Stress Corrosion Cracking of Tunnel Ventilation Fan Blades: A Case Study

Abstract

1. Introduction

1.1. Tunnel Installations

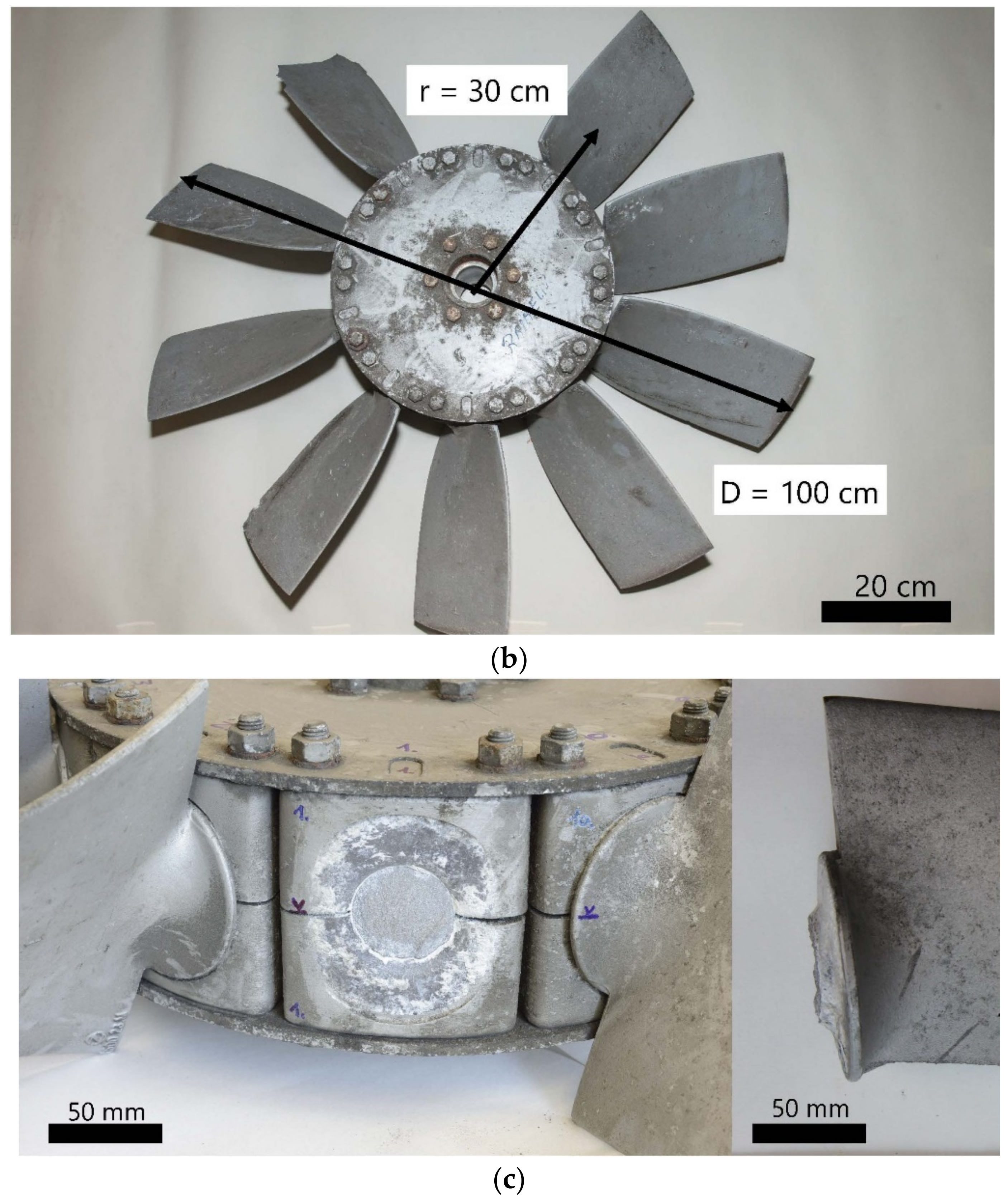

1.2. Description of the Failed Fans

1.3. Circumstances of the Event

1.4. Examinations on Site of the 2015 Event

2. Test Plan

- Visual inspection of the interfaces between the mounting and the blades;

- Corrosion chemistry analysis of the corrosion products found;

- Determination of chemical composition;

- Determination of material properties: static strength, impact fracture energy, fatigue and corrosion fatigue data;

- Fractography of the fracture surface;

- Metallography;

- Geometrical characterization and tip clearance measurement.

3. Investigations on the Failed Part and on a Reference Part

3.1. Visual Inspection

3.2. Corrosion Chemistry

3.3. Chemical Composition of the Aluminum Alloy

3.4. Mechanical Properties

3.5. Macroscopic and Microscopic Fractography

3.6. Metallography

3.7. Clearance Measurement

3.8. Intermediate Conclusions

4. Fracture Mechanics Assessment

- Estimation of fracture toughness of the material;

- Determination of the normalized stress intensity of the critical crack front size;

- Determination of the stress level at the fractured cross section.

4.1. Estimation of Fracture Toughness

4.2. Determination of Stress Intensity

4.3. Determination of Stress Level in the Critical Cross Section under Service Loads

4.4. Determination of Stress Intensity under Service Loads

4.5. Intermediate Conclusions

- A material sensitive to stress corrosion cracking by hydrogen embrittlement;

- Corrosive environment;

- High tensile stresses in the component acting for a long time.

5. Hypothesis for High Tensile Stresses in the Root of the Blades

6. Assessment of the Corrosion, Fatigue, and Corrosion Fatigue Properties of Aluminum Alloys

6.1. Evaluation of the Corrosion Resistance

6.2. Evaluation of Fatigue Properties

6.3. Evaluation of Corrosion Fatigue Properties

7. Discussion

8. Conclusions

- (1)

- Formation of a crack

- (2)

- Propagation of the crack

- (3)

- Final fracture

- (4)

- Correction actions

Author Contributions

Funding

Informed Consent Statement

Data Availability Statement

Acknowledgments

Conflicts of Interest

References

- ASTRA. Fachhandbuch Tunnel/Geotechnik: Technisches Merkblatt 24001–10304. Available online: https://www.astra.admin.ch/astra/de/home/fachleute/dokumente-nationalstrassen/fachdokumente/fachunterstuetzung/fachhandbuch-tunnel-geotechnik.html (accessed on 8 August 2022).

- ASTRA. Fachhandbuch BSA: Technisches Merkblatt 23001–12120 Werkstoffwahl und Korrosionsschutz. Available online: https://www.astra.admin.ch/astra/de/home/fachleute/dokumente-nationalstrassen/fachdokumente/fachunterstuetzung/fachhandbuch-betriebs-sicherheitsausruestungen.html (accessed on 3 August 2022).

- EN 12101-3:2015; Rauch- und Wärmefreihaltung—Teil 3: Bestimmungen für Maschinelle Rauch- und Wärmeabzugsgeräte. DIN: Berlin, Germany, 2015.

- Tuchschmid, M.; Werner, R. Vergleichende Untersuchungen Korrosiver Brandgaskondensate; Allianz: Wallisellen, Switzerland, 2001. [Google Scholar]

- EN 1706; Aluminium and Aluminium Alloys–Castings–Chemical Composition and Mechanical Properties. DIN: Berlin, Germany, 2010.

- Konečná, R.; Nicoletto, G.; Kunz, L.; Svoboda, M.; Bača, A. Fatigue Strength Degradation of AlSi12CuNiMg Alloy Due to High Temperature Exposure: A Structural Investigation. Procedia Eng. 2014, 74, 43–46. [Google Scholar] [CrossRef]

- Braun, R. On the stress corrosion cracking behaviour of 6XXX series aluminium alloys. Int. J. Mater. Res. 2010, 101, 657–668. [Google Scholar] [CrossRef]

- ISO. 6892-1; Metallic Materials—Tensile Testing—Part 1: Method of Test at Room Temperature. ISO: Vernier, Switzerland, 2016.

- ISO. 148-1; Metallic Materials—Charpy Pendulum Impact Test—Part 1: Test Method. ISO: Vernier, Switzerland, 2016.

- Schindler, H.J.; Morf, U. A Closer Look at Estimation of Fracture-Toughness from Charpy V-Notch Tests. Int. J. Press. Vessel. Pip. 1993, 55, 203–212. [Google Scholar] [CrossRef]

- Ranganatha, S.; Srinivasan, M.N. Fracture toughness of cast aluminium alloys. Bull. Mater. Sci. 1982, 4, 29–35. [Google Scholar] [CrossRef]

- Peterson, R.E. Stress Concentration Factors; John Wiley & Sons: New York, NY, USA, 1974. [Google Scholar]

- Total Material Database “Stress Corrosion Cracking of Alumnium Alloys”. Available online: http://www.totalmateria.com/Article17.htm (accessed on 3 August 2022).

- Davis, J.R. Corrosion of Aluminum and Aluminum Alloys; ASM International: Almere, The Netherlands, 1999. [Google Scholar]

- Speidel, M.O. Hydrogen Embrittlement of Aluminium Alloys? In Hydrogen in Metals; ASM International: Almere, The Netherlands, 1974; pp. 249–271. [Google Scholar]

- Lynch, S.P. Mechanisms of Hydrogen-Assisted Cracking. Met. Forum 1979, 2, 189–200. [Google Scholar]

- Gest, R.J.; Troiano, A.R. Stress Corrosion and Hydrogen Embrittlement in an Aluminum Alloy. Corrosion 1974, 30, 274–279. [Google Scholar] [CrossRef]

- DIN. 50100; Load Controlled Fatigue Testing—Execution and Evaluation of Cyclic Tests at Constant Load Amplitudes on Metallic Specimens and Components. DIN: Berlin, Germany, 2015.

- EN 50113; Prüfung metallischer Werkstoffe-Umlaufbiegeversuch. DIN: Berlin, Germany, 2018.

| Variable | Failure Case 2015 |

|---|---|

| Rotor diameter D | 1000 mm |

| Number of blades | 10 |

| Root minimum diameter, D1 | 44 mm |

| Root outer diameter, D2 | 58 mm |

| Radius of the root to platform transition, ρ | 10 mm |

| Blade total weight | 2.2 kg |

| Blade wing weight | 1.9 kg |

| Center of gravity of blade wing, r | 0.3 m |

| Material | Rest Potential (mVSCE) * | Free Corrosion Current Density at Rest Potential (µA/cm2) | Corrosion Velocity ** (mm/a) | Pitting Corrosion Potential (mVSCE) * |

|---|---|---|---|---|

| AlSi1MgMn (6082-T4) | −860 | 3 | 0.03 | −720 |

| AlSi9Mg (EN AC-43300-T5) | −760 | 2 | 0.02 | −760 |

| AlSi10MnMg (EN AC-43500-T5) | −730 | 2.5 | 0.03 | −730 |

| AlSi12CuMgNi (EN AC-48000-T5) | −680 | 9.5 | 0.1 | −720 |

| Al (99 %) | −780 | 0.6 | 0.006 | −650 |

Publisher’s Note: MDPI stays neutral with regard to jurisdictional claims in published maps and institutional affiliations. |

© 2022 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (https://creativecommons.org/licenses/by/4.0/).

Share and Cite

Michel, S.; Tuchschmid, M.; Sauder, M.; Frey, S. Stress Corrosion Cracking of Tunnel Ventilation Fan Blades: A Case Study. Metals 2022, 12, 2065. https://doi.org/10.3390/met12122065

Michel S, Tuchschmid M, Sauder M, Frey S. Stress Corrosion Cracking of Tunnel Ventilation Fan Blades: A Case Study. Metals. 2022; 12(12):2065. https://doi.org/10.3390/met12122065

Chicago/Turabian StyleMichel, Silvain, Martin Tuchschmid, Martin Sauder, and Simon Frey. 2022. "Stress Corrosion Cracking of Tunnel Ventilation Fan Blades: A Case Study" Metals 12, no. 12: 2065. https://doi.org/10.3390/met12122065

APA StyleMichel, S., Tuchschmid, M., Sauder, M., & Frey, S. (2022). Stress Corrosion Cracking of Tunnel Ventilation Fan Blades: A Case Study. Metals, 12(12), 2065. https://doi.org/10.3390/met12122065