Modeling of Laser Melting Deposition Equipment Based on Digital Twin

Abstract

:1. Introduction

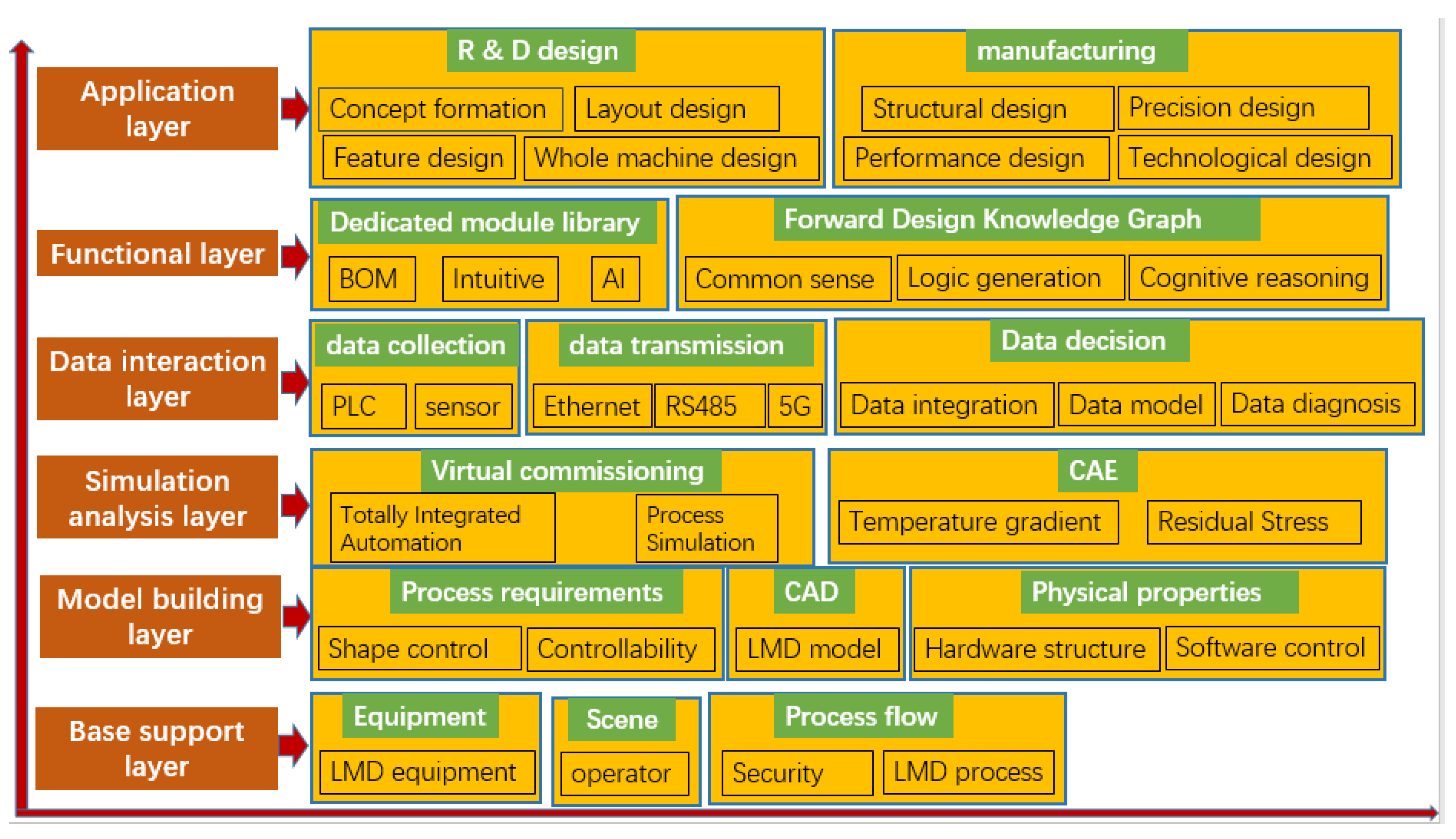

2. Structure Frame of LMD Equipment Based on Digital Twin

3. LMD Equipment Model Based on Digital Twin

3.1. Virtual Assembly

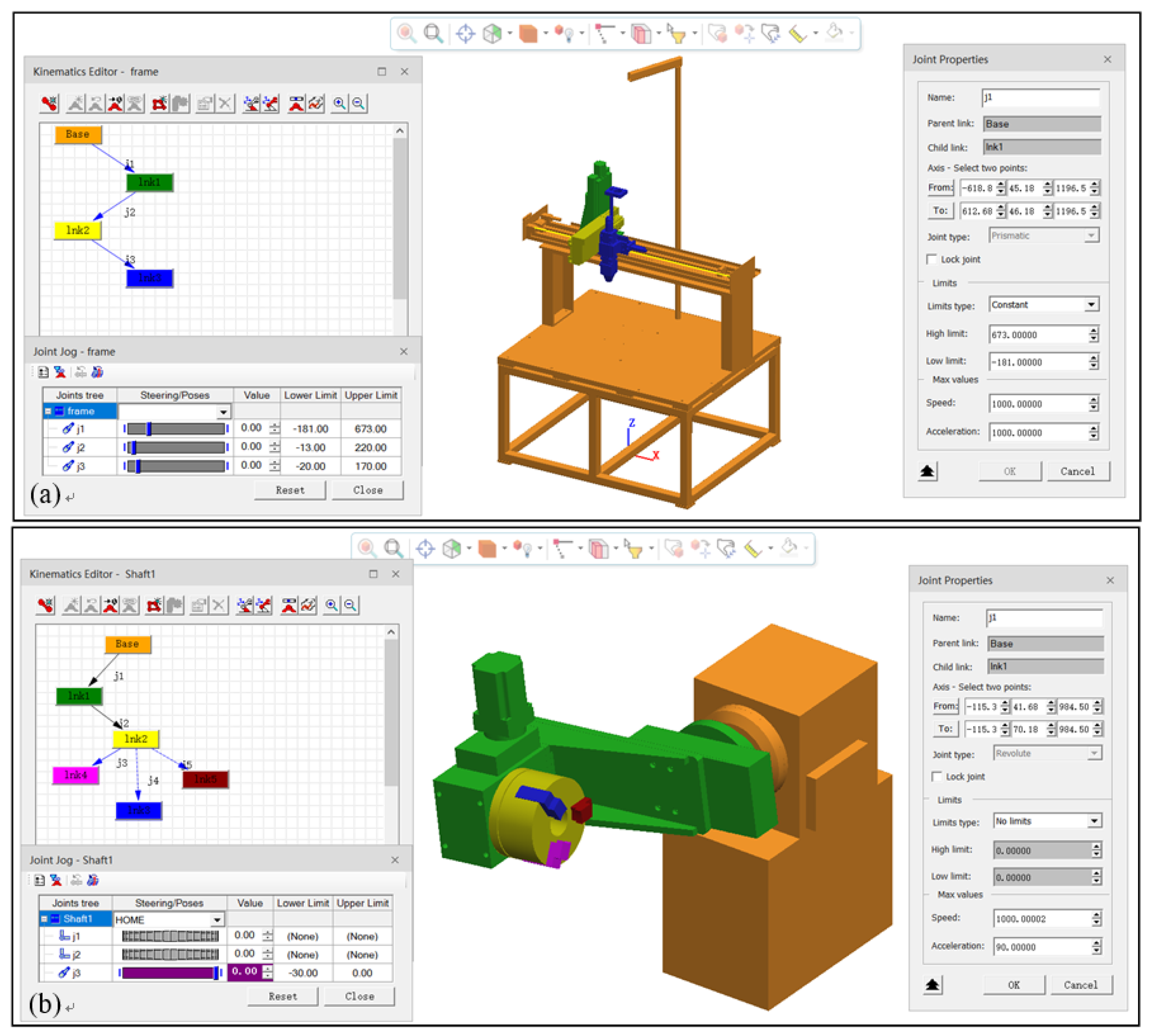

3.2. Sports Settings

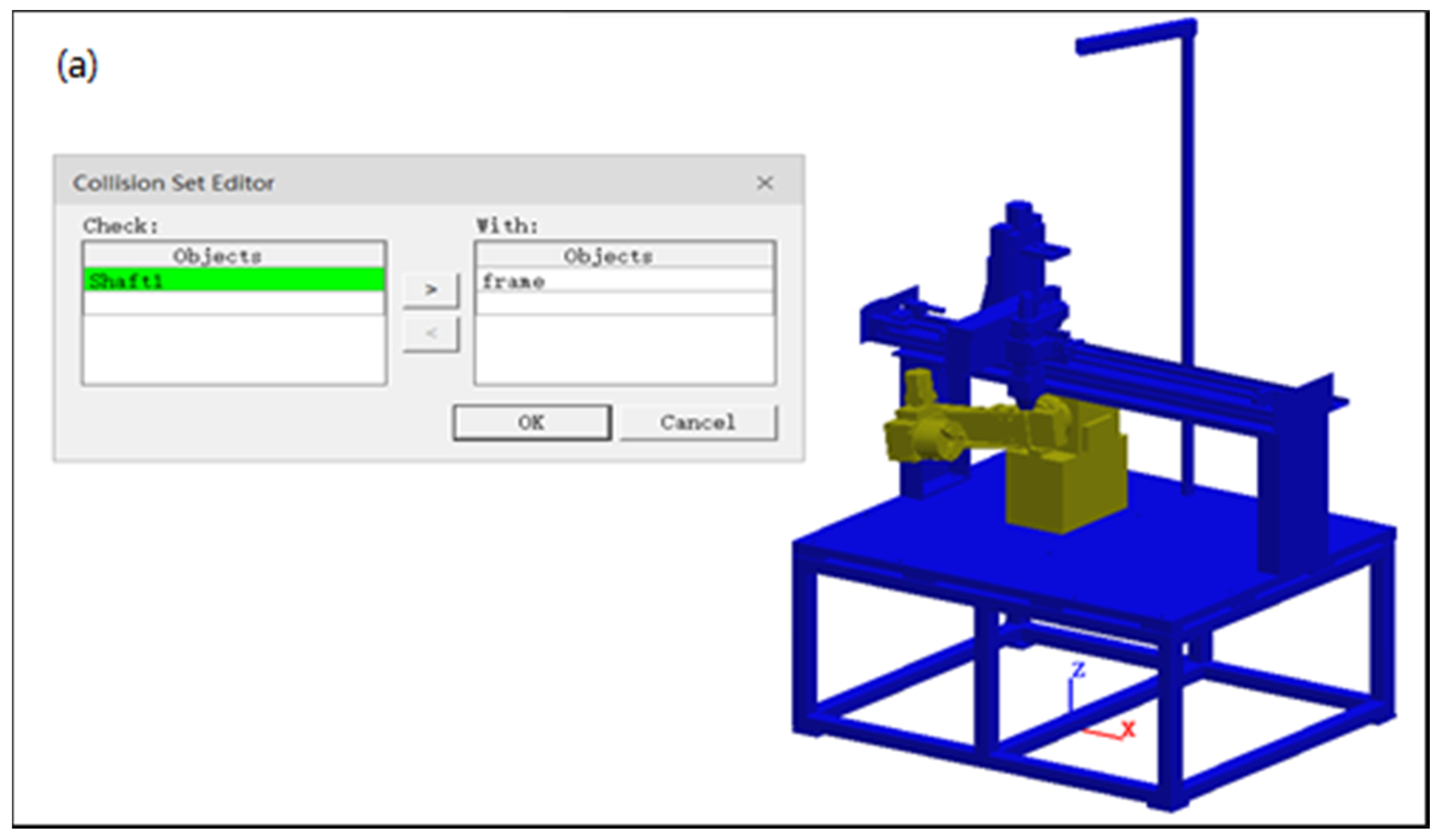

3.3. Collision Inspection

3.4. PLC Debugging

4. Conclusions

Author Contributions

Funding

Institutional Review Board Statement

Informed Consent Statement

Data Availability Statement

Conflicts of Interest

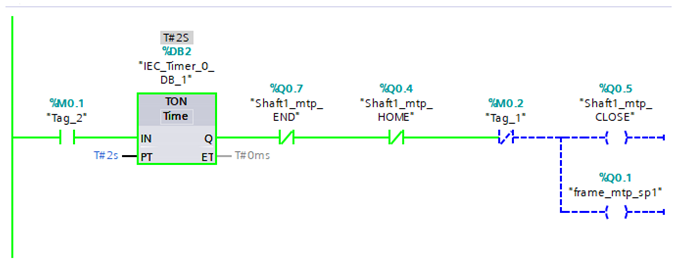

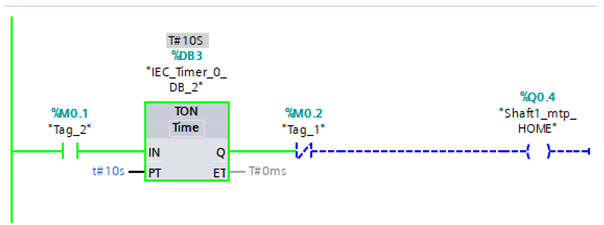

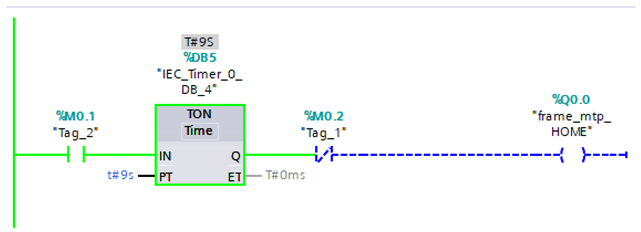

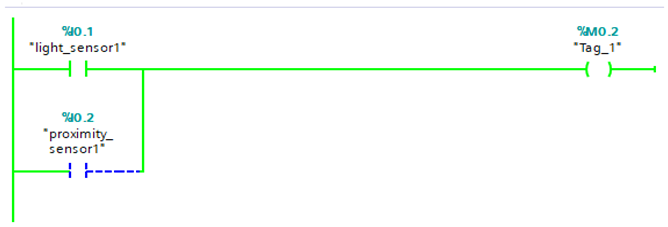

Appendix A. PLC Programming for Virtual Check of Safety Warning

References

- Tao, F.; Zhang, L.; Lu, K.; Zhao, D. Research on manufacturing grid resource service optimal-selection and composition framework. Enterp. Inf. Syst. 2012, 6, 237–264. [Google Scholar] [CrossRef]

- Tao, F.; Feng, Y.; Zhang, L.; Liao, T.W. CLPS-GA: A case library and Pareto solution-based hybrid genetic algorithm for en-ergy-aware cloud service scheduling. Appl. Soft Comput. 2014, 19, 264–279. [Google Scholar] [CrossRef]

- Tao, F.; Zhang, M. Digital Twin Shop-Floor: A New Shop-Floor Paradigm towards Smart Manufacturing. IEEE Access 2017, 5, 20418–20427. [Google Scholar] [CrossRef]

- Grieves, M. Virtually Perfect: Driving Innovate and Lean Products through Product Levycle Management; NCMS: Ann Arobr, MI, USA, 2011. [Google Scholar]

- Tao, F.; Sui, F.; Liu, A.; Qi, Q.; Zhang, M.; Song, B.; Guo, Z.; Lu, S.C.-Y.; Nee, A.Y.C. Digital twin-driven product design framework. Int. J. Prod. Res. 2019, 57, 3935–3953. [Google Scholar] [CrossRef] [Green Version]

- Tao, F.; Cheng, J.; Qi, Q.; Zhang, M.; Zhang, H.; Sui, F. Digital twin-driven product design, manufacturing and service with big data. Int. J. Adv. Manuf. Technol. 2018, 94, 3563–3576. [Google Scholar] [CrossRef]

- Singh, V.; Willcox, K.E. Engineering Design with Digital Thread. AIAA J. 2018, 56, 4515–4528. [Google Scholar] [CrossRef]

- Helu, M.; Joseph, A.; Hedberg, T. A standards-based approach for linking as-planned to as-fabricated product data. CIRP Ann. 2018, 67, 487–490. [Google Scholar] [CrossRef] [PubMed]

- Rosen, R.; Heinzerling, T.; Schmidt, P. The role of simulation in the context of digital twins Virtual commissioning models as mediator between phases and applications. ATP Mag. 2021, 4, 82–89. [Google Scholar] [CrossRef]

- Stavropoulos, P.; Papacharalampopoulos, A.; Athanasopoulou, L. A molecular dynamics based digital twin for ultrafast laser material removal processes. Int. J. Adv. Manuf. Technol. 2020, 108, 413–426. [Google Scholar] [CrossRef]

- Haberland, C.; Elahinia, M.; Walker, J.M.; Meier, H.; Frenzel, J. On the development of high quality NiTi shape memory and pseudoelastic parts by additive manufacturing. Smart Mater. Struct. 2014, 23, 2. [Google Scholar] [CrossRef]

- Breuninger, J. Additive manufacturing: Challenges and advantages for the medical industry. Puerto Rico Health Sci. J. 2000, 19, 57. [Google Scholar]

- Xu, W.; Lui, E.; Pateras, A.; Qian, M.; Brandt, M. In situ tailoring microstructure in additively manufactured Ti-6Al-4V for superior mechanical performance. Acta Mater. 2017, 125, 390–400. [Google Scholar] [CrossRef]

- Abdel-latif, M.; Abdel-Ghany, K.; El-Mahallawy, N. Effect of Laser Speed on Microstructure and Mechanical Properties of AISI H13 Tool Steel Prepared by Laser Powder Bed Fusion Process. J. Mater. Eng. Perform. 2021, 30, 8821–8830. [Google Scholar] [CrossRef]

- Yu, L.; Chen, K.; Zhang, Y.L.; Liu, J.; Yang, L.; Shi, Y. Microstructures and mechanical properties of NiTi shape memory alloys fabricated by wire arc additive manufacturing. J. Alloys Compd. 2022, 892, 162193. [Google Scholar] [CrossRef]

- Tang, L.; Landers, R.G. Melt Pool Temperature Control for Laser Metal Deposition Processes-Part I: Online Temper-ature Control. J. Manuf. Sci. Eng. 2010, 132, 1. [Google Scholar] [CrossRef]

- Cui, X.; Zhang, S.; Zhang, C.; Chen, J.; Zhang, J.; Dong, S. A comparison on microstructure features of 24CrNiMo low alloy steel prepared by selective laser melting and laser melting deposition. Vacuum 2021, 191, 110394. [Google Scholar] [CrossRef]

- Chekotu, J.C.; Groarke, R.; O’Toole, K.; Brabazon, D. Advances in Selective Laser Melting of Nitinol Shape Memory Alloy Part Production. Materials 2019, 12, 809. [Google Scholar] [CrossRef] [Green Version]

- Wang, X.; Kustov, S.; Van Humbeeck, J. A Short Review on the Microstructure, Transformation Behavior and Functional Properties of NiTi Shape Memory Alloys Fabricated by Selective Laser Melting. Materials 2018, 11, 1683. [Google Scholar] [CrossRef] [Green Version]

- Gu, D.; Meiners, W.; Wissenbach, K.; Poprawe, R. Laser additive manufacturing of metallic components: Materials, processes and mechanisms. Int. Mater. Rev. 2012, 57, 133–164. [Google Scholar] [CrossRef]

- Wang, T.; Zhu, Y.Y.; Zhang, S.Q.; Tang, H.B.; Wang, H.M. Grain morphology evolution behavior of titanium alloy com-ponents during laser melting deposition additive manufacturing. J. Alloys Compd. 2015, 623, 505–513. [Google Scholar] [CrossRef]

- Chen, X.; Liu, K.; Guo, W.; Gangil, N.; Siddiquee, A.N.; Konovalov, S. The fabrication of NiTi shape memory alloy by selec-tive laser melting: A review. Rapid Prototyp. J. 2019, 25, 1421–1432. [Google Scholar] [CrossRef]

- Huang, Y.; Leu, M.C.; Mazumder, J.; Donmez, A. Additive Manufacturing: Current State, Future Potential, Gaps and Needs, and Recommendations. J. Manuf. Sci. Eng. 2015, 137, 014001. [Google Scholar] [CrossRef] [Green Version]

- Wagener, R.; Scurria, M.; Bein, T. About a Digital Twin for the Fatigue Approach of Additively Manufactured Components. In Proceedings of the 11th International Conference on Porous Metals and Metallic Foams (MetFoam 2019); Springer: Berlin/Heidelberg, Germany, 2019; pp. 371–382. [Google Scholar]

- DebRoy, T.; Zhang, W.; Turner, J.; Babu, S.S. Building digital twins of 3D printing machines. Scr. Mater. 2017, 135, 119–124. [Google Scholar] [CrossRef]

- Bhatt, P.M.; Kulkarni, A.; Malhan, R.K.; Shah, B.C.; Yoon, Y.J.; Gupta, S.K. Automated Planning for Robotic Multi-Resolution Additive Manufacturing. J. Comput. Inf. Sci. Eng. 2022, 22, 1–18. [Google Scholar] [CrossRef]

- Liu, J.; Li, G.; Sun, Q.; Li, H.; Sun, J.; Wang, X. Understanding the effect of scanning strategies on the microstructure and crystallographic texture of Ti-6Al-4V alloy manufactured by laser powder bed fusion. J. Mater. Process. Technol. 2021, 299, 117366. [Google Scholar] [CrossRef]

- Knapp, G.L.; Mukherjee, T.; Zuback, J.S.; Wei, H.L.; Palmer, T.A.; De, A.; DebRoy, T. Building blocks for a digital twin of additive manufacturing. Acta Mater. 2017, 135, 390–399. [Google Scholar] [CrossRef]

- Klingaa, C.; Mohanty, S.; Funch, C.; Hjermitslev, A.; Haahr-Lillevang, L.; Hattel, J. Towards a digital twin of laser powder bed fusion with a focus on gas flow variables. J. Manuf. Process. 2021, 65, 312–327. [Google Scholar] [CrossRef]

- Stavropoulos, P.; Papacharalampopoulos, A.; Michail, C.K.; Chryssolouris, G. Robust Additive Manufacturing Performance through a Control Oriented Digital Twin. Metals 2021, 11, 708. [Google Scholar] [CrossRef]

- Wang, H.; Hu, Y.; Ning, F.; Cong, W. Ultrasonic vibration-assisted laser engineered net shaping of Inconel 718 parts: Effects of ultrasonic frequency on microstructural and mechanical properties. J. Mater. Process. Technol. 2020, 276, 116395. [Google Scholar] [CrossRef]

- Khamidullin, B.; Tsivilskiy, I.; Gorunov, A.; Gilmutdinov, A. Modeling of the effect of powder parameters on laser cladding using coaxial nozzle. Surf. Coat. Technol. 2019, 364, 430–443. [Google Scholar] [CrossRef]

- Zhang, Z.; Kovacevic, R. A thermo-mechanical model for simulating the temperature and stress distribution during laser cladding process. Int. J. Adv. Manuf. Technol. 2019, 102, 457–472. [Google Scholar] [CrossRef]

- DebRoy, T.; Wei, H.L.; Zuback, J.S.; Mukherjee, T.; Elmer, J.W.; Milewski, J.O.; Beese, A.M.; Wilson-Heid, A.; De, A.; Zhang, W. Additive manufacturing of metallic components–Process, structure and properties. Prog. Mater. Sci. 2018, 92, 112–224. [Google Scholar] [CrossRef]

- Nassar, A.R.; Keist, J.; Reutzel, E.; Spurgeon, T.J. Intra-layer closed-loop control of build plan during directed energy additive manufacturing of Ti–6Al–4V. Addit. Manuf. 2015, 6, 39–52. [Google Scholar] [CrossRef]

- Farshidianfar, M.H.; Khajepour, A.; Gerlich, A.P. Real-time control of microstructure in laser additive manufacturing. Int. J. Adv. Manuf. Technol. 2016, 82, 1173–1186. [Google Scholar] [CrossRef]

Publisher’s Note: MDPI stays neutral with regard to jurisdictional claims in published maps and institutional affiliations. |

© 2022 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (https://creativecommons.org/licenses/by/4.0/).

Share and Cite

Feng, A.; Chen, C.; Wu, C.; Wei, Y.; Wang, Y. Modeling of Laser Melting Deposition Equipment Based on Digital Twin. Metals 2022, 12, 169. https://doi.org/10.3390/met12020169

Feng A, Chen C, Wu C, Wei Y, Wang Y. Modeling of Laser Melting Deposition Equipment Based on Digital Twin. Metals. 2022; 12(2):169. https://doi.org/10.3390/met12020169

Chicago/Turabian StyleFeng, Aixin, Chunlun Chen, Chengmeng Wu, Yacheng Wei, and Yu Wang. 2022. "Modeling of Laser Melting Deposition Equipment Based on Digital Twin" Metals 12, no. 2: 169. https://doi.org/10.3390/met12020169

APA StyleFeng, A., Chen, C., Wu, C., Wei, Y., & Wang, Y. (2022). Modeling of Laser Melting Deposition Equipment Based on Digital Twin. Metals, 12(2), 169. https://doi.org/10.3390/met12020169