Effect of Ti/Al Ratio on Precipitation Behavior during Aging of Ni-Cr-Co-Based Superalloys

Abstract

:1. Introduction

2. Experimental Procedure

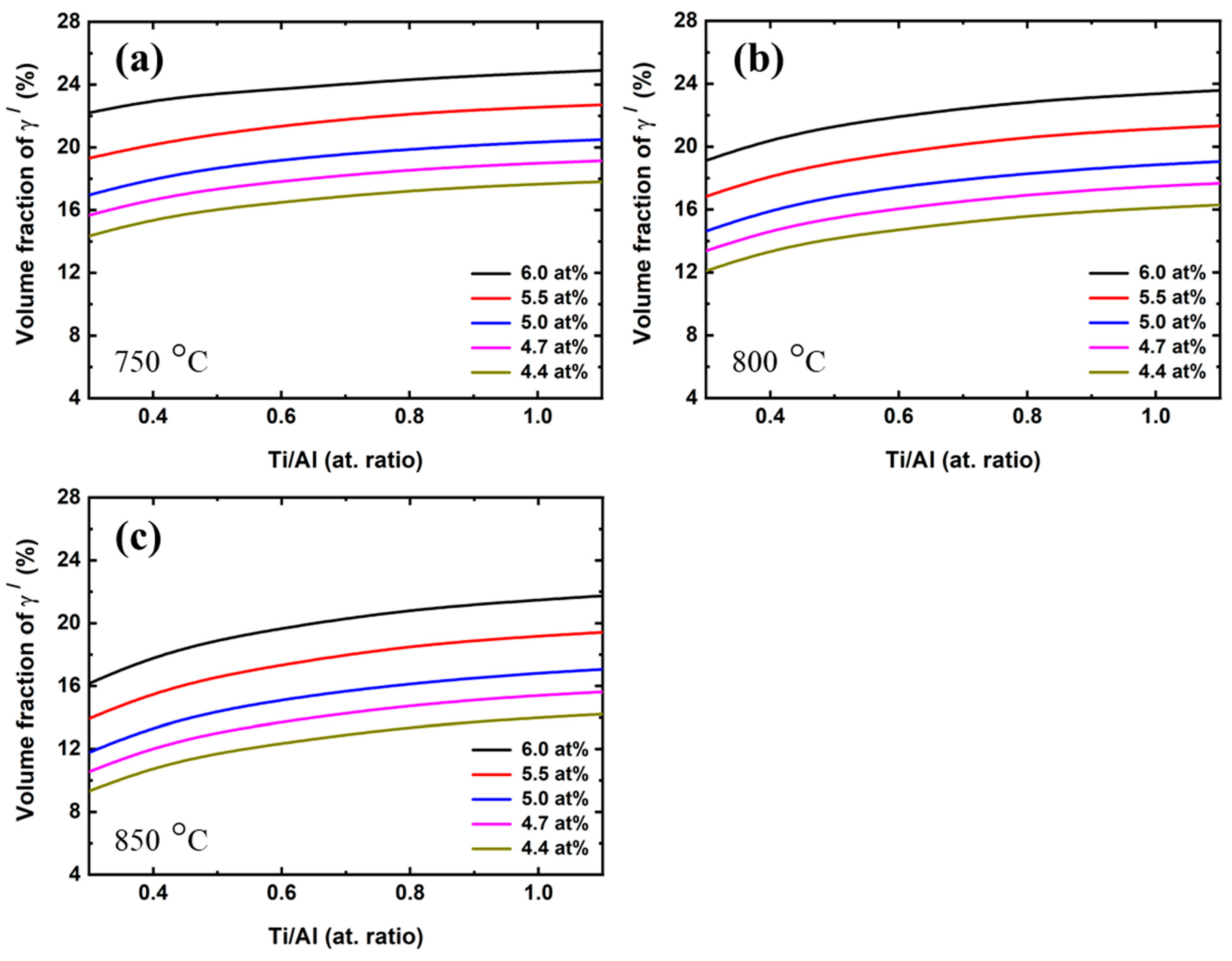

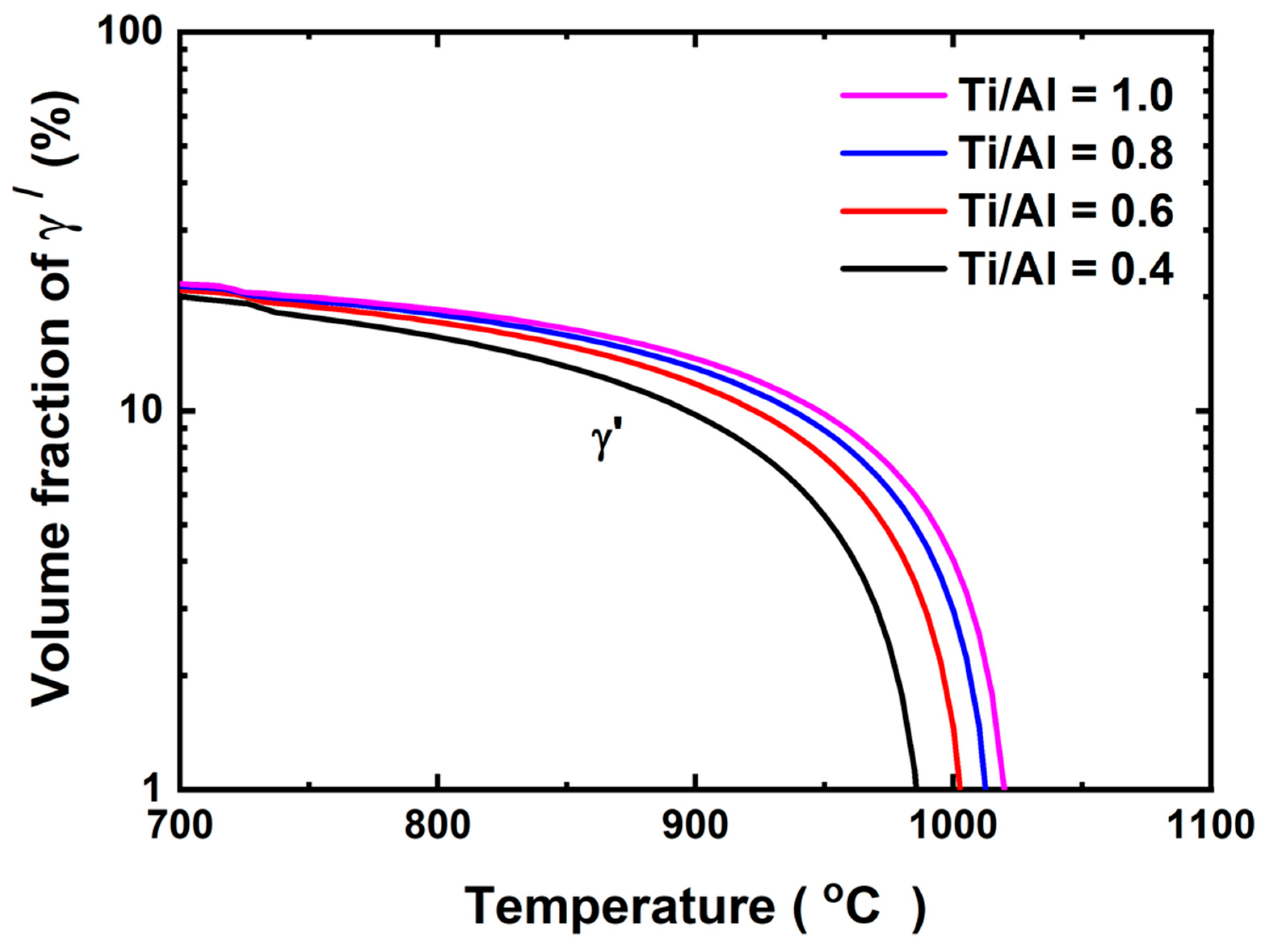

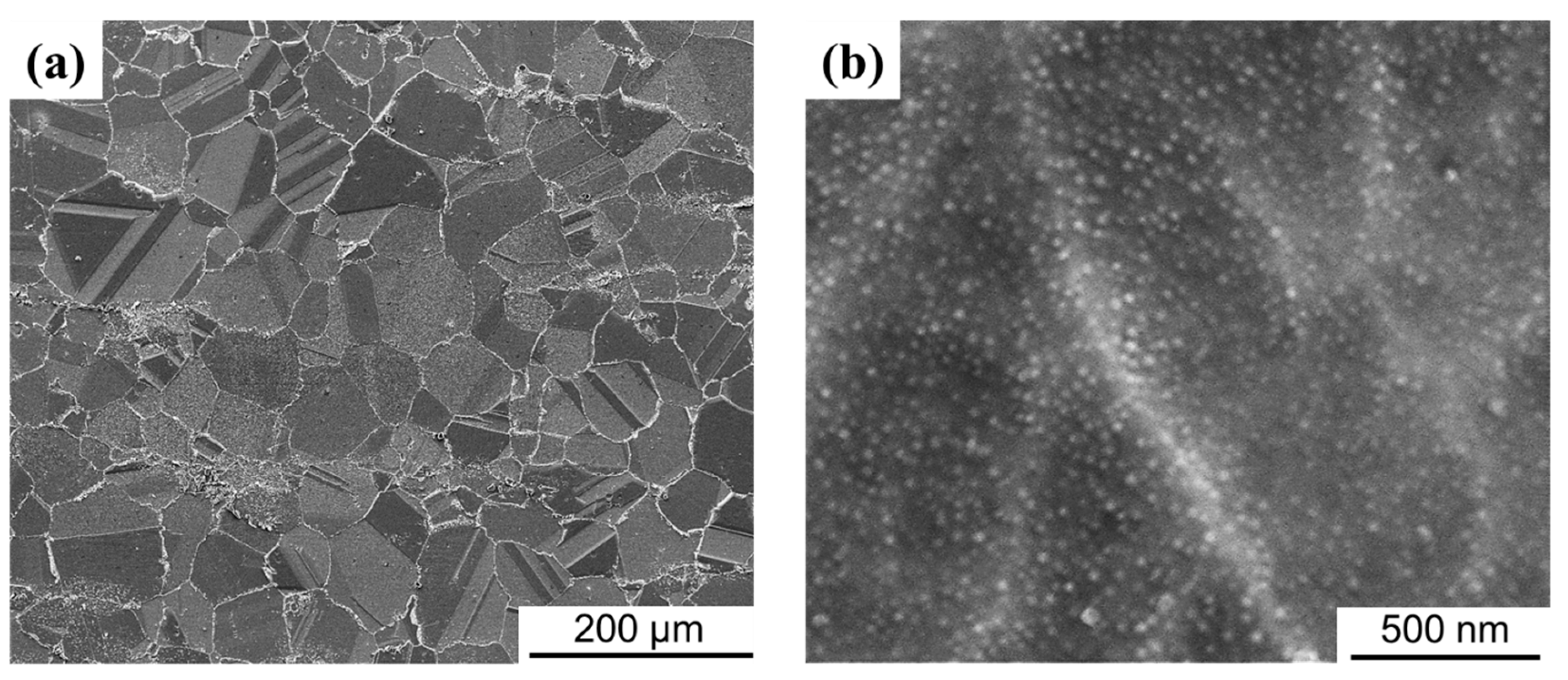

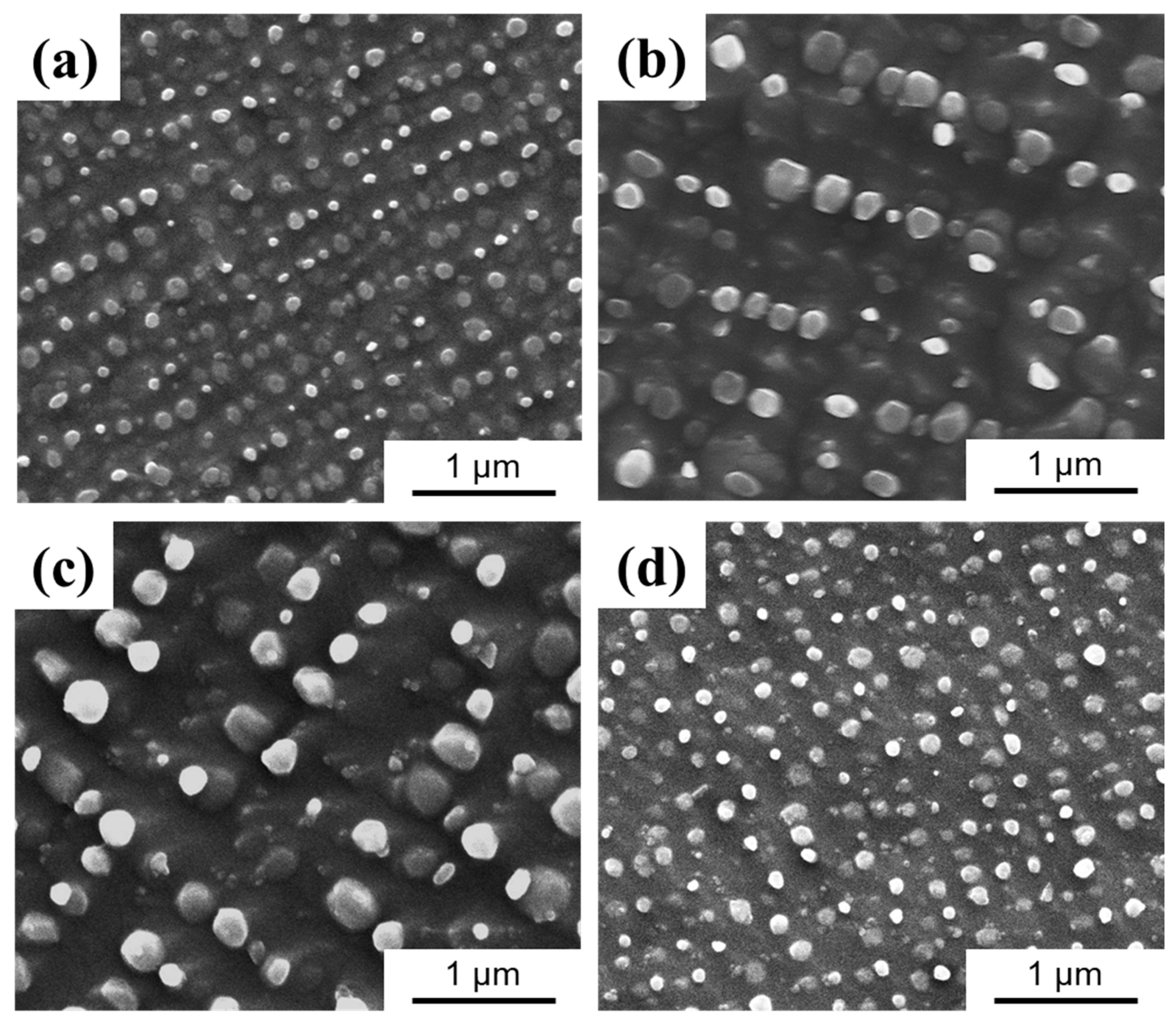

3. Results and Discussion

4. Conclusions

Author Contributions

Funding

Data Availability Statement

Conflicts of Interest

References

- Smith, T.M.; Esser, B.D.; Antolin, N.; Carlsson, A.; Williams, R.E.A.; Wessman, A.; Hanlon, T.; Fraser, H.L.; Windl, W.; McComb, D.W.; et al. Phase Transformation Strengthening of High-Temperature Superalloys. Nat. Commun. 2016, 7, 13434. [Google Scholar] [CrossRef]

- Wu, Z.; Chen, X.; Fan, Z.; Zhou, Y.; Dong, J. Studies of High-Temperature Fatigue Behavior and Mechanism for Nickel-Based Superalloy Inconel 625. Metals 2022, 12, 755. [Google Scholar] [CrossRef]

- Shin, G.S.; Yun, J.Y.; Chul Park, M.; Kim, S.J. Effect of Mo on the Thermal Stability of Γ′ Precipitate in Inconel 740 Alloy. Mater. Charact. 2014, 95, 180–186. [Google Scholar] [CrossRef]

- Li, H.; Feng, W.; Zhuang, W.; Hua, L. Microstructure Analysis and Segmented Constitutive Model for Ni-Cr-Co-Based Superalloy during Hot Deformation. Metals 2022, 12, 357. [Google Scholar] [CrossRef]

- Ma, Y.W.; Lee, K.W.; Kong, B.O.; Hong, H.U.; Lee, Y.S. Evaluation of Weld Joint Strength Reduction Factor Due to Creep in Alloy 740H to P92 Dissimilar Metal Weld Joint. Met. Mater. Int. 2021, 27, 4408–4417. [Google Scholar] [CrossRef]

- Xie, X.; Chi, C.; Zhao, S.; Dong, J.; Lin, F. Superalloys and the Development of Advanced Ultra-Supercritical Power Plants. Mater. Sci. Forum 2013, 748, 594–603. [Google Scholar] [CrossRef]

- Hanning, F.; Khan, A.K.; Steffenburg-Nordenström, J.; Ojo, O.; Andersson, J. Investigation of the Effect of Short Exposure in the Temperature Range of 750–950 °C on the Ductility of Haynes® 282® by Advanced Microstructural Characterization. Metals 2019, 9, 1357. [Google Scholar] [CrossRef]

- Wei, L.; Wang, S.; Yang, Q.; Cheng, Y.; Tan, S. Investigation on Precipitation Phenomena and Mechanical Properties of Ni-25Cr-20Co Alloys Aged at High Temperature. J. Mater. Res. 2018, 33, 3479–3489. [Google Scholar] [CrossRef]

- Wang, X.; Liu, Y.; Song, Y.; Li, H.; Hu, X.; Ji, Y. Application of Neural Network in Micromechanical Deformation Behaviors of Inconel 740H Alloy. Int. J. Adv. Manuf. Technol. 2023, 125, 2339–2348. [Google Scholar] [CrossRef]

- Kim, D.M.; Kim, C.; Yang, C.H.; Park, J.U.; Jeong, H.W.; Yim, K.H.; Hong, H.U. Heat Treatment Design of Inconel 740H Superalloy for Microstructure Stability and Enhanced Creep Properties. J. Alloys Compd. 2023, 946, 169341. [Google Scholar] [CrossRef]

- Yan, C.; Zhengdong, L.; Godfrey, A.; Wei, L.; Yuqing, W. Microstructure Evolution and Mechanical Properties of Inconel 740H during Aging at 750 °C. Mater. Sci. Eng. A 2014, 589, 153–164. [Google Scholar] [CrossRef]

- Zhao, S.; Xie, X.; Smith, G.D.; Patel, S.J. Gamma Prime Coarsening and Age-Hardening Behaviors in a New Nickel Base Superalloy. Mater. Lett. 2004, 58, 1784–1787. [Google Scholar] [CrossRef]

- Mehdizadeh, M.; Farhangi, H. Investigation of Microstructural Evolution and Mechanical Properties of IN617 Superalloy During Long-Term Operating at High Temperature. Met. Mater. Int. 2022, 28, 2719–2734. [Google Scholar] [CrossRef]

- Liang, X.; Wu, J.; Zhao, Y. Creep Fracture Mechanism of a Single Crystal Nickel Base Alloy Under High Temperature and Low Stress. Met. Mater. Int. 2022, 28, 841–847. [Google Scholar] [CrossRef]

- Reed, R. The Superalloys: Fundamentals and Applications; Cambridge University Press: Cambridge, UK, 2006; Volume 1999, ISBN 9780521859042. [Google Scholar]

- Enomoto, M.; Harada, H. Analysis of g’/g Equilibrium in Nickel-Aluminum-X Alloys by the Cluster Variation Method with the Lennard-Jones Potential. Metall. Trans. A Phys. Metall. Mater. Sci. 1989, 20A, 649–664. [Google Scholar] [CrossRef]

- Xu, Y.; Zhang, L.; Li, J.; Xiao, X.; Cao, X.; Jia, G.; Shen, Z. Relationship between Ti/Al Ratio and Stress-Rupture Properties in Nickel-Based Superalloy. Mater. Sci. Eng. A 2012, 544, 48–53. [Google Scholar] [CrossRef]

- Ou, M.; Ma, Y.; Ge, H.; Xing, W.; Zhou, Y.; Zheng, S.; Liu, K. Microstructure Evolution and Mechanical Properties of a New Cast Ni-Base Superalloy with Various Ti Contents. J. Alloys Compd. 2018, 735, 193–201. [Google Scholar] [CrossRef]

- Dodaran, M.; Ettefagh, A.H.; Guo, S.M.; Khonsari, M.M.; Meng, W.J.; Shamsaei, N.; Shao, S. Effect of Alloying Elements on the γ’ Antiphase Boundary Energy in Ni-Base Superalloys. Intermetallics 2020, 117, 106670. [Google Scholar] [CrossRef]

- Gorbatov, O.I.; Lomaev, I.L.; Gornostyrev, Y.N.; Ruban, A.V.; Furrer, D.; Venkatesh, V.; Novikov, D.L.; Burlatsky, S.F. Effect of Composition on Antiphase Boundary Energy in Ni3Al Based Alloys: Ab Initio Calculations. Phys. Rev. B 2016, 93, 224106. [Google Scholar] [CrossRef]

- Chen, E.; Tamm, A.; Wang, T.; Epler, M.E.; Asta, M.; Frolov, T. Modeling Antiphase Boundary Energies of Ni3Al-Based Alloys Using Automated Density Functional Theory and Machine Learning. npj Comput. Mater. 2022, 8, 80. [Google Scholar] [CrossRef]

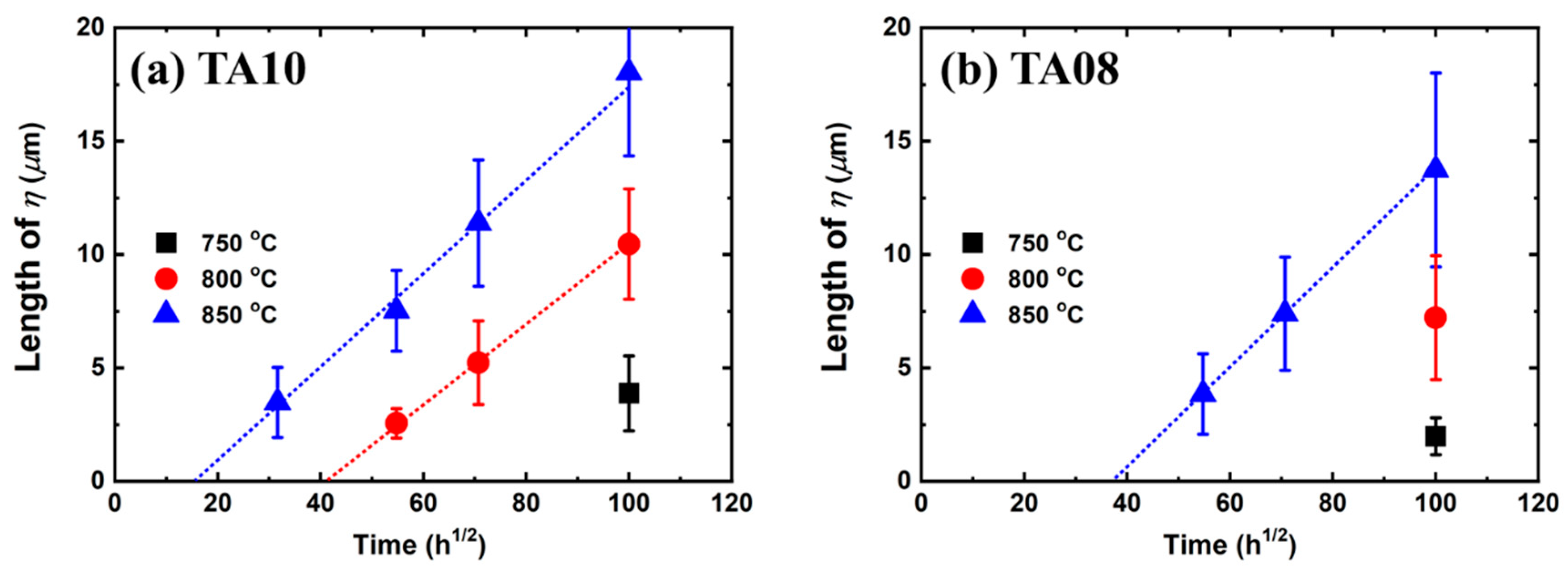

- Cui, C.Y.; Gu, Y.F.; Ping, D.H.; Harada, H.; Fukuda, T. The Evolution of η Phase in Ni-Co Base Superalloys. Mater. Sci. Eng. A 2008, 485, 651–656. [Google Scholar] [CrossRef]

- Shingledecker, J.P.; Pharr, G.M. The Role of Eta Phase Formation on the Creep Strength and Ductility of Inconel Alloy 740 at 1023 k (750 °C). Metall. Mater. Trans. A Phys. Metall. Mater. Sci. 2012, 43, 1902–1910. [Google Scholar] [CrossRef]

- Li, J.; Wu, Y.; Liu, Y.; Li, C.; Ma, Z.; Yu, L.; Li, H.; Liu, C.; Guo, Q. Enhancing Tensile Properties of Wrought Ni-Based Superalloy ATI 718Plus at Elevated Temperature via Morphology Control of η Phase. Mater. Charact. 2020, 169, 110547. [Google Scholar] [CrossRef]

- Detrois, M.; Jablonski, P.D.; Hawk, J.A. The Effect of η Phase Precipitates on the Creep Behavior of Alloy 263 and Variants. Mater. Sci. Eng. A 2021, 799, 140337. [Google Scholar] [CrossRef]

- Liu, G.; Kong, L.; Xiao, X.; Birosca, S. Microstructure Evolution and Phase Transformation in a Nickel-Based Superalloy with Varying Ti/Al Ratios: Part 1—Microstructure Evolution. Mater. Sci. Eng. A 2022, 831, 142228. [Google Scholar] [CrossRef]

- Liu, G.; Xiao, X.; Véron, M.; Birosca, S. The Nucleation and Growth of η Phase in Nickel-Based Superalloy during Long-Term Thermal Exposure. Acta Mater. 2020, 185, 493–506. [Google Scholar] [CrossRef]

- Oh, J.H.; Yoo, B.G.; Choi, I.C.; Santella, M.L.; Jang, J. Il Influence of Thermo-Mechanical Treatment on the Precipitation Strengthening Behavior of Inconel 740, a Ni-Based Superalloy. J. Mater. Res. 2011, 26, 1253–1259. [Google Scholar] [CrossRef]

- Asgari, S.; Sharghi-Moshtaghin, R.; Sadeghahmadi, M.; Pirouz, P. On Phase Transformations in a Ni-Based Superalloy. Philos. Mag. 2013, 93, 1351–1370. [Google Scholar] [CrossRef]

- Zener, C. Theory of Growth of Spherical Precipitates from Solid Solution. J. Appl. Phys. 1949, 20, 950–953. [Google Scholar] [CrossRef]

- Frank, F.C. Radially Symmetric Phase Growth Controlled by Diffusion. Proc. R. Soc. London. Ser. A. Math. Phys. Sci. 1950, 201, 586–599. [Google Scholar] [CrossRef]

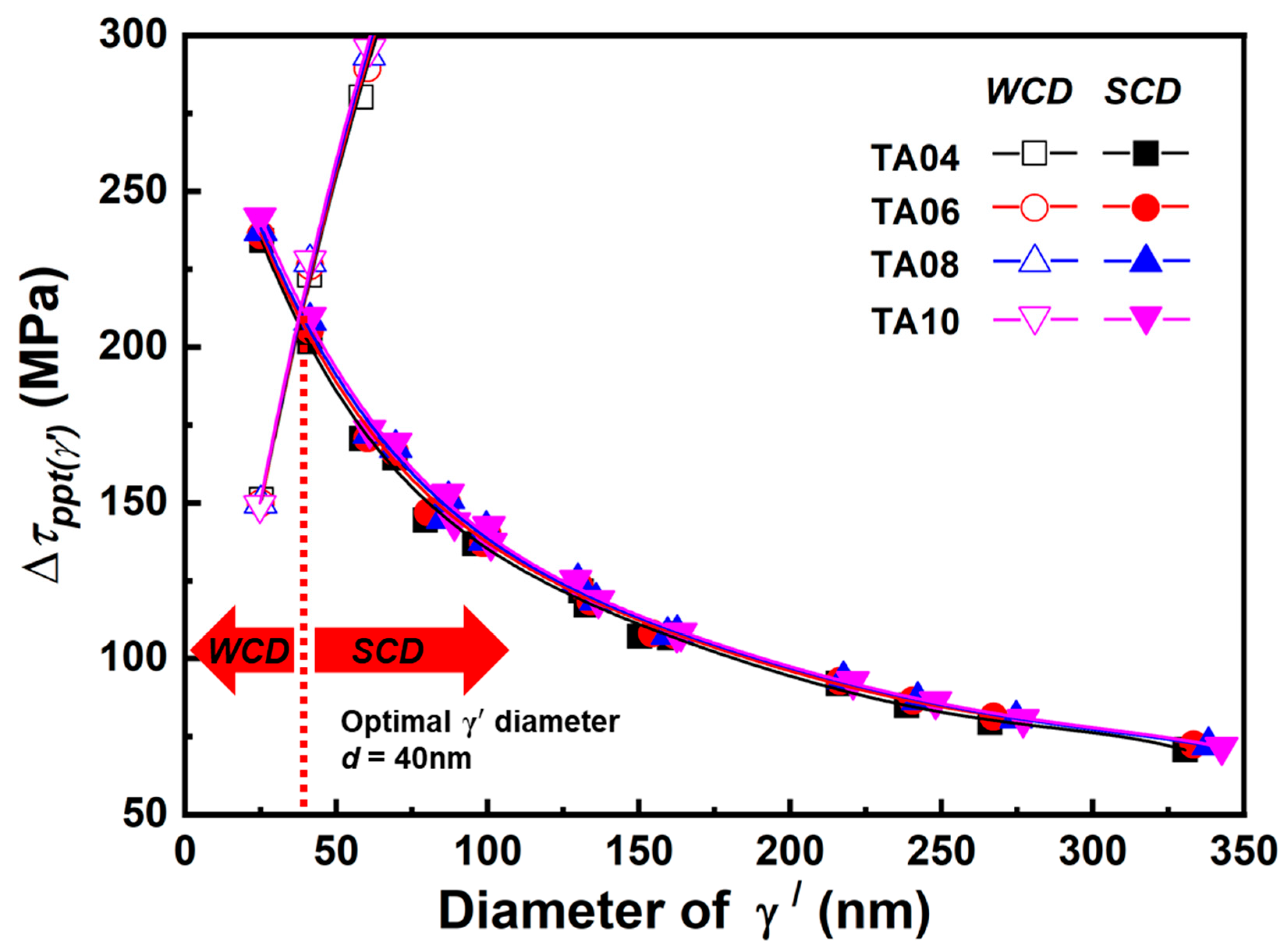

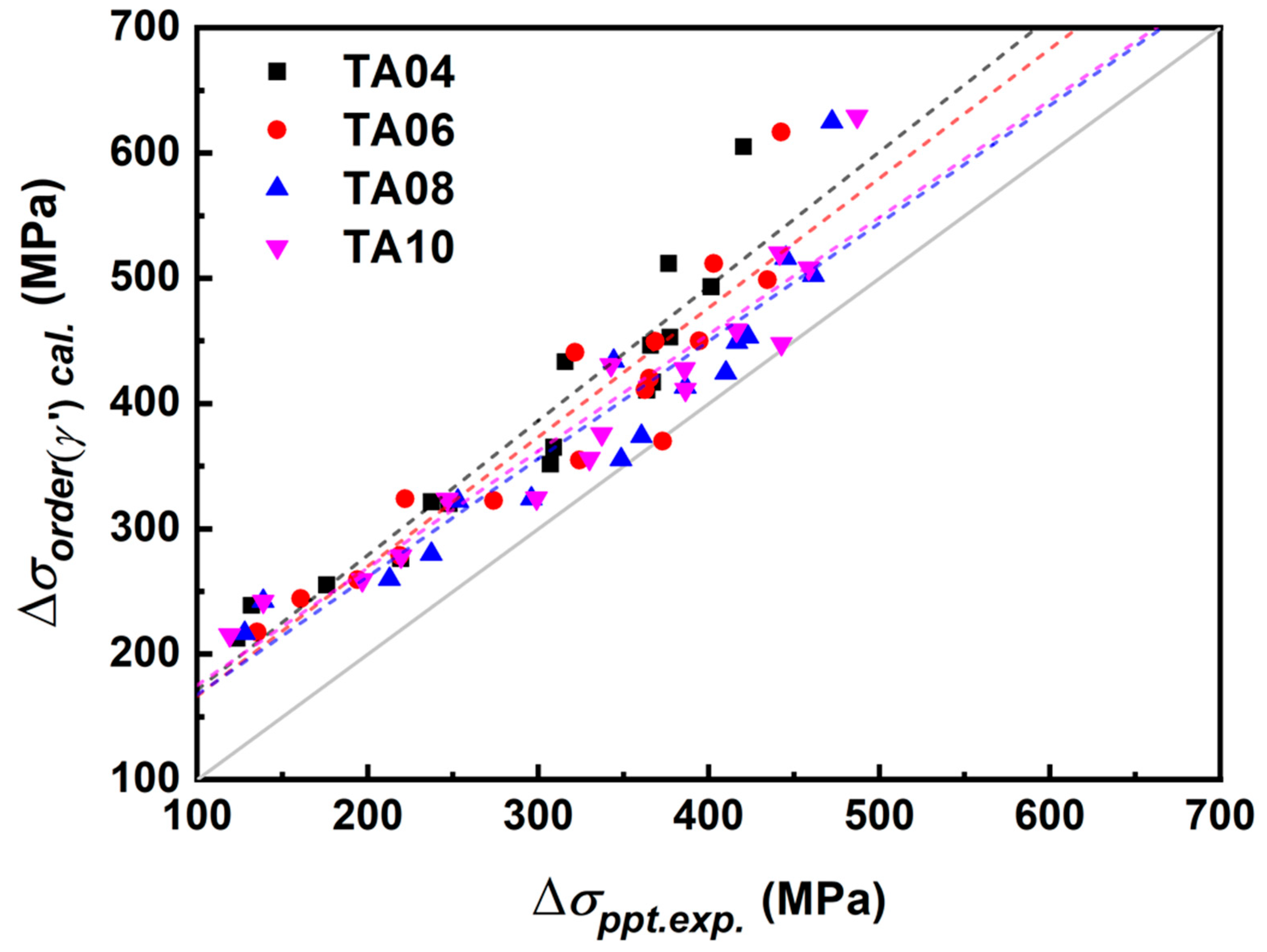

- Reppich, B. Some New Aspects Concerning Particle Hardening Mechanisms in γ’ Precipitating Ni-Base Alloys-I. Theoretical Concept. Acta Metall. 1982, 30, 87–94. [Google Scholar] [CrossRef]

- Dimiduk, D.M.; Thompson, A.W.; Williams, J.C. The Compositional Dependence of Antiphase-Boundary Energies and the Mechanism of Anomalous Flow in Ni3 Al Alloys. Philos. Mag. A Phys. Condens. Matter. Struct. Defects Mech. Prop. 1993, 67, 675–698. [Google Scholar] [CrossRef]

- Zhou, D.; Ye, X.; Teng, J.; Li, C.; Li, Y. Effect of Nb on Microstructure and Mechanical Property of Novel Powder Metallurgy Superalloys during Long-Term Thermal Exposure. Materials 2021, 14, 656. [Google Scholar] [CrossRef]

- Galindo-Nava, E.I.; Connor, L.D.; Rae, C.M.F. On the Prediction of the Yield Stress of Unimodal and Multimodal γ’ Nickel-Base Superalloys. Acta Mater. 2015, 98, 377–390. [Google Scholar] [CrossRef]

- Goodfellow, A.J.; Galindo-Nava, E.I.; Schwalbe, C.; Stone, H.J. The Role of Composition on the Extent of Individual Strengthening Mechanisms in Polycrystalline Ni-Based Superalloys. Mater. Des. 2019, 173, 107760. [Google Scholar] [CrossRef]

- Wu, H.; Zhuang, X.; Nie, Y.; Li, Y.; Jiang, L. Effect of Heat Treatment on Mechanical Property and Microstructure of a Powder Metallurgy Nickel-Based Superalloy. Mater. Sci. Eng. A 2019, 754, 29–37. [Google Scholar] [CrossRef]

- Osada, T.; Gu, Y.; Nagashima, N.; Yuan, Y.; Yokokawa, T.; Harada, H. Optimum Microstructure Combination for Maximizing Tensile Strength in a Polycrystalline Superalloy with a Two-Phase Structure. Acta Mater. 2013, 61, 1820–1829. [Google Scholar] [CrossRef]

| Alloy | Ni | Cr | Co | Mo | Nb | Ti | Al | C | Ti/Al (at%) | Ti + Al (at%) |

|---|---|---|---|---|---|---|---|---|---|---|

| TA04 | Bal. | 23.1 | 20.2 | 0.52 | 1.5 | 1.46 | 1.83 | 0.03 | 0.45 | 5.57 |

| TA06 | Bal. | 25.2 | 20.0 | 0.48 | 1.4 | 1.75 | 1.62 | 0.03 | 0.61 | 5.43 |

| TA08 | Bal. | 25.2 | 19.5 | 0.50 | 1.4 | 2.15 | 1.50 | 0.03 | 0.80 | 5.64 |

| TA10 | Bal. | 22.8 | 20.2 | 0.48 | 1.5 | 2.47 | 1.28 | 0.03 | 1.09 | 5.63 |

| Alloy | YS | Hv | YS/Hv |

|---|---|---|---|

| TA04 | 827.0 | 356.0 | 2.32 |

| TA06 | 840.9 | 360.0 | 2.33 |

| TA08 | 853.5 | 381.3 | 2.24 |

| TA10 | 927.8 | 396.6 | 2.34 |

Disclaimer/Publisher’s Note: The statements, opinions and data contained in all publications are solely those of the individual author(s) and contributor(s) and not of MDPI and/or the editor(s). MDPI and/or the editor(s) disclaim responsibility for any injury to people or property resulting from any ideas, methods, instructions or products referred to in the content. |

© 2023 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (https://creativecommons.org/licenses/by/4.0/).

Share and Cite

Chu, D.-J.; Park, C.; Lee, J.; Jung, W.-S. Effect of Ti/Al Ratio on Precipitation Behavior during Aging of Ni-Cr-Co-Based Superalloys. Metals 2023, 13, 1959. https://doi.org/10.3390/met13121959

Chu D-J, Park C, Lee J, Jung W-S. Effect of Ti/Al Ratio on Precipitation Behavior during Aging of Ni-Cr-Co-Based Superalloys. Metals. 2023; 13(12):1959. https://doi.org/10.3390/met13121959

Chicago/Turabian StyleChu, Dong-Ju, Chanhee Park, Joonho Lee, and Woo-Sang Jung. 2023. "Effect of Ti/Al Ratio on Precipitation Behavior during Aging of Ni-Cr-Co-Based Superalloys" Metals 13, no. 12: 1959. https://doi.org/10.3390/met13121959

APA StyleChu, D.-J., Park, C., Lee, J., & Jung, W.-S. (2023). Effect of Ti/Al Ratio on Precipitation Behavior during Aging of Ni-Cr-Co-Based Superalloys. Metals, 13(12), 1959. https://doi.org/10.3390/met13121959