Enhancement of Wear Resistance on H13 Tool and Die Steels by Trace Nanoparticles

Abstract

:1. Introduction

2. Materials and Methods

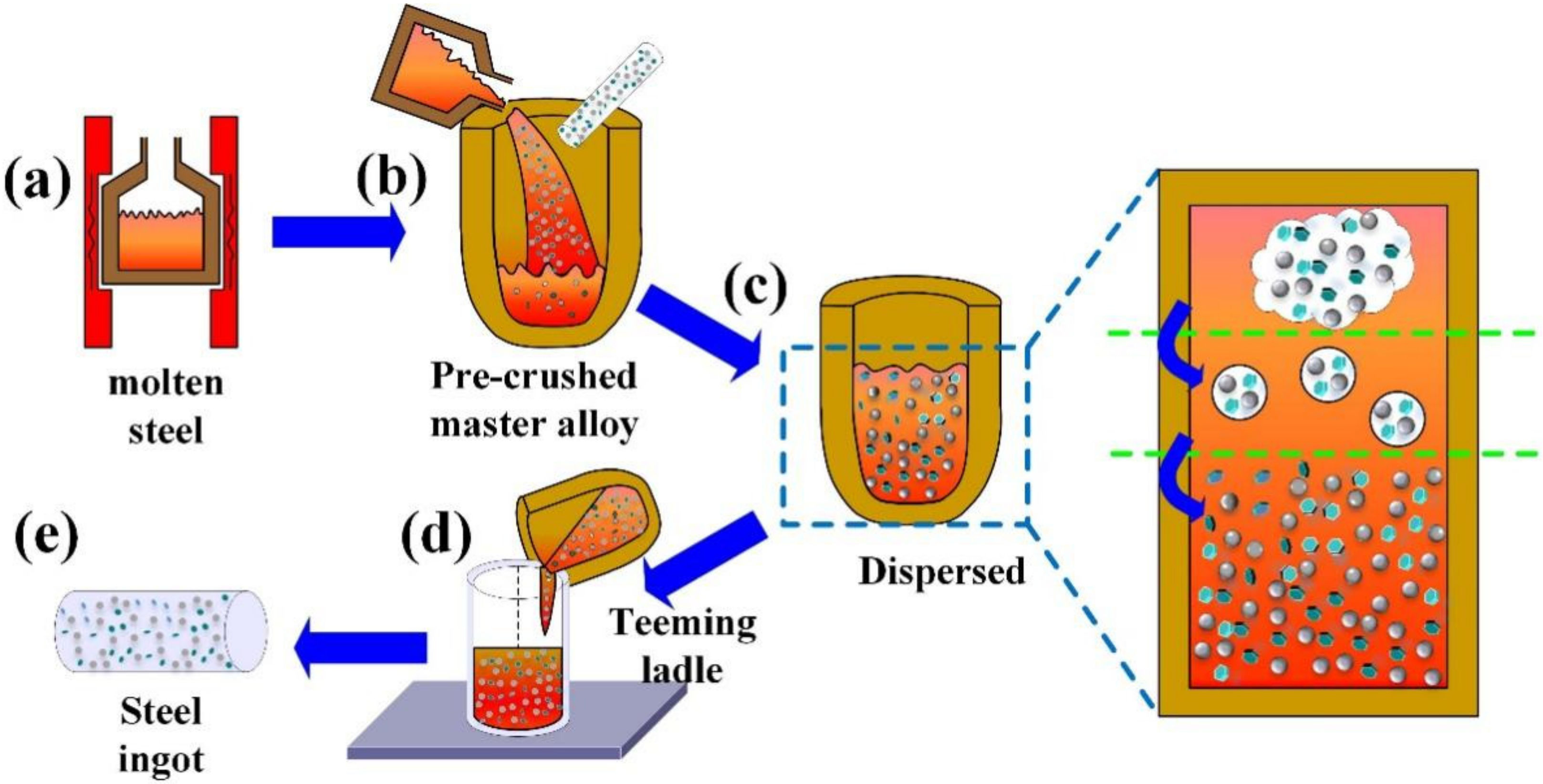

2.1. Preparation of H13 Tool and Die Steels Manipulated by Trace Nanoparticles

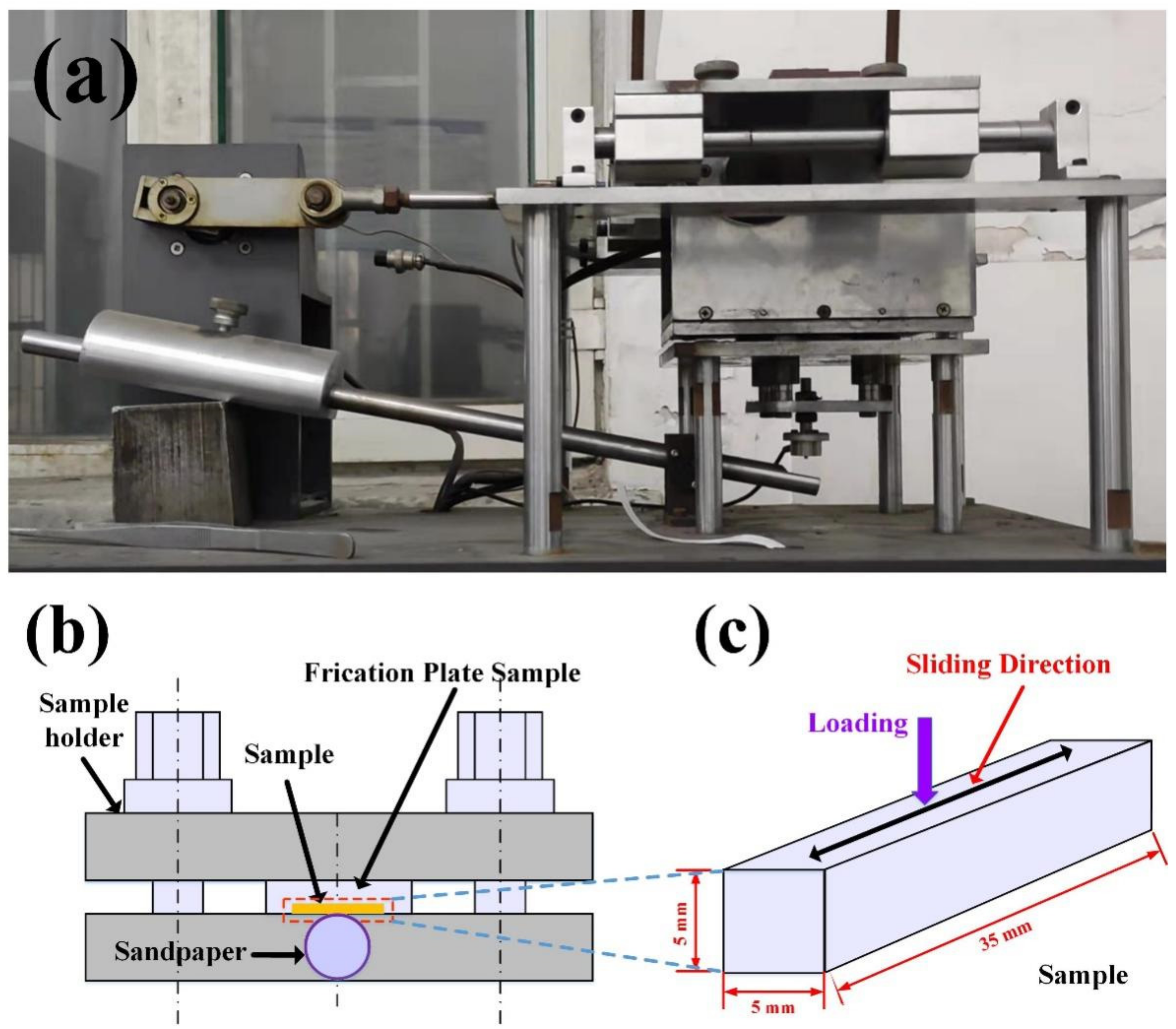

2.2. Characterization and Performance Testing

3. Results and Discussion

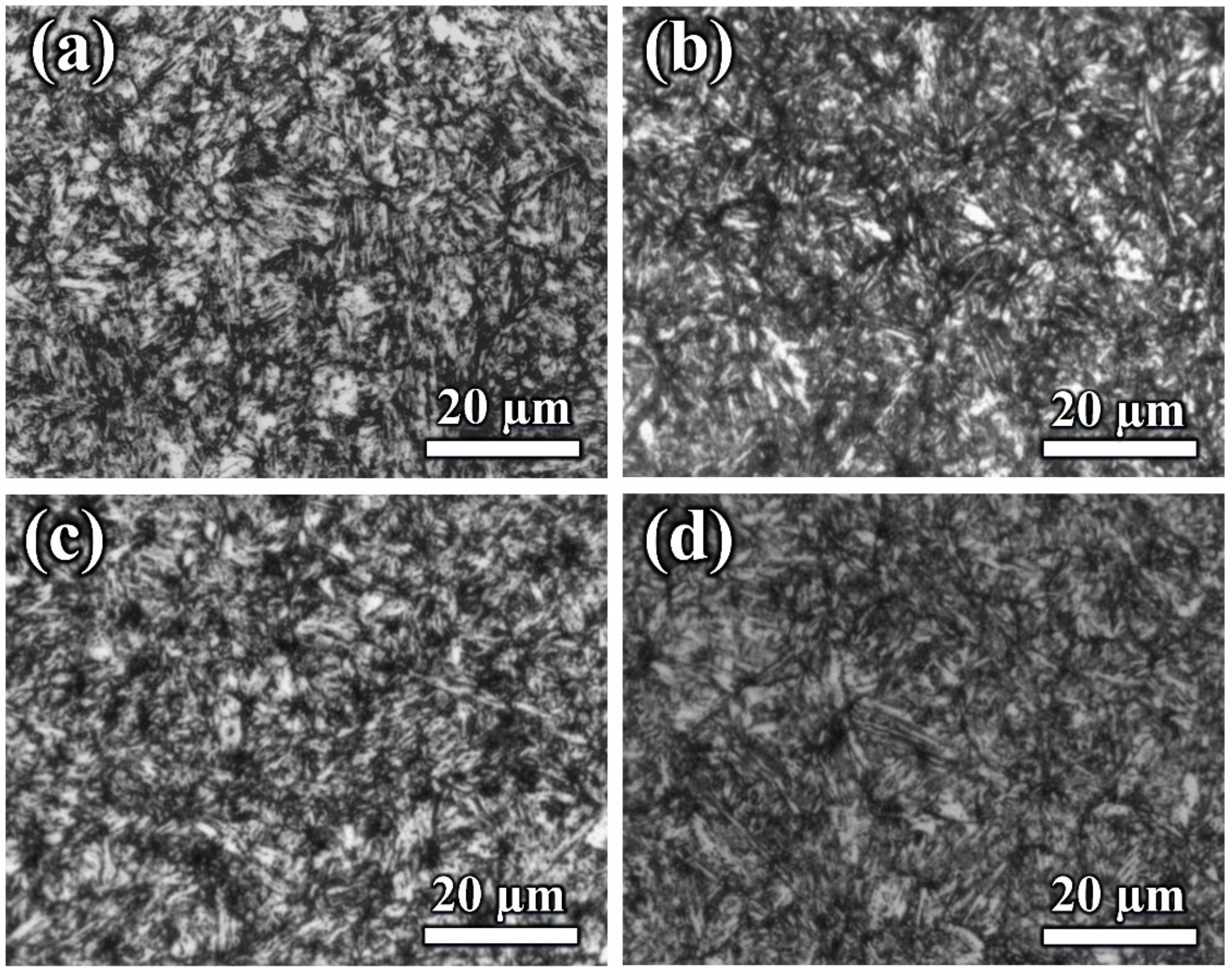

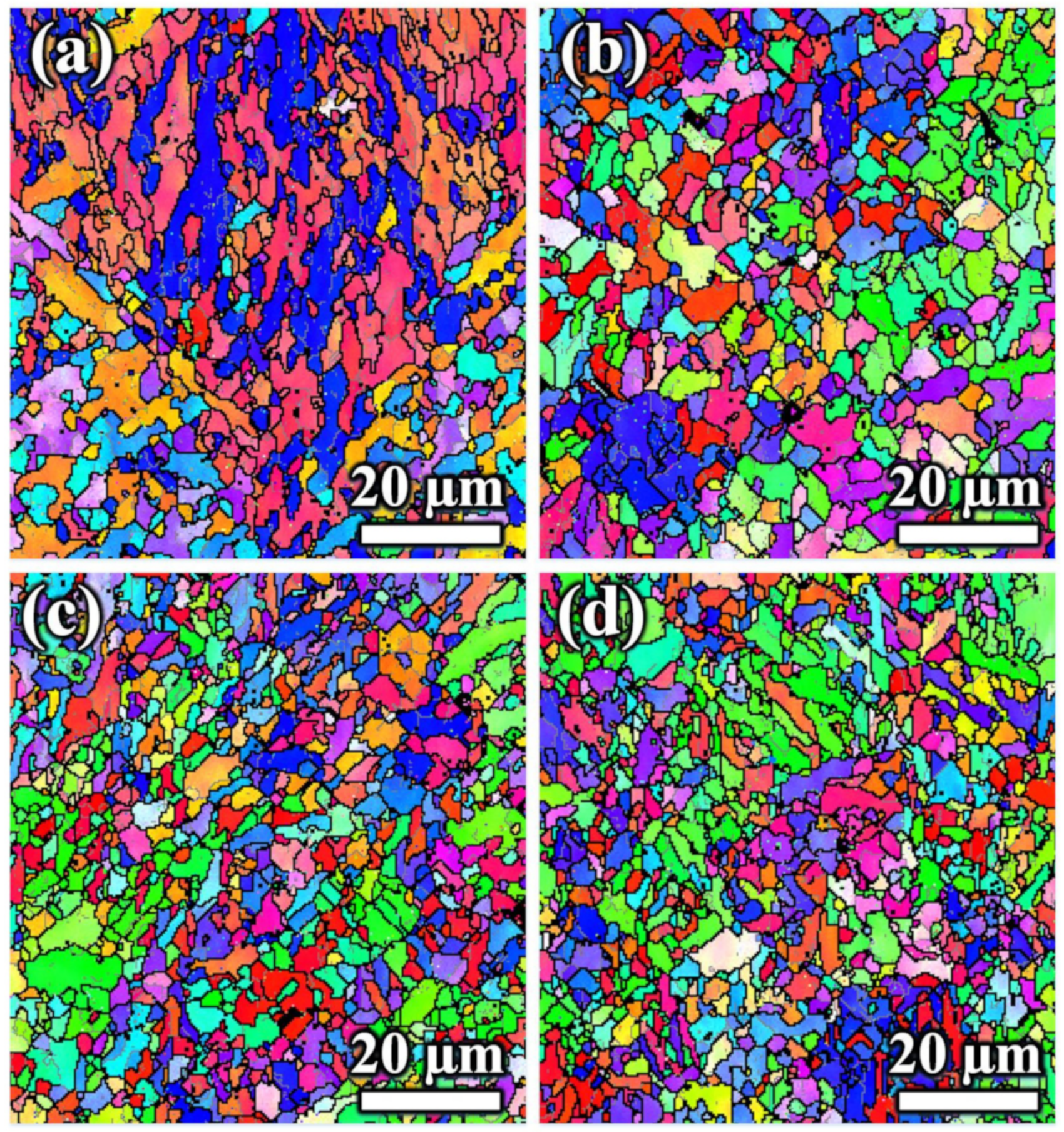

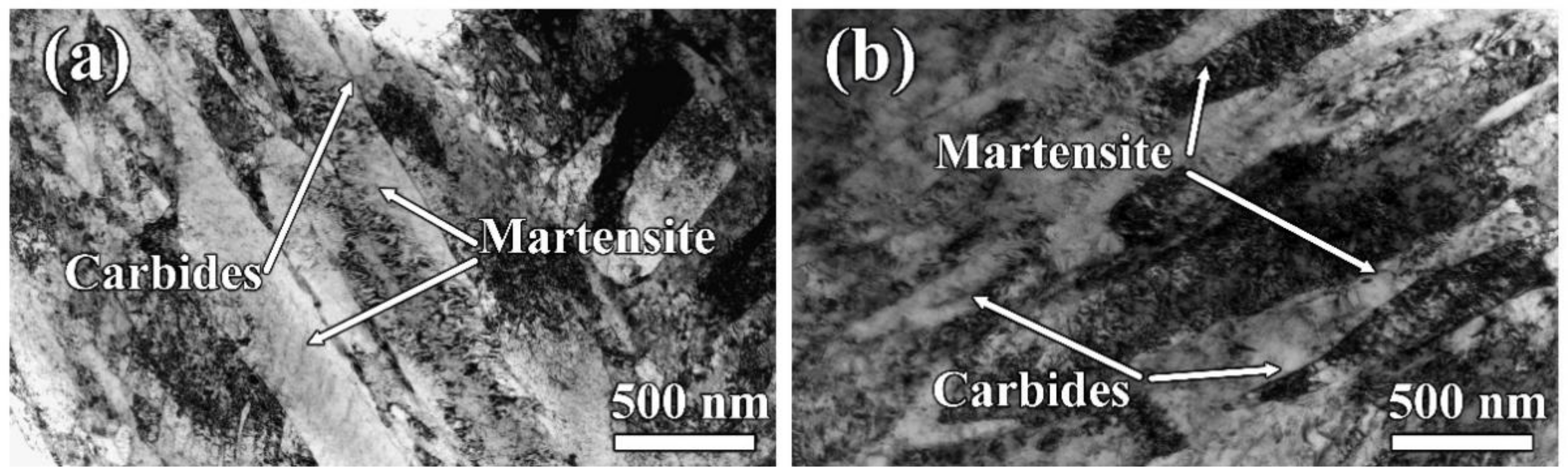

3.1. Microstructure of H13 Steels Manipulated by Trace Nanoparticles

3.2. Mechanical Properties of H13 Steels Manipulated by Trace Nanoparticles

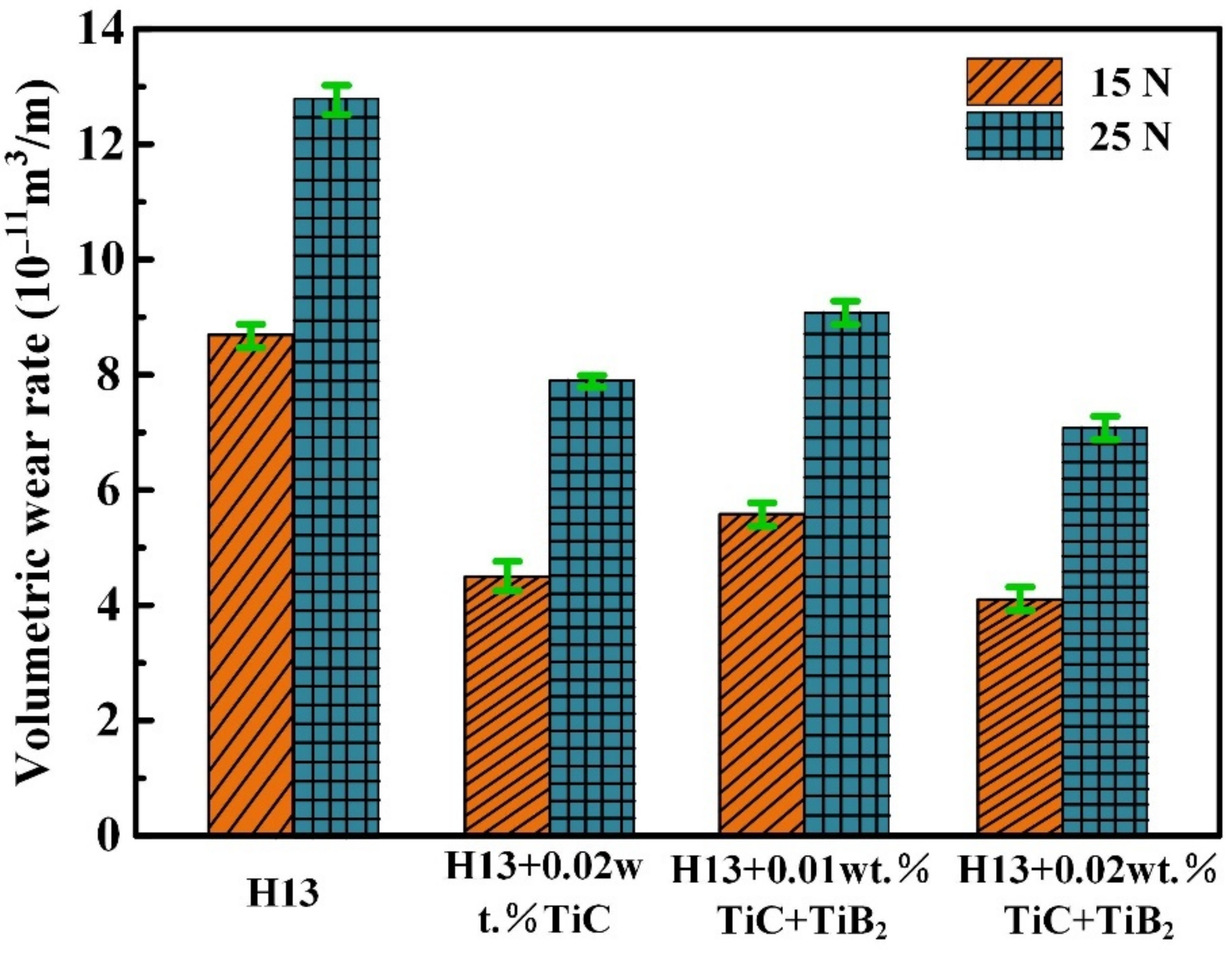

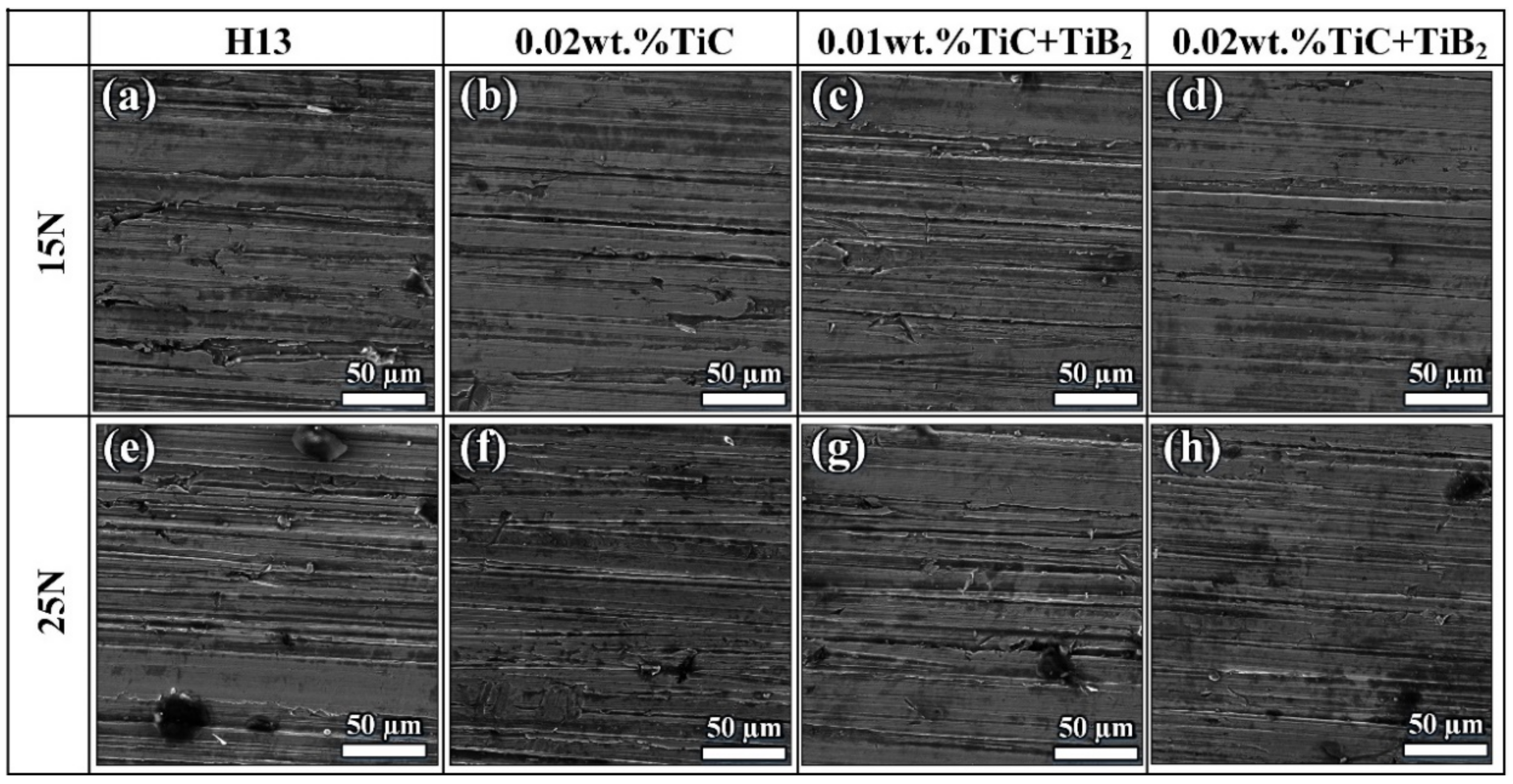

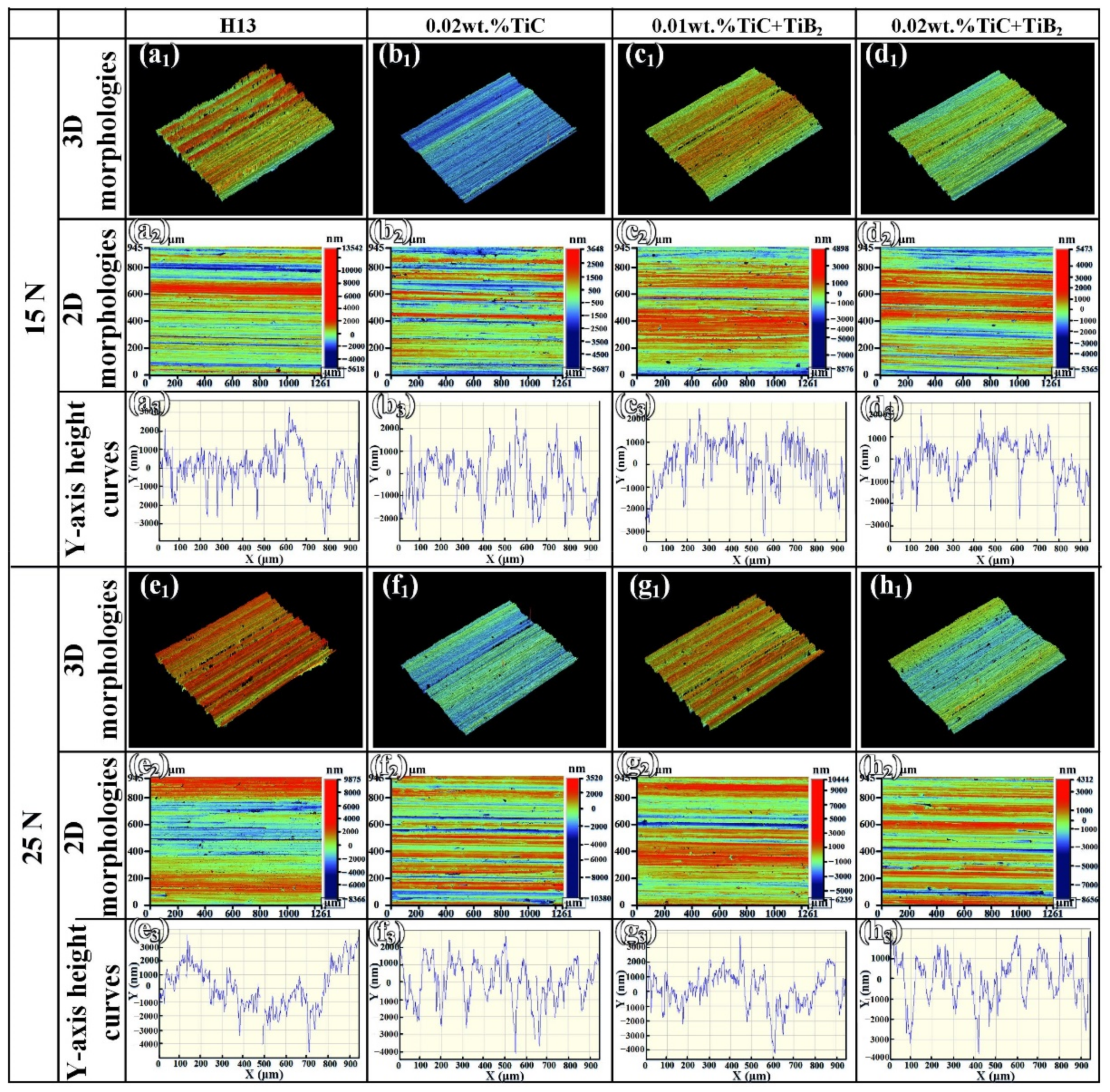

3.3. Abrasive Wear Behavior of H13 Steel Manipulated by Trace Nanoparticles

4. Conclusions

Author Contributions

Funding

Institutional Review Board Statement

Informed Consent Statement

Data Availability Statement

Conflicts of Interest

References

- Ma, K.J.; Stankus, J. Case study and design of steel set support for aged belt entry rehabilitation. Int. J. Min. Sci. Technol. 2018, 28, 101–106. [Google Scholar] [CrossRef]

- Zhenjun, S.; Porter, I.; Nemcik, J.; Baafi, E. Comparing the reinforcement capacity of welded steel mesh and a thin spray-on liner using large scale laboratory tests. Int. J. Min. Sci. Technol. 2014, 24, 373–377. [Google Scholar] [CrossRef]

- Li, X.; Lin, J.; Xia, Z.; Zhang, Y.; Fu, H. Influence of Deposition Patterns on Distortion of H13 Steel by Wire-Arc Additive Manufacturing. Metals 2021, 11, 485. [Google Scholar] [CrossRef]

- Yang, H.-Y.; Yan, Y.-F.; Liu, T.-S.; Dong, B.-X.; Chen, L.-Y.; Shu, S.-L.; Qiu, F.; Jiang, Q.-C.; Zhang, L.-C. Unprecedented enhancement in strength-plasticity synergy of (TiC+Al6MoTi+Mo)/Al cermet by multiple length-scale microstructure stimulated synergistic deformation. Compos. B Eng. 2021, 225, 109265. [Google Scholar] [CrossRef]

- Qiu, F.; Liu, T.-S.; Zhang, X.; Chang, F.; Shu, S.-L.; Yang, H.-Y.; Zhao, Q.-L.; Jiang, Q.-C. Application of nanoparticles in cast steel: An overview. China Foundry 2020, 17, 111–126. [Google Scholar] [CrossRef]

- Saucedo-Muñoz, M.L. Precipitation kinetics of carbides during cyclical and isothermal aging of 2.25Cr–1Mo steel and its effect on mechanical properties. J. Iron Steel Res. Int. 2021, 28, 1282–1290. [Google Scholar] [CrossRef]

- Chang, F.; Zhang, H.; Gao, Y.-L.; Shu, S.-L.; Qiu, F.; Jiang, Q.-C. Microstructure evolution and mechanical property enhancement of high-Cr hot work die steel manipulated by trace amounts of nano-sized TiC. Mater. Sci. Eng. A-Struct. 2021, 824, 141788. [Google Scholar] [CrossRef]

- Xu, T.; Song, G.; Yang, Y.; Ge, P.-X.; Tang, L.-X. Visualization and simulation of steel metallurgy processes. Int. J. Miner. Metall. Mater. 2021, 28, 1387. [Google Scholar] [CrossRef]

- Li, Y.; Zeng, Y.-P.; Wang, Z.-C. Interfacial microstructure evolution of 12Cr1MoV/TP347H dissimilar steel welded joints during aging. Int. J. Miner. Metall. Mater. 2021, 28, 1497. [Google Scholar] [CrossRef]

- Zhang, J.-J.; Zhai, B.-Y.; Zhang, L.; Wang, W.-l. A comparison study on interfacial properties of fluorine-bearing and fluorine-free mold flux for casting advanced high-strength steels. J. Iron Steel Res. Int. 2022, 1–6. [Google Scholar] [CrossRef]

- Liu, Y.; Sun, Y.-H.; Wu, H.-T. Effects of chromium on the microstructure and hot ductility of Nb-microalloyed steel. Int. J. Miner. Metall. Mater. 2021, 28, 1011. [Google Scholar] [CrossRef]

- Srivastava, G.K.; Vemavarapu, M.S.R.M. Drillability prediction in some metamorphic rocks using composite penetration rate index (CPRI)—An approach. Int. J. Min. Sci. Technol. 2021, 31, 631–641. [Google Scholar] [CrossRef]

- Huang, Y.; Cheng, G.; Zhu, M. Effect of Ti Content on the Behavior of Primary Carbides in H13 Ingots. Metals 2020, 10, 837. [Google Scholar] [CrossRef]

- Han, X.; Zhang, Z.; Wang, B.; Thrush, S.J.; Barber, G.C.; Qiu, F. Microstructures, compressive residual stress, friction behavior, and wear mechanism of quenched and tempered shot peened medium carbon steel. Wear 2022, 488, 204131. [Google Scholar] [CrossRef]

- Yang, H.-Y.; Wang, Z.; Yue, X.; Ji, P.-J.; Shu, S.-L. Simultaneously improved strength and toughness of in situ bi-phased TiB2-Ti(C,N)-Ni cermets by Mo addition. J. Alloys Compd. 2020, 820, 153068. [Google Scholar] [CrossRef]

- Mohalik, N.K.; Mandal, S.; Ray, S.K.; Khan, A.M.; Mishra, D.; Pandey, J.K. TGA/DSC study to characterise and classify coal seams conforming to susceptibility towards spontaneous combustion. Int. J. Min. Sci. Technol. 2021, 32, 75–88. [Google Scholar] [CrossRef]

- Zhao, X.; Hai, X. Microstructure and tribological behavior of the nickel-coated-graphite-reinforced Babbitt metal composite fabricated via selective laser melting. Int. J. Miner. Metall. Mater. 2022, 29, 320–326. [Google Scholar] [CrossRef]

- Zhou, Y.; Jiang, W. Effect of sliding speed on elevated-temperature wear behavior of AISI H13 steel. J. Iron Steel Res. Int. 2021, 28, 1180–1189. [Google Scholar] [CrossRef]

- Zhao, Y.; Liu, N.; Zheng, X.; Zhang, N. Mechanical model for controlling floor heave in deep roadways with U-shaped steel closed support. Int. J. Min. Sci. Technol. 2015, 25, 713–720. [Google Scholar] [CrossRef]

- Han, X.; Zhang, Z.; Hou, J.; Barber, G.C.; Qiu, F. Tribological behavior of shot peened/austempered AISI 5160 steel. Tribol. Int. 2020, 145, 106197. [Google Scholar] [CrossRef]

- Kang, C.-P.; Liu, F.-B.; Zheng, H.-B.; Li, H.-B.; Jiang, Z.-H.; Chen, K.; Suo, H.-Y.; Yu, X.-H. Microstructure evolution and mechanical properties of PESR 55Cr17Mo1VN plastic die steel during quenching and tempering treatment. J. Iron Steel Res. Int. 2021, 28, 1625–1633. [Google Scholar] [CrossRef]

- Zhao, F.; He, G.-N.; Liu, Y.-Z.; Zhang, Z.-H.; Xie, J.-X. Effect of titanium microalloying on microstructure and mechanical properties of vanadium microalloyed steels for hot forging. J. Iron Steel Res. Int. 2021, 1–12. [Google Scholar] [CrossRef]

- Li, C.-S.; Li, B.-Z.; Jin, X.; Wang, Y. Microstructure and mechanical properties in core of a carburizing 20CrNi2MoV bearing steel subjected to cryogenic treatment. J. Iron Steel Res. Int. 2021, 28, 360–369. [Google Scholar] [CrossRef]

- Cai, W.; Chang, Z.; Zhang, D.; Wang, X.; Cao, W.; Zhou, Y. Roof filling control technology and application to mine roadway damage in small pit goaf. Int. J. Min. Sci. Technol. 2019, 29, 477–482. [Google Scholar] [CrossRef]

- Li, C.-L.; Qiu, F.; Chang, F.; Zhao, X.-M.; Geng, R.; Yang, H.-Y.; Zhao, Q.-L.; Jiang, Q.-C. Simultaneously Enhanced Strength, Toughness and Ductility of Cast 40Cr Steels Strengthened by Trace Biphase TiCx-TiB2 Nanoparticles. Metals 2018, 8, 707. [Google Scholar] [CrossRef] [Green Version]

- Chen, L.-Y.; Liang, S.-X.; Liu, Y.; Zhang, L.-C. Additive manufacturing of metallic lattice structures: Unconstrained design, accurate fabrication, fascinated performances, and challenges. Mater. Sci. Eng. R-Rep. 2021, 146, 100648. [Google Scholar] [CrossRef]

- Yang, X.-H.; Chen, X.-H.; Pan, S.-W.; Wang, Z.-D.; Chen, K.-X.; Li, D.-Y.; Qin, J.-W. Microstructure and mechanical properties of ultralow carbon high-strength steel weld metals with or without Cu−Nb addition. Int. J. Miner. Metall. Mater. 2021, 28, 120. [Google Scholar] [CrossRef]

- Zhu, J.; Zhang, Z.-H.; Xie, J.-X. Relationship between martensite microstructure and ductility of H13 steel from aspect of crystallography. J. Iron Steel. Res. Int. 2021, 28, 1268–1281. [Google Scholar] [CrossRef]

- Qiu, G.-X.; Zhan, D.-P.; Cao, L.; Zhang, H.-S. Effect of zirconium on inclusions and mechanical properties of China low activation martensitic steel. J. Iron Steel Res. Int. 2021, 28, 1168–1179. [Google Scholar] [CrossRef]

- Le, Z.; Yu, Q.; Zhu, W.; Liu, H.; Yang, T. Experimental study on the effect of granular backfill with various gradations on the mechanical behavior of rock. Int. J. Min. Sci. Technol. 2021, 31, 889–899. [Google Scholar] [CrossRef]

- Zhou, J.-H.; Shen, Y.-F.; Jia, N. Strengthening mechanisms of reduced activation ferritic/martensitic steels: A review. Int. J. Miner. Metall. Mater. 2021, 28, 335. [Google Scholar] [CrossRef]

- Lin, L.; Zeng, J.-Q. Consideration of green intelligent steel processes and narrow window stability control technology on steel quality. Int. J. Miner. Metall. Mater. 2021, 28, 1264. [Google Scholar] [CrossRef]

- Zhang, H.; Wang, W.-X.; Chang, F.; Li, C.-L.; Shu, S.-L.; Wang, Z.-F.; Han, X.; Zou, Q.; Qiu, F.; Jiang, Q. Microstructure manipulation and strengthening mechanisms of 40Cr steel via trace TiC nanoparticles. Mater. Sci. Eng. A-Struct. 2021, 822, 141693. [Google Scholar] [CrossRef]

- Zheng, G.Y.; Luo, X.; Huang, B.; Li, P.T.; Yang, Y.Q. Distributions of grains and precipitates in gradient lamellae Al-Zn-Mg-Cu alloy by ultrasonic surface rolling processing. Mater. Sci. Eng. A-Struct. 2021, 825, 141911. [Google Scholar] [CrossRef]

- Qu, T.-P.; Wang, D.-Y.; Wang, H.-H.; Hou, D.; Tian, J.; Hu, S.-Y.; Su, L.-J. Interface characteristics between TiN and matrix and their effect on solidification structure. J. Iron Steel Res. Int. 2021, 28, 1149–1158. [Google Scholar] [CrossRef]

- Huang, Y.; Liu, W.-N.; Zhao, A.-M.; Han, J.-K.; Wang, Z.-G.; Yin, H.-X. Effect of Mo content on the thermal stability of Ti–Mo-bearing ferritic steel. Int. J. Miner. Metall. Mater. 2021, 28, 412. [Google Scholar] [CrossRef]

- Li, S.-Y.; Qin, S.-Y.; Xi, X.-J.; Sun, G.-Y.; Yang, W.-S.; Guo, J.; Guo, H.-J. Solidified Structure Refinement of H13 Tool Steel under a Multi-Rotational Speed Super Gravity Field. Metals 2020, 10, 1428. [Google Scholar] [CrossRef]

- Luo, X.; Yang, L.; Zhao, A.W.; Lu, W.J.; Gan, B.; Yang, Y.Q. Al2O3 nanoparticle reinforced heterogeneous CrCoNi-matrix composites with improved strength-ductility synergy. Mater. Sci. Eng. A-Struct. 2022, 832, 142398. [Google Scholar] [CrossRef]

- Liu, D.-K.; Yang, J.; Zhang, Y.-H.; Xu, L.-Y. Effect of Mo content on nano-scaled particles, prior austenite grains and impact toughness of CGHAZ in offshore engineering steels. J. Iron Steel Res. Int. 2021, 1–13. [Google Scholar] [CrossRef]

- Liu, R.-Z.; Gu, W.-W.; Yang, Y.; Lu, Y.; Tan, H.-B.; Yang, J.-F. Microstructure and mechanical properties of reaction-bonded B4C–SiC composites. Int. J. Miner. Metall. Mater. 2021, 28, 1828. [Google Scholar] [CrossRef]

- Li, H.; Ji, H.; Cui, X.; Che, X.; Zhang, Q.; Zhong, J.; Jin, R.; Wang, L.; Luo, Y. Kinetics, thermodynamics, and equilibrium of As(III), Cd(II), Cu(II) and Pb(II) adsorption using porous chitosan bead-supported MnFe2O4 nanoparticles. Int. J. Min. Sci. Technol. 2021, 31, 1107–1115. [Google Scholar] [CrossRef]

- Wang, B.; Qiu, F.; Cui, W.; Jin, Y.; Zhang, Y.; Hu, Z.; Barber, G.C. Microstructure and Tensile Properties of Graphite Ductile Iron Improved by Minor Amount of Dual-Phased TiC-TiB2 Nanoparticles. Adv. Eng. Mater. 2021, 23, 2100246. [Google Scholar] [CrossRef]

- Qian, F.; Li, H.-L.; Yang, W.-G.; Guo, H.-R.; Liu, G.-Q.; Li, H.-X.; Ma, B.-Y. Corrosion resistance of BN–ZrO2 ceramics with different additives by molten steel. J. Iron Steel Res. Int. 2022, 1–9. [Google Scholar] [CrossRef]

- Liu, T.-S.; Qiu, F.; Dong, B.-X.; Geng, R.; Zha, M.; Yang, H.-Y.; Shu, S.-L.; Jiang, Q.-C. Role of trace nanoparticles in establishing fully optimized microstructure configuration of cold-rolled Al alloy. Mater Design. 2021, 206, 109743. [Google Scholar] [CrossRef]

- Li, Q.; Dong, B.-X.; Liu, T.-S.; Yang, H.-Y.; Shu, S.-L.; Qiu, F.; Jiang, Q.-C. Insight into solidification microstructure control by trace TiCN-TiB2 particles for yielding fine-tuned nanoprecipitates in a hypoeutectic Al-Si-Mg alloy. Mater. Sci. Eng. A-Struct. 2021, 827, 142093. [Google Scholar] [CrossRef]

- Zhu, L.; Liu, T.-S.; Duan, T.-T.; Li, T.-T.; Qiu, F.; Yang, H.-Y.; Bai, Z.-H.; Liu, Y.-Y.; Jiang, Q.-C. Design of a new Al-Cu alloy manipulated by in-situ nanocrystals with superior high temperature tensile properties and its constitutive equation. Mater. Design. 2019, 181, 107945. [Google Scholar] [CrossRef]

- Fu, Z.-X.; Yang, G.-W.; Han, R.-Y.; Xu, Y.-W.; Mao, X.-P.; Bao, S.-Q.; Zhao, G. Influence of coiling temperature on microstructure and mechanical properties of a hot-rolled high-strength steel microalloyed with Ti, Mo and V. J. Iron Steel Res. Int. 2021. [Google Scholar] [CrossRef]

- Kiahosseini, S.R.; Ahmadian, H. Effect of residual structural strain caused by the addition of Co3O4 nanoparticles on the structural, hardness and magnetic properties of an Al/Co3O4 nanocomposite produced by powder metallurgy. Int. J. Miner. Metall. Mater. 2020, 27, 384. [Google Scholar] [CrossRef]

- Yang, H.; Yue, X.; Wang, Z.; Shao, Y.; Shu, S. Strengthening mechanism of TiC/Al composites using Al-Ti-C/CNTs with doping alloying elements (Mg, Zn and Cu). J. Mater. Res. Technol-JMRT. 2020, 9, 6475–6487. [Google Scholar] [CrossRef]

- Li, Q.; Qiu, F.; Dong, B.-X.; Gao, X.; Shu, S.-L.; Yang, H.-Y.; Jiang, Q.-C. Processing, multiscale microstructure refinement and mechanical property enhancement of hypoeutectic Al-Si alloys via in situ bimodal-sized TiB2 particles. Mater. Sci. Eng. A-Struct. 2020, 777, 139081. [Google Scholar] [CrossRef]

- Yang, H.-Y.; Cai, Z.-J.; Zhang, Q.; Shao, Y.; Dong, B.-X.; Xuan, Q.-Q.; Qiu, F. Comparison of the effects of Mg and Zn on the interface mismatch and compression properties of 50 vol% TiB2/Al composites. Ceram. Int. 2021, 47, 22121–22129. [Google Scholar] [CrossRef]

- Zhang, J.-W.; Cao, Y.-G.; Zhang, C.-G.; Li, Z.-D.; Wang, W.-X. Effect of Nb addition on microstructure and mechanical properties of 25CrNiMoV (DZ2) steel for high-speed railway axles. J. Iron Steel Res. Int. 2021. [Google Scholar] [CrossRef]

- Shi, R.-J.; Wang, Z.-D.; Qiao, L.-J.; Pang, X.-L. Effect of in-situ nanoparticles on the mechanical properties and hydrogen embrittlement of high-strength steel. Int. J. Miner. Metall. Mater. 2021, 28, 644. [Google Scholar] [CrossRef]

- Zang, J.; Dai, P.; Yang, Y.; Liu, S.; Huang, B.; Ru, J.; Luo, X. Study on the Relationship between High Temperature Mechanical Properties and Precipitates Evolution of 7085 Al Alloy after Long Time Thermal Exposures. Metals 2021, 11, 1483. [Google Scholar] [CrossRef]

- Lu, T.-X.; Chen, C.-G.; Guo, Z.-M.; Li, P.; Guo, M.-X. Tungsten nanoparticle-strengthened copper composite prepared by a sol-gel method and in-situ reaction. Int. J. Miner. Metall. Mater. 2019, 26, 1477. [Google Scholar] [CrossRef]

- Gómez-Esparza, C.D.; Duarte-Moller, A.; León, C.L.-D.D.; Martínez-Sánchez, R.; Hernández-Paz, J.F.; Rodríguez-González, C.A. Influence of ZnO nanoparticles on the microstructure of a CoCrFeMoNi matrix via powder metallurgy. Int. J. Miner. Metall. Mater. 2019, 26, 1467. [Google Scholar] [CrossRef]

- Wang, S.; Wu, G.; Mao, X. Titanium microalloying in steel: A review of its effects on processing, microstructure and mechanical properties. Int. J. Miner. Metall. Mater. 2021. [Google Scholar] [CrossRef]

- Zhu, L.; Qiu, F.; Qiu, D.; Duan, T.-T.; Chang, F.; Li, T.-T.; Shu, S.-L.; Yang, H.-Y.; He, Y.; Jiang, Q.-C. Efficient microstructure refinement of Al-Si-Mg alloy manipulated by nanocrystals formed by in-situ crystallization in melt. Mater. Sci. Eng. A-Struct. 2019, 751, 90–98. [Google Scholar] [CrossRef]

- Kou, S.-Q.; Gao, Y.-L.; Song, W.; Zhao, H.-L.; Guo, Y.-B.; Zhang, S.; Yang, H.-Y. Compression properties and work-hardening behavior of the NiAl matrix composite reinforced with in situ TaC ceramic particulates. Vacuum 2021, 186, 110035. [Google Scholar] [CrossRef]

- Zhu, L.; Qiu, F.; Zou, Q.; Han, X.; Shu, S.-L.; Yang, H.-Y.; Jiang, Q.-C. Multiscale design of alpha-Al, eutectic silicon and Mg2Si phases in Al-Si-Mg alloy manipulated by in situ nanosized crystals. Mater. Sci. Eng. A-Struct. 2021, 802, 140627. [Google Scholar] [CrossRef]

- Wang, B.; Zhang, Y.; Qiu, F.; Cai, G.; Cui, W.; Hu, Z.; Zhang, H.; Tyrer, N.; Barber, G.C. Role of trace nanoparticles in manipulating the widmanstatten structure of low carbon steel. Mater. Lett. 2022, 306, 130853. [Google Scholar] [CrossRef]

- Geng, R.; Qiu, F.; Jiang, Q.-C. Reinforcement in Al Matrix Composites: A Review of Strengthening Behavior of Nano-Sized Particles. Adv. Eng. Mater. 2018, 20, 1701089. [Google Scholar] [CrossRef]

- Chen, R.; Wang, Z.; He, J.; Zhu, F.; Li, C. Effects of Rare Earth Elements on Microstructure and Mechanical Properties of H13 Die Steel. Metals 2020, 10, 918. [Google Scholar] [CrossRef]

- Qiu, F.; Zhang, H.; Li, C.-L.; Wang, Z.-F.; Chang, F.; Yang, H.-Y.; Li, C.-D.; Han, X.; Jiang, Q.-C. Simultaneously enhanced strength and toughness of cast medium carbon steels matrix composites by trace nano-sized TiC particles. Mater. Sci. Eng. A-Struct. 2021, 819, 141485. [Google Scholar] [CrossRef]

- Wang, B.; Qiu, F.; Zhang, Y.; Yang, J.; Cui, W.; Jin, Y.; Cai, G.; Yuan, Y.; Guo, S.; Li, H.; et al. Influences of dual-phased nanoparticles on microstructure, mechanical properties and wear resistance of vermicular graphite cast iron. Mater. Lett. 2022, 308, 131296. [Google Scholar] [CrossRef]

- Wang, G.; Li, Y.; Wang, E.; Huang, Q.; Wang, S.; Li, H. Experimental study on preparation of nanoparticle-surfactant nanofluids and their effects on coal surface wettability. Int. J. Min. Sci. Technol. 2022. [Google Scholar] [CrossRef]

- Li, Y.; Bian, X.; Liu, Y.; Wu, W.; Fu, G. Synthesis and characterization of ceria nanoparticles by complex-precipitation route. Int. J. Miner. Metall. Mater. 2022, 29, 292–297. [Google Scholar] [CrossRef]

- Wang, X.; Li, G.; Liu, Y.; Cao, Y.; Wang, F.; Wang, Q. Investigation of Primary Carbides in a Commercial-Sized Electroslag Remelting Ingot of H13 Steel. Metals 2019, 9, 1247. [Google Scholar] [CrossRef] [Green Version]

- Wang, B.; Qiu, F.; Barber, G.C.; Zou, Q.; Wang, J.; Guo, S.; Yuan, Y.; Jiang, Q. Role of nano-sized materials as lubricant additives in friction and wear reduction: A review. Wear 2022, 490-491, 204–206. [Google Scholar] [CrossRef]

- Sakthivel, S.; Prasanna Venkatesh, R. Solid state synthesis of nano-mineral particles. Int. J. Min. Sci. Technol. 2012, 22, 651–655. [Google Scholar] [CrossRef]

- Dong, B.-X.; Ma, X.-D.; Liu, T.-S.; Li, Q.; Yang, H.-Y.; Shu, S.-L.; Zhang, B.-Q.; Qiu, F.; Jiang, Q.-C. Reaction behaviors and specific exposed crystal planes manipulation mechanism of TiC nanoparticles. J. Am. Ceram. Soc. 2021, 104, 2820–2835. [Google Scholar] [CrossRef]

- Luo, X.; Huang, B.; Guo, X.; Lu, W.; Zheng, G.; Huang, B.; Li, J.; Li, P.; Yang, Y. High ZT Value of Pure SnSe Polycrystalline Materials Prepared by High-Energy Ball Milling plus Hot Pressing Sintering. ACS Appl. Mater. Interfaces 2021, 13, 43011–43021. [Google Scholar] [CrossRef] [PubMed]

- Dong, B.-X.; Li, Q.; Wang, Z.-F.; Liu, T.-S.; Yang, H.-Y.; Shu, S.-L.; Chen, L.-Y.; Qiu, F.; Jiang, Q.-C.; Zhang, L.-C. Enhancing strength-ductility synergy and mechanisms of Al-based composites by size-tunable in-situ TiB2 particles with specific spatial distribution. Compos. B Eng. 2021, 217, 108912. [Google Scholar] [CrossRef]

- Yang, H.-Y.; Wang, Z.; Chen, L.-Y.; Shu, S.-L.; Qiu, F.; Zhang, L.-C. Interface formation and bonding control in high-volume-fraction (TiC+TiB2)/Al composites and their roles in enhancing properties. Compos. B Eng. 2021, 209, 108605. [Google Scholar] [CrossRef]

- Dong, B.-X.; Li, Q.; Yang, H.-Y.; Liu, T.-S.; Qiu, F.; Shu, S.-L.; Jiang, Q.-C.; Zhang, L.-C. Synergistic optimization in solidification microstructure and mechanical performance of novel (TiCxNy−TiB2)p/Al nanocomposites: Design, tuning and mechanism. Compos. Part A-Appl. S 2022, 155, 106843. [Google Scholar] [CrossRef]

- Coronado, J.J.; Sinatora, A. Effect of abrasive size on wear of metallic materials and its relationship with microchips morphology and wear micromechanisms: Part 1. Wear 2011, 271, 1794–1803. [Google Scholar] [CrossRef]

- Tressia, G.; Penagos, J.J.; Sinatora, A. Effect of abrasive particle size on slurry abrasion resistance of austenitic and martensitic steels. Wear 2017, 376, 63–69. [Google Scholar] [CrossRef]

- Chacon-Nava, J.G.; Martinez-Villafañe, A.; Almeraya-Calderon, F.; Cabral-Miramontes, J.A.; Stack, M.M. Some remarks on particle size effects on the abrasion of a range of Fe based alloys. Tribol. Int. 2010, 43, 1307–1317. [Google Scholar] [CrossRef] [Green Version]

| Sample | C | Cr | Mo | V | Si | Mn | P | S | Fe |

|---|---|---|---|---|---|---|---|---|---|

| H13 | 0.41 | 5.5 | 1.75 | 1.20 | 1.20 | 0.50 | <0.03 | <0.03 | Bal. |

| Sample | Hardness (HRC) | σ0.2 (MPa) | σUTS (MPa) | εf (%) | UE (%) | Product of Strength Plasticity (MPa·%) | Non-NotchedImpact Toughness (J/cm2) | U-Notched Impact Toughness (J/cm2) |

|---|---|---|---|---|---|---|---|---|

| H13 | 46.9 ± 0.1 | 1023 ± 6 | 1325 ± 7 | 14.8 ± 0.2 | 5.3 ± 0.2 | 16,348 ± 340 | 332.9 ± 2.4 | 30.94 ± 0.6 |

| H13 + 0.02 wt.% TiC | 47.5 ± 0.2 | 1131 ± 8 | 1415 ± 5 | 16.8 ± 0.4 | 5.6 ± 0.3 | 19,835 ± 325 | 406.8 ± 3.1 | 33.93 ± 1.3 |

| H13 + 0.01 wt.% TiC + TiB2 | 48.2 ± 0.1 | 1035 ± 6 | 1343 ± 6 | 17.2 ± 0.2 | 8.9 ± 0.3 | 19,989 ± 296 | 419.6 ± 3.3 | 38.46 ± 0.8 |

| H13 + 0.02 wt.% TiC + TiB2 | 48.7 ± 0.1 | 1142 ± 12 | 1426 ± 15 | 16.9 ± 1.2 | 8.7 ± 0.5 | 20,662 ± 492 | 449.3 ± 2.9 | 41.39 ± 1.0 |

| Sample | Weight Loss (g) | Volumetric Wear Rate (10−11 m3/m) | ||

|---|---|---|---|---|

| 15N | 25N | 15N | 25N | |

| H13 | 0.1024 ± 0.0023 | 0.1507 ± 0.0037 | 8.7 ± 0.2 | 12.8 ± 0.3 |

| H13 + 0.02 wt.% TiC | 0.0530 ± 0.0035 | 0.0930 ± 0.0011 | 4.5 ± 0.3 | 7.9 ± 0.1 |

| H13 + 0.01 wt.% TiC + TiB2 | 0.0659 ± 0.0019 | 0.1072 ± 0.0021 | 5.6 ± 0.2 | 9.1 ± 0.2 |

| H13 + 0.02 wt.% TiC + TiB2 | 0.0483 ± 0.0016 | 0.0836 ± 0.0018 | 4.1 ± 0.2 | 7.1 ± 0.2 |

| Sample | The Depth of the Worn Surface (nm) | The Maximum Depth Difference (nm) | The Width of the Wear Scar (μm) | |||

|---|---|---|---|---|---|---|

| 15 N | 25 N | 15 N | 25 N | 15 N | 25 N | |

| H13 | −3720–3260 | −4750–3900 | 6980 | 8650 | 165 | 165 |

| H13 + 0.02 wt.% TiC | −2800–2900 | −4200–−2500 | 5700 | 6700 | 175 | 115 |

| H13 + 0.01 wt.%TiC + TiB2 | −3250–2500 | −4250–3750 | 5750 | 8000 | 135 | 150 |

| H13 + 0.02 wt.%TiC + TiB2 | −3400–2200 | −3800–2250 | 5600 | 6050 | 125 | 90 |

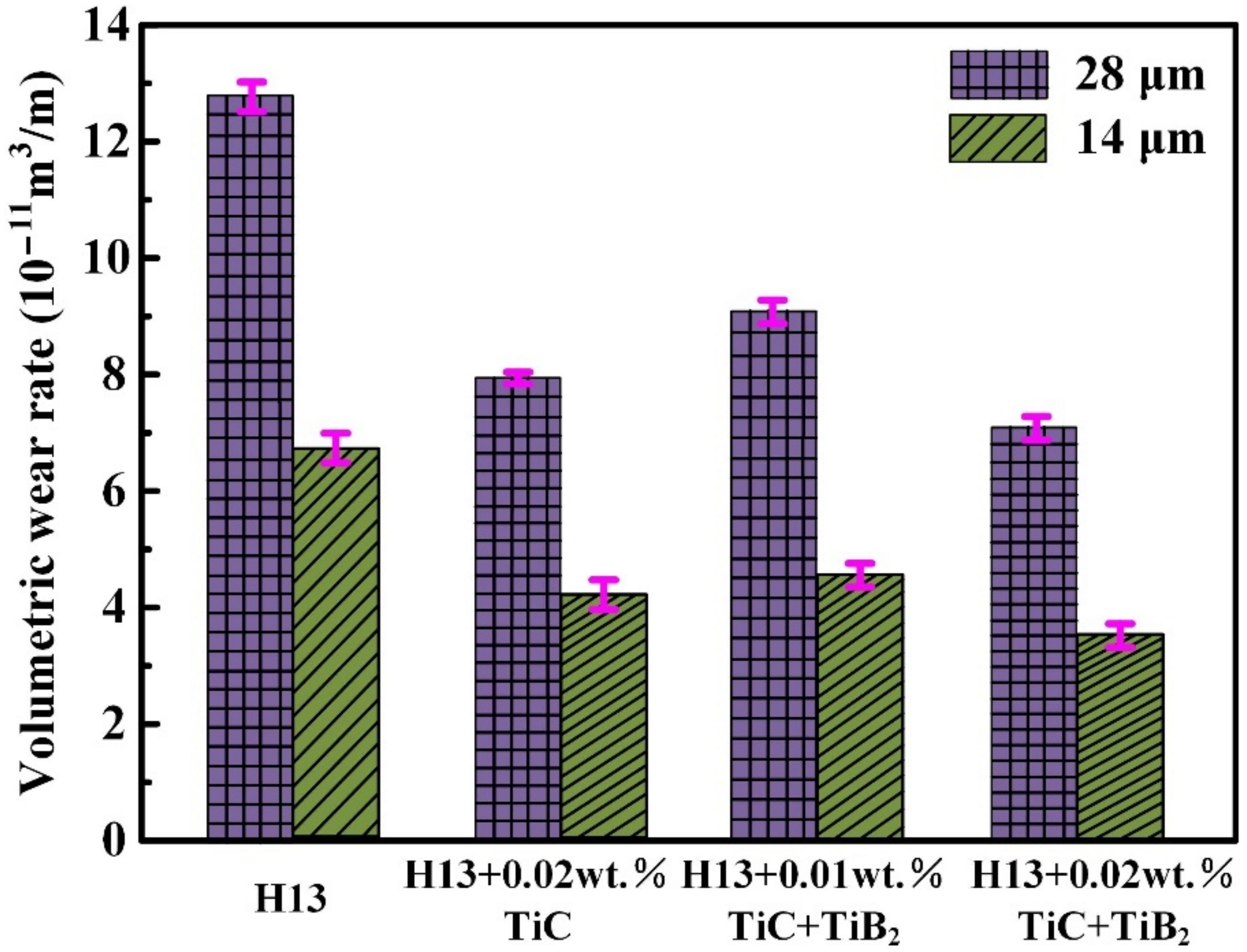

| Sample | Weight Loss (g) | Volumetric Wear Rate (10−11m3/m) | ||

|---|---|---|---|---|

| 28 μm | 14 μm | 28 μm | 14 μm | |

| H13 | 0.1507 ± 0.0037 | 0.0789 ± 0.0029 | 12.8 ± 0.3 | 6.7 ± 0.3 |

| H13 + 0.02 wt.% TiC | 0.0930 ± 0.0011 | 0.0495 ± 0.0031 | 7.9 ± 0.1 | 4.2 ± 0.3 |

| H13 + 0.01 wt.% TiC + TiB2 | 0.1072 ± 0.0021 | 0.0530 ± 0.0035 | 9.1 ± 0.2 | 4.5 ± 0.2 |

| H13 + 0.02 wt.% TiC + TiB2 | 0.0836 ± 0.0018 | 0.0412 ± 0.0020 | 7.1 ± 0.2 | 3.5 ± 0.2 |

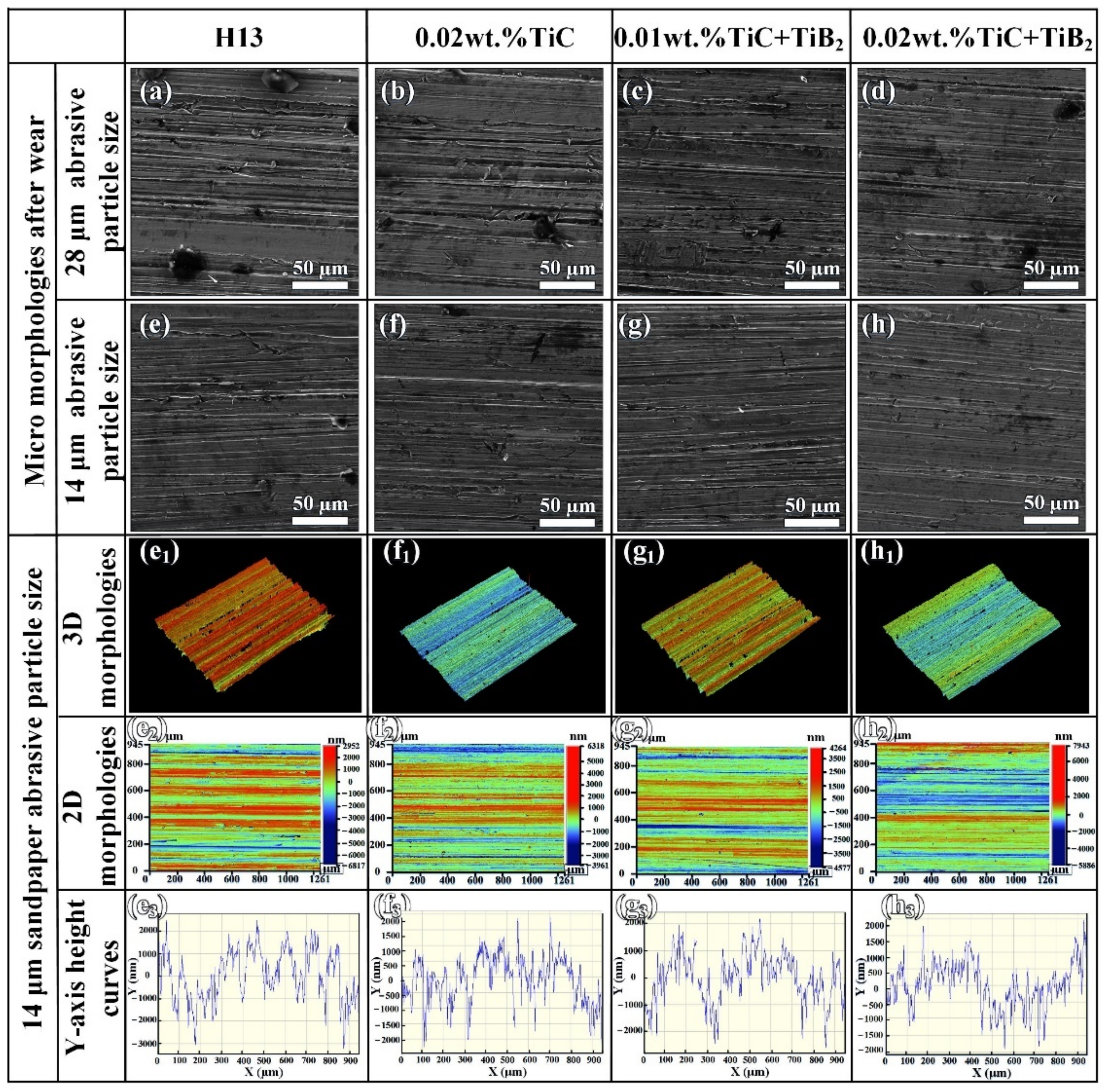

| Sample | The Depth of the Worn Surface (nm) | The Maximum Depth Difference (nm) | The Width of the Wear Scar (μm) |

|---|---|---|---|

| H13 | −3250–2500 | 5750 | 150 |

| H13 + 0.02 wt.% TiC | −2300–1800 | 4100 | 150 |

| H13 + 0.01 wt.%TiC + TiB2 | −2600–2200 | 4800 | 115 |

| H13 + 0.02 wt.%TiC + TiB2 | −1950–2000 | 3950 | 75 |

Publisher’s Note: MDPI stays neutral with regard to jurisdictional claims in published maps and institutional affiliations. |

© 2022 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (https://creativecommons.org/licenses/by/4.0/).

Share and Cite

Kou, S.-Q.; Dai, J.-N.; Wang, W.-X.; Zhang, C.-K.; Wang, S.-Y.; Li, T.-Y.; Chang, F. Enhancement of Wear Resistance on H13 Tool and Die Steels by Trace Nanoparticles. Metals 2022, 12, 348. https://doi.org/10.3390/met12020348

Kou S-Q, Dai J-N, Wang W-X, Zhang C-K, Wang S-Y, Li T-Y, Chang F. Enhancement of Wear Resistance on H13 Tool and Die Steels by Trace Nanoparticles. Metals. 2022; 12(2):348. https://doi.org/10.3390/met12020348

Chicago/Turabian StyleKou, Shu-Qing, Jun-Nan Dai, Wen-Xin Wang, Chun-Kai Zhang, Si-Yu Wang, Tai-Yu Li, and Fang Chang. 2022. "Enhancement of Wear Resistance on H13 Tool and Die Steels by Trace Nanoparticles" Metals 12, no. 2: 348. https://doi.org/10.3390/met12020348

APA StyleKou, S.-Q., Dai, J.-N., Wang, W.-X., Zhang, C.-K., Wang, S.-Y., Li, T.-Y., & Chang, F. (2022). Enhancement of Wear Resistance on H13 Tool and Die Steels by Trace Nanoparticles. Metals, 12(2), 348. https://doi.org/10.3390/met12020348