Liquid Metal Embrittlement Cracking in Uncoated Transformation-Induced Plasticity Steel during Consecutive Resistance Spot Welding

Abstract

:1. Introduction

2. Materials and Methods

3. Results and Discussion

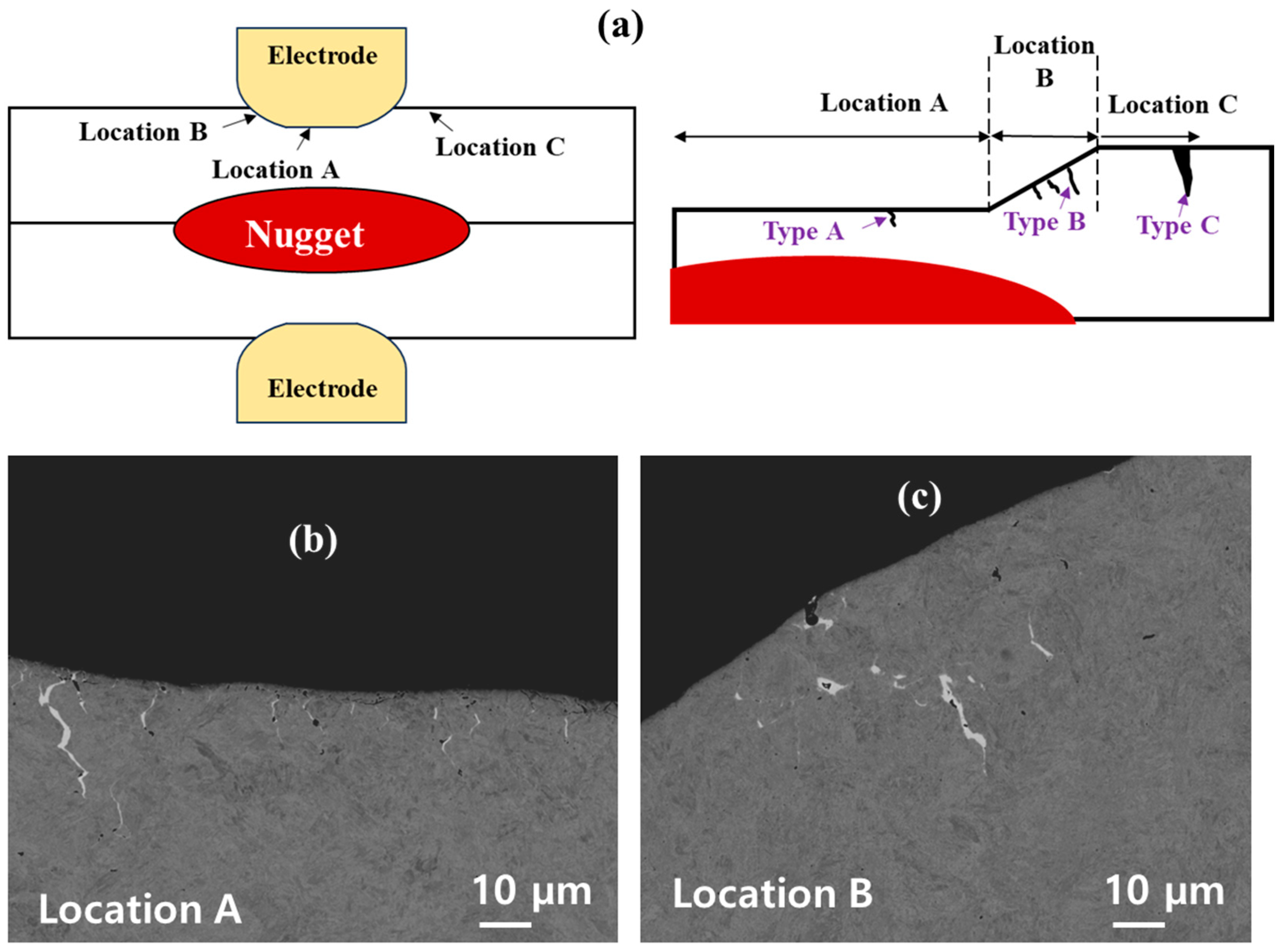

3.1. LME Cracks in the Uncoated TRIP Steel Joints

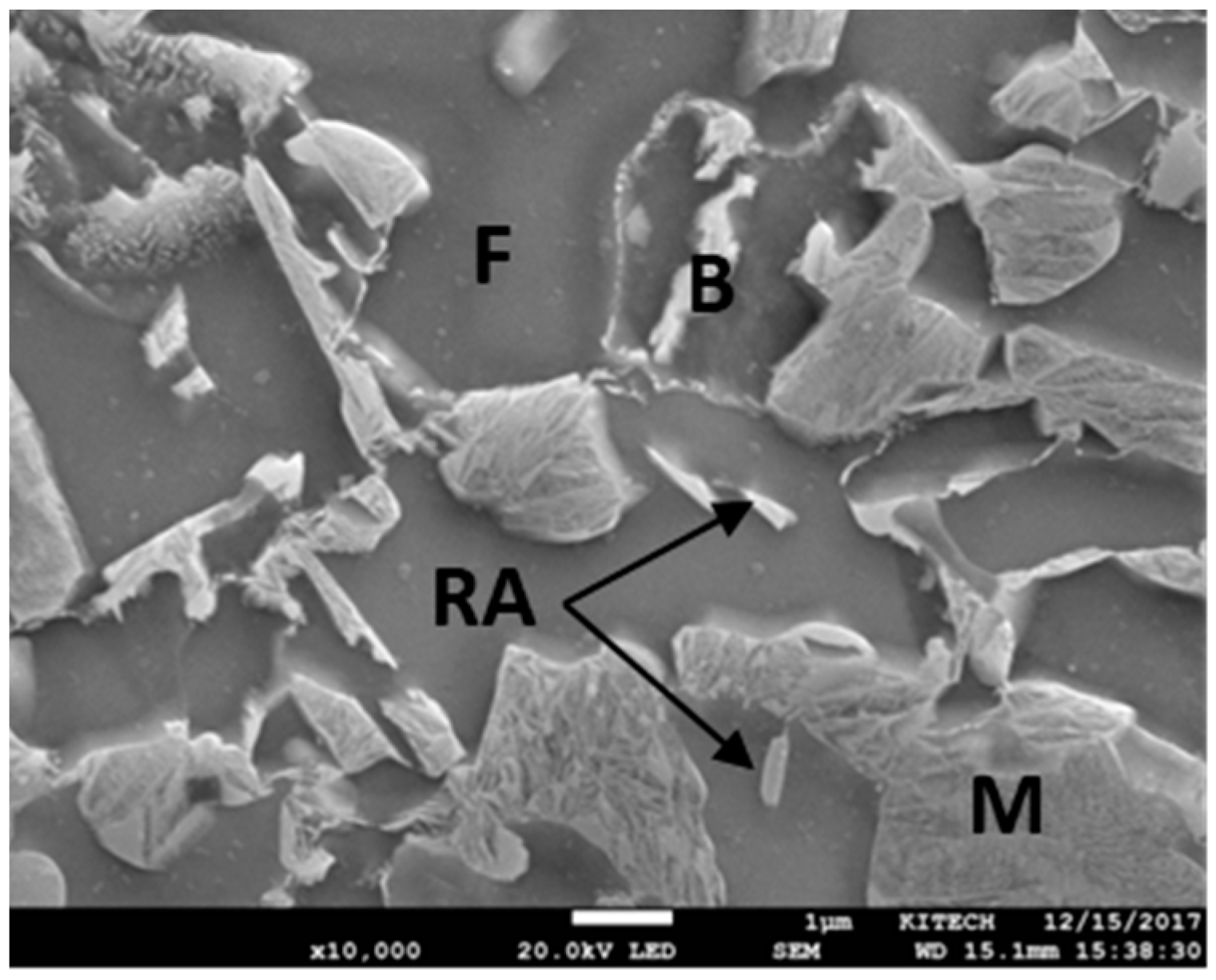

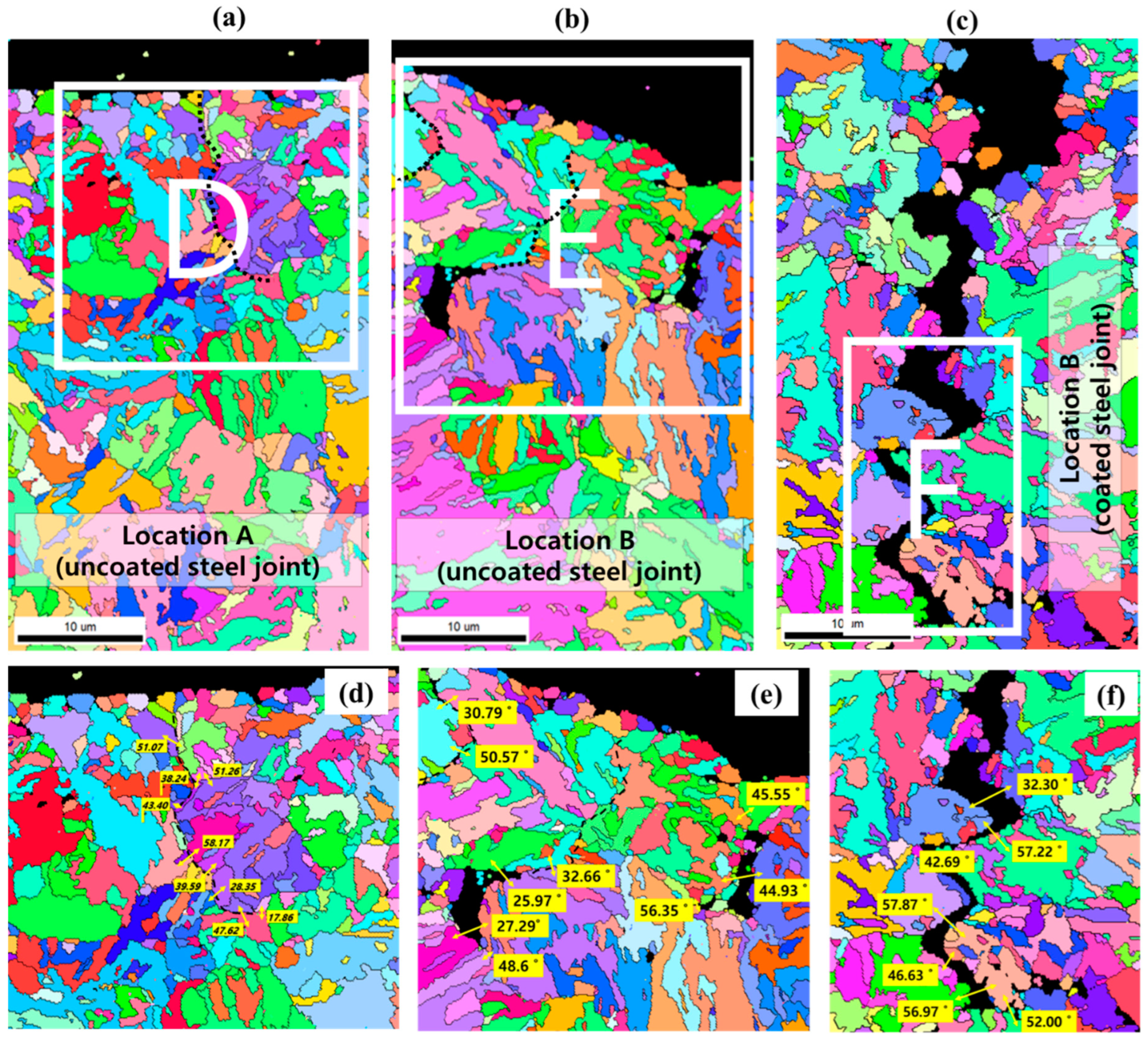

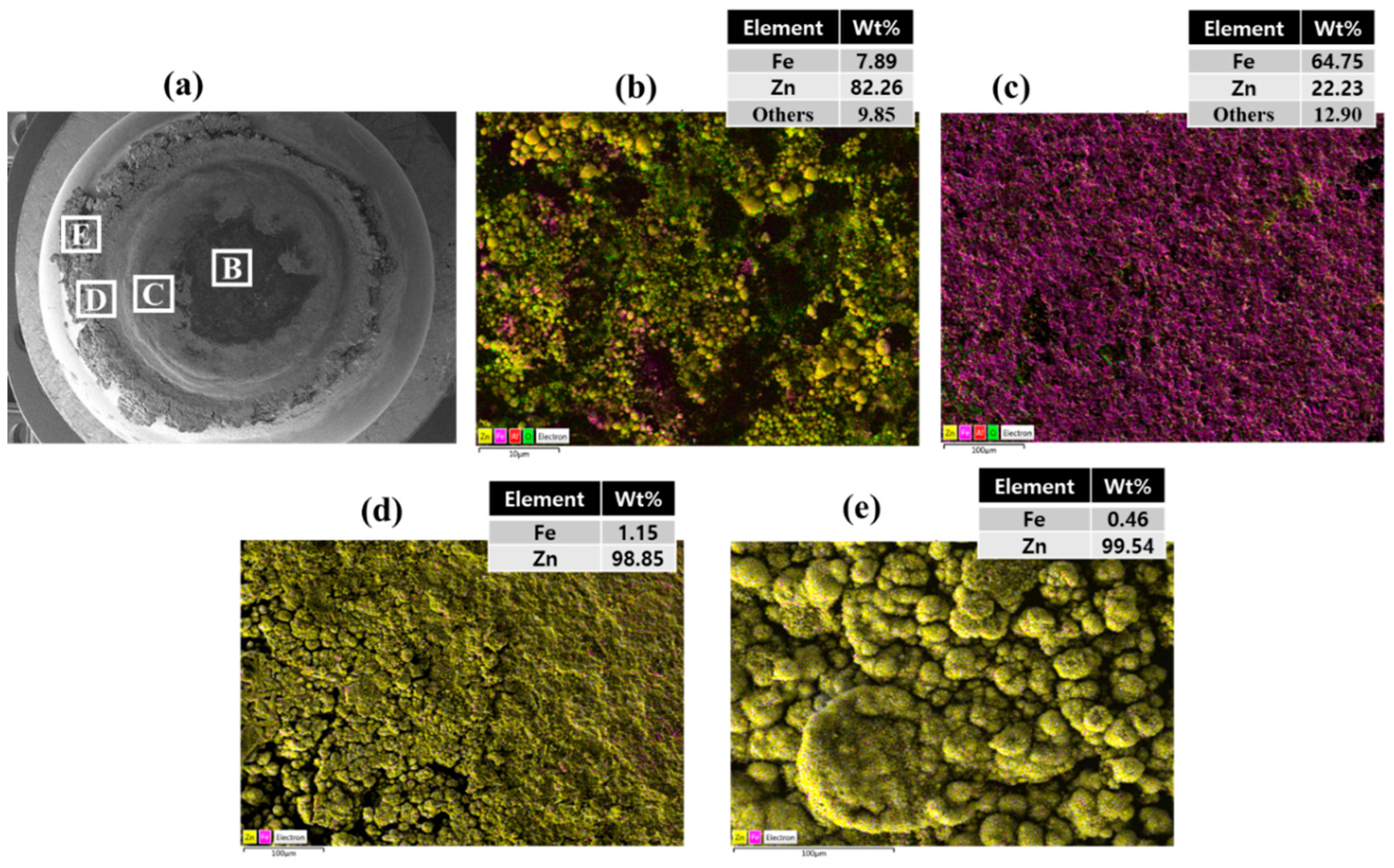

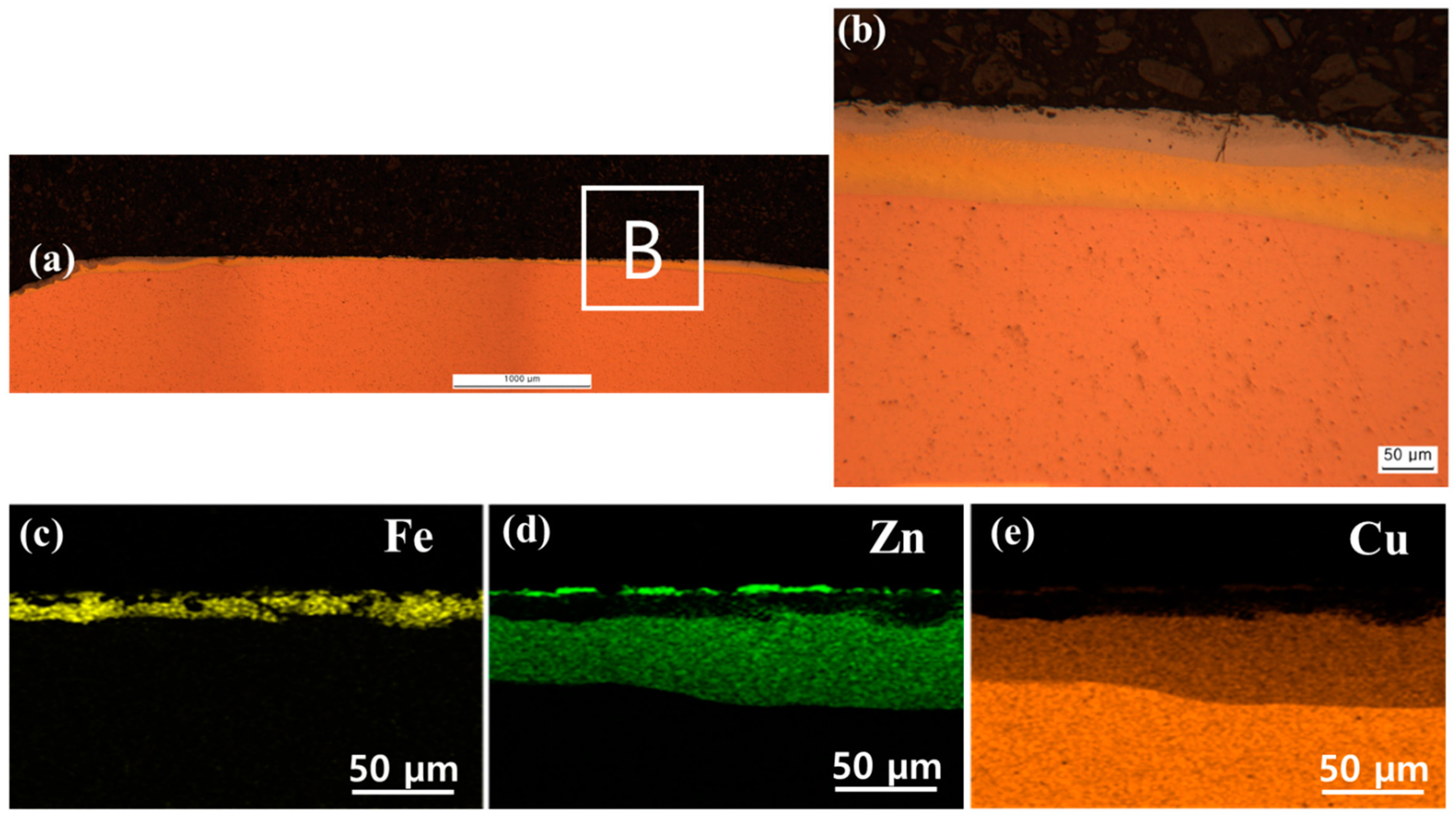

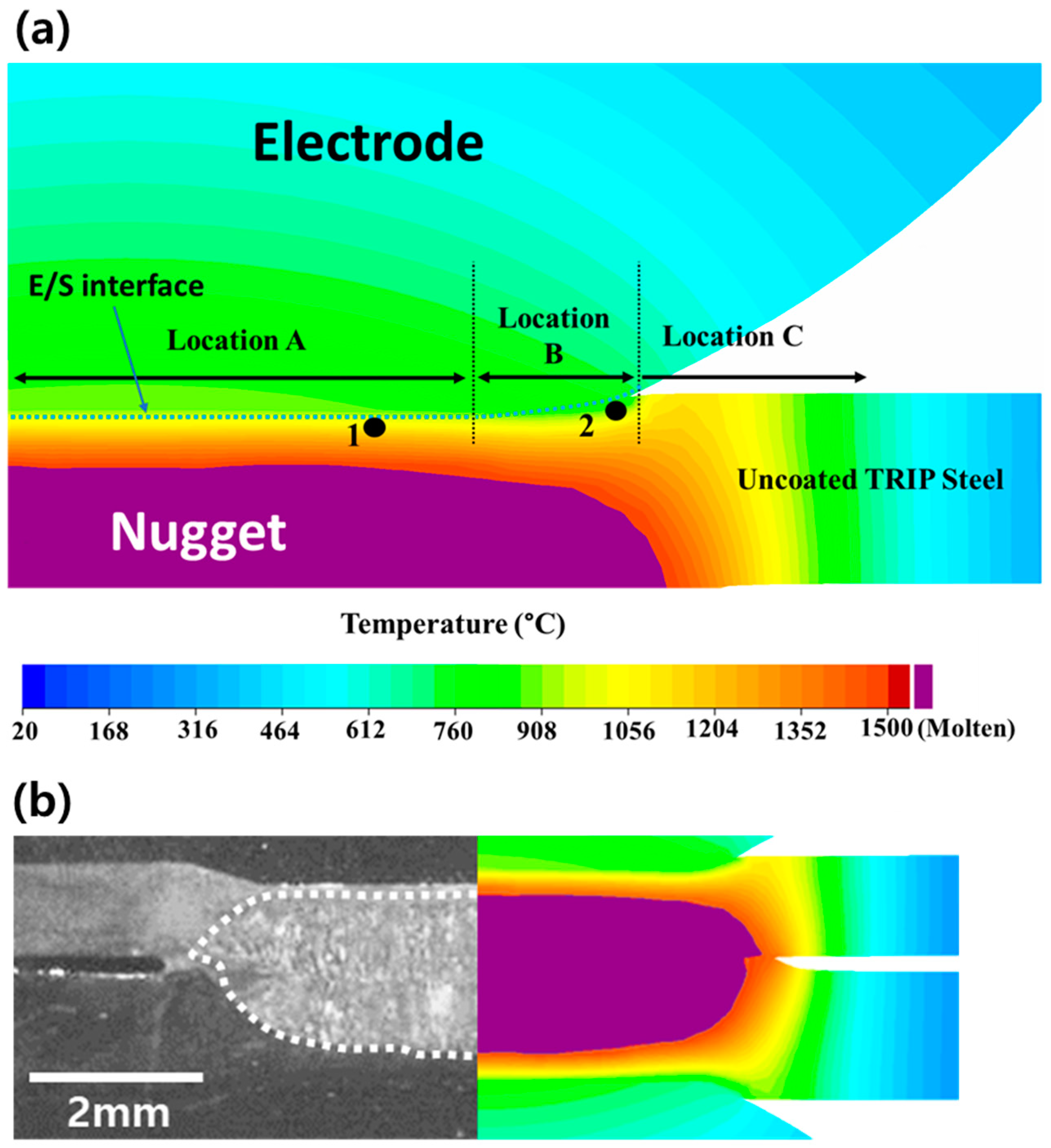

3.2. Formation Mechanism of the LME Cracks in the Uncoated TRIP Steel Joint

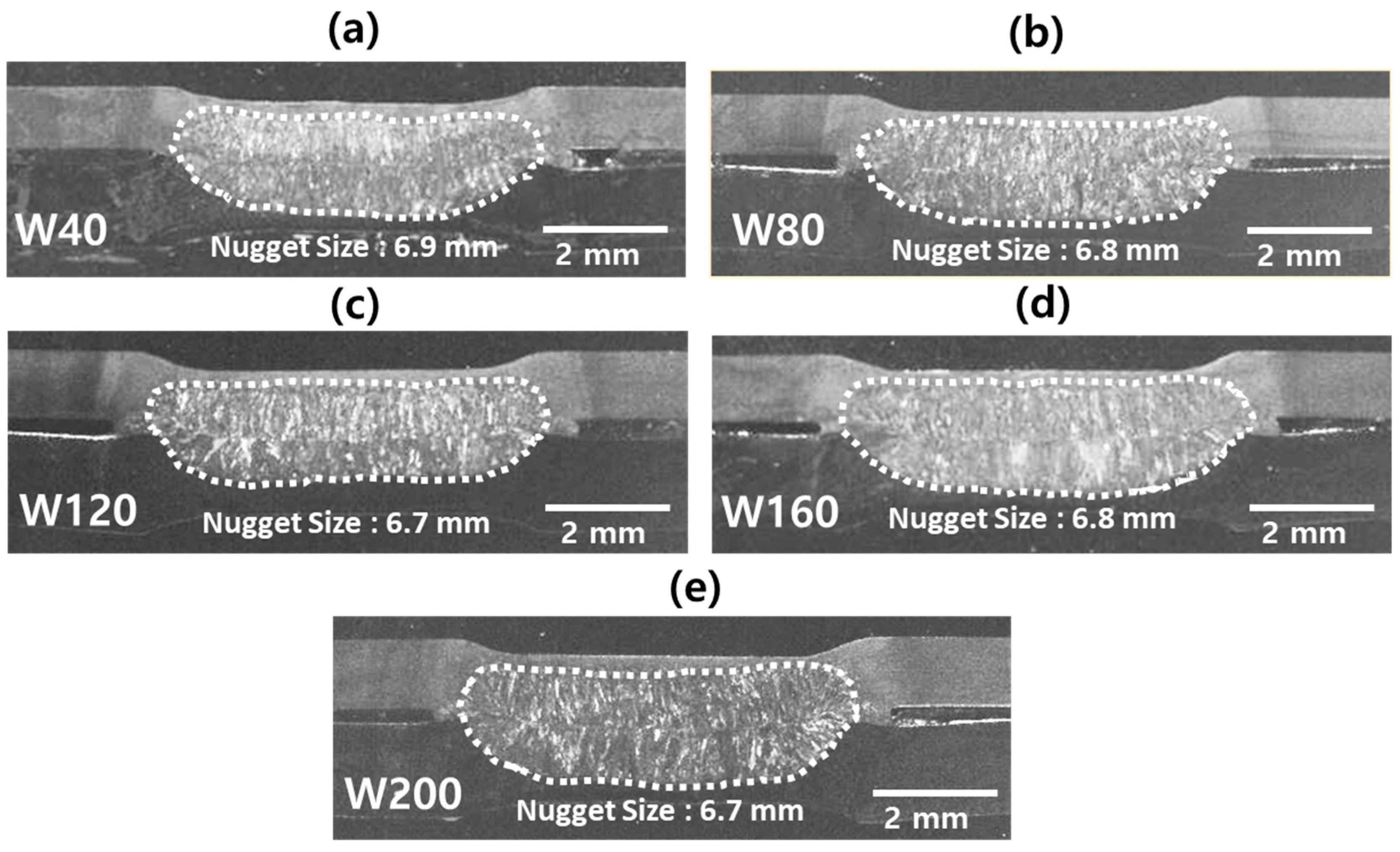

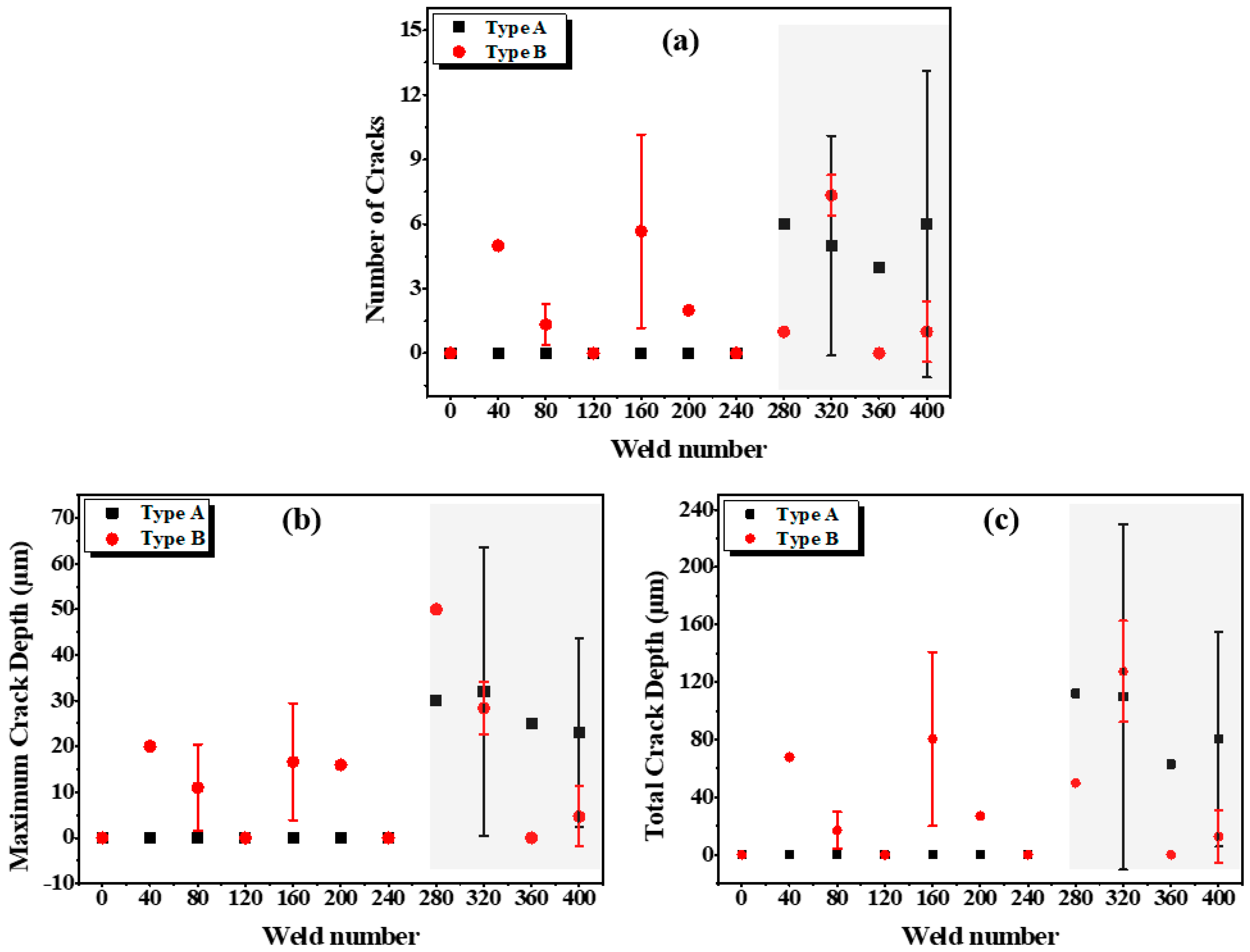

3.3. Statistics of the LME Cracks in the Consecutive Welding

4. Conclusions

- (1)

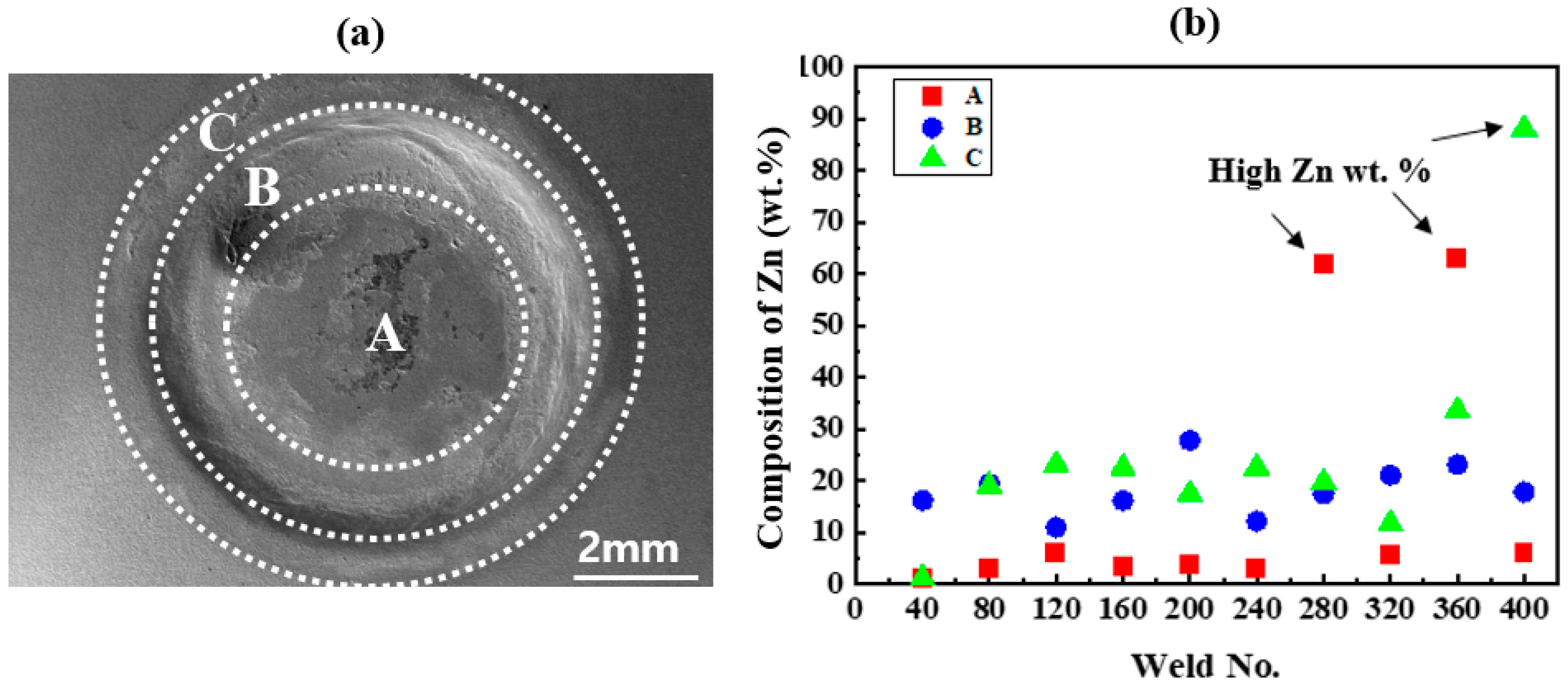

- Small cracks were observed at the surface of the uncoated steel joints with a maximum length of about 30 µm and 50 µm in Location A (weld center) and Location B (shoulder of the weld), respectively, which were confirmed to be LME cracks.

- (2)

- During the consecutive welding, the electrode experienced metallurgical degradation or contamination with Zn (formation of different Cu-Zn phases) from the galvannealed steel. When welding the uncoated steel, owing to the heat generation at the electrode/sheet interface, the Cu-Zn phases melted, exposing the uncoated steel surface to liquid Zn and Cu, leading to LME cracking.

- (3)

- The occurrence and characteristics of the crack formation differed for each location as the number of welds increased due to the variation in Zn content. Type A cracks did not form when the number of welds was less than 280. However, several cracks with a total length of approximately 30 μm were formed between 280 and 400 welds. On the other hand, type B cracks began to appear after 40 welds. However, the number and size of these exhibited inconsistency as the number of welds increased.

Author Contributions

Funding

Data Availability Statement

Acknowledgments

Conflicts of Interest

References

- Kim, Y.-M.; Hwang, I.; Cheon, J. Recent Research Trend of Resistance Spot Welding Quality Monitoring Technology in Korea. J. Weld. Join. 2023, 41, 90–99. [Google Scholar] [CrossRef]

- Soomro, I.A.; Pedapati, S.R.; Awang, M. A review of advances in resistance spot welding of automotive sheet steels: Emerging methods to improve joint mechanical performance. Int. J. Adv. Manuf. Technol. 2022, 118, 1335–1366. [Google Scholar] [CrossRef]

- Keeler, S.; Kimchi, M. Advanced High-Strength Steels Application Guidelines V5; WorldAutoSteel: Brussels, Belgium, 2015. [Google Scholar]

- Shome, M.; Tumuluru, M. Welding and Joining of Advanced High Strength Steels (AHSS); Woodhead Publishing: Sawston, UK, 2015. [Google Scholar]

- Shim, J.Y.; Park, M.W.; Kim, I.S. An Overview of Resistance Element Welding with Focus on Mechanical and Microstructure Joint and Optimization in Automotive Metal Joints. J. Weld. Join. 2023, 41, 37–48. [Google Scholar] [CrossRef]

- Mahmud, K.; Murugan, S.P.; Cho, Y.; Ji, C.; Nam, D.; Park, Y.-D. Geometrical degradation of electrode and liquid metal embrittlement cracking in resistance spot welding. J. Manuf. Process. 2021, 61, 334–348. [Google Scholar] [CrossRef]

- Park, G.; Uhm, S.; Lee, C. Review on the Resistance spot weldability of medium-Mn TRIP steel. J. Weld. Join. 2021, 39, 239–245. [Google Scholar] [CrossRef]

- Bhattacharya, D.; Cho, L.; Van Der Aa, E.; Pichler, A.; Pottore, N.; Ghassemi-Armaki, H.; Findley, K.; Speer, J. Influence of the starting microstructure of an advanced high strength steel on the characteristics of Zn-Assisted liquid metal embrittlement. Mater. Sci. Eng. A 2021, 804, 140391. [Google Scholar] [CrossRef]

- Christodoulou, P.I.; Kermanidis, A.T. A Combined Numerical–Analytical Study for Notched Fatigue Crack Initiation Assessment in TRIP Steel: A Local Strain and a Fracture Mechanics Approach. Metals 2023, 13, 1652. [Google Scholar] [CrossRef]

- Marder, A.R. The metallurgy of zinc-coated steel. Prog. Mater. Sci. 2000, 45, 191–271. [Google Scholar] [CrossRef]

- Tumuluru, M. The effect of coatings on the resistance spot welding behavior of 780 MPa dual-phase steel. Weld. J. 2007, 86, 161. [Google Scholar]

- Razmpoosh, M.H.; Biro, E.; Chen, D.L.; Goodwin, F.; Zhou, Y. Liquid metal embrittlement in laser lap joining of TWIP and medium-manganese TRIP steel: The role of stress and grain boundaries. Mater. Charact. 2018, 145, 627–633. [Google Scholar] [CrossRef]

- DiGiovanni, C.; Biro, E.; Zhou, N.Y. Impact of liquid metal embrittlement cracks on resistance spot weld static strength. Sci. Technol. Weld. Join. 2019, 24, 218–224. [Google Scholar] [CrossRef]

- Jin, W.; Lalachan, A.; Murugan, S.P.; Ji, C. Effect of Process Parameters and Nugget Growth Rate on Liquid Metal Embrittlement (LME) Cracking in the Resistance Spot Welding of Zinc-Coated Steels. J. Weld. Join. 2022, 40, 464–477. [Google Scholar] [CrossRef]

- Yang, K.; Meschut, G.; Seitz, G.; Biegler, M.; Rethmeier, M. The Identification of a New Liquid Metal Embrittlement (LME) Type in Resistance Spot Welding of Advanced High− Strength Steels on Reduced Flange Widths. Metals 2023, 13, 1754. [Google Scholar] [CrossRef]

- van der Aa, E.; Rana, R. Optimization of Hot Forming Temperature to Minimize Liquid Metal Embrittlement Induced Cracking in Resistance Spot Welded Zinc-Coated Medium Manganese Steel. Steel Res. Int. 2023, 2300045. [Google Scholar] [CrossRef]

- DiGiovanni, C.; He, L.; Pistek, U.; Goodwin, F.; Biro, E.; Zhou, N. Role of spot weld electrode geometry on liquid metal embrittlement crack development. J. Manuf. Process. 2020, 49, 1–9. [Google Scholar] [CrossRef]

- DiGiovanni, C.; Kalashami, A.G.; Goodwin, F.; Biro, E.; Zhou, N. Occurrence of sub-critical heat affected zone liquid metal embrittlement in joining of advanced high strength steel. J. Mater. Process. Technol. 2021, 288, 116917. [Google Scholar] [CrossRef]

- Murugan, S.P.; Mahmud, K.; Ji, C.; Jo, I.; Park, Y.-D. Critical design parameters of the electrode for liquid metal embrittlement cracking in resistance spot welding. Weld. World 2019, 63, 1613–1632. [Google Scholar] [CrossRef]

- Tolf, E.; Hedegård, J.; Melander, A. Surface breaking cracks in resistance spot welds of dual phase steels with electrogalvanised and hot dip zinc coating. Sci. Technol. Weld. Join. 2013, 18, 25–31. [Google Scholar] [CrossRef]

- Society, A.W. Recommended Practices for Test Methods for Evaluating the Resistance Spot Welding Behavior of Automotive Sheet Steel Materials; American Welding Society Florida: Doral, FL, USA, 2002. [Google Scholar]

- Murugan, S.; Vijayan, V.; Ji, C.; Park, Y. Four types of LME cracks in RSW of Zn-coated AHSS. Weld J. 2020, 99, 75s–92s. [Google Scholar] [CrossRef]

- Sage, D.; Fink, C. Understanding temperature and dwell time dependence of liquid metal embrittlement in austenitic stainless steel by liquid zinc and copper. Materialia 2022, 24, 101502. [Google Scholar] [CrossRef]

- Razmpoosh, M.; Macwan, A.; Goodwin, F.; Biro, E.; Zhou, Y. Role of random and coincidence site lattice grain boundaries in liquid metal embrittlement of iron (FCC)-Zn couple. Metall. Mater. Trans. A 2020, 51, 3938–3944. [Google Scholar] [CrossRef]

- Lee, S.-J.; Shin, S.E.; Ushioda, K.; Fujii, H. Microstructure, mechanical properties, and damping capacity in stir zone after friction stir welding of Fe–17Mn damping alloy. J. Alloys Compd. 2019, 803, 1155–1167. [Google Scholar] [CrossRef]

- Okamoto, H.; Massalski, T. Binary Alloy Phase Diagrams; ASM International: Materials Park, OH, USA, 1990; Volume 12. [Google Scholar]

- DiGiovanni, C.; Kalashami, A.G.; Biro, E.; Zhou, N. Liquid metal embrittlement transport mechanism in the Fe/Zn system: Stress-assisted diffusion. Materialia 2021, 18, 101153. [Google Scholar] [CrossRef]

- Kondo, M.; Konishi, T.; Nomura, K.; Kokawa, H. Degradation mechanism of electrode tip during alternate resistance spot welding of zinc coated and uncoated steel sheets. Sci. Technol. Weld. Join. 2010, 15, 76–80. [Google Scholar] [CrossRef]

| Chemical Composition (wt. %) | Mechanical Properties | |||||

|---|---|---|---|---|---|---|

| Fe | C | Si | Mn | Ultimate tensile strength (MPa) | Yield strength (MPa) | Elongation (%) |

| Bal. | 0.2 | 1.5 | 2.4 | 980 | 625 | 21 |

| Electrode Force (kN) | Welding Current (kA) | Time (Cycle *) | ||

|---|---|---|---|---|

| Squeeze | Weld | Hold | ||

| 4 | 9 | 45 | 30 | 5 |

Disclaimer/Publisher’s Note: The statements, opinions and data contained in all publications are solely those of the individual author(s) and contributor(s) and not of MDPI and/or the editor(s). MDPI and/or the editor(s) disclaim responsibility for any injury to people or property resulting from any ideas, methods, instructions or products referred to in the content. |

© 2023 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (https://creativecommons.org/licenses/by/4.0/).

Share and Cite

Kim, J.W.; Manladan, S.M.; Mahmud, K.; Jin, W.; Krishna, T.; Ji, C.; Nam, D.-G.; Park, Y.-D. Liquid Metal Embrittlement Cracking in Uncoated Transformation-Induced Plasticity Steel during Consecutive Resistance Spot Welding. Metals 2023, 13, 1826. https://doi.org/10.3390/met13111826

Kim JW, Manladan SM, Mahmud K, Jin W, Krishna T, Ji C, Nam D-G, Park Y-D. Liquid Metal Embrittlement Cracking in Uncoated Transformation-Induced Plasticity Steel during Consecutive Resistance Spot Welding. Metals. 2023; 13(11):1826. https://doi.org/10.3390/met13111826

Chicago/Turabian StyleKim, Jae Won, Sunusi Marwana Manladan, Kaisar Mahmud, Woosung Jin, Tejaswin Krishna, Changwook Ji, Dae-Geun Nam, and Yeong-Do Park. 2023. "Liquid Metal Embrittlement Cracking in Uncoated Transformation-Induced Plasticity Steel during Consecutive Resistance Spot Welding" Metals 13, no. 11: 1826. https://doi.org/10.3390/met13111826

APA StyleKim, J. W., Manladan, S. M., Mahmud, K., Jin, W., Krishna, T., Ji, C., Nam, D.-G., & Park, Y.-D. (2023). Liquid Metal Embrittlement Cracking in Uncoated Transformation-Induced Plasticity Steel during Consecutive Resistance Spot Welding. Metals, 13(11), 1826. https://doi.org/10.3390/met13111826