Abstract

Nd-Fe-B magnets containing no heavy rare earth (HRE) elements exhibit insufficient coercivity to withstand the demagnetization field at elevated temperatures. The grain boundary diffusion (GBD) process provides the best route to fabricate high-coercive Nd-Fe-B magnets with low consumption of expensive HRE resources. Here we give a special review on the grain boundary diffusion sources and their coating methods. Up to now, various types of grain boundary sources have been developed, starting from the earliest Tb or Dy metal. The HRE-M eutectic alloys were firstly proposed for reducing the cost of the diffusion source. After that, the diffusion sources based on light rare earth and even non rare earth elements have also been proposed, leading to new understanding of GBD. Now, the diffusion sources including inorganic compounds, metals, and alloys have been employed in the industry. At the same time, to coat the diffusion source on the magnets before diffusion treatment, various methods have been developed. Different from the previous review articles for GBD, this review gives an introduction of typical types of diffusion sources and their fabrication approaches. The effects of diffusion source on the microstructure and magnetic properties are summarized briefly. In particular, the principles and applicability of different coating approaches were discussed in detail. It is believed that this review can provide a technical guidance for the industry for designing the diffusion process and products meeting specific requirements.

1. Introduction

Nd-Fe-B permanent magnets have been widely used in various fields including conventional electric motors, renewable energy, and mobile communication industries [1,2,3]. The total world production of sintered Nd-Fe-B magnets in 2019 was 1.9 × 105 tons, and the demand of Nd-Fe-B magnets is constantly increasing due to the large employment of electric motors and generators in the near future [4]. The magnets in the motors and generators should operate at temperatures greater than 150 °C [3], but the Nd-Fe-B magnets without the addition of heavy rare earth (HRE) elements have insufficient coercivity (Hcj) to withstand the demagnetization field at high such temperatures because the hard magnetic Nd2Fe14B (2:14:1 phase) compound has a low Curie point (Tc) of ~312 °C, and its anisotropy field (HA) decreases drastically with the increasing temperature [5,6]. A conventional route for fabricating high-coercive Nd-Fe-B magnets is adding the HRE elements of Dy and Tb during smelting. However, it results in a large consumption of expensive HRE resource and a sacrifice of remanence (Jr).

The grain boundary diffusion (GBD) process for the Nd-Fe-B magnets, which was firstly proposed in 2005, provides the best route to enhance the Hcj with less consumption of HRE [7,8]. By this way, HRE infiltrates from the surface to the interior of the magnets during a diffusion heat treatment, mainly strengthening the surface of Nd2Fe14B grains by forming (Nd,HRE)2Fe14B structured shells. With the coercivity increment of 560 kA/m, the amount of Dy introduced by GBD is only 10% of that added by the conventional route [8]. Up to now, GBD has attracted much interest from both industry and academic, and it has become an important approach for the industry to fabricate cheap yet strong products. Now, most commercial Nd-Fe-B magnets with Hcj > 1600 kA/m (SH grade) are fabricated by GBD [9]. Their maximum working temperatures can be greater than 150 °C.

The HRE-based compound is regarded as the first generation of diffusion source. To get rid of the dependence of HRE, in 2010, a diffusion alloy of Nd-Cu without any HRE element was demonstrated effective for coercivity enhancement, which started the research and development (R&D) of the second generation of sources based on light rare earth (LRE) elements [10]. Subsequently, in 2015, a cost-effective diffusion source of MgO was proposed [11]. It gave an idea that the non-rare earth (non-RE) compound or alloy can be used to modify the grain boundary (GB) phase as the next generation of diffusion source.

The GBD process for the Nd-Fe-B magnets have been extensively reviewed in some recently published articles [12,13,14,15,16]. The development of GBD sources and their positive effects on magnetic properties have been discussed in detail. Different from them, this review mainly focuses on the introduction of the design and fabrication of several typical types of GBD sources. Their coating methods of the diffusion sources are described in detail. The advantages, disadvantages, and the applied ranges of various coating methods are discussed. Since the Nd-Fe-B products are mainly fabricated under customization, different diffusion sources and coating methods can be employed to meet the specific applications. It is believed that this review can provide a technical guidance for the industry for designing the diffusion process and products.

2. Development of Diffusion Sources and Their Fabrication

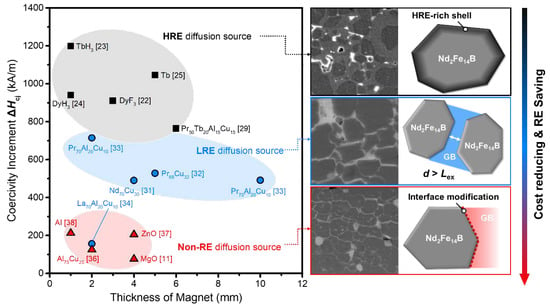

Figure 1 shows a comparison of the coercivity increment after GBD by HRE, LRE, and non-RE based diffusion sources, as well as their underlying mechanisms of coercivity improvement. Among the three types of GBD sources, the HRE-based one can directly enhance the Hcj by increasing the HA of 2:14:1 phase, and has been industrialized. Generally, a two-step diffusion heat treatment is needed for commercial sintered magnets. During the first step GBD, the heating temperature range is generally selected at 800 to 1000 °C to ensure that the melting GB phase provides effective diffusion channels for HRE atoms. At this stage, the surface of Nd2Fe14B grains also melts due to the eutectic reaction of Nd-Nd2Fe14B system at ~685 °C [17], which is lower than the temperature of the first step GBD. In this case, HRE atoms substitute Nd atoms in the 2:14:1 lattice at the surface of the 2:14:1 grain, forming (Nd,HRE)2Fe14B shells around the hard magnetic grains [18,19]. The temperature of the second step GBD is usually selected between 400 to 600 °C to modify the distribution of GB phase, i.e., facilitating the formation of continuous GB layers for magnetic decoupling. The reported HRE-based diffusion sources can enhance the Hcj by > 900 kA/m for the magnets with a thickness of <5 mm. The effective HRE containing GBD sources mainly include fluorides, hydrides, and metals/alloys [20,21,22,23,24,25,26,27,28,29].

Figure 1.

A comparison of coercivity increment in sintered magnets for different types of diffusion sources, including HRE, LRE, and non-RE based metals, compounds and alloys. The main mechanisms of the three generations of diffusion sources on coercivity enhancement are given.

The LRE-based alloys with low melting points can form thick and continuous GB layers, effectively isolating the hard magnetic grains for decoupling. The GBD conditions of LRE sources are similar to those of the HRE sources, i.e., using a two-step heat treatment process. At present, the effective LRE-based diffusion sources mainly include Pr- and Nd-based low-melting alloys [30,31,32,33,34,35,36]. The coercivity increment caused by Pr-Al-Cu reaches 700 kA/m and ~500 kA/m for 2 mm- and 10 mm-thick magnets, respectively [33]. In addition to the Pr- and Nd-based diffusion alloys, high-abundance La- and Ce-based alloys have been also studied as diffusion sources recently [34,35,36]. However, their caused coercivity enhancement is still marginal. Some recent researches demonstrated that the non-RE elements have positive effects on microstructure modification, i.e., wetting the GB phase and reducing the defects at 2:14:1grain/GB interfaces [11,36,37,38,39]. Therefore, various non-RE metals, alloys, and compounds have been selected as the diffusion sources. The diffusion of ZnO can lead to a coercivity enhancement of 205 kA/m in a 4-mm thick magnet [37]. So far, although the coercivity enhancement by the non-RE diffusion (<250 kA/m) is still much lower than that by the RE diffusion, the non-RE GBD is expected to improve the corrosion resistance and mechanical properties of the magnets.

2.1. HRE-Based Diffusion Sources and Their Fabrication

The HRE-based diffusion sources mainly include fluorides, hydrides, and metals/alloys. Generally, various rare earth (RE) oxides symbiotically exist in ores, and HRE elements should be separated from other RE elements for application. HRE oxides can be directly used for diffusion sources, but, due to their great stability and high melting points of >2000 °C, they generally exhibit poor diffusion efficiency [7,40]. Furthermore, the HRE atoms are difficult to enter into the 2:14:1 phase from the oxides, leading to a low coercivity enhancement. Therefore, the HRE oxides should be further modified to the diffusion sources with higher efficiency.

HRE fluorides are important raw materials for producing single HRE metals by thermal reduction. In the industry, the fluorides with high purity are generally fabricated from oxides by using hydrogen fluoride (HF) and ammonium hydrogen fluoride (NH4HF2) gases, and their reaction equations are HRE2O3 + 6HF → 2HREF3 + 3H2O, and HRE2O3 + 6NH4HF2 → 2HREF3 + 6NH4F + 3H2O (HRE = Dy, Tb), respectively. By using the HF gas as the reducing agent, less impurity is introduced, but, due to its high reaction temperature of 600 to 700 °C and strong causticity, it is difficult to treat the tail gas. In comparison, the reaction product from using NH4HF2 is easy to be recycled due to its relatively low reaction temperature of <300 °C, but it needs several repeated fluorination processes for controlling the oxygen content. DyF3 and TbF3 have much lower melting points of 1360 and 1172 °C, respectively, than their oxides, indicating that the HRE-F bonds have stronger tendency than HRE-O to be broken during the diffusion heat treatment at ~900 °C. This is beneficial for HRE atoms to enter into the 2:14:1 grain for improving the HA. In addition, F- has positive effects on saving the HRE resources. For instance, since a reaction of Nd2O3 + 2DyF3 → (Nd,Dy)4O3F6 occurs during GBD, Dy is suppressed to be consumed at a stable (Nd,Dy)2O3 phase [41,42]. The chemical potential for Dy diffusion can be increased by F− anions in Nd2Fe14B grain, and thus the Dy atoms in the (Nd,Dy)4O3F6 phase can diffuse into the 2:14:1 lattice [43,44].

Mass-produced HRE metals with high purity are mainly prepared by thermal reduction from their fluorides. Active non-RE metals of Ca, Mg, and Li can be employed as reductants, and Ca metal is used most widely in the industry. The reaction of 2HREF3 + 3Ca → 2HRE + 3CaF2 occurs during the reduction process. The melting points of Dy and Tb are 1409 and 1356 °C, respectively, slightly higher than their fluorides. However, it has been reported that Dy and Tb have a higher diffusion rate than their fluorides due to the different reactions occurring in the GB phase, and thus perform better in coercivity enhancement [45]. For achieving higher efficiency, the metallic HRE can be alloyed by LRE elements of Pr, Nd, La, and Ce, and non-RE elements of Al, Cu, Mg, etc., to form eutectic alloys with low melting points [26,28,32,45,46,47]. These added elements also play important roles in enhancing the coercivity through thickening the GBs for magnetic decoupling or reducing the defects at the interface to hinder the nucleation of reversed domains. In addition, the HRE content in the diffusion source can be reduced for reducing the material cost.

The HRE hydrides can be produced from HRE metals under a hydrogen pressure at 350 to 450 °C [48]. Compared with the HRE metals, the HRE hydride powders are more stable, indicating that the hydrides can be fabricated into the powders with smaller size. Furthermore, the hydrogen tends to be desorbed during the diffusion heat treatment. For instance, two dehydrogenation reactions of DyH3 are 2DyH3 → 2DyH2 + H2 (352.4 °C, ΔH > 0) and DyH2 → Dy + H2 (984.5 °C, ΔH > 0) [48]. Once the hydrogen is desorbed, the powders become very reactive, which is beneficial to the diffusion of HRE. Furthermore, since a reaction of NdOx + xH2 → Nd + xH2O occurs during GBD, the deoxidized Nd-rich phases have better wettability with the main phase grain, helping the formation of continuous GB layer surrounding the 2:14:1 grain for decoupling. This is also beneficial to forming the uniform HRE-rich shells [19,41,48]. However, during the GBD, the 2:14:1 could also absorb the hydrogen with a reaction of Nd2Fe14B + (2 ± x) H2 → 2NdH2±x + 12Fe +Fe2B + ΔH2. The caused volume expansion could lead to the propagation of crack along the GB, which is not beneficial to the mechanical properties of the magnets.

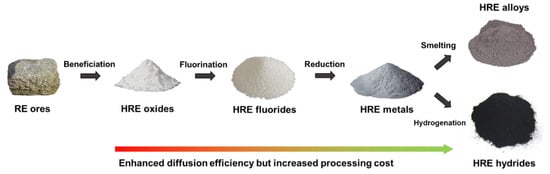

Figure 2 summarizes the fabrication steps of the HRE-based diffusion sources. With the further treatment of HRE oxides, the diffusion efficiency of HRE sources can be enhanced. As a result, a higher coercivity increment can be obtained, and a thicker magnet can be treated. However, the processing cost of the diffusion sources is also increased. Therefore, the industry should select the diffusion source reasonably according to the performance requirement of the products.

Figure 2.

Fabrication steps of the HRE-based diffusion sources.

2.2. Design of LRE-Based Diffusion Sources

In comparison to the HRE-based diffusion sources, the LRE-based ones are still not widely industrialized. Due to their much lower material prices, the LRE-based diffusion sources will attract more attention in the near future and have a foreseeable development. This section mainly introduces several principles to design LRE-based diffusion alloys.

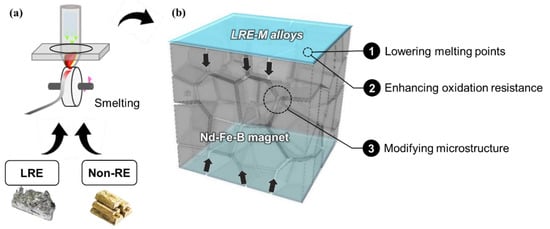

Based on the basic underlying mechanism of the LRE-based diffusion sources on coercivity improvement, most of the effective LRE sources are low-melting alloys at present. Forming LRE-M (LRE = Pr, Nd, La, Ce; M = Cu, Al, Mg, Zn, Ni) eutectic alloys by melting is a common method to obtain the low-melting diffusion sources (Figure 3a). The LRE elements, on the one hand, play significant roles in increasing the amount of the RE-rich intergranular phase for magnetic decoupling, and on the other hand, could replace Nd atoms within the 2:14:1 grains. In this case, Pr2Fe14B exhibits higher HA of 87 kOe than Nd2Fe14B (67 kOe) at 300 K [6], and thus the substitution of Nd by Pr in the main phase can enhance the coercivity. In contrast, poor intrinsic magnetic properties were found in the 2:14:1 compounds of La and Ce [5,49], and the induced La and Ce are expected to segregate at GB. Previous results showed that the La, Ce-based alloys still performs much more inferior than the Pr/Nd-based ones as the diffusion source [36]. This is attributed to not only the different diffusion behavior of RE elements, but also the different wettability between the modified intergranular phase and the 2:14:1 grain.

Figure 3.

(a) Fabrication of LRE-M diffusion alloys, and (b) design principles in selecting non-RE alloy elements.

The non-RE elements play important roles in lowering the melting points of the diffusion source, and they also should exhibit positive effects on magnetic properties. These non-RE elements can greatly influence the diffusion behavior of LRE elements, and determine the improvement of magnetic properties at a certain extent. For instance, it was found that the coercivity enhancement caused by Pr-Al-Cu diffusion was quite sensitive to the ratio of Al/Cu [33]. The diffusion of Pr70Al20Cu10 alloy can lead to an Hcj increase of 712 kA/m, much higher than that caused by Pr70Al10Cu20 diffusion (360 kA/m). A similar phenomenon can be observed in the La-Al-Cu system [34]. Therefore, the selection of non-RE alloying elements is very important for designing effective LRE-M diffusion source. Furthermore, the non-RE elements such as Al and Ni can also modify the 2:14:1 phase by substituting Fe for a higher HA [16]. The positive effects of the non-RE elements on microstructure modification have been summarized in a recent review article [16], which is not described in detail here.

Since the intergranular phases possess much lower corrosion potentials than the Nd2Fe14B main phase, a galvanic corrosion tends to occur in corrosive medium, leading to a preferential failure of GB phases and a resultant detachment of main phase grains [50,51]. Therefore, the corrosion resistance of the magnets should be considered for practical applications, especially for those employed in seashore wind turbines. However, recent results showed that the diffusion of LRE-based alloys, such as Pr-Al-Cu and La-Al-Cu, unexpectedly decreased the corrosion resistance of the magnets due to the formed multiple intergranular phases [36]. In this case, introducing the non-RE elements with high chemical stability in GB through GBD could be a feasible route to improve the corrosion resistance of the magnets, and this deserves more attention for the future investigations. Furthermore, since LRE elements are reactive to oxygen [52], the oxidation of the alloy diffusion sources during storage and diffusion heat treatment could be a crucial reason which limits the employment of the LRE-based diffusion sources. The oxidation could severely decrease the diffusion efficiency, and particularly, deteriorate the wettability between the liquid GB phase and the 2:14:1 phase. In this case, theoretically, the non-RE elements of Al, Ni, Ti, and Cr, which exhibit a self-passivation effect in air, can be selected to alloy with the LRE to form diffusion alloys for a higher oxidation resistance. However, not many investigations have been focused on this point at the present. Much effort should be made to reveal the effects of the non-RE elements on the chemical stability of LRE-M diffusion alloys.

In summary, the design principles for LRE-M diffusion alloys in selecting non-RE alloy elements are present in Figure 3b. Firstly, the non-RE elements should be able to form eutectic alloys with the LRE elements for high diffusion efficiency. Secondly, these elements should enhance the chemical stability of the diffusion sources to avoid the oxidation during the storage and diffusion heat treatment. Finally, the added non-RE elements should also have positive effects on optimizing the microstructure. Noted that the microstructure modification is not only for enhancing the coercivity by forming continuous GB phase or reducing the amount of defects at the GB/2:14:1 interface, but also for improving the corrosion resistance of the magnets by reducing the corrosion potential between the GB and 2:14:1 phases. If the coercivity and corrosion resistance can be simultaneously enhanced by GBD process, the surface protection by anti-corrosion coatings for the Nd-Fe-B products can even be canceled, which is beneficial to further cut down the process cost. Unfortunately, the reported LRE-M diffusion sources tend to deteriorate the corrosion resistance of the magnets due to the formation of multiple RE-rich intergranular phases [36]. Therefore, the LRE-M systems should be painstakingly optimized in future investigations.

2.3. Design of Non-RE-Based Diffusion Sources

Inspired from the LRE-based diffusion alloys, if any introduced elements can modify the microstructure and wet the liquid phase to form continuous and uniform GB layers, they are candidates to be employed in the diffusion sources for the Nd-Fe-B magnets. This indicates that the critical RE elements may be not necessary for GBD. The reported non-RE based diffusion sources includes compounds and metals/alloys [34,35,36]. Although their positive effects on coercivity enhancement are still weaker than those of RE-based sources, it was found interesting that the diffusion of non-RE elements is effective to improve the chemical stability of the magnets [34,35,36]. The existing results imply that the non-RE GBD could have a broader application range than the RE GBD.

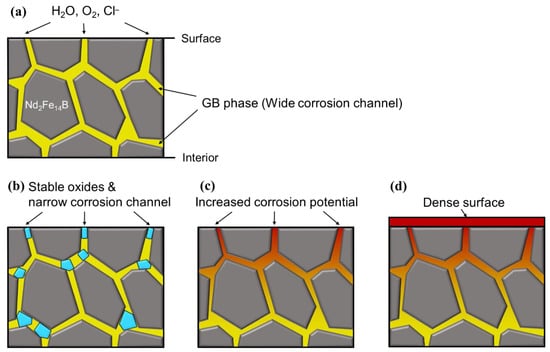

Previous investigations gave several feasible approaches to enhancing corrosion resistance of the Nd-Fe-B magnets by non-RE diffusion with different physical mechanisms. Figure 4a shows the corrosion mechanism of Nd-Fe-B magnets. Due to the strong corrosion tendency of intergranular phase, the corrosion tends to occur along the GB and corrosive media such as H2O, O2, and Cl- can easily enter from the surface into the interior of the magnets through the wide corrosion channels. The GBD of non-RE oxides, including MgO [11] and ZnO [37], have been demonstrated effective to resist the corrosive medium infiltrating into the magnet. As shown in Figure 4b, the diffusion of non-RE oxides mainly lead to the formation of stable block oxides, such as Nd-Fe-O-Mg and Nd-Fe-O-Zn at triple-junction regions, which narrows the corrosion channels. The low-melting non-RE metals or alloys, such as Al [38] and Al75Cu25 [36], enhance the chemical stability of the magnets mostly by modifying the GB phases to increase their corrosion potentials (Figure 4c). These two types of non-RE sources mainly resist the corrosion process from kinetics and thermodynamics aspects, respectively, but their protection may not be as effective as that caused by an anti-corrosion coating. Since the anti-corrosion coatings can greatly isolate the reactive magnet substrate from the corrosive environment, we proposed an annealed Al-Cr coating recently for combining both surface coating and GBD [39]. Refractory Cr element was selected to modify the diffusion of Al, i.e., during the annealing, a small amount of Al was allowed to enter into the magnet for GB modification, while the added Cr led to a dense surface coating (Figure 4d). The results showed that the coercivity of the Al62.5Cr37.5 diffused magnet was increased from 1089 to 1178 kA/m. Meanwhile, in 3.0 wt.% NaCl solution, the corrosion current density of this magnet decreased significantly from 35.32 to 2.53 μA/cm2. This method gives an idea to integrate the surface protection with the GBD process, which could further improve the competitiveness of non-RE based diffusion sources.

Figure 4.

(a) The corrosion mechanism for Nd-Fe-B magnets. The schematic of improvement of corrosion resistance by GBDs by non-RE based (b) oxides, (c) low-melting metals/alloys, and (d) high-melting alloys.

3. Coating Methods of Diffusion Sources

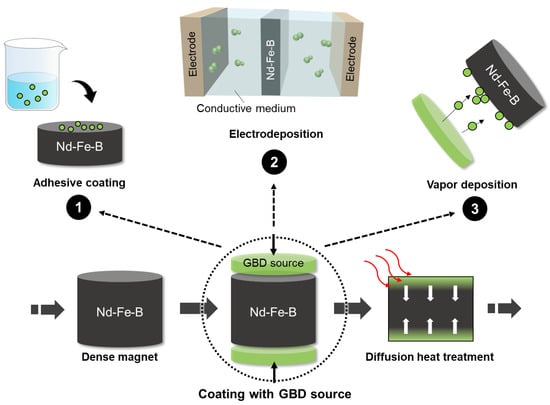

Section 2 introduced various sources for GBD. Compared with the investigations of diffusion sources, the studies about how the sources can be deposited onto the magnets are relatively insufficient. However, this issue is quite critical for the industry. With the development of GBD process, more and more coating techniques have been employed for coating the diffusion sources. This section summarizes various coating methods for GBD sources and show how they have been applied or they will be employed. As shown in Figure 5, at present, the coating methods for GBD sources can be mainly classified into three types: adhesive coating, electrodeposition, and vapor deposition.

Figure 5.

Processing steps of GBD and a classification of coating methods for GBD sources.

3.1. Adhesive Coating

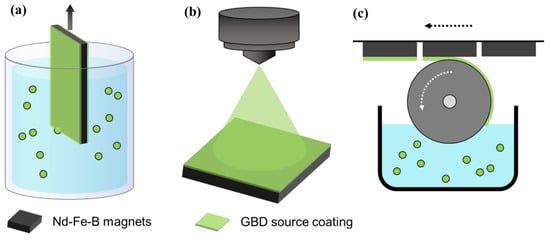

By the adhesive coating, the powder-form diffusion sources are firstly mixed with liquid organic binders to obtain suspensions or slurries. Subsequently, the suspensions or slurries are deposited onto the surface of the magnets by dipping, spraying, and roller coating.

Dipping has been a common method to deposit the HRE inorganic compounds, including oxides [7], fluorides [7,53], and hydrides [19,41,53]. The particle size of those compounds is generally controlled at 1 to 5 μm [7,41]. By this method, the magnets are immersed in the suspensions of the diffusion source, soaked for a short time, and then removed from the container, as shown in Figure 6a. During the removal of the coated magnets, the excess diffusion sources will flow back into the container. Therefore, the dipping exhibits a high production efficiency and a simple process to deposit thick coatings with a thickness of 20 to 30 μm. However, it was suggested that the dipped coatings of diffusion sources are uneven and rough [22], indicating that it could cause an unexpected waste of HRE resource or an inhomogeneous diffusion. Furthermore, the consumption of diffusion source cannot be greatly controlled, which is not beneficial to obtaining the products with high stability.

Figure 6.

Schematics of (a) dipping, (b) spraying, and (c) roller coating methods for GBD sources.

Spraying is also effective for the inorganic compounds with small particle size of several micrometers. By the spraying, the suspensions of the diffusion source are atomized by a spray gun and deposited onto the surface of magnets, as shown in Figure 6b. This method also possesses a high production efficiency, and is suitable for both manual work and automatic production. Compared with the dipping, the spraying can easily fabricate a flat coating of diffusion source, but more diffusion sources will be consumed upon the deposition process. In addition, the highly dispersed spray can lead to a fierce volatilization of the organic solvents, which is not environmentally friendly and does harm to human health. Both the dipping and the spraying can treat profiled and large-scale magnets. For these two methods, the viscosity of the suspension greatly influences the quality of the coatings, i.e., an over-low viscosity causes an insufficient thickness of coatings while an over-high viscosity leads to a formation of uneven and over-thick coatings.

In comparison to the inorganic compounds, HRE metals/alloys are more difficult to suspend in the organic solvents due to their relatively low affinity to the organic solvents. It requires the metal/alloy powders to have a much smaller size than inorganic compound particles. However, the metal/alloy powders, especially the LRE-based alloys, are too reactive to be pulverized into fine powders. Hence, most of the reported alloy sources such as Dy-Ni-Al [3], Pr-Al [54], and Pr-Dy-Al [54], were mixed with paraffin and polyvinyl pyrrolidone (PVP), respectively, and were painted onto the surface of magnets. In this case, the roller coating provides a feasible approach to deposit the metal or alloy diffusion source carried by a roller (Figure 6c), since it is applied for not only the suspensions, but also the slurries with high viscosity. This method exhibits a simple process and is suitable to treat the large-scale magnets with regular shapes such as cube and cuboid.

In general, the adhesive coating methods exhibit a simple process and are suitable to treat magnets with large sizes. However, the amount of source coating cannot be precisely controlled. Furthermore, the organic solvents added into the diffusion sources play quite important roles to obtain an appropriate viscosity of adhesive coatings, but they have not been the focus of research. In addition, high contents of carbon [55] and oxygen [56,57] in the magnets have negative impacts on GBD since they facilitate the formation of refractory Nd-carbides and Nd-oxides, respectively, in GB. Therefore, during the temperature-rise period of diffusion heat treatment, the organic solvents should decompose into products with strong volatility to ensure the less residual carbon and oxygen on the surface of magnets. For industrialization, more attention should be focused on develop suitable solvents for various diffusion sources.

3.2. Electrodeposition

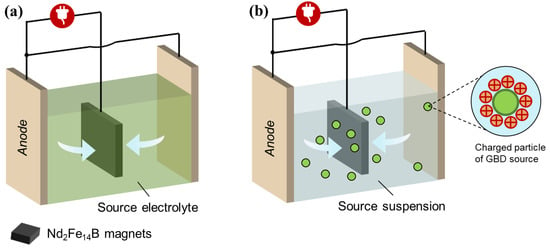

The electrodeposition for GBD sources mainly includes electroplating and electrophoresis. These two methods have quite different deposition principles, and thus exhibit different applications.

As shown in Figure 7a, by the electroplating, reduction-oxidation (REDOX) reactions occur and the metal ions in electrolytes are reduced on the surface of magnets to form metal/alloy source coatings. The magnet substrate generally acts as a cathode. In Nd-Fe-B industry, the electroplating is mainly used for depositing anti-corrosion coatings, such as Ni-P and Ni/Cu/Ni [58,59]. If the metal or alloy diffusion sources can be also prepared by electroplating, it is convenient for the companies to make full use of the existing production line. The metal and alloy source coatings, including Dy [60] and Nd-Cu [61], have been successfully fabricated by electroplating. The composition of alloy coatings can be controlled by the mixing ratio of their precursors. For instance, the Nd/Cu ratio can be regulated by changing the ratio of Nd(NO3)3 and Cu(NO3)2 in the electrolytes or the deposition potential [61]. The electroplating has a distinct advantage on fabricating smooth and thick coatings. However, the environmental concerns still exist and the pollution problems are urgent to be solved.

Figure 7.

Schematic of electrodeposition methods for GBD sources: (a) electroplating and (b) electrophoresis. The GBD source particle is assumed to be electropositive in (b).

Compared with the electroplating, the electrophoresis is more applicable for GBD sources of inorganic compounds, such as Dy2O3 [40], DyF3 [22,62], and TbF3 [63,64]. As shown in Figure 7b, during the electrophoretic process, the charged particles of diffusion sources in the suspensions move towards the magnet electrodes with an opposite polarity, and the deposition can be realized. Based on the different polarity of the source particles, the magnet substrate can be anode or cathode. It was suggested that compared with the dipping, the electrophoretic deposition can fabricate the uniform coatings with lower porosity, which is beneficial to the efficient use of diffusion sources [22,64]. Under the same condition of diffusion heat treatment, the DyF3 coatings deposited by dipping and electrophoresis enhanced the coercivity of the sintered magnets from 1200 to 1540 and 1620 kA/m, respectively [22]. However, by the electrophoretic deposition, the bonding between source particles in the coating is mainly dependent on the van der Waals force, indicating that the coatings could be easily detached from the magnets due to the poor coating/substrate adhesion. Therefore, the agglomerants such as polyethyleneimine (PEI) [40], are needed to be introduced into the suspensions.

Generally, the electrodeposition methods are applicable to treating the profiled magnets. They have advantages on fabricating dense and even coatings with thickness >10 μm, which is easy to employ for mass production. The thickness of the coating can be controlled by regulating deposition potential and keeping time. However, their processing cost is higher than that of adhesive coating methods due to their relatively longer processing cycle.

3.3. Vapor Deposition

Up to now, the vapor deposition for GBD sources is mainly physical vapor deposition (PVD). PVD is a rapidly growing technology in recent decades, which vaporizes the material source into gaseous atoms and molecules, or partially ionizes into ions by physical methods under vacuum, and realizes the deposition of films at room temperature. In comparison to the two mentioned coating methods of the adhesive coating and the electrodeposition, PVD can prepare the GBD source coatings without any effluent disposal, and therefore it can be regarded as the “greenest” coating techniques for GBD sources [65,66]. Based on the different ways to vaporize or ionize the material sources, the PVD can be mainly clarified into three types: evaporation deposition, sputtering deposition, and ion plating.

By evaporation deposition, the heated GBD sources are vaporized and sublimated onto the surface of the magnet. This method is mostly applicable for fabricating metallic and alloy coatings, and its deposition rate is relatively high among the PVD methods. Table 1 presents the temperature of several RE elementary substances for GBD in different vapor pressures. Generally, the temperature at which the saturated vapor pressure is 10−2 Torr is defined as the vaporization point. All of the listed RE metals for GBD exhibit the high vaporization points of >1000 °C, indicating that the costs from both equipment and energy consumption are undoubtedly increased. Previous work mainly paid attention to the evaporation of HRE metals of Dy [67] and Tb [68,69]. Among the critical RE elements of Pr, Nd, Dy, and Tb, the vaporization points of Nd and Dy are relatively low, and thus their metals and alloys are more capable for evaporation deposition.

Table 1.

Temperatures of several RE metals in different vapor pressures. The data are extracted from [52].

By sputtering deposition, solid GBD source targets are bombarded by accelerated particles, and the escaped atoms or molecules reach the surface of the magnet substrates to form coatings. This approach has been widely used to deposit not only HRE metals/alloys of Dy [20,70], Tb [70], Dy-Zn [71], and Dy-Mg [72], but also non-RE diffusion sources of MgO [11], ZnO [37], and Al [38]. Compared with the evaporation, the sputtering deposition can obtain greater coating/substrate adhesion and more stable product quality. Furthermore, the thickness of coatings can be precisely controlled at a nanometer level by modifying the sputtering power and deposition time. Therefore, sputtered GBD sources is also promising to treat Nd-Fe-B films for micromechanical devices and magnetic recording media. A sputtered 50-nm thick Dy film can enhance the coercivity from 963 for a 120-nm thick Nd-Dy-Fe-B layer to 1552 kA/m, obtaining an increase of 61% [73]. However, the sputtering targets are consumable items, and in particular, the effective availability of targets are of <30%, which increase the processing cost to a certain extent.

Ion plating is a method which integrates the evaporation and the sputtering, i.e., the evaporated GBD sources can be partially ionized by gas discharge, and the ions can be accelerated by an electric field to reach the surface of the magnet substrates. This leads to a significantly improved ionization rate and, therefore, the deposition rate of ion plating is generally higher than that of the sputtering. In addition, the high ionization rate is beneficial to treat profiled magnets because the ions can move along the electric field, wrapping around the substrate and forming uniform coatings. However, the ion plating has not been widely used for depositing GBD sources, mostly due to the high evaporation temperatures of the RE metals and the caused difficulty in the equipment manufacture.

Table 2 summarizes the advantages, disadvantages, and application ranges of different coating approaches for diffusion sources. Among the mentioned coating methods, the vapor deposition has an overwhelming advantage regarding environmental protection. Meanwhile, it can precisely control the consumption of GBD sources, which is beneficial for saving the critical RE resources and improving the stability of the product. However, owing to the necessary vacuum environment and the relatively low deposition rate, the production efficiency is lower than those of the adhesive coating and the electrodeposition. Furthermore, the vapor deposition still exhibits high costs from equipment and processing. Therefore, this approach applies to small quantities of products.

Table 2.

Advantages, disadvantages, and application ranges of various coating methods for depositing GBD sources.

4. Summary and Future Prospect

With the R&D of GBD process for over 20 years, the diffusion sources for Nd-Fe-B magnets have been developed for three generations of HRE, LRE, and non-RE based compounds or metals/alloys, in order to reduce the use critical RE elements and cost. At present, the GBD process can be employed to enhance not only the magnetic properties, but also other service performance such as corrosion resistance. Since the permanent magnets with less critical RE elements emerge rapidly in recent years, such as multi-main phase (MMP) magnets [54,74] and (La,Ce,Y)-Fe-B magnets [75,76], the non-RE diffusion sources are competitive to treat these cost-effective magnets. With the industrialization of GBD, various coating approaches for diffusion sources have been employed, including adhesive coating, electrodeposition, and vapor deposition. These methods have their own advantages, disadvantages, and application ranges. Since the Nd-Fe-B products are mainly fabricated under customization, the different diffusion sources and the various coating methods will be selected to meet specific applications. GBD is still in its rapid development and is far from mature. For the future investigations, more attention should be paid to develop not only efficient yet cheap diffusion sources, but also cost-effective coating methods.

Author Contributions

Conceptualization, J.H., J.C. and Z.Y.; methodology, J.H.; validation, H.Y., M.H. and Z.L.; formal analysis, J.H.; investigation, J.H.; resources, Z.L.; data curation, J.C., Z.Y. and W.S.; writing—original draft preparation, J.H.; writing—review and editing, J.H.; visualization, J.H.; supervision, Z.L.; project administration, Z.L.; funding acquisition, Z.L. All authors have read and agreed to the published version of the manuscript.

Funding

This research was funded by National Natural Science Foundation of China, grant number 51774146 and 52071143.

Institutional Review Board Statement

Not applicable.

Informed Consent Statement

Not applicable.

Data Availability Statement

Data available in a publicly accessible repository.

Acknowledgments

This work is supported by National Natural Science Foundation of China (Nos. 51774146 and 52071143).

Conflicts of Interest

The authors declare no conflict of interest.

References

- Coey, J.M.D. Hard magnetic materials: A perspective. IEEE Trans. Magn. 2011, 47, 4671–4681. [Google Scholar] [CrossRef]

- Gutfleisch, O.; Willard, M.A.; Bruck, E.; Chen, C.H.; Sankar, S.G.; Liu, J.P. Magnetic materials and devices for the 21st century: Stronger, lighter, and more energy efficient. Adv. Mater. 2011, 23, 821–842. [Google Scholar] [CrossRef]

- Oono, N.; Sagawa, M.; Kasada, R.; Matsui, H.; Kimura, A. Production of thick high-performance sintered neodymium magnets by grain boundary diffusion treatment with dysprosium–nickel–aluminum alloy. J. Magn. Magn. Mater. 2011, 323, 297–300. [Google Scholar] [CrossRef]

- Hu, B. Status quo of rare earth permanent magnet industry. In Proceedings of the Conference on Green Development and Efficient Utilization of Rare Earth Resources, Ganzhou, China, 20 October 2020. [Google Scholar]

- Grossinger, R.; Sun, X.K.; Eibler, R.; Buschow, K.H.J.; Kirchmayr, H.R. Temperature dependence of anisotropy fields and initial susceptibilities in R2Fe14B compounds. J. Magn. Magn. Mater. 1986, 58, 55–60. [Google Scholar] [CrossRef]

- Hirosawa, S.; Matsuura, Y.; Yamamoto, H.; Fujimura, S.; Sagawa, M.; Yamauchi, H. Magnetization and magnetic anisotropy of R2Fe14B measured on single crystals. J. Appl. Phys. 1986, 59, 873–879. [Google Scholar] [CrossRef]

- Nakamura, H.; Hirota, K.; Shimao, M.; Minowa, T.; Honshima, M. Magnetic properties of extremely small Nd-Fe-B sintered magnets. IEEE Trans. Magn. 2005, 41, 3844–3846. [Google Scholar] [CrossRef]

- Sugimoto, S. Current status and recent topics of rare-earth permanent magnets. J. Phys. D Appl. Phys. 2011, 44, 064001. [Google Scholar] [CrossRef]

- JLMAG RARE-EARTH CO., LTD. Available online: http://www.jlmag.com.cn/view44-1.html (accessed on 7 August 2021).

- Sepehri-Amin, H.; Ohkubo, T.; Nishiuchi, T.; Hirosawa, S.; Hono, K. Coercivity enhancement of hydrogenation–disproportionation–desorption–recombination processed Nd–Fe–B powders by the diffusion of Nd–Cu eutectic alloys. Scr. Mater. 2010, 63, 1124–1127. [Google Scholar] [CrossRef]

- Zhou, Q.; Liu, Z.W.; Zhong, X.C.; Zhang, G.Q. Properties improvement and structural optimization of sintered NdFeB magnets by non-rare earth compound grain boundary diffusion. Mater. Des. 2015, 86, 114–120. [Google Scholar] [CrossRef]

- Chen, F. Recent progress of grain boundary diffusion process of Nd-Fe-B magnets. J. Magn. Magn. Mater. 2020, 514, 167227. [Google Scholar] [CrossRef]

- Lv, M.; Kong, T.; Zhang, W.; Zhu, M.; Jin, H.; Li, W.; Li, Y. Progress on modification of microstructures and magnetic properties of Nd-Fe-B magnets by the grain boundary diffusion engineering. J. Magn. Magn. Mater. 2021, 517, 167278. [Google Scholar] [CrossRef]

- Liu, Z.; He, J. Several issues on the grain boundary diffusion process for Nd-Fe-B permanent magnets. Acta Metall. Sin. 2021, 57, 1155–1170. (in Chinese). [Google Scholar]

- Liu, Z.; He, J.; Ramanujan, R.V. Significant progress of grain boundary diffusion process for cost-effective rare earth permanent magnets: A review. Mater. Des. 2021, 209, 110004. [Google Scholar] [CrossRef]

- Liu, Z.; He, J.; Zhou, Q.; Huang, Y.; Jiang, Q. Development of non-rare earth grain boundary modification techniques for Nd-Fe-B permanent magnets. J. Mater. Sci. Technol. 2021, 98, 51–61. [Google Scholar] [CrossRef]

- Seelam, U.M.R.; Ohkubo, T.; Abe, T.; Hirosawa, S.; Hono, K. Faceted shell structure in grain boundary diffusion-processed sintered Nd-Fe-B magnets. J. Alloys. Compd. 2014, 617, 884–892. [Google Scholar] [CrossRef] [Green Version]

- Löewe, K.; Brombacher, C.; Katter, M.; Gutfleisch, O. Temperature-dependent Dy diffusion processes in Nd–Fe–B permanent magnets. Acta Mater. 2015, 83, 248–255. [Google Scholar] [CrossRef]

- Kim, T.H.; Sasaki, T.T.; Koyama, T.; Fujikawa, Y.; Miwa, M.; Enokido, Y.; Ohkubo, T.; Hono, K. Formation mechanism of Tb-rich shell in grain boundary diffusion processed Nd–Fe–B sintered magnets. Scr. Mater. 2020, 178, 433–437. [Google Scholar] [CrossRef]

- Park, K.T.; Hiraga, K.; Sagawa, M. Effect of metal-coating and consecutive heat treatment on coercivity of thin Nd-Fe-B sintered magnets. In Proceedings of the 16th Workshop on Rare Earth Permanent Magnet and their Applications, Sendai, Japan, 1 February 2000; pp. 257–264. [Google Scholar]

- Hirota, K.; Nakamura, H.; Minowa, T.; Honshima, M. Coercivity enhancement by the grain boundary diffusion process to Nd–Fe–B sintered magnets. IEEE Trans. Magn. 2006, 42, 2909–2911. [Google Scholar] [CrossRef]

- Soderžnik, M.; Rožman, K.Ž.; Kobe, S.; McGuiness, P. The grain-boundary diffusion process in Nd–Fe–B sintered magnets based on the electrophoretic deposition of DyF3. Intermetallics 2012, 23, 158–162. [Google Scholar] [CrossRef]

- Liu, W.Q.; Chang, C.; Yue, M.; Yang, J.S.; Zhang, D.T.; Zhang, J.X.; Liu, Y.Q. Coercivity, microstructure, and thermal stability of sintered Nd–Fe–B magnets by grain boundary diffusion with TbH3 nanoparticles. Rare Met. 2014, 36, 718–722. [Google Scholar] [CrossRef]

- Ji, W.; Liu, W.; Yue, M.; Zhang, D.; Zhang, J. Coercivity enhancement of recycled Nd–Fe–B sintered magnets by grain boundary diffusion with DyH3 nano-particles. Phys. B 2015, 476, 147–149. [Google Scholar] [CrossRef]

- Loewe, K.; Benke, D.; Kübel, C.; Lienig, T.; Skokov, K.P.; Gutfleisch, O. Grain boundary diffusion of different rare earth elements in Nd-Fe-B sintered magnets by experiment and FEM simulation. Acta Mater. 2017, 124, 421–429. [Google Scholar] [CrossRef]

- Liu, Y.; He, J.; Yu, H.; Liu, Z.; Zhang, G. Restoring and enhancing the coercivity of waste sintered (Nd,Ce,Gd)FeB magnets by direct Pr-Tb-Cu grain boundary diffusion. Appl. Phys. A 2020, 126, 657. [Google Scholar] [CrossRef]

- Liu, Y.; Liao, X.; He, J.; Yu, H.; Zhong, X.; Zhou, Q.; Liu, Z. Magnetic properties and microstructure evolution of in-situ Tb-Cu diffusion treated hot-deformed Nd-Fe-B magnets. J. Magn. Magn. Mater. 2020, 504, 166685. [Google Scholar] [CrossRef]

- Lu, K.; Bao, X.; Tang, M.; Chen, G.; Mu, X.; Li, J.; Gao, X. Boundary optimization and coercivity enhancement of high (BH)max Nd-Fe-B magnet by diffusing Pr-Tb-Cu-Al alloys. Scr. Mater. 2017, 138, 83–87. [Google Scholar] [CrossRef]

- Chen, G.; Bao, X.; Lu, K.; Lv, X.; Ding, Y.; Zhang, M.; Wang, C.; Gao, X. Microstructure and magnetic properties of Nd-Fe-B sintered magnet by diffusing Pr-Cu-Al and Pr-Tb-Cu-Al alloys. J. Magn. Magn. Mater. 2019, 477, 17–21. [Google Scholar] [CrossRef]

- Akiya, T.; Liu, J.; Sepehri-Amin, H.; Ohkubo, T.; Hioki, K.; Hattori, A.; Hono, K. Low temperature diffusion process using rare earth-Cu eutectic alloys for hot-deformed Nd-Fe-B bulk magnets. J. Appl. Phys. 2014, 115, 17a766. [Google Scholar] [CrossRef]

- Chen, F.; Zhang, T.; Wang, J.; Zhang, L.; Zhou, G. Coercivity enhancement of a Nd–Fe–B sintered magnet by diffusion of Nd70Cu30 alloy under pressure. Scr. Mater. 2015, 107, 38–41. [Google Scholar] [CrossRef]

- Lu, K.; Bao, X.; Tang, M.; Sun, L.; Li, J.; Gao, X. Influence of annealing on microstructural and magnetic properties of Nd-Fe-B magnets by grain boundary diffusion with Pr-Cu and Dy-Cu alloys. J. Magn. Magn. Mater. 2017, 441, 517–522. [Google Scholar] [CrossRef]

- Zeng, H.; Liu, Z.; Li, W.; Zhang, J.; Zhao, L.; Zhong, X.; Yu, H.; Guo, B. Significantly enhancing the coercivity of NdFeB magnets by ternary Pr-Al-Cu alloys diffusion and understanding the elements diffusion behavior. J. Magn. Magn. Mater. 2019, 471, 97–104. [Google Scholar] [CrossRef]

- Zeng, H.X.; Wang, Q.X.; Zhang, J.S.; Liao, X.F.; Zhong, X.C.; Yu, H.Y.; Liu, Z.W. Grain boundary diffusion treatment of sintered NdFeB magnets by low cost La-Al-Cu alloys with various Al/Cu ratios. J. Magn. Magn. Mater. 2019, 490, 165498. [Google Scholar] [CrossRef]

- Zeng, H.X.; Yu, H.Y.; Zhou, Q.; Zhang, J.S.; Liao, X.F.; Liu, Z.W. Clarifying the effects of La and Ce in the grain boundary diffusion sources on sintered NdFeB magnets. Mater. Res. Express 2019, 6, 106105. [Google Scholar] [CrossRef]

- Zeng, H.X.; Liu, Z.W.; Zhang, J.S.; Liao, X.F.; Yu, H.Y. Towards the diffusion source cost reduction for NdFeB grain boundary diffusion process. J. Mater. Sci. Technol. 2020, 36, 50–54. [Google Scholar] [CrossRef]

- Wang, E.; Xiao, C.; He, J.; Lu, C.; Hussain, M.; Tang, R.; Zhou, Q.; Liu, Z. Grain boundary modification and properties enhancement of sintered Nd-Fe-B magnets by ZnO solid diffusion. Appl. Surf. Sci. 2021, 565, 150545. [Google Scholar] [CrossRef]

- Chen, W.; Huang, Y.L.; Luo, J.M.; Hou, Y.H.; Ge, X.J.; Guan, Y.W.; Liu, Z.W.; Zhong, Z.C.; Wang, G.P. Microstructure and improved properties of sintered Nd-Fe-B magnets by grain boundary diffusion of non-rare earth. J. Magn. Magn. Mater. 2019, 476, 134–141. [Google Scholar] [CrossRef]

- He, J.; Liao, X.; Lan, X.; Qiu, W.; Yu, H.; Zhang, J.; Fan, W.; Zhong, X.; Liu, Z. Annealed Al-Cr coating: A hard anti-corrosion coating with grain boundary modification effect for Nd-Fe-B magnets. J. Alloys. Compd. 2021, 870, 159229. [Google Scholar] [CrossRef]

- Guan, Y.W.; Huang, Y.L.; Rao, Q.; Li, W.; Hou, Y.H.; Luo, J.M.; Pang, Z.S.; Mao, H.Y. Investigation on the grain boundary diffusion of Dy2O3 film prepared by electrophoretic deposition for sintered Nd-Fe-B magnets. J. Alloys. Compd. 2020, 857, 157606. [Google Scholar] [CrossRef]

- Kim, T.H.; Lee, S.R.; Kim, H.J.; Lee, M.W.; Jang, T.S. Simultaneous application of Dy–X ( X = F or H) powder doping and dip-coating processes to Nd–Fe–B sintered magnets. Acta Mater. 2015, 93, 95–104. [Google Scholar] [CrossRef]

- Takashima, M.; Kano, G. Preparation and electrical conductivity of binary rare earth metal fluoride oxides. Solid State Ionics Diffus. React. 1987, 23, 99–106. [Google Scholar] [CrossRef]

- Kim, T.H.; Lee, S.R.; Kim, H.J.; Lee, M.W.; Jang, T.S. Magnetic and microstructural modification of the Nd-Fe-B sintered magnet by mixed DyF3/DyHx powder doping. J. Appl. Phys. 2014, 115, 17A763. [Google Scholar] [CrossRef]

- Park, S.E.; Kim, T.H.; Lee, S.R.; Kim, D.H.; Nam-Kung, S.; Jang, T.S. Magnetic and microstructural characteristics of Nd-Fe-B sintered magnets doped with Dy2O3 and DyF3 powders. IEEE Trans. Magn. 2011, 47, 3259–3262. [Google Scholar] [CrossRef]

- Li, D.; Suzuki, S.; Kawasaki, T.; Machida, K.I. Grain interface modification and magnetic properties of Nd–Fe–B sintered magnets. Japn. J. Appl. Phys. 2008, 47, 7876–7878. [Google Scholar] [CrossRef]

- Wong, Y.J.; Chang, H.W.; Lee, Y.I.; Chang, W.C.; Chiu, C.H.; Mo, C.C. Comparison on the coercivity enhancement of sintered NdFeB magnets by grain boundary diffusion with low-melting (Tb, R)75Cu25 alloys (R= None, Y, La, and Ce). AIP Adv. 2019, 9, 125238. [Google Scholar] [CrossRef] [Green Version]

- Wong, Y.J.; Chang, H.W.; Lee, Y.I.; Chang, W.C.; Chiu, C.H.; Mo, C.C. Coercivity enhancement of thicker sintered NdFeB magnets by grain boundary diffusion with low-melting Tb75-xCexCu25 (x = 0–45) alloys. J. Magn. Magn. Mater. 2020, 515, 167287. [Google Scholar] [CrossRef]

- Liu, P.; Ma, T.; Wang, X.; Zhang, Y.; Yan, M. Role of hydrogen in Nd-Fe-B sintered magnets with DyHx addition. J. Alloys. Compd. 2015, 628, 282–286. [Google Scholar] [CrossRef]

- Yan, M.; Jin, J.; Ma, T. Grain boundary restructuring and La/Ce/Y application in Nd–Fe–B magnets. Chin. Phys. B 2019, 28, 077507. [Google Scholar] [CrossRef]

- Wu, Y.; Gao, Z.; Xu, G.; Liu, J.; Xuan, H.; Liu, Y.; Yi, X.; Chen, J.; Han, P. Current status and challenges in corrosion and protection strategies for sintered NdFeB magnets. Acta Metall. Sin. 2020, 57, 171–181. (In Chinese) [Google Scholar]

- Peng, B.; Jin, J.; Liu, Y.; Lu, C.; Li, L.; Yan, M. Towards peculiar corrosion behavior of multi-main-phase Nd-Ce-Y-Fe-B permanent material with heterogeneous microstructure. Corros. Sci. 2020, 177, 108972. [Google Scholar] [CrossRef]

- Gschneidner, K.A.; Eyring, L.; Hüfner, S. Handbook on the Physics and Chemistry of Rare Earths, 4th ed.; North Holland: North Holland, The Netherlands, 1994. [Google Scholar]

- Bae, K.H.; Kim, T.H.; Lee, S.R.; Kim, H.J.; Lee, M.W.; Jang, T.S. Magnetic and microstructural characteristics of DyF3/DyHx dip-coated Nd–Fe–B sintered magnets. J. Alloys. Compd. 2014, 612, 183–188. [Google Scholar] [CrossRef]

- Jin, J.; Chen, W.; Li, M.; Liu, X.; Yan, M. PrAl and PrDyAl diffusion into Nd-La-Ce-Fe-B sintered magnets: Critical role of surface microstructure in the magnetic performance. Appl. Surf. Sci. 2020, 529, 147028. [Google Scholar] [CrossRef]

- Sasaki, T.T.; Ohkubo, T.; Une, Y.; Kubo, H.; Sagawa, M.; Hono, K. Effect of carbon on the coercivity and microstructure in fine-grained Nd–Fe–B sintered magnet. Acta Mater. 2015, 84, 506–514. [Google Scholar] [CrossRef] [Green Version]

- Mo, W.; Zhang, L.; Liu, Q.; Shan, A.; Wu, J.; Komuro, M. Dependence of the crystal structure of the Nd-rich phase on oxygen content in an Nd–Fe–B sintered magnet. Scr. Mater. 2008, 59, 179–182. [Google Scholar] [CrossRef]

- Bae, K.H.; Lee, S.R.; Kim, H.J.; Lee, M.W.; Jang, T.S. Effect of oxygen content of Nd–Fe–B sintered magnet on grain boundary diffusion process of DyH2 dip-coating. J. Appl. Phys. 2015, 118, 203902. [Google Scholar] [CrossRef]

- Minowa, T.; Yoshikawa, M.; Honshima, M. Improvement of the corrosion resistance on Nd-Fe-B magnet with nickel plating. IEEE Trans. Magn. 1989, 25, 3776–3778. [Google Scholar] [CrossRef]

- Cheng, C.W.; Man, H.C.; Cheng, F.T. Magnetic and corrosion characteristics of Nd-Fe-B magnet with various surface coatings. IEEE Trans. Magn. 1997, 33, 3910–3912. [Google Scholar] [CrossRef]

- Tang, X.T.; Lu, Z.W.; Sun, A.Z. The effect of sintered Nd-Fe-B with Dy infiltration to the plating crafts. J. Magn. Magn. Mater. 2019, 475, 10–13. [Google Scholar] [CrossRef]

- Lee, S.; Kwon, J.; Cha, H.-R.; Kim, K.M.; Kwon, H.W.; Lee, J.; Lee, D. Enhancement of coercivity in sintered Nd-Fe-B magnets by grain-boundary diffusion of electrodeposited Cu-Nd Alloys. Met. Mater. Int. 2016, 22, 340–344. [Google Scholar] [CrossRef]

- Cao, X.J.; Chen, L.; Guo, S.; Li, X.B.; Yi, P.P.; Yan, A.R.; Yan, G.L. Coercivity enhancement of sintered Nd–Fe–B magnets by efficiently diffusing DyF3 based on electrophoretic deposition. J. Alloys. Compd. 2015, 631, 315–320. [Google Scholar] [CrossRef]

- Cao, X.; Chen, L.; Guo, S.; Chen, R.; Yan, G.; Yan, A. Impact of TbF3 diffusion on coercivity and microstructure in sintered Nd–Fe–B magnets by electrophoretic deposition. Scr. Mater. 2016, 116, 40–43. [Google Scholar] [CrossRef]

- Soderžnik, M.; Korent, M.; Žagar Soderžnik, K.; Katter, M.; Üstüner, K.; Kobe, S. High-coercivity Nd-Fe-B magnets obtained with the electrophoretic deposition of submicron TbF3 followed by the grain-boundary diffusion process. Acta Mater. 2016, 115, 278–284. [Google Scholar] [CrossRef]

- Navinšek, B.; Panjan, P.; Milošev, I. PVD coatings as an environmentally clean alternative to electroplating and electroless processes. Surf. Coat. Technol. 1999, 116–119, 476–487. [Google Scholar] [CrossRef]

- He, J.; Lan, X.; Wan, J.; Liu, H.; Liu, Z.; Jiao, D.; Zhong, X.; Cheng, Y.; Qiu, W. Modifying Cr/CrN composite structure by Fe addition: Toward manufacturing cost-effective and tough hard coatings. Appl. Surf. Sci. 2021, 545, 149025. [Google Scholar] [CrossRef]

- Sepehri-Amin, H.; Ohkubo, T.; Hono, K. The mechanism of coercivity enhancement by the grain boundary diffusion process of Nd–Fe–B sintered magnets. Acta Mater. 2013, 61, 1982–1990. [Google Scholar] [CrossRef]

- Watanabe, N.; Itakura, M.; Kuwano, N.; Li, D.; Suzuki, S.; Machida, K.I. Microstructure analysis of sintered Nd-Fe-B magnets improved by Tb-vapor sorption. Mater. Trans. 2007, 48, 915–918. [Google Scholar] [CrossRef] [Green Version]

- Watanabe, N.; Umemoto, H.; Ishimaru, M.; Itakura, M.; Nishida, M.; Machida, K. Microstructure analysis of Nd-Fe-B sintered magnets improved by Tb-metal vapour sorption. J. Micros. 2009, 236, 104–108. [Google Scholar] [CrossRef]

- Matchida, K.; Suzuki, S.; Kawasaki, T.; Li, D.S.; Kitamon, T.; Nakamura, K.; Shimizu, Y. High-coercive Nd-Fe-B sintered magnets diffused with Dy or Tb metal and their applications. In Proceeding of the INTERMAG Asia 2005: Digest of the IEEE International Magnetics Conference, Nagoya, Japan, 4–8 April 2005; pp. 947–948. [Google Scholar]

- Li, J.; Guo, C.; Zhou, T.; Qi, Z.; Yu, X.; Yang, B.; Zhu, M. Effects of diffusing DyZn film on magnetic properties and thermal stability of sintered NdFeB magnets. J. Magn. Magn. Mater. 2018, 454, 215–220. [Google Scholar] [CrossRef]

- Zhong, S.; Munan, Y.; Rehman, S.U.; Yaojun, L.; Jiajie, L.; Yang, B. Microstructure, magnetic properties and diffusion mechanism of DyMg co-deposited sintered Nd-Fe-B magnets. J. Alloys. Compd. 2020, 819, 153002. [Google Scholar] [CrossRef]

- Gong, W.J.; Wang, X.; Liu, W.; Guo, S.; Wang, Z.H.; Cui, W.B.; Zhu, Y.L.; Zhang, Y.Q.; Zhang, Z.D. Enhancing the perpendicular anisotropy of NdDyFeB films by Dy diffusion process. J. Appl. Phys. 2012, 111, 07a729. [Google Scholar] [CrossRef]

- Jin, J.; Yan, M.; Liu, Y.; Peng, B.; Bai, G. Attaining high magnetic performance in as-sintered multi-main-phase Nd-La-Ce-Fe-B magnets: Toward skipping the post-sinter annealing treatment. Acta Mater. 2019, 169, 248–259. [Google Scholar] [CrossRef]

- Zhang, J.S.; Liao, X.F.; Xu, K.; He, J.Y.; Fan, W.B.; Yu, H.Y.; Zhong, X.C.; Liu, Z.W. Enhancement in hard magnetic properties of nanocrystalline (Ce,Y)–Fe–Si–B alloys due to microstructure evolution caused by chemical heterogeneity. J. Mater. Chem. C 2020, 8, 14855–14863. [Google Scholar] [CrossRef]

- Liao, X.; Zhang, J.; He, J.; Fan, W.; Yu, H.; Zhong, X.; Liu, Z. Development of cost-effective nanocrystalline multi-component (Ce,La,Y)-Fe-B permanent magnetic alloys containing no critical rare earth elements of Dy, Tb, Pr and Nd. J. Mater. Sci. Technol. 2021, 76, 215–221. [Google Scholar] [CrossRef]

Publisher’s Note: MDPI stays neutral with regard to jurisdictional claims in published maps and institutional affiliations. |

© 2021 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (https://creativecommons.org/licenses/by/4.0/).