Near-Surface and Bulk Dissolution Behavior of γ′ Precipitates in Nickel-Based VDM® Alloy 780 Studied with In-Situ Lab-Source and Synchrotron X-ray Diffraction

Abstract

:1. Introduction

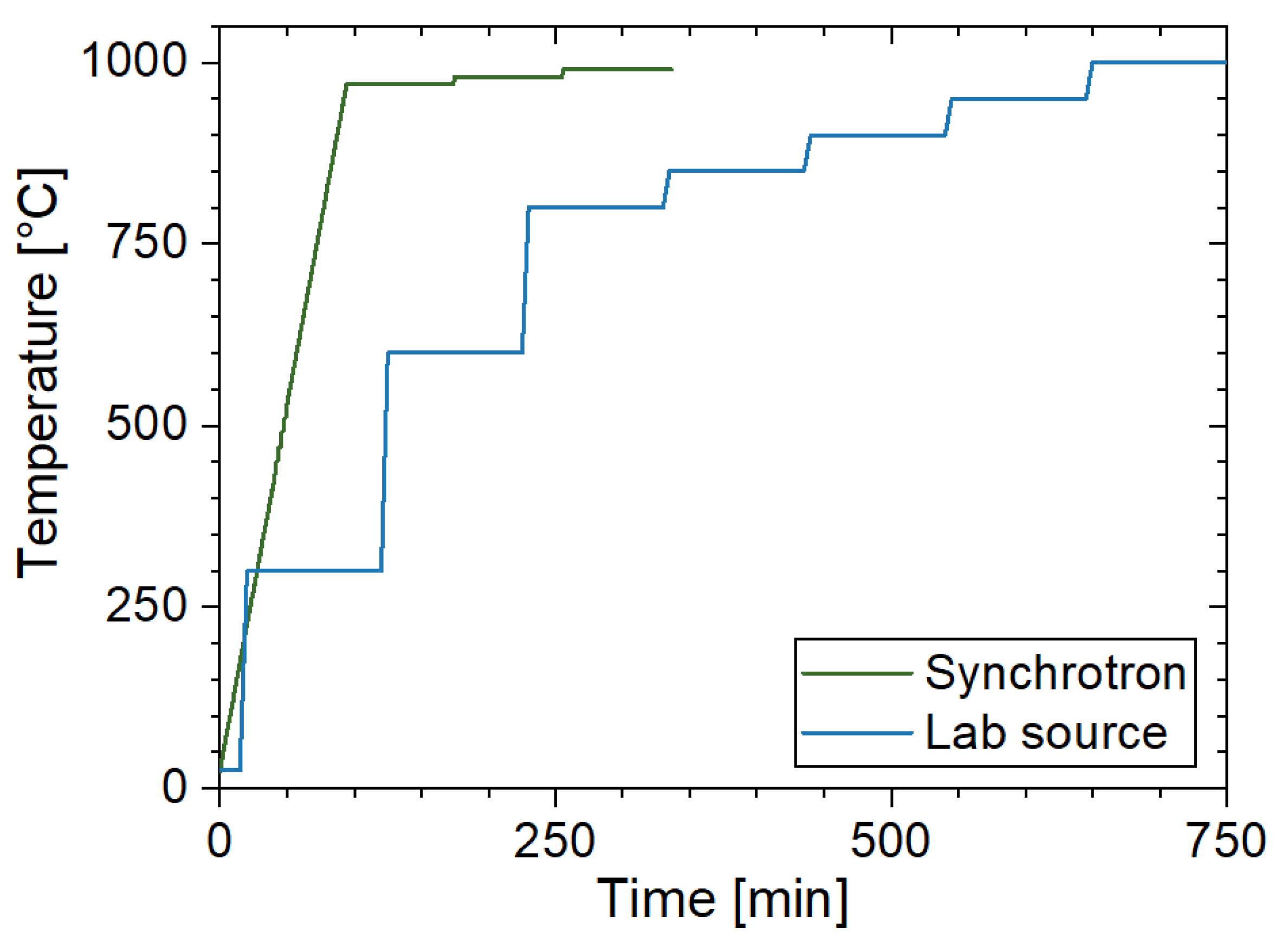

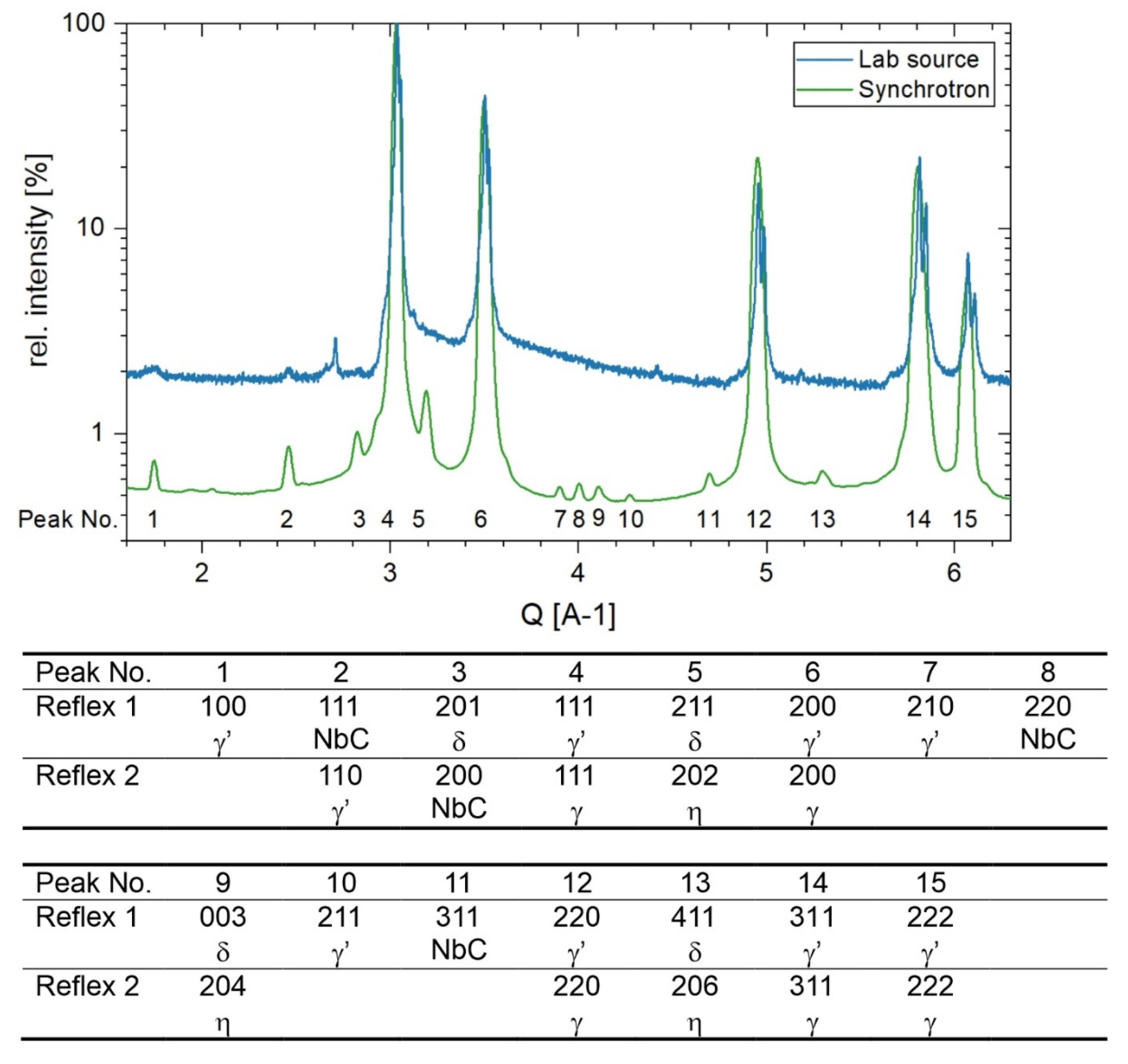

2. Experimental Procedure

3. Results

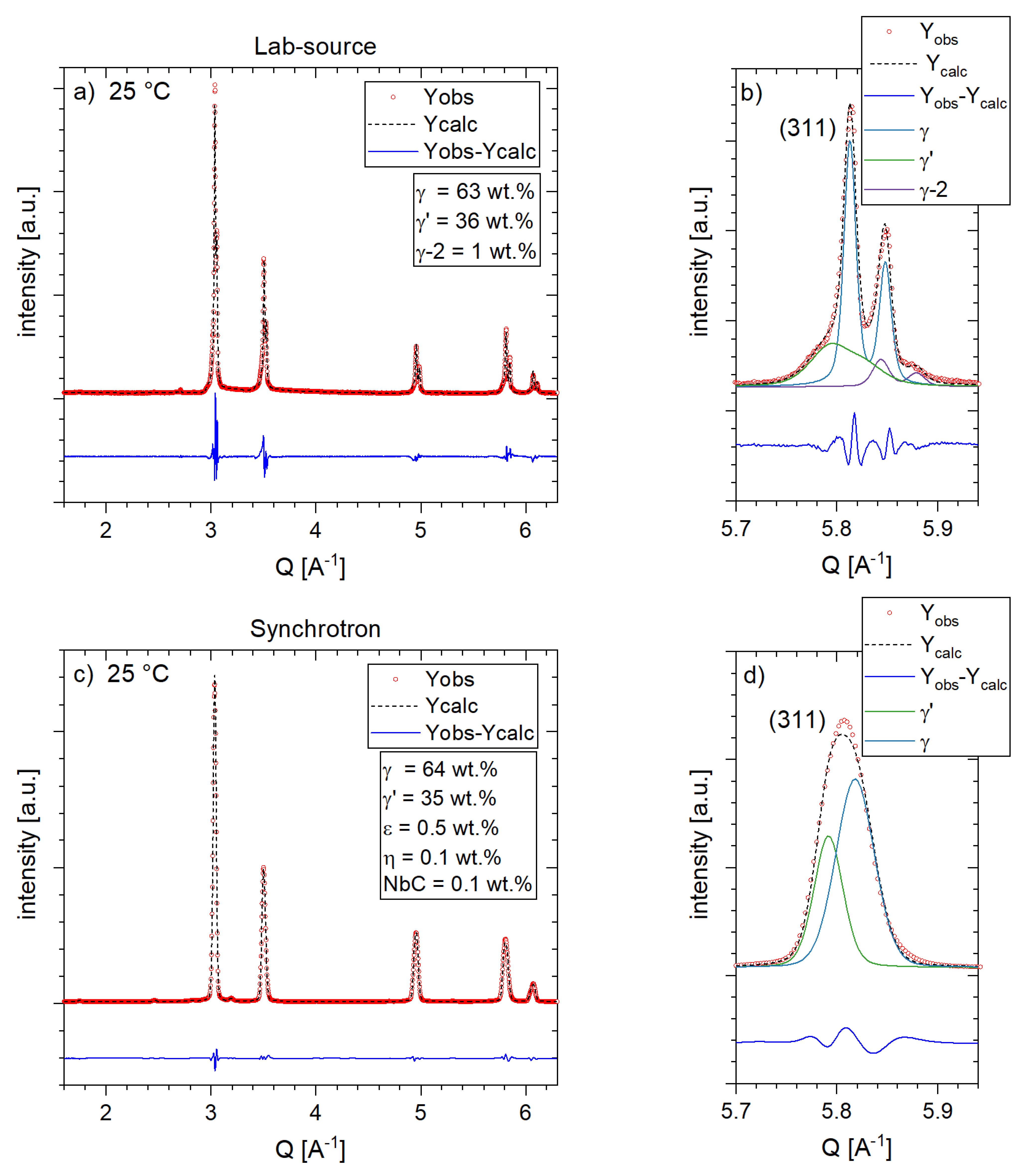

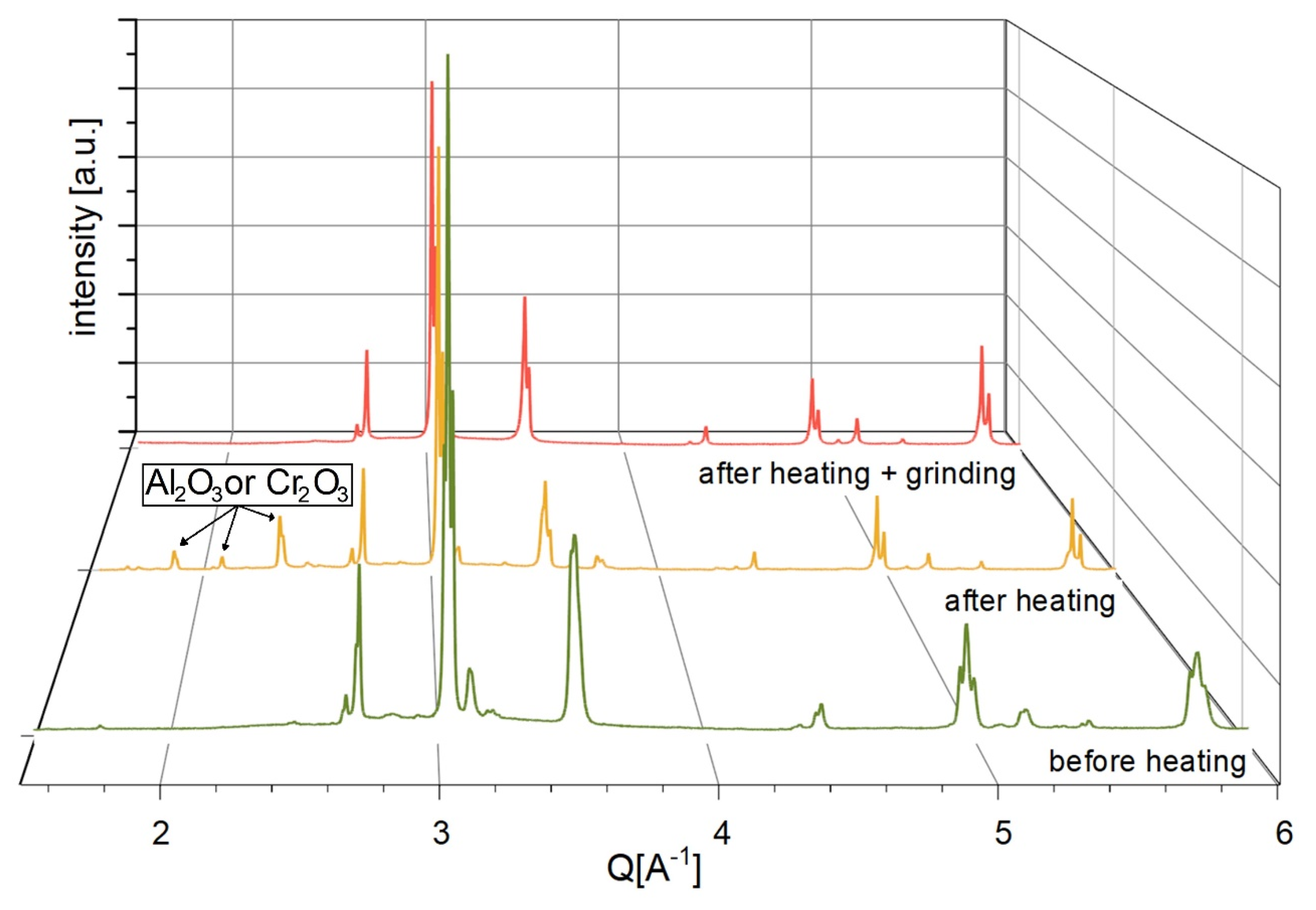

3.1. Lattice Parameters and Weight Fractions at Room Temperature

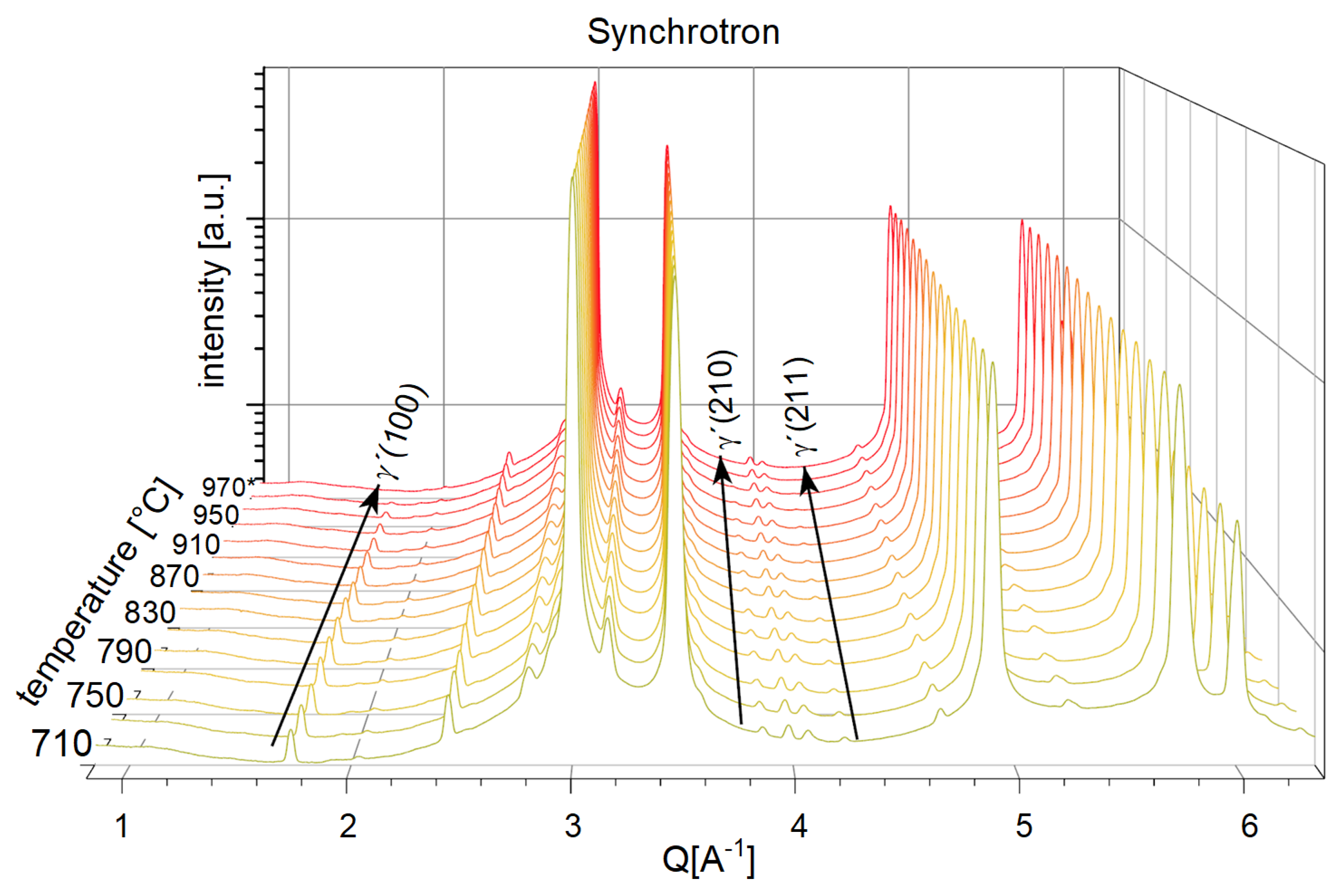

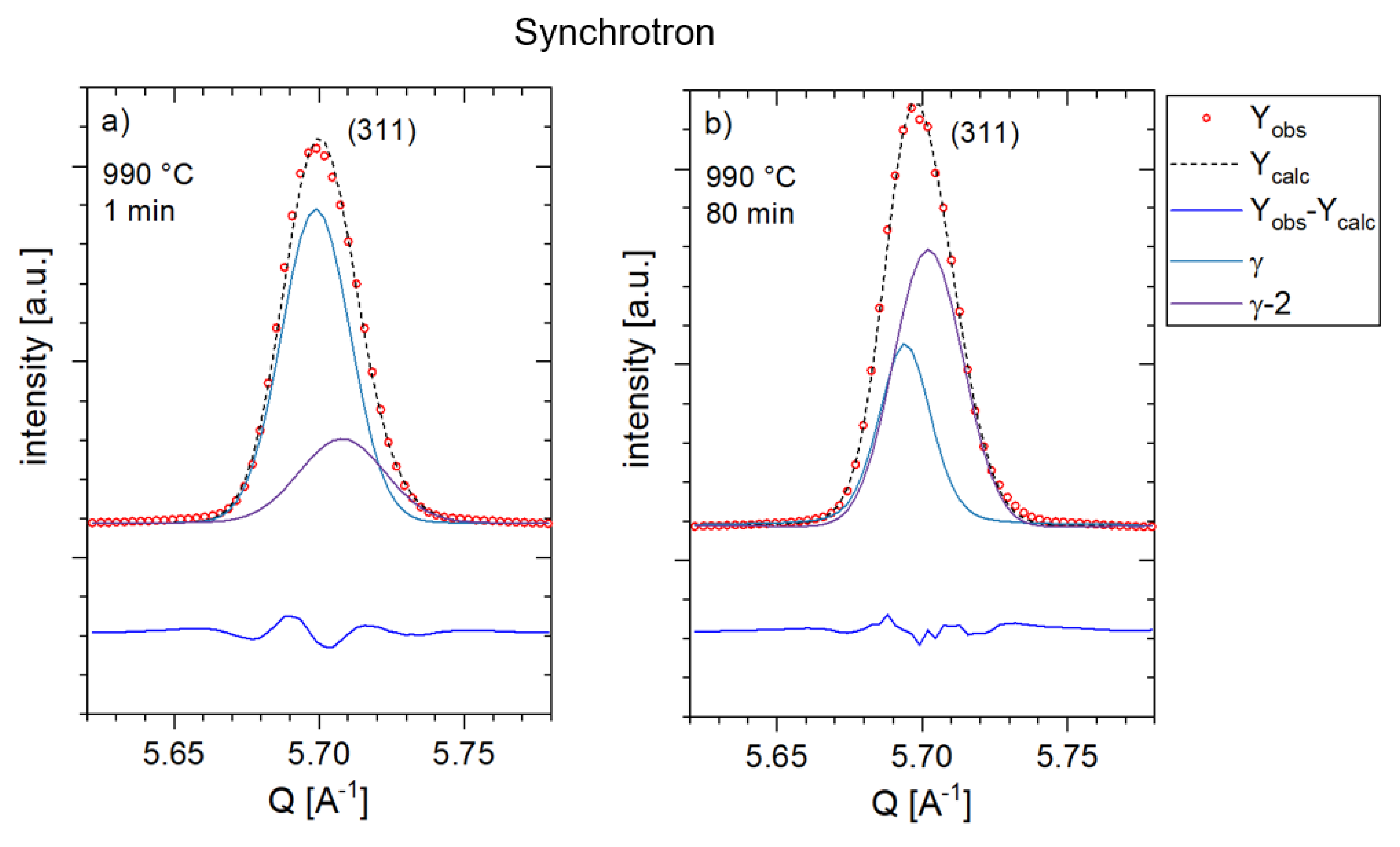

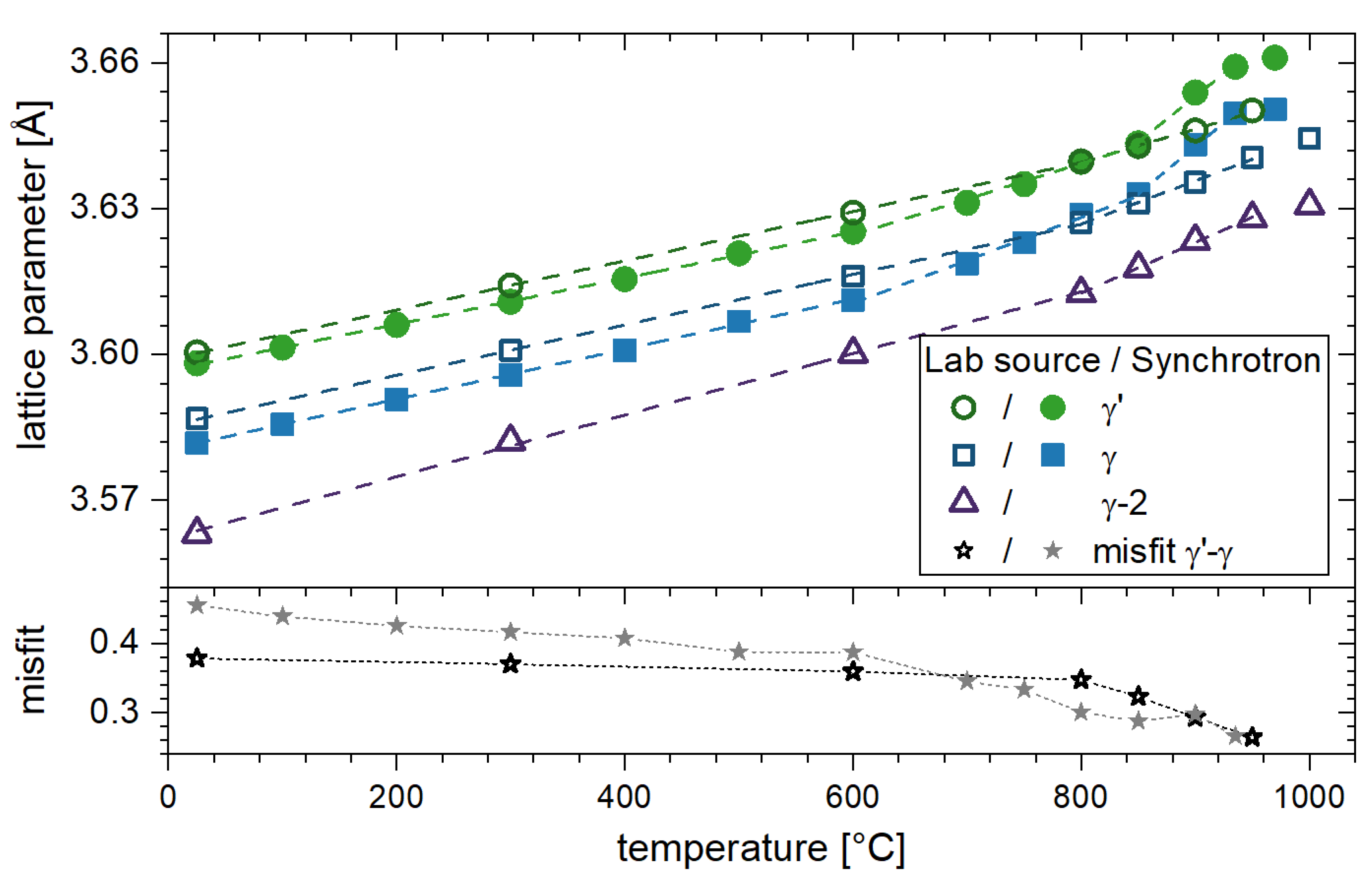

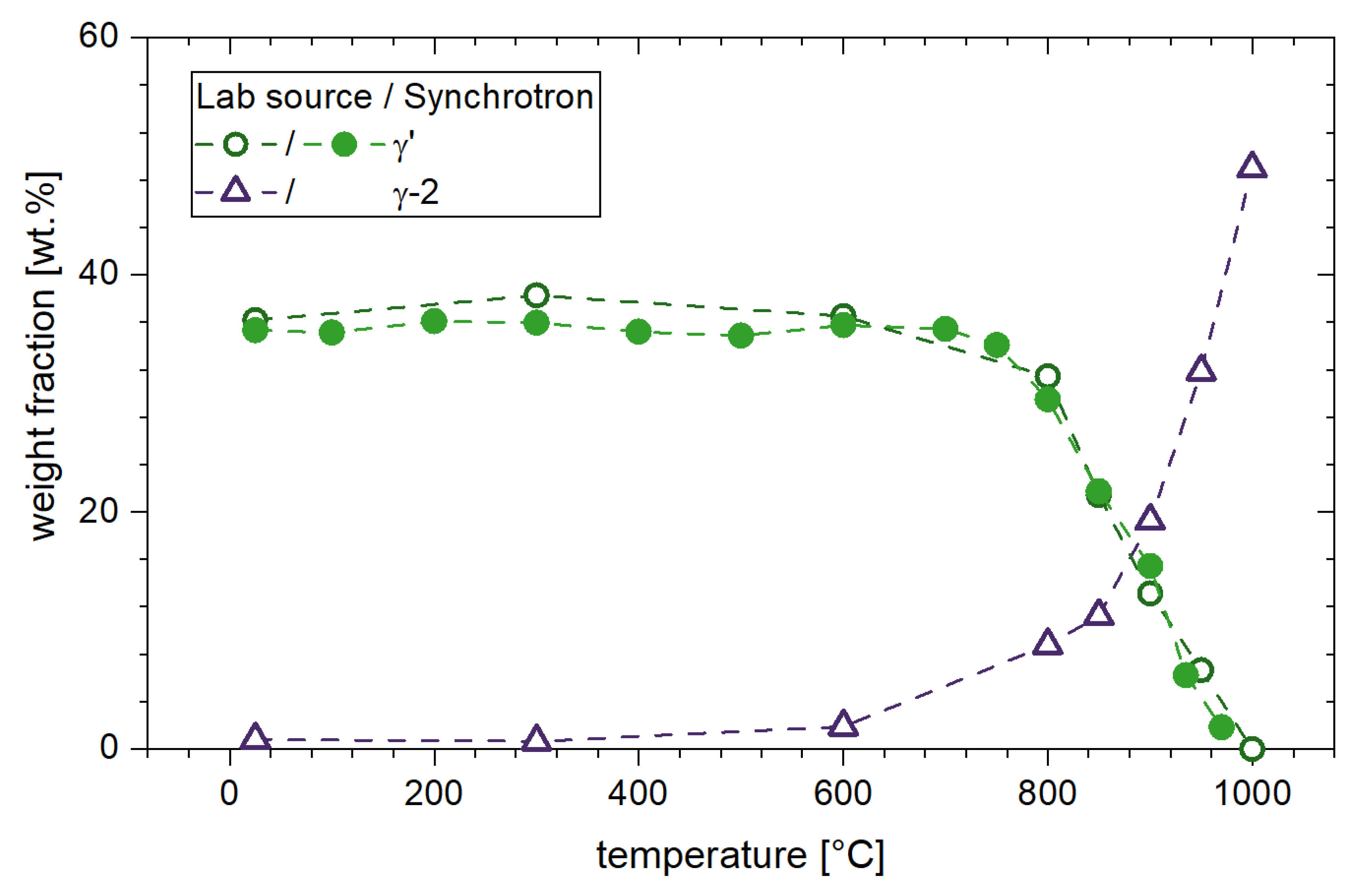

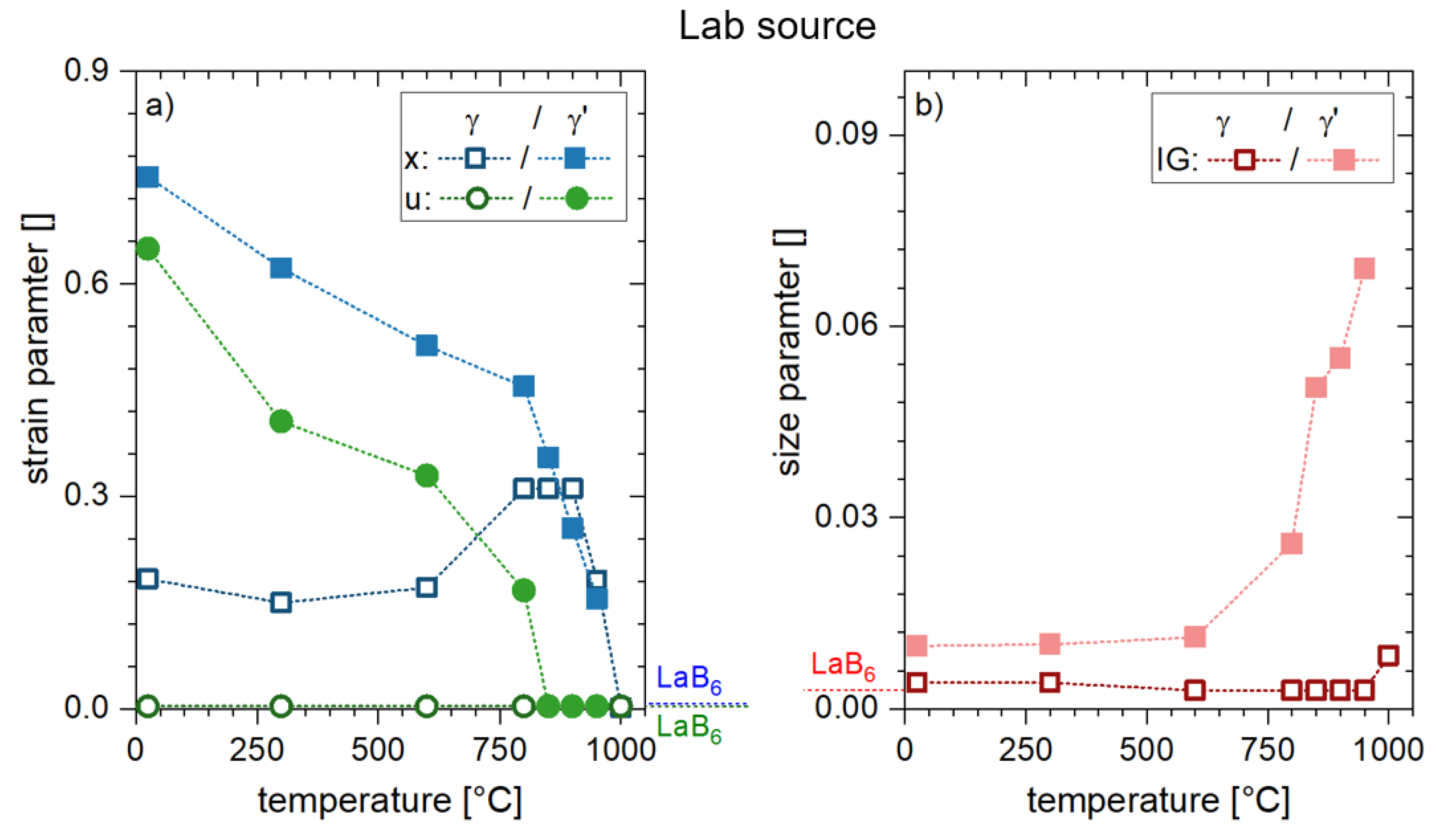

3.2. Evolution of Lattice Parameters and Weight Fractions of the γ- and γ′-Phases at Elevated Temperatures

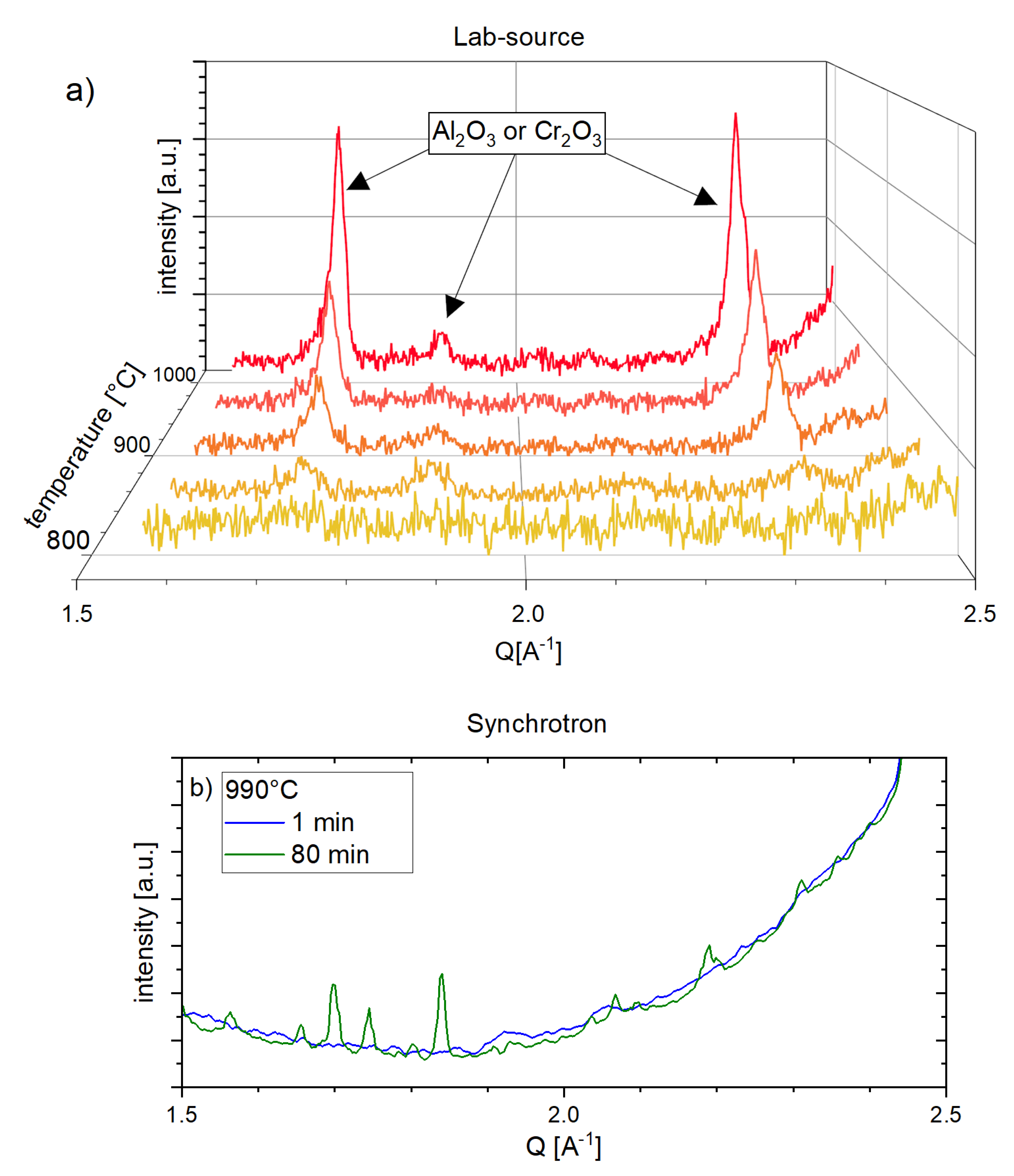

3.3. Surface Oxidation Effects

4. Discussion

- The weight fraction and size of the γ′ phase remained nearly constant from room temperature until approximately 750 °C in the surface and bulk regions of the sample. This temperature range was characterized by a linear reduction in the lattice misfit between γ′ and γ, due to the higher thermal expansion coefficient of the matrix. As a result, the strain in the γ′ phase continuously decreased with increasing temperature. This linear reduction in the lattice misfit in the temperature range from 25 °C to 750 °C is known for a variety of Ni-based superalloys; see, e.g., references [9,10,11].

- The phase fraction of γ′ rapidly decreased at higher temperatures (800–970 °C). No γ′ was measured at temperatures exceeding 970 °C. The decreasing fraction of γ′ was accompanied by an increasing size-broadening parameter of the γ′ peaks, which indicated a decreasing crystallite size. Furthermore, the lattice misfit and strain significantly reduced in this temperature range.

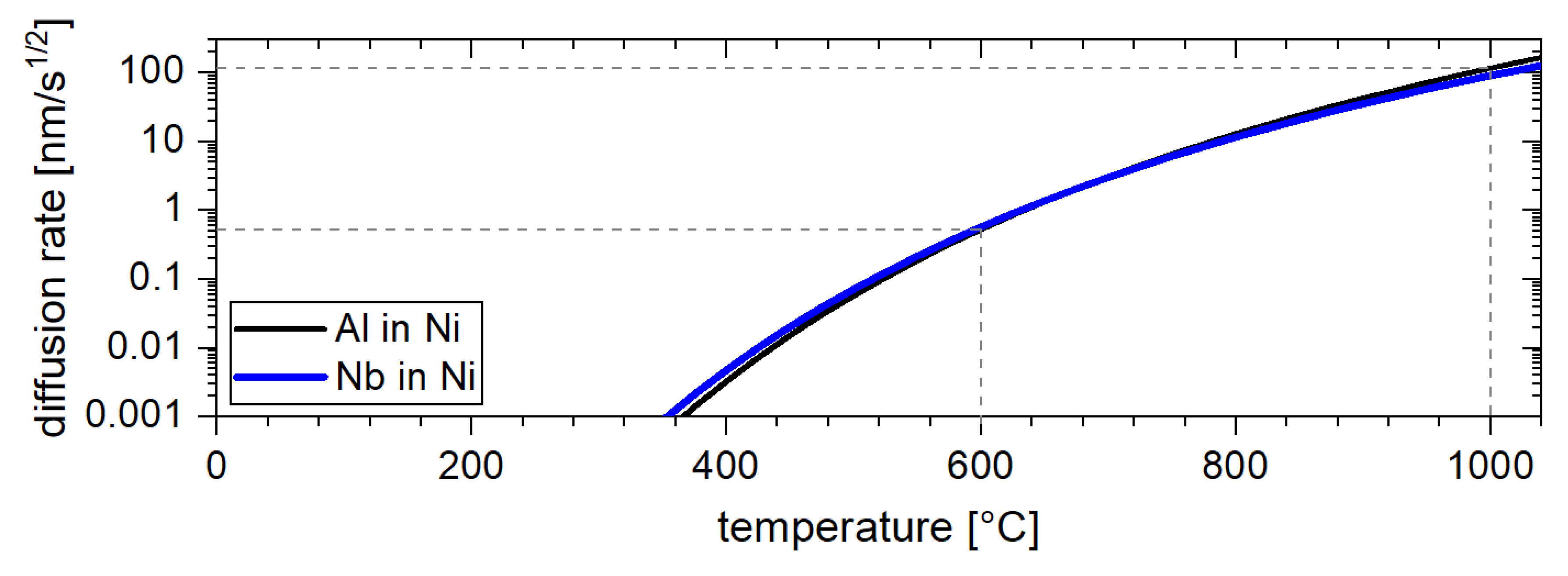

- The dissolution of the γ′-forming elements Al and Nb into the γ matrix led to an increasing γ lattice parameter. This may be better explained by the significantly higher atomic radii of the γ′-forming elements Al and Nb (1.432 Å and 1.47 Å) [42] than by the atomic radii of γ forming elements Ni, Co and Cr (1.246 Å, 1.253 Å and 1.29 Å) [42]. Previous ND results [25] revealed that a decreasing amount of γ′ leads to an increasing γ lattice parameter.

- Surface oxidation occurs at temperatures higher than 800 °C. It is well known from the relevant literature that the thickness of the oxide layer strongly depends on the testing temperature, time, and atmosphere. The oxides in Ni-based superalloys preferably bind Al, Cr, Fe, Mo and Nb [43,44]. According to the literature, an oxide layer thickness of a few nanometers when tested at room temperature [44], increases to a thickness of tens of micrometers when tested at 750 °C [45].As a result of the oxidation, a chemically modified γ phase (γ-2) developed in the sub-surface area, which was enriched in Ni and depleted in the oxide-forming elements [44]. This rich γ-2 layer was much thicker than the oxide layer, due to the high diffusibility of the oxide-forming elements.

5. Conclusions

- The dissolution behavior of the strengthening γ′ phase with increasing temperatures was nearly identical in the surface and bulk regions in the investigated VDM® Alloy 780. The γ′ weight fraction and size remained nearly constant until a temperature of approximately 750 °C was reached. The γ′-phase fraction rapidly decreased at higher temperatures and no γ′ was measured at temperatures exceeding 970 °C.

- The dissolution of the larger γ′-forming elements, Al and Nb, into the γ matrix led to an increasing γ lattice parameter. However, the extent significantly differed at the surface or in the bulk of the sample. This may be explained by the surface oxidation effects at temperatures exceeding 800 °C.

- The increase of the γ lattice parameters was much higher in the bulk region compared to the surface region. The larger Al and Nb atoms, which originated from the dissolving γ′ precipitates, fully dissolved within the γ-matrix in the bulk region.

- These elements diffused to the surface to build oxides in the sub-surface area. As a result, a chemically modified γ phase (γ-2) with a smaller lattice parameter as its parental γ phase developed.

- The results showed that the investigated VDM® Alloy 780 is a suitable candidate for highly stressed parts in the hot sections of modern gas turbine engines and power generation applications, where temperatures of up to 750 °C are targeted. The γ′ fraction remained stable at high temperature values up to 800 °C.

Author Contributions

Funding

Acknowledgments

Conflicts of Interest

References

- Pollock, T.M.; Argon, A.S. Creep resistance of CMSX-3 nickel base superalloy single crystals. Acta Metall. Mater. 1992, 40, 1–30. [Google Scholar] [CrossRef]

- Chen, J.H.; Rogers, P.M.; Little, J.A. Oxidation behaviour of several chromia-forming commercial nickel-base superalloys. Oxid. Met. 1997, 47, 381–410. [Google Scholar] [CrossRef]

- Murakumo, T.; Kobayashi, T.; Koizumi, Y.; Harada, H. Creep behaviour of Ni-base single-crystal superalloys with various γ′ volume fraction. Acta Mater. 2004, 52, 3737–3744. [Google Scholar] [CrossRef]

- Pineau, A.; Antolovich, S.D. High temperature fatigue of nickel-base superalloys—A review with special emphasis on deformation modes and oxidation. Eng. Fail. Anal. 2009, 16, 2668–2697. [Google Scholar] [CrossRef]

- Li, J.; Wahi, R.P. Investigation of γ/γ′ lattice mismatch in the polycrystalline nickel-base superalloy IN738LC: Influence of heat treatment and creep deformation. Acta Metall. Mater. 1995, 43, 507–517. [Google Scholar] [CrossRef]

- Soula, A.; Renollet, Y.; Boivin, D.; Pouchou, J.-L.; Locq, D.; Caron, P.; Bréchet, Y. Analysis of high-temperature creep deformation in a polycrystalline nickel-base superalloy. Mater. Sci. Eng. A 2009, 510–511, 301–306. [Google Scholar] [CrossRef]

- Cozar, R.; Pineau, A. Morphology of y′ and y″ precipitates and thermal stability of inconel 718 type alloys. Metall. Trans. 1973, 4, 47–59. [Google Scholar] [CrossRef]

- Kotval, P.S. The microstructure of superalloys. Metallography 1969, 1, 251–285. [Google Scholar] [CrossRef]

- Grose, D.A.; Ansell, G.S. The influence of coherency strain on the elevated temperature tensile behaviour of Ni-15Cr-AI-Ti-Mo alloys. Metall. Trans. A 1981, 12, 1631–1645. [Google Scholar] [CrossRef]

- Nathal, M.V.; Mackay, R.A.; Garlick, R.G. Temperature dependence of γ-γ′ lattice mismatch in Nickel-base superalloys. Mater. Sci. Eng. 1985, 75, 195–205. [Google Scholar] [CrossRef]

- Kamara, A.B.; Ardell, A.J.; Wagner, C.N.J. Lattice misfits in four binary Ni-Base γ/γ 1 alloys at ambient and elevated temperatures. Metall. Mater. Trans. A 1996, 27, 2888–2896. [Google Scholar] [CrossRef]

- Collier, J.P.; Selius, A.O.; Tien, J.K. On developing a microstructurally and thermally stable iron-nickel base superalloy. Superalloys 1988, 1988, 43–52. [Google Scholar]

- Zenk, C.H.; Neumeier, S.; Stone, H.J.; Göken, M. Mechanical properties and lattice misfit of γ/γ′ strengthened Co-base superalloys in the Co–W–Al–Ti quaternary system. Intermetallics 2014, 55, 28–39. [Google Scholar] [CrossRef]

- Gao, S.; Hou, J.; Yang, F.; Guo, Y.; Zhou, L. Effect of Ta on microstructural evolution and mechanical properties of a solid-solution strengthening cast Ni-based alloy during long-term thermal exposure at 700 °C. J. Alloys Compd. 2017, 729, 903–913. [Google Scholar] [CrossRef]

- Azadian, S.; Wei, L.-Y.; Warren, R. Delta phase precipitation in Inconel 718. Mater. Charact. 2004, 53, 7–16. [Google Scholar] [CrossRef]

- Messé, O.M.; Barnard, J.S.; Pickering, E.J.; Midgley, P.A.; Rae, C.M.F. On the precipitation of delta phase in ALLVAC® 718Plus. Philos. Mag. 2014, 94, 1132–1152. [Google Scholar] [CrossRef]

- Mitchell, A. Primary Carbides in Alloy 718. In Proceedings of the 7th International Symposium on Superalloy 718 and Derivatives, Pittsburgh, PA, USA, 10–13 October 2012; pp. 161–167. [Google Scholar]

- Oblak, J.M.; Paulonis, D.F.; Duvall, D.S. Coherency strengthening in Ni base alloys hardened by DO22 γ′ precipitates. Metall. Trans. 1974, 5, 143–153. [Google Scholar] [CrossRef]

- Sundararaman, M.; Mukhopadhyay, P.; Banerjee, S. Precipitation of the δ-Ni3Nb phase in two nickel base superalloys. Metall. Trans. A 1988, 19, 453–465. [Google Scholar] [CrossRef]

- Cao, W.-D.; Kennedy, R. Role of chemistry in 718-type alloys—Allvac® 718plus™ alloy development. Superalloys 2004, 2004, 91–99. [Google Scholar]

- Kirchmayer, A.; Lyu, H.; Pröbstle, M.; Houllé, F.; Förner, A.; Huenert, D.; Göken, M.; Felfer, P.J.; Bitzek, E.; Neumeier, S. Combining Experiments and Atom Probe Tomography-Informed Simulations on γ′ Precipitation Strengthening in the Polycrystalline Ni-Base Superalloy A718Plus. Adv. Eng. Mater. 2020, 22, 2000149. [Google Scholar] [CrossRef]

- Neumeier, S.; Freund, L.P.; Göken, M. Novel wrought γ/γ′ cobalt base superalloys with high strength and improved oxidation resistance. Scr. Mater. 2015, 109, 104–107. [Google Scholar] [CrossRef]

- Bergner, M.; Rösler, J.; Gehrmann, B.; Klöwer, J. Effect of Heat Treatment on Microstructure and Mechanical Properties of VDM Alloy 780 Premium. In Proceedings of the 9th International Symposium on Superalloy 718 & Derivatives: Energy, Aerospace, and Industrial Applications; Ott, E., Liu, X., Andersson, J., Bi, Z., Bockenstedt, K., Dempster, I., Groh, J., Heck, K., Jablonski, P., Kaplan, M., et al., Eds.; Springer International Publishing: Cham, Switzerland, 2018; pp. 489–499. [Google Scholar]

- Rösler, J.; Hentrich, T.; Gehrmann, B. On the Development Concept for a New 718-Type Superalloy with Improved Temperature Capability. Metals 2019, 9, 1130. [Google Scholar] [CrossRef] [Green Version]

- Solís, C.; Munke, J.; Bergner, M.; Kriele, A.; Mühlbauer, M.J.; Cheptiakov, D.V.; Gehrmann, B.; Rösler, J.; Gilles, R. In Situ Characterization at Elevated Temperatures of a New Ni-Based Superalloy VDM-780 Premium. Metall. Mater. Trans. A Phys. Metall. Mater. Sci. 2018, 49, 4373–4381. [Google Scholar] [CrossRef] [Green Version]

- Solís, C.; Munke, J.; Hofmann, M.; Mühlbauer, S.; Bergner, M.; Gehrmann, B.; Rösler, J.; Gilles, R. In situ characterization at high temperature of VDM Alloy 780 premium to determine solvus temperatures and phase transformations using neutron diffraction and small-angle neutron scattering. In Characterization of Minerals, Metals, and Materials 2019; Minerals, Metals and Materials Series; Springer: Cham, Switzerland, 2019; pp. 23–32. [Google Scholar]

- Ghica, C.; Solís, C.; Munke, J.; Stark, A.; Gehrmann, B.; Bergner, M.; Rösler, J.; Gilles, R. HRTEM analysis of the high-temperature phases of the newly developed high-temperature Ni-base superalloy VDM 780 Premium. J. Alloys Compd. 2020, 814, 152–157. [Google Scholar] [CrossRef]

- Kümmel, F.; Kirchmayer, A.; Solís, C.; Hofmann, M.; Neumeier, S.; Gilles, R. Deformation Mechanisms in Ni-Based Superalloys at Room and Elevated Temperatures Studied by In Situ Neutron Diffraction and Electron Microscopy. Metals 2021, 11, 719. [Google Scholar] [CrossRef]

- Gilles, R.; Mukherji, D.; del Genovese, D.; Strunz, P.; Barbier, B.; Kockelmann, W.; Rösler, J.; Fuess, H. Misfit investigations of Nickel-base superalloys. Mater. Sci. Forum 2003, 426–432, 821–826. [Google Scholar]

- Mukherji, D.; Gilles, R.; Barbier, B.; Genovese, D.D.; Hasse, B.; Strunz, P.; Wroblewski, T.; Fuess, H.; Rösler, J. Lattice misfit measurement in Inconel 706 containing coherent γ′ and γ″ precipitates. Scr. Mater. 2003, 48, 333–339. [Google Scholar] [CrossRef]

- Schell, N.; King, A.; Beckmann, F.; Fischer, T.; Müller, M.; Schreyer, A. The High Energy Materials Science Beamline (HEMS) at PETRA III. Mater. Sci. Forum 2014, 772, 57–61. [Google Scholar]

- Hammersley, A.P. FIT2D: An Introduction and Overview, ESRF Internal Report ESRF97HA02T (1997). Available online: https://www.esrf.fr/computing/scientific/FIT2D/FIT2D_INTRO/fit2d.html (accessed on 15 January 2022).

- Rodríguez-Carvajal, J. Recent advances in magnetic structure determination by neutron powder diffraction. Phys. B 1993, 192, 55–69. [Google Scholar] [CrossRef]

- Thompson, P.; Cox, D.E.; Hastings, J.B. Rietveld refinement of Debye–Scherrer synchrotron X-ray data from Al2O3. J. Appl. Crystallogr. 1987, 20, 79–83. [Google Scholar] [CrossRef] [Green Version]

- Solís, C.; Kirchmayer, A.; Silva, I.d.; Kümmel, F.; Mühlbauer, S.; Beran, P.; Gehrmann, B.; Haghighat, M.H.; Neumeier, S.; Gilles, R. Monitoring the precipitation of the hardening phase in the new VDM® Alloy 780 by insitu high-temperature small-angle neutron scattering, neutron diffraction and complementary microscopy techniques. J. Alloys Compd. 2022, accepted. [Google Scholar]

- Hwang, J.-W. Thermal Expansion of Nickel and Iron, and the Influence of Nitrogen on the Lattice Parameter of Iron at the Curie Temperature. Master’s Thesis, University of Missouri, Columbia, MI, USA, 1972. [Google Scholar]

- Gilles, R.; Krimmer, B.; Boysen, H.; Fuess, H. Status of the new structure powder diffractometer (SPODI) at the FRM-II in Garching. Appl. Phys. A 2002, 74, s148–s150. [Google Scholar] [CrossRef]

- Hoelzel, M.; Senyshyn, A.; Juenke, N.; Boysen, H.; Schmahl, W.; Fuess, H. High-resolution neutron powder diffractometer SPODI at research reactor FRM II. Nucl. Instrum. Methods Phys. Res. Sect. A 2012, 667, 32–37. [Google Scholar]

- Hoelzel, M.; Senyshyn, A.; Dolotko, O. SPODI: High resolution powder diffractometer. J. Large-Scale Res. Facil. JLSRF 2015, 1, 5. [Google Scholar] [CrossRef]

- Allison, H.W.; Samelson, H. Diffusion of Aluminum, Magnesium, Silicon, and Zirconium in Nickel. J. Appl. Phys. 1959, 30, 1419–1424. [Google Scholar] [CrossRef]

- Sohrabi, M.J.; Mirzadeh, H. Revisiting the Diffusion of Niobium in an As-Cast Nickel-Based Superalloy During Annealing at Elevated Temperatures. Met. Mater. Int. 2020, 26, 326–332. [Google Scholar] [CrossRef]

- Wiberg, E.; Wiberg, N. Hollemann-Wiberg, Lehrbuch der Anorganischen Chemie, 101; Walter de Gruyter & Co.: Berlin, Germany; New York, NY, USA, 1995. [Google Scholar]

- Nowak, W.J. Characterization of oxidized Ni-based superalloys by GD-OES. J. Anal. At. Spectrom. 2017, 32, 1730–1738. [Google Scholar] [CrossRef]

- Larsson, A.; D’Acunto, G.; Vorobyova, M.; Abbondanza, G.; Lienert, U.; Hegedüs, Z.; Preobrajenski, A.; Merte, L.R.; Eidhagen, J.; Delblanc, A.; et al. Thickness and composition of native oxides and near-surface regions of Ni superalloys. J. Alloys Compd. 2022, 895, 162657. [Google Scholar] [CrossRef]

- Cruchley, S.; Evans, H.; Taylor, M. An overview of the oxidation of Ni-based superalloys for turbine disc applications: Surface condition, applied load and mechanical performance. Mater. High Tep. 2016, 33, 465–475. [Google Scholar] [CrossRef]

| Element | Co | Cr | Nb | Mo | Al | Fe | Ti | Ni |

|---|---|---|---|---|---|---|---|---|

| at.% | 23.9 | 19.7 | 3.4 | 1.7 | 4.7 | 0.6 | 0.4 | 45.8 |

| APT Composition (at.%) | ||||||||

|---|---|---|---|---|---|---|---|---|

| Phase | Co | Cr | Nb | Mo | Al | Fe | Ti | Ni |

| γ | 31.2 | 28.2 | 1.4 | 0.9 | 0.1 | 1.1 | 2.4 | 34.7 |

| γ′ | 9.9 | 3.4 | 6.9 | 0.9 | 13.1 | 0.0 | 0.8 | 64.3 |

| Lab Source | |||

|---|---|---|---|

| Temperature Range [°C] | Linear Thermal Expansion Coefficient/10−6 [°C−1] | ||

| γ | γ′ | γ-2 | |

| 25–800 | 14.4 ± 0.2 | 14.1 ± 0.1 | 17.8 ± 0.4 |

| 800–950 | 24.8 ± 1.0 | 19.1 ± 0.1 | 29.1 ± 0.6 |

| Synchrotron | ||

|---|---|---|

| Temperature Range [°C] | Linear Thermal Expansion Coefficient/10−6 [°C−1] | |

| γ | γ′ | |

| 25–600 | 14.4 ± 0.2 | 13.2 ± 0.1 |

| 600–850 | 24.6 ± 1.1 | 20.5 ± 1.0 |

| 850–935 | 54.4 ± 1.4 | 52.1 ± 0.4 |

Publisher’s Note: MDPI stays neutral with regard to jurisdictional claims in published maps and institutional affiliations. |

© 2022 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (https://creativecommons.org/licenses/by/4.0/).

Share and Cite

Kümmel, F.; Fritton, M.; Solís, C.; Kriele, A.; Stark, A.; Gilles, R. Near-Surface and Bulk Dissolution Behavior of γ′ Precipitates in Nickel-Based VDM® Alloy 780 Studied with In-Situ Lab-Source and Synchrotron X-ray Diffraction. Metals 2022, 12, 1067. https://doi.org/10.3390/met12071067

Kümmel F, Fritton M, Solís C, Kriele A, Stark A, Gilles R. Near-Surface and Bulk Dissolution Behavior of γ′ Precipitates in Nickel-Based VDM® Alloy 780 Studied with In-Situ Lab-Source and Synchrotron X-ray Diffraction. Metals. 2022; 12(7):1067. https://doi.org/10.3390/met12071067

Chicago/Turabian StyleKümmel, Frank, Massimo Fritton, Cecilia Solís, Armin Kriele, Andreas Stark, and Ralph Gilles. 2022. "Near-Surface and Bulk Dissolution Behavior of γ′ Precipitates in Nickel-Based VDM® Alloy 780 Studied with In-Situ Lab-Source and Synchrotron X-ray Diffraction" Metals 12, no. 7: 1067. https://doi.org/10.3390/met12071067

APA StyleKümmel, F., Fritton, M., Solís, C., Kriele, A., Stark, A., & Gilles, R. (2022). Near-Surface and Bulk Dissolution Behavior of γ′ Precipitates in Nickel-Based VDM® Alloy 780 Studied with In-Situ Lab-Source and Synchrotron X-ray Diffraction. Metals, 12(7), 1067. https://doi.org/10.3390/met12071067