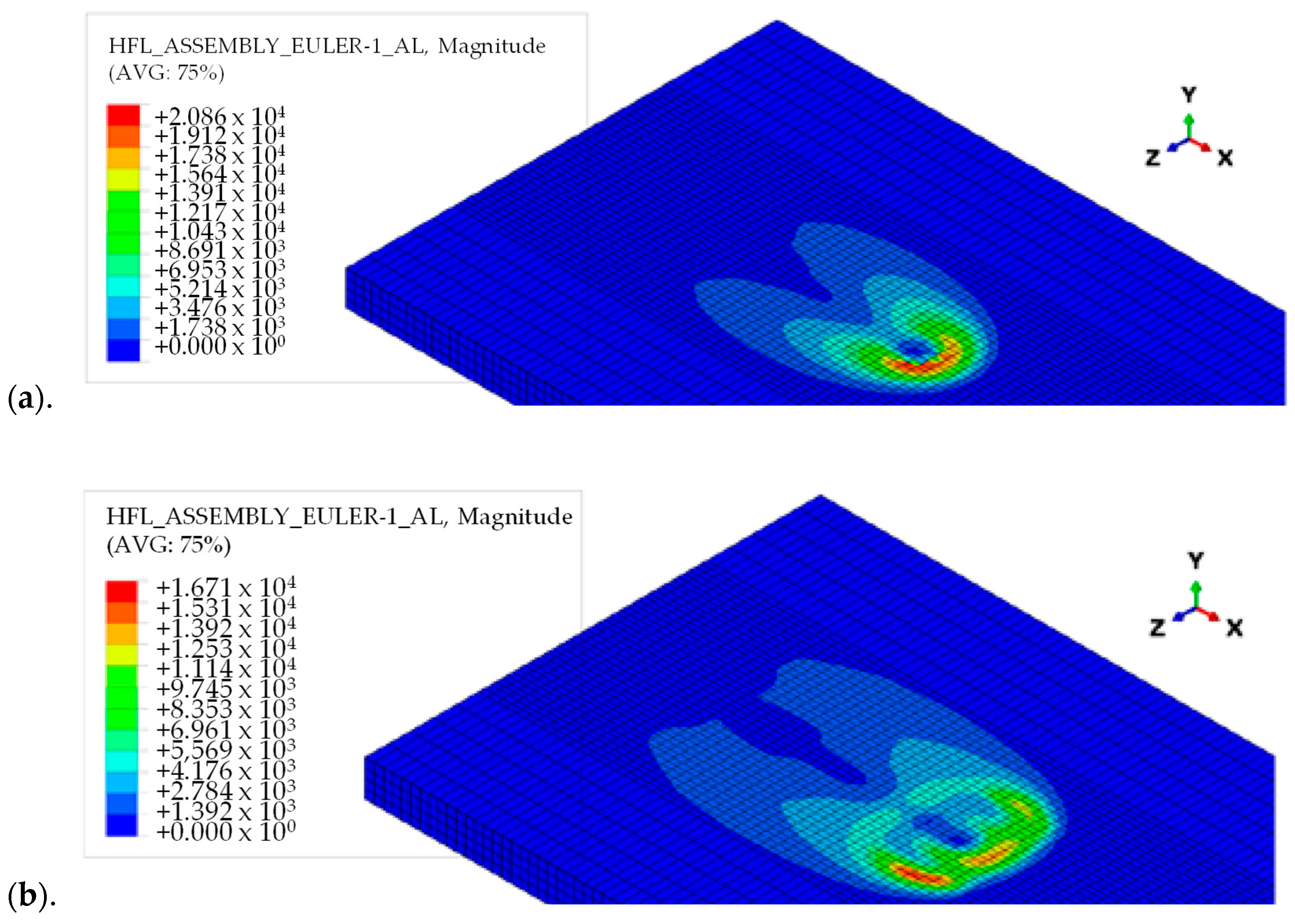

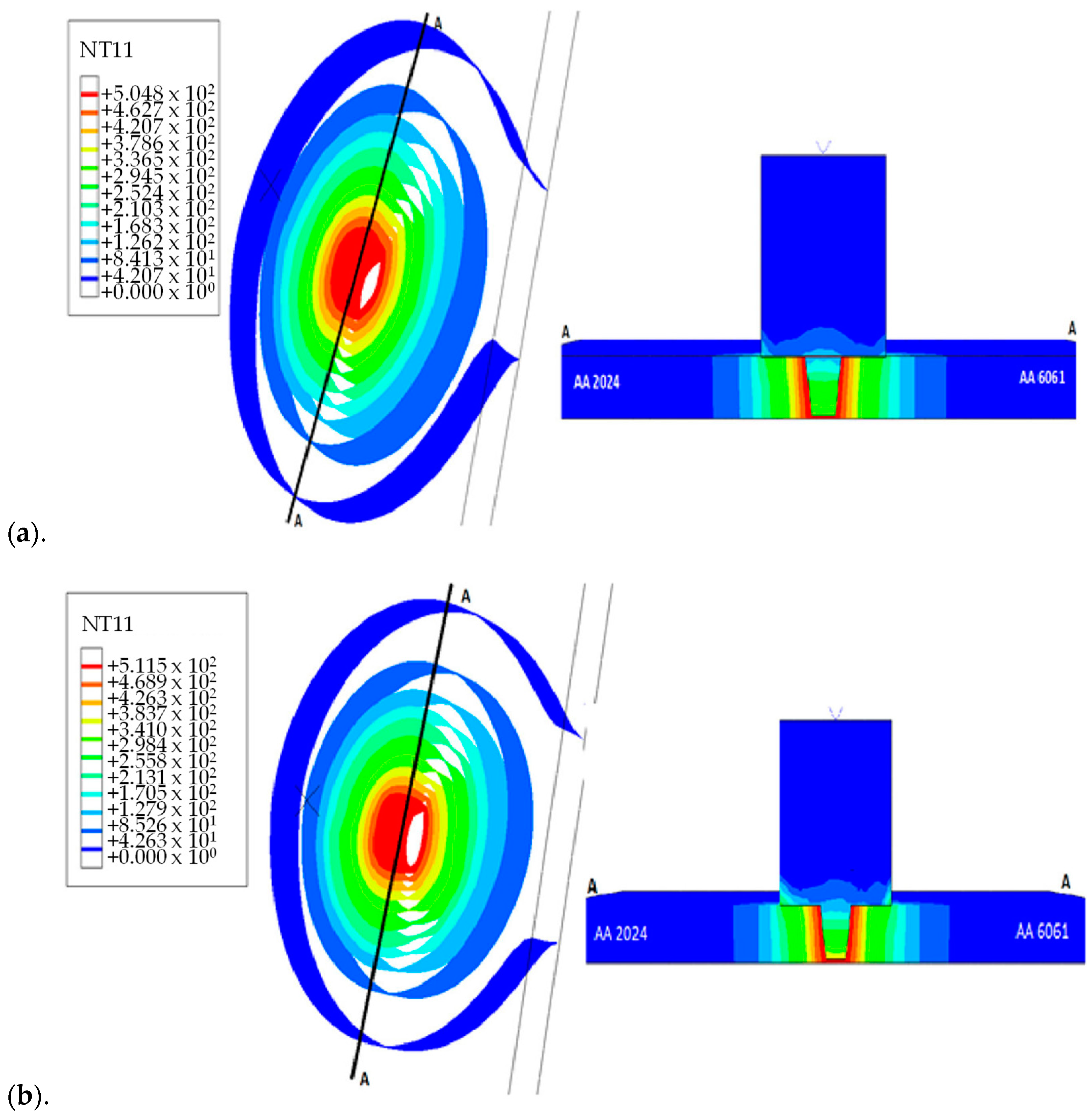

- Thermal Analysis: by considering factors such as tool rotation, tool traverse speed, and material properties, FEA can simulate the heat generation and distribution predicting the temperature distribution, the thermal cycles, and the heat-affected zone evolution during the welding process. This information is significant for understanding the thermal history and potential defects in the weld.

- Mechanical Analysis: by considering the interaction between the tool and workpiece, FEA can evaluate the mechanical aspects of FSW, including stress and deformation distribution predicting the material flow, the plastic deformation, and the residual stresses in the weld. This analysis helps to optimize tool geometry and process parameters to minimize residual stresses and distortion in the final weld [227].

- Process Optimization: FEA allows for parametric studies where different welding parameters and tool designs can be simulated to assess their impact on the welding process. By analyzing the temperature, stress, and deformation fields, FEA can help identify optimal process parameters that lead to improved weld quality, reduced defects, and enhanced mechanical properties.

- Defect Prediction: FEA can aid in identifying potential defects in the FSW process. For example, by analyzing the temperature field, FEA can predict the likelihood of defects like lack of fusion, voids, or excessive material flow. This information can guide process improvements and minimize the occurrence of defects.

- Tool Design and Optimization: by simulating the contact and frictional behavior between the tool and the workpiece, FEA can assess tool wear, heat generation, and stress distribution on the tool. This enables the development of tool designs that enhance performance, durability, and efficiency.

Computational Fluid Dynamics

- Fluid flow analysis: it helps in understanding the velocity profiles, the flow patterns, and the material displacement within the workpiece. By analyzing the fluid flow, it is possible to study the mixing and stirring of materials and identify regions of potential defects or inhomogeneity.

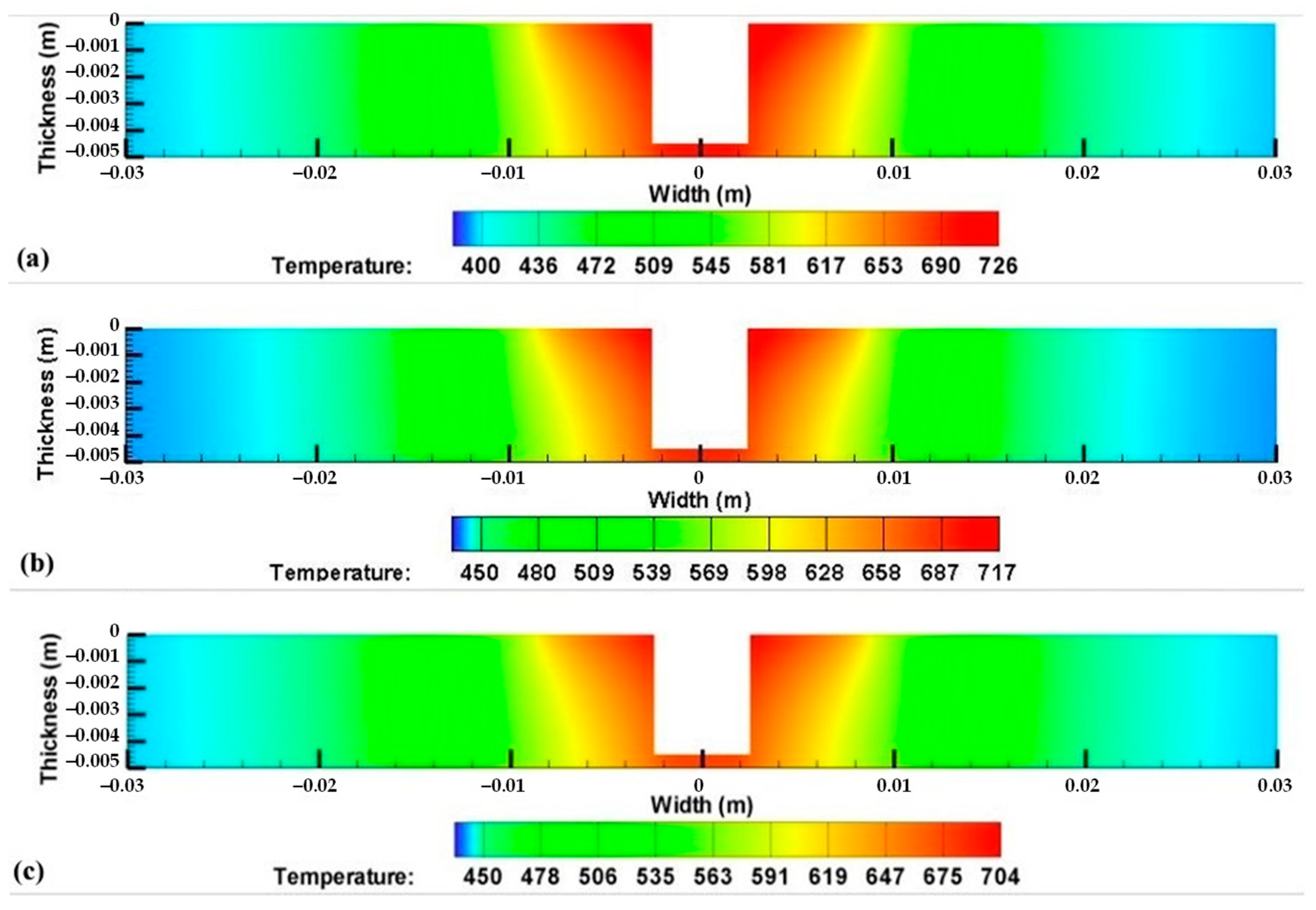

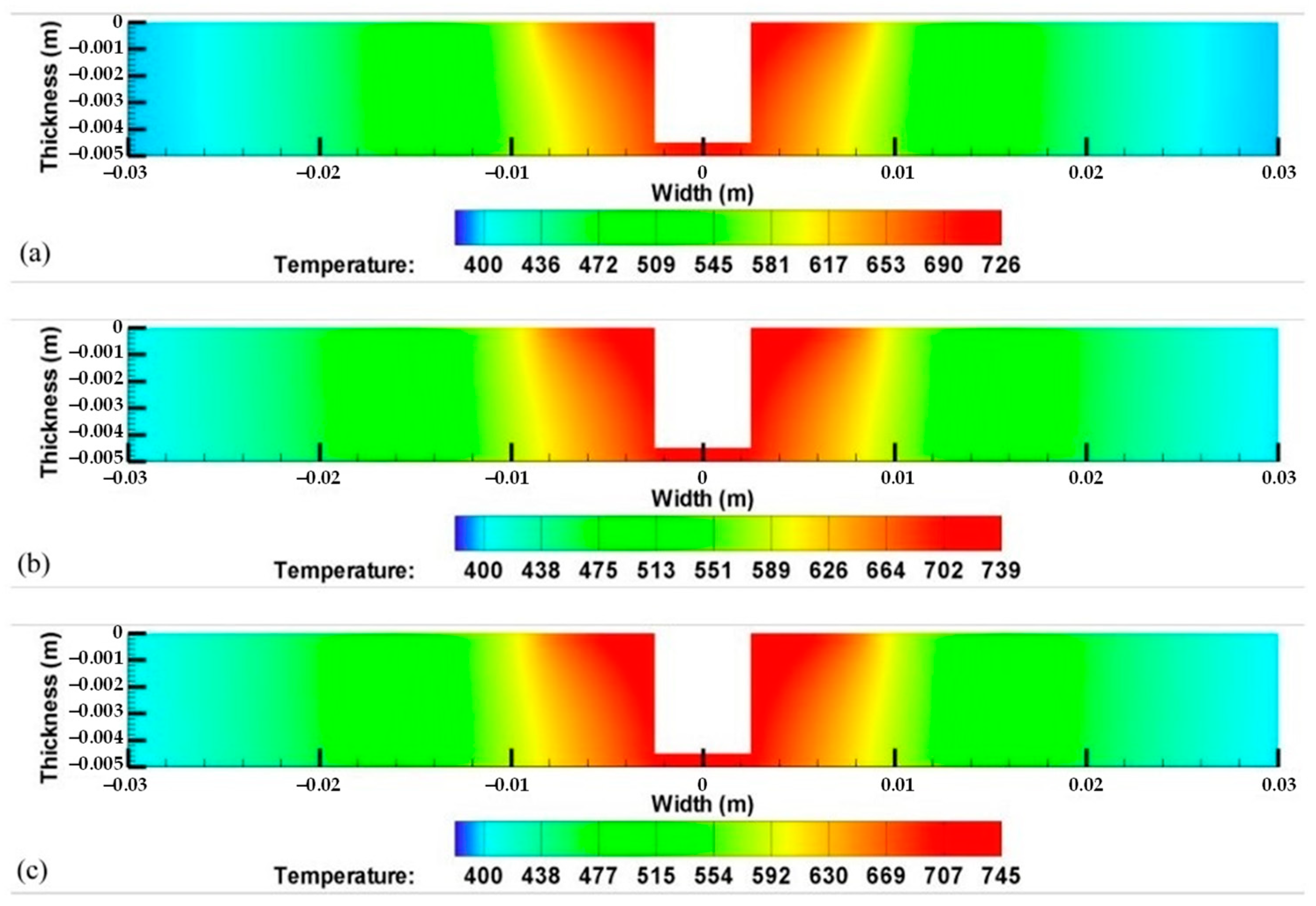

- Temperature distribution: by accounting for factors like heat generation, heat transfer, and cooling mechanisms, CFD simulations provide valuable insights into the temperature profiles and the gradients that influence the weld quality. This information helps in optimizing the welding parameters to control the heat input and avoid defects like overheating or insufficient heating.

- Residual stress and distortion analysis: the thermal and mechanical interactions between the tool, workpiece, and surrounding environment can be analyzed to predict the residual stresses and distortions that arise after welding. Understanding these effects aids in optimizing process parameters, tool design, and subsequent post-welding operations.

- Process optimization: CFD simulations allow for virtual experimentation, enabling the exploration of different process variables without the need for physical prototypes. It is possible to analyze the effects of tool geometry, rotational speed, traverse speed, and other parameters on the fluid flow, temperature distribution, and resulting weld quality [248].

4. Conclusions

- As for the tool tilt angle, angles between 1° and 3° favor the material flow allowing the increase in speeds and avoiding defects in the joint, the presence of groves or scrolls on the shoulder thus eliminated to tilt the tool.

- As for rotational and traverse speeds, these two parameters have a strong interaction and an inverse correlation. Higher tool rotation speeds and lower tool traverse speeds promote intimate mixing between dissimilar alloys. As rotational speed increases (from 1000 to 1200 rpm) and traverse speed decreases (from 120 to 90 mm/min), both factors contribute to increased heat generation, higher peak temperatures, and reduced maximum tensile residual stress.

- As for the position of the sheets (AS/RS), there is not always a complete agreement among the experimental results that are performed with different tool shapes, tilt angle and tool speeds. Most of them, however, agree on the fact that the higher mechanical properties of the weld zone were acquired when a relatively harder material was fixed at the retreating side.

- Finally, the axial force should be adjusted within the optimal range to achieve a balance between material deformation and process stability.

- The statistical approach inside a proper design of sxperiment is one of the most robust tools that researchers can use. Statistical analysis can be employed to investigate the relationship between process parameters, microstructure evolution, and resulting mechanical properties. This understanding helps researchers optimize the welding process for specific applications and predict material behavior under different loading conditions. Statistical approaches can also aid in assessing the reliability and fatigue life of FSW joints. By applying probabilistic models and using techniques like the Weibull analysis, researchers can estimate the probability of failure or predict the fatigue life of welds under different loading conditions. This information is vital for ensuring the long-term performance and durability of FSW structures. The previously cited goals can be obtained expanding the information using heuristic techniques (like neural networks and genetic algorithms), thus reducing the need for experiments. In addition, the latter tools can be successfully used for real-time monitoring and controlling of the welding process.

- On the contrary, numerical modelling like finite element analysis and Computational Fluid Dynamics are very powerful tools for researchers to study/analyze/predict the characteristics of the joint at all the varying parameters cited above. The extremely complex thermal/mechanical and metallurgical phenomena involved in the FSW process cannot be described by mathematical models; thus, the latter two approaches are the only valid support to design tools and/or optimize the process.

Author Contributions

Funding

Data Availability Statement

Conflicts of Interest

References

- Torzewski, J.; Łazińska, M.; Grzelak, K.; Szachogłuchowicz, I.; Mierzyński, J. Microstructure and Mechanical Properties of Dissimilar Friction Stir Welded Joint AA7020/AA5083 with Different Joining Parameters. Materials 2022, 15, 1910. [Google Scholar] [CrossRef]

- Kaushal, A.; Shankar, S.; Chattopadhyaya, S. Joining of Dissimilar Aluminum Alloys AA2024 and AA7075 by Friction Stir Welding: A Review. In Recent Advances in Manufacturing, Automation, Design and Energy Technologies; Springer: Singapore, 2022; pp. 95–103. [Google Scholar]

- Sivaraman, P.; Nithyanandhan, T.; Karthick, M.; Kirivasan, S.M.; Rajarajan, S.; Sundar, M.S. Analysis of Tensile Strength of AA 2014 and AA 7075 Dissimilar Metals Using Friction Stir Welding. Mater. Today Proc. 2021, 37, 187–192. [Google Scholar] [CrossRef]

- Maddox, S. Review of Fatigue Assessment Procedures for Welded Aluminium Structures. Int. J. Fatigue 2003, 25, 1359–1378. [Google Scholar] [CrossRef]

- Boopathi, S.; Moorthi, K. Review on Effect of Process Parameters-Friction Stir Welding Process. Int. Res. J. Eng. Technol. 2017, 4, 272–278. [Google Scholar]

- Ahmed, M.M.Z.; El-Sayed Seleman, M.M.; Fydrych, D.; Çam, G. Friction Stir Welding of Aluminum in the Aerospace Industry: The Current Progress and State-of-the-Art Review. Materials 2023, 16, 2971. [Google Scholar] [CrossRef]

- Ahmed, S.; ur Rahman, R.A.; Awan, A.; Ahmad, S.; Akram, W.; Amjad, M.; Yahya, M.Y.; Rahimian Koloor, S.S. Optimization of Process Parameters in Friction Stir Welding of Aluminum 5451 in Marine Applications. J. Mar. Sci. Eng. 2022, 10, 1539. [Google Scholar] [CrossRef]

- Napolitano, F.; El Hassanin, A.; Scherillo, F.; Squillace, A. FSW of Extruded and Additively Manufactured Parts for Automotive Components. Mater. Manuf. Process. 2023, 38, 1445–1454. [Google Scholar] [CrossRef]

- Prakash, P.; Anand, R.S.; Jha, S.K. Experimental Analysis of Tensile Strength of Different Thicknesses and Dissimilar Aluminum Alloys in Friction Stir Welding. J. Mater. Eng. Perform. 2022, in press. [Google Scholar] [CrossRef]

- Christy, J.V.; Mourad, A.-H.I.; Sherif, M.M.; Shivamurthy, B. Review of Recent Trends in Friction Stir Welding Process of Aluminum Alloys and Aluminum Metal Matrix Composites. Trans. Nonferrous Met. Soc. China 2021, 31, 3281–3309. [Google Scholar] [CrossRef]

- Verma, R.P.; Pandey, K.N.; András, K.; Khargotra, R.; Singh, T. Difficulties and Redressal in Joining of Aluminium Alloys by GMA and GTA Welding: A Review. J. Mater. Res. Technol. 2023, 23, 2576–2586. [Google Scholar] [CrossRef]

- Di Bella, G.; Borsellino, C.; Khaskhoussi, A.; Proverbio, E. Effect of Tool Rotation Direction on Mechanical Strength of Single Lap Friction Stir Welded Joints between AA5083 Aluminum Alloy and S355J0 Steel for Maritime Applications. Metals 2023, 13, 411. [Google Scholar] [CrossRef]

- Cabibbo, M.; Forcellese, A.; Santecchia, E.; Paoletti, C.; Spigarelli, S.; Simoncini, M. New Approaches to Friction Stir Welding of Aluminum Light-Alloys. Metals 2020, 10, 233. [Google Scholar] [CrossRef]

- Gullino, A.; Matteis, P.; D’Aiuto, F. Review of Aluminum-To-Steel Welding Technologies for Car-Body Applications. Metals 2019, 9, 315. [Google Scholar] [CrossRef]

- Khaskhoussi, A.; Di Bella, G.; Borsellino, C.; Calabrese, L.; Proverbio, E. Microstructural and Electrochemical Characterization of Dissimilar Joints of Aluminum Alloy AW5083 and Carbon Steel S355 Obtained by Friction Welding. Metall. Ital. 2022, 9, 15–21. [Google Scholar]

- Meschut, G.; Merklein, M.; Brosius, A.; Drummer, D.; Fratini, L.; Füssel, U.; Gude, M.; Homberg, W.; Martins, P.A.F.; Bobbert, M.; et al. Review on Mechanical Joining by Plastic Deformation. J. Adv. Join. Process. 2022, 5, 100113. [Google Scholar] [CrossRef]

- Prabhakar, D.A.P.; Shettigar, A.K.; Herbert, M.A.; Patel, G.C.M.; Pimenov, D.Y.; Giasin, K.; Prakash, C. A Comprehensive Review of Friction Stir Techniques in Structural Materials and Alloys: Challenges and Trends. J. Mater. Res. Technol. 2022, 20, 3025–3060. [Google Scholar] [CrossRef]

- Nguyen, T.-T.; Nguyen, C.-T.; Van, A.-L. Sustainability-Based Optimization of Dissimilar Friction Stir Welding Parameters in Terms of Energy Saving, Product Quality, and Cost-Effectiveness. Neural Comput. Appl. 2023, 35, 5221–5249. [Google Scholar] [CrossRef]

- Kaygusuz, E.; Karaomerloglu, F.; Akinci, S. A Review of Friction Stir Welding Parameters, Process and Application Fields. Turk. J. Eng. 2023, 7, 286–295. [Google Scholar] [CrossRef]

- Ravi Kumar, B.V.R.; Upender, K.; Venkata Ramana, M.; Sreenivasarao, M.S. Visual Inspection on Friction Stir Welded Dissimilar Aluminum Alloy AA6082-AA5083 Using Conventional and Hybrid Tool Pin Profiles. Mater. Today Proc. 2023, in press. [Google Scholar] [CrossRef]

- Rabiezadeh, A.; Salafzon, A.; Mostafavi, N. Dissimilar Welding of AA5083/AA7039 by Self-Reacting Friction Stir Welding. J. Adhes. Sci. Technol. 2023, 1–22. [Google Scholar] [CrossRef]

- Hou, W.; Ding, Y.; Huang, G.; Huda, N.; Shah, L.H.A.; Piao, Z.; Shen, Y.; Shen, Z.; Gerlich, A. The Role of Pin Eccentricity in Friction Stir Welding of Al-Mg-Si Alloy Sheets: Microstructural Evolution and Mechanical Properties. Int. J. Adv. Manuf. Technol. 2022, 121, 7661–7675. [Google Scholar] [CrossRef]

- Ahmad Shah, L.H.; Midawi, A.R.H.; Walbridge, S.; Gerlich, A. Influence of Tool Eccentricity on the Material Flow and Microstructural Properties of AA6061 Aluminum Alloy Friction Stir Welds. J. Alloys Compd. 2020, 826, 154219. [Google Scholar] [CrossRef]

- Shah, L.H.; Huda, N.; Esmaeili, S.; Walbridge, S.; Gerlich, A.P. Structural Morphology of Al-Mg-Si Alloy Friction Stir Welds through Tool Eccentricity. Mater. Lett. 2020, 275, 128098. [Google Scholar] [CrossRef]

- Pookamnerd, Y.; Thosa, P.; Charonerat, S.; Prasomthong, S. Development of Mechanical Property Prediction Model and Optimization for Dissimilar Aluminum Alloy Joints with the Friction Stir Welding (FSW) Process. EUREKA Phys. Eng. 2023, 3, 112–128. [Google Scholar] [CrossRef]

- Cao, F.; Sun, T.; Hu, J.; Hou, W.; Huang, G.; Shen, Y.; Ma, N.; Geng, P.; Hu, W.; Qu, X. Enhanced Mechanical and Anticorrosion Properties in Cryogenic Friction Stir Processed Duplex Stainless Steel. Mater. Des. 2023, 225, 111492. [Google Scholar] [CrossRef]

- Sun, S.J.; Tian, Y.Z.; An, X.H.; Lin, H.R.; Wang, J.W.; Zhang, Z.F. Ultrahigh Cryogenic Strength and Exceptional Ductility in Ultrafine-Grained CoCrFeMnNi High-Entropy Alloy with Fully Recrystallized Structure. Mater. Today Nano 2018, 4, 46–53. [Google Scholar] [CrossRef]

- Patel, M.; Murugesan, J. Effect of the Tool Pin Eccentricity and Cooling Rate on Microstructure, Mechanical Properties, Fretting Wear, and Corrosion Behavior of Friction Stir Processed AA6063 Alloy. J. Mater. Eng. Perform. 2022, 31, 8554–8566. [Google Scholar] [CrossRef]

- Sabry, N.; Stroh, J.; Sediako, D. Characterization of Microstructure and Residual Stress Following the Friction Stir Welding of Dissimilar Aluminum Alloys. CIRP J. Manuf. Sci. Technol. 2023, 41, 365–379. [Google Scholar] [CrossRef]

- Mertinger, V.; Varbai, B.; Adonyi, Y.; DeBacker, J.; Nagy, E.; Leskó, M.; Kárpáti, V. Microstructure Evaluation of Dissimilar AA2024 and AA7050 Aluminum Joints Made by Corner Stationary-Shoulder Friction Stir Welding. Weld. World 2022, 66, 1623–1635. [Google Scholar] [CrossRef]

- Patel, V.; Li, W.; Wang, G.; Wang, F.; Vairis, A.; Niu, P. Friction Stir Welding of Dissimilar Aluminum Alloy Combinations: State-of-the-Art. Metals 2019, 9, 270. [Google Scholar] [CrossRef]

- Khalafe, W.H.; Sheng, E.L.; Bin Isa, M.R.; Omran, A.B.; Shamsudin, S. Bin The Effect of Friction Stir Welding Parameters on the Weldability of Aluminum Alloys with Similar and Dissimilar Metals: Review. Metals 2022, 12, 2099. [Google Scholar] [CrossRef]

- Prabhu, S.; Sri, M.N.S.; Anusha, P.; Saravanan, G.; Kannan, K.; Manickam, S. Improvement of Mechanical Behavior of FSW Dissimilar Aluminum Alloys by Postweld Heat Treatments. Adv. Mater. Sci. Eng. 2022, 2022, 3608984. [Google Scholar] [CrossRef]

- Cavaliere, P.; Nobile, R.; Panella, F.W.; Squillace, A. Mechanical and Microstructural Behaviour of 2024–7075 Aluminium Alloy Sheets Joined by Friction Stir Welding. Int. J. Mach. Tools Manuf. 2006, 46, 588–594. [Google Scholar] [CrossRef]

- Tucci, F.; Carlone, P.; Silvestri, A.T.; Parmar, H.; Astarita, A. Dissimilar Friction Stir Lap Welding of AA2198-AA6082: Process Analysis and Joint Characterization. CIRP J. Manuf. Sci. Technol. 2021, 35, 753–764. [Google Scholar] [CrossRef]

- Battina, N.M.; Vanthala, V.S.P.; Ch, H.K. Effect of Friction Stir Welding Process Parameters on Mechanical and Metallurgical Behavior of AA6061-T6 and AA2017-T6 Tailored Blanks. Eng. Res. Express 2021, 3, 025043. [Google Scholar] [CrossRef]

- Abnar, B.; Gashtiazar, S.; Javidani, M. Friction Stir Welding of Non-Heat Treatable Al Alloys: Challenges and Improvements Opportunities. Crystals 2023, 13, 576. [Google Scholar] [CrossRef]

- de Viveiros, B.V.G.; da Silva, R.M.P.; Donatus, U.; Costa, I. Welding and Galvanic Coupling Effects on the Electrochemical Activity of Dissimilar AA2050 and AA7050 Aluminum Alloys Welded by Friction Stir Welding (FSW). Electrochim. Acta 2023, 449, 142196. [Google Scholar] [CrossRef]

- Essa, A.; Ahmed, M.; Mohamed, A. Weld Pitch Effects on Friction Stir Welding of Aluminum Alloys. J. Pet. Min. Eng. 2021, 23, 102–106. [Google Scholar] [CrossRef]

- Tiwari, S.; Shukla, D.K.; Chandra, R. Friction Stir Welding of Aluminum Alloys: A Review. Int. J. Mech. Aerosp. Ind. Mechatron. Eng. 2013, 7, 1315–1320. [Google Scholar]

- Shyamlal, C.; Rajesh, S.; Suresh Kumar, S. A Comprehensive Review on the Effect of Precipitation on Mechanical Properties of Friction Stir Welded Aluminium Alloys. Proc. Inst. Mech. Eng. C J. Mech. Eng. Sci. 2021, 235, 6345–6356. [Google Scholar] [CrossRef]

- Beygi, R.; Talkhabi, A.A.; Mehrizi, M.Z.; Marques, E.A.S.; Carbas, R.J.C.; da Silva, L.F.M. A Novel Lap-Butt Joint Design for FSW of Aluminum to Steel in Tee-Configuration: Joining Mechanism, Intermetallic Formation, and Fracture Behavior. Metals 2023, 13, 1027. [Google Scholar] [CrossRef]

- Beygi, R.; Galvão, I.; Akhavan-Safar, A.; Pouraliakbar, H.; Fallah, V.; da Silva, L.F.M. Effect of Alloying Elements on Intermetallic Formation during Friction Stir Welding of Dissimilar Metals: A Critical Review on Aluminum/Steel. Metals 2023, 13, 768. [Google Scholar] [CrossRef]

- Beygi, R.; Carbas, R.J.C.; Barbosa, A.Q.; Marques, E.A.S.; da Silva, L.F.M. Buttering for FSW: Enhancing the Fracture Toughness of Al-Fe Intermetallics through Nanocrystallinity and Suppressing Their Growth. J. Manuf. Process. 2023, 90, 233–241. [Google Scholar] [CrossRef]

- Buffa, G.; Baffari, D.; Di Caro, A.; Fratini, L. Friction Stir Welding of Dissimilar Aluminium–Magnesium Joints: Sheet Mutual Position Effects. Sci. Technol. Weld. Join. 2015, 20, 271–279. [Google Scholar] [CrossRef]

- Ambrosio, D.; Wagner, V.; Dessein, G.; Paris, J.-Y.; Jlaiel, K.; Cahuc, O. Plastic Behavior-Dependent Weldability of Heat-Treatable Aluminum Alloys in Friction Stir Welding. Int. J. Adv. Manuf. Technol. 2021, 117, 635–652. [Google Scholar] [CrossRef]

- Lu, H.; Xu, W.; Wang, H.; Wang, X.-Z. Microstructure Evolution and Its Effect on the Corrosion of Dissimilar Aluminum Alloys Friction Stir Welding Joint. Corros. Sci. 2023, 220, 111249. [Google Scholar] [CrossRef]

- Meng, X.; Huang, Y.; Cao, J.; Shen, J.; dos Santos, J.F. Recent Progress on Control Strategies for Inherent Issues in Friction Stir Welding. Prog. Mater. Sci. 2021, 115, 100706. [Google Scholar] [CrossRef]

- Leng, L.; Zhang, Z.J.; Duan, Q.Q.; Zhang, P.; Zhang, Z.F. Improving the Fatigue Strength of 7075 Alloy through Aging. Mater. Sci. Eng. A 2018, 738, 24–30. [Google Scholar] [CrossRef]

- Liu, H.J.; Chen, Y.C.; Feng, J.C. Effect of heat treatment on tensile properties of friction stir welded joints of 2219-T6 aluminium alloy. Mat. Sci. Technol. 2006, 22, 237–241. [Google Scholar] [CrossRef]

- Karlsen, M.; Frigaard, Ø.; Hjelen, J.; Grong, Ø.; Norum, H. SEM-EBSD Characterisation of the Deformation Microstructure in Friction Stir Welded 2024 T351 Aluminium Alloy. In Materials Science Forum; Trans Tech Publications: Bäch, Switzerland, 2003; pp. 2861–2866. [Google Scholar] [CrossRef]

- Linton, V.M.; Ripley, M.I. Influence of Time on Residual Stresses in Friction Stir Welds in Agehardenable 7xxx Aluminium Alloys. Acta Mater. 2008, 56, 4319–4327. [Google Scholar] [CrossRef]

- Sato, Y.S.; Kokawa, H.; Enomoto, M.; Jogan, S.; Hashimoto, T. Precipitation Sequence in Friction Stir Weld of 6063 Aluminum during Aging. Metall. Mater. Trans. A 1999, 30, 3125–3130. [Google Scholar] [CrossRef]

- Sato, Y.S.; Kokawa, H. Distribution of Tensile Property and Microstructure in Friction Stir Weld of 6063 Aluminum. Metall. Mater. Trans. A 2001, 32, 3023–3031. [Google Scholar] [CrossRef]

- Kalemba, I.; Hamilton, C.; Dymek, S. Natural Aging in Friction Stir Welded 7136-T76 Aluminum Alloy. In Friction Stir Welding and Processing VIII; Springer International Publishing: Cham, Switzerland, 2015; pp. 107–114. [Google Scholar]

- Liu, H.J.; Fujii, H.; Maeda, M.; Nogi, K. Mechanical Properties of Friction Stir Welded Joints of 1050—H24 Aluminium Alloy. Sci. Technol. Weld. Join. 2003, 8, 450–454. [Google Scholar] [CrossRef]

- Threadgill, P.L. Terminology in Friction Stir Welding. Sci. Technol. Weld. Join. 2007, 12, 357–360. [Google Scholar] [CrossRef]

- Abnar, B.; Kazeminezhad, M.; Kokabi, A.H. Effects of Heat Input in Friction Stir Welding on Microstructure and Mechanical Properties of AA3003-H18 Plates. Trans. Nonferrous Met. Soc. China 2015, 25, 2147–2155. [Google Scholar] [CrossRef]

- Beygi, R.; Zarezadeh Mehrizi, M.; Akhavan-Safar, A.; Mohammadi, S.; da Silva, L.F.M. A Parametric Study on the Effect of FSW Parameters and the Tool Geometry on the Tensile Strength of AA2024–AA7075 Joints: Microstructure and Fracture. Lubricants 2023, 11, 59. [Google Scholar] [CrossRef]

- Bussu, G.; Irving, P. The Role of Residual Stress and Heat Affected Zone Properties on Fatigue Crack Propagation in Friction Stir Welded 2024-T351 Aluminium Joints. Int. J. Fatigue 2003, 25, 77–88. [Google Scholar] [CrossRef]

- James, M.N.; Bradley, G.R.; Lombard, H.; Hattingh, D.G. The Relationship between Process Mechanisms and Crack Paths in Friction Stir Welded 5083-H321 and 5383-H321 Aluminium Alloys. Fatigue Fract. Eng. Mater. Struct. 2005, 28, 245–256. [Google Scholar] [CrossRef]

- Frigaard, Ø.; Grong, Ø.; Midling, O.T. A Process Model for Friction Stir Welding of Age Hardening Aluminum Alloys. Metall. Mater. Trans. A 2001, 32, 1189–1200. [Google Scholar] [CrossRef]

- Dimopoulos, A.; Vairis, A.; Vidakis, N.; Petousis, M. On the Friction Stir Welding of Al 7075 Thin Sheets. Metals 2020, 11, 57. [Google Scholar] [CrossRef]

- Lertora, E.; Campanella, D.; Pizzorni, M.; Mandolfino, C.; Buffa, G.; Fratini, L. Comparative Evaluation of the Effect of the Substrate Thickness and Inherent Process Defects on the Static and Fatigue Performance of FSW and Adhesive-Bonded Overlap-Joints in an AA6016 Alloy. J. Manuf. Process. 2021, 64, 785–792. [Google Scholar] [CrossRef]

- Beygi, R.; Marques, E.; da Silva, L.F.M. Computational Concepts in Simulation of Welding Processes; Springer: Cham, Switzerland, 2022. [Google Scholar]

- Imam, M.; Sun, Y.; Fujii, H.; Aoki, Y.; MA, N.; Tsutsumi, S.; Murakawa, H. Friction Stir Welding of Thick Aluminium Welds—Challenges and Perspectives. In Friction Stir Welding and Processing IX; Springer: Cham, Switzerland, 2017; pp. 119–124. [Google Scholar]

- Perrett, J.G.; Martin, J.; Threadgill, P.L.; Ahmed, M.M.Z. Recent Developments in Friction Stir Welding of Thick Section Aluminium Alloys. In Proceedings of the 6th World Congress, Aluminium Two Thousand, Florence, Italy, 13–17 March 2007. [Google Scholar]

- Yuan, K.; Yu, H.; Xu, X.; Zheng, B. Semi-Analytical Model for Material Flow Behavior in Thick Plates via Friction Stir Welding. Int. J. Adv. Manuf. Technol. 2022, 121, 487–501. [Google Scholar] [CrossRef]

- Mallieswaran, K.; Padmanabhan, R. Effect of Sheet Thickness on the FSW Parameters for Dissimilar Aluminium Grades Tailor Welded Blanks. Adv. Mater. Process. Technol. 2021, 7, 150–165. [Google Scholar] [CrossRef]

- Mamgain, A.; Singh, V.; Pratap Singh, A. Influence of Welding Parameters on Mechanical Property during Friction Stir Welded Joint on Aluminium Alloys: A Review. J. Kejuruter. 2023, 35, 13–28. [Google Scholar] [CrossRef]

- Sunnapu, C.; Kolli, M. Tool Shoulder and Pin Geometry’s Effect on Friction Stir Welding: A Study of Literature. Mater. Today Proc. 2021, 39, 1565–1569. [Google Scholar] [CrossRef]

- Maji, P.; Karmakar, R.; Kanti Nath, R.; Paul, P. An Overview on Friction Stir Welding/Processing Tools. Mater. Today Proc. 2022, 58, 57–64. [Google Scholar] [CrossRef]

- Kalemba-Rec, I.; Kopyściański, M.; Miara, D.; Krasnowski, K. Effect of Process Parameters on Mechanical Properties of Friction Stir Welded Dissimilar 7075-T651 and 5083-H111 Aluminum Alloys. Int. J. Adv. Manuf. Technol. 2018, 97, 2767–2779. [Google Scholar] [CrossRef]

- Ghaffarpour, M.; Kazemi, M.; Mohammadi Sefat, M.J.; Aziz, A.; Dehghani, K. Evaluation of Dissimilar Joints Properties of 5083-H12 and 6061-T6 Aluminum Alloys Produced by Tungsten Inert Gas and Friction Stir Welding. Proc. Inst. Mech. Eng. Part L J. Mater. Des. Appl. 2017, 231, 297–308. [Google Scholar] [CrossRef]

- Bijanrostami, K.; Barenji, R.V.; Hashemipour, M. Effect of Traverse and Rotational Speeds on the Tensile Behavior of the Underwater Dissimilar Friction Stir Welded Aluminum Alloys. J. Mater. Eng. Perform. 2017, 26, 909–920. [Google Scholar] [CrossRef]

- Reza-E-Rabby, M.; Tang, W.; Reynolds, A.P. Effect of Tool Pin Features on Process Response Variables during Friction Stir Welding of Dissimilar Aluminum Alloys. Sci. Technol. Weld. Join. 2015, 20, 425–432. [Google Scholar] [CrossRef]

- Muthu Vaidyanathan, R.; Sivaraman, N.; Patel, M.; Woldegioris, M.M.; Atiso, T.A. A Review on the Effects of Shoulder Diameter to Pin Diameter (D/d) Ratio on Friction Stir Welded Aluminium Alloys. Mater. Today Proc. 2021, 45, 4792–4798. [Google Scholar] [CrossRef]

- Chandana, R.; Saraswathamma, K. Impact of Tool Pin Profiles in Friction Stir Welding Process—A Review. Mater. Today Proc. 2023, 76, 602–606. [Google Scholar] [CrossRef]

- Azmal Hussain, M.; Zaman Khan, N.; Noor Siddiquee, A.; Akhtar Khan, Z. Effect of Different Tool Pin Profiles On The Joint Quality Of Friction Stir Welded AA 6063. Mater. Today Proc 2018, 5, 4175–4182. [Google Scholar] [CrossRef]

- Arora, A.; De, A.; DebRoy, T. Toward Optimum Friction Stir Welding Tool Shoulder Diameter. Scr. Mater. 2011, 64, 9–12. [Google Scholar] [CrossRef]

- Ramanjaneyulu, K.; Madhusudhan Reddy, G.; Venugopal Rao, A.; Markandeya, R. Structure-Property Correlation of AA2014 Friction Stir Welds: Role of Tool Pin Profile. J. Mater. Eng. Perform. 2013, 22, 2224–2240. [Google Scholar] [CrossRef]

- Thomas, W.M.; Johnson, K.I.; Wiesner, C.S. Friction Stir Welding—Recent Developments in Tool and Process Technologies. Adv. Eng. Mater. 2003, 5, 485–490. [Google Scholar] [CrossRef]

- Khan, N.Z.; Khan, Z.A.; Siddiquee, A.N. Effect of Shoulder Diameter to Pin Diameter (D/d) Ratio on Tensile Strength of Friction Stir Welded 6063 Aluminium Alloy. Mater. Today Proc. 2015, 2, 1450–1457. [Google Scholar] [CrossRef]

- Vijayavel, P.; Balasubramanian, V.; Sundaram, S. Effect of Shoulder Diameter to Pin Diameter (D/d) Ratio on Tensile Strength and Ductility of Friction Stir Processed LM25AA-5% SiCp Metal Matrix Composites. Mater. Des. 2014, 57, 1–9. [Google Scholar] [CrossRef]

- Sahlot, P.; Jha, K.; Dey, G.K.; Arora, A. Wear-Induced Changes in FSW Tool Pin Profile: Effect of Process Parameters. Metall. Mater. Trans. A 2018, 49, 2139–2150. [Google Scholar] [CrossRef]

- Meilinger, Á.; Török, I. The Importance of Friction Stir Welding Tool. Prod. Process. Syst. 2013, 6, 25–34. [Google Scholar]

- Joshi, S.K.; Gandhi, J.D. Influence of Tool Shoulder Geometry on Friction Stir Welding: A Literature Review. In Proceedings of the 2nd International Conference on Multidisciplinary Research & Practice, Gujarat, India, 24 December 2015; pp. 261–264. [Google Scholar]

- Verma, S.; Kumar, V. Optimization of Friction Stir Welding Parameters of Dissimilar Aluminium Alloys 6061 and 5083 by Using Response Surface Methodology. Proc. Inst. Mech. Eng. C J. Mech. Eng. Sci. 2021, 235, 7009–7020. [Google Scholar] [CrossRef]

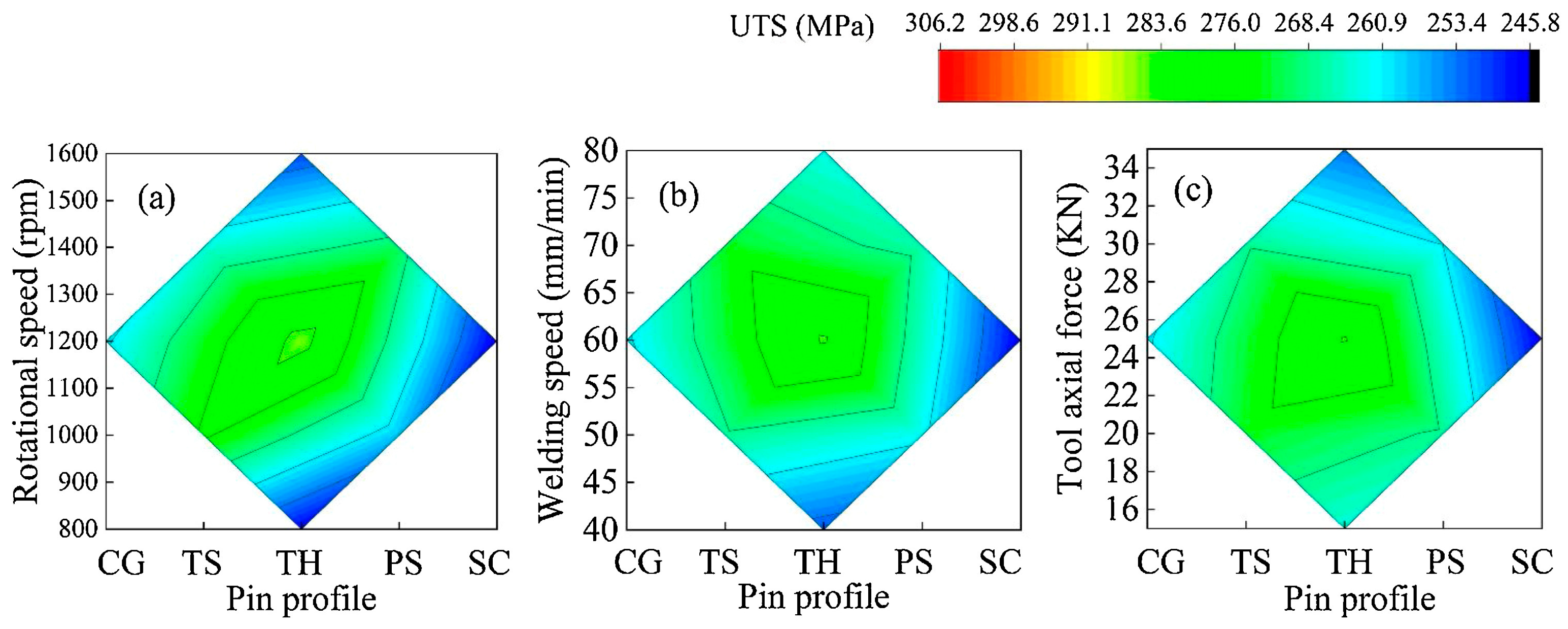

- Palanivel, R.; Laubscher, R.; Vigneshwaran, S.; Dinaharan, I. Prediction and Optimization of the Mechanical Properties of Dissimilar Friction Stir Welding of Aluminum Alloys Using Design of Experiments. Proc. Inst. Mech. Eng. B J. Eng. Manuf. 2018, 232, 1384–1394. [Google Scholar] [CrossRef]

- Azmi, M.H.; Hasnol, M.Z.; Zaharuddin, M.F.A.; Sharif, S.; Rhee, S. Effect of Tool Pin Profile on Friction Stir Welding of Dissimilar Materials AA5083 and AA7075 Aluminium Alloy. Arch. Metall. Mater. 2022, 67, 465–470. [Google Scholar] [CrossRef]

- Hasan, M.M.; Ishak, M.; Rejab, M.R.M. Effect of Pin Tool Flute Radius on the Material Flow and Tensile Properties of Dissimilar Friction Stir Welded Aluminum Alloys. Int. J. Adv. Manuf. Technol. 2018, 98, 2747–2758. [Google Scholar] [CrossRef]

- Ilangovan, M.; Rajendra Boopathy, S.; Balasubramanian, V. Effect of Tool Pin Profile on Microstructure and Tensile Properties of Friction Stir Welded Dissimilar AA 6061–AA 5086 Aluminium Alloy Joints. Def. Technol. 2015, 11, 174–184. [Google Scholar] [CrossRef]

- Balamurugan, S.; Jayakumar, K.; Anbarasan, B.; Rajesh, M. Effect of Tool Pin Shapes on Microstructure and Mechanical Behaviour of Friction Stir Welding of Dissimilar Aluminium Alloys. Mater. Today Proc. 2023, 72, 2181–2185. [Google Scholar] [CrossRef]

- Sambasivam, S.; Gupta, N.; Saeed jassim, A.; Singh, D.P.; Kumar, S.; Mohan Giri, J.; Gupta, M. A Review Paper of FSW on Dissimilar Materials Using Aluminum. Mater. Today Proc. 2023, in press. [Google Scholar] [CrossRef]

- Kumar, K.K.; Kumar, A.; Sundar, S. Investigation of Microstructure Characteristics and Work Hardening Behaviour of Water-Cooled FSW Dissimilar Aluminium Alloys. Mater. Today Commun. 2023, 35, 105857. [Google Scholar] [CrossRef]

- Kryukov, I.; Schüddekopf, S.; Böhm, S.; Mund, M.; Kreling, S.; Dilger, K. Non-Destructive Online-Testing Method for Friction Stir Welding Using Infrared Thermography. In Proceedings of the 19th World Conference on Non-Destructive Testing, Munich, Germany, 13–17 June 2016. [Google Scholar]

- Shine, K.; Jayakumar, K. Effect of Tool Pin Profile on the Mechanical and Microstructural Properties of Dissimilar Friction Stir Welded AA5083-H111 and AA6061-T6 Aluminium Alloys. J. Chin. Inst. Eng. 2022, 45, 227–236. [Google Scholar] [CrossRef]

- Stephen Leon, J.; Essadiqi, E.; Lakshmanan, T.; Ravi, R.; Selvaraj, M. Numerical Modeling of Thermal Field during Friction Stir Welding Using Tool with Polygonal Pin Profile. J. Phys. Conf. Ser. 2021, 2054, 012006. [Google Scholar] [CrossRef]

- Tiwan; Ilman, M.N.; Kusmono; Sehono. Microstructure and Mechanical Performance of Dissimilar Friction Stir Spot Welded AA2024-O/AA6061-T6 Sheets: Effects of Tool Rotation Speed and Pin Geometry. Int. J. Lightweight Mater. Manuf. 2023, 6, 1–14. [Google Scholar] [CrossRef]

- Mehta, K.P.; Badheka, V.J. Effects of Tool Pin Design on Formation of Defects in Dissimilar Friction Stir Welding. Procedia Technol. 2016, 23, 513–518. [Google Scholar] [CrossRef]

- Palani, K.; Elanchezhian, C.; Vijaya Ramnath, B.; Bhaskar, G.B.; Naveen, E. Effect of Pin Profile and Rotational Speed on Microstructure and Tensile Strength of Dissimilar AA8011, AA01-T6 Friction Stir Welded Aluminum Alloys. Mater. Today Proc. 2018, 5, 24515–24524. [Google Scholar] [CrossRef]

- Raturi, M.; Garg, A.; Bhattacharya, A. Joint Strength and Failure Studies of Dissimilar AA6061-AA7075 Friction Stir Welds: Effects of Tool Pin, Process Parameters and Preheating. Eng. Fail. Anal. 2019, 96, 570–588. [Google Scholar] [CrossRef]

- Raturi, M.; Bhattacharya, A. Appraising Tool Wear during Secondary Heating Assisted Dissimilar Friction Stir Welding between 6061 and 7075 Aluminium Alloys. Mater. Trans. 2023, 64, 485–491. [Google Scholar] [CrossRef]

- Mehta, M.; Reddy, G.M.; Rao, A.V.; De, A. Numerical Modeling of Friction Stir Welding Using the Tools with Polygonal Pins. Def. Technol. 2015, 11, 229–236. [Google Scholar] [CrossRef]

- Yuvaraj, K.P.; Ashoka Varthanan, P.; Haribabu, L.; Madhubalan, R.; Boopathiraja, K.P. Optimization of FSW Tool Parameters for Joining Dissimilar AA7075-T651 and AA6061 Aluminium Alloys Using Taguchi Technique. Mater. Today Proc. 2021, 45, 919–925. [Google Scholar] [CrossRef]

- Krishna, M.; Udaiyakumar, K.C.; Mohan Kumar, D.K.; Mohammed Ali, H. Analysis on Effect of Using Different Tool Pin Profile and Mechanical Properties by Friction Stir Welding on Dissimilar Aluminium Alloys Al6061 and Al7075. IOP Conf. Ser. Mater. Sci. Eng. 2018, 402, 012099. [Google Scholar] [CrossRef]

- El-Hafez, H.A.; El-Megharbel, A. Friction Stir Welding of Dissimilar Aluminum Alloys. World J. Eng. Technol. 2018, 6, 408–419. [Google Scholar] [CrossRef]

- Abd El-Hafez, H. Mechanical Properties and Welding Power of Friction Stirred AA2024-T35 Joints. J. Mater. Eng. Perform. 2011, 20, 839–845. [Google Scholar] [CrossRef]

- Kumar, N.; Monga, I.; Kumar, M. An Experimental Investigation to Find out the Effect of Different Pin Profile Tools on AA 6061 T6 and AA 2014 T4 with Friction Stir Welding. Int. J. Technol. Res. Eng. 2015, 2, 1622–1625. [Google Scholar]

- Battina, N.M.; Vanthala, V.S.P.; Chirala, H.K. Influence of Tool Pin Profile on Mechanical and Metallurgical Behavior of Friction Stir Welded AA6061-T6 and AA2017-T6 Tailored Blanks. Eng. Res. Express 2021, 3, 035026. [Google Scholar] [CrossRef]

- Jayaprakash, S.; Siva Chandran, S.; Sathish, T.; Gugulothu, B.; Ramesh, R.; Sudhakar, M.; Subbiah, R. Effect of Tool Profile Influence in Dissimilar Friction Stir Welding of Aluminium Alloys (AA5083 and AA7068). Adv. Mater. Sci. Eng. 2021, 2021, 7387296. [Google Scholar] [CrossRef]

- Meyghani, B.; Awang, M. The Influence of the Tool Tilt Angle on the Heat Generation and the Material Behavior in Friction Stir Welding (FSW). Metals 2022, 12, 1837. [Google Scholar] [CrossRef]

- Dialami, N.; Cervera, M.; Chiumenti, M. Effect of the Tool Tilt Angle on the Heat Generation and the Material Flow in Friction Stir Welding. Metals 2018, 9, 28. [Google Scholar] [CrossRef]

- Khan, N.Z.; Siddiquee, A.N.; Khan, Z.A.; Shihab, S.K. Investigations on Tunneling and Kissing Bond Defects in FSW Joints for Dissimilar Aluminum Alloys. J. Alloys Compd. 2015, 648, 360–367. [Google Scholar] [CrossRef]

- Di Bella, G.; Alderucci, T.; Favaloro, F.; Borsellino, C. Effect of Tool Tilt Angle on Mechanical Resistance of AA6082/AA5083 Friction Stir Welded Joints for Marine Applications. In Proceedings of the 16th CIRP Conference on Intelligent Computation in Manufacturing Engineering, CIRP ICME ’22, Naples, Italy, 13–15 July 2022. [Google Scholar]

- Kunnathur Periyasamy, Y.; Perumal, A.V.; Kunnathur Periyasamy, B. Influence of Tool Shoulder Concave Angle and Pin Profile on Mechanical Properties and Microstructural Behaviour of Friction Stir Welded AA7075-T651 and AA6061 Dissimilar Joint. Trans. Indian Inst. Met. 2019, 72, 1087–1109. [Google Scholar] [CrossRef]

- Fuller, C.B. Friction Stir Tooling: Tool Materials and Designs. In Friction Stir Welding and Processing; Mishra, R.S., Mahoney, M.W., Eds.; Springer: Cham, Switzerland, 2007. [Google Scholar]

- Mishra, R.S.; Ma, Z.Y. Friction Stir Welding and Processing. Mater. Sci. Eng. R Rep. 2005, 50, 1–78. [Google Scholar] [CrossRef]

- Prabha, K.A.; Putha, P.K.; Prasad, B.S. Effect of Tool Rotational Speed on Mechanical Properties of Aluminium Alloy 5083 Weldments in Friction Stir Welding. Mater. Today Proc. 2018, 5, 18535–18543. [Google Scholar] [CrossRef]

- Varunraj, S.; Ruban, M. Investigation of the Microstructure and Mechanical Properties of AA6063 and AA7075 Dissimilar Aluminium Alloys by Friction Stir Welding Process. Mater. Today Proc. 2022, 68, 1654–1657. [Google Scholar] [CrossRef]

- Mastanaiah, P.; Sharma, A.; Reddy, G.M. Dissimilar Friction Stir Welds in AA2219-AA5083 Aluminium Alloys: Effect of Process Parameters on Material Inter-Mixing, Defect Formation, and Mechanical Properties. Trans. Indian Inst. Met. 2016, 69, 1397–1415. [Google Scholar] [CrossRef]

- Kasman, Ş.; Yenier, Z. Analyzing Dissimilar Friction Stir Welding of AA5754/AA7075. Int. J. Adv. Manuf. Technol. 2014, 70, 145–156. [Google Scholar] [CrossRef]

- Forcellese, A.; Simoncini, M.; Casalino, G. Influence of Process Parameters on the Vertical Forces Generated during Friction Stir Welding of AA6082-T6 and on the Mechanical Properties of the Joints. Metals 2017, 7, 350. [Google Scholar] [CrossRef]

- Amatullah, M.; Jan, M.; Farooq, M.; Zargar, A.S.; Maqbool, A.; Khan, N.Z. Effect of Tool Rotational Speed on the Friction Stir Welded Aluminum Alloys: A Review. Mater. Today Proc. 2022, 62, 245–250. [Google Scholar] [CrossRef]

- Yan, J.; Sutton, M.A.; Reynolds, A.P. Process–Structure–Property Relationships for Nugget and Heat Affected Zone Regions of AA2524–T351 Friction Stir Welds. Sci. Technol. Weld. Join. 2005, 10, 725–736. [Google Scholar] [CrossRef]

- Wang, Y.; Ma, H.; Chai, P.; Zhang, Y. Strength and Fracture Behavior of AA2A14-T6 Aluminum Alloy Friction Stir Welded Joints. Weld. World 2021, 65, 1483–1499. [Google Scholar] [CrossRef]

- Goyal, A.; Garg, R.K. Effect of Tool Rotational and Transverse Speed on Mechanical Properties of Friction Stir Welded AA5086-H32 Aluminium Alloy. Int. J. Microstruct. Mater. Prop. 2017, 12, 79–93. [Google Scholar] [CrossRef]

- Moshwan, R.; Yusof, F.; Hassan, M.A.; Rahmat, S.M. Effect of Tool Rotational Speed on Force Generation, Microstructure and Mechanical Properties of Friction Stir Welded Al–Mg–Cr–Mn (AA 5052-O) Alloy. Mater. Des. 2015, 66, 118–128. [Google Scholar] [CrossRef]

- Li, Y.; Sun, D.; Gong, W. Effect of Tool Rotational Speed on the Microstructure and Mechanical Properties of Bobbin Tool Friction Stir Welded 6082-T6 Aluminum Alloy. Metals 2019, 9, 894. [Google Scholar] [CrossRef]

- Rezaei, H.; Mirbeik, M.H.; Bisadi, H. Effect of Rotational Speeds on Microstructure and Mechanical Properties of Friction Stir-Welded 7075-T6 Aluminium Alloy. Proc. Inst. Mech. Eng. C J. Mech. Eng. Sci. 2011, 225, 1761–1773. [Google Scholar] [CrossRef]

- Laska, A.; Szkodo, M.; Cavaliere, P.; Perrone, A. Influence of the Tool Rotational Speed on Physical and Chemical Properties of Dissimilar Friction-Stir-Welded AA5083/AA6060 Joints. Metals 2022, 12, 1658. [Google Scholar] [CrossRef]

- Ghaffarpour, M.; Kolahgar, S.; Dariani, B.M.; Dehghani, K. Evaluation of Dissimilar Welds of 5083-H12 and 6061-T6 Produced by Friction Stir Welding. Metall. Mater. Trans. A 2013, 44, 3697–3707. [Google Scholar] [CrossRef]

- Peel, M.J.; Steuwer, A.; Withers, P.J.; Dickerson, T.; Shi, Q.; Shercliff, H. Dissimilar Friction Stir Welds in AA5083-AA6082. Part I: Process Parameter Effects on Thermal History and Weld Properties. Metall. Mater. Trans. A 2006, 37, 2183–2193. [Google Scholar] [CrossRef]

- Devaiah, D.; Kishore, K.; Laxminarayana, P. Optimal FSW Process Parameters for Dissimilar Aluminium Alloys (AA5083 and AA6061) Using Taguchi Technique. Mater. Today Proc. 2018, 5, 4607–4614. [Google Scholar] [CrossRef]

- Palanivel, R.; Koshy Mathews, P.; Murugan, N.; Dinaharan, I. Effect of Tool Rotational Speed and Pin Profile on Microstructure and Tensile Strength of Dissimilar Friction Stir Welded AA5083-H111 and AA6351-T6 Aluminum Alloys. Mater. Des. 2012, 40, 7–16. [Google Scholar] [CrossRef]

- Goriparthi, V.; Nallu, R.; Chebolu, R.; Indupuri, S.; Rudrapati, R. Experimental Studies on Mechanical Behavior of TIG and Friction Stir Welded AA5083 -AA7075 Dissimilar Aluminum Alloys. Adv. Mater. Sci. Eng. 2023, 2023, 8622525. [Google Scholar] [CrossRef]

- Devaraju, A.; Jeshrun Shalem, M.; Manichandra, B. Effect of Rotation Speed on Tensile Properties & Microhardness of Dissimilar Al Alloys 6061-T6 to 2024 -T6 Welded via Solid State Joining Technique. Mater. Today Proc. 2019, 18, 3286–3290. [Google Scholar] [CrossRef]

- Das, U.; Toppo, V. Effect of Tool Rotational Speed on Temperature and Impact Strength of Friction Stir Welded Joint of Two Dissimilar Aluminum Alloys. Mater. Today Proc. 2018, 5, 6170–6175. [Google Scholar] [CrossRef]

- Das, U.; Das, R.; Toppo, V. Analysis of Some Mechanical Properties of Friction Stir Welded Joints of AA6101 and AA6351 Aluminum Alloys under T6 Condition. Mater. Today Proc. 2021, 44, 2700–2704. [Google Scholar] [CrossRef]

- Jamshidi Aval, H. Microstructure and Residual Stress Distributions in Friction Stir Welding of Dissimilar Aluminium Alloys. Mater. Des. 2015, 87, 405–413. [Google Scholar] [CrossRef]

- De Giorgi, M.; Scialpi, A.; Panella, F.W.; De Filippis, L.A.C. Effect of Shoulder Geometry on Residual Stress and Fatigue Properties of AA6082 Fsw Joints. J. Mech. Sci. Technol. 2009, 23, 26–35. [Google Scholar] [CrossRef]

- Richards, D.G.; Prangnell, P.B.; Withers, P.J.; Williams, S.W.; Nagy, T.; Morgan, S. Efficacy of Active Cooling for Controlling Residual Stresses in Friction Stir Welds. Sci. Technol. Weld. Join. 2010, 15, 156–165. [Google Scholar] [CrossRef]

- Campanelli, S.; Casalino, G.; Casavola, C.; Moramarco, V. Analysis and Comparison of Friction Stir Welding and Laser Assisted Friction Stir Welding of Aluminum Alloy. Materials 2013, 6, 5923–5941. [Google Scholar] [CrossRef] [PubMed]

- Haribalaji, V.; Boopathi, S.; Mohammed Asif, M. Optimization of Friction Stir Welding Process to Join Dissimilar AA2014 and AA7075 Aluminum Alloys. Mater. Today Proc. 2022, 50, 2227–2234. [Google Scholar] [CrossRef]

- Zuiko, I.S.; Malopheyev, S.; Mironov, S.; Kaibyshev, R. Dissimilar Friction Stir Welding of AA2519 and AA5182. Materials 2022, 15, 8776. [Google Scholar] [CrossRef]

- Tarkono, T.; Tenando, F.; Nafrizal, N.; Sukmana, I. The Effect of Rotational Speed on Friction Stir Welding (FSW) Quality of Dissimilar Aluminum Alloy Series AA 1100 and AA 5052. J. Polimesin 2023, 21, 21–24. [Google Scholar]

- Sivaselvan, S.; Natarajan, M.; Devadasan, S.R.; Sivaram, N.M. Influence of Friction Stir Welding Parameters on the Tribological Behavior of Dissimilar Aluminum Alloy Joint. Ind. Lubr. Tribol. 2023, 75, 197–203. [Google Scholar] [CrossRef]

- Heramo, W.T.; Workneh, H.Z. Optimization of Process Parameters in Friction Stir Welding of Dissimilar Aluminum Alloys (AA6061–T6 and AA5052–H32). Res. Sq. 2022, in press. [Google Scholar] [CrossRef]

- Wang, Z.; Zhu, W.; Zhang, Z.; Wang, B.; Xue, P.; Ni, D.; Liu, F.; Xiao, B.; Ma, Z.; Wang, F.; et al. Dissimilar Friction Stir Welding of 2219-T8 and 2195-T8 Aluminum Alloys: Part I—Microstructure Evolution and Mechanical Properties. J. Mater. Sci. 2023, 58, 9737–9754. [Google Scholar] [CrossRef]

- Ahmed, M.M.Z.; Ataya, S.; El-Sayed Seleman, M.M.; Mahdy, A.M.A.; Alsaleh, N.A.; Ahmed, E. Heat Input and Mechanical Properties Investigation of Friction Stir Welded AA5083/AA5754 and AA5083/AA7020. Metals 2020, 11, 68. [Google Scholar] [CrossRef]

- Palanivel, R.; Koshy Mathews, P.; Dinaharan, I.; Murugan, N. Mechanical and Metallurgical Properties of Dissimilar Friction Stir Welded AA5083-H111 and AA6351-T6 Aluminum Alloys. Trans. Nonferrous Met. Soc. China 2014, 24, 58–65. [Google Scholar] [CrossRef]

- Ghosh, M.; Husain, M.M.; Kumar, K.; Kailas, S.V. Friction Stir-Welded Dissimilar Aluminum Alloys: Microstructure, Mechanical Properties, and Physical State. J. Mater. Eng. Perform. 2013, 22, 3890–3901. [Google Scholar] [CrossRef]

- Devaiah, D.; Kishore, K.; Laxminarayana, P. Effect of Welding Speed on Mechanical Properties of Dissimilar Friction Stir Welded AA5083-H321 and AA6061-T6 Aluminum Alloys. Int. J. Adv. Eng. Res. Sci. 2017, 4, 22–28. [Google Scholar] [CrossRef]

- Jia, H.; Wu, K.; Sun, Y.; Hu, F.; Chen, G. Evaluation of Axial Force, Tool Torque and Weld Quality of Friction Stir Welded Dissimilar 6061/5083 Aluminum Alloys. CIRP J. Manuf. Sci. Technol. 2022, 37, 267–277. [Google Scholar] [CrossRef]

- Anandan, B.; Manikandan, M. Effect of Welding Speeds on the Metallurgical and Mechanical Property Characterization of Friction Stir Welding between Dissimilar Aerospace Grade 7050 T7651-2014A T6 Aluminium Alloys. Mater. Today Commun. 2023, 35, 106246. [Google Scholar] [CrossRef]

- Dimov, N.; Weisz-Patrault, D.; Tanguy, A.; Sapanathan, T.; Benoist, J.; Charkaluk, E.; Simar, A. Strain and Damage Analysis Using High Resolution Digital Image Correlation in the Stir Zone of an AA6061-AA7075 Dissimilar Friction Stir Weld. Mater. Today Commun. 2023, 34, 105359. [Google Scholar] [CrossRef]

- Khan, N.Z.; Bajaj, D.; Siddiquee, A.N.; Khan, Z.A.; Abidi, M.H.; Umer, U.; Alkhalefah, H. Investigation on Effect of Strain Rate and Heat Generation on Traverse Force in FSW of Dissimilar Aerospace Grade Aluminium Alloys. Materials 2019, 12, 1641. [Google Scholar] [CrossRef]

- Ahmed, M.M.Z.; Ataya, S.; El-Sayed Seleman, M.M.; Ammar, H.R.; Ahmed, E. Friction Stir Welding of Similar and Dissimilar AA7075 and AA5083. J. Mater. Process. Technol. 2017, 242, 77–91. [Google Scholar] [CrossRef]

- Alemdar, A.S.A.; Jalal, S.R.; Mulapeer, M.M.S. Influence of Friction Stir Welding Process on the Mechanical Characteristics of the Hybrid Joints AA2198-T8 to AA2024-T3. Adv. Mater. Sci. Eng. 2022, 2022, 7055446. [Google Scholar] [CrossRef]

- Barbini, A.; Carstensen, J.; Dos Santos, J.F. Influence of Alloys Position, Rolling and Welding Directions on Properties of AA2024/AA7050 Dissimilar Butt Weld Obtained by Friction Stir Welding. Metals 2018, 8, 202. [Google Scholar] [CrossRef]

- Cavaliere, P.; De Santis, A.; Panella, F.; Squillace, A. Effect of Welding Parameters on Mechanical and Microstructural Properties of Dissimilar AA6082–AA2024 Joints Produced by Friction Stir Welding. Mater. Des. 2009, 30, 609–616. [Google Scholar] [CrossRef]

- Niu, P.; Li, W.; Yang, C.; Chen, Y.; Chen, D. Low Cycle Fatigue Properties of Friction Stir Welded Dissimilar 2024-to-7075 Aluminum Alloy Joints. Mater. Sci. Eng. A 2022, 832, 142423. [Google Scholar] [CrossRef]

- Cole, E.G.; Fehrenbacher, A.; Duffie, N.A.; Zinn, M.R.; Pfefferkorn, F.E.; Ferrier, N.J. Weld Temperature Effects during Friction Stir Welding of Dissimilar Aluminum Alloys 6061-T6 and 7075-T6. Int. J. Adv. Manuf. Technol. 2014, 71, 643–652. [Google Scholar] [CrossRef]

- Yan, Z.; Liu, X.; Fang, H. Effect of Sheet Configuration on Microstructure and Mechanical Behaviors of Dissimilar Al–Mg–Si/Al–Zn–Mg Aluminum Alloys Friction Stir Welding Joints. J. Mater. Sci. Technol. 2016, 32, 1378–1385. [Google Scholar] [CrossRef]

- Schmale, J.; Fehrenbacher, A.; Shrivastava, A.; Pfefferkorn, F.E. Calibration of Dynamic Tool–Workpiece Interface Temperature Measurement during Friction Stir Welding. Measurement 2016, 88, 331–342. [Google Scholar] [CrossRef]

- Simar, A.; Jonckheere, C.; Deplus, K.; Pardoen, T.; de Meester, B. Comparing Similar and Dissimilar Friction Stir Welds of 2017–6005A Aluminium Alloys. Sci. Technol. Weld. Join. 2010, 15, 254–259. [Google Scholar] [CrossRef]

- Kim, N.-K.; Kim, B.-C.; An, Y.-G.; Jung, B.-H.; Song, S.-W.; Kang, C.-Y. The Effect of Material Arrangement on Mechanical Properties in Friction Stir Welded Dissimilar A5052/A5J32 Aluminum Alloys. Met. Mater. Int. 2009, 15, 671–675. [Google Scholar] [CrossRef]

- Donatus, U.; Thompson, G.E.; Zhou, X.; Wang, J.; Beamish, K. Flow Patterns in Friction Stir Welds of AA5083 and AA6082 Alloys. Mater. Des. 2015, 83, 203–213. [Google Scholar] [CrossRef]

- Zhao, Z.; Liang, H.; Zhao, Y.; Yan, K. Effect of Exchanging Advancing and Retreating Side Materials on Mechanical Properties and Electrochemical Corrosion Resistance of Dissimilar 6013-T4 and 7003 Aluminum Alloys FSW Joints. J. Mater. Eng. Perform. 2018, 27, 1777–1783. [Google Scholar] [CrossRef]

- Park, S.-K.; Hong, S.-T.; Park, J.-H.; Park, K.-Y.; Kwon, Y.-J.; Son, H.-J. Effect of Material Locations on Properties of Friction Stir Welding Joints of Dissimilar Aluminium Alloys. Sci. Technol. Weld. Join. 2010, 15, 331–336. [Google Scholar] [CrossRef]

- Hong, S.-T. Mixing of materials in FSW of dissimilar aluminum alloys. Trans. Korean. Soc. Mech. Eng. A 2009, 33, 108–113. [Google Scholar] [CrossRef]

- Niu, P.L.; Li, W.Y.; Li, N.; Xu, Y.X.; Chen, D.L. Exfoliation Corrosion of Friction Stir Welded Dissimilar 2024-to-7075 Aluminum Alloys. Mater. Charact. 2019, 147, 93–100. [Google Scholar] [CrossRef]

- Sindhuja, M.; Neelakrishnan, S.; Davidson, B.S. Effect of Welding Parameters on Mechanical Properties of Friction Stir Welding of Dissimilar Metals—A Review. IOP Conf. Ser. Mater. Sci. Eng. 2021, 1185, 012019. [Google Scholar] [CrossRef]

- Prasanth, R.S.S.; Hans Raj, K. Determination of Optimal Process Parameters of Friction Stir Welding to Join Dissimilar Aluminum Alloys Using Artificial Bee Colony Algorithm. Trans. Indian Inst. Met. 2018, 71, 453–462. [Google Scholar] [CrossRef]

- Palanivel, R.; Koshy Mathews, P.; Murugan, N. Optimization of Process Parameters to Maximize Ultimate Tensile Strength of Friction Stir Welded Dissimilar Aluminum Alloys Using Response Surface Methodology. J. Cent. South Univ. 2013, 20, 2929–2938. [Google Scholar] [CrossRef]

- Ramamoorthi, R.; Yuvaraj, K.P.; Gokul, C.; Eashwar, S.J.; Arunkumar, N.; Abith Tamil Dheen, S. An Investigation of the Impact of Axial Force on Friction Stir-Welded AA5086/AA6063 on Microstructure and Mechanical Properties Butt Joints. Mater. Today Proc. 2021, 37, 3159–3163. [Google Scholar] [CrossRef]

- de Caetano, G.Q.; Silva, C.C.; Motta, M.F.; Miranda, H.C.; Farias, J.P.; Bergmann, L.A.; dos Santos, J.F. Influence of Rotation Speed and Axial Force on the Friction Stir Welding of AISI 410S Ferritic Stainless Steel. J. Mater. Process. Technol. 2018, 262, 430–436. [Google Scholar] [CrossRef]

- Srinivasan, R.; Ramesh, A.; Athithanambi, A. Effect of Axial Force on Microstructure and Mechanical Properties of Friction Stir Welded Squeeze Cast A413 Aluminium Alloy. Mater. Today Proc. 2018, 5, 13486–13494. [Google Scholar] [CrossRef]

- Venu, B.; BhavyaSwathi, I.; Raju, L.S.; Santhanam, G. A Review on Friction Stir Welding of Various Metals and Its Variables. Mater. Today Proc. 2019, 18, 298–302. [Google Scholar] [CrossRef]

- Elangovan, K.; Balasubramanian, V.; Valliappan, M. Influences of Tool Pin Profile and Axial Force on the Formation of Friction Stir Processing Zone in AA6061 Aluminium Alloy. Int. J. Adv. Manuf. Technol. 2008, 38, 285–295. [Google Scholar] [CrossRef]

- Jayaraman, M.; Sivasubramanian, R.; Balasubramanian, V.; Babu, S. Influences of Process Parameters on Tensile Strength of Friction Stir Welded Cast A319 Aluminium Alloy Joints. Met. Mater. Int. 2009, 15, 313–320. [Google Scholar] [CrossRef]

- Palanivel, R.; Mathews, P.K.; Balakrishnan, M.; Dinaharan, I.; Murugan, N. Effect of Tool Pin Profile and Axial Force on Tensile Behavior in Friction Stir Welding of Dissimilar Aluminum Alloys. Adv. Mater. Res. 2011, 415–417, 1140–1146. [Google Scholar] [CrossRef]

- Peng, C.; Jing, C.; Siyi, Q.; Siqi, Z.; Shoubo, S.; Ting, J.; Zhiqing, Z.; Zhihong, J.; Qing, L. Friction Stir Welding Joints of 2195-T8 Al–Li Alloys: Correlation of Temperature Evolution, Microstructure and Mechanical Properties. Mater. Sci. Eng. A 2021, 823, 141501. [Google Scholar] [CrossRef]

- Xue, F.; He, D.; Zhou, H. Effect of Ultrasonic Vibration in Friction Stir Welding of 2219 Aluminum Alloy: An Effective Model for Predicting Weld Strength. Metals 2022, 12, 1101. [Google Scholar] [CrossRef]

- Dewan, M.W.; Huggett, D.J.; Warren Liao, T.; Wahab, M.A.; Okeil, A.M. Prediction of Tensile Strength of Friction Stir Weld Joints with Adaptive Neuro-Fuzzy Inference System (ANFIS) and Neural Network. Mater. Des. 2016, 92, 288–299. [Google Scholar] [CrossRef]

- Yin, L.; Wang, J.; Hu, H.; Han, S.; Zhang, Y. Prediction of Weld Formation in 5083 Aluminum Alloy by Twin-Wire CMT Welding Based on Deep Learning. Weld. World 2019, 63, 947–955. [Google Scholar] [CrossRef]

- Agelet De Saracibar, C. Challenges to Be Tackled in the Computational Modeling and Numerical Simulation of FSW Processes. Metals 2019, 9, 573. [Google Scholar] [CrossRef]

- Meyghani, B.; Awang, M.; Wu, C.S. Finite Element Modeling of Friction Stir Welding (FSW) on a Complex Curved Plate. J. Adv. Join. Process. 2020, 1, 100007. [Google Scholar] [CrossRef]

- Meyghani, B.; Awang, M.B. Prediction of the Temperature Distribution During Friction Stir Welding (Fsw) with A Complex Curved Welding Seam: Application In The Automotive Industry. MATEC Web Conf. 2018, 225, 01001. [Google Scholar] [CrossRef]

- Luesak, P.; Pitakaso, R.; Sethanan, K.; Golinska-Dawson, P.; Srichok, T.; Chokanat, P. Multi-Objective Modified Differential Evolution Methods for the Optimal Parameters of Aluminum Friction Stir Welding Processes of AA6061-T6 and AA5083-H112. Metals 2023, 13, 252. [Google Scholar] [CrossRef]

- Kalil Rahiman, M.; Santhoshkumar, S.; Mythili, S.; Barkavi, G.E.; Velmurugan, G.; Sundarakannan, R. Experimental Analysis of Friction Stir Welded of Dissimilar Aluminium 6061 and Titanium TC4 Alloys Using Response Surface Methodology (RSM). Mater. Today Proc. 2022, 66, 1016–1022. [Google Scholar] [CrossRef]

- Kavitha, M.; Manickavasagam, V.M.; Sathish, T.; Gugulothu, B.; Sathish Kumar, A.; Karthikeyan, S.; Subbiah, R. Parameters Optimization of Dissimilar Friction Stir Welding for AA7079 and AA8050 through RSM. Adv. Mater. Sci. Eng. 2021, 2021, 9723699. [Google Scholar] [CrossRef]

- Kumar, P.; Kadiyan, S.; Kumar, R. Optimization of Process Parameters of Friction Stir Welded Joint of Dissimilar Aluminum Alloy by Response Surface Methodology. Int. J. Res. Eng. Innov. 2022, 6, 236–244. [Google Scholar]

- Jain, S.; Sharma, N.; Gupta, R. Dissimilar Alloys (AA6082/AA5083) Joining by FSW and Parametric Optimization Using Taguchi, Grey Relational and Weight Method. Eng. Solid Mech. 2018, 6, 51–66. [Google Scholar] [CrossRef]

- Koilraj, M.; Sundareswaran, V.; Vijayan, S.; Koteswara Rao, S.R. Friction Stir Welding of Dissimilar Aluminum Alloys AA2219 to AA5083—Optimization of Process Parameters Using Taguchi Technique. Mater. Des. 2012, 42, 1–7. [Google Scholar] [CrossRef]

- Abd Elnabi, M.M.; El Mokadem, A.; Osman, T. Optimization of Process Parameters for Friction Stir Welding of Dissimilar Aluminum Alloys Using Different Taguchi Arrays. Int. J. Adv. Manuf. Technol. 2022, 121, 3935–3964. [Google Scholar] [CrossRef]

- Asmare, A.; Al-Sabur, R.; Messele, E. Experimental Investigation of Friction Stir Welding on 6061-T6 Aluminum Alloy Using Taguchi-Based GRA. Metals 2020, 10, 1480. [Google Scholar] [CrossRef]

- Prasad, M.V.R.D.; kumar Namala, K. Process Parameters Optimization in Friction Stir Welding by ANOVA. Mater. Today Proc. 2018, 5, 4824–4831. [Google Scholar] [CrossRef]

- Raja, R.; Parthiban, A.; Nandha Gopan, S.; Degefa, D. Investigate the Process Parameter on the Friction Stir Welding of Dissimilar Aluminium Alloys. Adv. Mater. Sci. Eng. 2022, 2022, 4980291. [Google Scholar] [CrossRef]

- Salloomi, K.N.; Shammari, A.Z.M.; Ahmed, S.H. Evaluation of FSW Process Parameters of Dissimilar Aluminium Alloys. Innov. Syst. Des. Eng. 2016, 7, 55–69. [Google Scholar]

- Shojaeefard, M.H.; Khalkhali, A.; Akbari, M.; Asadi, P. Investigation of Friction Stir Welding Tool Parameters Using FEM and Neural Network. Proc. Inst. Mech. Eng. Part L J. Mater. Des. Appl. 2015, 229, 209–217. [Google Scholar] [CrossRef]

- Yu, F.; Zhao, Y.; Lin, Z.; Miao, Y.; Zhao, F.; Xie, Y. Prediction of Mechanical Properties and Optimization of Friction Stir Welded 2195 Aluminum Alloy Based on BP Neural Network. Metals 2023, 13, 267. [Google Scholar] [CrossRef]

- Elatharasan, G.; Kumar, V.S.S. Modelling and Optimization of Friction Stir Welding Parameters for Dissimilar Aluminium Alloys Using RSM. Procedia Eng. 2012, 38, 3477–3481. [Google Scholar] [CrossRef]

- Nait Salah, A.; Mehdi, H.; Mehmood, A.; Wahab Hashmi, A.; Malla, C.; Kumar, R. Optimization of Process Parameters of Friction Stir Welded Joints of Dissimilar Aluminum Alloys AA3003 and AA6061 by RSM. Mater. Today Proc. 2022, 56, 1675–1683. [Google Scholar] [CrossRef]

- Suhin, S.; Robin Divahar, S.; Edwin Raja Dhas, J.; Anton Savio Lewise, K.; Satyanarayana Gupta, M. Optimizing FSW Process Parameters Using RSM and Regression Analysis for Similar and Dissimilar Aluminium Materials. Mater. Today Proc. 2022, 64, 368–373. [Google Scholar] [CrossRef]

- Harachai, K.; Prasomthong, S. Investigation of the Optimal Parameters for Butt Joints in a Friction Stir Welding (FSW) Process with Dissimilar Aluminium Alloys. Mater. Res. Express 2023, 10, 026514. [Google Scholar] [CrossRef]

- Umamaheswarrao, P. Desirability Function Analysis Based Multi Response Optimization of Process Parameters during Friction Stir Welding of AA6061-AA7075. INCAS Bull. 2023, 15, 121–131. [Google Scholar] [CrossRef]

- Singaravel, B.; Chakradhar, B.; Soundar Rajan, D.; Kiran Kumar, A. Optimization of Friction Stir Welding Process Parameters Using MCDM Method. Mater. Today Proc. 2023, 76, 597–601. [Google Scholar] [CrossRef]

- Umamaheswarrao, P. Multi-Response Optimization of Process Parameters during Friction Stir Welding of AA2014-AA7075 Using TOPSIS Approach. INCAS Bull. 2023, 15, 107–117. [Google Scholar] [CrossRef]

- Akbari, M.; Asadi, P.; Besharati Givi, M.K.; Khodabandehlouie, G. Artificial Neural Network and Optimization. In Advances in Friction-Stir Welding and Processing; Elsevier: Amsterdam, The Netherlands, 2014; pp. 543–599. [Google Scholar]

- Arya, H.K.; Jaiswal, D. Study on Friction Stir Welding of Aluminium Plates Using an Artificial Neural Network. Turk. J. Comput. Math. Educ. 2021, 12, 5828–5835. [Google Scholar]

- Essa, A.R.S.; Ahmed, M.M.Z.; Aboud, A.R.K.; Alyamani, R.; Sebaey, T.A. Prediction of Tool Eccentricity Effects on the Mechanical Properties of Friction Stir Welded AA5754-H24 Aluminum Alloy Using ANN Model. Materials 2023, 16, 3777. [Google Scholar] [CrossRef] [PubMed]

- Okuyucu, H.; Kurt, A.; Arcaklioglu, E. Artificial Neural Network Application to the Friction Stir Welding of Aluminum Plates. Mater. Des. 2007, 28, 78–84. [Google Scholar] [CrossRef]

- Gupta, S.K.; Pandey, K.; Kumar, R. Artificial Intelligence-Based Modelling and Multi-Objective Optimization of Friction Stir Welding of Dissimilar AA5083-O and AA6063-T6 Aluminium Alloys. Proc. Inst. Mech. Eng. Part L J. Mater. Des. Appl. 2018, 232, 333–342. [Google Scholar] [CrossRef]

- Shojaeefard, M.H.; Behnagh, R.A.; Akbari, M.; Givi, M.K.B.; Farhani, F. Modelling and Pareto Optimization of Mechanical Properties of Friction Stir Welded AA7075/AA5083 Butt Joints Using Neural Network and Particle Swarm Algorithm. Mater. Des. 2013, 44, 190–198. [Google Scholar] [CrossRef]

- Kraiklang, R.; Chueadee, C.; Jirasirilerd, G.; Sirirak, W.; Gonwirat, S. A Multiple Response Prediction Model for Dissimilar AA-5083 and AA-6061 Friction Stir Welding Using a Combination of AMIS and Machine Learning. Computation 2023, 11, 100. [Google Scholar] [CrossRef]

- Elsheikh, A.H. Applications of Machine Learning in Friction Stir Welding: Prediction of Joint Properties, Real-Time Control and Tool Failure Diagnosis. Eng. Appl. Artif. Intell. 2023, 121, 105961. [Google Scholar] [CrossRef]

- Insua, P.; Nakkiew, W.; Wisittipanich, W. Post Weld Heat Treatment Optimization of Dissimilar Friction Stir Welded AA2024-T3 and AA7075-T651 Using Machine Learning and Metaheuristics. Materials 2023, 16, 2081. [Google Scholar] [CrossRef]

- Moradi, M.M.; Jamshidi Aval, H.; Jamaati, R. Microstructure and Mechanical Properties in Nano and Microscale SiC-Included Dissimilar Friction Stir Welding of AA6061-AA2024. Mater. Sci. Technol. 2018, 34, 388–401. [Google Scholar] [CrossRef]

- Verma, S.; Msomi, V.; Mabuwa, S.; Merdji, A.; Misra, J.P.; Batra, U.; Sharma, S. Machine Learning Application for Evaluating the Friction Stir Processing Behavior of Dissimilar Aluminium Alloys Joint. Proc. Inst. Mech. Eng. Part L J. Mater. Des. Appl. 2021, 236, 633–646. [Google Scholar] [CrossRef]

- Chiaranai, S.; Pitakaso, R.; Sethanan, K.; Kosacka-Olejnik, M.; Srichok, T.; Chokanat, P. Ensemble Deep Learning Ultimate Tensile Strength Classification Model for Weld Seam of Asymmetric Friction Stir Welding. Processes 2023, 11, 434. [Google Scholar] [CrossRef]

- Abd Elaziz, M.; Shehabeldeen, T.A.; Elsheikh, A.H.; Zhou, J.; Ewees, A.A.; Al-qaness, M.A.A. Utilization of Random Vector Functional Link Integrated with Marine Predators Algorithm for Tensile Behavior Prediction of Dissimilar Friction Stir Welded Aluminum Alloy Joints. J. Mater. Res. Technol. 2020, 9, 11370–11381. [Google Scholar] [CrossRef]

- Gupta, S.K.; Pandey, K.N.; Kumar, R. Experimental Modelling and Genetic Algorithm-Based Optimisation of Friction Stir Welding Process Parameters for Joining of Dissimilar AA5083-O and AA6063-T6 Aluminium Alloys. Int. J. Mater. Prod. Technol. 2018, 56, 253–270. [Google Scholar] [CrossRef]

- Yunus, M.; Alsoufi, M.S. Mathematical Modelling of a Friction Stir Welding Process to Predict the Joint Strength of Two Dissimilar Aluminium Alloys Using Experimental Data and Genetic Programming. Model. Simul. Eng. 2018, 2018, 4183816. [Google Scholar] [CrossRef]

- Hossfeld, M. Modeling Friction Stir Welding: On Prediction and Numerical Tool Development. Metals 2022, 12, 1432. [Google Scholar] [CrossRef]

- Sen, S.; Murugesan, J. Experimental and Numerical Analysis of Friction Stir Welding: A Review. Eng. Res. Express 2022, 4, 032004. [Google Scholar] [CrossRef]

- Eivani, A.R.; Vafaeenezhad, H.; Jafarian, H.R.; Zhou, J. A Novel Approach to Determine Residual Stress Field during FSW of AZ91 Mg Alloy Using Combined Smoothed Particle Hydrodynamics/Neuro-Fuzzy Computations and Ultrasonic Testing. J. Magnes. Alloys 2021, 9, 1304–1328. [Google Scholar] [CrossRef]

- Malik, V.; Sanjeev, N.K.; Bajakke, P. Review on Modelling of Friction Stir Welding Using Finite Element Approach and Significance of Formulations in Simulation. Int. J. Manuf. Res. 2020, 15, 107–135. [Google Scholar] [CrossRef]

- Das, D.; Bag, S.; Pal, S. Probing Finite Element Modelling of Defects in Friction Stir Welding by Tailoring Mass Scaling Factor. Mater. Today Commun. 2023, 35, 105646. [Google Scholar] [CrossRef]

- Saha, R.; Biswas, P. Thermomechanical Analysis of Induction Assisted Friction Stir Welding of Inconel 718 Alloy: A Finite Element Approach. Int. J. Press. Vessel. Pip. 2022, 199, 104731. [Google Scholar] [CrossRef]

- Meyghani, B.; Awang, M.; Emamian, S.S.; Mohd Nor, M.K.; Pedapati, S.R. A Comparison of Different Finite Element Methods in the Thermal Analysis of Friction Stir Welding (FSW). Metals 2017, 7, 450. [Google Scholar] [CrossRef]

- Kubit, A.; Trzepiecinski, T. A Fully Coupled Thermo-Mechanical Numerical Modelling of the Refill Friction Stir Spot Welding Process in Alclad 7075-T6 Aluminium Alloy Sheets. Arch. Civ. Mech. Eng. 2020, 20, 117. [Google Scholar] [CrossRef]

- Ambrosio, D.; Tongne, A.; Wagner, V.; Dessein, G.; Cahuc, O. A new damage evolution criterion for the coupled Eulerian-Lagrangian approach: Application to three-dimensional numerical simulation of segmented chip formation mechanisms in orthogonal cutting. J. Manuf. Process. 2022, 73, 149–163. [Google Scholar] [CrossRef]

- Das, D.; Bag, S.; Pal, S.; Sharma, A. Material Defects in Friction Stir Welding through Thermo–Mechanical Simulation: Dissimilar Materials with Tool Wear Consideration. Materials 2022, 16, 301. [Google Scholar] [CrossRef] [PubMed]

- Ambrosio, D.; Tongne, A.; Wagner, V.; Dessein, G.; Cahuc, O. Towards Material Flow Prediction in Friction Stir Welding Accounting for Mechanisms Governing Chip Formation in Orthogonal Cutting. J. Manuf. Process. 2023, 85, 450–465. [Google Scholar] [CrossRef]

- Shash, A.Y.; El-Moayed, M.H.; Abd Rabou, M.; El-Sherbiny, M.G. A Coupled Experimental and Numerical Analysis of AA6063 Friction Stir Welding. Proc. Inst. Mech. Eng. C J. Mech. Eng. Sci. 2022, 236, 8392–8400. [Google Scholar] [CrossRef]

- Meyghani, B.; Awang, M.; Emamian, S. A Comparative Study of Finite Element Analysis for Friction Stir Welding Application. ARPN J. Eng. Appl. Sci. 2016, 11, 12984–12989. [Google Scholar]

- Buffa, G.; Hua, J.; Shivpuri, R.; Fratini, L. Design of the Friction Stir Welding Tool Using the Continuum Based FEM Model. Mater. Sci. Eng. A 2006, 419, 381–388. [Google Scholar] [CrossRef]

- Sibalic, N.; Vukcevic, M. Numerical Simulation for FSW Process at Welding Aluminium Alloy AA6082-T6. Metals 2019, 9, 747. [Google Scholar] [CrossRef]

- Zahari, S.N.; Mohd Sani, M.S.; Ishak, M. Finite Element Modelling and Updating of Friction Stir Welding (FSW) Joint for Vibration Analysis. MATEC Web Conf. 2017, 90, 01021. [Google Scholar] [CrossRef]

- Sivasankara Raju, R.; Jagadish; Rao, C.; Kumar Aadapa, S.; Yanda, S. Predication of Temperature Distribution and Strain during FSW of Dissimilar Aluminum Alloys Using Deform 3D. Mater. Today Proc. 2022, 59, 1760–1767. [Google Scholar] [CrossRef]

- Salloomi, K.N.; Al-Sumaidae, S. Coupled Eulerian–Lagrangian Prediction of Thermal and Residual Stress Environments in Dissimilar Friction Stir Welding of Aluminum Alloys. J. Adv. Join. Process. 2021, 3, 100052. [Google Scholar] [CrossRef]

- Al-Badour, F.; Merah, N.; Shuaib, A.; Bazoune, A. Thermo-Mechanical Finite Element Model of Friction Stir Welding of Dissimilar Alloys. Int. J. Adv. Manuf. Technol. 2014, 72, 607–617. [Google Scholar] [CrossRef]

- Karash, E.T.; Ali, H.M.; Hamid, A.F. Mathematical Model for the Temperature Distribution on The Surface of Two Aluminum Alloys Welded by Friction Stir Welding. Ann. “Dunarea de Jos” Univ. Galati Fascicle XII Weld. Equip. Technol. 2022, 33, 47–58. [Google Scholar] [CrossRef]

- Nagathil, R.; Hou, G.; Demuren, A.; Williamson, K. Modeling Experience on Friction Stir Welding Using FLUENT; SAE International: Warrendale, PA, USA, 2005. [Google Scholar]

- Wang, X.; Xiao, Y.; Shi, L.; Zhai, M.; Wu, C.; Chen, G. Revealing the Mechanism of Tool Tilting on Suppressing the Formation of Void Defects in Friction Stir Welding. J. Mater. Res. Technol. 2023, 25, 38–54. [Google Scholar] [CrossRef]

- Ji, H.; Deng, Y.L.; Xu, H.Y.; Yin, X.; Zhang, T.; Wang, W.Q.; Dong, H.G.; Wang, T.Y.; Wu, J.P. Numerical Modeling for the Mechanism of Shoulder and Pin Features Affecting Thermal and Material Flow Behavior in Friction Stir Welding. J. Mater. Res. Technol. 2022, 21, 662–678. [Google Scholar] [CrossRef]

- Chen, J.; Wang, X.; Shi, L.; Wu, C.; Liu, H.; Chen, G. Numerical Simulation of Weld Formation in Friction Stir Welding Based on Non-Uniform Tool-Workpiece Interaction: An Effect of Tool Pin Size. J. Manuf. Process. 2023, 86, 85–97. [Google Scholar] [CrossRef]

- Tang, J.; Shen, Y. Numerical Simulation and Experimental Investigation of Friction Stir Lap Welding between Aluminum Alloys AA2024 and AA7075. J. Alloys Compd. 2016, 666, 493–500. [Google Scholar] [CrossRef]

- Padmanaban, R.; Kishore, V.R.; Balusamy, V. Numerical Simulation of Temperature Distribution and Material Flow During Friction Stir Welding of Dissimilar Aluminum Alloys. Procedia Eng. 2014, 97, 854–863. [Google Scholar] [CrossRef]

| Outer Surface | End Surface | ||

|---|---|---|---|

| Cylindrical | Smooth cylinder | Circle |  |

| Fluted cylinder | Three sided |  | |

| Four sided |  | ||

| Cylinder with flats | Triangle |  | |

| Square |  | ||

| Hexagonal |  | ||

| Threaded cylinder | Circle |  | |

| Threaded and fluted cylinder | Three sided |  | |

| Four sided |  | ||

| Threaded and flat cylinder | Triangle |  | |

| Square |  | ||

| Hexagonal |  | ||

| Tapered | Smooth | Circle |  |

| Fluted | Three sided |  | |

| Four sided |  | ||

| Taper with flats | Triangle |  | |

| Square |  | ||

| Hexagonal |  | ||

| Threaded | Circle |  | |

| Threaded with fluted | Three sided |  | |

| Four sided |  | ||

| Threaded with flat | Triangle |  | |

| Square |  | ||

| Hexagonal |  | ||

| Feature | Scheme |

|---|---|

| Scrolled |  |

| Knurled |  |

| Ridged |  |

| Grooved |  |

| Concentric Circles |  |

| Ref. | Sheet Material | Sheet Position AS/RS | Pin Profile | Tilt Angle (°) | Rotational Speed (rpm) | Welding Speed (mm/min) | Axial Force (kN) | Main Results |

|---|---|---|---|---|---|---|---|---|

| [110] | 2017-T6 6061-T6 | - | Straight hexagonal Straight pentagonal Straight cylindrical Straight square Taper square | 0 | 1600 | 32 | - | Straight square tool pin profile produces better metallurgical and mechanical properties. The properties are inferior to those of other pin profiles, but it is preferred because the related joint is defect-free. |

| [107] | 2024-T365 5083-H111 | - | Square Triangular Stepped | - | 900 | 16 | - | Square pin produces a good metal flow and, consequently, a good stirring. |

| [99] | 2024-O 6061-T6 | - | Cylindrical Stepped | - | 900 1400 1800 | - | - | Cylindrical profile—at 1400 rpm—promotes the material flow. |

| [91] | 2024-T351 7075-T651 | - | Flute radii: 0, 2, 3, 6, ∞ mm | - | 900 | 150 | - | Radius equal to that of the pin leads to the strongest joint. |

| [93] | 5052-H32 6061-T6 | AS RS | Taper cylinder Threaded cylinder | - | 900 | 60 | - | Taper pin profile leads to a fine grain microstructure. |

| [97] | 5083-H111 AA6061-T6 | - | Straight square Threaded cylinder Tapered cylinder | - | - | - | - | Straight square shows better mechanical properties. |

| [88] | 5083-O 6061-T6 | - | Square cylinder Straight cylinder Tapered cylinder | 1.11 | 1568 | 39.53 | - | Straight cylinder tool guarantees higher weld quality. |

| [89] | 5083 6351 | - | Partial impeller Full impeller Flat grove | - | - | - | - | Full impeller generates enhanced material flow. |

| [111] | 5083 7068 | - | Straight cylindrical Taper cylindrical Triangular tool | - | 800 1000 1200 1400 | 30 40 50 60 | 3 4 5 6 | The triangular tool offers the maximum tensile strength and microhardness of the investigation with the combination 1200 rpm/30 mm/min/3 kN. |

| [73] | 5083-H111 7075-T651 | RS AS | Triflute Tapered with a thread | - | 140 280 355 450 560 900 | 140 | 26.4 | Triflute pin—at 280 rpm—guarantees the higher tensile properties and a defect-free joint with a wider stir zone. |

| [90] | 5083 7075 | - | Threaded straight cylindrical, Tapered cylindrical, Threaded tapered cylindrical | - | 600 700 800 | 40 | - | The highest tensile strength and the defect-free joint is obtained by using the threaded tapered cylindrical pin tool at a rotational speed of 800 rpm. |

| [92] | 5086-O 6061-T6 | RS AS | Straight cylindrical Threaded cylindrical Tapered cylindrical | 1 | 1100 | 22 | 12 | Threaded pin profile guarantees defect-free joints, finer and uniformly distributed precipitates formation, circular onion rings and smaller grain. |

| [102] | 6061-T6 7075-T651 | AS RS | Cylindrical Cylindrical tapered Cylindrical threaded Trapezoidal tapered | 660 900 1200 1700 | 36 63 98 132 | Cylindrical threaded with three flat faces tool pin and cylindrical grooved tool pin—at intermediate tool rotation and feed rate—lead to good tensile and flexural strength. | ||

| [105] | AA6061 7075-T651 | - | Square Cylindrical Triangle | 2 3 4 | - | - | - | Square pin—with a 2° tilt angle—exhibits fine grains along the stir zone due to adequate heat generation. Triangular pin reveals granular grain structure. |

| [106] | 6061 7075 | RS/AS AS/RS | Straight cylinder Straight square Tapered hexagon | - | 950 | 60 | - | Straight cylinder provides a smooth and perfect welding. |

| Ref. | Sheet Material | Sheet Position AS/RS | Pin Profile | Tilt Angle (°) | Rotational Speed (rpm) | Welding Speed (mm/min) | Axial Force (kN) | Main Results |

|---|---|---|---|---|---|---|---|---|

| [146] | 1100 5052 | - | - | - | 1750 2230 3500 | 22 | - | A speed of 3500 rpm induces smooth surface and stable welding. |

| [144] | 2014 7075 | AS RS | Straight cylinder Tapered Threaded | 0 1 2 | 1000 1200 1400 | 30 45 60 | 3 6 9 | Rotational speed and axial force are significant factors in tensile strength and microhardness. The best combination for tensile properties is 1000 rpm/45 mm/min/6 kN/2°. The best combination for hardness properties is 1000 rpm/60 mm/min/6 kN/2°. These optimal parameters are obtained by utilizing a threaded tool pin profile. |

| [149] | 2195-T8 2219-T8 | AS/RS RS/AS | Threaded cylindrical | - | 800 1200 | 200 400 800 | - | The sound FSW joints are obtained under all the welding conditions. |

| [121] | 2219 5083 | RS AS | Frustum threaded | - | 400 800 1200 1600 2000 | 30 210 390 570 750 | - | Higher tool rotation speeds and lower tool traverse speeds promote intimate mixing between dissimilar alloys. |

| [137] | 2024 6061 | . | - | 1.5 | 900 1120 1400 | 40 | 5 | The presence of a well-defined grain boundary region distinguishes the recrystallized area (stirring zone) from the distorted regions within the thermo-mechanically affected zone. |

| [145] | 2519 5182 | AS RS | Cylindrical | - | 500/380 1000/760 | - | For both the combinations, the joint is defect-free. The 500/380 ratio allows a slightly higher ultimate tensile strength in the tensile test. | |

| [148] | 5052-H32 6061-T6 | - | Cylindrical Conical Square | - | 900 1100 1400 | 40 50 60 | - | The square pin profile, the rotational speed of 1400 rpm, and the transverse speed of 40 mm/min are the optimal parameters. |