Microstructure Change, Nano-Hardness and Surface Modification of CN-G01 Beryllium Induced by Helium Ions

Abstract

1. Introduction

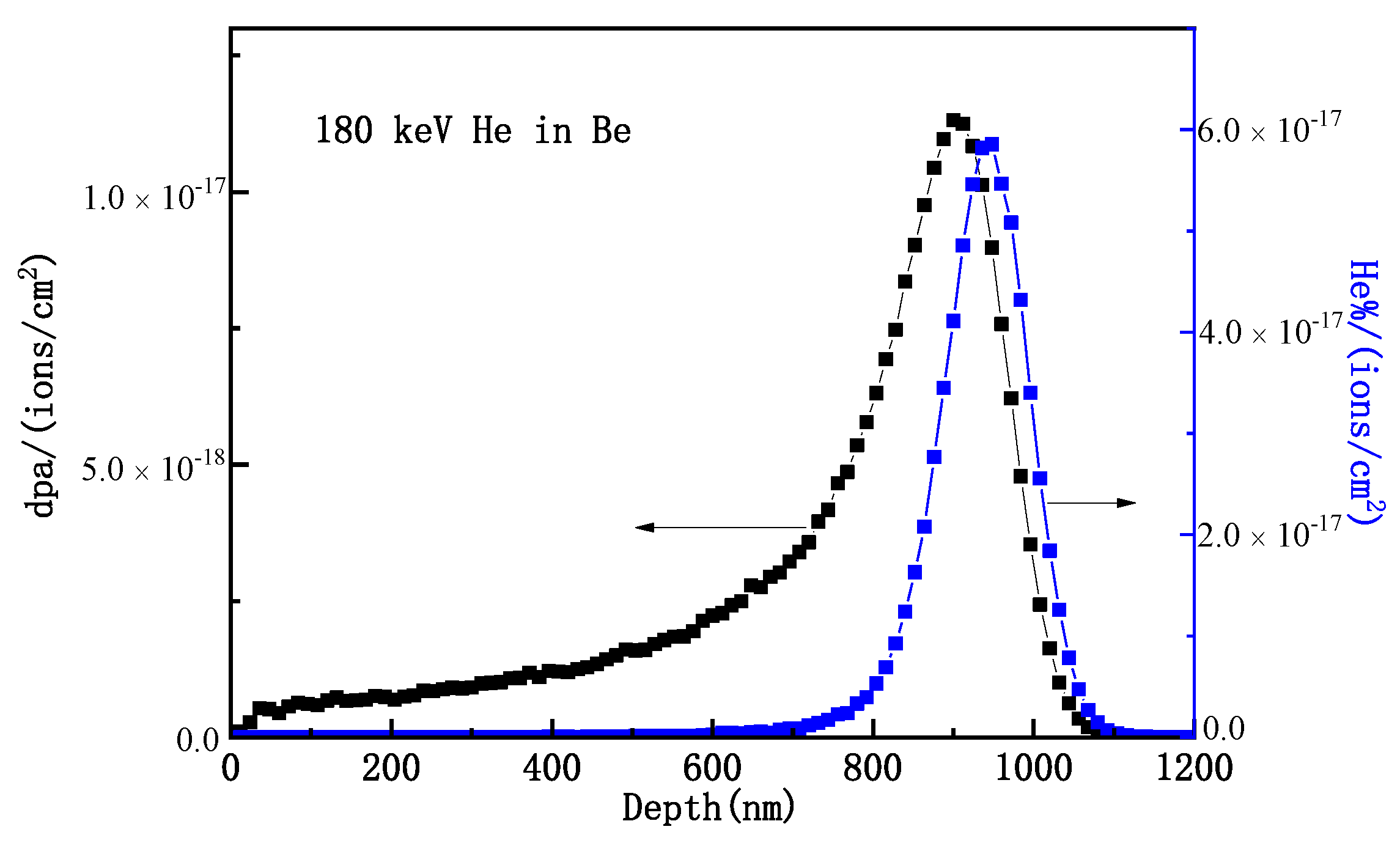

2. Materials and Methods

3. Results and Discussion

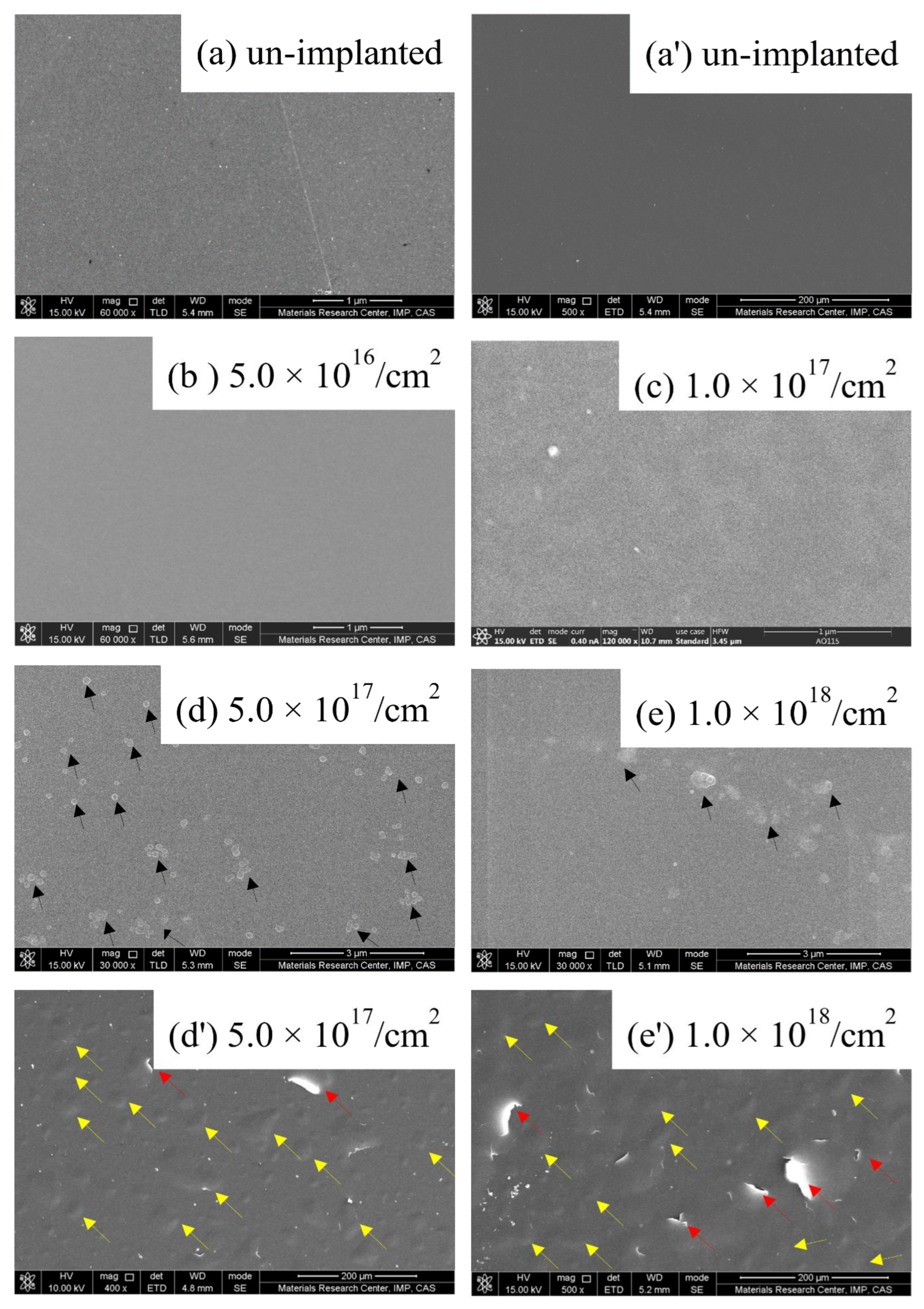

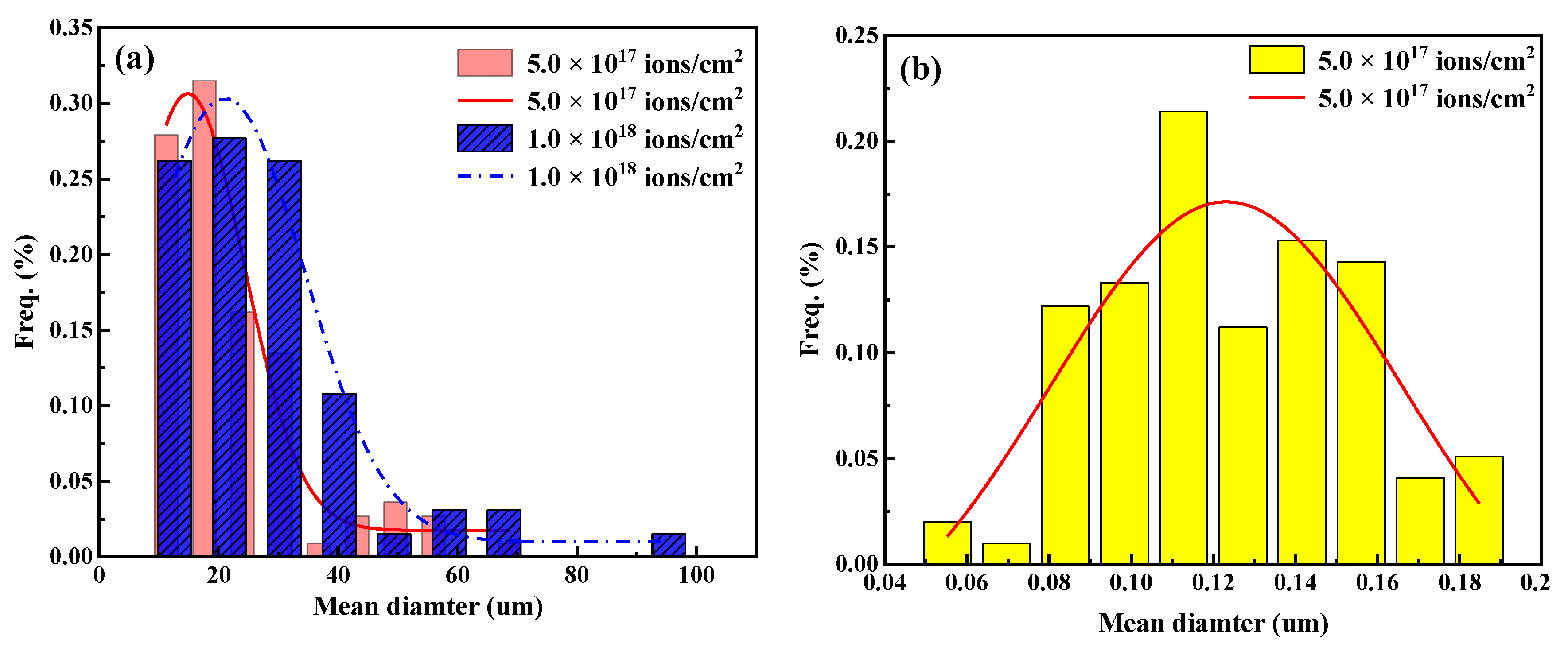

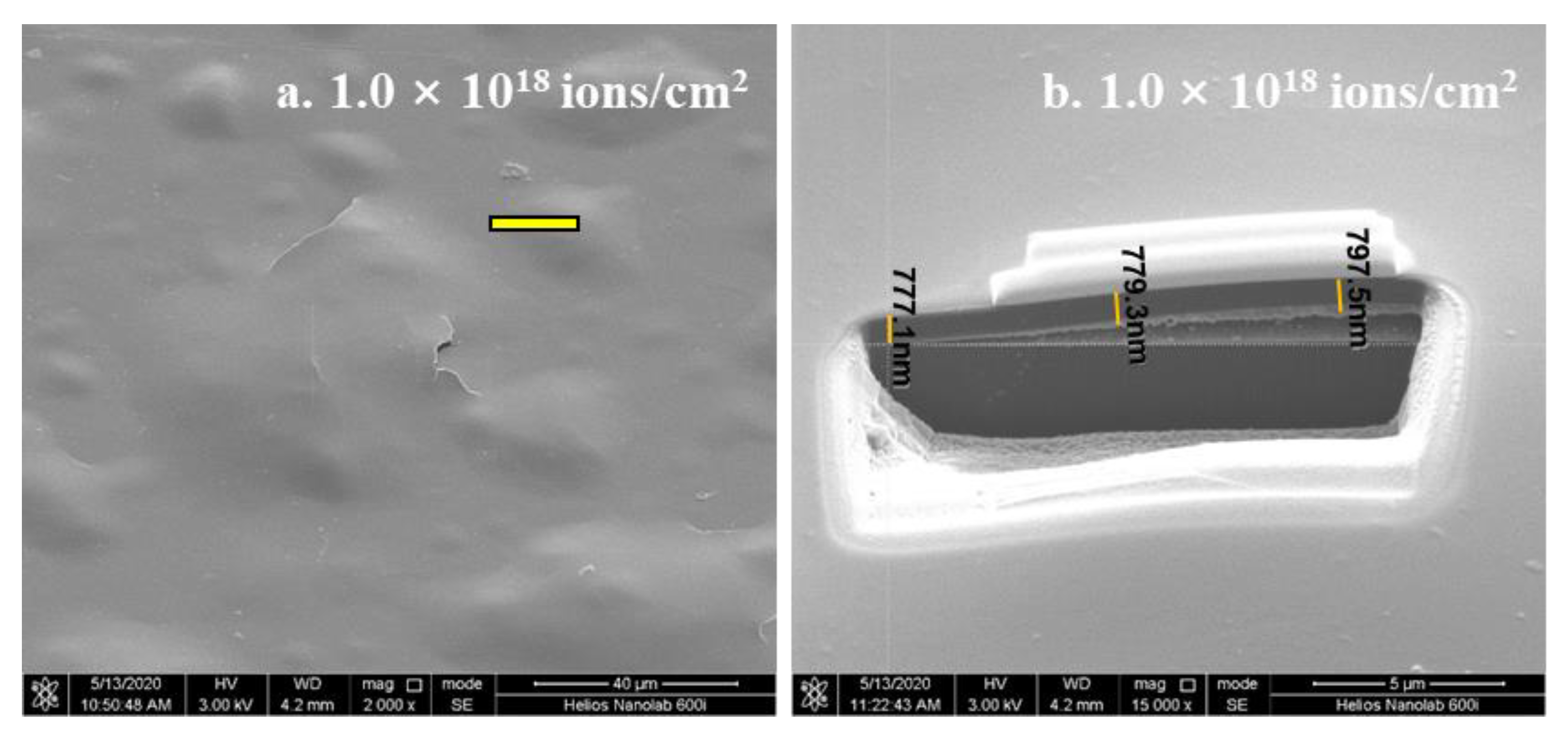

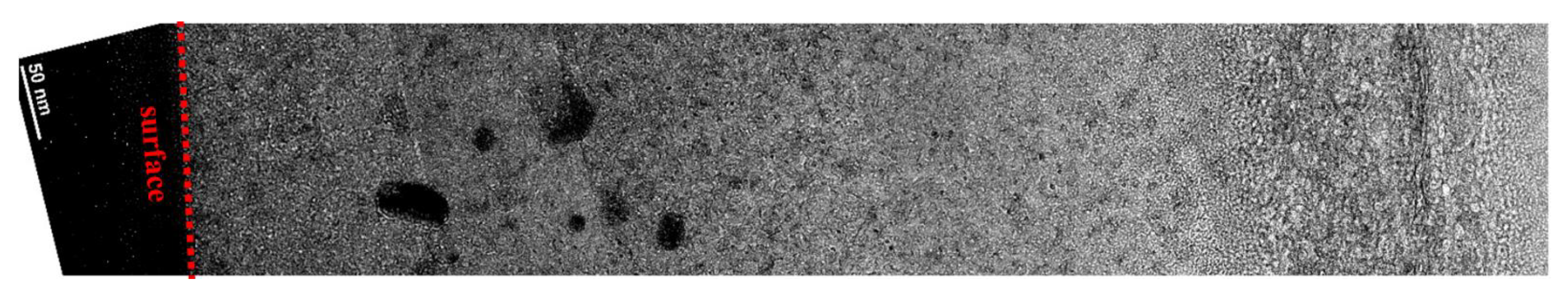

3.1. Surface and Sub-Surface Morphologies

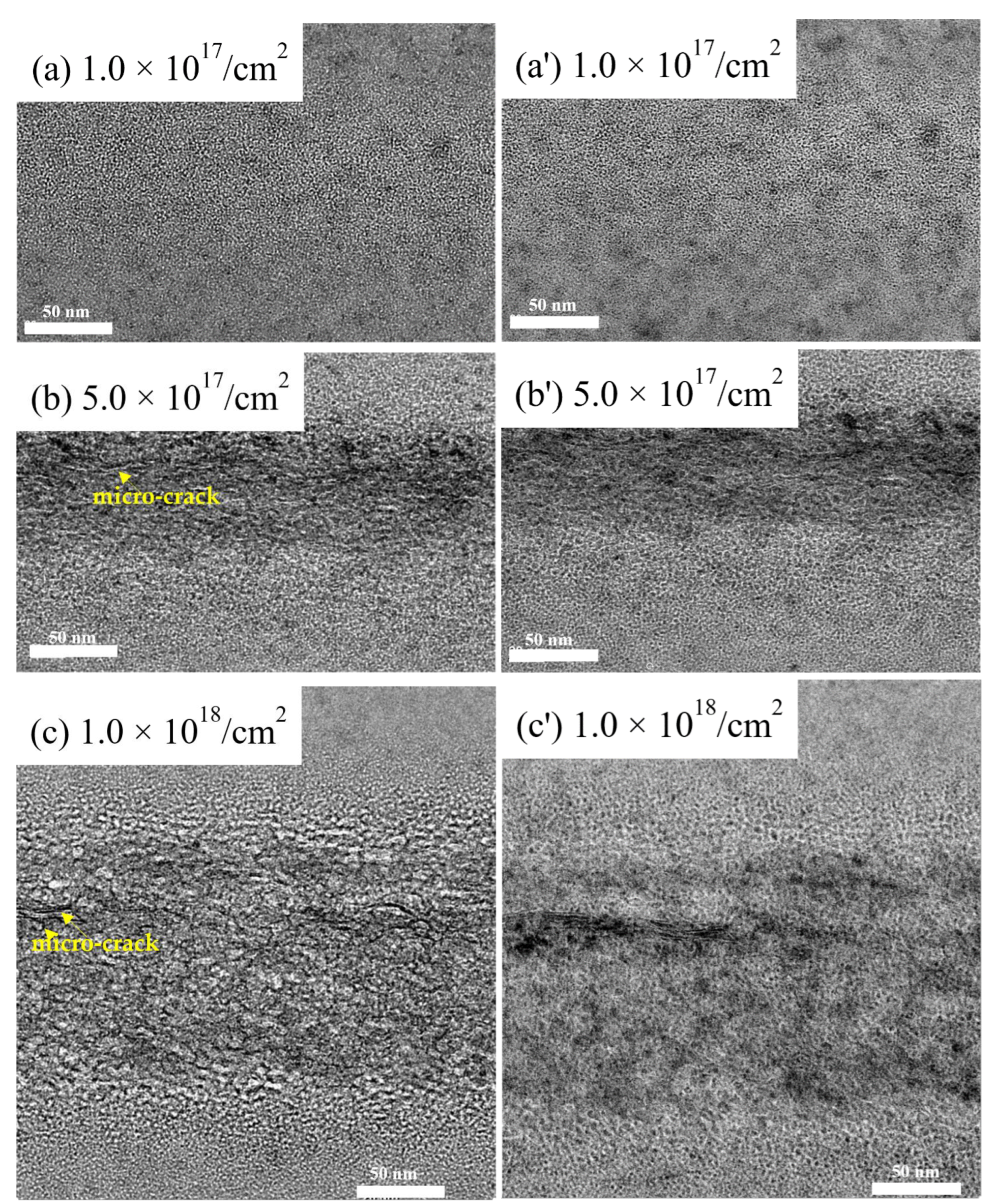

3.2. Microstructure Evolution of Helium Implanted Beryllium

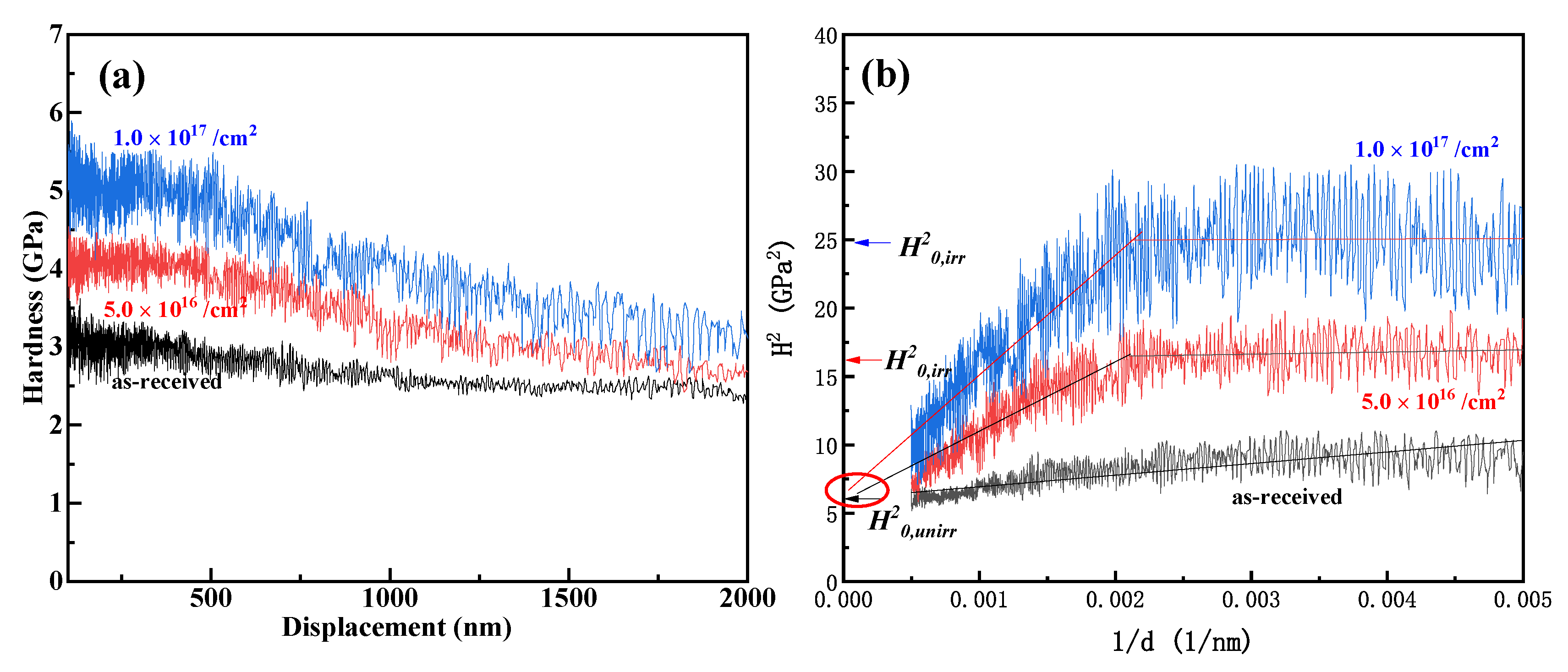

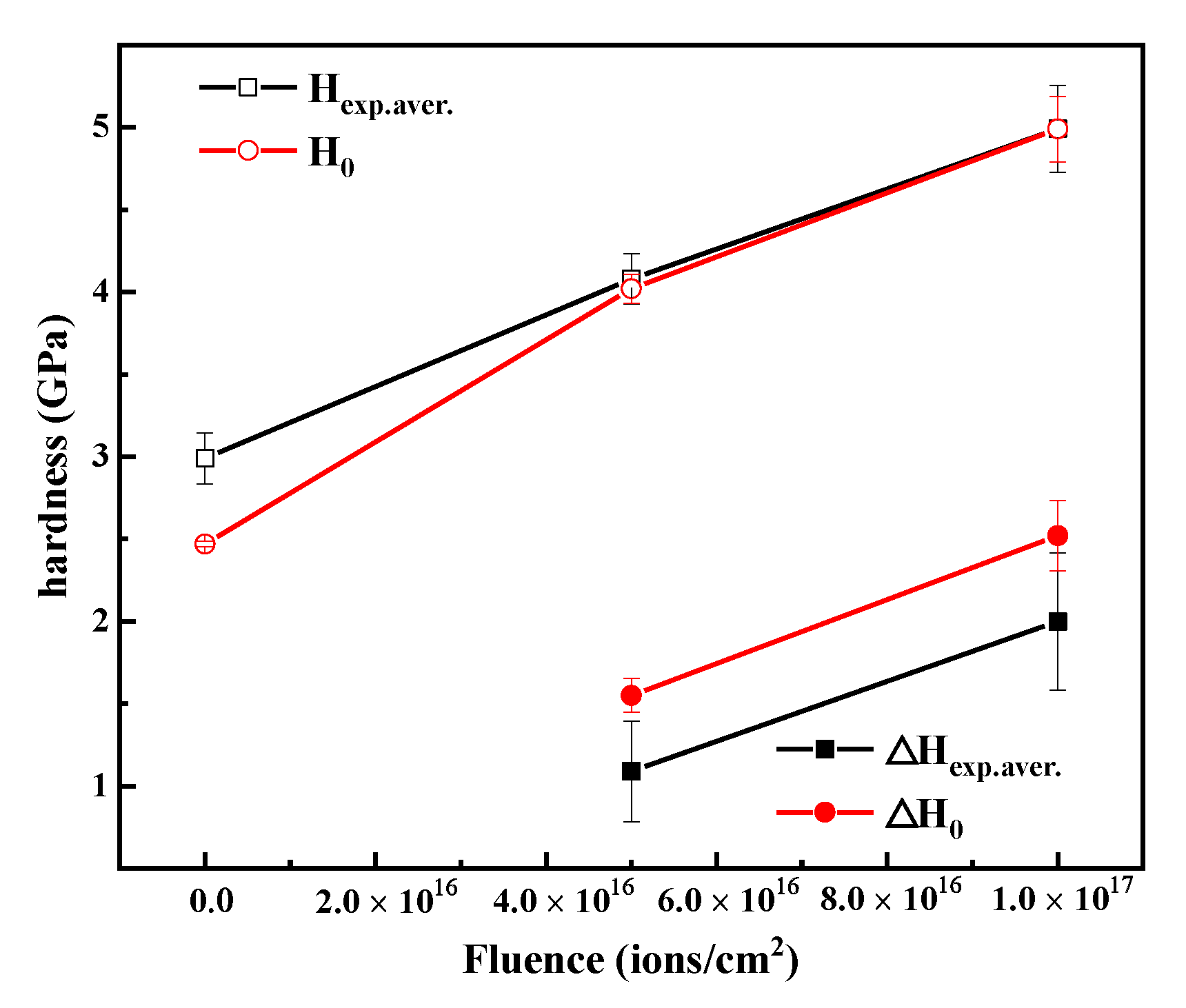

3.3. Nano-Indentation Test

4. Summary

Author Contributions

Funding

Data Availability Statement

Acknowledgments

Conflicts of Interest

References

- Kuksenko, V.; Lunev, A.; Darnbrough, E.; Densham, C.; Hurh, P.; Roberts, S. Radiation induced hardening of beryllium during low temperature He implantation. J. Nucl. Mater. 2021, 555, 153130. [Google Scholar] [CrossRef]

- Deksnis, E.B.; Peacock, A.T.; Altmann, H.; Ibbot, C.; Falter, H.D. Beryllium plasma-facing components: JET experience. Fusion Eng. Des. 1997, 37, 515–530. [Google Scholar] [CrossRef]

- Klimenkov, M.; Vladimirov, P.; Jäntsch, U.; Kuksenko, V.; Rolli, R.; Möslang, A.; Zimber, N. New insights into microstructure of irradiated beryllium based on experiments and computer simulations. Sci. Rep. 2020, 10, 8042. [Google Scholar] [CrossRef] [PubMed]

- Giancarli, L.M.; Barabash, V.; Campbell, D.J.; Chiocchio, S.; Cordier, J.J.; Dammann, A. Progress and challenges of the ITER TBM Program from the IO perspective. Fusion Eng. Des. 2016, 109, 1491–1497. [Google Scholar] [CrossRef]

- Kuksenko, V.; Ammigan, K.; Hartsell, B.; Densham, C.; Hurh, P.; Roberts, S. Irradiation effects in beryllium exposed to high energy protons of the NuMI neutrino source. J. Nucl. Mater. 2017, 490, 260–271. [Google Scholar] [CrossRef]

- Barabash, V.; Eaton, R.; Hirai, T.; Kupriyanov, I.; Nikolaev, G.; Wang, Z.; Linke, J. Summary of beryllium qualification activity for ITER first-wall applications. Phys. Scr. 2011, 14007. [Google Scholar] [CrossRef]

- Liu, X.; Chen, J.; Lian, Y.; Wu, J.; Xu, Z.; Zhang, N.; Zhong, J. Vacuum hot-pressed beryllium and TiC dispersion strengthened tungsten alloy developments for ITER and future fusion reactors. J. Nucl. Mater. 2013, 442, S309–S312. [Google Scholar] [CrossRef]

- Klimenkov, M.; Chakin, V.; Moeslang, A.; Rolli, R. TEM study of beryllium pebbles after neutron irradiation up to 3000 appm helium production. J. Nucl. Mater. 2013, 443, 409–416. [Google Scholar] [CrossRef]

- Zimber, N.; Vladimirov, P.; Klimenkov, M.; Kuksenko, V. Investigation of a high-dose irradiated beryllium microstructure. J. Nucl. Mater. 2020, 540, 152374. [Google Scholar] [CrossRef]

- Chakin, V.P.; Posevin, A.; Kupriyanov, I. Swelling, mechanical properties and microstructure of beryllium irradiated at 200 degrees C up to extremely high neutron doses. J. Nucl. Mater. 2007, 367, 1377–1381. [Google Scholar] [CrossRef]

- Chakin, V.P.; Ostrovsky, Z. Evolution of beryllium microstructure under high-dose neutron irradiation. J. Nucl. Mater. 2002, 307, 657–663. [Google Scholar] [CrossRef]

- Kupriyanov, I.B.; Gorokhov, V.A.; Melder, R.R.; Ostrovsky, Z.E.; Gervash, A.A. Investigation of ITER candidate beryllium grades irradiated at high temperature. J. Nucl. Mater. 1998, 258, 808–813. [Google Scholar] [CrossRef]

- Ziegler, J.F.; Biersack, J.; Littmark, U. The Stopping and Range of Ions in Solids; Pergamon: Oxford, UK, 1985; Available online: http://www.srim.org (accessed on 31 January 2021).

- Jackson, M.L.; Fossati, P.; Grimes, R. Simulations of threshold displacement in beryllium. J. Appl. Phys. 2016, 120, 45903. [Google Scholar] [CrossRef]

- Stoller, R.E.; Toloczko, M.B.; Was, G.S.; Certain, A.G.; Dwaraknath, S.; Garner, F.A. On the use of SRIM for computing radiation damage exposure. Nucl. Instrum. Methods Phys. Res. Sect. B Beam Interact. Mater. At. 2013, 310, 75–80. [Google Scholar] [CrossRef]

- Liu, P.P.; Zhan, Q.; Fu, Z.Y.; Wei, Y.P.; Wang, Y.M.; Wang, F.M. Surface and internal microstructure damage of He-ion-irradiated CLAM steel studied by cross-sectional transmission electron microscopy. J. Alloy. Compd. 2015, 649, 859–864. [Google Scholar] [CrossRef]

- Morishita, K.; Inoue, T.; Yoshida, N. Microstructural evolution in beryllium by fusion-relevant low energy helium ion irradiation. J. Nucl. Mater. 1999, 266, 997–1002. [Google Scholar] [CrossRef]

- Luo, X.F.; Gong, B.; Wang, L.; Cui, M.; Feng, Y. Influence of helium ion irradiation on the morphology and microstructure of CN-G01 beryllium. Mater. Res. Express 2020, 7, 126508. [Google Scholar] [CrossRef]

- Evans, J.H. Inter-Bubble Fracture Mechanism of Blister Formation on Helium-Irradiated Metals. J. Nucl. Mater. 1977, 68, 129–140. [Google Scholar] [CrossRef]

- Gusev, V.M.; Guseva, M.I.; Martynenko, Y.V.; Mansurova, A.N.; Morosov, V.N.; Chelnokov, O.I. Helium Blistering at High Irradiation Doses. J. Nucl. Mater. 1979, 85–86, 1101–1104. [Google Scholar] [CrossRef]

- Yang, X.Y.; Lu, Y.; Li, M.L.; Zhang, P. First-principles study of migration and diffusion mechanisms of helium in proportional to-Be. AIP Adv. 2016, 6, 35018. [Google Scholar] [CrossRef]

- Zhang, P.B.; Zhao, J.; Wen, B. Retention and diffusion of H, He, O, C impurities in Be. J. Nucl. Mater. 2012, 423, 164–169. [Google Scholar] [CrossRef]

- Bakai, A.S.; Timoshevskii, A.; Yanchitsky, B. On chemical bonding and helium distribution in hcp beryllium. Low Temp. Phys. 2011, 37, 791–797. [Google Scholar] [CrossRef]

- Ganchenkova, M.G.; Vladimirov, P.; Borodin, V. Vacancies, interstitials and gas atoms in beryllium. J. Nucl. Mater. 2009, 386–388, 79–81. [Google Scholar] [CrossRef]

- Cayphas, J.M.; Hou, M.; Coheur, L. The behaviour of helium in neutron irradiated beryllium: A molecular dynamics study. J. Nucl. Mater. 1997, 246, 171–179. [Google Scholar] [CrossRef]

- Jung, P. Diffusion and Retention of Implanted Helium in Beryllium. J. Nucl. Mater. 1993, 202, 210–215. [Google Scholar] [CrossRef]

- Vladimirov, P.V.; Moeslang, A. Ab initio static and molecular dynamics studies of helium behavior in beryllium. J. Nucl. Mater. 2013, 442, S694–S698. [Google Scholar] [CrossRef]

- Chernikov, V.N.; Ullmaier, H.; Zakharov, A. Gas bubbles in beryllium implanted with He ions at temperatures ≤700 K and after post-implantation annealing. J. Nucl. Mater. 1998, 258, 694–699. [Google Scholar] [CrossRef]

- Liu, P.P.; Xue, L.W.; Yu, L.P.; Liu, J.L.; Hu, W.; Zhan, Q.; Wan, F.R. Microstructure change and swelling of helium irradiated beryllium. Fusion Eng. Des. 2019, 140, 62–66. [Google Scholar] [CrossRef]

- Zheng, R.Y.; Han, W. Comparative study of radiation defects in ion irradiated bulk and thin-foil tungsten. Acta Mater. 2020, 186, 162–171. [Google Scholar] [CrossRef]

- Nix, W.D.; Gao, H. Indentation size effects in crystalline materials: A law for strain gradient plasticity. J. Mech. Phys. Solids 1998, 46, 411–425. [Google Scholar] [CrossRef]

- Kasada, R.; Takayama, Y.; Yabuuchi, K.; Kimura, A. A new approach to evaluate irradiation hardening of ion-irradiated ferritic alloys by nano-indentation techniques. Fusion Eng. Des. 2011, 86, 2658–2661. [Google Scholar] [CrossRef]

- Cui, M.H.; Shen, T.L.; Zhu, H.P.; Wang, J.; Cao, X.Z.; Zhang, P. Vacancy like defects and hardening of tungsten under irradiation with He ions at 800 degrees C. Fusion Eng. Des. 2017, 121, 313–318. [Google Scholar] [CrossRef]

- Hosemann, P.; Kiener, D.; Wang, Y.; Maloy, S.A. Issues to consider using nano indentation on shallow ion beam irradiated materials. J. Nucl. Mater. 2012, 425, 136–139. [Google Scholar] [CrossRef]

- Seeger, A.K. Basic Metallurgy and Fabrication of Fuels. In Proceedings of the 2nd International Conference on Peaceful Uses of Atomic Energy, Geneva, Switzerland, 1–13 September 1958; IAEA: Vienna, Austria, 1958; Volume 6, p. 250. [Google Scholar]

| Be | BeO | Al | C | Fe | Mg | Si | Others |

|---|---|---|---|---|---|---|---|

| >99 | 0.75 | 0.006 | 0.060 | 0.050 | 0.003 | 0.009 | <0.04 |

| Fluence (Ions/cm2) | 5.0 × 1016 | 1.0 × 1017 | 5.0 × 1017 | 1.0 × 1018 |

|---|---|---|---|---|

| Peak dpa | 0.565 | 1.13 | 5.65 | 11.3 |

| Peak helium concentration (%) | 2.93 | 5.85 | 29.3 | 58.5 |

| Fluence (ion/cm2) | Hexpaver (GPa) | Hexpaver (GPa) | H0 (GPa) | H0 (GPa) | h* (nm) |

|---|---|---|---|---|---|

| 0 | 2.99 ± 0.154 | - | 2.47 ± 0.016 | - | 139.27 ± 3.069 |

| 5.0 × 1016 | 4.08 ± 0.152 | 1.09 ± 0.306 | 4.02 ± 0.087 | 1.55 ± 0.103 | 9.74 ± 3.205 |

| 1.0 × 1017 | 4.99 ± 0.262 | 2.00 ± 0.417 | 4.99 ± 0.199 | 2.52 ± 0.215 | 1.60 ± 4.591 |

Disclaimer/Publisher’s Note: The statements, opinions and data contained in all publications are solely those of the individual author(s) and contributor(s) and not of MDPI and/or the editor(s). MDPI and/or the editor(s) disclaim responsibility for any injury to people or property resulting from any ideas, methods, instructions or products referred to in the content. |

© 2022 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (https://creativecommons.org/licenses/by/4.0/).

Share and Cite

Cui, M.; Jin, P.; Shen, T.; Zhu, Y.; Pang, L.; Wang, Z.; Luo, X.; Feng, Y.; Gong, B. Microstructure Change, Nano-Hardness and Surface Modification of CN-G01 Beryllium Induced by Helium Ions. Metals 2023, 13, 60. https://doi.org/10.3390/met13010060

Cui M, Jin P, Shen T, Zhu Y, Pang L, Wang Z, Luo X, Feng Y, Gong B. Microstructure Change, Nano-Hardness and Surface Modification of CN-G01 Beryllium Induced by Helium Ions. Metals. 2023; 13(1):60. https://doi.org/10.3390/met13010060

Chicago/Turabian StyleCui, Minghuan, Peng Jin, Tielong Shen, Yabin Zhu, Lilong Pang, Zhiguang Wang, Xiaofang Luo, Yongjin Feng, and Baoping Gong. 2023. "Microstructure Change, Nano-Hardness and Surface Modification of CN-G01 Beryllium Induced by Helium Ions" Metals 13, no. 1: 60. https://doi.org/10.3390/met13010060

APA StyleCui, M., Jin, P., Shen, T., Zhu, Y., Pang, L., Wang, Z., Luo, X., Feng, Y., & Gong, B. (2023). Microstructure Change, Nano-Hardness and Surface Modification of CN-G01 Beryllium Induced by Helium Ions. Metals, 13(1), 60. https://doi.org/10.3390/met13010060