3D Printing of Mg-Based Bulk Metallic Glasses with Proper Laser Power and Scanning Speed

Abstract

:1. Introduction

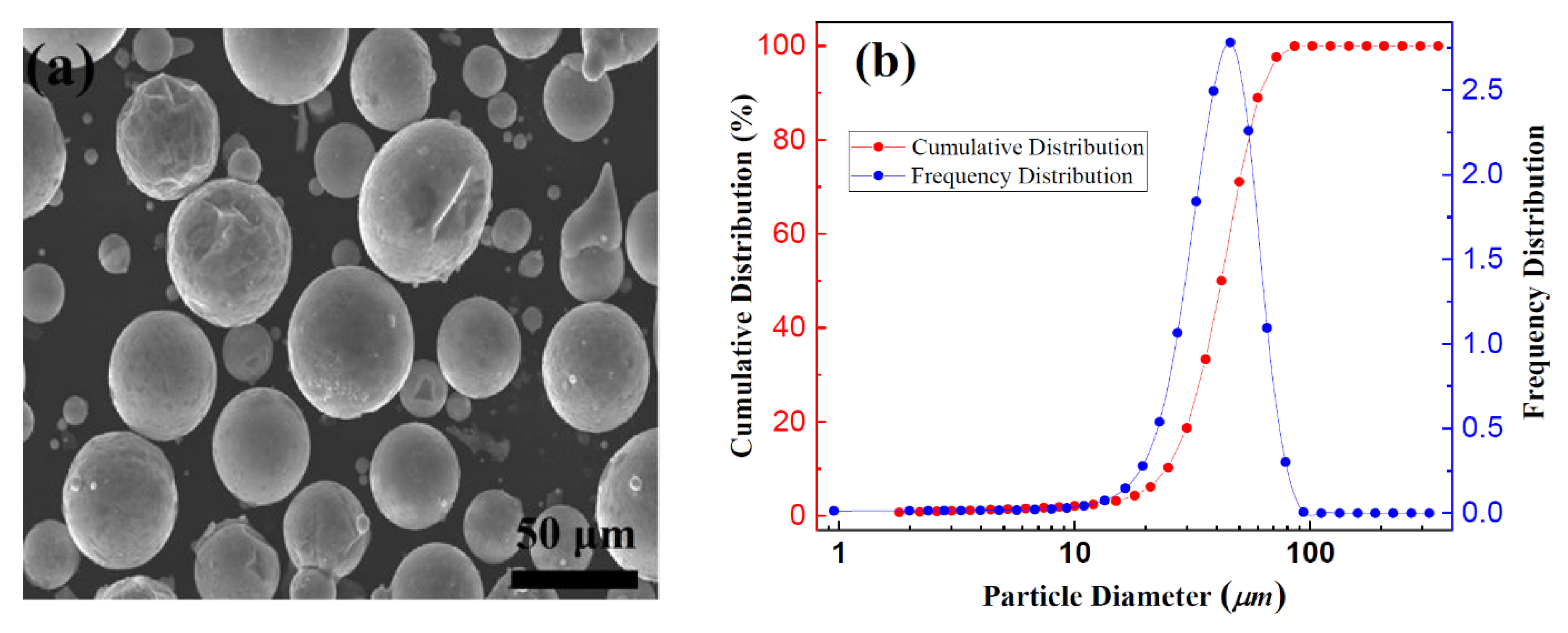

2. Materials and Methods

3. Results

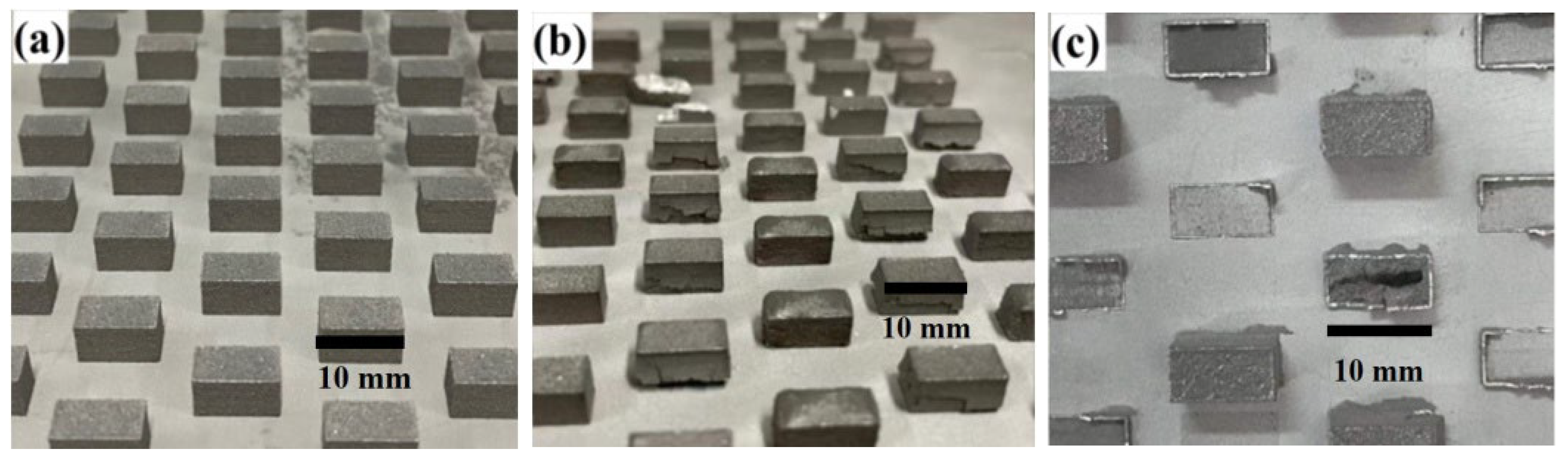

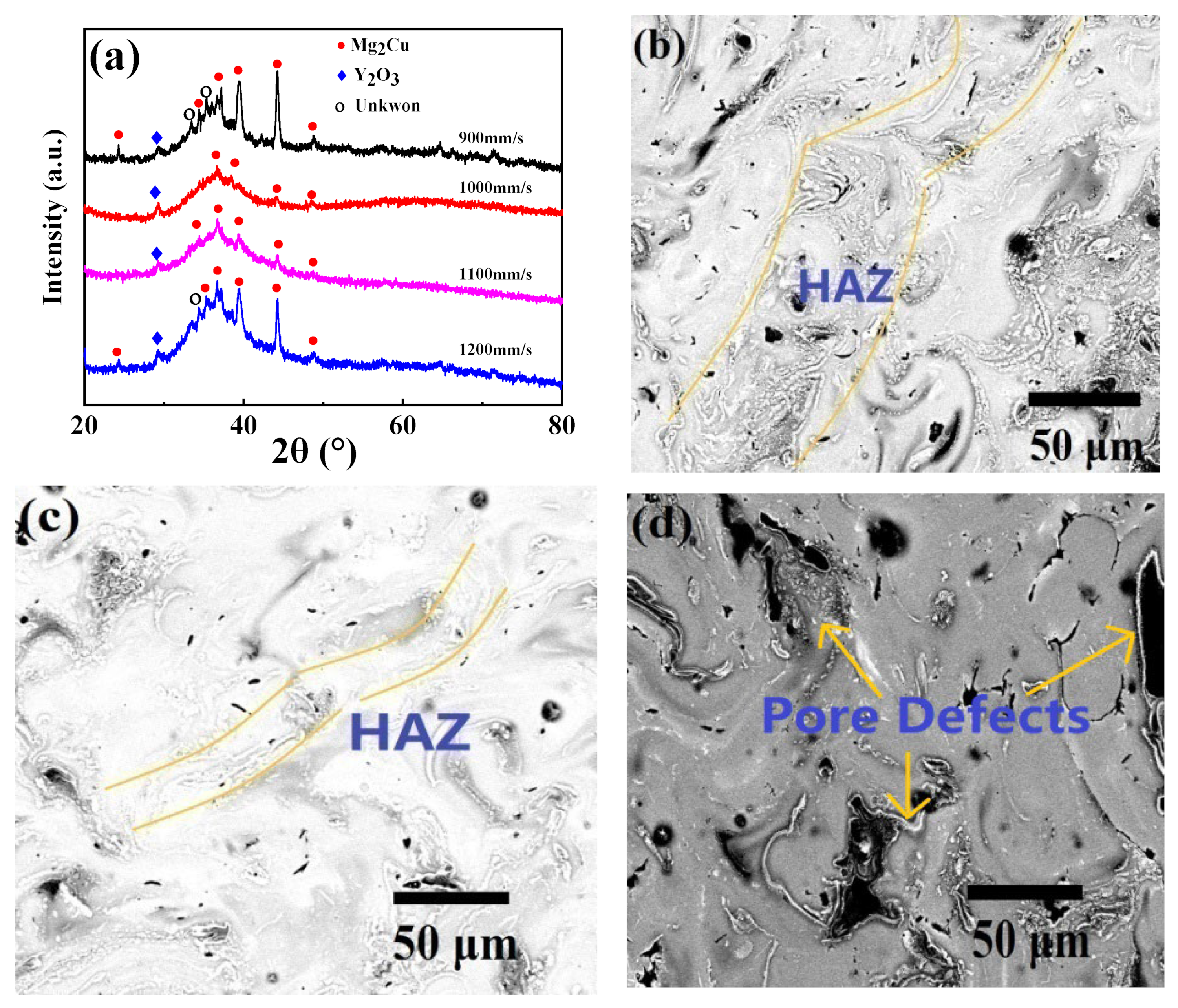

3.1. Effect of Scanning Speed on the Microstructures

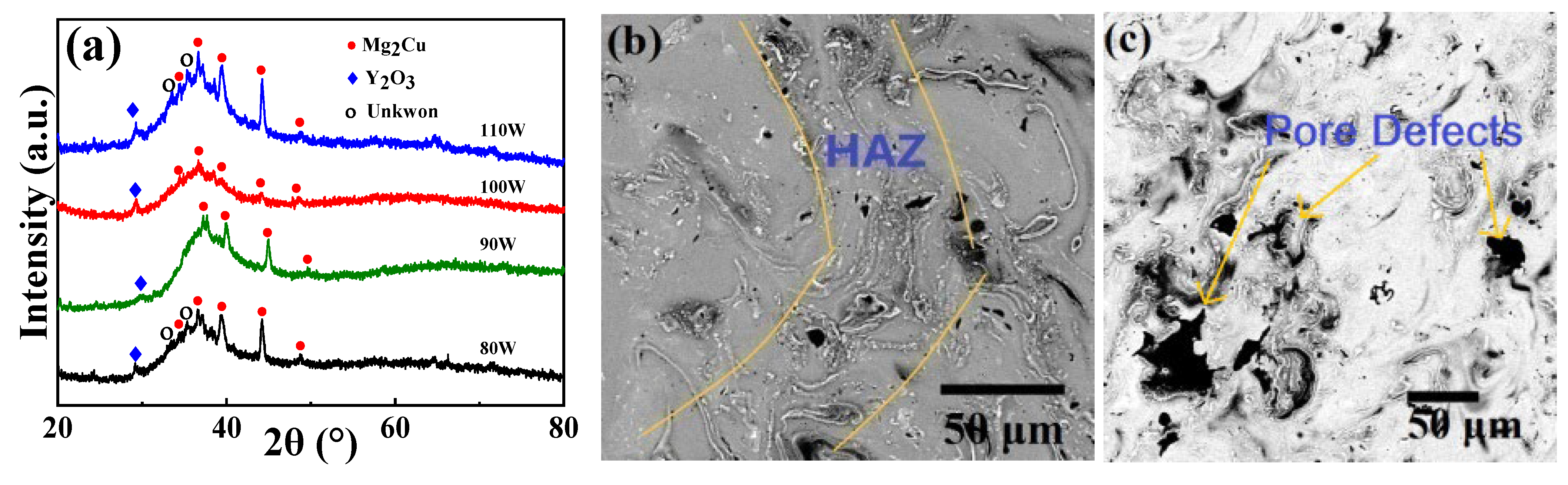

3.2. Effect of Laser Power on the Microstructures

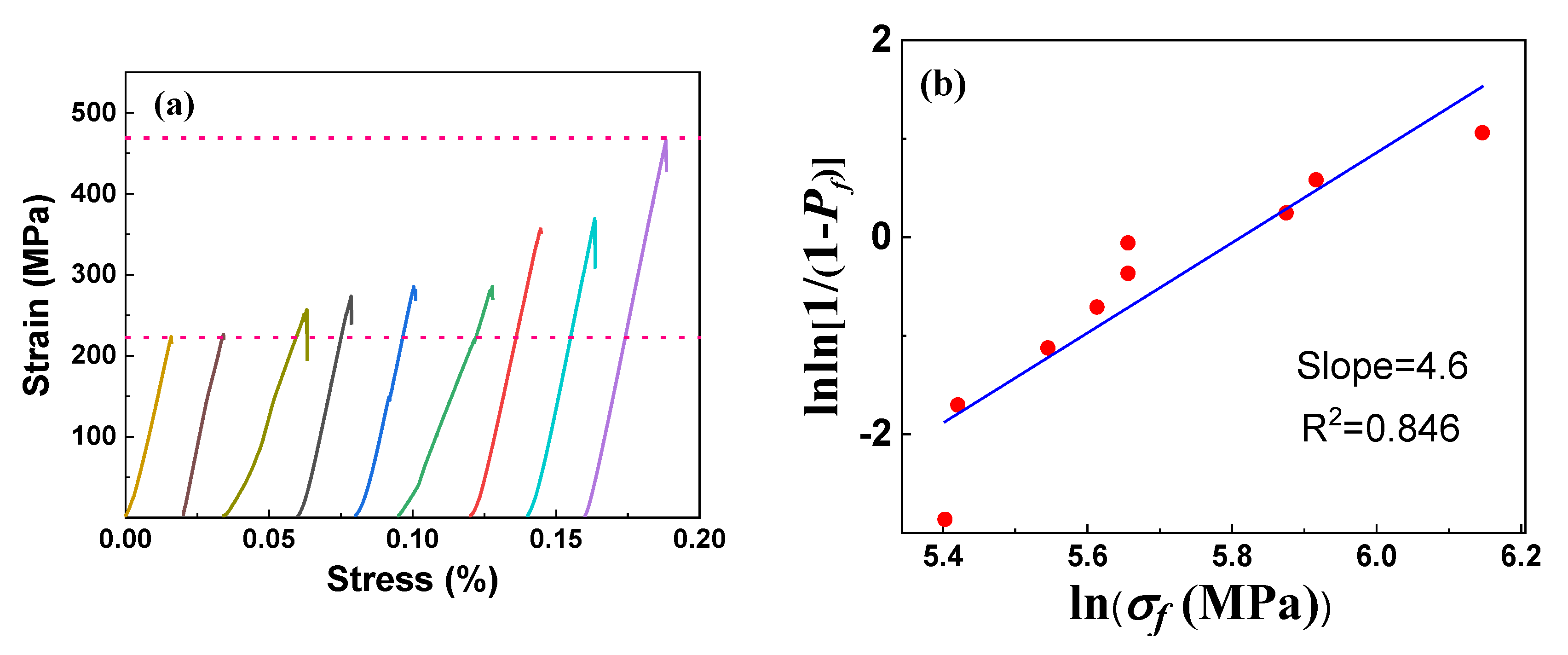

3.3. Mechanical Performance

4. Discussion

4.1. Effects of Laser Energy Density on the Structures

| Energy Density (J/mm2) | Laser Power (W) | Scanning Speed (mm/s) | Main Features |

|---|---|---|---|

| 22.2 | 80 | 1200 | Unfused powder |

| 26.7 | 80 | 1000 | Tens of microns irregular pores |

| 27.7 | 100 | 1200 | Tens of microns irregular pores |

| 33.3 | 100 | 1000 | 23% crystallinity |

| 36.7 | 110 | 1000 | 29% crystallinity |

| 37.0 | 100 | 900 | 31% crystallinity |

| 40.7 | 110 | 900 | Macrocrack |

4.2. Mechnical Performance

5. Conclusions

- The optimal energy density for 3D printing Mg65Cu20Zn5Y10 metallic glass is 33.3 J/mm2, with a laser power of 100 W, a scanning speed of 1000 mm/s, a layer thickness of 50 μm, and a hatch spacing of 60 μm, respectively.

- The decrement of laser energy density causes large pore defects, and further decreasing leads to unfused powder. The increment of laser energy density caused more crystalline phases in HAZs, and further increasing leads to macrocracks.

- The 3D-printed Mg-based metallic glasses show deteriorated mechanical performances, and Weibull statistics show that they are less reliable than their as-cast counterparts.

Author Contributions

Funding

Data Availability Statement

Conflicts of Interest

References

- Hufnagel, T.C.; Schuh, C.A.; Falk, M.L. Deformation of Metallic Glasses: Recent Developments in Theory, Simulations, and Experiments. Acta Mater. 2016, 109, 375–393. [Google Scholar] [CrossRef] [Green Version]

- Sun, B.A.; Wang, W.H. The Fracture of Bulk Metallic Glasses. Prog. Mater. Sci. 2015, 74, 211–307. [Google Scholar] [CrossRef]

- Li, Y.C.; Zhang, C.; Xing, W.; Guo, S.F.; Liu, L. Design of Fe-Based Bulk Metallic Glasses with Improved Wear Resistance. ACS Appl. Mater. Interfaces 2018, 10, 43144–43155. [Google Scholar] [CrossRef] [PubMed]

- Pang, S.J.; Zhang, T.; Asami, K.; Inoue, A. Synthesis of Fe–Cr–Mo–C–B–P Bulk Metallic Glasses with High Corrosion Resistance. Acta. Mater. 2002, 50, 489–497. [Google Scholar] [CrossRef]

- Poomathi, N.; Singh, S.; Prakash, C.; Subramanian, A.; Sahay, R.; Cinappan, A.; Ramakrishna, S. 3D Printing in Tissue Engineering: A State of the Art Review of Technologies and Biomaterials. Rap. Prot. J. 2020, 26, 1313–1334. [Google Scholar] [CrossRef]

- Khorasani, M.; Ghasemi, A.; Rolfe, B.; Gibson, I. Additive Manufacturing a Powerful Tool for the Aerospace Industry. Rap. Prot. J. 2022, 28, 87–199. [Google Scholar] [CrossRef]

- Mehrpouya, M.; Tuma, D.; Vaneker, T.; Mohamadreza, A.; Afrasiabi, M.; Bambach, M.; Gibson, I. Multimaterial Power Bed Fusion Techniques. Rap. Prot. J. 2022, 28, 1–19. [Google Scholar] [CrossRef]

- Zhang, C.; Ouyang, D.; Pauly, S.; Liu, L. 3D printing of Bulk Metallic Glasses. Mater. Sci. Eng. R 2021, 145, 100625. [Google Scholar] [CrossRef]

- Li, X.P.; Roberts, M.P.; O’Keeffe, S.; Sercombe, T.B. Selective Laser Melting of Zr-based Bulk Metallic Glasses: Processing, Microstructure and Mechanical Properties. Mater. Des. 2016, 112, 217–226. [Google Scholar] [CrossRef]

- Wang, L.; Wang, H.; Liu, Y.; Fu, Z.; Peng, T.; Shen, J.; Zhou, S.; Yan, M.; Wang, G.; Dai, Y. Selective Laser Melting Helps Fabricate Record-large Bulk Metallic Glass: Experiments, Simulation and Demonstrative Part. J. Alloy. Comp. 2019, 808, 151731. [Google Scholar] [CrossRef]

- Deng, L.; Wang, S.; Wang, P.; Kuhn, U.; Pauly, S. Selective Laser Melting of a Ti-based Bulk Metallic Glass. Mater. Lett. 2018, 212, 346–349. [Google Scholar] [CrossRef]

- Deng, L.; Zhang, L.; Kosiba, K.; Limbach, R.; Wondraczek, L.; Wang, G.; Gu, D.D.; Kuhn, U.; Pauly, S. CuZr-based Bulk Metallic Glass and Glass Matrix Composites Fabricated by Selective Laser Melting. J. Mater. Sci. Tech. 2021, 81, 139–150. [Google Scholar] [CrossRef]

- Madge, S.V.; Greer, A.L. Laser Additive Manufacturing of Metallic Glasses; Issues in Vitrification and Mechanical Properties. Oxf. Open Mater. Sci. 2021, 1, 1–13. [Google Scholar] [CrossRef]

- Zberg, B.; Uggowitzer, P.J.; Loffler, J.F. MgZnCa Glasses without Clinically Observable Hydrogen Evolution for Biodegradable Implants. Nat. Mater. 2009, 8, 887–891. [Google Scholar] [CrossRef]

- Bin, S.J.B.; Fong, K.S.; Chua, B.W.; Gupta, M. Mg-based Bulk Metallic Glasses: A Review of Recent Development. J. Magnes. Alloy. 2022, 10, 899–914. [Google Scholar] [CrossRef]

- Jin, C.; Liu, Z.; Yu, W.; Qin, C.; Yu, H.; Wang, Z. Biodegradable Mg-Zn-Ca-Based Metallic Glasses. Materials 2022, 15, 2172. [Google Scholar] [CrossRef] [PubMed]

- Men, H.; Hu, Z.Q.; Xu, J. Bulk Metallic Glass Formation in the Mg-Cu-Zn-Y System. Scr. Mater. 2002, 46, 699–703. [Google Scholar] [CrossRef]

- Hui, X.; Wei, D.; Wang, M.; Liu, X.; Yu, J.; Chen, G. In-situ Mg77Cu12Zn5Y6 Bulk Metallic Glass Matrix Composite with Extraordinary Plasticity. Chin. Sci. Bull. 2006, 51, 229–234. [Google Scholar] [CrossRef]

- Pacheco, V.; Karlsson, D.; Marattukalam, J.J.; Stolpe, M.; Hjorvarsson, B.; Jansson, U.; Sahlberg, M. Thermal Stability and Crystallization of a Zr-based Metallic Glass Produced by Suction Casting and Selective Laser Melting. J. Alloys Comp. 2020, 825, 153995. [Google Scholar] [CrossRef]

- Zhao, Y.Y.; Ma, E.; Xu, J. Reliability of Compressive Fracture Strength of Mg-Zn-Ca Bulk Metallic Glasses: Flaw Sensitivity and Weibull Statistics. Scr. Mater. 2008, 58, 496–499. [Google Scholar] [CrossRef]

- Ouyang, D.; Xing, W.; Li, N.; Li, Y.; Liu, L. Structural Evolutions in 3D-printed Fe-based Metallic Glass Fabricated by Selective Laser Melting. Addit. Manuf. 2018, 23, 246–252. [Google Scholar] [CrossRef]

- Xing, W.; Ouyang, D.; Chen, Z.; Liu, L. Effect of Energy Density on Defect Evolution in 3D Printed Zr-based Metallic Glasses by Selective Laser Melting. Sci. China Phys. Mech. Astron. 2020, 63, 226111. [Google Scholar] [CrossRef]

- Xiao, R.; Zhang, X. Problems and Issues in Laser Beam Welding of Aluminum-lithium Alloys. J. Manuf. Proc. 2014, 16, 166–175. [Google Scholar] [CrossRef]

- Prashanth, K.G.; Scudino, S.S.; Maity, T.; Das, J.; Eckert, J. Is the Energy Density a Reliable Parameter for Materials Synthesis by Selective Laser Melting? Mater. Res. Lett. 2017, 5, 386–390. [Google Scholar] [CrossRef] [Green Version]

- Zhang, C.; Li, X.M.; Liu, S.Q.; Liu, H.; Yu, L.J.; Liu, L. 3D Printing of Zr-based Bulk Metallic Glasses and Components for Potential Biomedical Applications. J. Alloy. Comp. 2019, 790, 963–973. [Google Scholar] [CrossRef]

- Li, N.; Zhang, J.; Xing, W.; Ouyang, D.; Liu, L. 3D Printing of Fe-based Bulk Metallic Glass Composites with Combined High Strength and Fracture Toughness. Mater. Des. 2018, 143, 285–296. [Google Scholar] [CrossRef]

- Gao, X.; Lin, X.; Yu, J.; Li, Y.; Hu, Y.; Fan, W.; Shi, S.; Huang, W. Selective Laser Melting(SLM) of In-situ Beta Phase Reinforced Ti/Zr-based Bulk Metallic Glass Matrix Composite. Scr. Mater. 2019, 171, 21–25. [Google Scholar] [CrossRef]

- Qiu, K.Q.; Hu, N.N.; Zhang, H.B.; Jiang, W.H.; Ren, Y.L.; Liaw, P.K. Mechanical Properties and Fracture Mechanism of as-cast Mg77TM12Zn5Y6 (TM=Cu, Ni) Bulk Amorphous Matrix Composites. J. Alloy. Comp. 2009, 478, 419–422. [Google Scholar] [CrossRef]

- Lee, J.I.; Ryu, W.H.; Yoon, K.N.; Park, E.S. In-situ synthesis of Mg-based Bulk Metallic Glass Matrix Composites with Primary α–Mg Phases. J. Alloy. Comp. 2021, 879, 160417. [Google Scholar] [CrossRef]

Publisher’s Note: MDPI stays neutral with regard to jurisdictional claims in published maps and institutional affiliations. |

© 2022 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (https://creativecommons.org/licenses/by/4.0/).

Share and Cite

Zhao, Z.; Yang, G.; Zhao, K. 3D Printing of Mg-Based Bulk Metallic Glasses with Proper Laser Power and Scanning Speed. Metals 2022, 12, 1318. https://doi.org/10.3390/met12081318

Zhao Z, Yang G, Zhao K. 3D Printing of Mg-Based Bulk Metallic Glasses with Proper Laser Power and Scanning Speed. Metals. 2022; 12(8):1318. https://doi.org/10.3390/met12081318

Chicago/Turabian StyleZhao, Zijian, Guang Yang, and Kun Zhao. 2022. "3D Printing of Mg-Based Bulk Metallic Glasses with Proper Laser Power and Scanning Speed" Metals 12, no. 8: 1318. https://doi.org/10.3390/met12081318

APA StyleZhao, Z., Yang, G., & Zhao, K. (2022). 3D Printing of Mg-Based Bulk Metallic Glasses with Proper Laser Power and Scanning Speed. Metals, 12(8), 1318. https://doi.org/10.3390/met12081318