Study of the Morphological and Structural Features of Inert Matrices Based on ZrO2–CeO2 Doped with Y2O3 and the Effect of Grain Sizes on the Strength Properties of Ceramics

Abstract

:1. Introduction

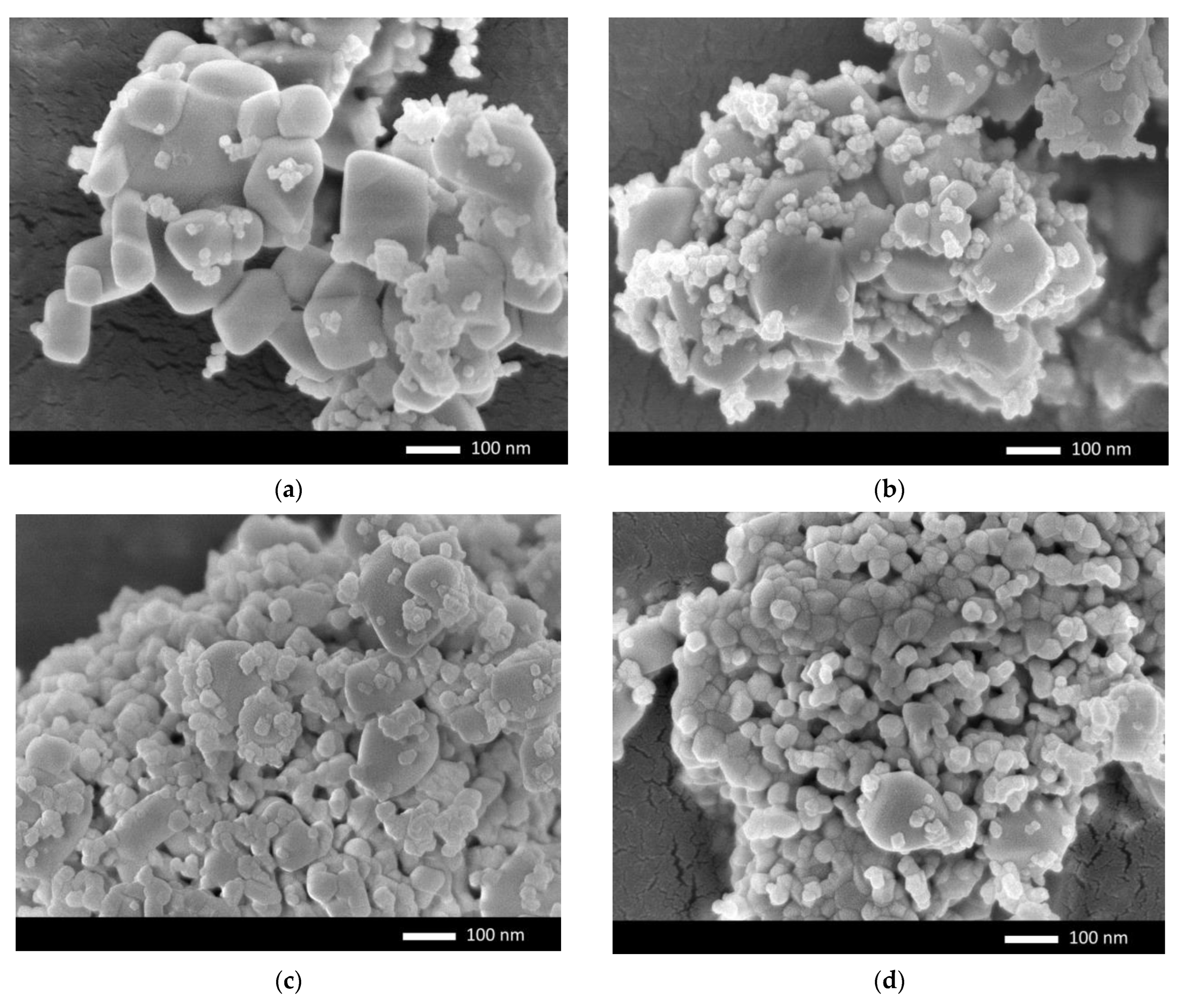

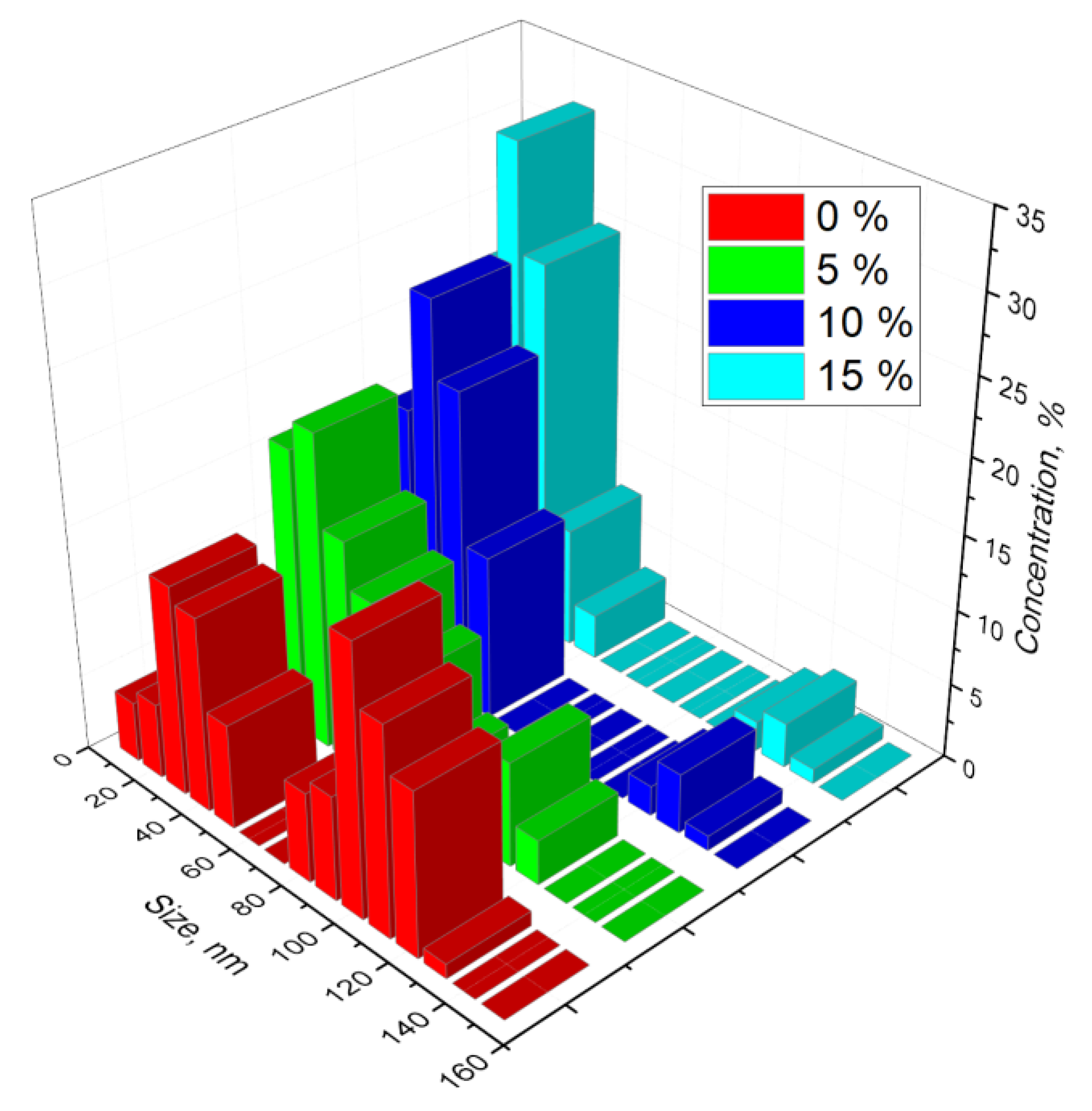

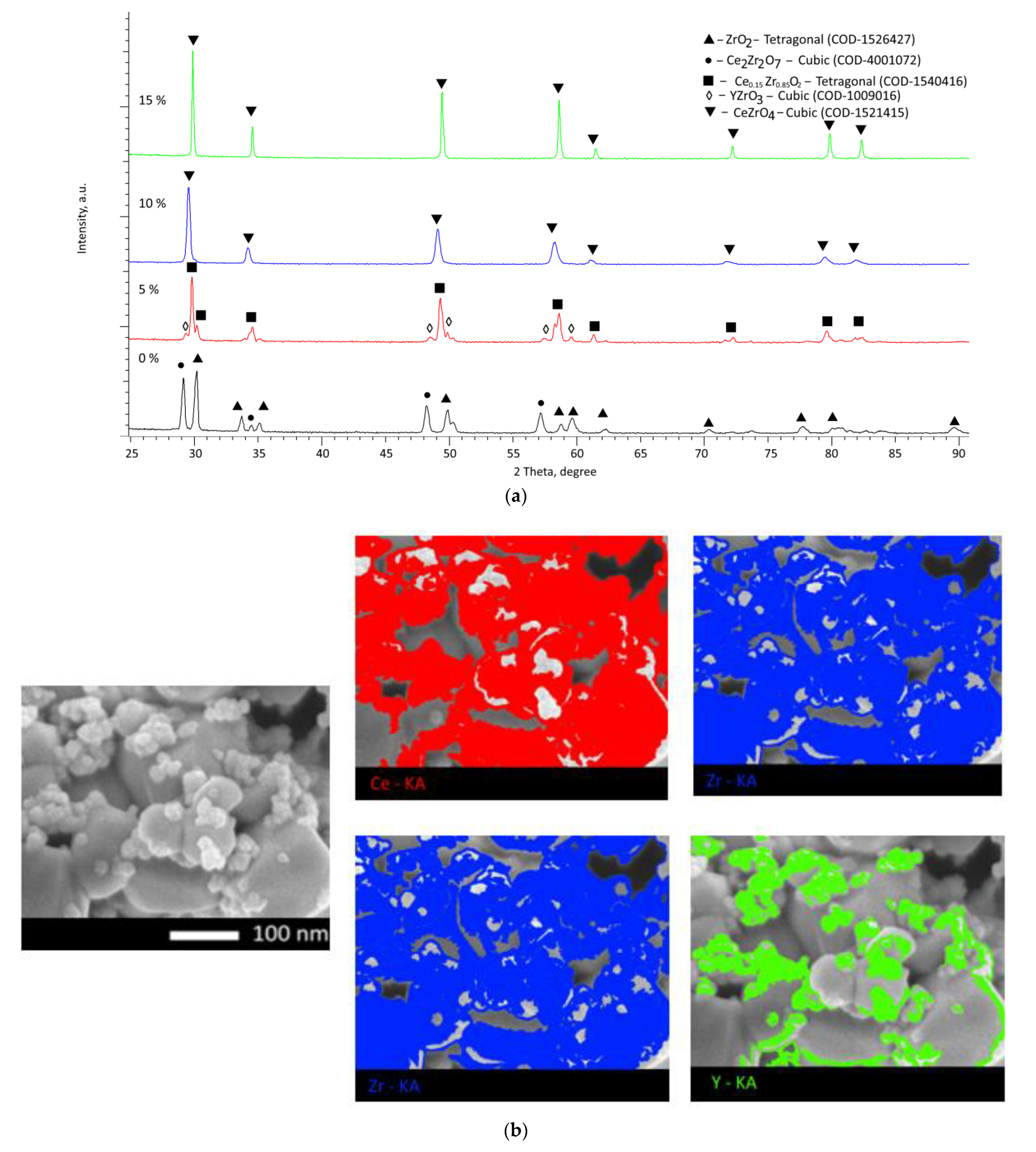

2. Experimental Part

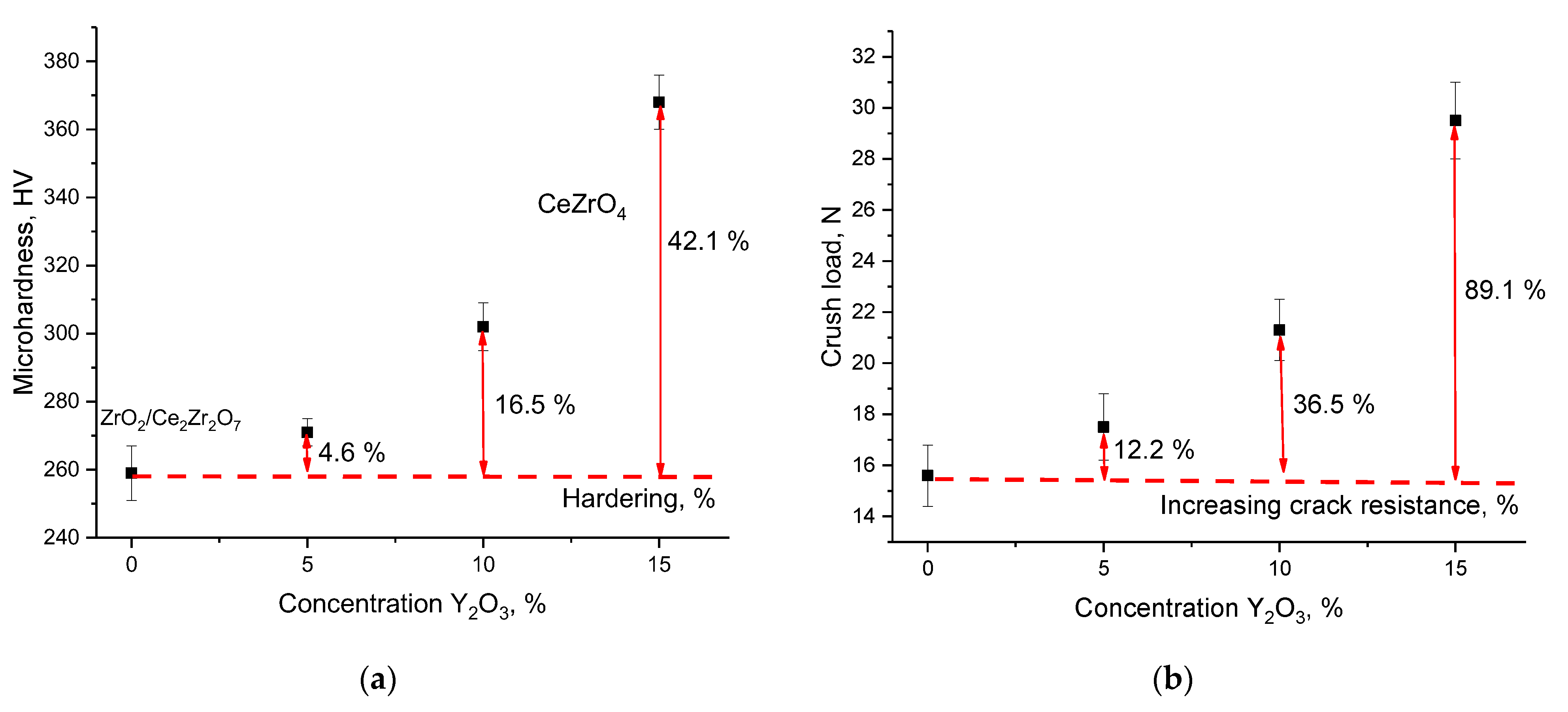

3. Results and Discussion

4. Conclusions

Author Contributions

Funding

Institutional Review Board Statement

Informed Consent Statement

Data Availability Statement

Acknowledgments

Conflicts of Interest

References

- Ikonen, T.; Tulkki, V. The importance of input interactions in the uncertainty and sensitivity analysis of nuclear fuel behavior. Nucl. Eng. Des. 2014, 275, 229–241. [Google Scholar] [CrossRef]

- MacDonald, P.E.; Lee, C.B. Use of thoria-urania fuels in PWRs: A general review of a NERI project to assess feasible core designs, economics, fabrication methods, in-pile thermal/mechanical behavior, and waste form characteristics. Nucl. Technol. 2004, 147, 1–7. [Google Scholar] [CrossRef]

- Humphrey, U.E.; Khandaker, M.U. Viability of thorium-based nuclear fuel cycle for the next generation nuclear reactor: Issues and prospects. Renew. Sustain. Energy Rev. 2018, 97, 259–275. [Google Scholar] [CrossRef]

- Lovecký, M.; Závorka, J.; Jiřičková, J.; Škoda, R. Increasing efficiency of nuclear fuel using burnable absorbers. Prog. Nucl. Energy 2020, 118, 103077. [Google Scholar] [CrossRef]

- Keiser, D.D., Jr. Fuel cladding chemical interaction in metallic sodium fast reactor fuels: A historical perspective. J. Nucl. Mater. 2019, 514, 393–398. [Google Scholar] [CrossRef]

- Lee, W.E.; Gilbert, M.; Murphy, S.T.; Grimes, R.W. Opportunities for advanced ceramics and composites in the nuclear sector. J. Am. Ceram. Soc. 2013, 96, 2005–2030. [Google Scholar] [CrossRef]

- Parker, H.M.O.; Joyce, M.J. The use of ionising radiation to image nuclear fuel: A review. Prog. Nucl. Energy 2015, 85, 297–318. [Google Scholar] [CrossRef] [Green Version]

- Galashev, A.Y. Recovery of actinides and fission products from spent nuclear fuel via electrolytic reduction: Thematic overview. Int. J. Energy Res. 2022, 46, 3891–3905. [Google Scholar] [CrossRef]

- Galahom, A.A.; Sharaf, I.M. Finding a suitable fuel type for the disposal of the accumulated minor actinides in the spent nuclear fuel in PWR. Prog. Nucl. Energy 2021, 136, 103749. [Google Scholar] [CrossRef]

- Kurniawan, T.A.; Othman, M.H.D.; Singh, D.; Avtar, R.; Hwang, G.H.; Setiadi, T.; Lo, W.-H. Technological solutions for long-term storage of partially used nuclear waste: A critical review. Ann. Nucl. Energy 2022, 166, 108736. [Google Scholar] [CrossRef]

- Frieß, F.; Liebert, W. Inert-matrix fuel for transmutation: Selected mid-and long-term effects on reprocessing, fuel fabrication and inventory sent to final disposal. Prog. Nucl. Energy 2022, 145, 104106. [Google Scholar] [CrossRef]

- Zhang, J.; Wang, H.; Wei, H.; Tang, C.; Lu, C.; Huang, C.; Ding, S.; Li, Y. Modelling of effective irradiation swelling for inert matrix fuels. Nucl. Eng. Technol. 2021, 53, 2616–2628. [Google Scholar] [CrossRef]

- Wang, Y.; Wang, J.; Wang, J.; Li, X.; Tang, Y.; Li, N. Preparation of MgO-Nd2Zr2O7 composite ceramics used for inert matrix fuel by one-step sintering method. Ceram. Int. 2022, 48, 27213–27216. [Google Scholar] [CrossRef]

- Nandi, C.; Danny, K.; Bhattacharya, S.; Prakash, A.; Behere, P. Phase evolution in M1 − xPuxO2 (0.0 ≤ x ≤ 0.6)(M = Zr, Th) as potential inert matrix fuel system under reducing and oxidizing conditions. J. Nucl. Mater. 2021, 547, 152800. [Google Scholar] [CrossRef]

- Hudák, I.; Skryja, P.; Bojanovský, J.; Jegla, Z.; Krňávek, M. The Effect of Inert Fuel Compounds on Flame Characteristics. Energies 2021, 15, 262. [Google Scholar] [CrossRef]

- Berguzinov, A.; Kozlovskiy, A.; Khametova, A.A.; Shlimas, D.I. Synthesis, Phase Transformations and Strength Properties of Nanostructured (1 − x) ZrO2 − xCeO2 Composite Ceramics. Nanomaterials 2022, 12, 1979. [Google Scholar] [CrossRef] [PubMed]

- Giniyatova, S.G.; Sailaukhanov, N.A.; Nesterov, E.; Zdorovets, M.V.; Kozlovskiy, A.L.; Shlimas, D.I. Research of Structural, Strength and Thermal Properties of ZrO2—CeO2 Ceramics Doped with Yttrium. Crystals 2022, 12, 242. [Google Scholar] [CrossRef]

- Alin, M.; Kozlovskiy, A.L.; Zdorovets, M.V.; Uglov, V.V. Study of the mechanisms of the t-ZrO2→ c-ZrO2 type polymorphic transformations in ceramics as a result of irradiation with heavy Xe22+ ions. Solid State Sci. 2022, 123, 106791. [Google Scholar] [CrossRef]

- Togatorop, E.; Suzuki-Muresan, T.; Harto, A.W. A review on the solubility of crystalline zirconium dioxide and thorium dioxide. AIP Conf. Proc. 2022, 2501, 030002. [Google Scholar]

- Ivanov, I.A.; Rspayev, R.M.; Sapar, A.D.; Mustafin, D.A.; Zdorovets, M.V.; Kozlovskiy, A.L. Study of the Effect of Y2O3 Doping on the Resistance to Radiation Damage of CeO2 Microparticles under Irradiation with Heavy Xe22+ Ions. Crystals 2021, 11, 1459. [Google Scholar] [CrossRef]

- Jin, E.; Yuan, L.; Yu, J.; Ding, D.; Xiao, G. Enhancement of thermal shock and slag corrosion resistance of MgO–ZrO2 ceramics by doping CeO2. Ceram. Int. 2022, 48, 13987–13995. [Google Scholar] [CrossRef]

- Zhao, L.; Jiang, Z.; Zhang, C.; Guo, W.; Jiang, Z.; Gao, X.; Cui, Y.; Shi, X. Theoretical modeling based on stress wave propagation and experimental verification of residual stress in stereolithography printed ZrO2 ceramic suspensions. Ceram. Int. 2021, 47, 26935–26941. [Google Scholar] [CrossRef]

- Fang, H.; Wang, W.; Huang, J.; Li, Y.; Ye, D. Corrosion behavior and thermos-physical properties of a promising Yb2O3 and Y2O3 co-stabilized ZrO2 ceramic for thermal barrier coatings subject to calcium-magnesium-aluminum-silicate (CMAS) deposition: Experiments and first-principles calculation. Corros. Sci. 2021, 182, 109230. [Google Scholar] [CrossRef]

- Fang, H.; Wang, W.; Deng, S.; Yang, T.; Zhu, H.; Huang, J.; Ye, D.; Guo, X. Interaction between Yb2O3-Y2O3 co-stabilized ZrO2 ceramic powder and molten silicate deposition, and its implication on thermal barrier coating application. Mater. Charact. 2021, 180, 111418. [Google Scholar] [CrossRef]

- Omata, T.; Kishimoto, H.; Otsuka-Yao-Matsuo, S.; Ohtori, N.; Umesaki, N. Vibrational spectroscopic and X-ray diffraction studies of cerium zirconium oxides with Ce/Zr composition ratio = 1 prepared by reduction and successive oxidation of t′-(Ce0.5Zr0.5)O2 phase. J. Solid State Chem. 1999, 147, 573–583. [Google Scholar] [CrossRef]

- Datta, P.; Rihko-Struckmann, L.K.; Sundmacher, K. Quantification of produced hydrogen in a cyclic water gas shift process with Mo stabilized iron oxide. Fuel Process. Technol. 2014, 128, 36–42. [Google Scholar] [CrossRef]

- Ingraci Neto, R.R.; Kardoulaki, E.; Valdez, J.A. The influence of the processing parameters on the reactive flash sintering of ZrO2-CeO2. J. Am. Ceram. Soc. 2022, 105, 3937–3948. [Google Scholar] [CrossRef]

- Kurapova, O.Y.; Glukharev, A.G.; Glumov, O.V.; Konakov, V.G. The effect of the sintering parameters on the structure and oxygen ion conductivity of Y2O3–ZrO2–CeO2 ceramics. Open Ceram. 2021, 5, 100086. [Google Scholar] [CrossRef]

- Wang, Q.; Du, F.; Hou, Y.; Zhang, Y.; Cui, M.; Zhang, Y. Preparation of a CeO2–ZrO2 based nano-composite with enhanced thermal stability by a novel chelating precipitation method. Ceram. Int. 2021, 47, 33057–33063. [Google Scholar] [CrossRef]

- Wu, K.; Liu, G.; Yu, P.; Ye, C.; Shi, J.; Shen, Y. Prediction of hardening effect by irradiation-induced vacancy clusters with dislocation dynamics. Int. J. Plast. 2022, 149, 103160. [Google Scholar] [CrossRef]

- Liu, K.; Long, X.; Li, B.; Xiao, X.; Jiang, C. A hardening model considering grain size effect for ion-irradiated polycrystals under nanoindentation. Nucl. Eng. Technol. 2021, 53, 2960–2967. [Google Scholar] [CrossRef]

- Wu, R.; Zaiser, M. Thermodynamic considerations on a class of dislocation-based constitutive models. J. Mech. Phys. Solids 2022, 159, 104735. [Google Scholar] [CrossRef]

- Periyasamy, K.; Aswathy, V.T.; Kumar, V.A.; Manikandan, M.; Shukla, R.; Tyagi, A.K.; Raja, T. An efficient robust fluorite CeZrO4 − δ oxide catalyst for the eco-benign synthesis of styrene. RSC Adv. 2015, 5, 3619–3626. [Google Scholar] [CrossRef]

- Monge, M.A.; Popov, A.I.; Ballesteros, C.; González, R.; Chen, Y.; Kotomin, E.A. Formation of anion-vacancy clusters and nanocavities in thermochemically reduced MgO single crystals. Phys. Rev. B 2000, 62, 9299. [Google Scholar] [CrossRef] [Green Version]

- Lushchik, A.; Dolgov, S.; Feldbach, E.; Pareja, R.; Popov, A.I.; Shablonin, E.; Seeman, V. Creation and thermal annealing of structural defects in neutron-irradiated MgAl2O4 single crystals. Nucl. Instrum. Methods Phys. Res. Sect. B Beam Interact. Mater. At. 2018, 435, 31–37. [Google Scholar] [CrossRef]

- Pankratov, V.; Popov, A.I.; Chernov, S.A.; Zharkouskaya, A.; Feldmann, C. Mechanism for energy transfer processes between Ce3+ and Tb3+ in LaPO4: Ce, Tb nanocrystals by time-resolved luminescence spectroscopy. Phys. Status Solidi B 2010, 247, 2252–2257. [Google Scholar] [CrossRef]

- Averback, R.S.; Ehrhart, P.; Popov, A.I.; Sambeek, A.V. Defects in ion implanted and electron irradiated MgO and Al2O3. Radiat. Eff. Defects Solids 1995, 136, 169–173. [Google Scholar] [CrossRef]

- Szenes, G.; Pászti, F.; Péter, Á.; Popov, A.I. Tracks induced in TeO2 by heavy ions at low velocities. Nucl. Instrum. Methods Phys. Res. Sect. B Beam Interact. Mater. At. 2000, 166, 949–953. [Google Scholar] [CrossRef]

| Phase | Lattice Parameter, Å | |||

|---|---|---|---|---|

| Concentration of Y2O3,% | ||||

| 0 | 5 | 10 | 15 | |

| ZrO2–tetragonal | a = 3.5971 ± 0.0024, c = 3.2233 ± 0.0016, V = 67.59 ± 1.12 Å3 | - | - | - |

| Ce2Zr2O7–Cubic | a = 10.6443 ± 0.0034, V = 1206.00 ± 1.21 Å3 | - | - | - |

| Ce0.15Zr0.85O2–Tetragonal | - | a = 3.6418 ± 0.0031, c = 5.2329 ± 0.0017, V = 69.40 ± 1.15 Å3 | - | - |

| YZrO3–Cubic | - | a = 10.5307, V = 1167.84 ± 0.93 Å3 | - | - |

| CeZrO4–Cubic | - | - | a = 10.47127 ± 0.0016, V = 1148.15 ± 1.16 Å3 | a = 10.3953 ± 0.0025, V = 1123.34 ± 0.96 Å3 |

Publisher’s Note: MDPI stays neutral with regard to jurisdictional claims in published maps and institutional affiliations. |

© 2022 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (https://creativecommons.org/licenses/by/4.0/).

Share and Cite

Kozlovskiy, A.L.; Zdorovets, M.V.; Shlimas, D.I. Study of the Morphological and Structural Features of Inert Matrices Based on ZrO2–CeO2 Doped with Y2O3 and the Effect of Grain Sizes on the Strength Properties of Ceramics. Metals 2022, 12, 1687. https://doi.org/10.3390/met12101687

Kozlovskiy AL, Zdorovets MV, Shlimas DI. Study of the Morphological and Structural Features of Inert Matrices Based on ZrO2–CeO2 Doped with Y2O3 and the Effect of Grain Sizes on the Strength Properties of Ceramics. Metals. 2022; 12(10):1687. https://doi.org/10.3390/met12101687

Chicago/Turabian StyleKozlovskiy, Artem L., Maxim V. Zdorovets, and Dmitriy I. Shlimas. 2022. "Study of the Morphological and Structural Features of Inert Matrices Based on ZrO2–CeO2 Doped with Y2O3 and the Effect of Grain Sizes on the Strength Properties of Ceramics" Metals 12, no. 10: 1687. https://doi.org/10.3390/met12101687

APA StyleKozlovskiy, A. L., Zdorovets, M. V., & Shlimas, D. I. (2022). Study of the Morphological and Structural Features of Inert Matrices Based on ZrO2–CeO2 Doped with Y2O3 and the Effect of Grain Sizes on the Strength Properties of Ceramics. Metals, 12(10), 1687. https://doi.org/10.3390/met12101687