Process Stability and Material Properties of TC4 Alloy Welded by Bypass Current Hot Wire Plasma Arc Welding (BC-PAW)

Abstract

1. Introduction

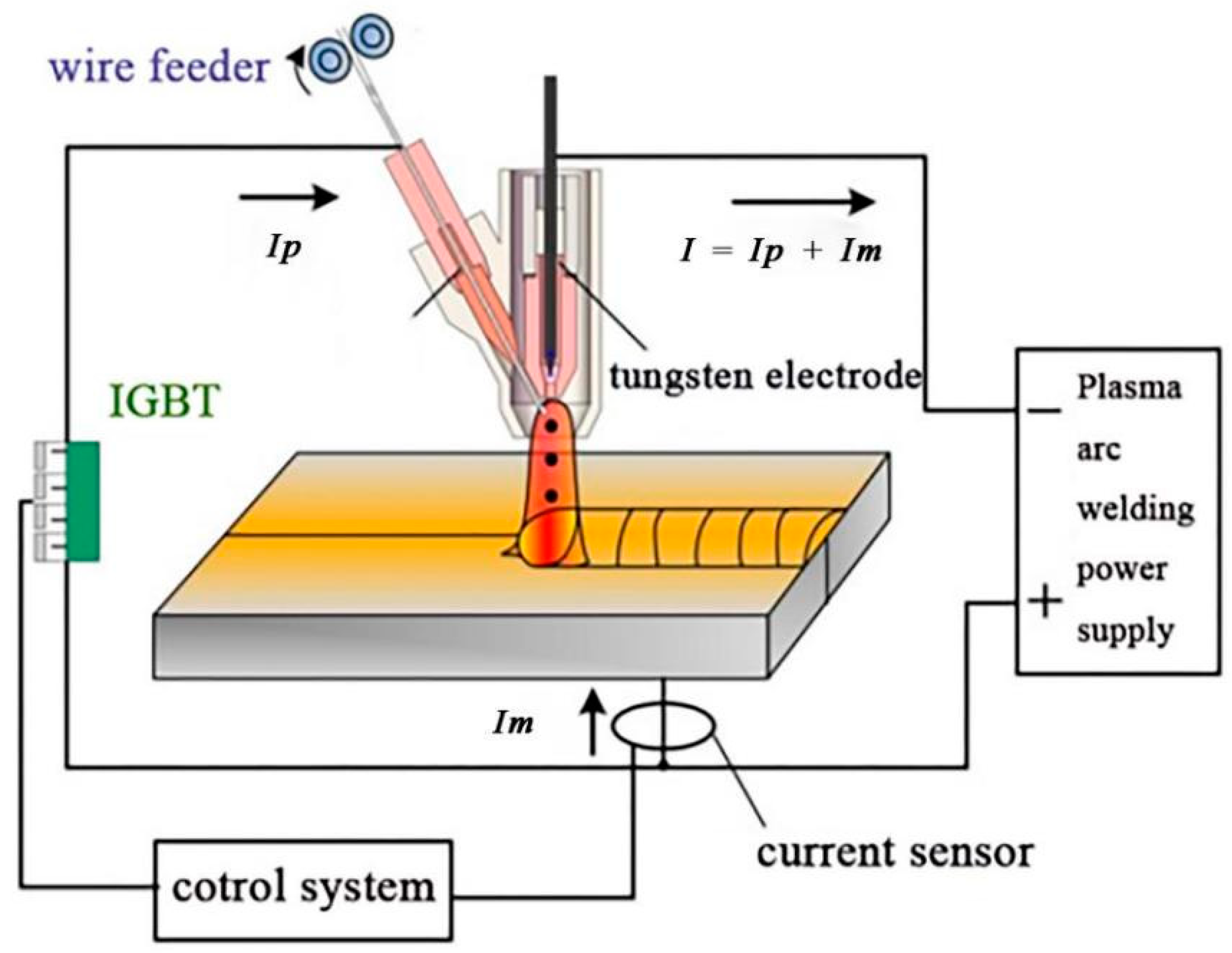

2. Materials and Methods

3. Results and Discussion

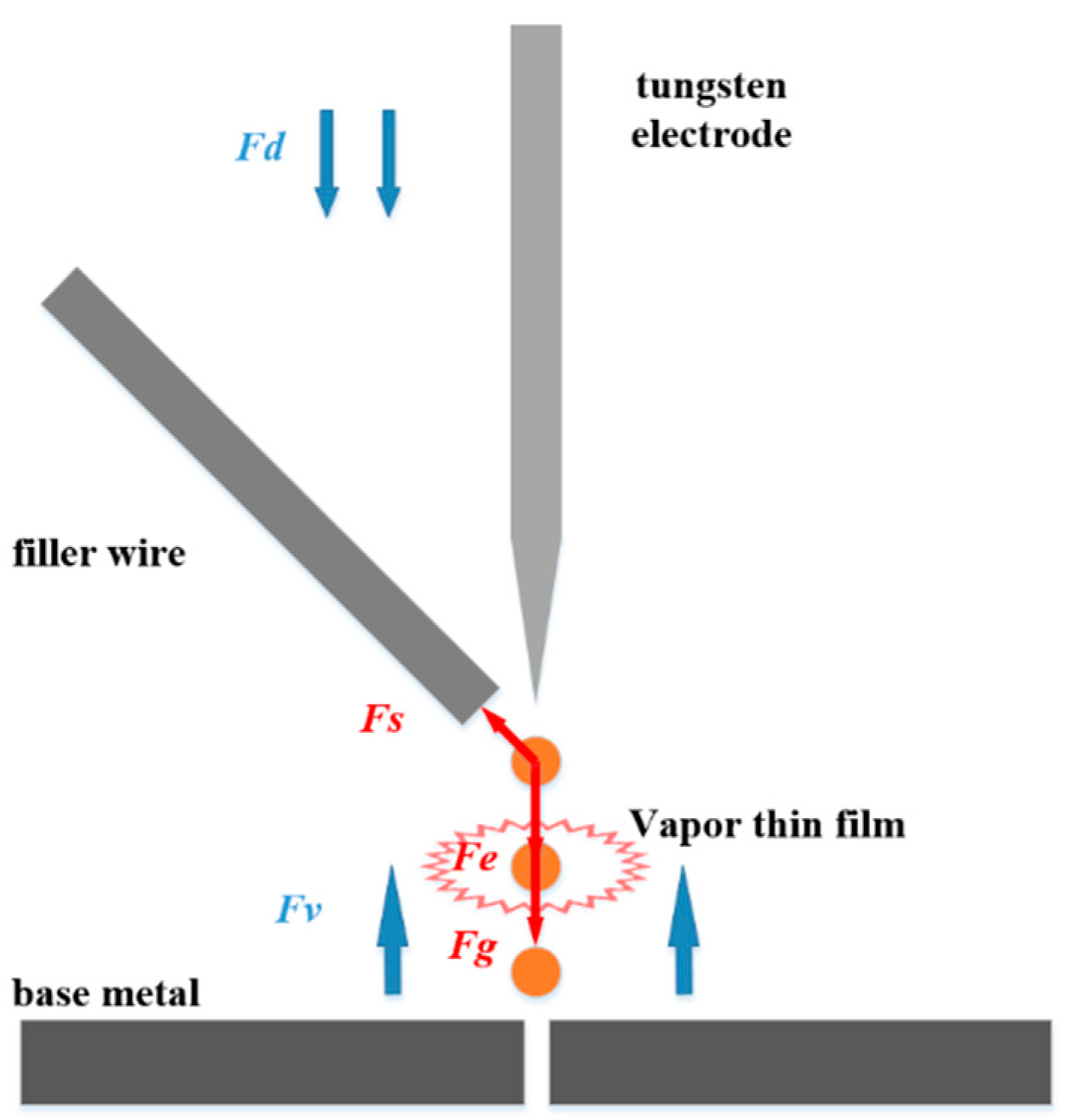

3.1. Droplet Transfer Behaviors

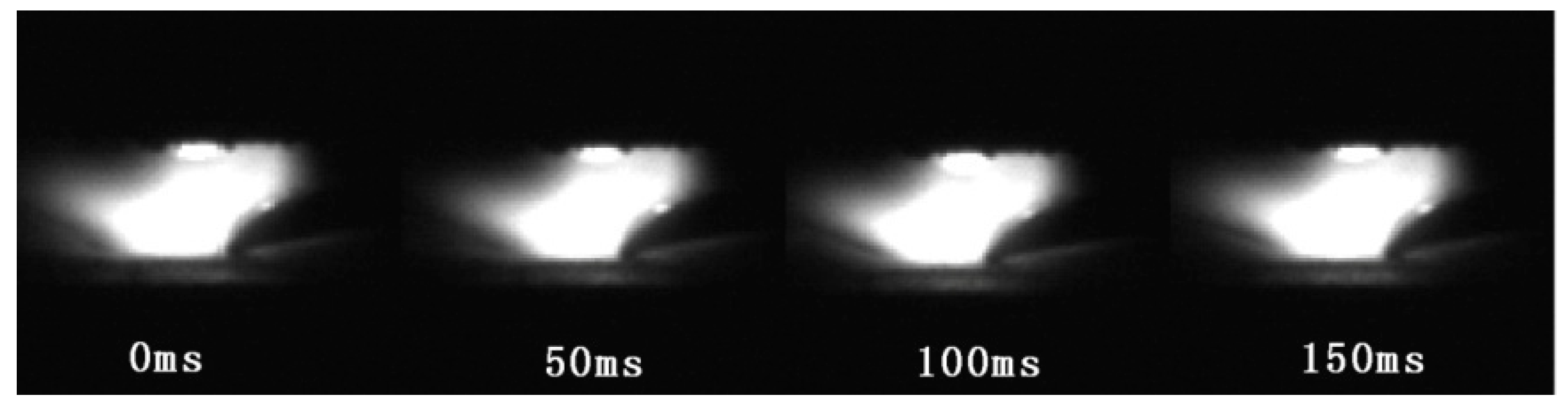

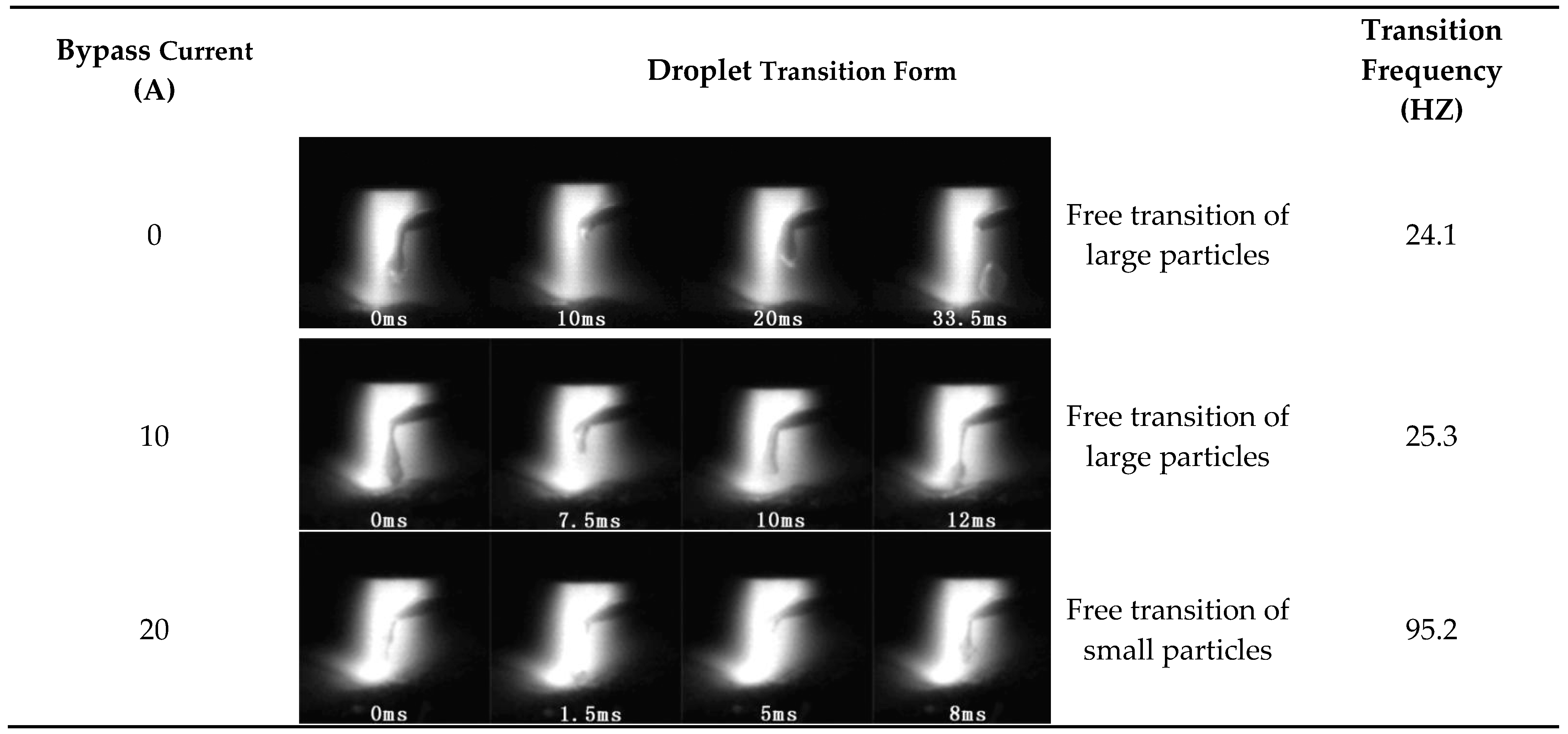

3.1.1. The Effects of the Distance between Wire Tips and the Work Piece on Droplet Transfer

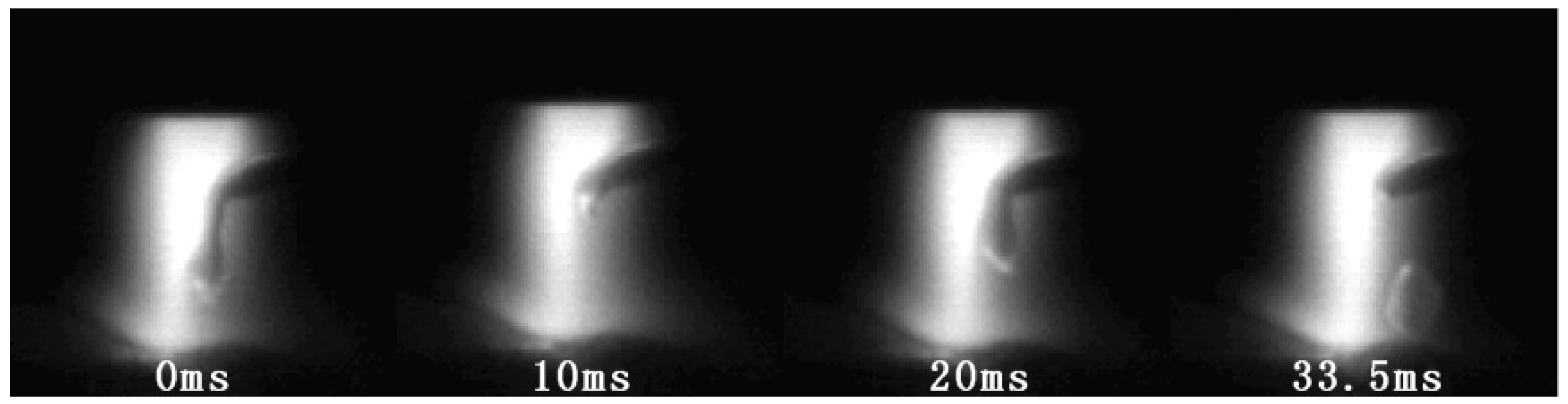

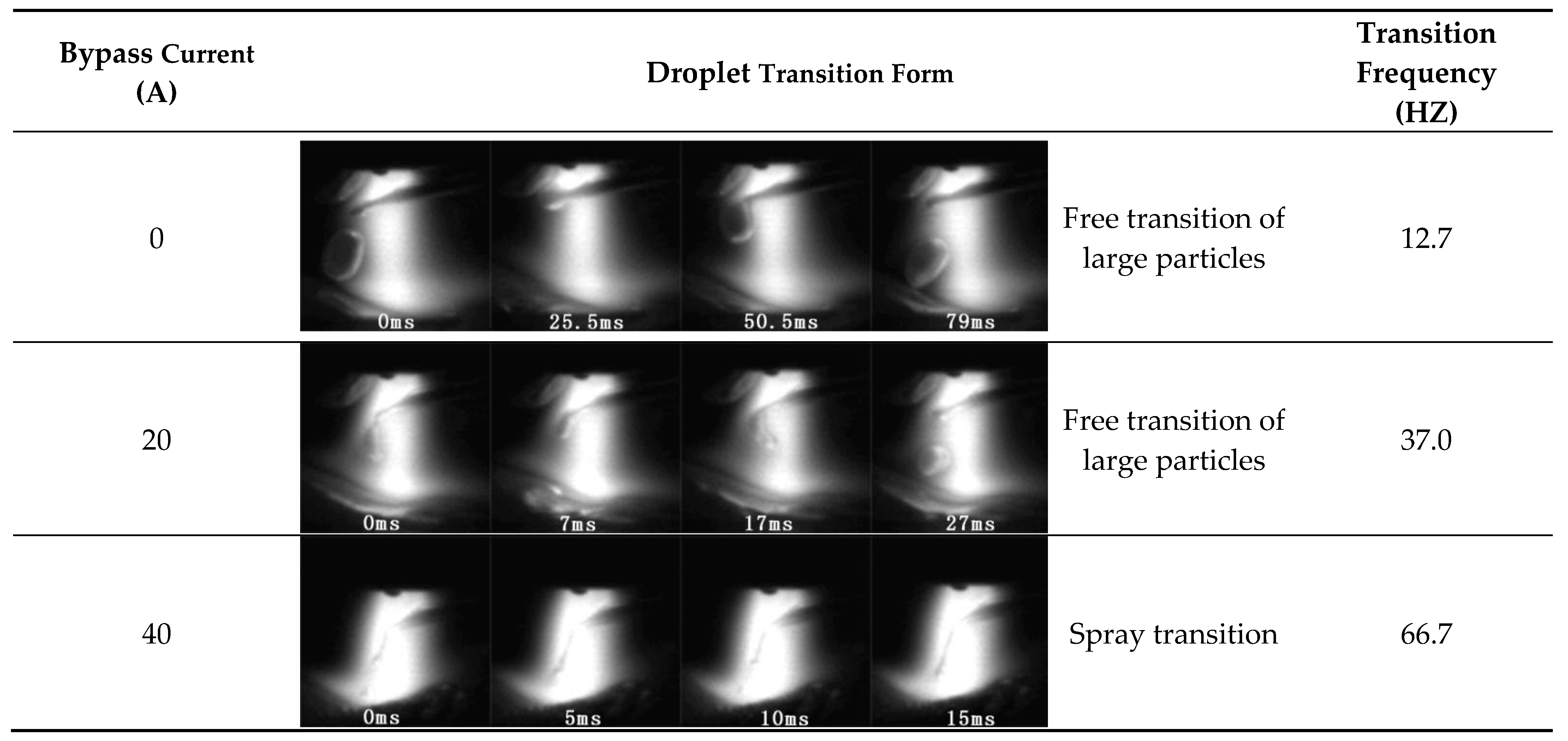

3.1.2. The Effect of Bypass Plasma Arc Current

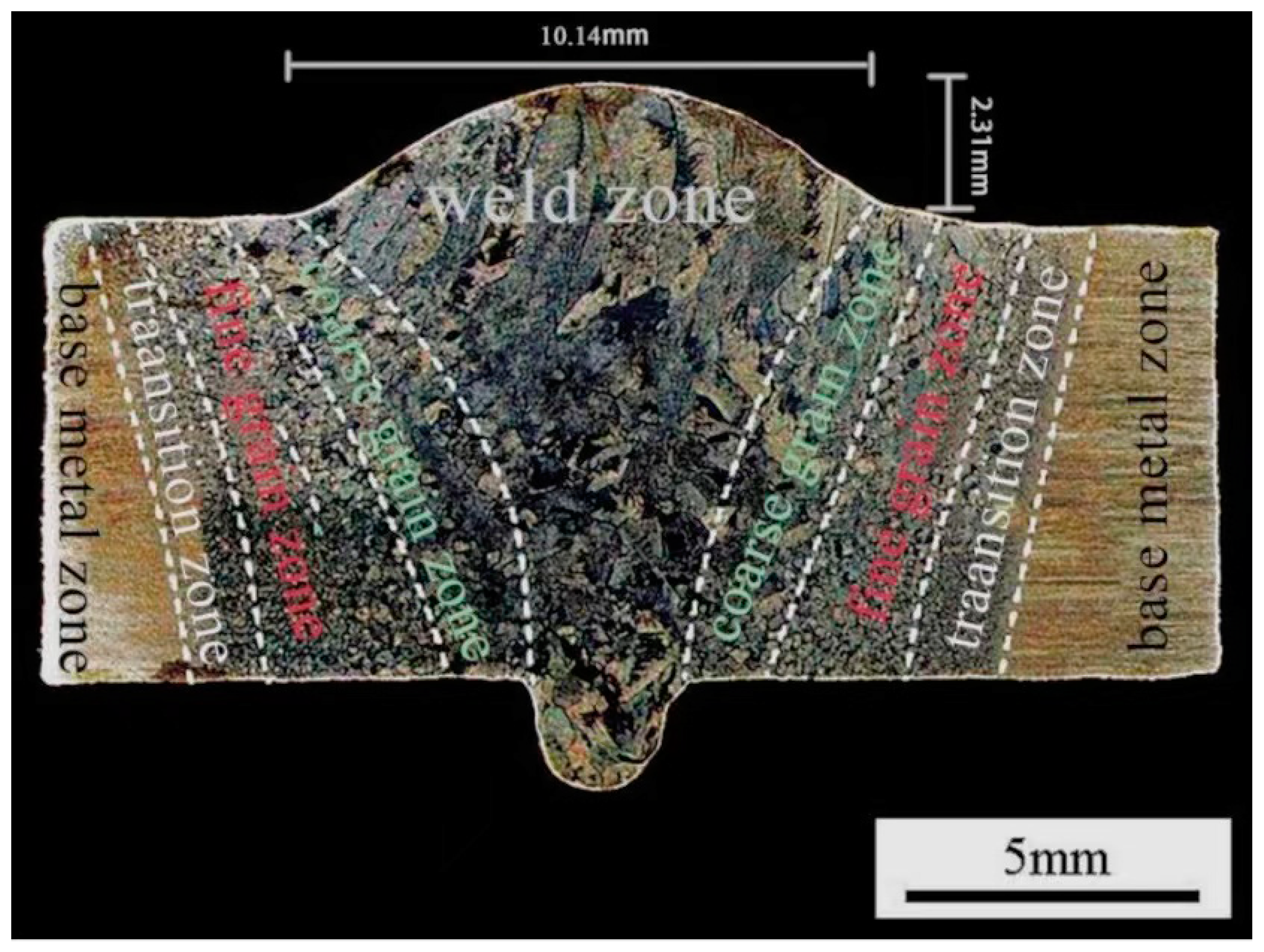

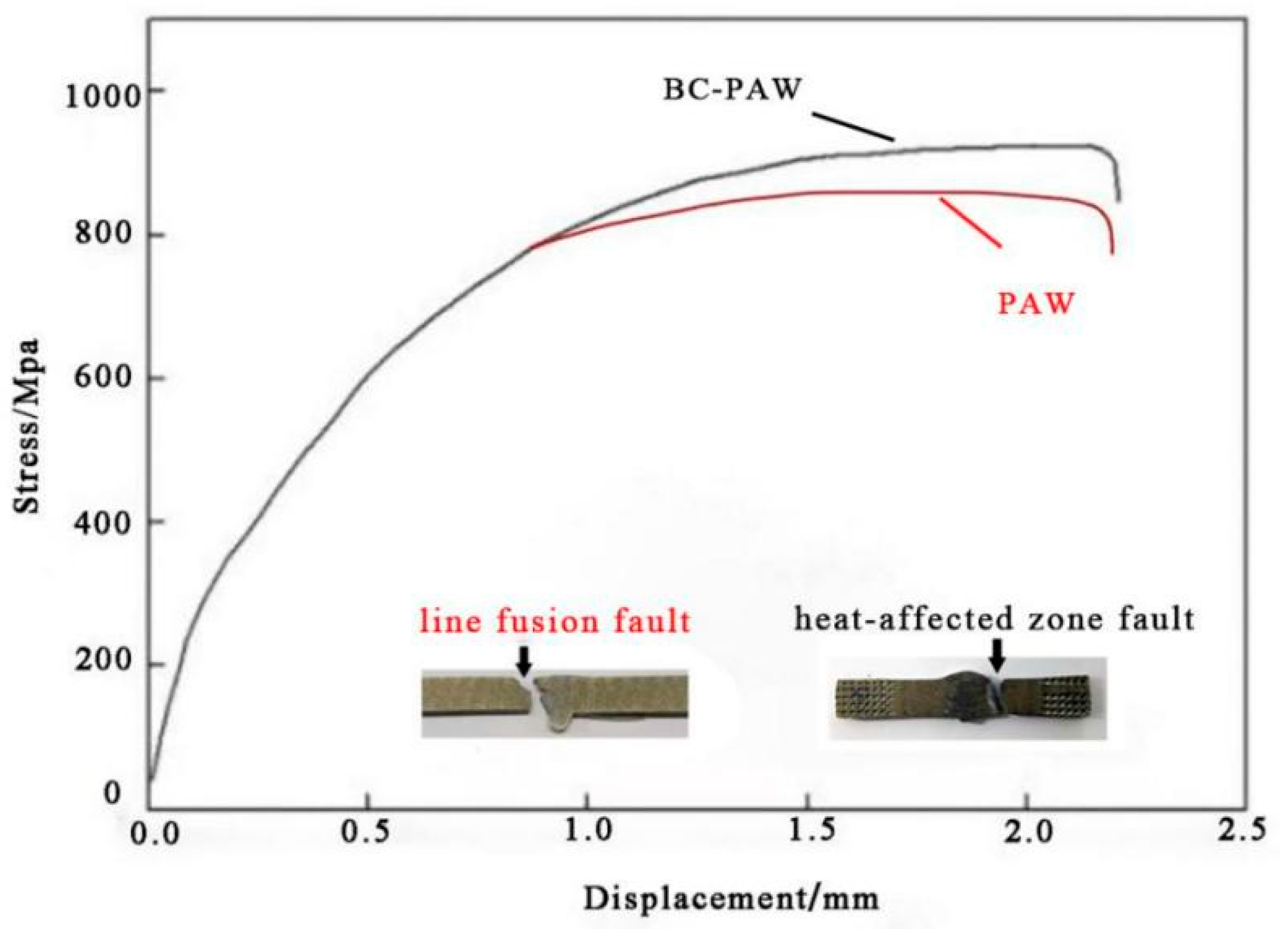

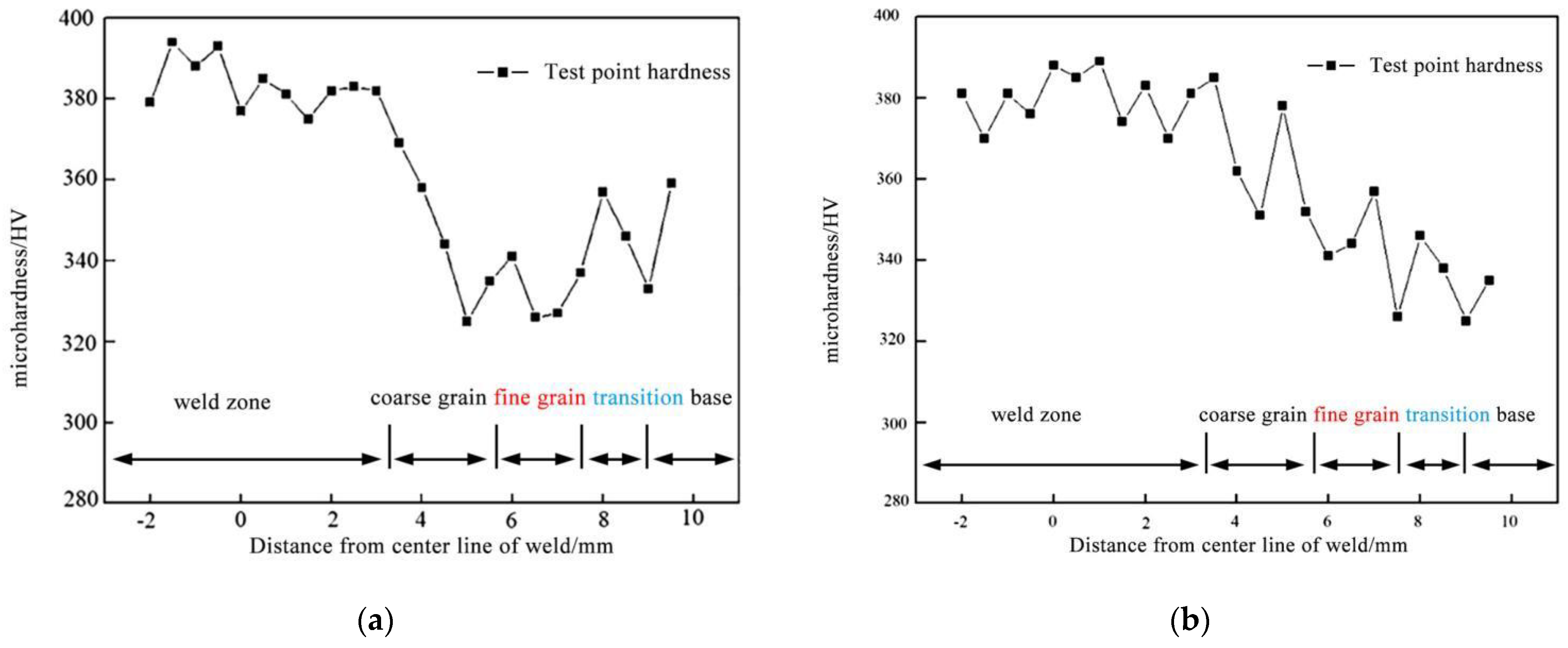

3.2. Microstructure

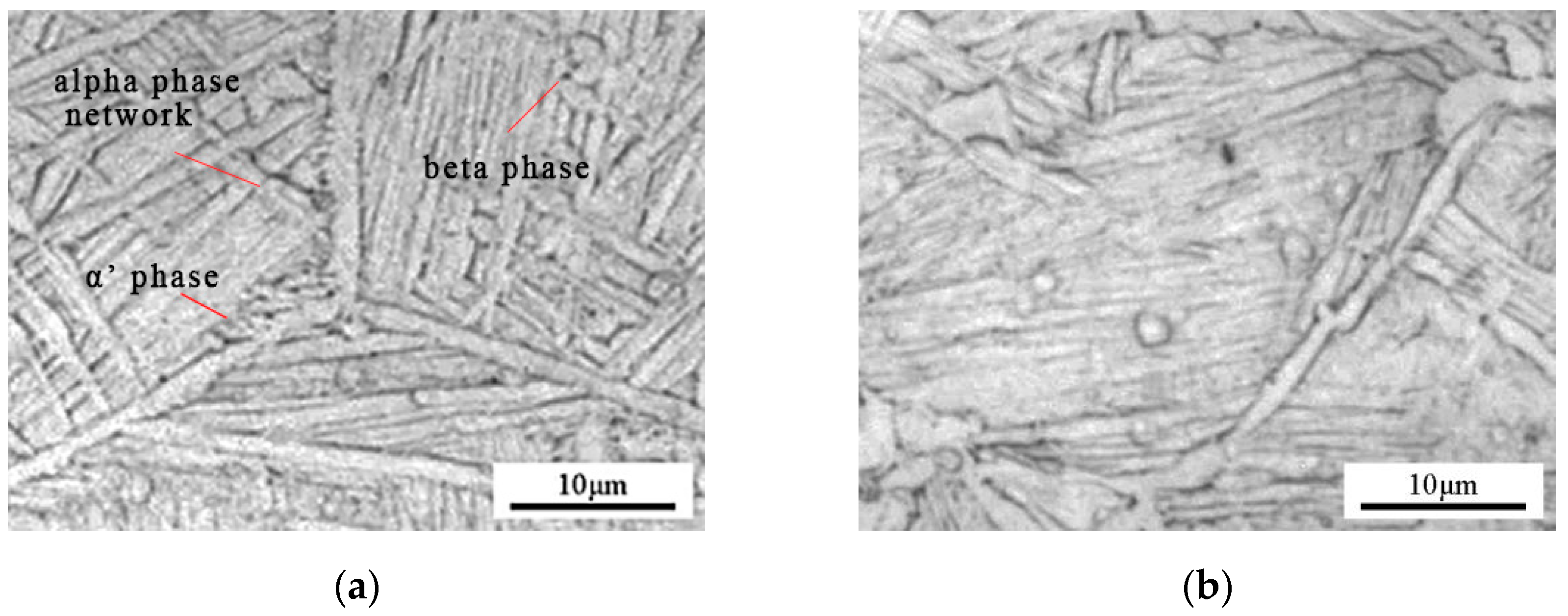

3.3. Microstructure Morphology

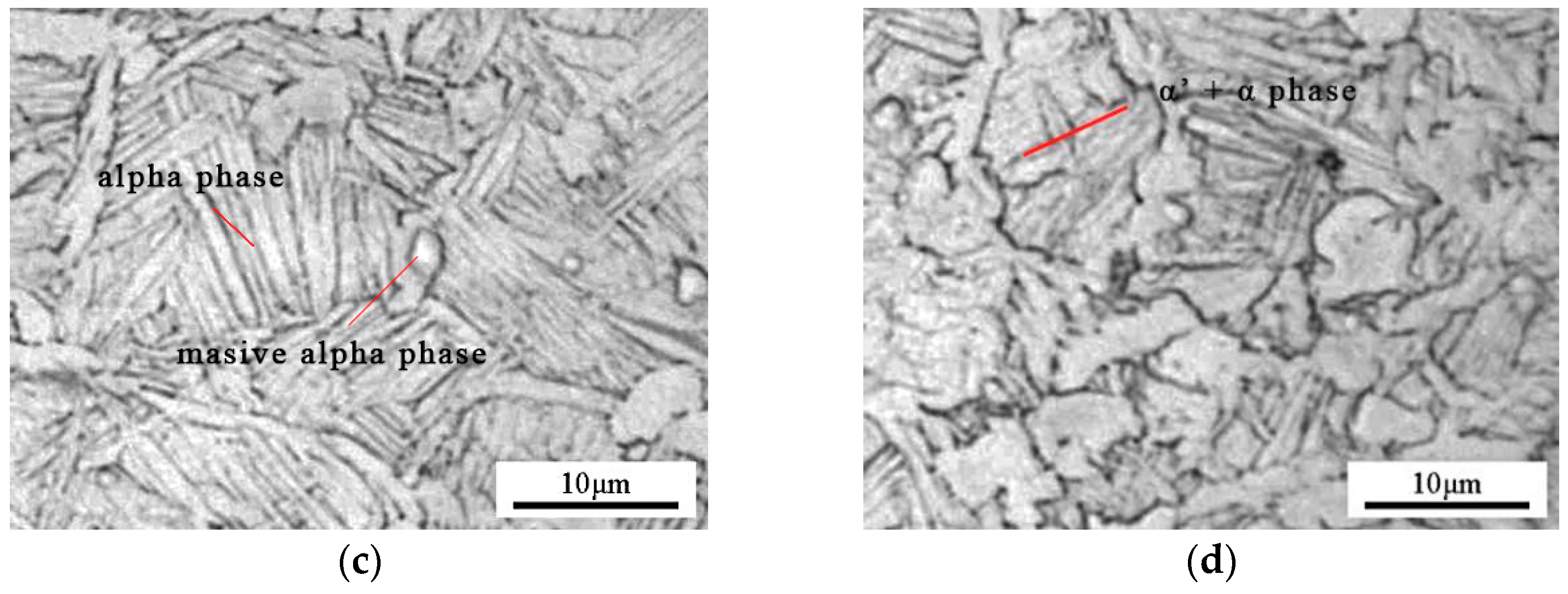

3.4. Mechanical Properties

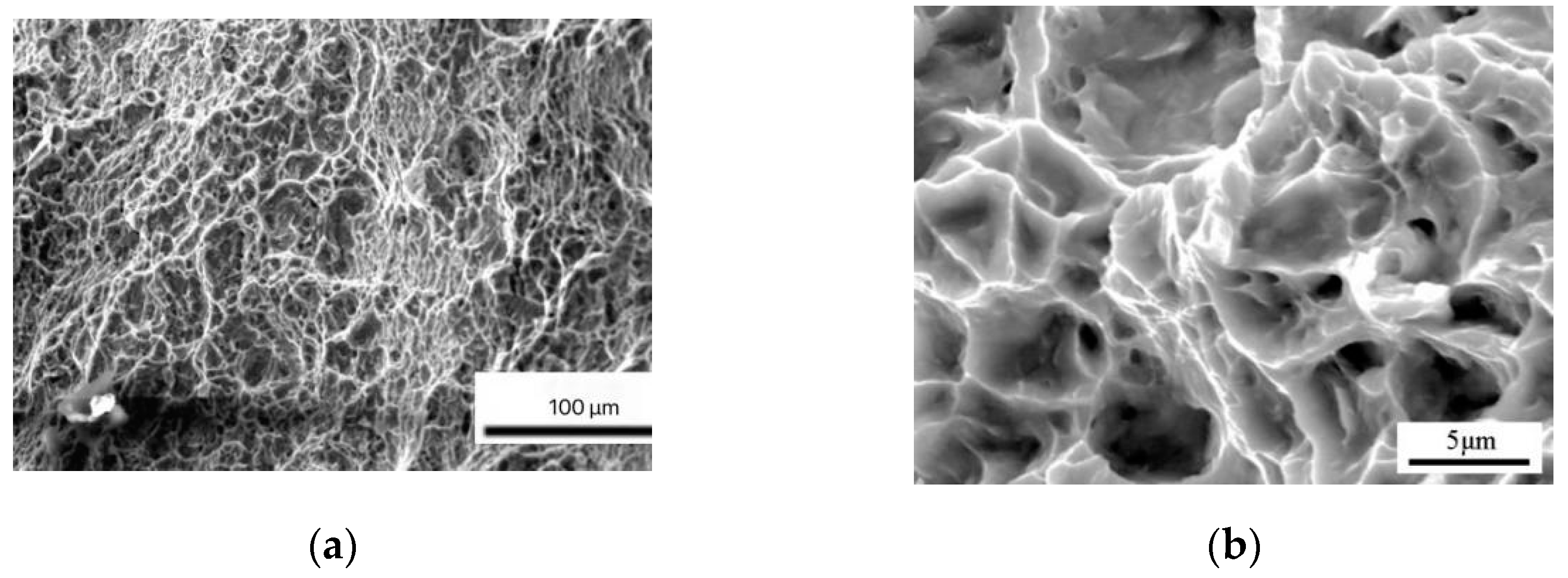

3.5. Fracture Morphology

4. Conclusions

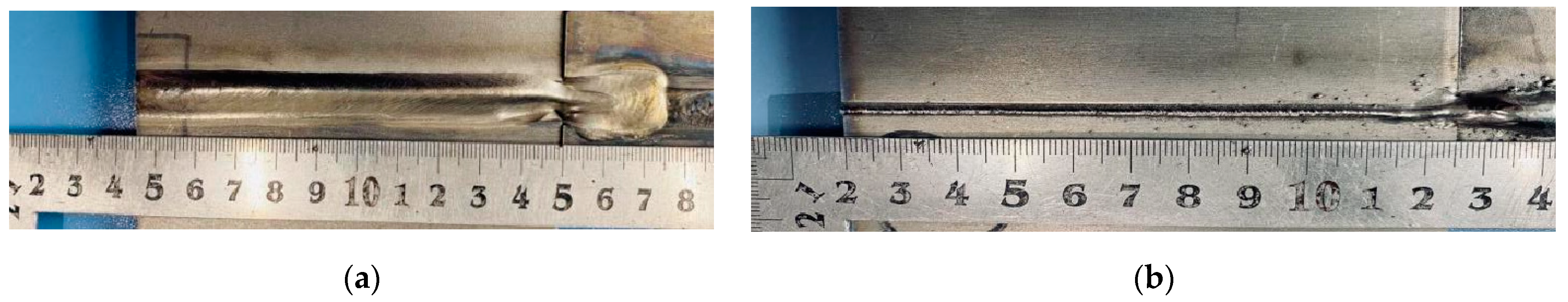

- BC-PAW significantly promotes welding efficiency through a rapid increase in wire melting during the welding. A hot wire using bypass current is easily implemented and is beneficial to welded TC4 components, contributing to an appealing surface finish with improved hardness and enhanced strength.

- Through the microstructure analysis, the weld zone has the largest grains, whose growth direction tends to the center of arc. The heat-affected zone has the small grains, with regular and fine equiaxed crystals.

- The average tensile strength of the BC-PAW TC4 joint is 986 MPa, which is about 98% of the base metal. The fracture occurs in the heat-affected zone, showing ductile fracture morphology. It is found that the mechanical strength of the TC4 alloy weld can be improved by BC-PAW welding with a hot wire.

Author Contributions

Funding

Data Availability Statement

Conflicts of Interest

References

- Xu, W.; Zhao, Y.; Chen, X.; Zhong, B.; Yu, H.; He, Y.; Tao, C. An Ultra-High Frequency Vibration-Based Fatigue Test and Its Comparative Study of a Titanium Alloy in the VHCF Regime. Metals 2020, 10, 1415. [Google Scholar] [CrossRef]

- Kaseem, M.; Choe, H.-C. Acceleration of Bone Formation and Adhesion Ability on Dental Implant Surface via Plasma Electrolytic Oxidation in a Solution Containing Bone Ions. Metals 2021, 11, 106. [Google Scholar] [CrossRef]

- Wang, L.; Chen, J.; Wu, C. Auxiliary energy-assisted arc welding processes and their modelling, sensing and control. Sci. Technol. Weld. Join. 2021, 26, 389–411. [Google Scholar] [CrossRef]

- Czuprynski, A. Microstructure and Abrasive Wear Resistance of Metal Matrix Composite Coatings Deposited on Steel Grade AISI 4715 by Powder Plasma Transferred Arc Welding Part 1. Mechanical and Structural Properties of a Cobalt-Based Alloy Surface Layer Reinforced with Particles of Titanium Carbide and Synthetic Metal-Diamond Composite. Materials 2021, 14, 2382. [Google Scholar] [CrossRef] [PubMed]

- Czuprynski, A. Microstructure and Abrasive Wear Resistance of Metal Matrix Composite Coatings Deposited on Steel Grade AISI 4715 by Powder Plasma Transferred Arc Welding Part 2. Mechanical and Structural Properties of a Nickel-Based Alloy Surface Layer Reinforced with Particles of Tungsten Carbide and Synthetic Metal-Diamond Composite. Materials 2021, 14, 2805. [Google Scholar] [CrossRef] [PubMed]

- DiCecco, L.-A.; Mehdi, M.; Edrisy, A. Dry-Sliding Wear Mechanisms of Shot-Peened Additive Manufactured Alpha Titanium Featuring TiB Particles. Tribol. Lett. 2021, 69, 90. [Google Scholar] [CrossRef]

- Gliszczynski, A.; Czechowski, L.; Wiacek, N. Heating and Compression at Elevated Temperature of Thin-Walled Titanium Channel Section Columns. Materials 2021, 14, 2928. [Google Scholar] [CrossRef] [PubMed]

- Huber, F.; Bartels, D.; Schmidt, M. In-Situ Alloy Formation of a WMoTaNbV Refractory Metal High Entropy Alloy by Laser Powder Bed Fusion (PBF-LB/M). Materials 2021, 14, 3095. [Google Scholar] [CrossRef]

- Rogala-Wielgus, D.; Majkowska-Marzec, B.; Zielinski, A.; Bartmanski, M.; Bartosewicz, B. Mechanical Behavior of Bi-Layer and Dispersion Coatings Composed of Several Nanostructures on Ti13Nb13Zr Alloy. Materials 2021, 14, 2905. [Google Scholar] [CrossRef] [PubMed]

- Schmeiser, F.; Krohmer, E.; Schell, N.; Uhlmann, E.; Reimers, W. Internal Stress Evolution and Subsurface Phase Transformation in Titanium Parts Manufactured by Laser Powder Bed Fusion—An In Situ X-Ray Diffraction Study. Adv. Eng. Mater. 2021. [Google Scholar] [CrossRef]

- Yamanaka, S.; Ikeda, K.-i.; Miura, S. The effect of titanium and silicon addition on phase equilibrium and mechanical properties of CoCrFeMnNi-based high entropy alloy. J. Mater. Res. 2021, 36, 2056–2070. [Google Scholar] [CrossRef]

- Mao, X.; Ou, M.; Chen, D.; Yang, M.; Long, W. Effect of Third-Stage Heat Treatments on Microstructure and Properties of Dual-Phase Titanium Alloy. Materials 2021, 14, 2776. [Google Scholar] [CrossRef] [PubMed]

- Brandl, E.; Baufeld, B.; Leyens, C.; Gault, R. Additive manufactured Ti6Al4V using welding wire: Comparison of laser and arc beam deposition and evaluation with respect to aerospace material specifications. Phys. Procedia 2010, 5 Pt B, 595–606. [Google Scholar] [CrossRef]

- Naksuk, N.; Poolperm, P.; Nakngoenthong, J.; Printrakoon, W.; Yuttawiriya, R. Experimental Investigation of Hot-Wire Laser Deposition for the Additive Manufacturing of Titanium Parts; IOP Publishing: Bristol, UK, 2022. [Google Scholar]

- Wu, Y.; Zhang, C.; Zhou, J.; Liang, W.; Li, Y. Analysis of the Microstructure and Mechanical Properties during Inertia Friction Welding of the Near-α TA19 Titanium Alloy. Chin. J. Mech. Eng. 2020, 33, 13. [Google Scholar]

- Zhang, Y.; Sun, D.Q.; Gu, X.Y.; Li, H.M. Nd:YAG pulsed laser welding of dissimilar metals of titanium alloy to stainless steel. International Journal of Advanced Manufacturing Technology. J. Adv. Manuf. Technol. 2018, 94, 1073–1085. [Google Scholar] [CrossRef]

- Zhang, Y.; Zhang, H.; Zhu, Z.; Pan, J. Microstructure, properties and first principles calculation of titanium alloy/steel by Nd: YAG laser self-fluxing welding. China Weld. 2018, 27, 10. [Google Scholar]

| Element | Al | V | Fe | C | N | H | O | Ti |

|---|---|---|---|---|---|---|---|---|

| Base | 5.5–6.75 | 3.5–4.5 | 0.3 | 0.08 | 0.05 | 0.015 | 0.2 | Bal |

| Wire | Ti-6Al-4V | |||||||

| Welding Parameters | Parameter Values |

|---|---|

| Main current (A) | 270 |

| Small main current (A) | 140–160 |

| Bypass current (A) | 20 |

| Ionic gas flow rate (L/min) | 2 |

| Protective gas flow (L/min) | 17 |

| Wire feeding speed (m/min) | 3.43 |

| Welding speed (m/min) | 0.25 |

| Nozzle diameter (mm) | 3 |

| Distance from nozzle to workpiece (mm) | 5 |

| Front protective gas flow (L/min) | 50 |

| Back protective gas flow (L/min) | 20 |

Publisher’s Note: MDPI stays neutral with regard to jurisdictional claims in published maps and institutional affiliations. |

© 2022 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (https://creativecommons.org/licenses/by/4.0/).

Share and Cite

Miao, Y.; Wu, Y.; Wang, Z.; Zhao, Y.; Li, C.; Liu, J. Process Stability and Material Properties of TC4 Alloy Welded by Bypass Current Hot Wire Plasma Arc Welding (BC-PAW). Metals 2022, 12, 1949. https://doi.org/10.3390/met12111949

Miao Y, Wu Y, Wang Z, Zhao Y, Li C, Liu J. Process Stability and Material Properties of TC4 Alloy Welded by Bypass Current Hot Wire Plasma Arc Welding (BC-PAW). Metals. 2022; 12(11):1949. https://doi.org/10.3390/met12111949

Chicago/Turabian StyleMiao, Yugang, Yifan Wu, Ziran Wang, Yuyang Zhao, Chunwang Li, and Ji Liu. 2022. "Process Stability and Material Properties of TC4 Alloy Welded by Bypass Current Hot Wire Plasma Arc Welding (BC-PAW)" Metals 12, no. 11: 1949. https://doi.org/10.3390/met12111949

APA StyleMiao, Y., Wu, Y., Wang, Z., Zhao, Y., Li, C., & Liu, J. (2022). Process Stability and Material Properties of TC4 Alloy Welded by Bypass Current Hot Wire Plasma Arc Welding (BC-PAW). Metals, 12(11), 1949. https://doi.org/10.3390/met12111949