Determination of the Feasibility of Using Eco-Friendly Walnut Shell Abrasive Particles for Pocket Milling of Titanium Workpieces by Abrasive Waterjet Technology

Abstract

:1. Introduction

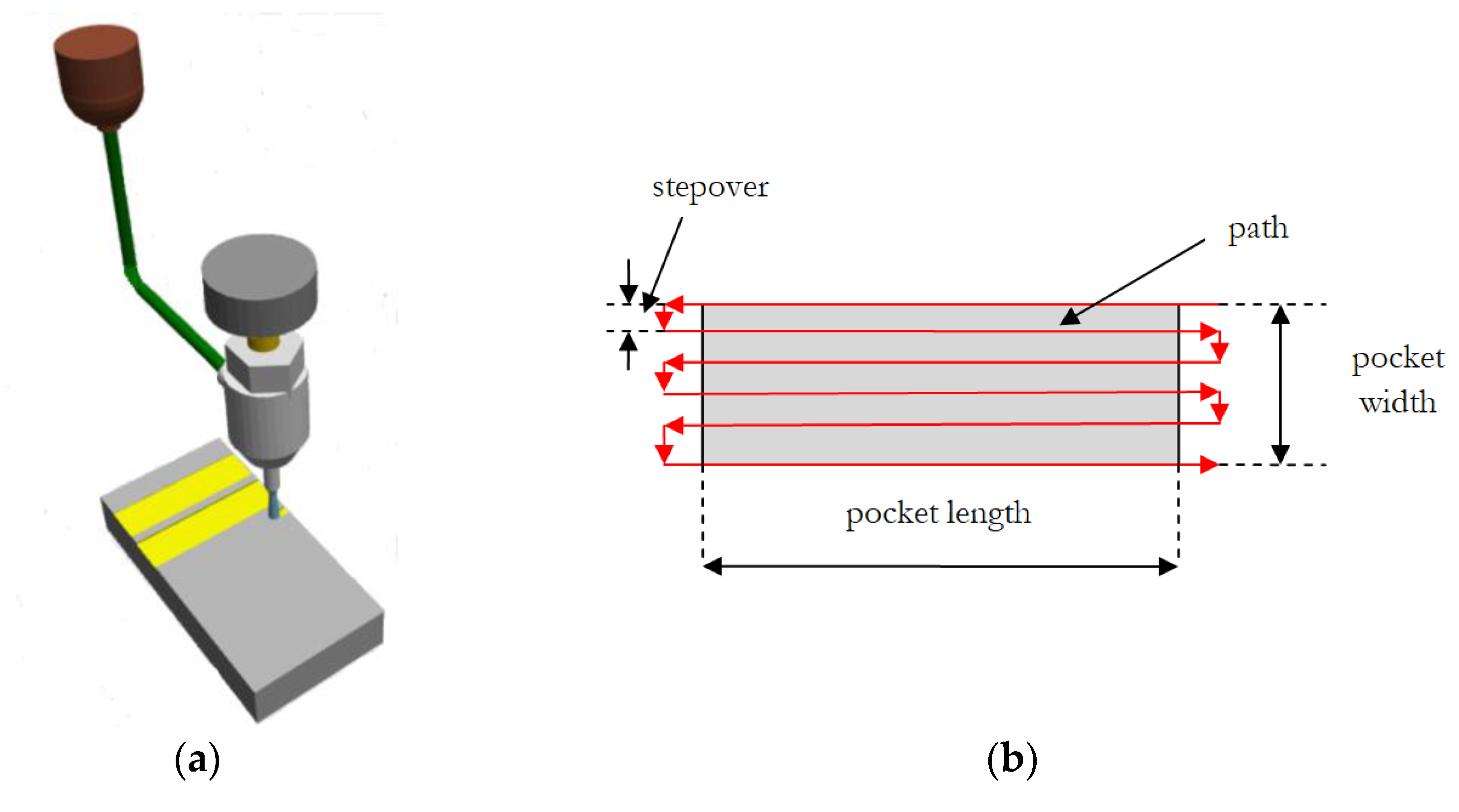

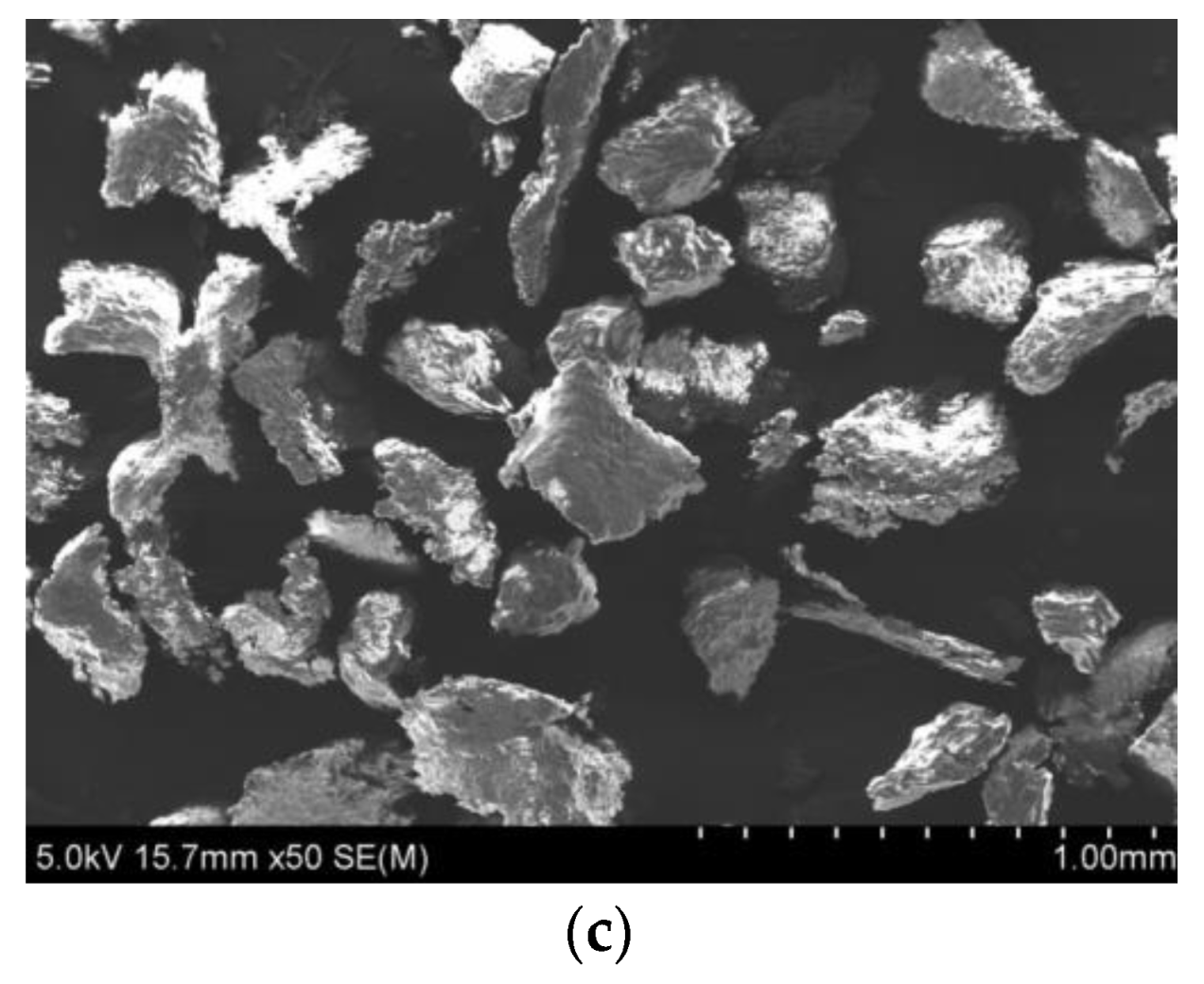

2. Materials and Methods

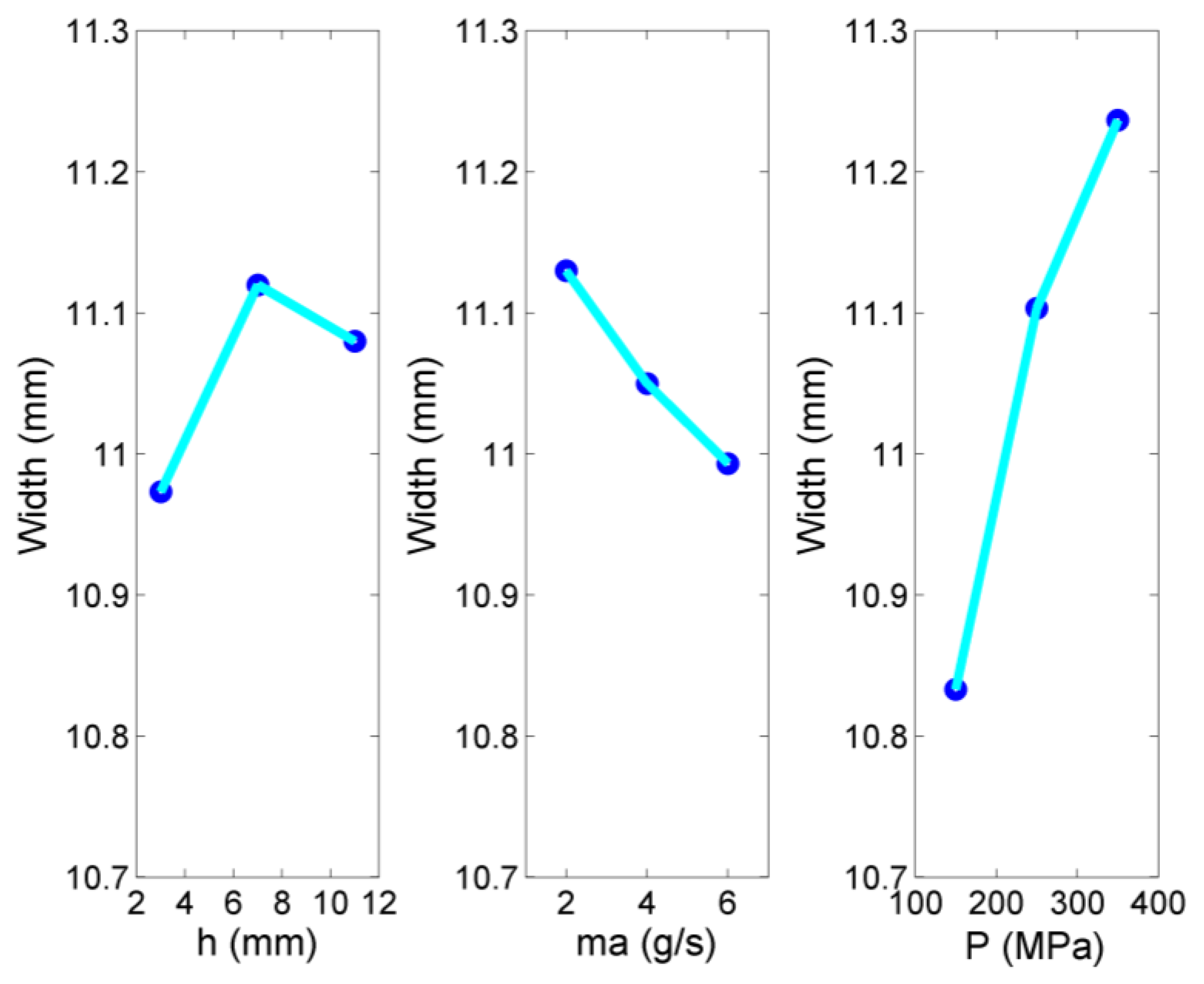

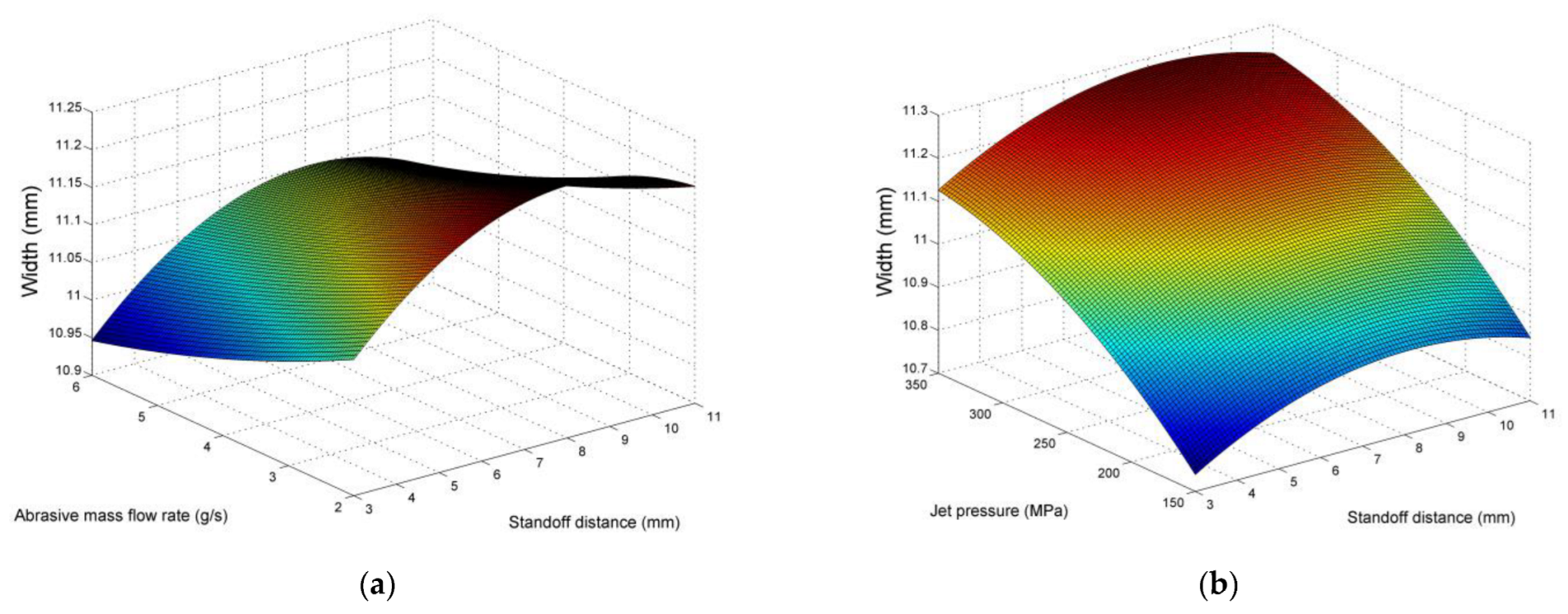

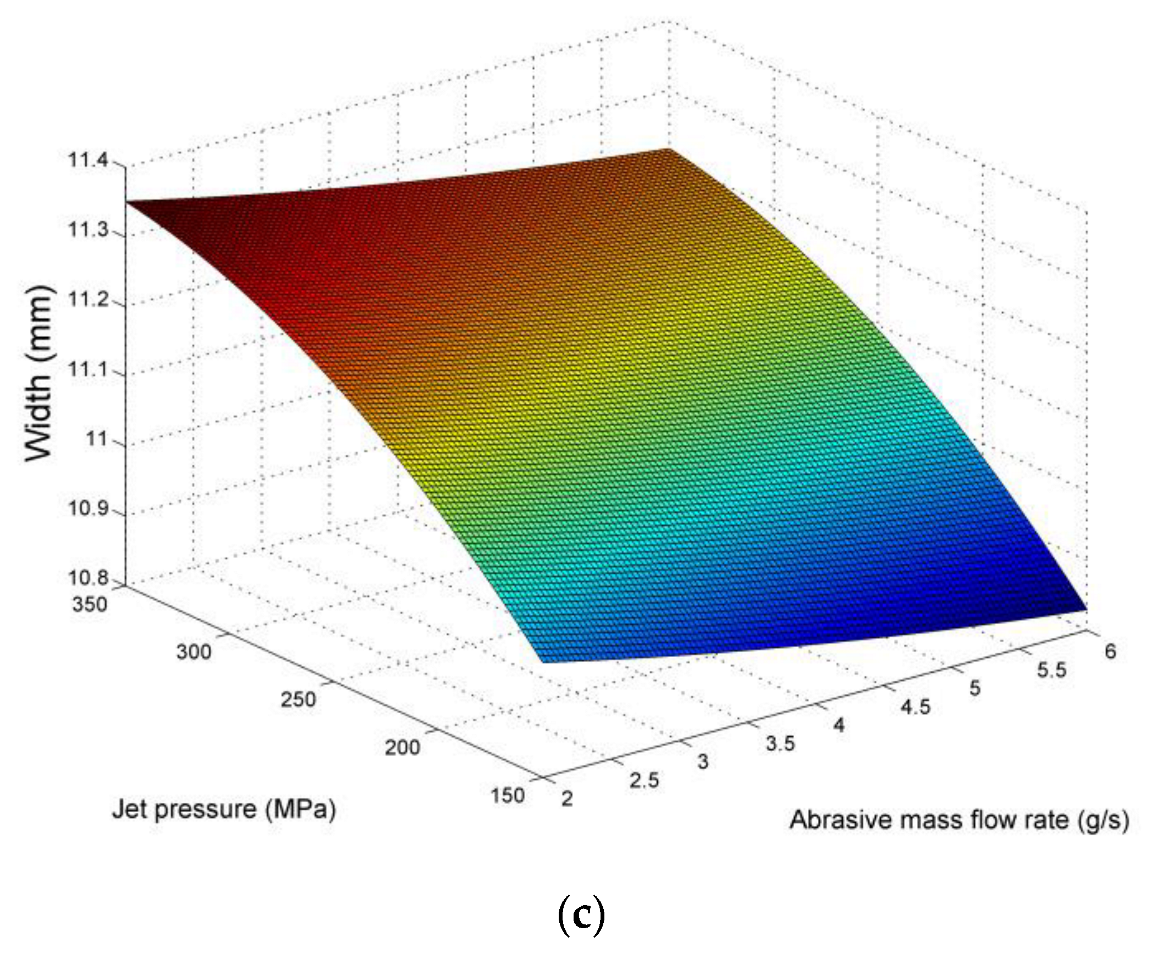

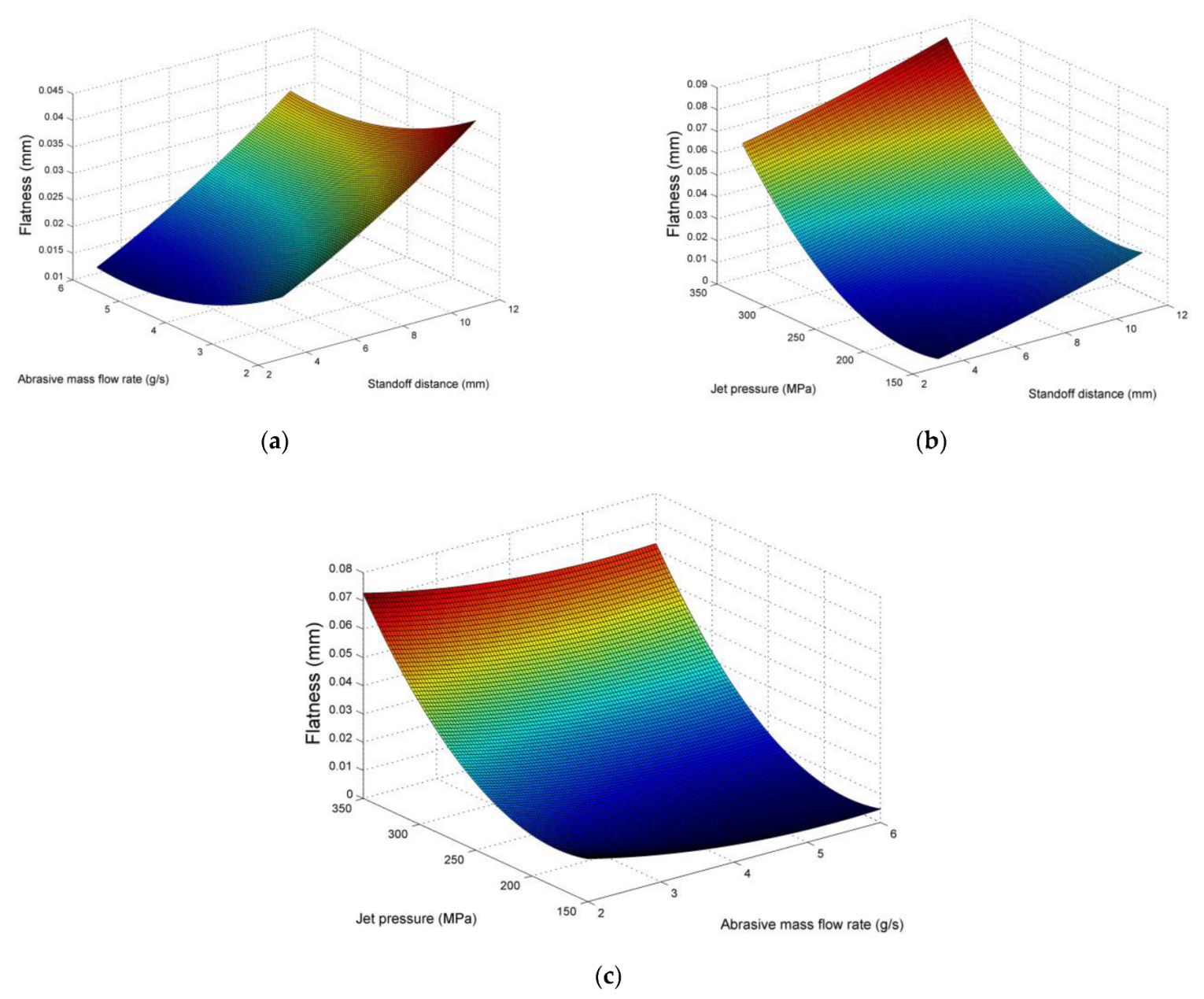

3. Results and Discussion

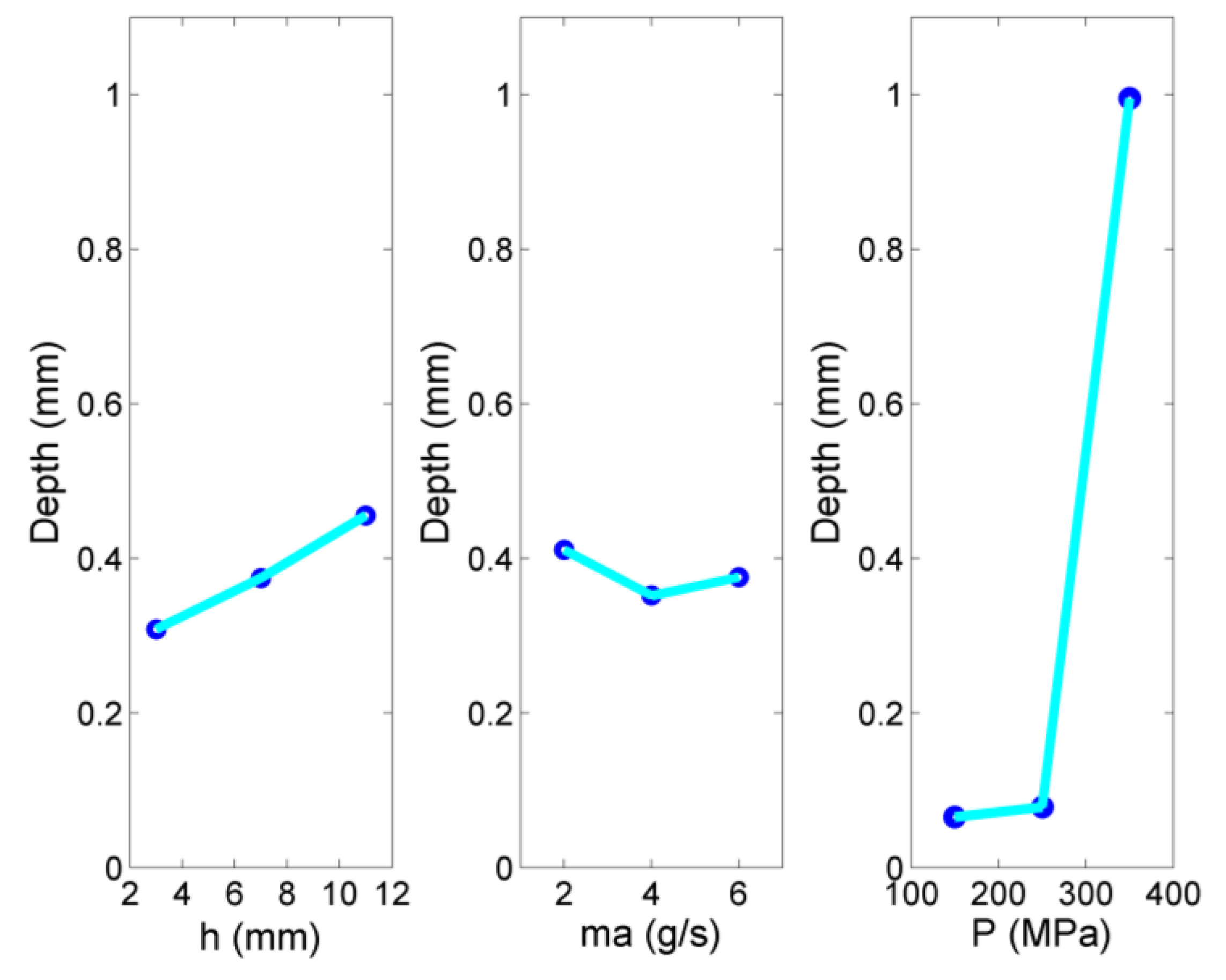

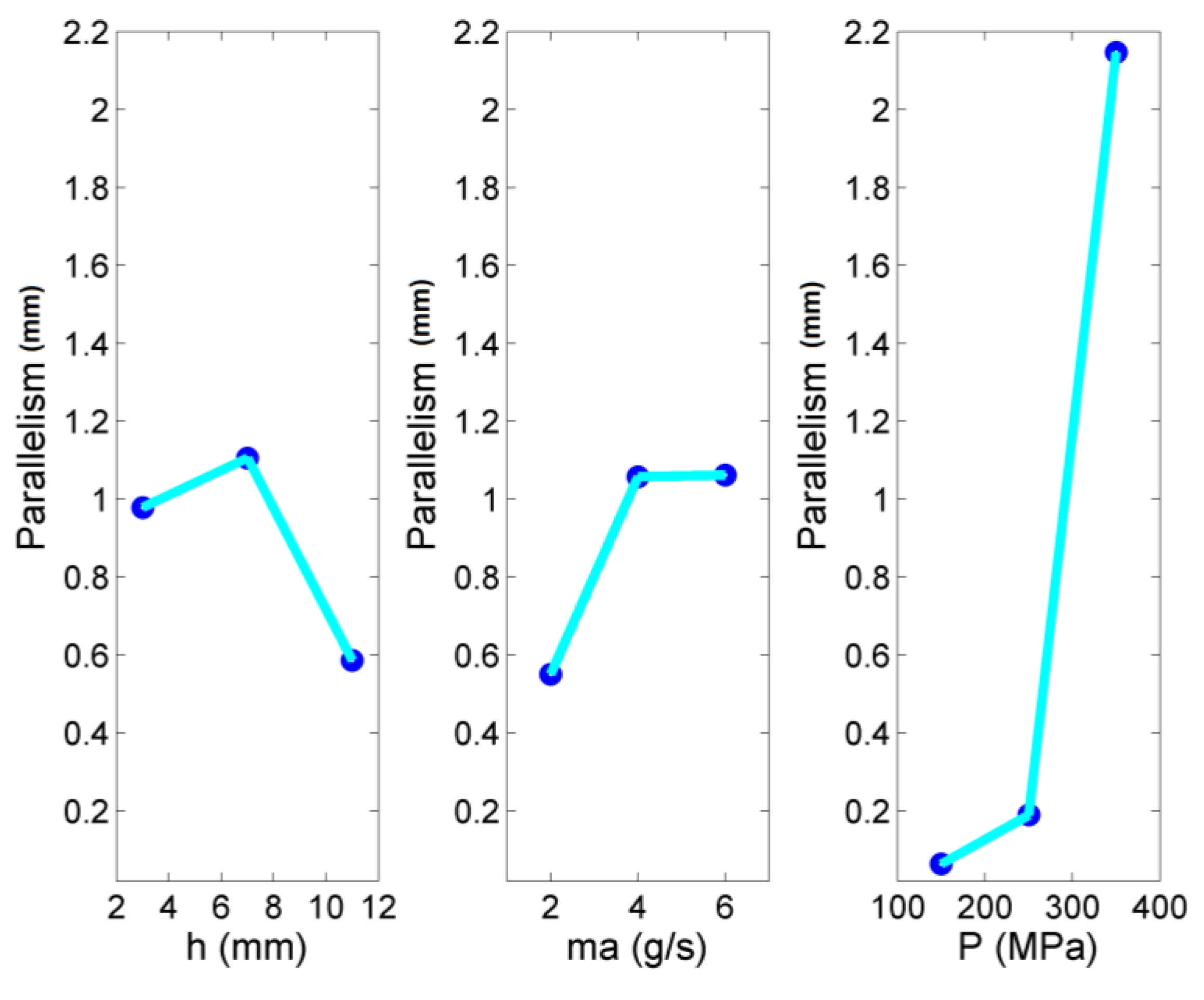

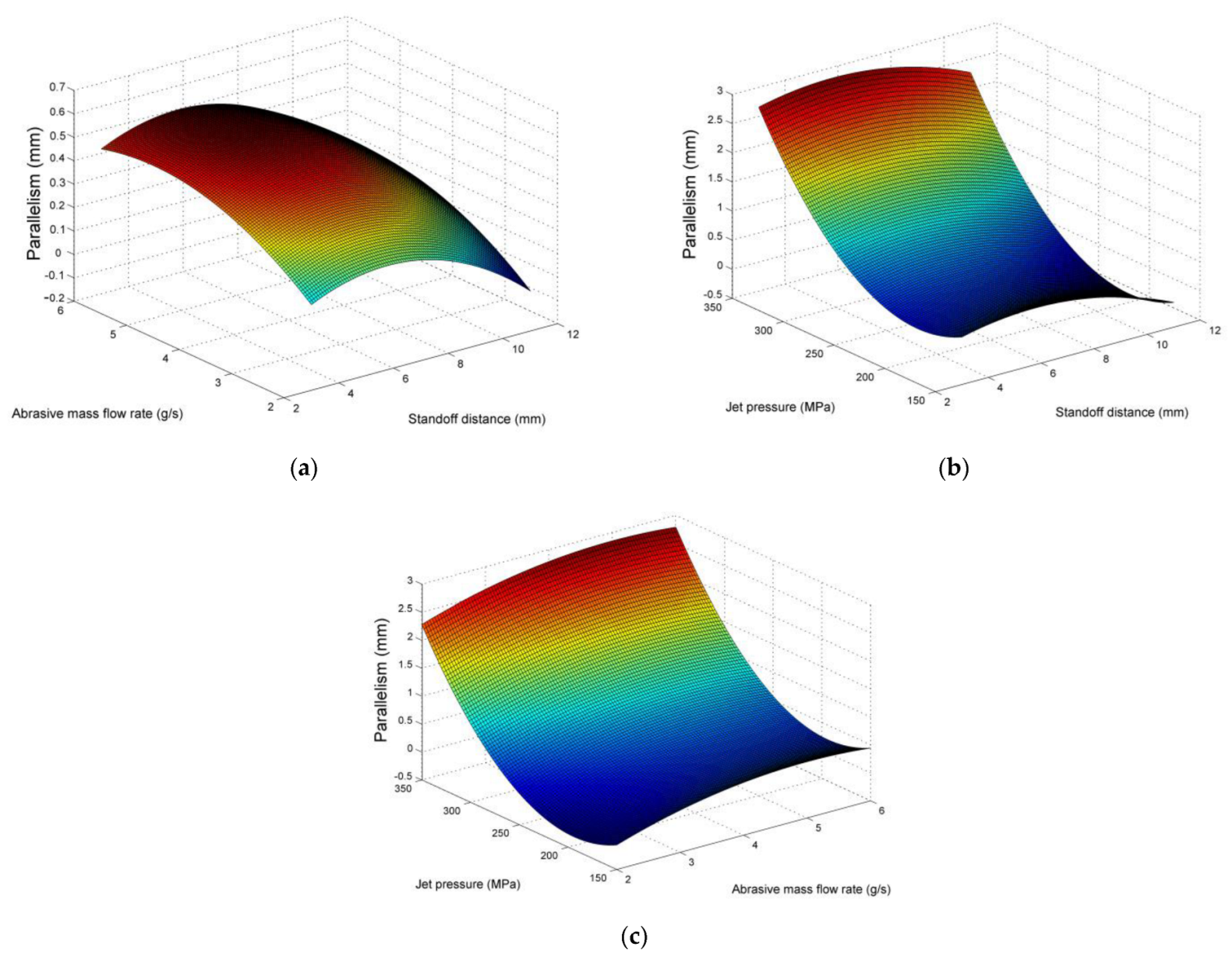

3.1. First Series of Experiments

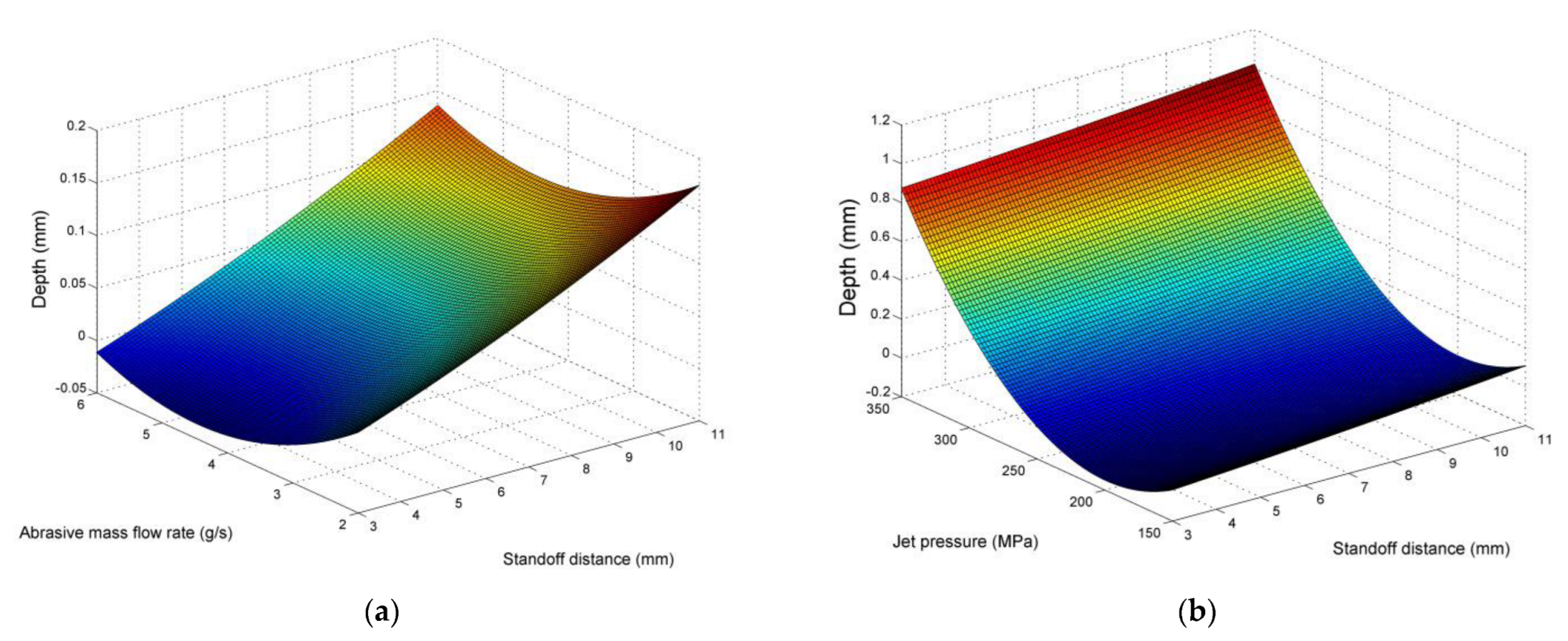

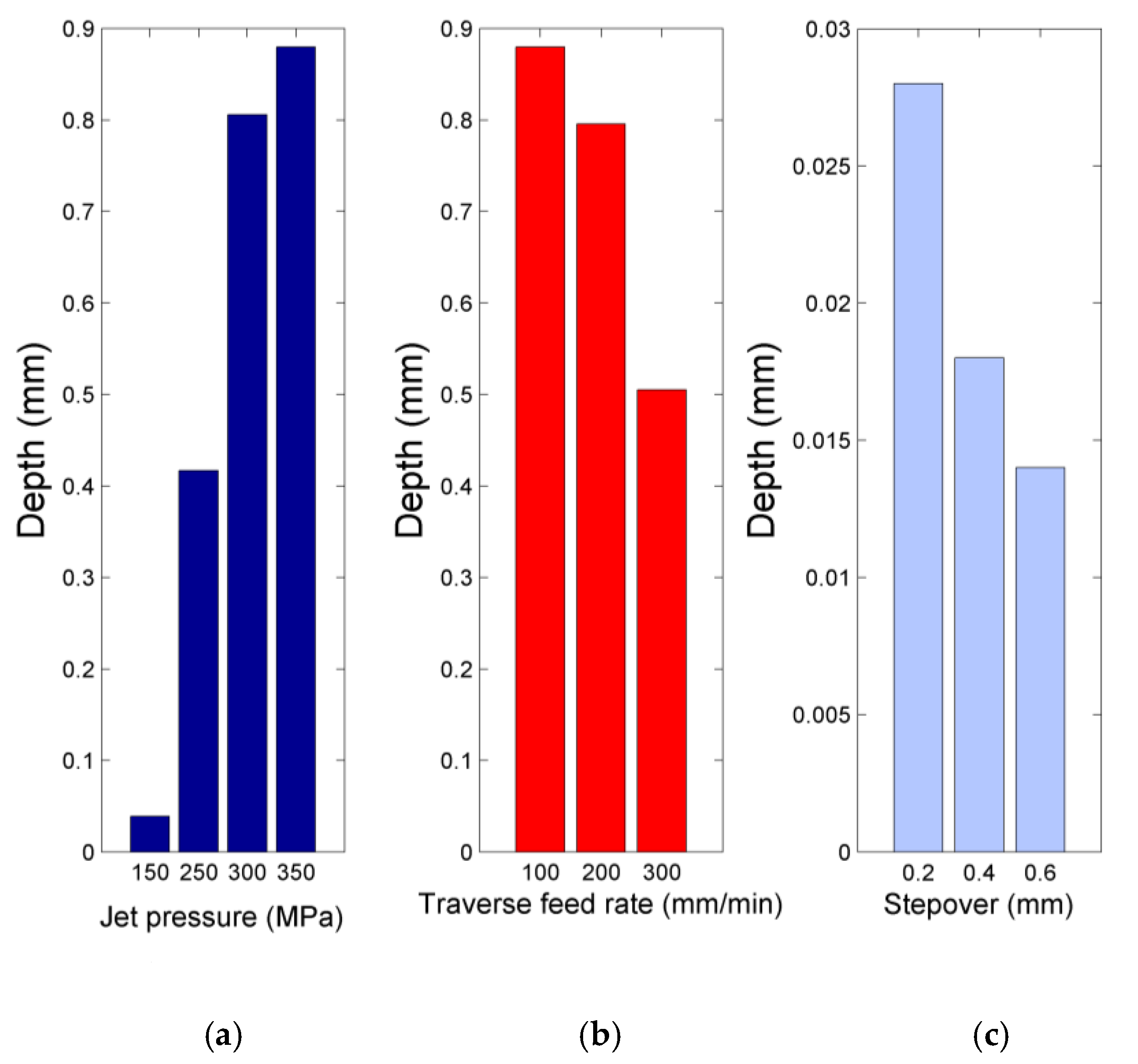

3.2. Additional Series of Experiments

4. Conclusions

Author Contributions

Funding

Data Availability Statement

Conflicts of Interest

References

- Alvarez, M.E.P.; Barcena, M.M.; Gonzalez, F.A. On the sustainability of machining processes. Proposal for a unified framework through the triple bottom-line from an understanding review. J. Clean. Prod. 2017, 142, 3890–3904. [Google Scholar] [CrossRef]

- Natarajan, Y.; Murugesan, P.K.; Mohan, M.; Khan, S.A.L.A. Abrasive water jet machining process: A state of art of review. J. Manuf. Process 2020, 49, 271–322. [Google Scholar]

- Liu, X.; Liang, Z.; Wen, G.; Yuan, X. Waterjet machining and research developments: A review. Int. J. Adv. Manuf. Technol. 2019, 102, 1257–1335. [Google Scholar]

- Dong, Y.; Liu, W.; Zhang, H.; Zhang, H. On-line recycling of abrasives in abrasive water jet cleaning. Procedia CIRP 2014, 15, 278–282. [Google Scholar] [CrossRef]

- Perec, A. Disintegration and recycling possibility of selected abrasives for water jet cutting. DYNA 2017, 84, 249–256. [Google Scholar] [CrossRef]

- Perec, A. Environmental aspects of abrasive water jet cutting. Annu. Set. Environ. Prot. 2018, 20, 258–274. [Google Scholar]

- Perec, A.; Radomska-Zalas, A.; Fajdek-Bieda, A.; Kawecka, E. Efficiency of tool steel cutting by water jet with recycled abrasive materials. Materials 2022, 15, 3978. [Google Scholar] [CrossRef] [PubMed]

- Kantha Babu, M.; Krishnaiah Chetty, O.V. A study on recycling of abrasives in abrasive water jet machining. Wear 2003, 254, 763–773. [Google Scholar] [CrossRef]

- Pi, V.N.; Chau, H.V.; Hung, T.Q. A study on recycling of supreme garnet in abrasive waterjet machining. Appl. Mech. Mater. 2013, 248, 499–503. [Google Scholar] [CrossRef]

- Kantha Babu, M.; Krishnaiah Chetty, O.V. Studies on recharging of abrasives in abrasive water jet machining. Int. J. Adv. Manuf. Technol. 2002, 19, 697–703. [Google Scholar] [CrossRef]

- Yang, M.; Liu, H.; Ye, B.; Qian, W. Recycling of printed circuit boards by abrasive waterjet cutting. Process Saf. Environ. Prot. 2021, 148, 805–812. [Google Scholar] [CrossRef]

- Shinzato, M.C.; Hypolito, R. Solid waste from aluminum recycling process: Characterization and reuse of its economically valuable constituents. Waste Manag. 2005, 25, 37–46. [Google Scholar] [CrossRef] [PubMed]

- Tsai, T.H. Silicon sawing waste treatment by electrophoresis and gravitational settling. J. Hazard. Mater. 2011, 189, 526–530. [Google Scholar] [CrossRef]

- Aydin, G.; Kaya, S.; Karakurt, I. Utilization of solid-cutting waste of granite as an alternative abrasive in abrasive waterjet cutting of marble. J. Clean. Prod. 2017, 159, 241–247. [Google Scholar] [CrossRef]

- Sarici, D.E.; Ozdemir, E. Utilization of granite waste as alternative abrasive material in marble grinding processes. J. Clean. Prod. 2018, 201, 516–525. [Google Scholar] [CrossRef]

- Sabarinathan, P.; Annamalai, V.E.; Rajkumar, K. Sustainable application of grinding wheel waste as abrasive for abrasive water jet machining process. J. Clean. Prod. 2020, 261, 121225. [Google Scholar] [CrossRef]

- Muthukumaran, N.; Devaraj, P.; Arunkumar, P.; Sekar, T. Re-use of abandoned sanitary ware waste as abrasive particles for abrasive jet machine. Mater. Today Proc. 2021, 45, 562–568. [Google Scholar] [CrossRef]

- Murari, K.; Siddique, R.; Jain, K.K. Use of waste copper slag, a sustainable material. J. Mater. Cycles Waste Manag. 2015, 17, 13–26. [Google Scholar] [CrossRef]

- Barsukov, G.; Zhuravleva, T.; Kozhus, O. Study of the effect of heat treatment of copper slag particles on abrasiveness for abrasive waterjet cutting. Int. J. Adv. Manuf. Technol. 2023. [Google Scholar] [CrossRef]

- Kim, Y.J.; Kim, S.B.; Park, H.H.; Cho, S.B. Effect of disagglomeration on the recovery of abrasives from waste sludge. Geosystem Eng. 2007, 10, 37–40. [Google Scholar] [CrossRef]

- Sabarinathan, P.; Veiravan, A.; Kaliyamoorthy, R.; Kumar, V. Sustainable solution to low-cost alternative abrasive from electric ceramic insulator waste for use in abrasive water jet machining. Int. J. Adv. Manuf. Technol. 2022, 120, 5243–5257. [Google Scholar]

- Sabarinathan, P.; Annamalai, V.E. Removal of aluminosilicate bond and processs optimization on recovery of sol gel alumina abrasive grain from abrasive industry waste. Silicon 2021, 13, 495–505. [Google Scholar] [CrossRef]

- Fonseca, S.C.L. Characterization and Testing of Ferrous Granules as an Abrasive for Water Jet Cutting. Master’s Thesis, University of British Columbia, Vancouver, BC, Canada, 2018. [Google Scholar]

- Schuler, M.; Day, R.; Bergs, T. Benchmark of abrasives for different applications. In Proceedings of the WJTA Conference & Expo 2022. Conference Proceedings, New Orleans, LA, USA, 1–3 November 2022. [Google Scholar]

- Perec, A. Experimental research into alternative abrasive material for the abrasive water-jet cutting of titanium. Int. J. Adv. Manuf. Technol. 2018, 97, 1529–1540. [Google Scholar] [CrossRef]

- Zulkarnain, I.; Lai, L.S.; Syakir, M.I.; Rahman, A.A.; Yusuff, S.; Hanafiah, M.M. Life cycle assessment of crushed glass abrasive manufacturing from recycled glass. IOP Conf. Ser. Earth Environ. Sci. 2021, 880, 12054. [Google Scholar] [CrossRef]

- Deo, A.; Bagal, D.K.; Pattanaik, A.K.; Panda, S.N.; Barua, A.; Barkey, R.K.; Jeet, S. Recent advancements in ice jet machining process as an alternative of AWJM. Mater. Today Proc. 2022, 50, 981–985. [Google Scholar] [CrossRef]

- Jerman, M.; Orbanic, H.; Junkar, M.; Lebar, A. Thermal aspects of ice abrasive water jet technology. Adv. Mech. Eng. 2015, 7, 1687814015597619. [Google Scholar] [CrossRef]

- Jerman, M.; Orbanic, H.; Valentincic, J. CFD analysis of thermal fields for ice abrasive water jet. Int. J. Mech. Sci. 2022, 220, 107154. [Google Scholar] [CrossRef]

- Lavorel, F.; El Mansori, M.; Chegdani, F.; Tazibt, A. Wear under brittle removal regime of an under-expanded cryogenic nitrogen jet machining of bio-composites. Wear 2021, 477, 203795. [Google Scholar] [CrossRef]

- Natarajan, Y.; Murugasen, P.K.; Sundarajan, L.R.; Arunachalam, R. Experimental investigation on cryogenic assisted abrasive waterjet machining of aluminium alloy. Int. J. Precis. Eng. Manuf. 2019, 6, 415–432. [Google Scholar]

- Kohli, R. Microabrasive technology for prediction cleaning and processing. In Developments in Surface Contamination and Cleaning, 2nd ed.; Kohli, R., Mittal, K.L., Eds.; William Andrew Publishing: San Diego, CA, USA, 2016; Volume 1, pp. 627–666. [Google Scholar]

- Islam, M.B.; Islam, M.; Islam, S.U. Facile fabrication of abrasive materials for sandpaper from waste materials. Clean. Waste Syst. 2023, 4, 100066. [Google Scholar] [CrossRef]

- Jiang, Z.; Cong, Y.; Li, X.; Xu, J.; Wang, M. Application of sodium bicarbonate abrasive jet technology for PCB desmear process: Conditions and simulation. J. Clean. Prod. 2023, 396, 136584. [Google Scholar] [CrossRef]

- Osa, J.L.; Mondragon, G.; Ortega, N.; Marzo, F.F.; Pena-Rodriguez, C. On the friability of mussel shells as abrasive. J. Clean. Prod. 2022, 375, 134020. [Google Scholar] [CrossRef]

- Awadh, S.M.; Ali Khalid, S. Tigris river sediments as abrasive for polishing marble. Nat. Resour. Res. 2019, 28, 1371–1383. [Google Scholar] [CrossRef]

- Srinivasu, D.S.; Axinte, D.A. Maskless pocket milling of composites by abrasive waterjets: An experimental investigation. J. Manuf. Sci. Eng. 2014, 136, 41005. [Google Scholar] [CrossRef]

- Mikó, B.; Rácz, G. Investigation of Flatness and Angularity in Case of Ball-End Milling. In Proceedings of the International Symposium for Production Research 2018; Durakbasa, N., Gencyilmaz, M., Eds.; Springer: Cham, Switzerland, 2019. [Google Scholar]

- Bustillo, A.; Pimenov, D.Y.; Mia, M.; Kapłonek, W. Machine-learning for automatic prediction of flatness deviation considering the wear of the face mill teeth. J. Intell. Manuf. 2021, 32, 895–912. [Google Scholar] [CrossRef]

- Tai, B.L.; Shih, A.J.; Stephenson, D.A. Improvement of surface flatness in face milling by varying the tool cutting depth and feed rate. In Proceedings of the ASME 2009 International Manufacturing Science and Engineering Conference MSEC2009, West Lafayette, IN, USA, 4–7 October 2009. [Google Scholar]

- Agarwal, A.; Desai, K.A. Tool and workpiece deflection induced flatness errors in milling of thin-walled components. Procedia CIRP 2020, 93, 1411–1416. [Google Scholar] [CrossRef]

- Hazarika, M.; Dixit, U.S.; Deb, S. Effect of datum surface roughness on parallelism and perpendicularity tolerances in milling of prismatic parts. Proc. IMecheE Part. B J. Eng. Manuf. 2009, 224, 1377–1388. [Google Scholar] [CrossRef]

- Khan, M.I.; Ma, S.; Saifullah, S. New method of plane to plane parallelism error measurement based on flatness plane. Adv. Mater. Res. 2014, 941–944, 2209–2218. [Google Scholar] [CrossRef]

- Zha, J.; Zhang, H.; Chen, Y. A strategy to evaluate and minimize parallelism errors of a rotor system in a precision rotary table. Int. J. Adv. Manuf. Technol. 2020, 106, 3641–3648. [Google Scholar] [CrossRef]

- Yuan, Y.; Chen, J.; Gao, H.; Wang, X. An investigation into the abrasive waterjet milling circular pocket on titanium alloy. Int. J. Adv. Manuf. Technol. 2020, 107, 4503–4515. [Google Scholar] [CrossRef]

- Gopichand, G.; Sreenivasarao, M. Multi-response parametric optimisation of abrasive waterjet milling of Hastelloy C-276. SN Appl. Sci. 2020, 2, 1764. [Google Scholar] [CrossRef]

- Escobar-Palafox, G.A.; Gault, R.S.; Ridgway, K. Characterisation of abrasive water-jet process for pocket milling in Inconel 718. Procedia CIRP 2012, 1, 404–408. [Google Scholar] [CrossRef]

- Natarajan, Y.; Naresh Raj, K.L.; Tandon, P. Measurement and analysis of pocket milling features in abrasive waterjet machining of Ti-6Al-4V alloy. Arch. Civil. Mech. Eng. 2023, 23, 42. [Google Scholar] [CrossRef]

- Goutham, U.; Hasu, B.S.; Chakraverti, G.; Kanthababu, M. Experimental investigation of pocket milling on Inconel 825 using abrasive water jet machining. Int. J. Curr. Eng. Technol. 2016, 6, 295–302. [Google Scholar]

- Popan, A.; Balc, N.; Carean, A.; Luca, A.; Miron, A. Research on Abrasive Waterjet milling of the planar surfaces, slots and profiles. Appl. Mech. Mater. 2015, 760, 409–414. [Google Scholar] [CrossRef]

- Kong, M.C.; Srinivasu, D.; Axinte, D.; Voice, W.; McGourlay, J.; Hon, B. On geometric accuracy and integrity of surfaces in multi-mode abrasive waterjet machining of NiTi shape memory alloys. CIRP Ann. Manuf. Technol. 2013, 62, 555–558. [Google Scholar] [CrossRef]

- Nair, A.; Kumanan, S. Multi performance optimization of abrasive waterjet machining of Inconel 617 using WPCA. Mater. Manuf. Process. 2016, 32, 693–699. [Google Scholar] [CrossRef]

| Parameter | Values |

|---|---|

| Stand-off distance (mm) | 3, 7, 11 |

| Abrasive mass flow rate (g/s) | 2, 4, 6 |

| Jet pressure (MPa) | 150, 250, 350 |

| Jet impingement angle (o) | 90 |

| Orifice diameter (mm) | 0.3 |

| Nozzle diameter (mm) | 1.0 |

| Traverse feed rate (mm/min) | 100 |

| Stepover (mm) | 0.6 |

| Titanium (%) | Iron (%) | Oxygen (%) | Carbon (%) | Nitrogen (%) | Hydrogen (%) |

|---|---|---|---|---|---|

| 98.9 | 0.3 | 0.25 | 0.08 | 0.03 | 0.015 |

| No. | h (mm) | ma (g/s) | P (MPa) | d (mm) | σd (mm) | w (mm) | σw (mm) | MRR (mm3/min) | σΜRR(mm3/min) | Flatness (mm) | Parallelism (mm) |

|---|---|---|---|---|---|---|---|---|---|---|---|

| 1 | 3 | 2 | 150 | 0.014 | 0.002 | 10.78 | 0.153 | 0.727 | 0.1043 | 0.015 | 0.108 |

| 2 | 3 | 4 | 250 | 0.031 | 0.003 | 10.97 | 0.108 | 1.637 | 0.1592 | 0.007 | 0.050 |

| 3 | 3 | 6 | 350 | 0.880 | 0.011 | 11.17 | 0.062 | 47.335 | 0.6473 | 0.029 | 2.777 |

| 4 | 7 | 2 | 250 | 0.065 | 0.004 | 11.32 | 0.085 | 3.543 | 0.2196 | 0.011 | 0.166 |

| 5 | 7 | 4 | 350 | 0.951 | 0.015 | 11.25 | 0.052 | 51.519 | 0.8467 | 0.057 | 3.095 |

| 6 | 7 | 6 | 150 | 0.108 | 0.009 | 10.79 | 0.040 | 5.611 | 0.468 | 0.014 | 0.056 |

| 7 | 11 | 2 | 350 | 1.154 | 0.014 | 11.29 | 0.056 | 62.738 | 0.8184 | 0.078 | 1.379 |

| 8 | 11 | 4 | 150 | 0.074 | 0.005 | 10.93 | 0.117 | 3.895 | 0.2664 | 0.013 | 0.028 |

| 9 | 11 | 6 | 250 | 0.139 | 0.007 | 11.02 | 0.042 | 7.376 | 0.3725 | 0.030 | 0.352 |

Disclaimer/Publisher’s Note: The statements, opinions and data contained in all publications are solely those of the individual author(s) and contributor(s) and not of MDPI and/or the editor(s). MDPI and/or the editor(s) disclaim responsibility for any injury to people or property resulting from any ideas, methods, instructions or products referred to in the content. |

© 2023 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (https://creativecommons.org/licenses/by/4.0/).

Share and Cite

Karkalos, N.E.; Karmiris-Obratański, P. Determination of the Feasibility of Using Eco-Friendly Walnut Shell Abrasive Particles for Pocket Milling of Titanium Workpieces by Abrasive Waterjet Technology. Metals 2023, 13, 1645. https://doi.org/10.3390/met13101645

Karkalos NE, Karmiris-Obratański P. Determination of the Feasibility of Using Eco-Friendly Walnut Shell Abrasive Particles for Pocket Milling of Titanium Workpieces by Abrasive Waterjet Technology. Metals. 2023; 13(10):1645. https://doi.org/10.3390/met13101645

Chicago/Turabian StyleKarkalos, Nikolaos E., and Panagiotis Karmiris-Obratański. 2023. "Determination of the Feasibility of Using Eco-Friendly Walnut Shell Abrasive Particles for Pocket Milling of Titanium Workpieces by Abrasive Waterjet Technology" Metals 13, no. 10: 1645. https://doi.org/10.3390/met13101645

APA StyleKarkalos, N. E., & Karmiris-Obratański, P. (2023). Determination of the Feasibility of Using Eco-Friendly Walnut Shell Abrasive Particles for Pocket Milling of Titanium Workpieces by Abrasive Waterjet Technology. Metals, 13(10), 1645. https://doi.org/10.3390/met13101645