Investigating Nanoscale Contact Using AFM-Based Indentation and Molecular Dynamics Simulations

Abstract

:1. Introduction

2. Materials and Methods

2.1. Experimental

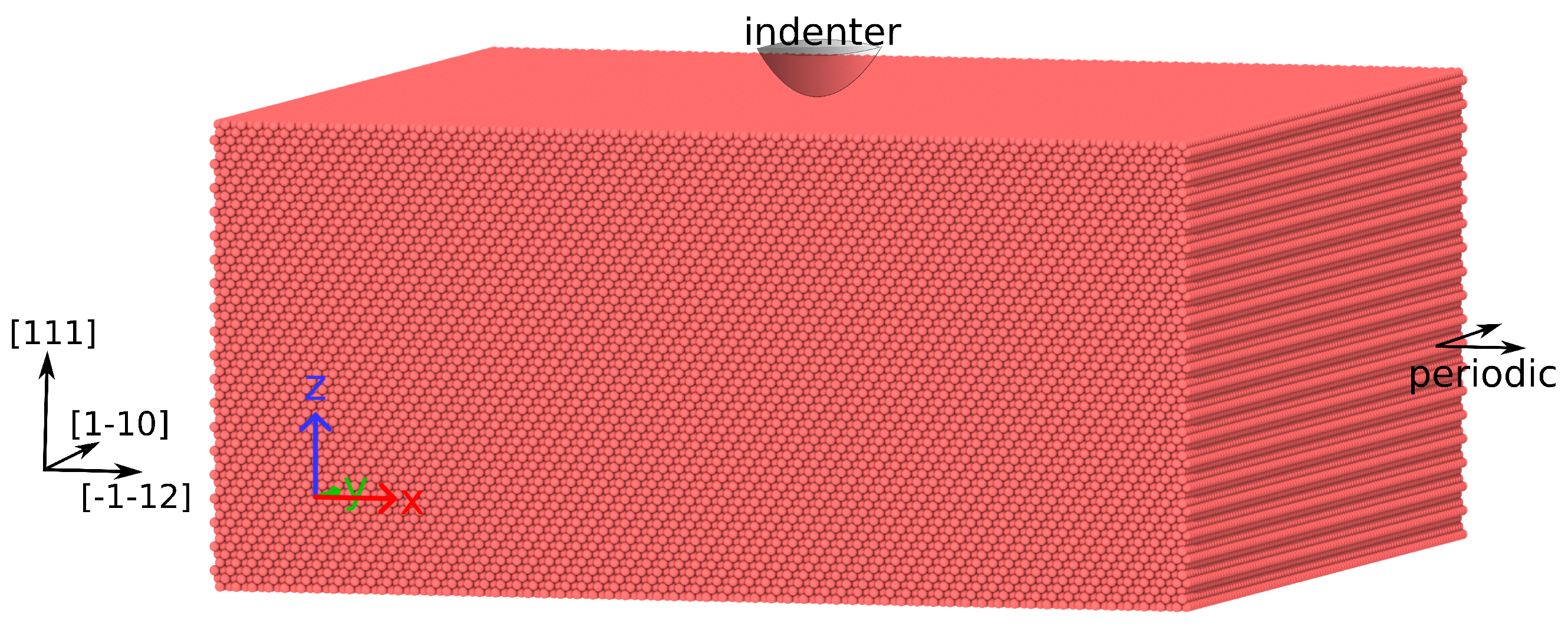

2.2. Computational

- Static relaxation at 10 K by the conjugate gradient.

- Relaxation at 10 K via 30,000 MD time steps with a time step of 3 fs.

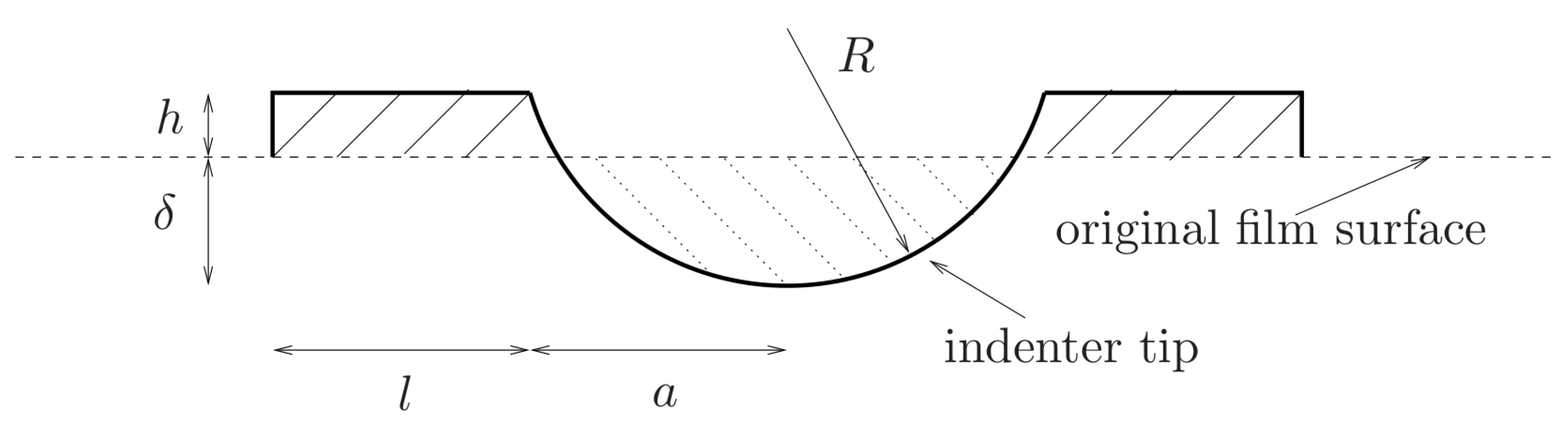

- Indentation of the film at 10 K at a constant rate of , up to a depth equal to 3.36 nm. Once reaching the maximum depth, the indenter is kept static during the following steps.

- Heating the system up to the target temperature between 200 K and 1100 K, which is lower than the melting point, using the Nosé-Hoover thermostat during 100,000 MD time steps. In combination with the Parrinello-Rahman dynamics, the volume is allowed to change. We note that the global pressures and are not set to zero but fixed at the values reached at the end of indentation (previous step). This accelerates all thermally activated processes while ensuring that the effect of thermal expansion on the relaxation of the internal stresses generated during indentation is minimized.

- The simulation is continued in the constant-temperature constant-stress ensemble for 400,000 additional MD time steps, in order to allow thermally activated processes to take place.

- During the last two stages, replicas of the system are quenched periodically via conjugate gradient. The quenched systems are employed to identify and visualize the dislocation structures via the common neighbor analysis.

3. Results

3.1. Experimental Results

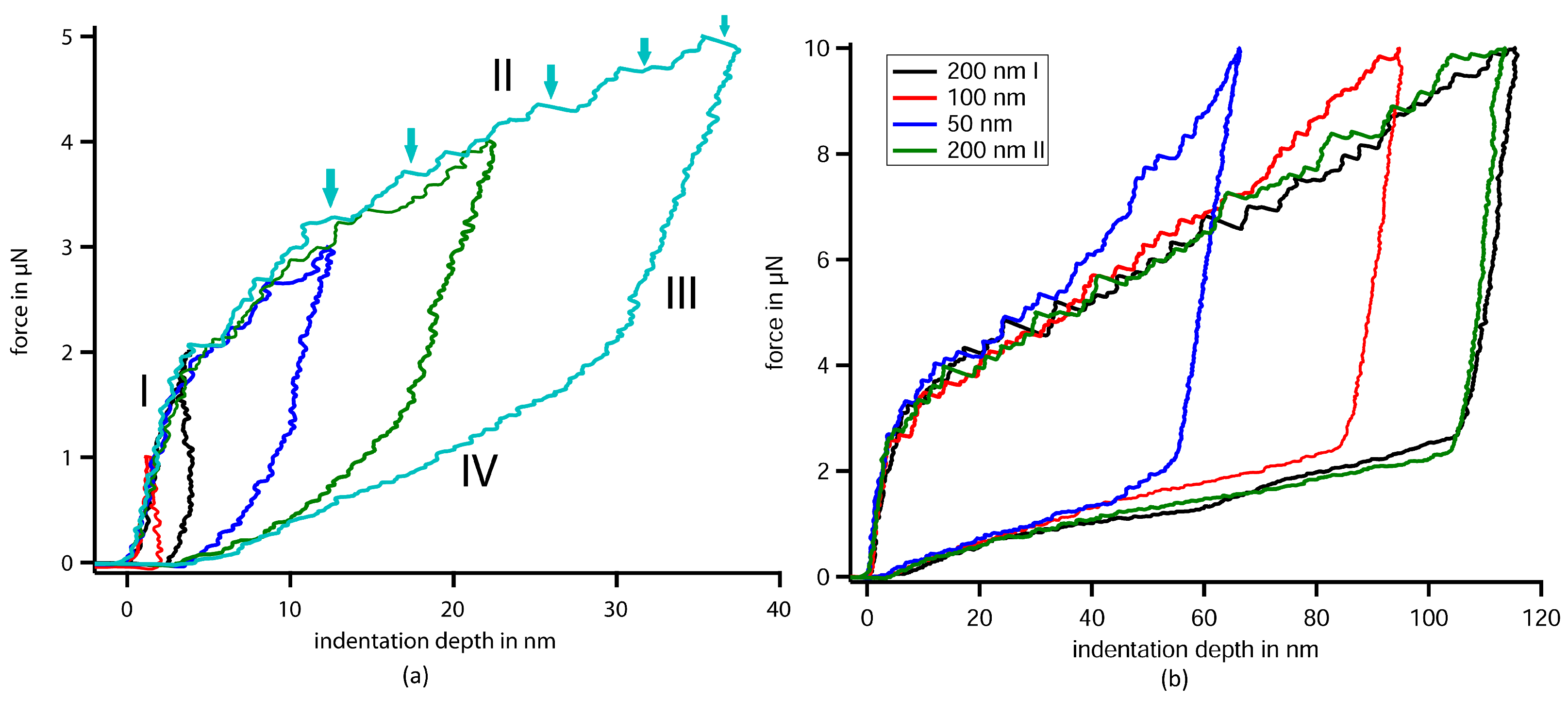

3.1.1. Indentation Curves

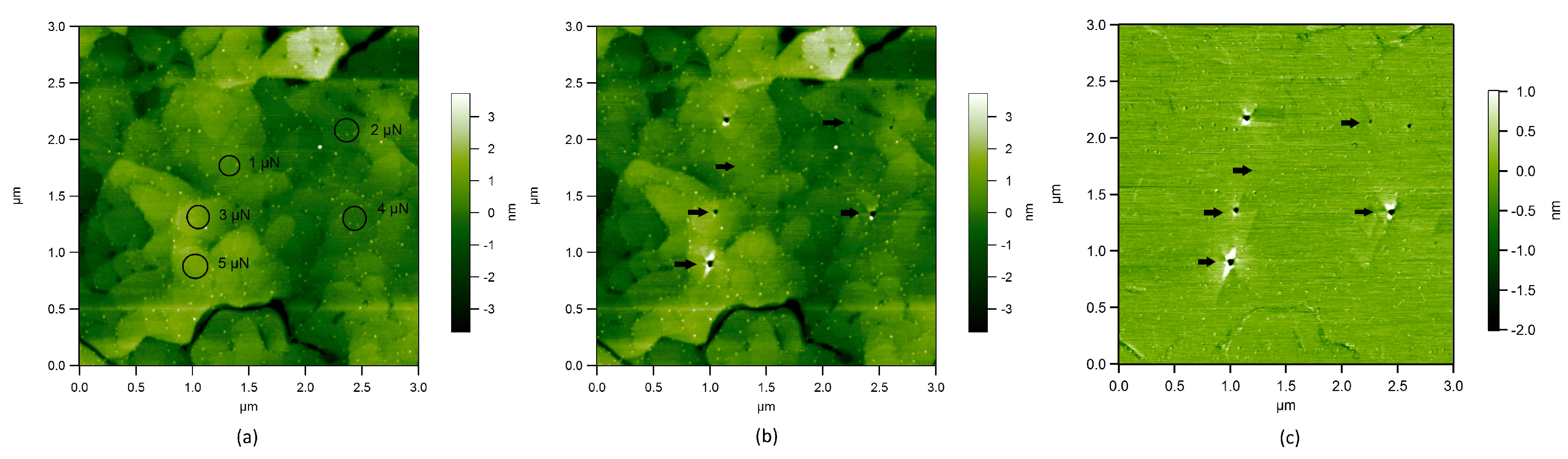

3.1.2. Post-Indentation Surface Topography

3.1.3. Post-Indentation Dislocation Structure

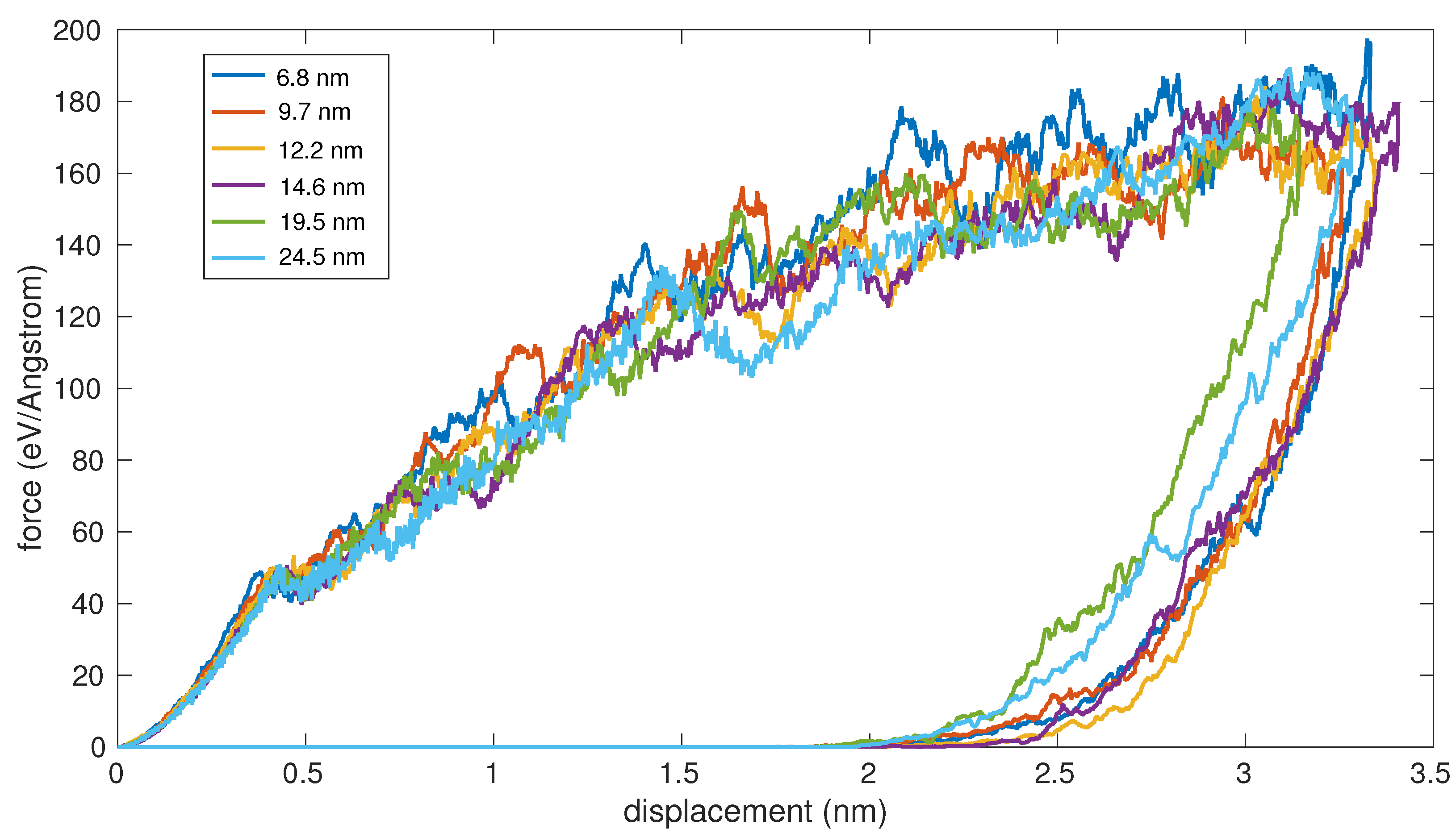

3.2. Computational Results

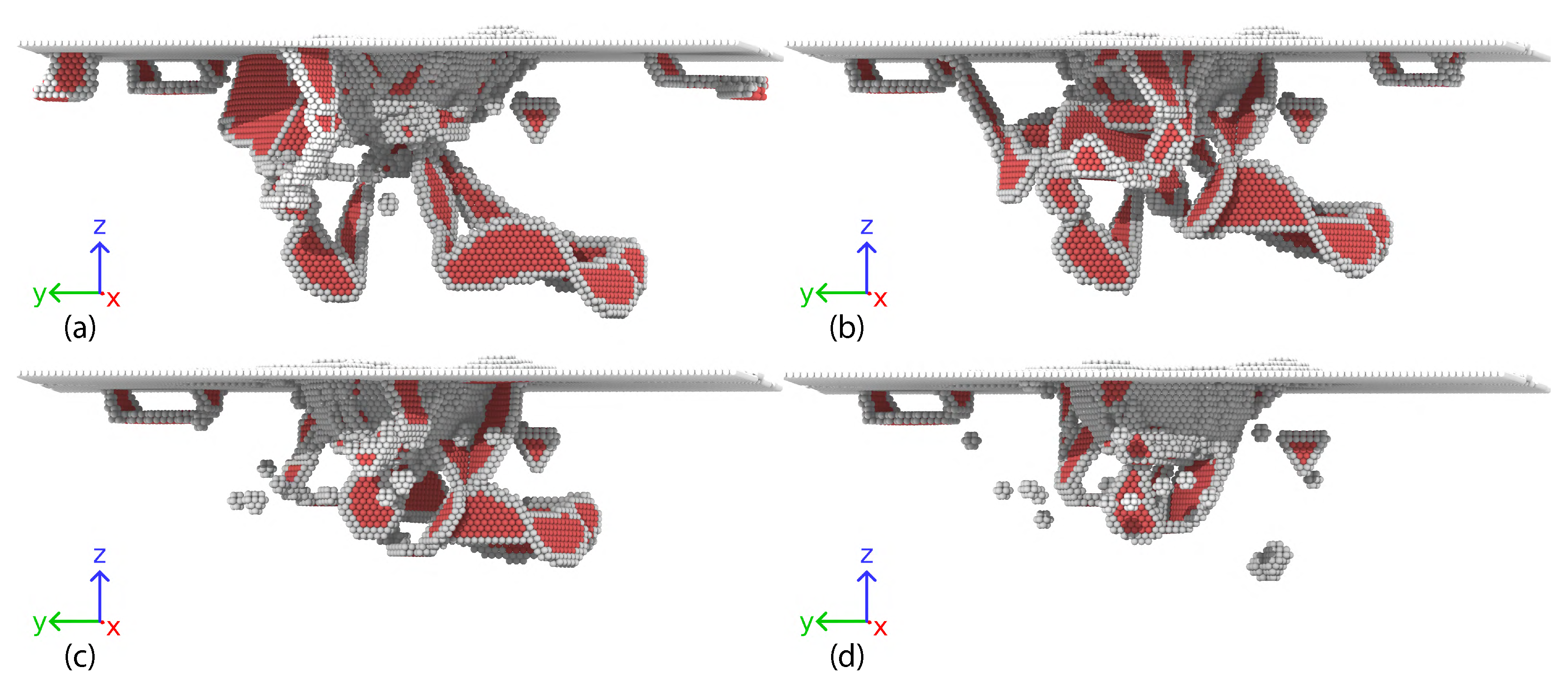

3.2.1. Forming the Plastic Zone Beneath the Indenter

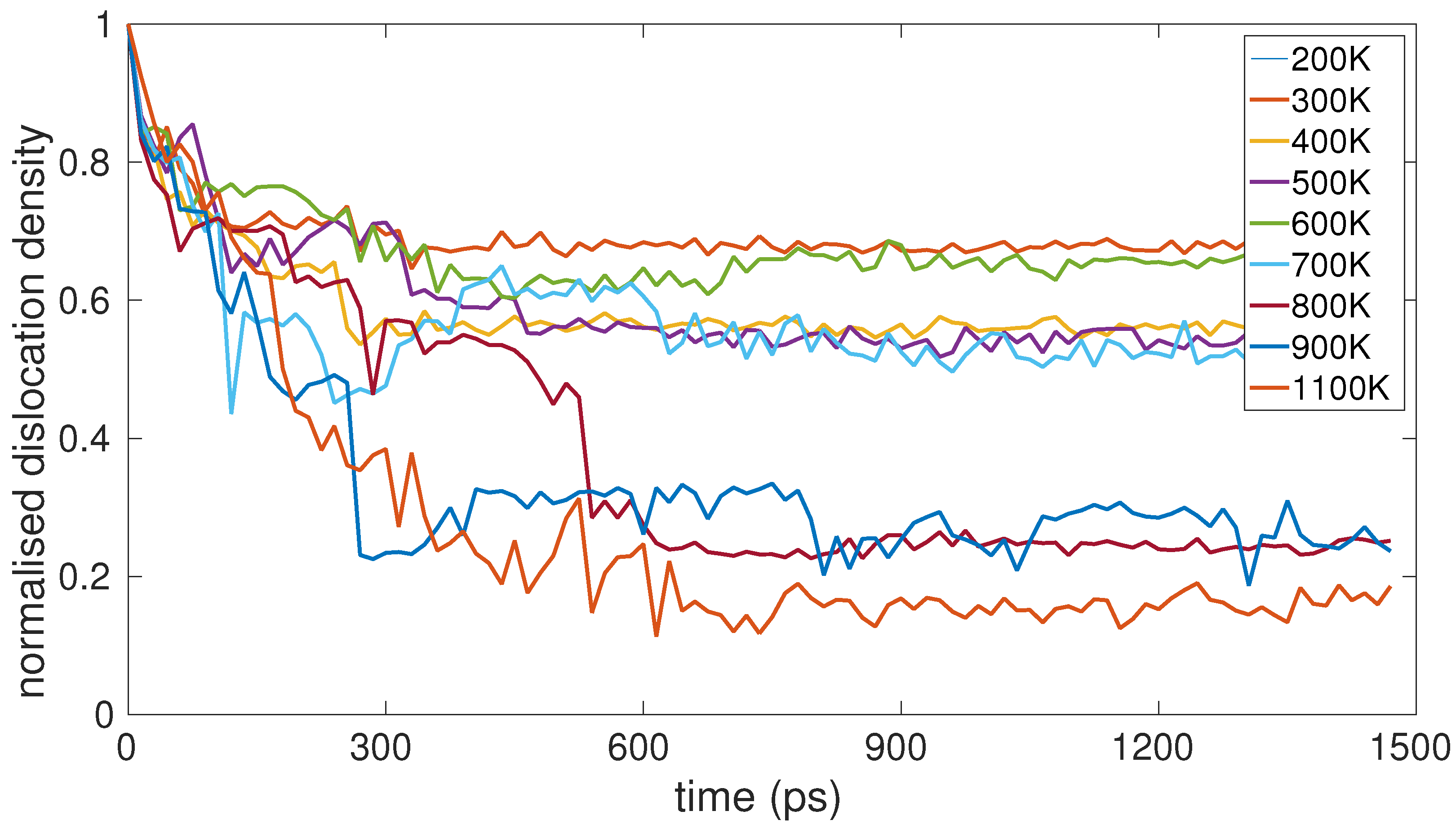

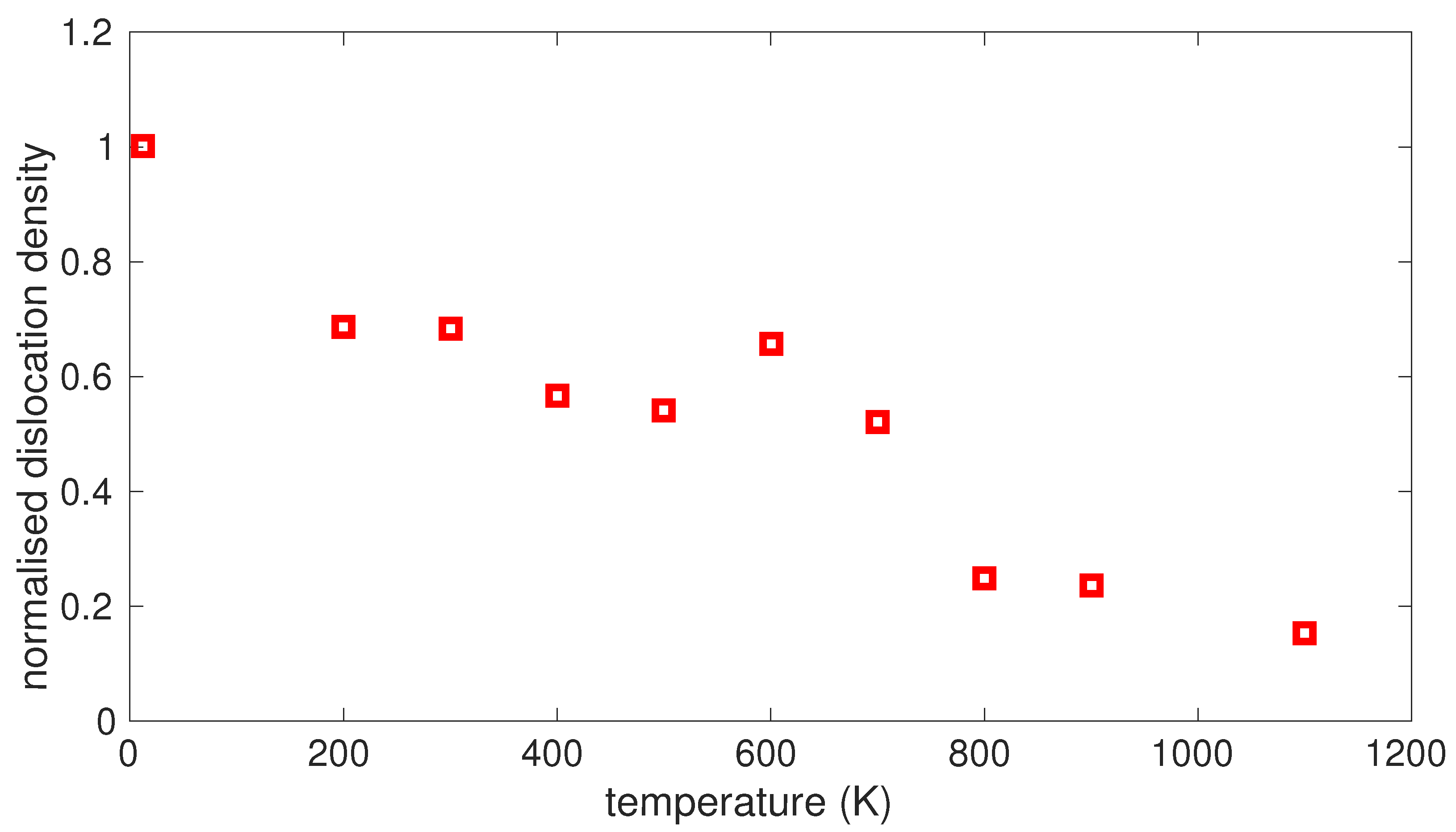

3.2.2. Microstructure Evolution in Heated Thin films

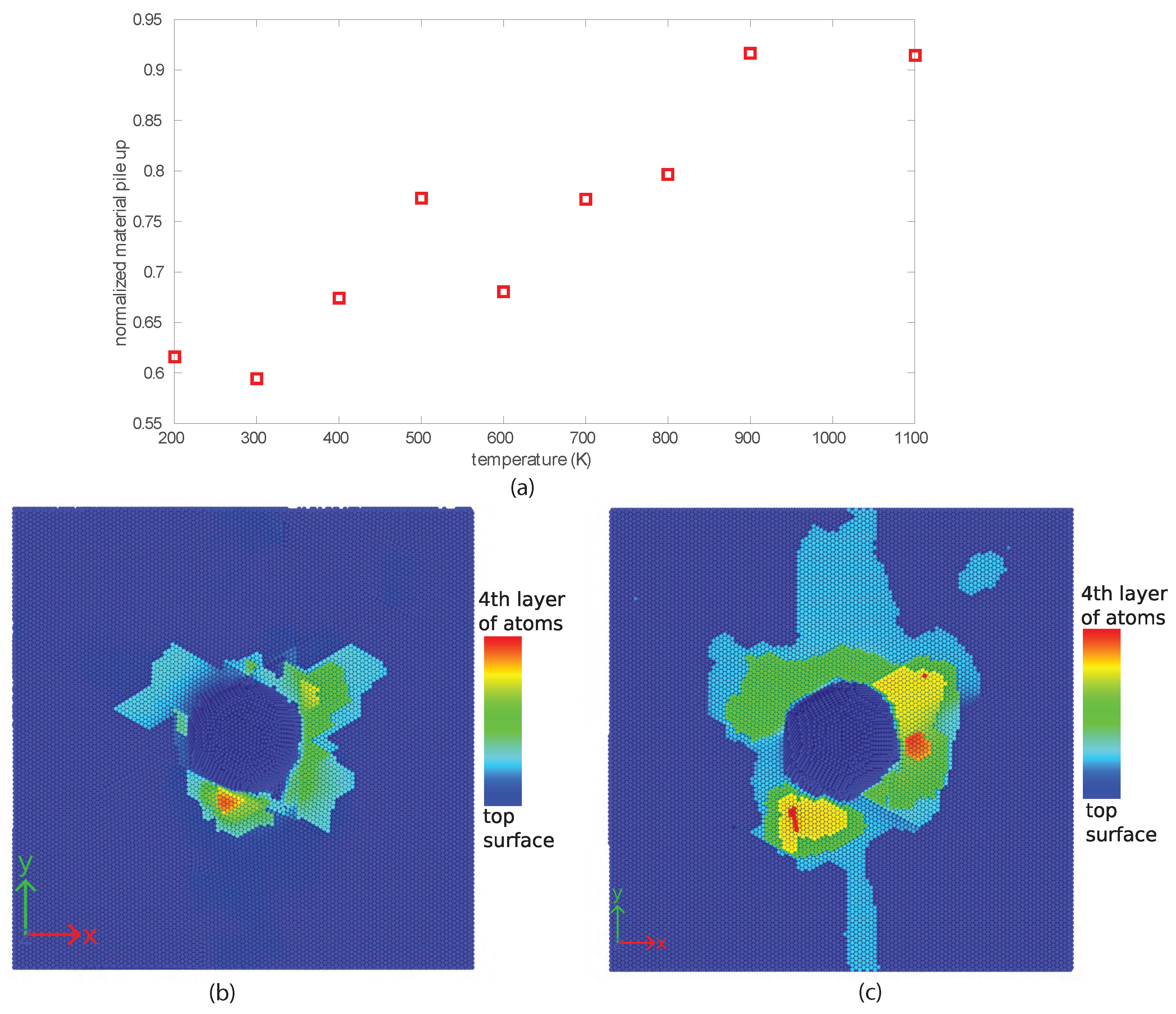

3.3. Post-Indentation Surface Topography in the MD Simulations

4. Discussion

4.1. Experimental Results Compared to Literature

4.2. Annihilation of the Dislocation Structure in the Plastic Zone

4.3. Material Transfer to the Upper Surface

5. Conclusions

Author Contributions

Funding

Institutional Review Board Statement

Informed Consent Statement

Data Availability Statement

Acknowledgments

Conflicts of Interest

References

- Zemła, J.; Bobrowska, J.; Kubiak, A.; Zieliński, T.; Pabijan, J.; Pogoda, K.; Bobrowski, P.; Lekka, M. Indenting soft samples (hydrogels and cells) with cantilevers possessing various shapes of probing tip. Eur. Biophys. J. 2020, 49, 485–495. [Google Scholar] [CrossRef]

- Qian, L.; Zhao, H. Nanoindentation of Soft Biological Materials. Micromachines 2018, 9, 654. [Google Scholar] [CrossRef] [PubMed] [Green Version]

- Doss, B.L.; Rahmani Eliato, K.; Lin, K.h.; Ros, R. Quantitative mechanical analysis of indentations on layered, soft elastic materials. Soft Matter 2019, 15, 1776–1784. [Google Scholar] [CrossRef] [PubMed]

- Cortelli, G.; Patruno, L.; Cramer, T.; Murgia, M.; Fraboni, B.; de Miranda, S. Atomic Force Microscopy Nanomechanics of Hard Nanometer-Thick Films on Soft Substrates: Insights into Stretchable Conductors. ACS Appl. Nano Mater. 2021, 4, 8376–8382. [Google Scholar] [CrossRef] [PubMed]

- Liu, Y.; Sokolov, I.; Dokukin, M.E.; Xiong, Y.; Peng, P. Can AFM be used to measure absolute values of Young’s modulus of nanocomposite materials down to the nanoscale? Nanoscale 2020, 12, 12432–12443. [Google Scholar] [CrossRef]

- Falin, A.; Cai, Q.; Santos, E.J.G.; Scullion, D.; Qian, D.; Zhang, R.; Yang, Z.; Huang, S.; Watanabe, K.; Taniguchi, T.; et al. Mechanical properties of atomically thin boron nitride and the role of interlayer interactions. Nat. Commun. 2017, 8, 15815. [Google Scholar] [CrossRef] [Green Version]

- Asenjo, A.; Jaafar, M.; Carrasco, E.; Rojo, J.M. Dislocation mechanisms in the first stage of plasticity of nanoindented Au(111) surfaces. Phys. Rev. B 2006, 73, 075431. [Google Scholar] [CrossRef]

- Navarro, V.; Rodríguez de la Fuente, O.; Mascaraque, A.; Rojo, J.M. Uncommon Dislocation Processes at the Incipient Plasticity of Stepped Gold Surfaces. Phys. Rev. Lett. 2008, 100, 105504. [Google Scholar] [CrossRef] [Green Version]

- Tranchida, D.; Piccarolo, S. Combining Atomic Force Microscopy and Depth-Sensing Instruments for the Nanometer-Scale Mechanical Characterization of Soft Matter. In Scanning Probe Microscopy in Nanoscience and Nanotechnology; Bhushan, B., Ed.; Springer: Berlin/Heidelberg, Germany, 2010; pp. 199–223. [Google Scholar] [CrossRef]

- Filleter, T.; Maier, S.; Bennewitz, R. Atomic-scale yield and dislocation nucleation in KBr. Phys. Rev. B 2006, 73, 155433. [Google Scholar] [CrossRef]

- Egberts, P.; Bennewitz, R. Atomic-scale nanoindentation: Detection and identification of single glide events in three dimensions by force microscopy. Nanotechnology 2011, 22, 425703. [Google Scholar] [CrossRef]

- Caron, A. Quantitative Hardness Measurement by Instrumented AFM-indentation. JoVE 2016, 117, e54706. [Google Scholar] [CrossRef] [PubMed]

- Amat, E.; del Moral, A.; Fernández-Regúlez, M.; Evangelio, L.; Lorenzoni, M.; Gharbi, A.; Rademaker, G.; Pourteau, M.L.; Tiron, R.; Bausells, J.; et al. Exploring Strategies to Contact 3D Nano-Pillars. Nanomaterials 2020, 10, 716. [Google Scholar] [CrossRef] [PubMed] [Green Version]

- Ohmura, T.; Wakeda, M. Pop-In Phenomenon as a Fundamental Plasticity Probed by Nanoindentation Technique. Materials 2021, 14, 1879. [Google Scholar] [CrossRef] [PubMed]

- Dietiker, M.; Nyilas, R.D.; Solenthaler, C.; Spolenak, R. Nanoindentation of single-crystalline gold thin films: Correlating hardness and the onset of plasticity. Acta Mater. 2008, 56, 3887–3899. [Google Scholar] [CrossRef]

- Lilleodden, E.T.; Nix, W.D. Microstructural length-scale effects in the nanoindentation behavior of thin gold films. Acta Mater. 2006, 54, 1583–1593. [Google Scholar] [CrossRef]

- Graça, S.; Carvalho, P.A.; Colaço, R. Dislocation structures in nanoindented ductile metals—A transmission electron microscopy direct observation. J. Phys. D Appl. Phys. 2011, 44, 335402. [Google Scholar] [CrossRef] [Green Version]

- Gouldstone, A.; Koh, H.J.; Zeng, K.Y.; Giannakopoulos, A.E.; Suresh, S. Discrete and continuous deformation during nanoindentation of thin films. Acta Mater. 2000, 48, 2277–2295. [Google Scholar] [CrossRef]

- Nix, W.D.; Gao, H. Indentation size effects in crystalline materials: A law for strain gradient plasticity. J. Mech. Phys. Solids 1998, 46, 411–425. [Google Scholar] [CrossRef]

- Kelchner, C.L.; Plimpton, S.J.; Hamilton, J.C. Dislocation nucleation and defect structure during surface indentation. Phys. Rev. B 1998, 58v, 11085–11088. [Google Scholar] [CrossRef]

- Chang, H.J.; Fivel, M.; Rodney, D.; Verdier, M. Multiscale modelling of indentation in FCC metals: From atomic to continuum. C. R. Phys. 2010, 11, 285–292. [Google Scholar] [CrossRef]

- Kositski, R.; Mordehai, D. Depinning-controlled plastic deformation during nanoindentation of BCC iron thin films and nanoparticles. Acta Mater. 2015, 90, 370–379. [Google Scholar] [CrossRef]

- Fivel, M.; Robertson, C.; Canova, G.; Boulanger, L. Three-dimensional modeling of indent-induced plastic zone at a mesoscale. Acta Mater. 1998, 46, 6183–6194. [Google Scholar] [CrossRef]

- Gagel, J.; Weygand, D.; Gumbsch, P. Formation of extended prismatic dislocation structures under indentation. Acta Mater. 2016, 111, 399–406. [Google Scholar] [CrossRef]

- Roy, S.; Gatti, R.; Devincre, B.; Mordehai, D. A multiscale study of the size-effect in nanoindentation of Au nanoparticles. Comput. Mater. Sci. 2019, 162, 47–59. [Google Scholar] [CrossRef]

- Durst, K.; Backes, B.; Göken, M. Indentation size effect in metallic materials: Correcting for the size of the plastic zone. Scr. Mater. 2005, 52, 1093–1097. [Google Scholar] [CrossRef]

- Zhang, J.-I.; Zaefferer, S.; Raabe, D. A study on the geometry of dislocation patterns in the surrounding of nanoindents in a TWIP steel using electron channeling contrast imaging and discrete dislocation dynamics simulations. Mater. Sci. Eng. A 2015, 636, 231–242. [Google Scholar] [CrossRef]

- Walters, D.A.; Cleveland, J.P.; Thomson, N.H.; Hansma, P.K.; Wendman, M.A.; Gurley, G.; Elings, V. Short cantilevers for atomic force microscopy. Rev. Sci. Instruments 1996, 67, 3583–3590. [Google Scholar] [CrossRef]

- Grochola, G.; Russo, S.P.; Snook, I.K. On fitting a gold embedded atom method potential using the force matching method. J. Chem. Phys. 2005, 123, 204719. [Google Scholar] [CrossRef]

- Xia, W.; Dehm, G.; Brinckmann, S. Unraveling indentation-induced slip steps in austenitic stainless steel. Mater. Des. 2019, 183, 108169. [Google Scholar] [CrossRef]

- Roa, J.; Oncins, G.; Dias, F.; Vieira, V.; Schaf, J.; Segarra, M. AFM as an alternative for Young’s modulus determination in ceramic materials in elastic deformation regime. Phys. C Supercond. 2011, 471, 544–548. [Google Scholar] [CrossRef]

- Gao, N.; Perez, D.; Lu, G.; Wang, Z. Molecular dynamics study of the interaction between nanoscale interstitial dislocation loops and grain boundaries in BCC iron. J. Nucl. Mater. 2018, 498, 378–386. [Google Scholar] [CrossRef]

- Mordehai, D.; Kazakevich, M.; Srolovitz, D.J.; Rabkin, E. Nanoindentation size effect in single-crystal nanoparticles and thin films: A comparative experimental and simulation study. Acta Mater. 2011, 59, 2309–2321. [Google Scholar] [CrossRef]

- Ohmura, T.; Matsuoka, S.; Tanaka, K.; Yoshida, T. Nanoindentation load-displacement behavior of pure face centered cubic metal thin films on a hard substrate. Thin Solid Film 2001, 385, 198–204. [Google Scholar] [CrossRef]

- Carrasco, E.; Rodríguez de la Fuente, O.; González, M.A.; Rojo, J.M. Dislocation cross slip and formation of terraces around nanoindentations in Au(001). Phys. Rev. B 2003, 68, 180102. [Google Scholar] [CrossRef]

- Carrasco, E.; González, M.; Rodríguez de la Fuente, O.; Rojo, J. Analysis at atomic level of dislocation emission and motion around nanoindentations in gold. Surf. Sci. 2004, 572, 467–475. [Google Scholar] [CrossRef]

- Filleter, T.; Paul, W.; Bennewitz, R. Atomic structure and friction of ultrathin films of KBr on Cu(100). Phys. Rev. B 2008, 77, 035430. [Google Scholar] [CrossRef]

- Malka-Markovitz, A.; Mordehai, D. Cross-slip in face-centered cubic metals: A general Escaig stress-dependent activation energy line tension model. Philos. Mag. 2018, 98, 347–370. [Google Scholar] [CrossRef]

- Landau, P.; Mordehai, D.; Venkert, A.; Makov, G. Universal strain–temperature dependence of dislocation structures at the nanoscale. Scr. Mater. 2012, 66, 135–138. [Google Scholar] [CrossRef]

- Vegge, T.; Jacobsen, K.W. Atomistic simulations of dislocation processes in copper. J. Phys. Condens. Matter 2002, 14, 2929–2956. [Google Scholar] [CrossRef]

- Caillard, D.; Martin, J. (Eds.) Thermally Activated Mechanisms in Crystal Plasticity; Pergamon: Oxford, UK, 2003. [Google Scholar]

- Bonneville, J.; Escaig, B.; Martin, J. A study of cross-slip activation parameters in pure copper. Acta Metall. 1988, 36, 1989–2002. [Google Scholar] [CrossRef]

- Bonneville, J.; Escaig, B. Cross-slipping process and the stress-orientation dependence in pure copper. Acta Metall. 1979, 27, 1477–1486. [Google Scholar] [CrossRef]

- Tangena, A.G.; Hurkx, G.A.M. The Determination of Stress-Strain Curves of Thin Layers Using Indentation Tests. J. Eng. Mater. Technol. 1986, 108, 230–232. [Google Scholar] [CrossRef]

- Roy, S.; Mordehai, D. Annihilation of edge dislocation loops via climb during nanoindentation. Acta Mater. 2017, 127, 351–358. [Google Scholar] [CrossRef]

- Pathak, S.; Riesterer, J.L.; Kalidindi, S.R.; Michler, J. Understanding pop-ins in spherical nanoindentation. Appl. Phys. Lett. 2014, 105, 161913. [Google Scholar] [CrossRef] [Green Version]

- Kucharski, S.; Jarząbek, D. Depth Dependence of Nanoindentation Pile-Up Patterns in Copper Single Crystals. Metall. Mater. Trans. A 2014, 45, 4997–5008. [Google Scholar] [CrossRef] [Green Version]

Publisher’s Note: MDPI stays neutral with regard to jurisdictional claims in published maps and institutional affiliations. |

© 2022 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (https://creativecommons.org/licenses/by/4.0/).

Share and Cite

Roy, S.; Wille, S.; Mordehai, D.; Volkert, C.A. Investigating Nanoscale Contact Using AFM-Based Indentation and Molecular Dynamics Simulations. Metals 2022, 12, 489. https://doi.org/10.3390/met12030489

Roy S, Wille S, Mordehai D, Volkert CA. Investigating Nanoscale Contact Using AFM-Based Indentation and Molecular Dynamics Simulations. Metals. 2022; 12(3):489. https://doi.org/10.3390/met12030489

Chicago/Turabian StyleRoy, Shyamal, Sönke Wille, Dan Mordehai, and Cynthia A. Volkert. 2022. "Investigating Nanoscale Contact Using AFM-Based Indentation and Molecular Dynamics Simulations" Metals 12, no. 3: 489. https://doi.org/10.3390/met12030489

APA StyleRoy, S., Wille, S., Mordehai, D., & Volkert, C. A. (2022). Investigating Nanoscale Contact Using AFM-Based Indentation and Molecular Dynamics Simulations. Metals, 12(3), 489. https://doi.org/10.3390/met12030489