Relationship between Microstructure and Properties of 1380 MPa Grade Bainitic Rail Steel Treated by Online Bainite-Based Quenching and Partitioning Concept

Abstract

:1. Introduction

2. Experimental Procedure

3. Results and Discussion

3.1. Microstructure

3.2. Mechanical Stability of Retained Austenite

3.3. Mechanical Properties

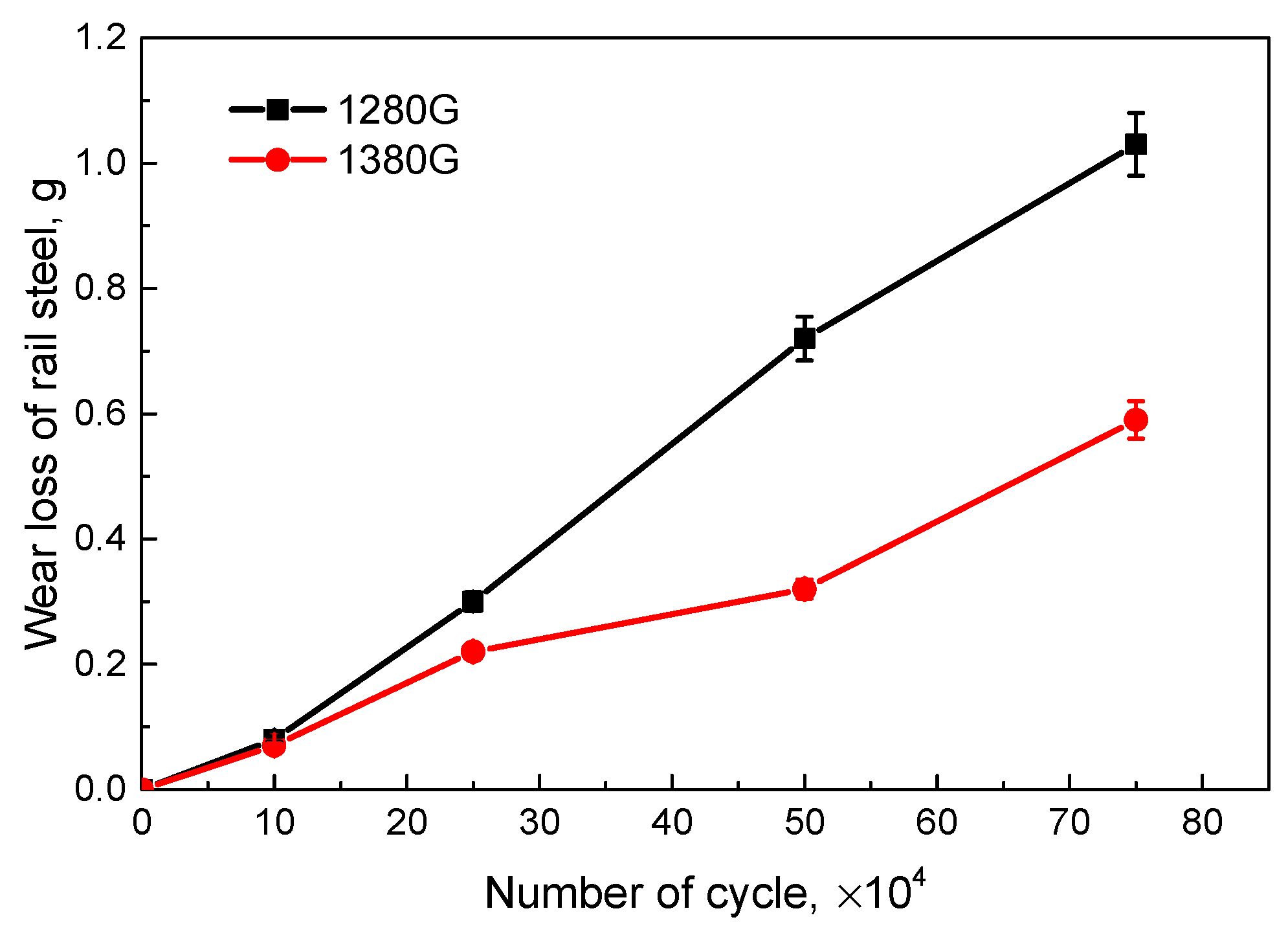

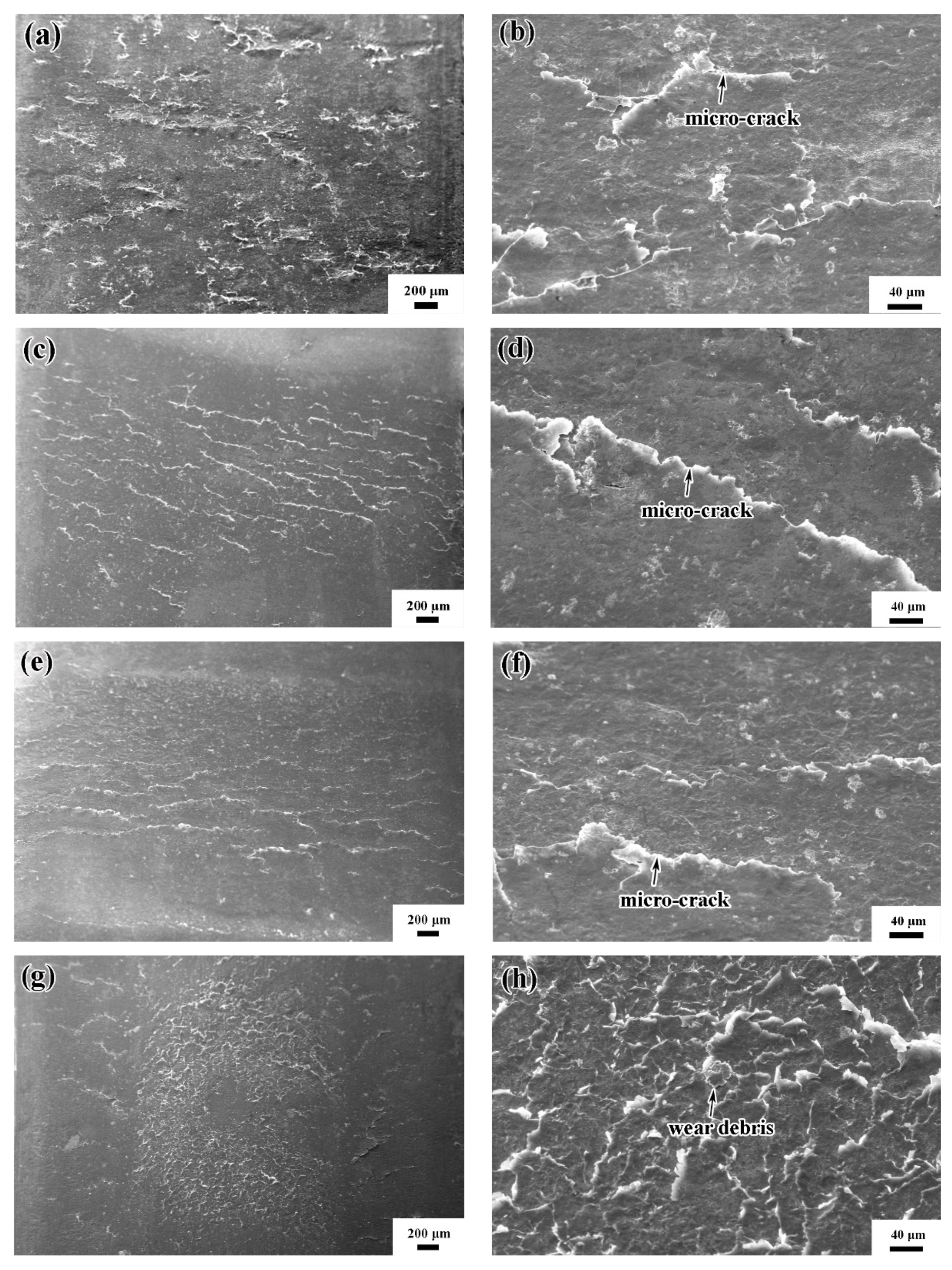

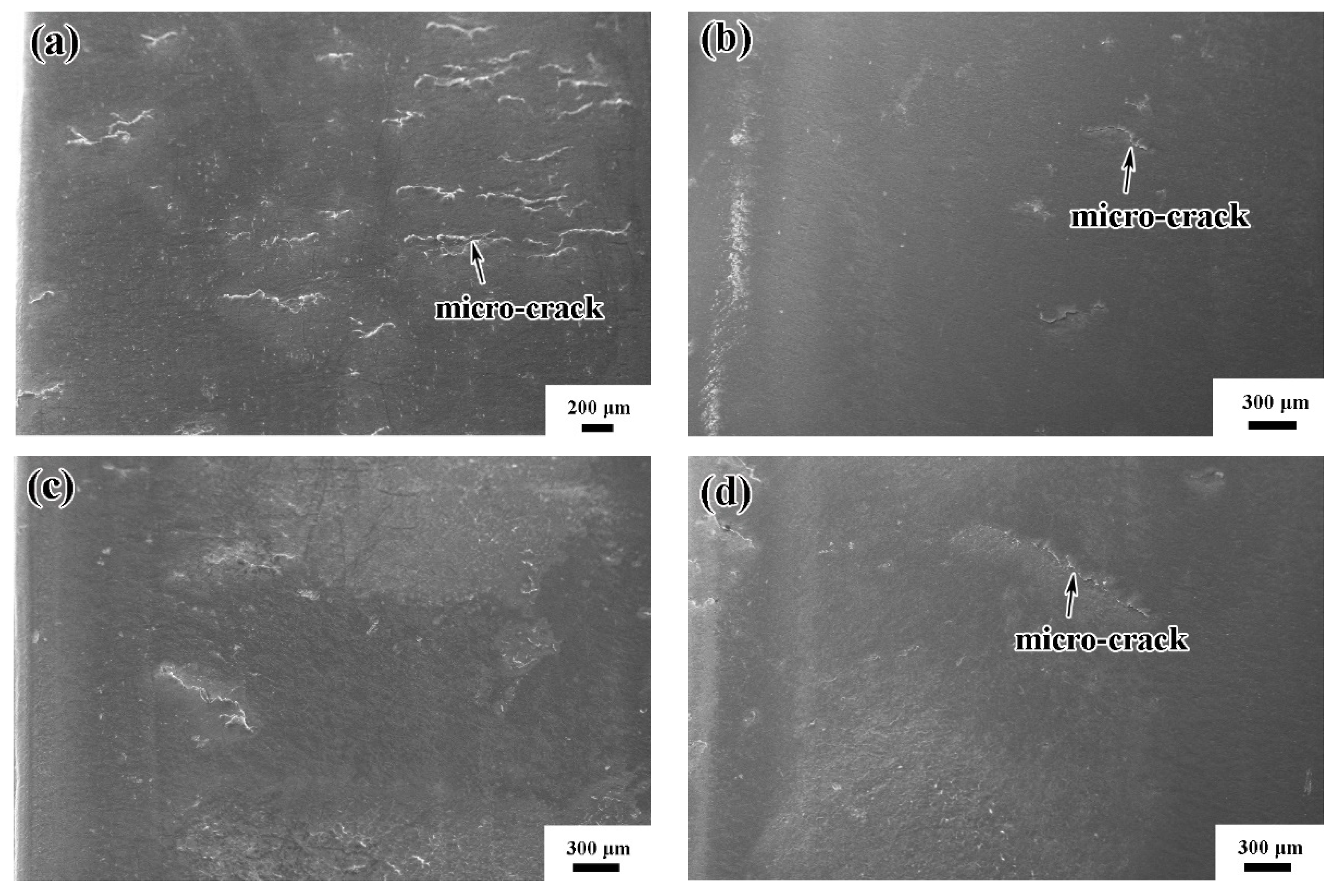

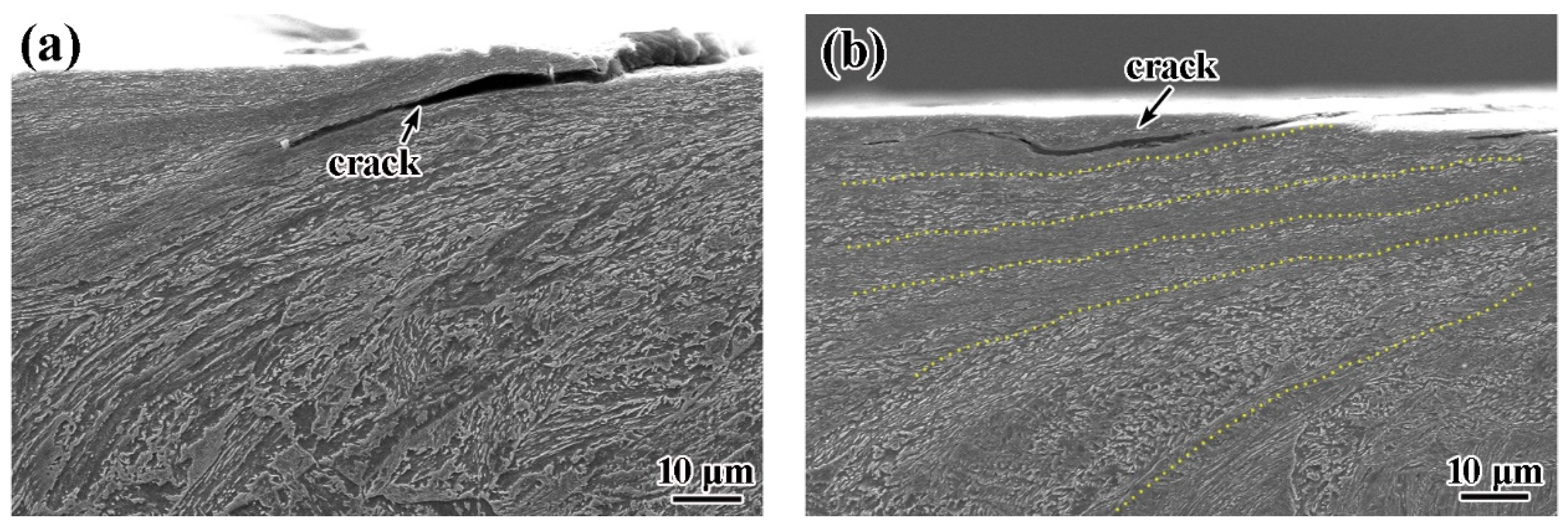

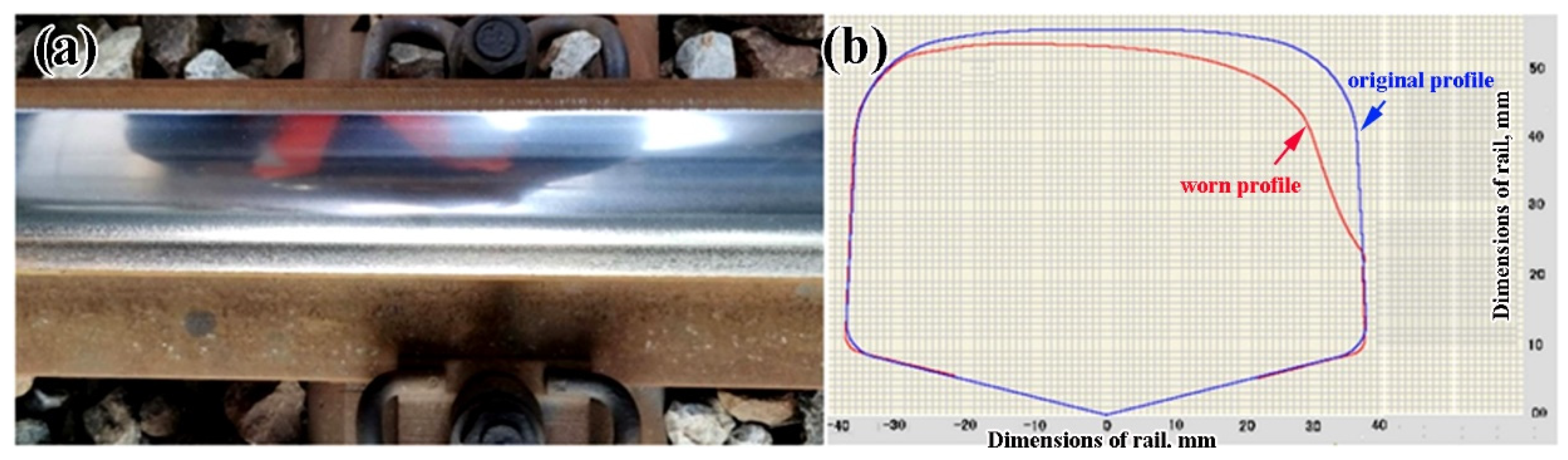

3.4. Wear Resistance of Bainitic Rail Steel

4. Conclusions

- (1)

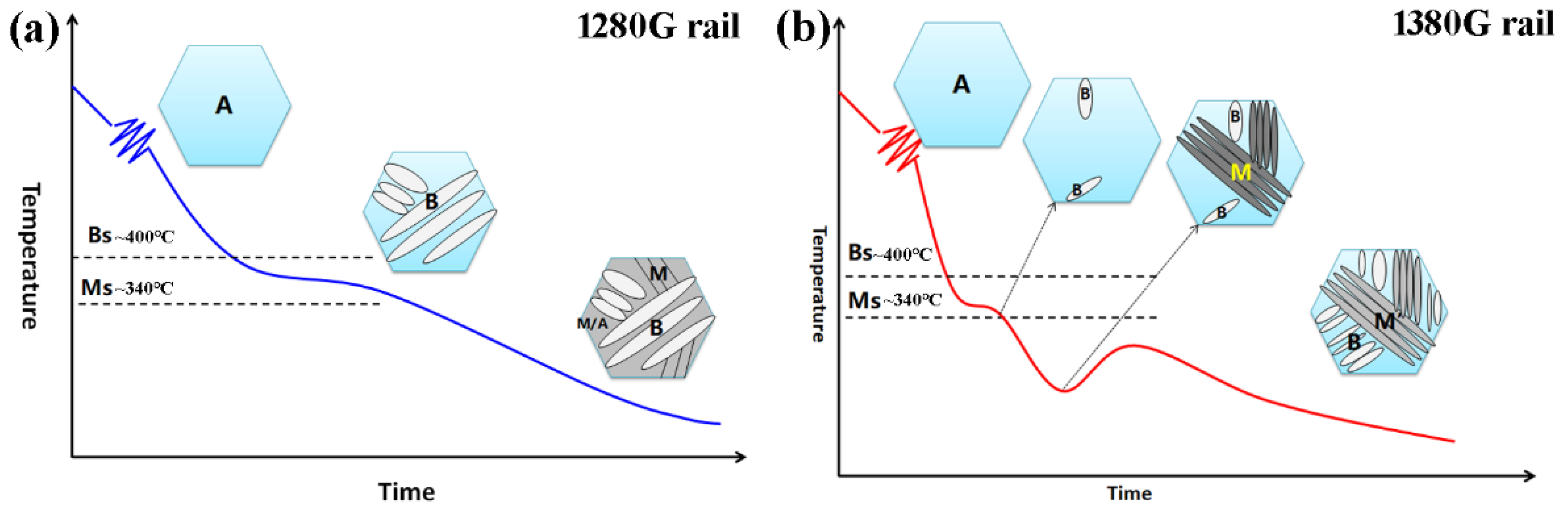

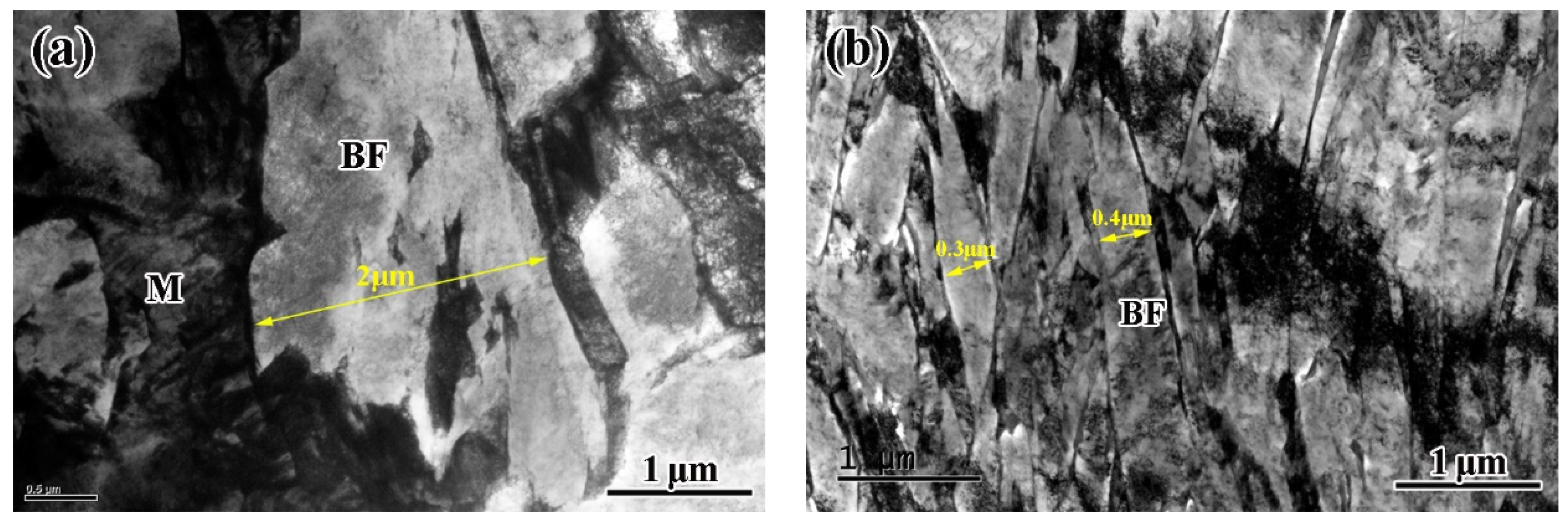

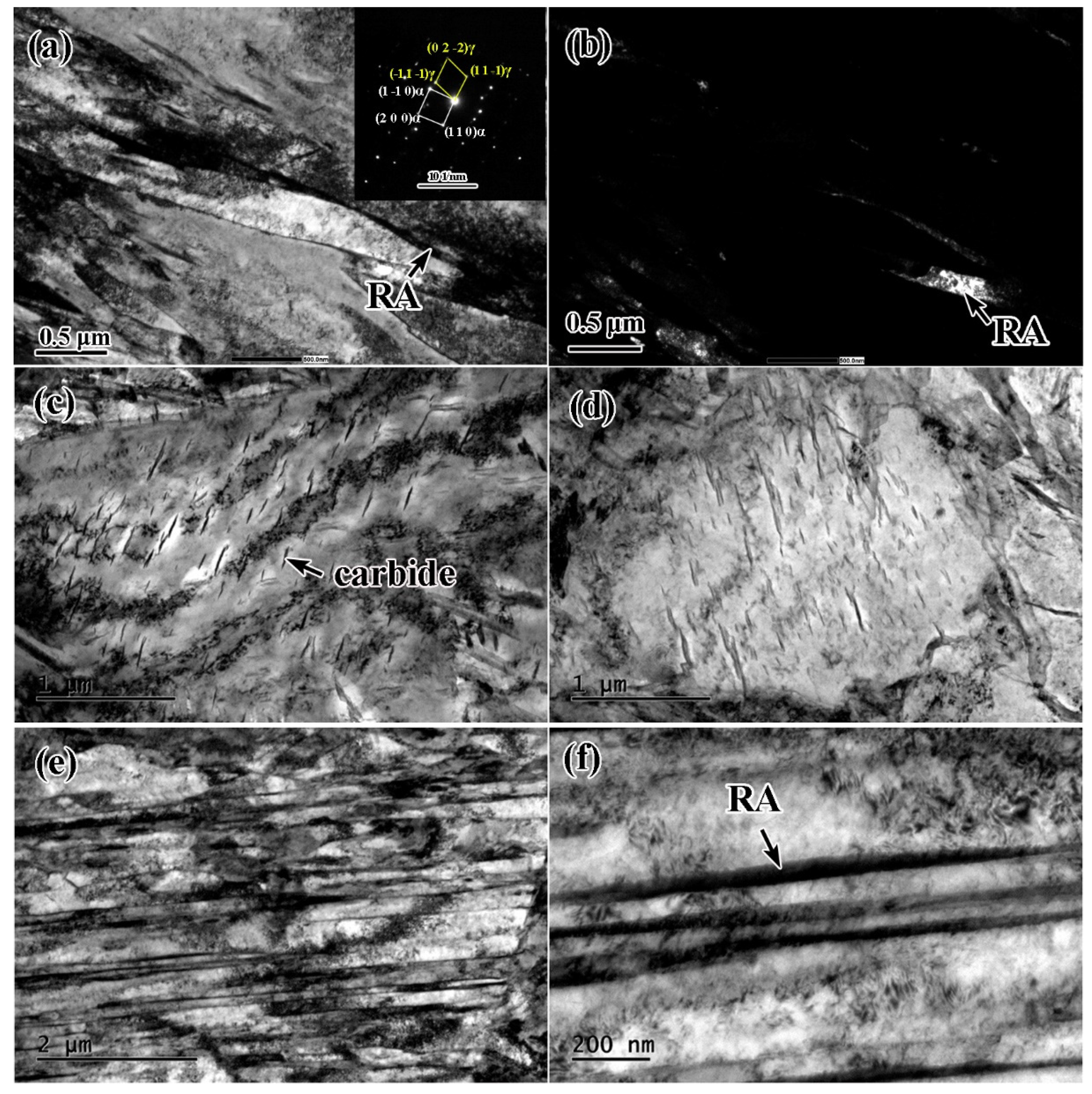

- The microstructure in the 1280 G bainitic rail steel is composed of granular bainite and coarse martensite/austenite islands. In contrast, the microstructure in the 1380 G bainitic rail steel is composed of fine lath bainite, lower bainite, carbon-depleted martensite, and film-like retained austenite.

- (2)

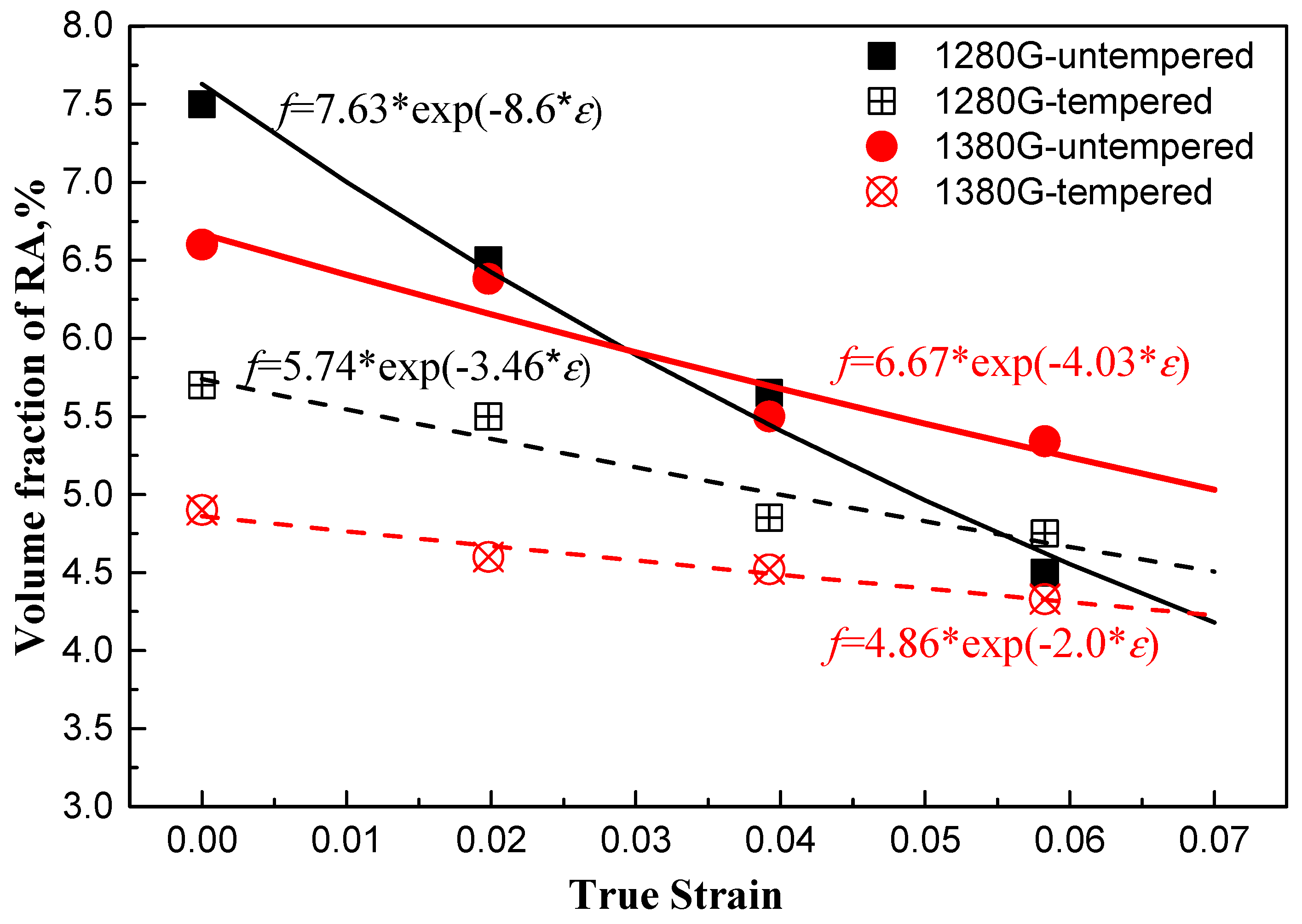

- The retained austenite in the 1380 G bainitic rail steel has higher mechanical stability compared with the 1280 G variant. This is mainly attributed to the small size of the film-like retained austenite in the 1380 G bainitic rail steel.

- (3)

- An excellent combination of strength, ductility, and toughness was achieved in the 1380 G bainitic rail steel (ultimate tensile strength: 1390 MPa; total elongation: 15%; impact toughness: 104 J; and fracture toughness at −20 °C: 107 MPa·m1/2). The enhanced mechanical properties are attributed to the refined microstructure and higher mechanical stability of the retained austenite.

- (4)

- The wear mass loss of the 1280 G bainitic rail steel (~1.03 g) is almost twice that of the 1380 G variant (~0.59 g) when the cyclic number reaches 7.5 × 105. Meanwhile, the rolling contact fatigue cracks are rarely found in the 1380 G rail steel. The improved performances of wear and rolling contact fatigue of the 1380 G bainitic rail steel are attributed to the resistance of plastic deformation and crack propagation.

Author Contributions

Funding

Data Availability Statement

Acknowledgments

Conflicts of Interest

References

- Olivares, R.O.; Garcia, C.I.; DeArdo, A.; Kalay, S.; Hernández, F.R. Advanced metallurgical alloy design and thermomechanical processing for rails steels for North American heavy haul use. Wear 2011, 271, 364–373. [Google Scholar] [CrossRef]

- Pan, R.; Ren, R.; Chen, C.; Zhao, X. The microstructure analysis of white etching layer on treads of rails—ScienceDirect. Eng. Fail. Anal. 2017, 82, 39–46. [Google Scholar] [CrossRef]

- Clayton, P.; Su, X. Surface initiated fatigue of pearlitic and bainitic steels under water lubricated rolling/sliding contact. Wear 1996, 200, 63–73. [Google Scholar] [CrossRef]

- Bhadeshia, H.K. High Performance Bainitic Steels. Mater. Sci. Forum 2005, 500–501, 63–74. [Google Scholar] [CrossRef]

- Yokoyama, H.; Mitao, S.; Yamamoto, S. High Strength Bainitic Steel Rails for Heavy Haul Railways with Superior Damage Resistance. Nkk Tech. Rev. 2001, 84, 44–51. [Google Scholar]

- Sawley, K.; Kristan, J. Development of bainitic rail steels with potential resistance to rolling contact fatigue. Fatigue Fract. Eng. Mater. Struct. 2010, 26, 1019–1029. [Google Scholar] [CrossRef]

- Pacyna, J. The microstructure and properties of the new bainitic rail steels. J. Achiev. Mater. Manuf. Eng. 2008, 28, 19–22. [Google Scholar]

- Bevan, A.; Jaiswal, J.; Smith, A.; Ojeda Cabral, M. Judicious Selection of Available Rail Steels to Reduce Life Cycle Costs. Proc. Inst. Mech. Eng. Part F J. Rail Rapid Transit 2018, 234, 257–275. [Google Scholar] [CrossRef]

- Kumar, A.; Makineni, S.; Dutta, A.; Goulas, C.; Steenbergen, M.; Petrov, R.; Sietsma, J. Design of high-strength and damage-resistant carbide-free fine bainitic steels for railway crossing applications. Mater. Sci. Eng. A 2019, 759, 210–223. [Google Scholar] [CrossRef]

- Hajizad, O.; Kumar, A.; Li, Z.; Petrov, R.H.; Sietsma, J.; Dollevoet, R. Influence of Microstructure on Mechanical Properties of Bainitic Steels in Railway Applications. Metals 2019, 9, 778. [Google Scholar] [CrossRef] [Green Version]

- Hasan, S.M.; Chakrabarti, D.; Singh, S.B. Dry rolling/sliding wear behaviour of pearlitic rail and newly developed carbide-free bainitic rail steels. Wear 2018, 408–409, 151–159. [Google Scholar] [CrossRef]

- Moon, A.P.; Sangal, S.; Layek, S.; Giribaskar, S.; Mondal, K. Corrosion Behavior of High-Strength Bainitic Rail Steels. Metall. Mater. Trans. A 2015, 46, 1500–1518. [Google Scholar] [CrossRef]

- Li, Y.; Zhang, F.; Chen, C.; Lv, B.; Yang, Z.; Zheng, C. Effects of deformation on the microstructures and mechanical properties of carbide-free bainitic steel for railway crossing and its hydrogen embrittlement characteristics. Mater. Sci. Eng. A 2016, 651, 945–950. [Google Scholar] [CrossRef]

- Gui, X.; Wang, K.; Gao, G.; Misra, R.D.K.; Tan, Z.; Bai, B. Rolling contact fatigue of bainitic rail steels: The significance of microstructure. Mater. Sci. Eng. A 2016, 657, 82–85. [Google Scholar] [CrossRef]

- Zhang, F.C.; Zheng, C.L.; Lv, B. Effects of hydrogen on the properties of bainitic steel crossing. Eng. Fail. Anal. 2009, 16, 1461–1467. [Google Scholar] [CrossRef]

- Gao, G.; Liu, R.; Fan, Y.; Qian, G.; Gui, X.; Misra, R.D.K.; Bai, B. Mechanism of subsurface microstructural fatigue crack initiation during high and very-high cycle fatigue of advanced bainitic steels. J. Mater. Sci. Technol. 2022, 108, 142–157. [Google Scholar] [CrossRef]

- Zhang, R.; Zheng, C.; Chen, C.; Lv, B.; Gao, G.; Yang, Z.; Yang, Y.; Zhang, F. Study on fatigue wear competition mechanism and microstructure evolution on the surface of a bainitic steel rail. Wear 2021, 482–483, 203978. [Google Scholar] [CrossRef]

- Schino, A.D. Analysis of phase transformation in high strength low alloyed steels. Metalurgija 2017, 56, 349–352. [Google Scholar]

- Gui, X.; Gao, G.; Guo, H.; Zhao, F.; Tan, Z.; Bai, B. Effect of bainitic transformation during BQ&P process on the mechanical properties in an ultrahigh strength Mn-Si-Cr-C steel. Mater. Sci. Eng. A 2017, 684, 598–605. [Google Scholar]

- Qiu, J.; Zhang, M.; Tan, Z.; Gao, G.; Bai, B. Research on the Microstructures and Mechanical Properties of Bainite/Martensite Rail Treated by the Controlled-Cooling Process. Materials 2019, 12, 3061. [Google Scholar] [CrossRef] [Green Version]

- Van Dijk, N.H.; Butt, A.M.; Zhao, L.; Sietsma, J.; Offerman, S.E.; Wright, J.P.; Van Der Zwaag, S. Thermal stability of retained austenite in TRIP steels studied by synchrotron X-ray diffraction during cooling. Acta Mater. 2005, 53, 5439–5447. [Google Scholar] [CrossRef]

- Zhu, J.; Tan, Z.; Tian, Y.; Gao, B.; Zhang, M.; Wang, J.; Weng, Y. Effect of Tempering Temperature on Microstructure and Mechanical Properties of Bainitic Railway Wheel Steel with Thermal Damage Resistance by Alloy Design. Metals 2020, 10, 1221. [Google Scholar] [CrossRef]

- Li, Q.G.; Huang, X.F.; Huang, W.G. Fatigue property and microstructure deformation behavior of multiphase microstructure in a medium-carbon bainite steel under rolling contact condition. Int. J. Fatigue 2019, 125, 381–393. [Google Scholar] [CrossRef]

- Zhang, L.M. Analysis of Wheel/Rail Contact Stresses and Rail Corrugation. J. South West Jiaotong Univ. 2003, 38, 1. [Google Scholar]

- Forouzan, F.; Borasi, L.; Vuorinen, E.; Mücklich, F. Optimization of Quenching Temperature to Minimize the Micro Segregation Induced Banding Phenomena in Quenching and Partitioning (Q&P) Steels. Steel Res. Int. 2018, 90, 1800281. [Google Scholar]

- Li, Q.G.; Huang, X.F.; Huang, W.G. Microstructure and mechanical properties of a medium-carbon bainitic steel by a novel quenching and dynamic partitioning (Q-DP) process. Mater. Sci. Eng. A 2016, 662, 129–135. [Google Scholar] [CrossRef]

- Liu, M.; Wang, J.; Zhang, Q.; Hu, H.; Xu, G. Optimized Properties of a Quenching and Partitioning Steel by Quenching at Fine Martensite Start Temperature. Met. Mater. Int. 2021, 27, 2473–2480. [Google Scholar] [CrossRef]

- Gao, G.; Wang, K.; Su, H.; Gui, X.; Li, Z.; Misra, R.D.K.; Bai, B. The potential of mechanical twinning in ultrafine retained austenite to enhance high cycle fatigue property of advanced bainitic steels. Int. J. Fatigue 2020, 139, 105804. [Google Scholar] [CrossRef]

- Schino, A.D.; Gaggiotti, M.; Testani, C. Heat Treatment Effect on Microstructure Evolution in a 7% Cr Steel for Forging. Metals 2020, 10, 808. [Google Scholar] [CrossRef]

- Peng, F.; Xu, Y.; Gu, X.; Wang, Y.; Liu, X.; Li, J. The relationships of microstructure-mechanical properties in quenching and partitioning (Q&P) steel accompanied with microalloyed carbide precipitation. Mater. Sci. Eng. A 2018, 723, 247–258. [Google Scholar]

- Sugimoto, K.I.; Kobayashi, M.; Hashimoto, S.I. Ductility and strain-induced transformation in a high-strength transformation-induced plasticity-aided dual-phase steel. Metall. Trans. A 1992, 23, 3085–3091. [Google Scholar] [CrossRef]

- Trummer, G.; Marte, C.; Dietmaier, P.; Sommitsch, C.; Six, K. Modeling surface rolling contact fatigue crack initiation taking severe plastic shear deformation into account. Wear 2016, 352–353, 136–145. [Google Scholar] [CrossRef]

- Chen, Y.; Ren, R.; Zhao, X.; Chen, C.; Pan, R. Study on the surface microstructure evolution and wear property of bainitic rail steel under dry sliding wear. Wear 2020, 448–449, 203217. [Google Scholar] [CrossRef]

- Zhong, W.; Hu, J.; Shen, P.; Wang, C.; Lius, Q. Experimental investigation between rolling contact fatigue and wear of high-speed and heavy-haul railway and selection of rail material. Wear 2011, 271, 2485–2493. [Google Scholar] [CrossRef]

| Sample | C | Mn | Si | Cr | Ni | Mo |

|---|---|---|---|---|---|---|

| Bainitic rail | 0.2 | 2.2 | 1.0 | 1.0 | 0.5 | 0.3 |

| Sample | RA % (Untempered) | C % in RA (Untempered) | RA % (Tempered) | C % in RA (Tempered) |

|---|---|---|---|---|

| 1280G | 7.5 vol.% | 1.34 wt.% | 5.6 % | 1.39% |

| 1380G | 6.6 vol.% | 1.14 wt.% | 4.9% | 1.17% |

| Sample | Rm, MPa | Rp, MPa | A, % | AKU, J | KIC at −20 °C, MPa·m1/2 |

|---|---|---|---|---|---|

| 1280G | 1335 ± 8 | 1208 ± 12 | 14.5 ± 0.5 | 79 ± 2 | 77 ± 12 |

| 1380G | 1390 ± 5 | 1263 ± 10 | 15.0 ± 0.5 | 104 ± 1 | 107 ± 4 |

Publisher’s Note: MDPI stays neutral with regard to jurisdictional claims in published maps and institutional affiliations. |

© 2022 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (https://creativecommons.org/licenses/by/4.0/).

Share and Cite

Liu, M.; Fan, Y.; Gui, X.; Hu, J.; Wang, X.; Gao, G. Relationship between Microstructure and Properties of 1380 MPa Grade Bainitic Rail Steel Treated by Online Bainite-Based Quenching and Partitioning Concept. Metals 2022, 12, 330. https://doi.org/10.3390/met12020330

Liu M, Fan Y, Gui X, Hu J, Wang X, Gao G. Relationship between Microstructure and Properties of 1380 MPa Grade Bainitic Rail Steel Treated by Online Bainite-Based Quenching and Partitioning Concept. Metals. 2022; 12(2):330. https://doi.org/10.3390/met12020330

Chicago/Turabian StyleLiu, Miao, Yusong Fan, Xiaolu Gui, Jie Hu, Xi Wang, and Guhui Gao. 2022. "Relationship between Microstructure and Properties of 1380 MPa Grade Bainitic Rail Steel Treated by Online Bainite-Based Quenching and Partitioning Concept" Metals 12, no. 2: 330. https://doi.org/10.3390/met12020330

APA StyleLiu, M., Fan, Y., Gui, X., Hu, J., Wang, X., & Gao, G. (2022). Relationship between Microstructure and Properties of 1380 MPa Grade Bainitic Rail Steel Treated by Online Bainite-Based Quenching and Partitioning Concept. Metals, 12(2), 330. https://doi.org/10.3390/met12020330