Mechanical Behaviour and Failure Mode of High Interstitially Alloyed Austenite under Combined Compression and Cyclic Torsion

Abstract

:1. Introduction

2. Materials and Methods

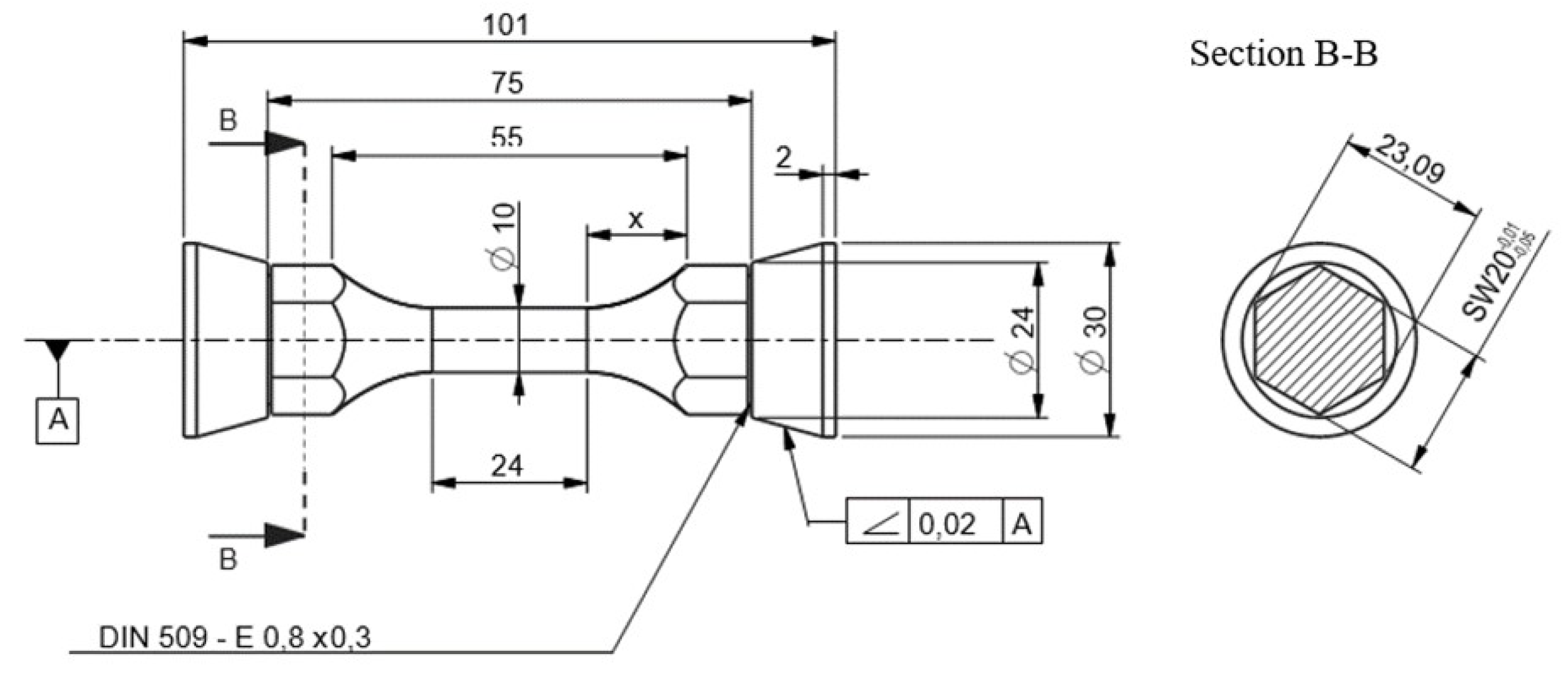

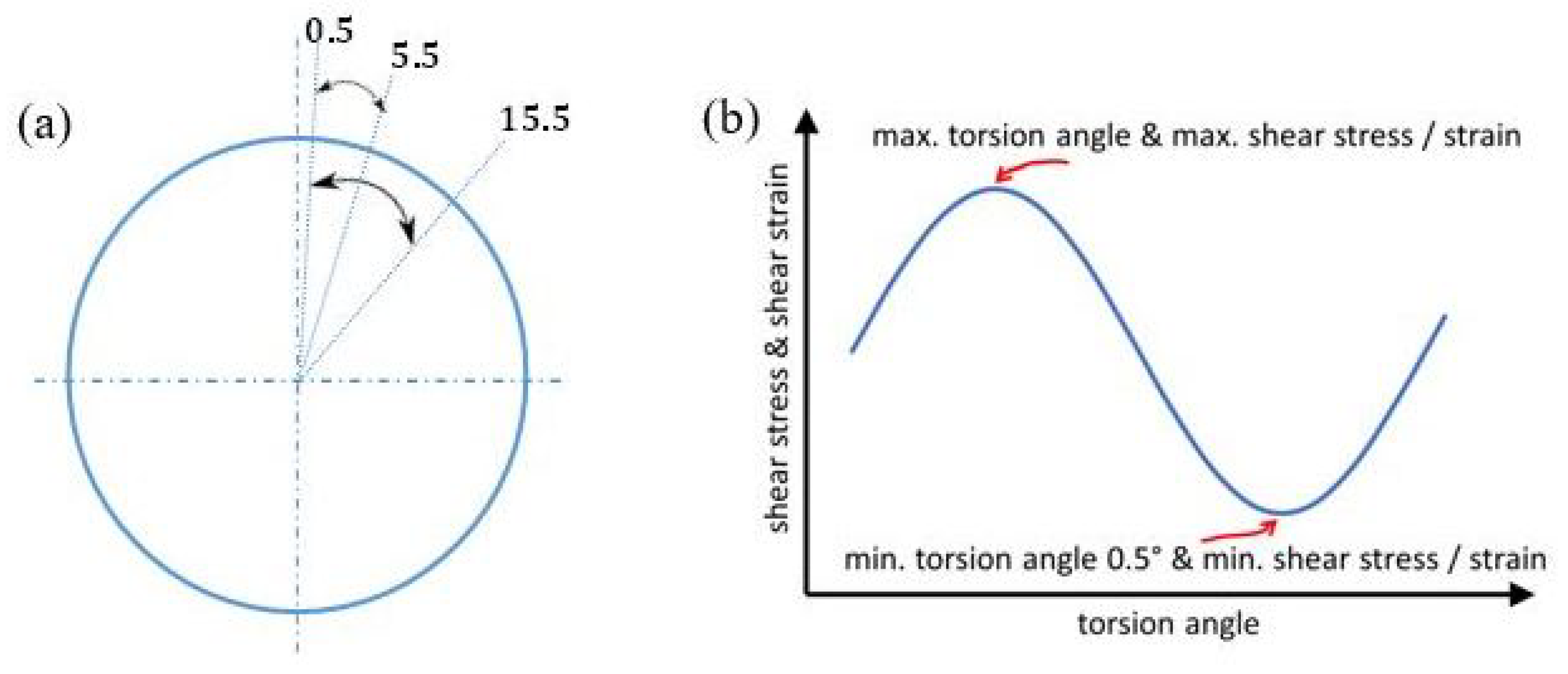

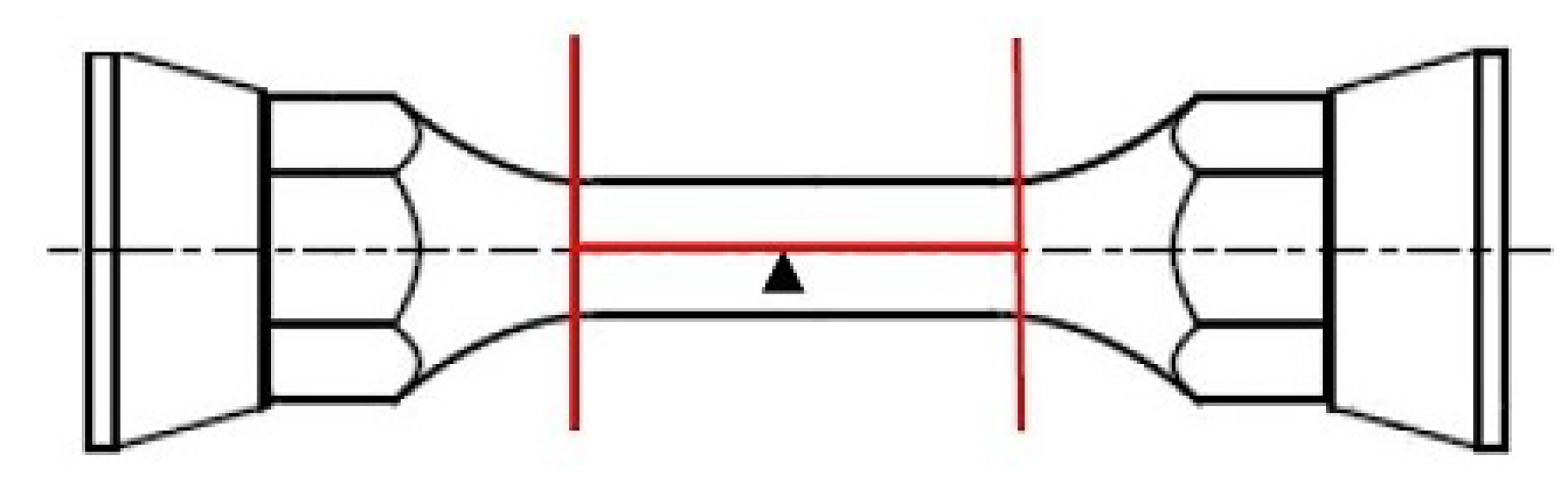

2.1. Multiaxial Fatigue Tests

2.2. Metallography

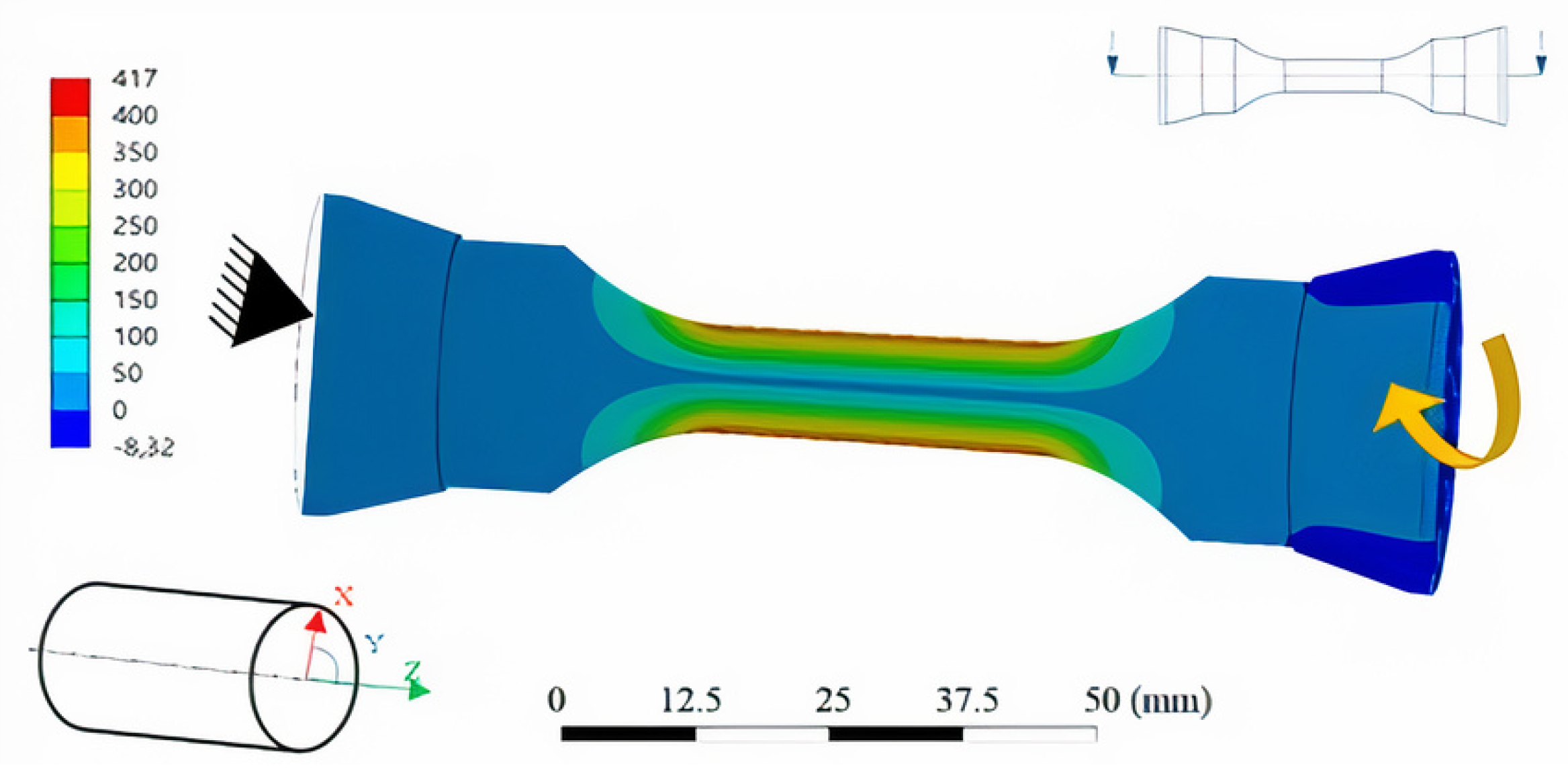

2.3. Finite Element Modelling

3. Results

3.1. Evolution of Shear Stresses

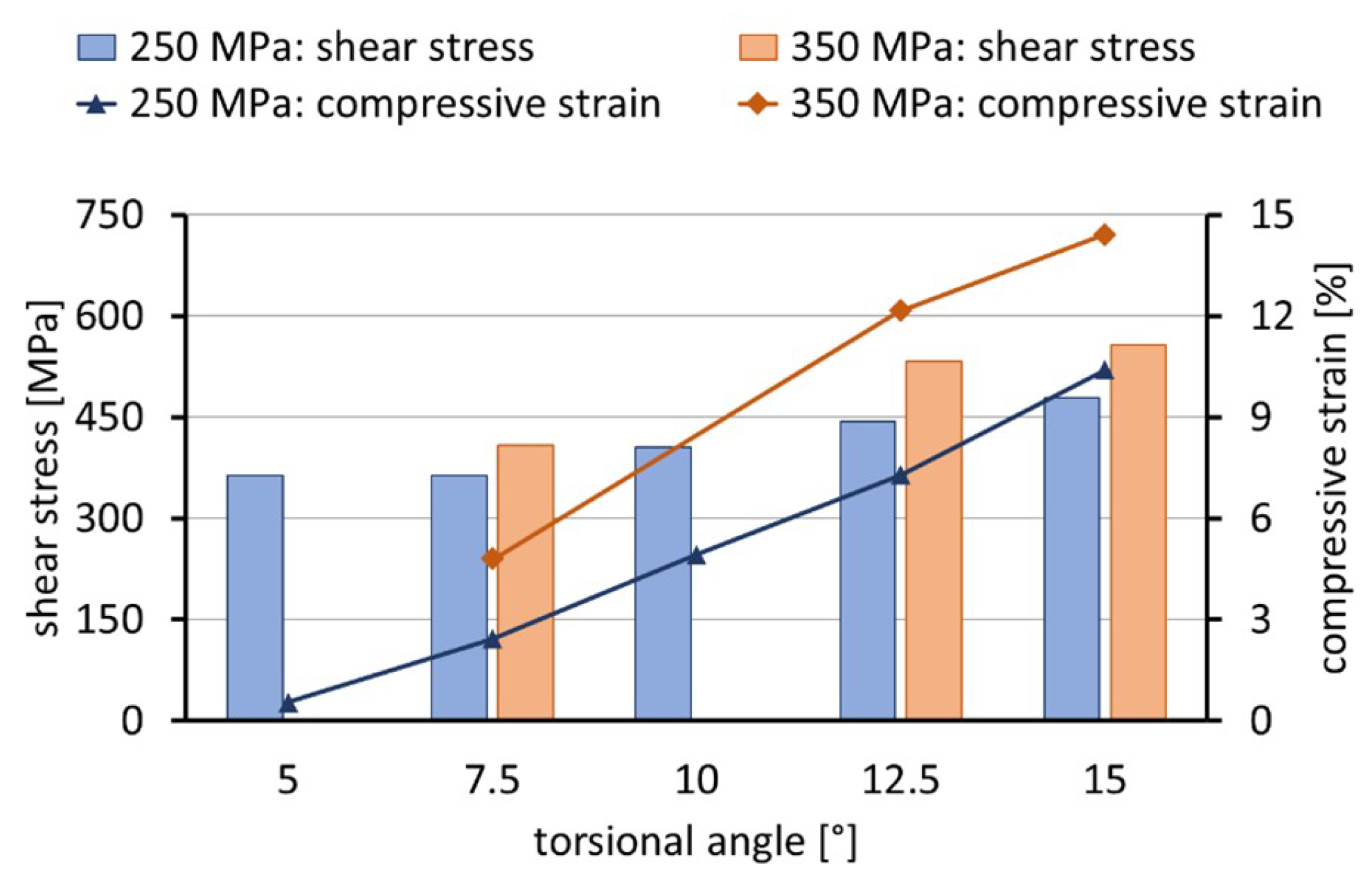

3.1.1. Maximum Shear Stress and Maximum Compressive Strain

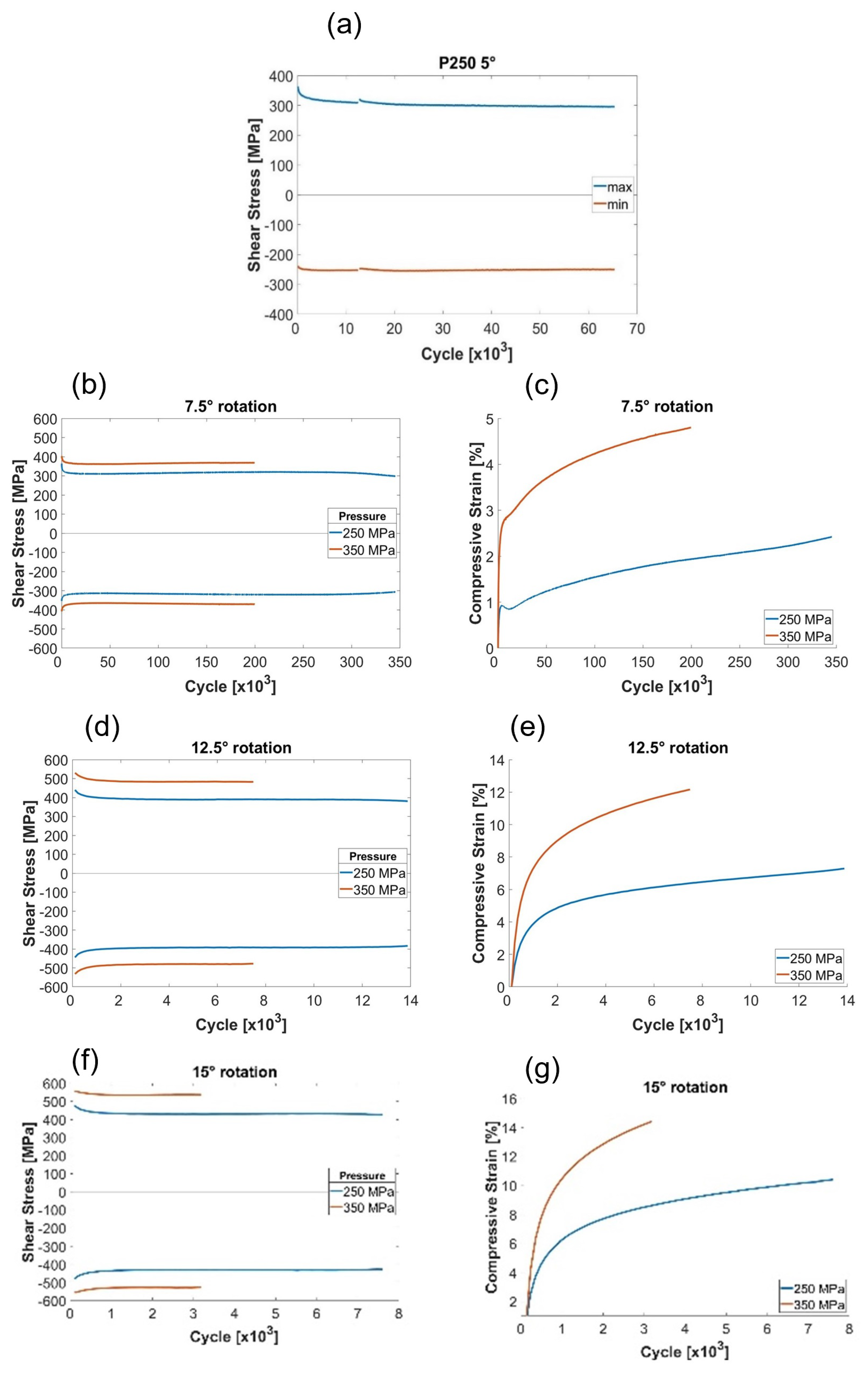

3.1.2. Shear Stress and Compressive Strain Evolution over the Test Duration

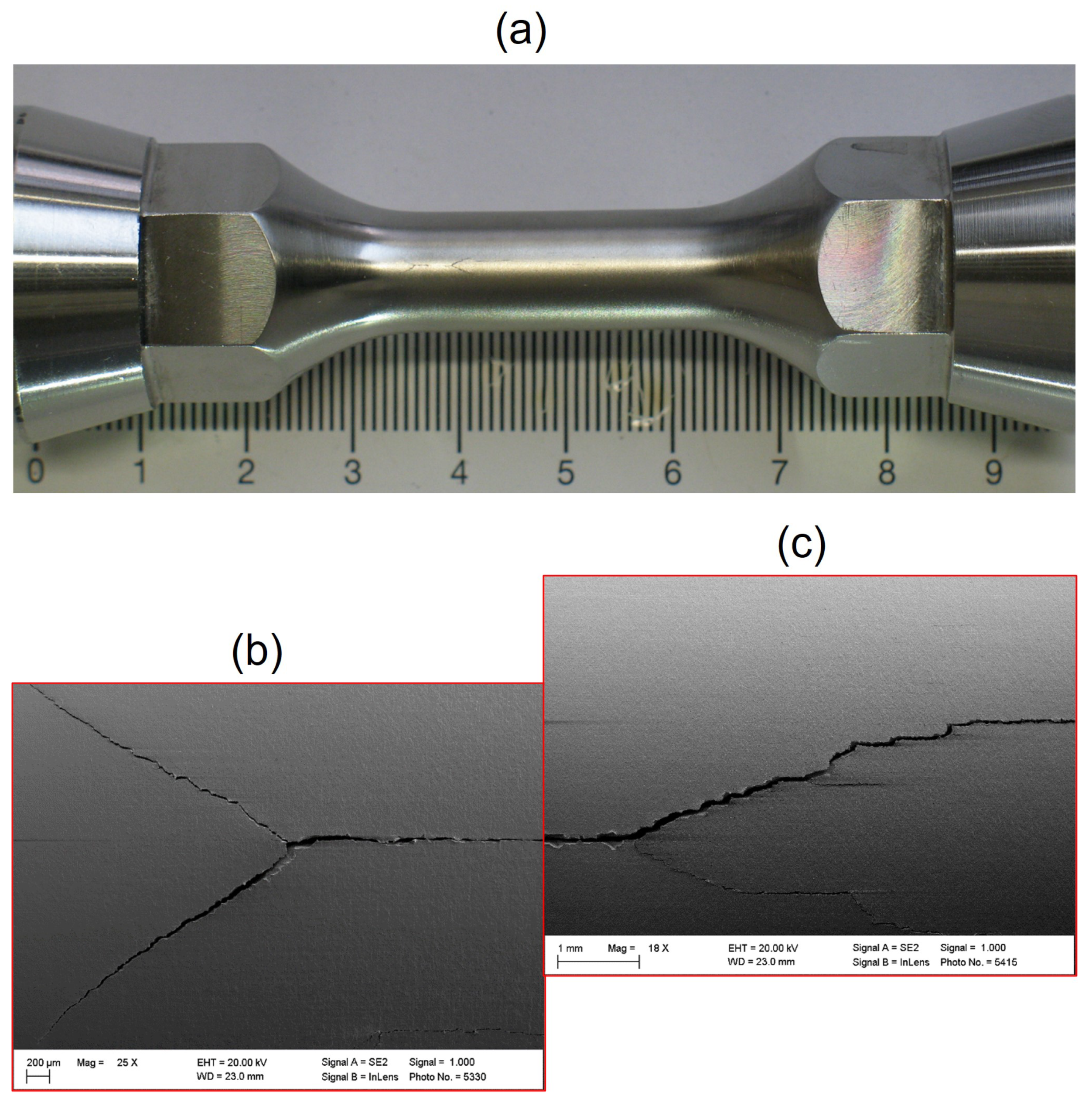

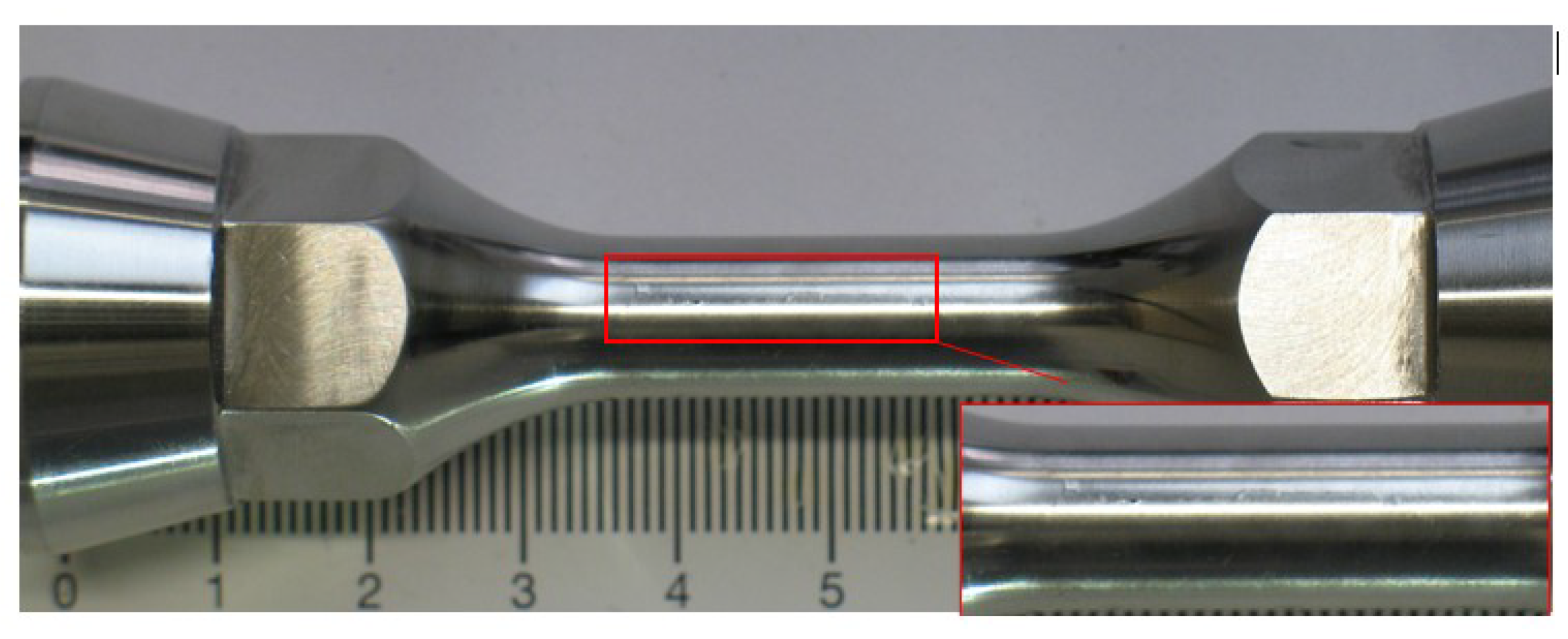

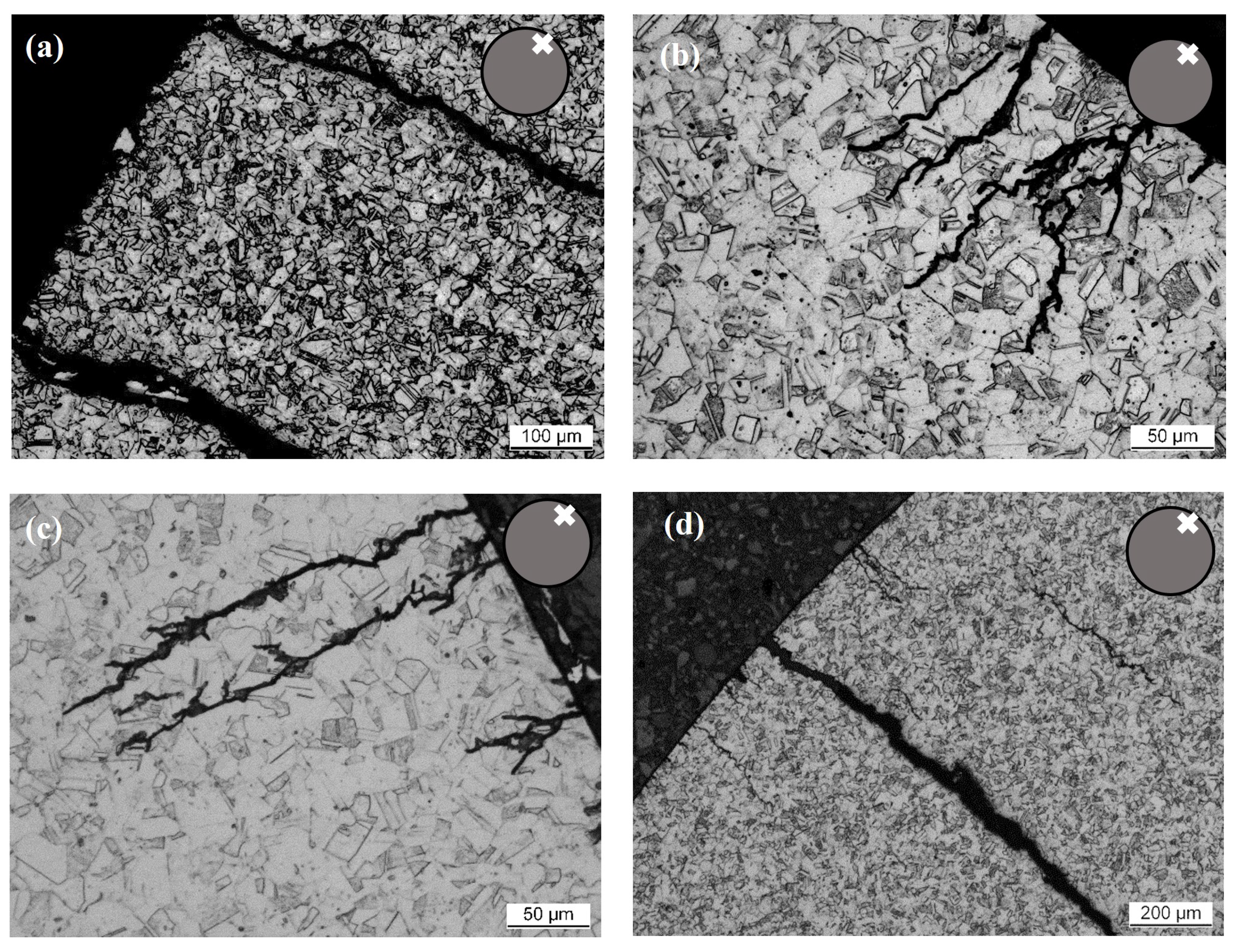

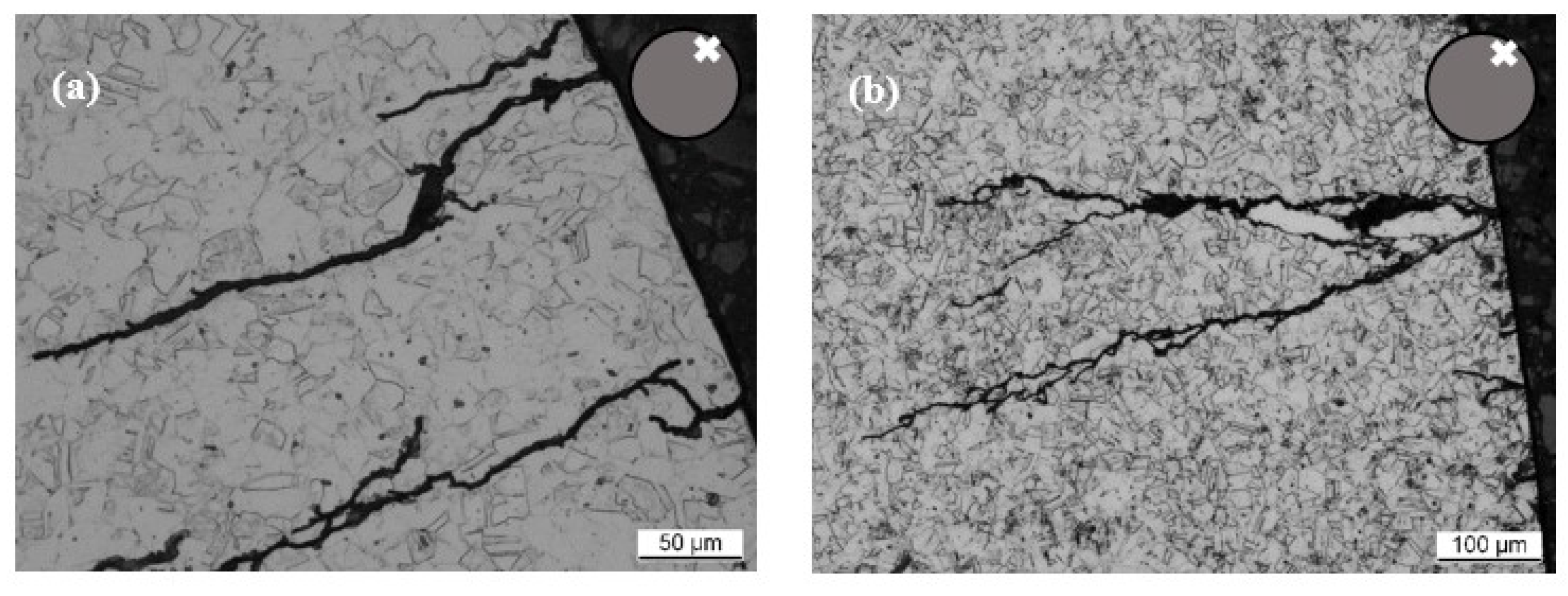

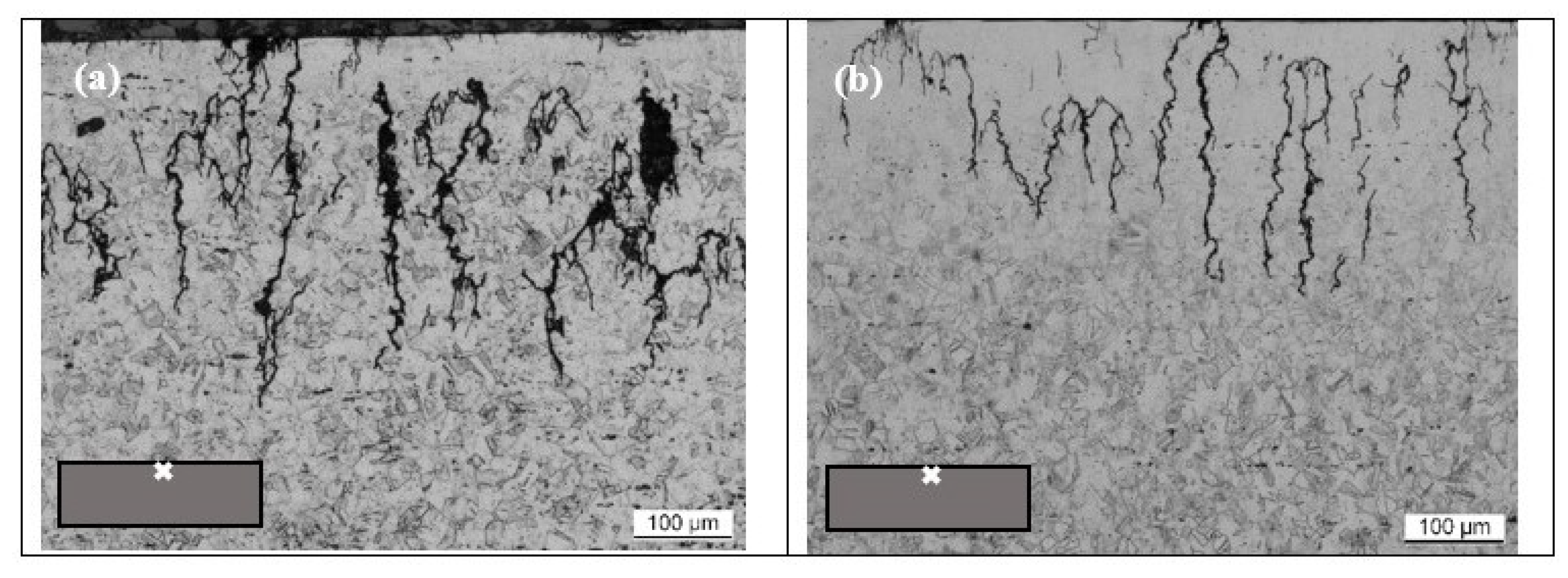

3.2. Damage and Crack Formation

4. Discussion

5. Summary and Conclusions

Author Contributions

Funding

Institutional Review Board Statement

Informed Consent Statement

Data Availability Statement

Conflicts of Interest

References

- Janssens, K. Proportionally and non-proportionally perturbed fatigue of stainless steel. Int. J. Fatigue 2017, 110, 42–48. [Google Scholar] [CrossRef]

- Mei, J.; Dong, P. A new path-dependent fatigue damage model for non-proportional multiaxial loading. Int. J. Fatigue 2016, 90, 210–221. [Google Scholar] [CrossRef]

- Wang, C.H.; Brown, M.W. A Path-independent Parameter for Fatigue under Proportional and Non-proportional Loading. Fatigue Fract. Eng. Mater. Struct. 1993, 16, 1285–1297. [Google Scholar] [CrossRef]

- Li, J.; Qiu, Y.Y. A path-dependent multiaxial fatigue life estimation criterion for metals under various loading conditions. Int. J. Fatigue 2021, 149, 106300. [Google Scholar] [CrossRef]

- Gates, N.; Fatemi, A. Multiaxial variable amplitude fatigue life analysis including notch effects. Int. J. Fatigue 2016, 91 Pt 2, 337–351. [Google Scholar] [CrossRef]

- Itoh, T.; Sakane, M.; Ohnami, M.; Socie, D.F. Nonproportional Low Cycle Fatigue Criterion for Type 304 Stainless Steel. ASME J. Eng. Mater. Technol. 1995, 117, 285–295. [Google Scholar] [CrossRef]

- Bemfica, C.; Mamiya, E.; Castro, F. Axial-torsional fatigue and cyclic deformation of 304L stainless steel at room temperature. MATEC Web Conf. 2019, 300, 08004. [Google Scholar] [CrossRef] [Green Version]

- Fatemi, A.; Socie, D.F. A Critical Plane Approach to multiaxial Fatigue Damage Including Out-of-phase Loading. Fatigue Fract. Eng. Mater. Struct. 1988, 11, 149–165. [Google Scholar] [CrossRef]

- Murakami, Y. Multiaxial Fatigue Testing, Mechanical Testing and Evaluation. In Mechanical Testing and Evaluation; Kuhn, H., Medlin, D., Eds.; ASM International: Almere, The Netherlands, 2000; pp. 779–785. [Google Scholar] [CrossRef]

- Alaswad, A.; Benyounis, K.; Olabi, A.G. Optimization Techniques in Material Processing. In Reference Module in Materials Science and Materials Engineering; Elsevier B.V.: Amsterdam, The Netherlands, 2015. [Google Scholar] [CrossRef]

- Forsyth, P.J.E. A two stage process of fatigue crack growth. Proc. Crack Propag. Symp. 1962, 1, 76–94. [Google Scholar]

- Zhang, W.; Akid, R. Mechanisms and fatigue performance of two steels in cyclic torsion with axial static tension/compression. Fatigue Fract. Eng. Mater. Struct. 2007, 20, 547–557. [Google Scholar] [CrossRef]

- Močilnik, V.; Gubeljak, N.N.; Predan, J. The influence of a static constant normal stress level on the fatigue resistance of high strength spring steel. Theor. Appl. Fract. Mech. 2017, 91, 139–147. [Google Scholar] [CrossRef]

- Li, Y.; Aubin, V.; Rey, C.; Bompard, P. Microstructural modeling of fatigue crack initiation in austenitic steel 304. Procedia Eng. 2012, 31, 541–549. [Google Scholar] [CrossRef]

- Rodak, K.; Pawlicki, J. Efficiency of the compression with oscillatory torsion method in grain refinement in Al. Arch. Civ. Mech. Eng. 2016, 16, 805–812. [Google Scholar] [CrossRef]

- Shanina, B.; Tyshchenko, A.; Glavatskyy, I.; Runov, V.; Petrov, Y.; Berns, H.; Gavriljuk, V. Chemical nano-scale homogeneity of austenitic CrMnCN steels in relation to electronic and magnetic properties. J. Mater. Sci. 2011, 46, 7725–7736. [Google Scholar] [CrossRef]

- Zuber, M. Implantatlegierung mit hohen Anforderungen an Korrosions- und Ermüdungsbeständigkeit. Available online: https://www.hempel-metals.com/de/werkstoffe/sonderwerkstoffe/rex-734/ (accessed on 24 December 2021).

- Griza, S.; Santos, S.; Ueki, M.; Bertoni, F.; Strohaecker, T. Case study and analysis of a fatigue failure in a THA stem. Eng. Fail. Anal. 2013, 28, 166–175. [Google Scholar] [CrossRef]

- Kang, G.; Gao, Q.; Lx, C.; Sun, Y. Experimental study on uniaxial and nonproportionally multiaxial ratcheting of SS304 stainless steel at room and high temperatures. Nucl. Eng. Des. 2002, 216, 13–26. [Google Scholar] [CrossRef]

- Meggiolaro, M.A.; Castro, J.T.P. Evaluation of multiaxial stress-strain models and fatigue life prediction methods under proportional loading. In Mechanics of Solids in Brazil 2009; da Costas Mattos, H.S., Alves, M., Eds.; Brazilian Society of Mechanical Science and Engineering: Rio de Janeiro, Brazil, 2009; pp. 365–384. [Google Scholar]

- Razmjoo, G. Fatigue of load-carrying fillet welded joints under multiaxial loading. In Proceedings of the 5th International Conference on Biaxial/multiaxial Fatigue & Fracture, Cracow, Poland, 8–12 September 1997; pp. 53–70. [Google Scholar]

- Pejkowski, Ł.; Skibicki, D.; Sempruch, J. High-Cycle Fatigue Behavior of Austenitic Steel and Pure Copper under Uniaxial, Proportional and Non-Proportional Loading. J. Mech. Eng. 2014, 60, 549–560. [Google Scholar] [CrossRef]

- Yousefi, F.; Witt, M.; Zenner, H. Fatigue strength of welded joints under multiaxial loading: Experiments and calculations. Fatigue Fract. Eng. Mater. Struct. 2001, 24, 339–355. [Google Scholar] [CrossRef]

- Siljander, A.; Kurath, P.; Lawrence, F. Nonproportional fatigue of welded structures. In Advances in Fatigue Lifetime Predictive Techniques; ASTM International: West Conshohocken, PA, USA, 1992. [Google Scholar]

- Facheris, G.; Janssens, K.; Foletti, S. Multiaxial fatigue behavior of AISI 316L subjected to strain-controlled and ratcheting paths. Int. J. Fatigue 2014, 68, 195–208. [Google Scholar] [CrossRef]

- Chaves, V.; Navarro, A.M.; Madrigal, C. Stage I crack directions under in-phase axial–torsion fatigue loading for AISI 304L stainless steel. Int. J. Fatigue 2015, 80, 10–21. [Google Scholar] [CrossRef]

- Suresh, S.; Ritchie, R.O. Propagation of short fatigue cracks. Int. Mater. Rev. 1984, 29, 445–475. [Google Scholar] [CrossRef]

| C | Si | Mg | P | S | Cr |

| ≤0.08 | ≤0.75 | 2–2.45 | ≤0.025 | ≤0.010 | 19.5 |

| Mo | Ni | Nb | N | Cu | Fe |

| 2–3 | 9–11 | 0.25–0.8 | 0.25–0.5 | ≤0.25 | rest |

| Electrolyte | 10 % Oxalic acid |

| Temperature | 7 °C |

| Voltage | 12 V |

| Flow rate | 10 |

| Time | 30 s |

| Compressive Stress (MPa) | Maximum Torsion Angle ° | Shear Stress (MPa) | Von Mises Stress (MPa) | Compressive Strain (%) |

|---|---|---|---|---|

| 250 | 5 | 363 | 677 | 0.55 |

| 250 | 7.5 | 364 | 678 | 2.42 |

| 250 | 10 | 406 | 746 | 4.93 |

| 250 | 12.5 | 444 | 809 | 7.29 |

| 250 | 15 | 478 | 865 | 10.40 |

| 350 | 7.5 | 408 | 789 | 4.80 |

| 350 | 12.5 | 532 | 986 | 12.16 |

| 350 | 15 | 557 | 1026 | 14.42 |

Publisher’s Note: MDPI stays neutral with regard to jurisdictional claims in published maps and institutional affiliations. |

© 2022 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (https://creativecommons.org/licenses/by/4.0/).

Share and Cite

Ngeru, T.; Kurtulan, D.; Karkar, A.; Hanke, S. Mechanical Behaviour and Failure Mode of High Interstitially Alloyed Austenite under Combined Compression and Cyclic Torsion. Metals 2022, 12, 157. https://doi.org/10.3390/met12010157

Ngeru T, Kurtulan D, Karkar A, Hanke S. Mechanical Behaviour and Failure Mode of High Interstitially Alloyed Austenite under Combined Compression and Cyclic Torsion. Metals. 2022; 12(1):157. https://doi.org/10.3390/met12010157

Chicago/Turabian StyleNgeru, Timothy, Dzhem Kurtulan, Ahmet Karkar, and Stefanie Hanke. 2022. "Mechanical Behaviour and Failure Mode of High Interstitially Alloyed Austenite under Combined Compression and Cyclic Torsion" Metals 12, no. 1: 157. https://doi.org/10.3390/met12010157

APA StyleNgeru, T., Kurtulan, D., Karkar, A., & Hanke, S. (2022). Mechanical Behaviour and Failure Mode of High Interstitially Alloyed Austenite under Combined Compression and Cyclic Torsion. Metals, 12(1), 157. https://doi.org/10.3390/met12010157