Effect of Return Fines Embedding on the Sintering Behaviour of Vanadium Titanium Magnetite Concentrates

Abstract

1. Introduction

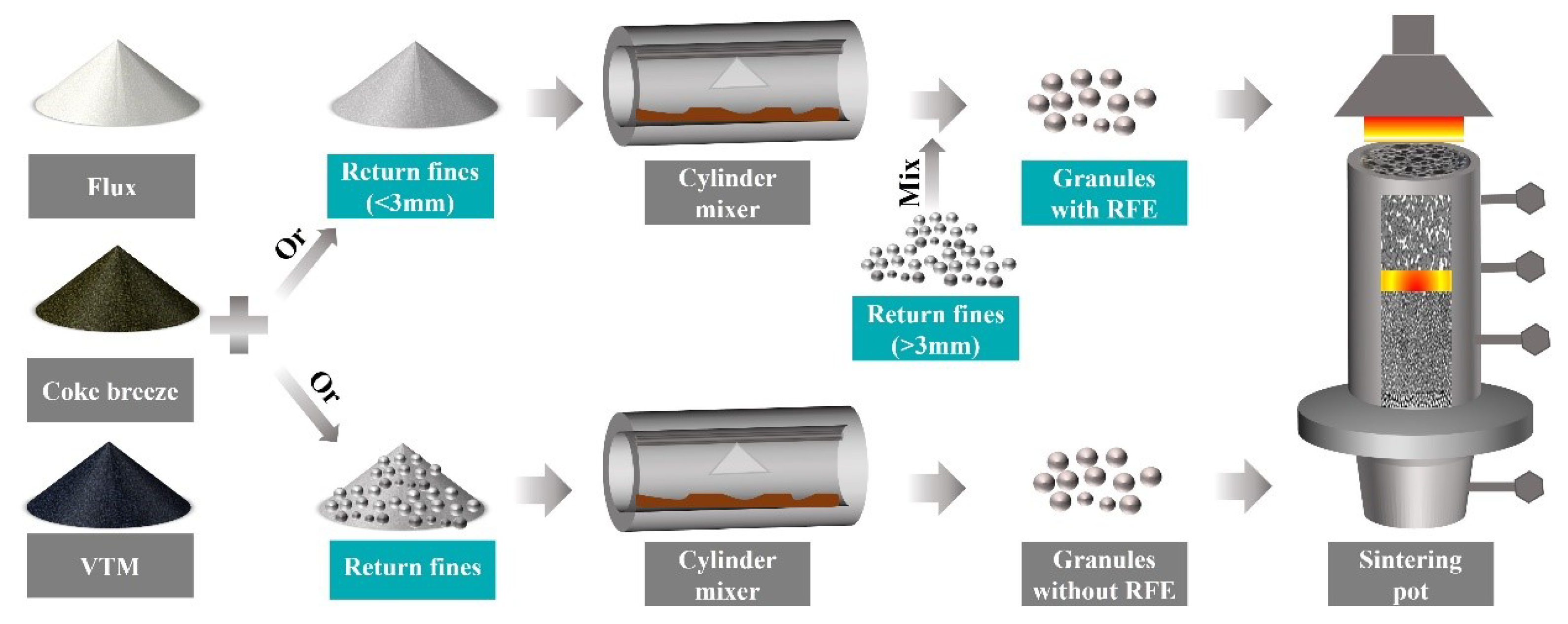

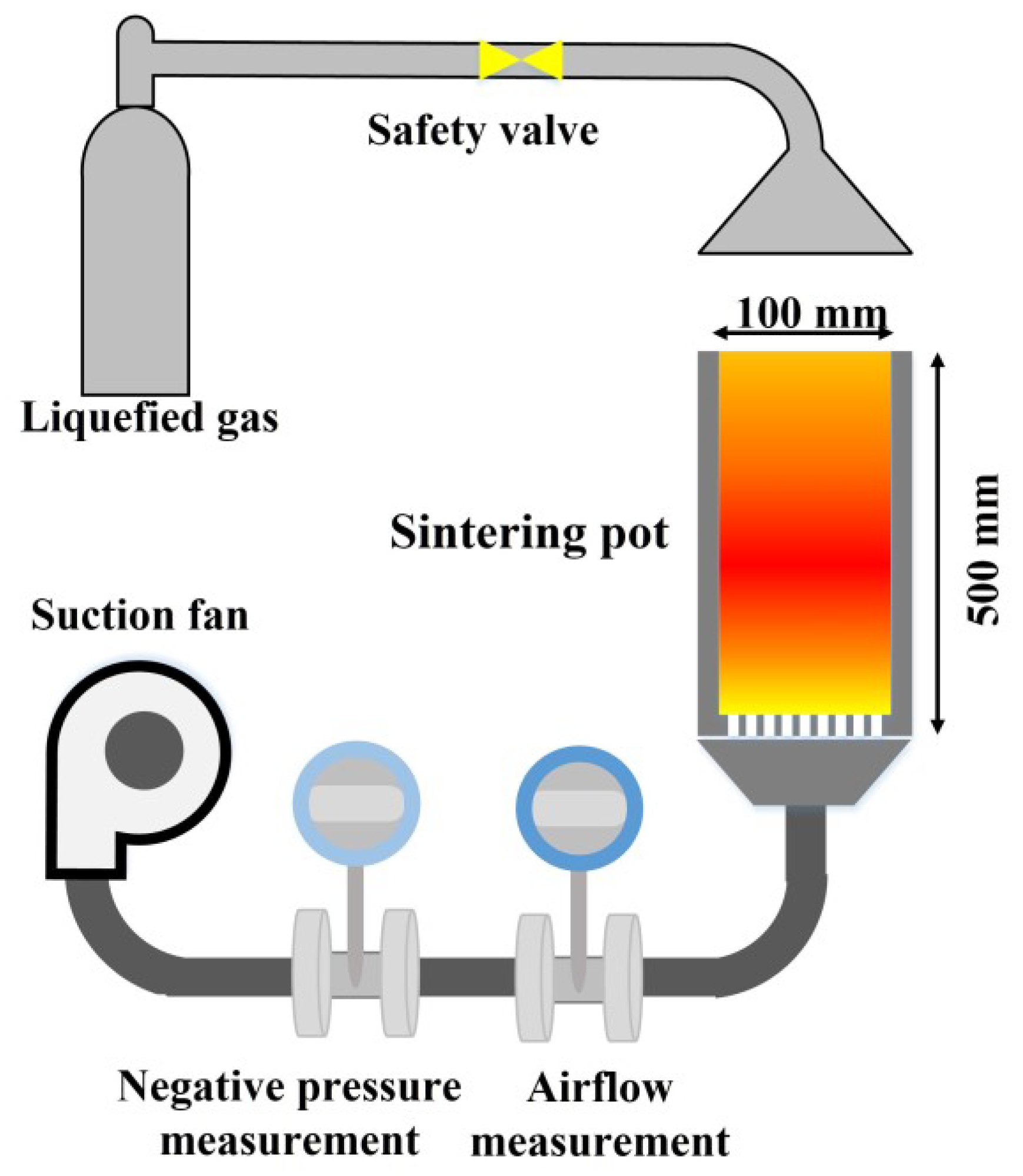

2. Materials and Methods

2.1. Raw Materials

2.2. Metallurgical Characterization of VTM Sinter

2.3. Permeability

3. Results

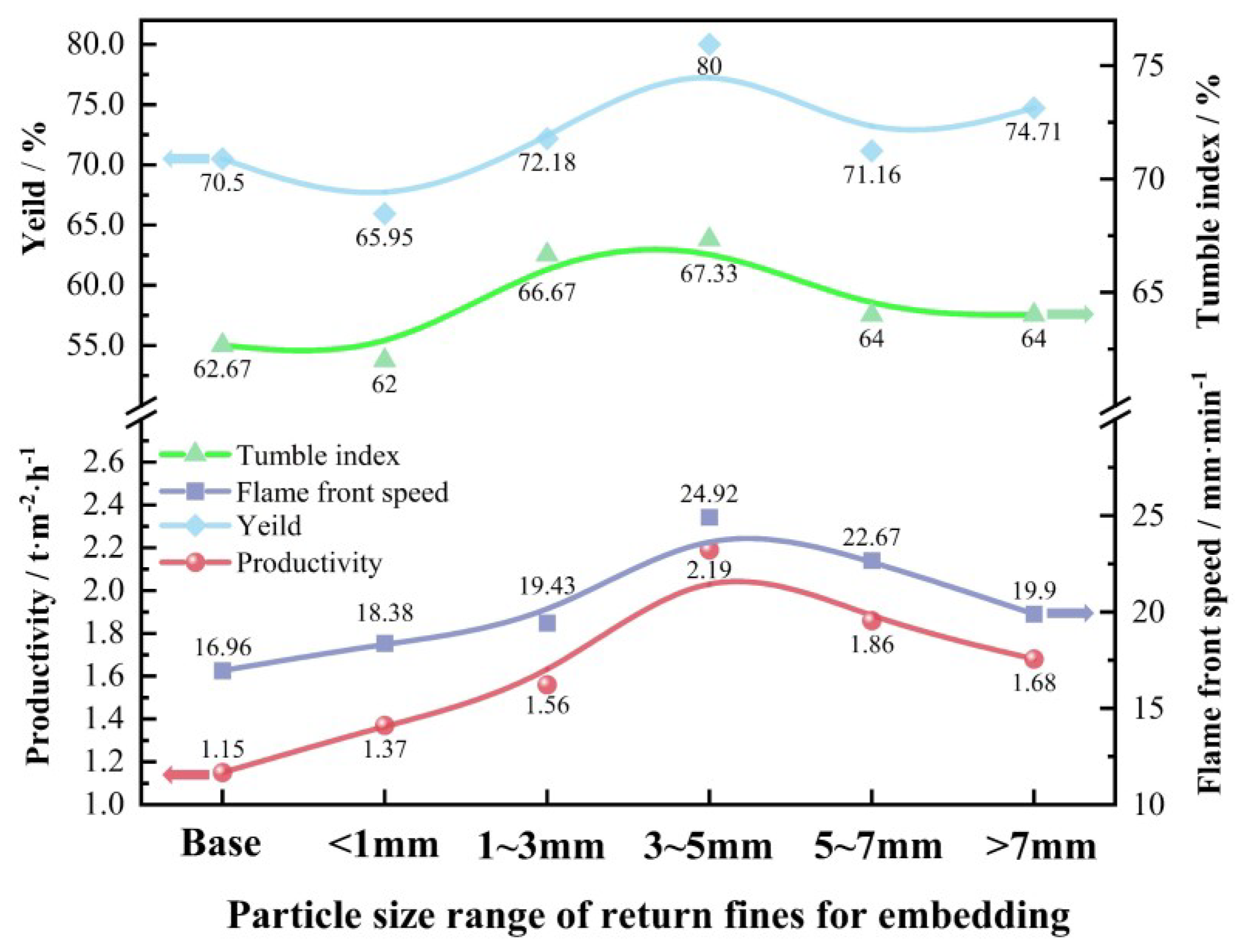

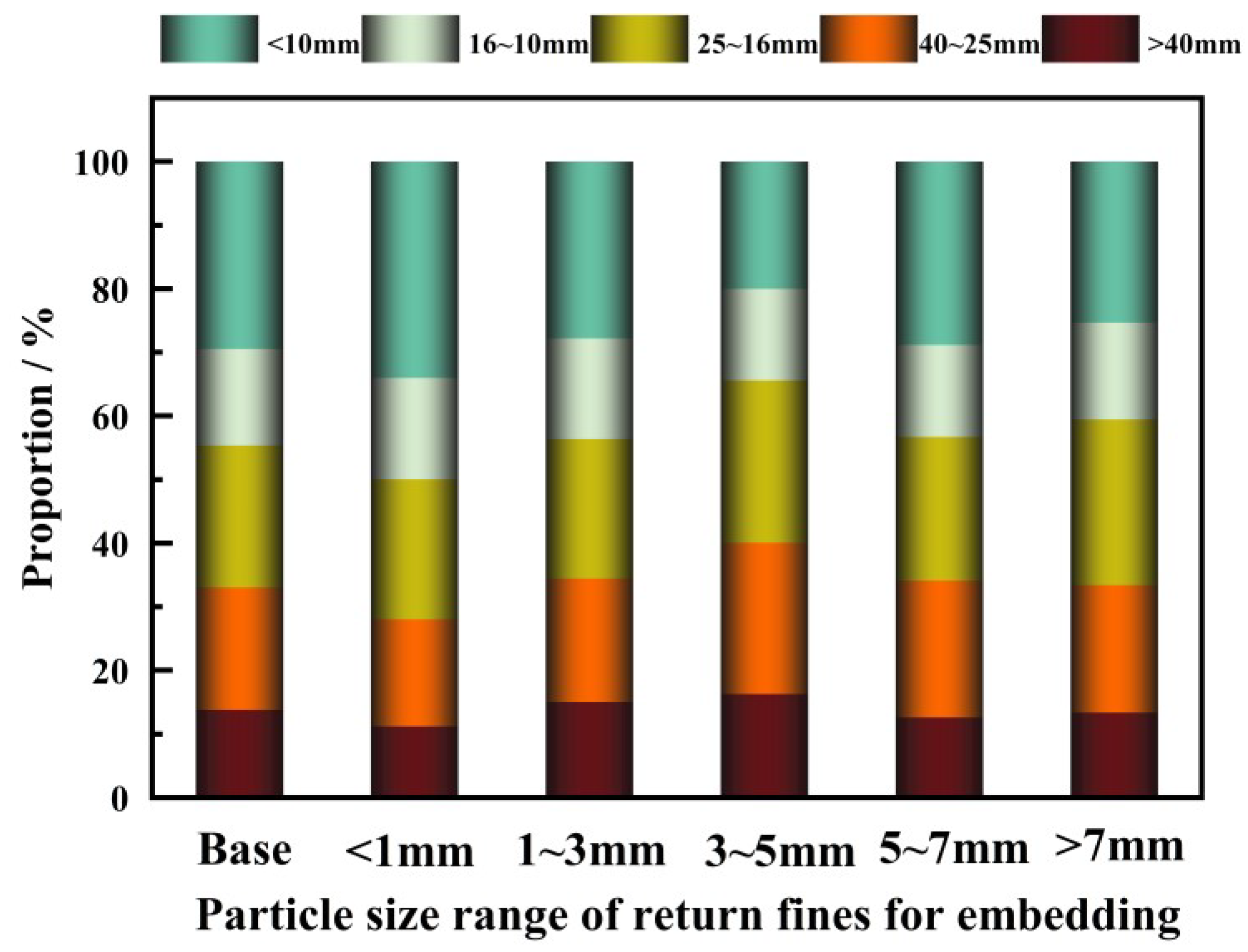

3.1. Effect of Particle Size Range of Return Fines for Embedding

3.2. Effect of Mass Ratio of Return Fines for Embedding

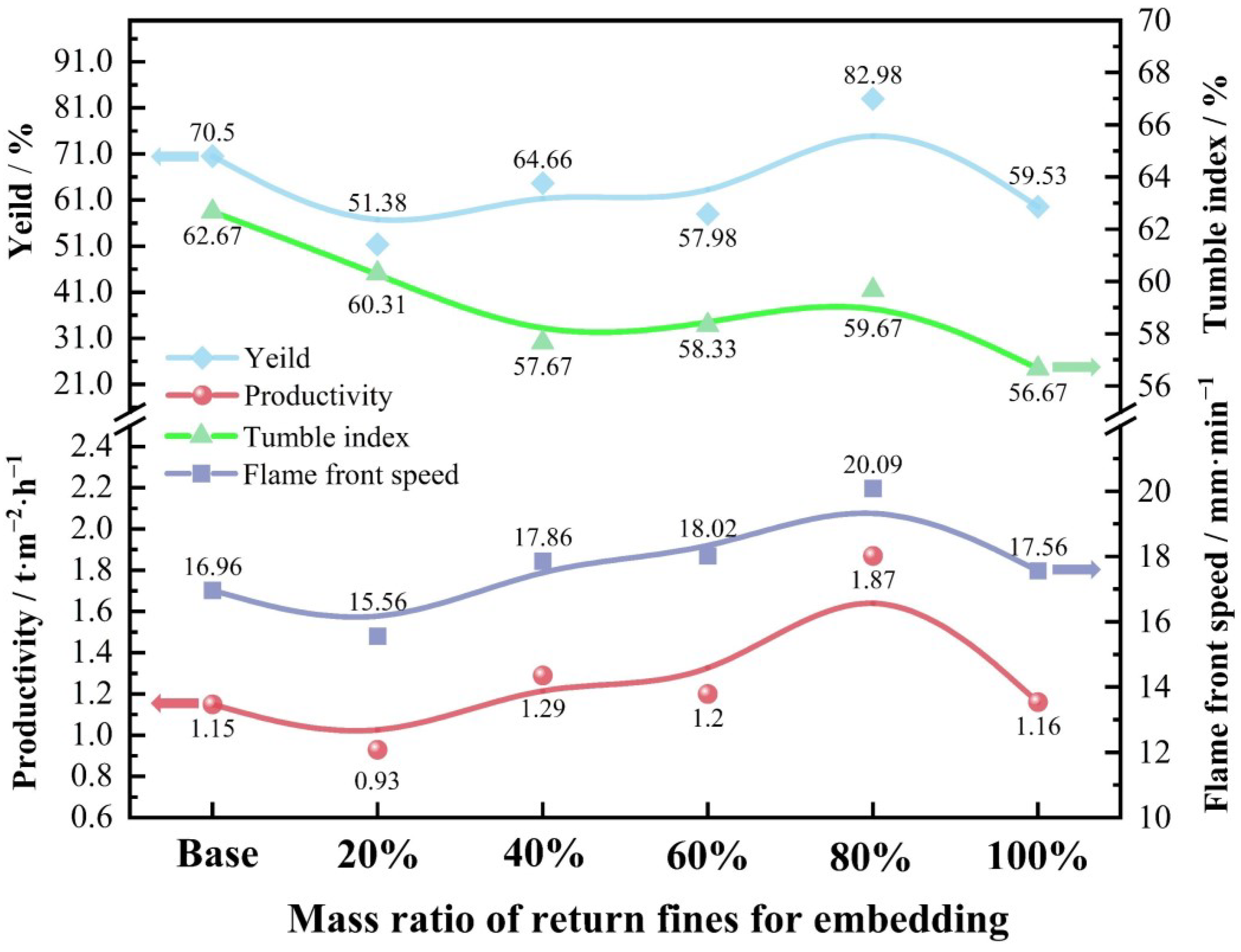

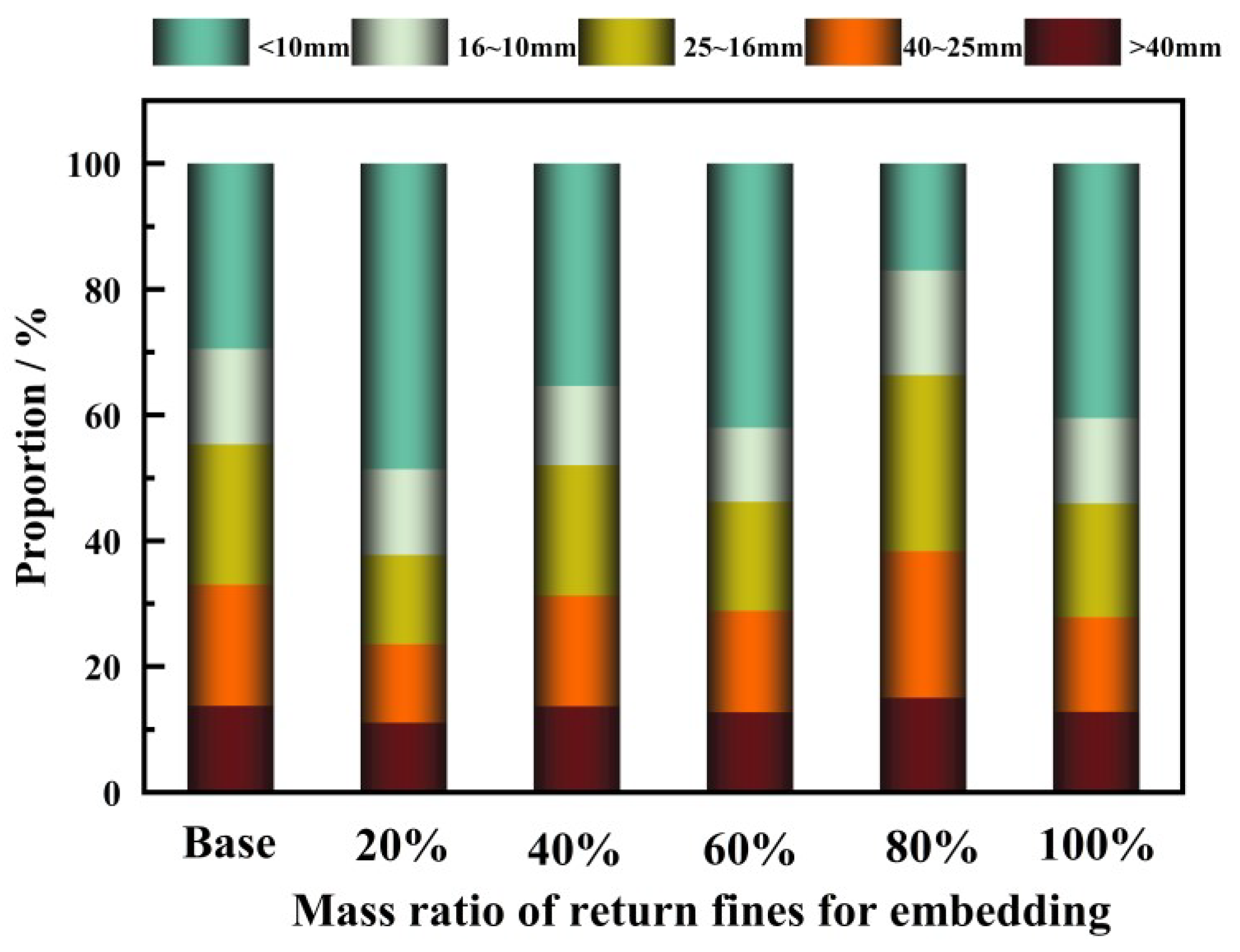

3.3. Effect of Layer Location of Return Fines for Embedding

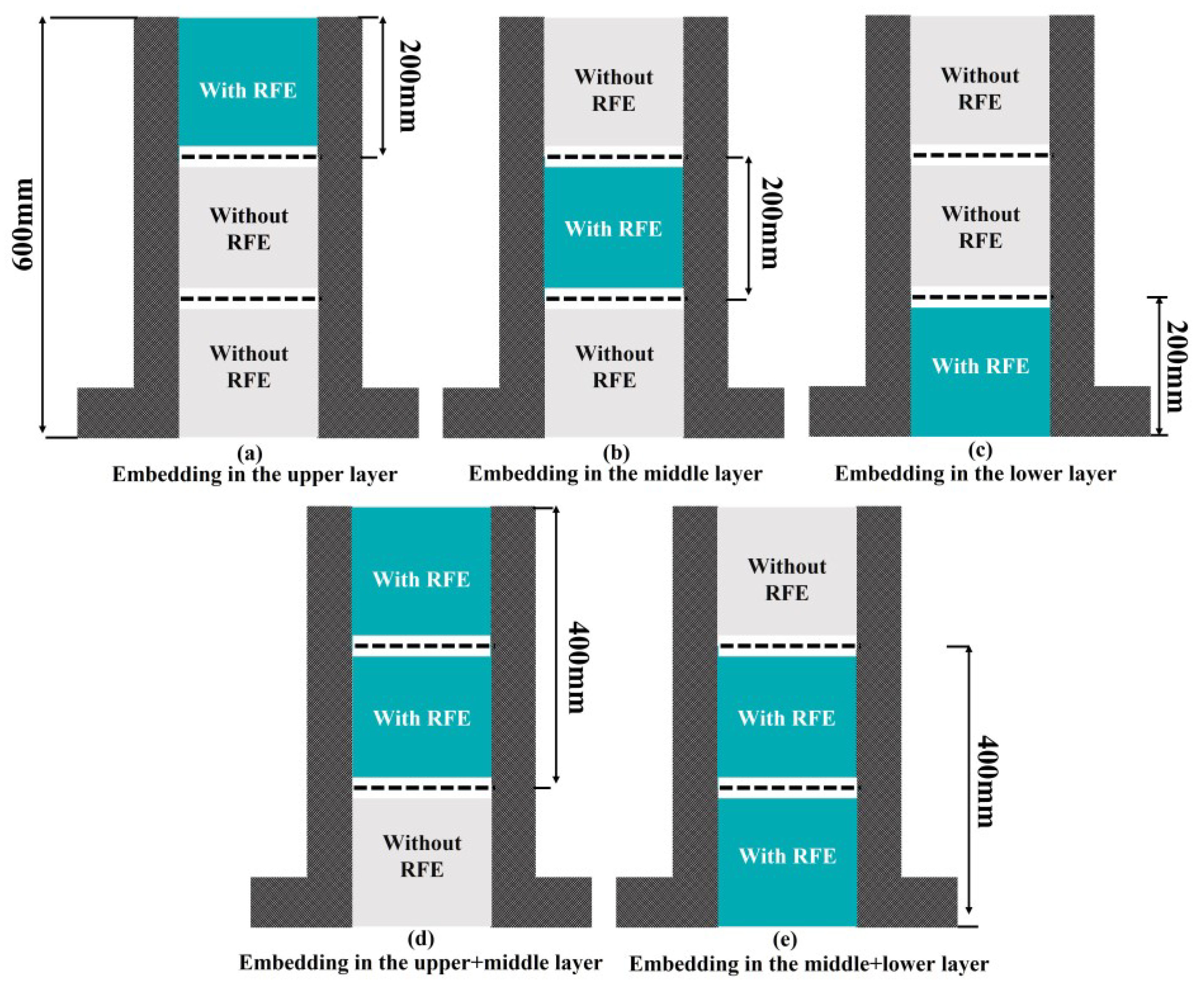

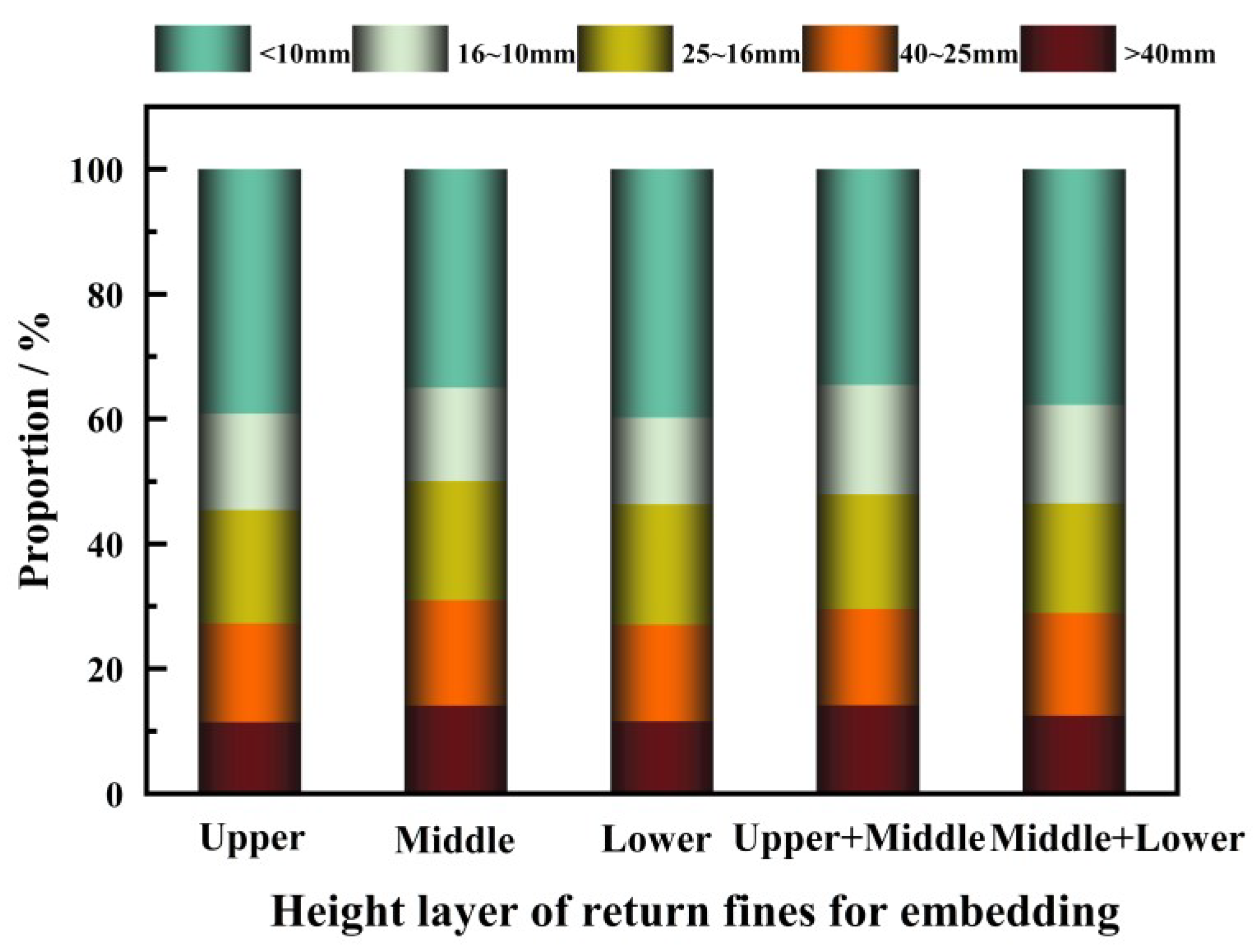

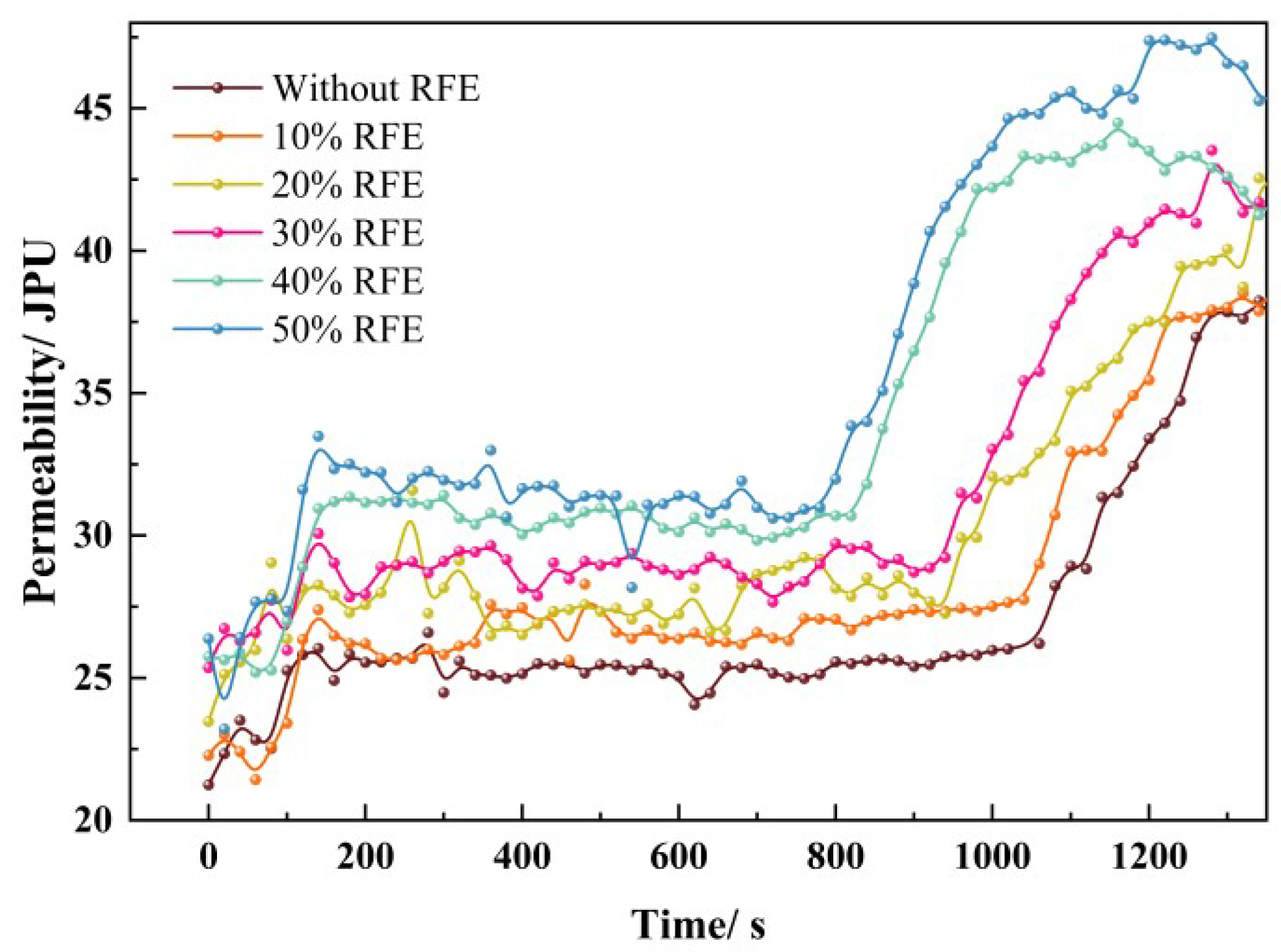

3.4. Effect of Mass Ratio of Return Fines for Embedding on Sinter Bed Permeability

4. Conclusions

- (1)

- The productivity, yield, flame front speed, and tumble index of the VTM sintering process are all increased to a certain extent after embedding different sizes of returned fines. Most notably, the optimal productivity, yield, flame front speed, and tumble index occur when the particle size of return fines for embedding is 3~5 mm.

- (2)

- The optimal mass ratio of return fines for embedding was confirmed at 80%, due to its FFS reaching 20.09 mm/min−1, which is the most favourable mass ratios. A continued increase in the mass ratio results in a decrease in FFS, yield, productivity, and TI.

- (3)

- Among the five different possible locations of embedded return fine layer, the middle-lower layer corresponds to the highest FFS. By contrast, using the upper layer as the embedded layer, both FFS and productivity reach minima.

- (4)

- As the mass ratio of return fines for embedding enhances from 0% to 50%, the permeability of the sinter packed bed is improved at each stage of sintering. In addition, the time taken for permeability to peak consequently shortens, which implies a reduction in sintering time and an increase in FFS.

Author Contributions

Funding

Institutional Review Board Statement

Informed Consent Statement

Data Availability Statement

Acknowledgments

Conflicts of Interest

References

- Zhang, S.; Liu, S.; Ma, W.; Zhu, K.; Cao, L.; Dai, Y. Present Status and Development of Comprehensive Utilization of Vanadium-Titanium Magnetite. Rare Met. Technol. 2017, 2017, 203–210. [Google Scholar]

- Zhou, M.; Zhou, H.; O’dea, D.P.; Ellis, B.G.; Honeyands, T.; Guo, X. Characterization of Granule Structure and Packed Bed Properties of Iron Ore Sinter Feeds that Contain Concentrate. ISIJ Int. 2017, 57, 1004–1011. [Google Scholar] [CrossRef]

- Zhou, M.; Xu, J.; Zhou, H. Evaluating the permeability properties of green bed in iron ore sintering using high resolution X-ray computed tomography and orthogonal array tests. Powder Technol. 2020, 375, 360–368. [Google Scholar] [CrossRef]

- Lu, Y.; Wu, S.; Niu, L.; Liu, Z.; Zhou, H.; Hong, Z.; Song, S. Treatment of vanadium–titanium magnetite based on composite agglomeration process (CAP). Ironmak. Steelmak. 2020, 48, 477–482. [Google Scholar] [CrossRef]

- Ax, K.; Feise, H.; Sochon, R.; Hounslow, M.; Salman, A. Influence of liquid binder dispersion on agglomeration in an intensive mixer. Powder Technol. 2008, 179, 190–194. [Google Scholar] [CrossRef]

- Gong, S.; Zuo, Z.; Xie, G.; Lu, H.; Zhang, J. Numerical simulation of wet particle flows in an intensive mixer. Powder Technol. 2019, 346, 301–315. [Google Scholar] [CrossRef]

- You, Y.; Guo, J.; Lv, X.; Wu, S.; Li, Y.; Tang, K.; Yu, Y. Numerical Simulation of Particle Mixing Behavior in High Speed Shear Mixer and Cylinder Mixer. ISIJ Int. 2021, 61, 2059–2065. [Google Scholar] [CrossRef]

- Ji, Z.; Zhang, Y.; Gan, M.; Fan, X.; Chen, X.; Huang, X. Importance of intensive mixing on sintering with fine-grained iron ore materials: Characterization and function mechanism. J. Mater. Res. Technol. 2020, 9, 14443–14453. [Google Scholar] [CrossRef]

- Yang, C.; Zhu, D.; Pan, J.; Lu, L. Granulation Effectiveness of Iron Ore Sinter Feeds: Effect of Ore Properties. ISIJ Int. 2018, 58, 1427–1436. [Google Scholar] [CrossRef]

- You, Y.; Guo, J.; Li, G.; Lv, X.; Wu, S.; Li, Y.; Yang, R. Investigation the iron ore fine granulation effects and particle adhesion behavior in a horizontal high-shear granulator. Powder Technol. 2021, 394, 162–170. [Google Scholar] [CrossRef]

- Tardos, G.I. Critical parameters and limiting conditions in binder granulation. Powder Technol. 1997, 94, 245–258. [Google Scholar] [CrossRef]

- Linhares, F.M.; Victor, C.C.F.; Lemos, L.R.; Bagatini, M.C. Effect of three different binders and pellet feed on granulation behaviour of sintering mixtures. Ironmak. Steelmak. 2019, 47, 991–997. [Google Scholar] [CrossRef]

- Zhang, F.; Zhu, D.-Q.; Pan, J.; Mo, Y.-P.; Guo, Z.-Q. Improving the sintering performance of blends containing Canadian specularite concentrate by modifying the binding medium. Int. J. Miner. Metall. Mater. 2018, 25, 598–608. [Google Scholar] [CrossRef]

- Zhou, H.; Zhou, M.; O’dea, D.P.; Ellis, B.G.; Chen, J.; Cheng, M. Influence of Binder Dosage on Granule Structure and Packed Bed Properties in Iron Ore Sintering Process. ISIJ Int. 2016, 56, 1920–1928. [Google Scholar] [CrossRef]

- Nandy, B.; Chaudhury, M.K.; Paul, J.; Bhattacharjee, D. Sintering Characteristics of Indian Chrome Ore Fines. Metall. Mater. Trans. B 2009, 40, 662–675. [Google Scholar] [CrossRef]

- Roshan, V.; Kumar, K.; Kumar, R.; Nageswara Rao, G.V.S. Preparation of Iron Ore Micro-pellets and Their Effect on Sinter Bed Permeability. Trans. Indian Inst. Met. 2018, 71, 2157–2164. [Google Scholar] [CrossRef]

- Lv, X.W.; Bai, C.G.; Zhou, C.Q.; Xie, H.; Shi, R.M. New method to determine optimum water content for iron ore granulation. Ironmak. Steelmak. 2013, 37, 407–413. [Google Scholar] [CrossRef]

- Higuchi, T.; Lu, L.; Kasai, E.; Yamamoto, T.; Matsuno, H. Inter−particle water infiltration dynamics of iron ore fines during granulation process. Powder Technol. 2018, 339, 550–559. [Google Scholar] [CrossRef]

- Litster, J.D. Influence of the Material Properties of iron Ore Sinter Feed on Granulation Effectiveness. Powder Technol. 1988, 55, 144–151. [Google Scholar] [CrossRef]

- Otsu, T.; Nakamura, H.; Ohsaki, S.; Watano, S.; Fujiwara, S.; Higuchi, T. Determining Optimum Water Content for Iron Ore Granulation using Agitation Torque of Wet Ore Powder. ISIJ Int. 2022, 62, 1381–1388. [Google Scholar] [CrossRef]

- Zhu, D.; Guo, Z.; Pan, J.; Zhang, F. A study of pre-briquetting granulation sintering of the mixtures with high ratio of Brazilian specularite concentrate. Ironmak. Steelmak. 2016, 43, 721–729. [Google Scholar] [CrossRef]

- Zhou, H.; Lai, Z.; Lv, L.; Fang, H.; Meng, H.; Zhou, M.; Cen, K. Improvement in the permeability of sintering beds by drying treatment after granulating sinter raw materials containing concentrates. Adv. Powder Technol. 2020, 31, 3297–3306. [Google Scholar] [CrossRef]

- Huang, X.; Lv, X.; Bai, C.; Qiu, G.; Lu, L. Effect of Pre-wetting Treatment on the Granulation Behavior of Iron Ore Fines. ISIJ Int. 2014, 54, 2721–2727. [Google Scholar] [CrossRef]

- Kasai, E. Design of Bed Structure Aiming the Control of Void Structure Formed in the Sinter Cake. ISIJ Int. 2005, 45, 535–543. [Google Scholar] [CrossRef]

- Kasai, E. Heat Transfer Analysis of the Mosaic Embedding Iron Ore Sintering (MEBIOS) Process. ISIJ Int. 2009, 49, 681–686. [Google Scholar]

- Matsumura, M.; Yamaguchi, Y.; Hara, M.; Kamijo, C.; Kawaguchi, T.; Nakagawa, Y. Improvement of Sinter Productivity by Adding Return Fine on Raw Materials after Granulation Stage. ISIJ Int. 2013, 53, 34–40. [Google Scholar] [CrossRef]

- Wang, Z. Study on process of strengthening granulation based on sinter returns and BF returns shunting. Sinter. Pelletizing 2018, 43, 12–16. [Google Scholar]

- Liu, J. Research on MEBIOS technology of different particle sizes and its application. Sinter. Pelletizing 2020, 45, 22–26. [Google Scholar]

- Yang, S.; Tang, W.; Zhou, M.; Jiang, T.; Xue, X.; Zhang, W. Effects of Dolomite on Mineral Compositions and Metallurgical Properties of Chromium-Bearing Vanadium–Titanium Magnetite Sinter. Minerals 2017, 7, 210. [Google Scholar] [CrossRef]

- Zhou, M.; Yang, S.T.; Jiang, T.; Xue, X.X. Influence of MgO in form of magnesite on properties and mineralogy of high chromium, vanadium, titanium magnetite sinters. Ironmak. Steelmak. 2014, 42, 217–225. [Google Scholar] [CrossRef]

- Zhang, L.; Yang, S.; Tang, W.; Yang, H.; Xue, X. Effect of coke breeze content on sintering mechanism and metallurgical properties of high-chromium vanadium-titanium magnetite. Ironmak. Steelmak. 2019, 47, 821–827. [Google Scholar] [CrossRef]

- Zhang, L.; Gao, Z.; Yang, S.; Tang, W.; Xue, X. Effect of Basicity on Sintering Behavior and Metallurgical Properties of High-Chromium Vanadium-Titanium Magnetite. Metals 2020, 10, 569. [Google Scholar] [CrossRef]

- Zhou, M.; Yang, S.-T.; Jiang, T.; Zhang, L.-H.; Xiao, J.-T.; Xue, X.; Zhang, W.-J. Effects of carbon content on the sintering behavior of low-titanium vanadium-titanium magnetite. Metall. Res. Technol. 2016, 113, 612. [Google Scholar] [CrossRef]

- Tang, W.-D.; Yang, S.-T.; Zhang, L.-H.; Huang, Z.; Yang, H.; Xue, X.-X. Effects of basicity and temperature on mineralogy and reduction behaviors of high-chromium vanadium-titanium magnetite sinters. J. Cent. South Univ. 2019, 26, 132–145. [Google Scholar] [CrossRef]

- Li, G.; Lv, X.; Zheng, Z.; Ling, J.; Qiu, G. Effect of Preformed Calcium Ferrite Addition on Sintering Behavior of Vanadium Titanium Magnetite Ore. JOM 2020, 73, 316–325. [Google Scholar] [CrossRef]

- Yang, S.; Zhou, M.; Jiang, T.; Xue, X. Study on Sintering Characteristics of Ultra-Poor Vanadium-Titanium Magnetite. Minerals 2021, 11, 515. [Google Scholar] [CrossRef]

- Zhou, M.; Jiang, T.; Yang, S.-T.; Xue, X.-X. Sintering behaviors and consolidation mechanism of high-chromium vanadium and titanium magnetite fines. Int. J. Miner. Metall. Mater. 2015, 22, 917–925. [Google Scholar] [CrossRef]

- Han, H.; Lu, L. Recent advances in sintering with high proportions of magnetite concentrates. Miner. Process. Extr. Metall. Rev. 2017, 39, 217–230. [Google Scholar] [CrossRef]

- Zhou, H.; Ma, P.; Cheng, M.; Zhou, M.; Li, Y. Effects of Temperature and Circulating Flue Gas Components on Combustion and NOx Emissions Characteristics of Four Types Quasi-particles in Iron Ore Sintering Process. ISIJ Int. 2018, 58, 1650–1658. [Google Scholar] [CrossRef]

| Materials | TFe | SiO2 | CaO | MgO | Al2O3 | S | TiO2 | V2O5 | H2O |

|---|---|---|---|---|---|---|---|---|---|

| VTM | 54.59 | 5.42 | 2.76 | 2.46 | 3.11 | 0.42 | 6.10 | 0.50 | 8.54 |

| Quick-lime | 0.50 | 2.00 | 87.00 | 0.81 | 1.49 | 0.04 | |||

| Limestone | 0.50 | 3.00 | 28.50 | 20.50 | 1.54 | 1.00 | 3.00 | ||

| Return fines | 48.48 | 5.59 | 13.08 | 3.18 | 3.24 | 0.12 | 5.40 | 0.45 |

| Fixed Carbon | Total Sulfur | Volatile | Ash (14.30) | ∑ | |||||

|---|---|---|---|---|---|---|---|---|---|

| FeO | SiO2 | CaO | MgO | Al2O3 | Others | ||||

| 84.00 | 0.8 | 1.21 | 1.16 | 100 | 1.15 | 0.34 | 4.30 | 0.02 | 100 |

| Raw Materials | VTM | Quick-Lime | Limestone | Coke Breeze | Return Fines |

|---|---|---|---|---|---|

| wt.% | 52.85 | 5.85 | 2.40 | 3.90 | 35.00 |

| Item | Parameter | Item | Parameter | Item | Parameter |

|---|---|---|---|---|---|

| Sinter bed depth | 600 mm | Sintering pot diameter | 300 mm | Granulation time | 7 min |

| Ignition vacuum | 8 kpa | Sintering vacuum | 15 kpa | Ignition time | 2 min |

| Ignition temperature | 1273 K | Moisture | 7.5 ± 0.1 % | Basicity (R = CaO/SiO2) | 2.34 |

| Mass Ratio/% | 20 | 40 | 60 | 80 | 100 |

|---|---|---|---|---|---|

| Embedding mass/kg | 2.73 | 5.46 | 8.19 | 10.92 | 13.65 |

Disclaimer/Publisher’s Note: The statements, opinions and data contained in all publications are solely those of the individual author(s) and contributor(s) and not of MDPI and/or the editor(s). MDPI and/or the editor(s) disclaim responsibility for any injury to people or property resulting from any ideas, methods, instructions or products referred to in the content. |

© 2022 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (https://creativecommons.org/licenses/by/4.0/).

Share and Cite

Peng, S.; Liu, H.; Hua, H.; Sun, Z.; Qin, Y.; Meng, F.; Liu, W.; Wang, G. Effect of Return Fines Embedding on the Sintering Behaviour of Vanadium Titanium Magnetite Concentrates. Metals 2023, 13, 62. https://doi.org/10.3390/met13010062

Peng S, Liu H, Hua H, Sun Z, Qin Y, Meng F, Liu W, Wang G. Effect of Return Fines Embedding on the Sintering Behaviour of Vanadium Titanium Magnetite Concentrates. Metals. 2023; 13(1):62. https://doi.org/10.3390/met13010062

Chicago/Turabian StylePeng, Shihong, Hao Liu, Huangjie Hua, Zezheng Sun, Yuelin Qin, Fei Meng, Weiqiang Liu, and Guang Wang. 2023. "Effect of Return Fines Embedding on the Sintering Behaviour of Vanadium Titanium Magnetite Concentrates" Metals 13, no. 1: 62. https://doi.org/10.3390/met13010062

APA StylePeng, S., Liu, H., Hua, H., Sun, Z., Qin, Y., Meng, F., Liu, W., & Wang, G. (2023). Effect of Return Fines Embedding on the Sintering Behaviour of Vanadium Titanium Magnetite Concentrates. Metals, 13(1), 62. https://doi.org/10.3390/met13010062