Effect of MgO Content on Heat Capacity of Synthetic BF Slag and Heat Release Behavior during Cooling Process

Abstract

:1. Introduction

2. Experimental

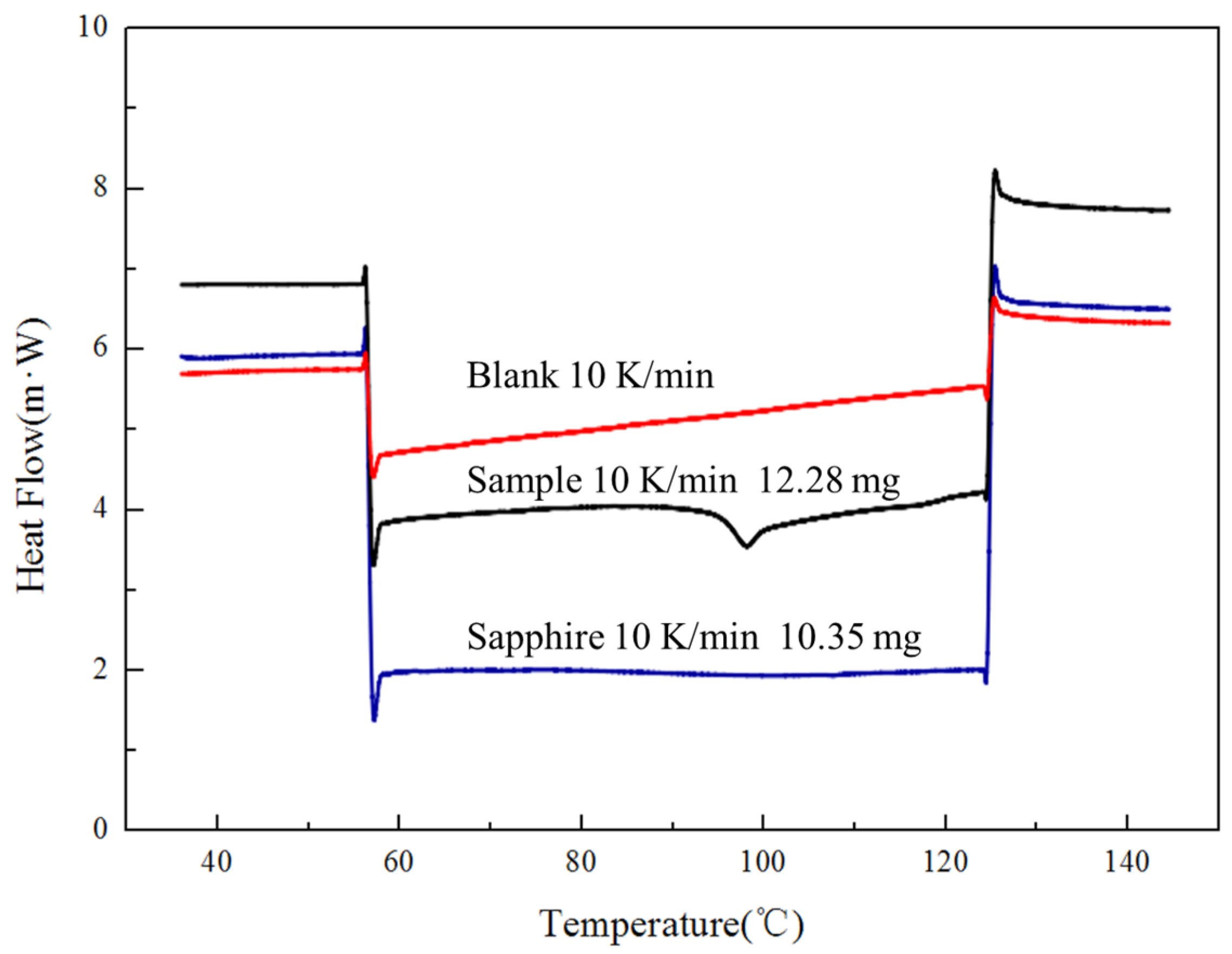

2.1. Testing Fundamentals

2.2. Experimental Scheme

3. Results and Discussion

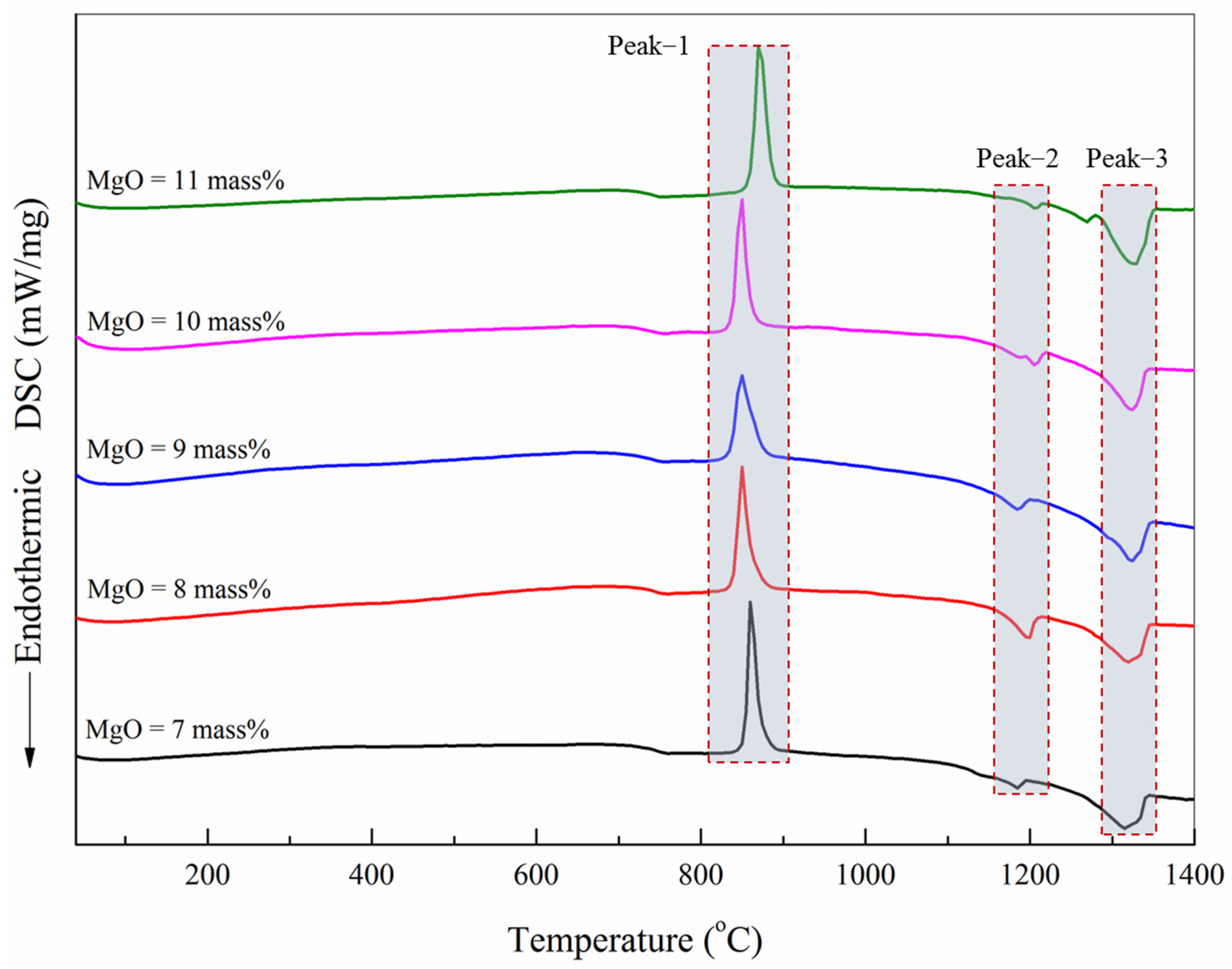

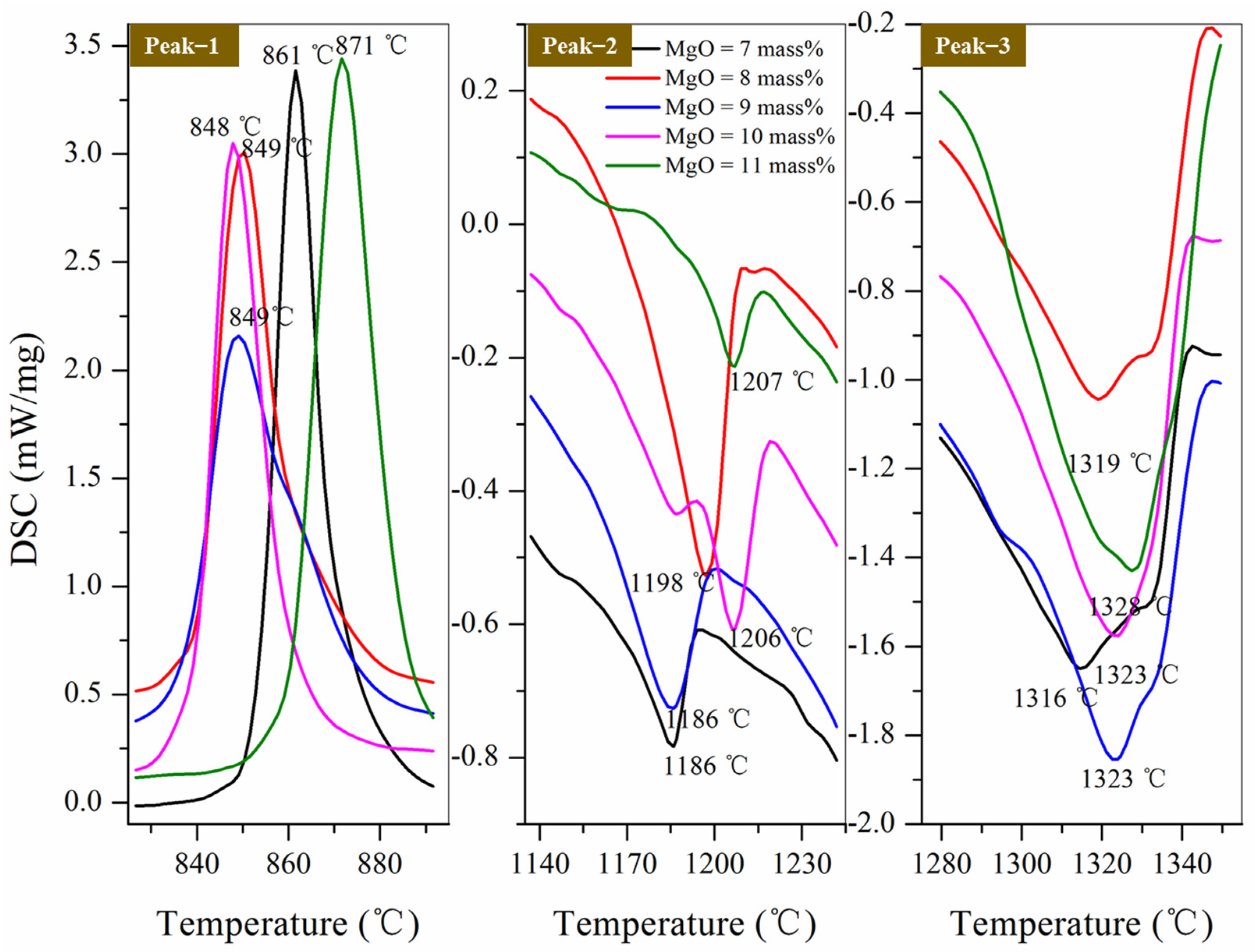

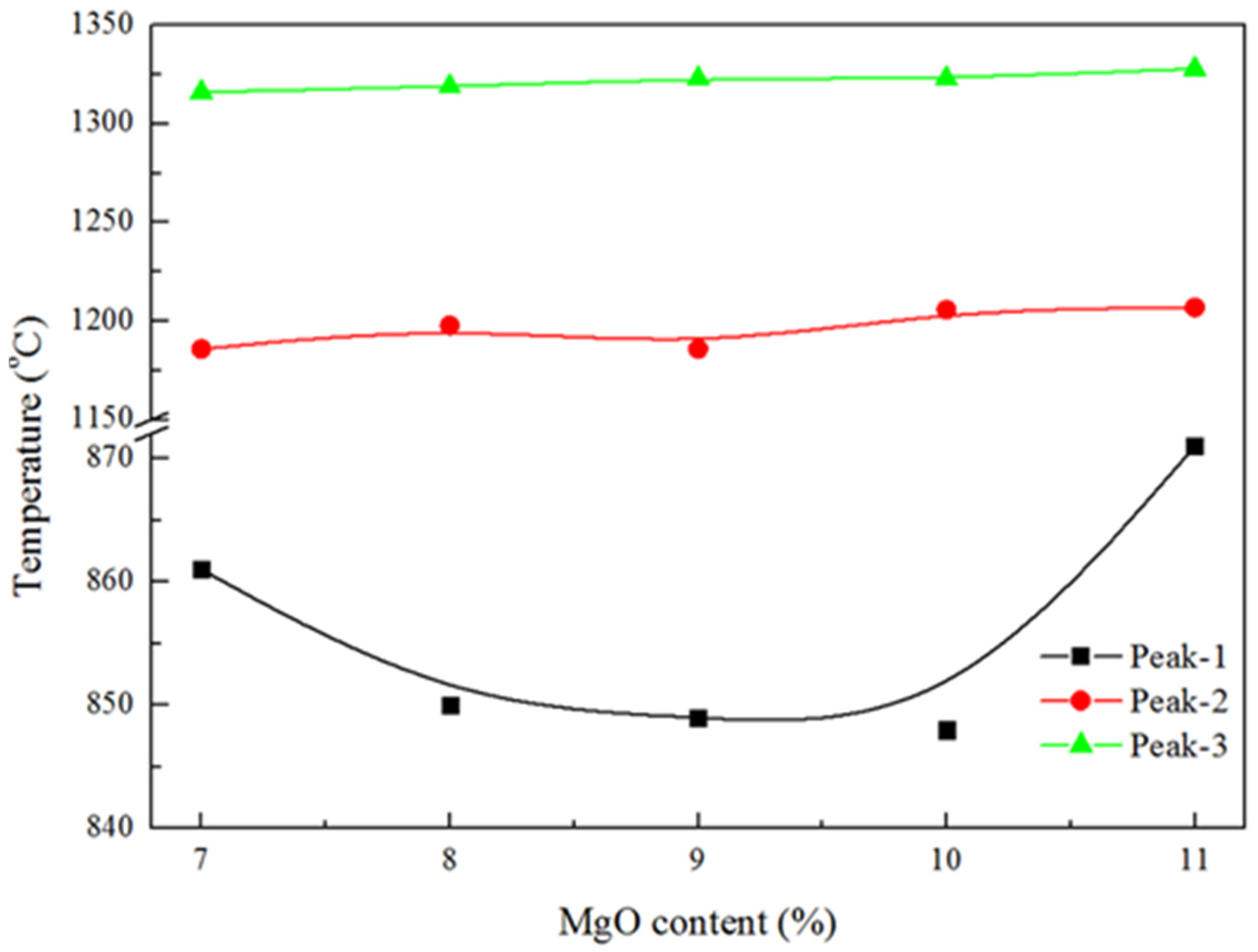

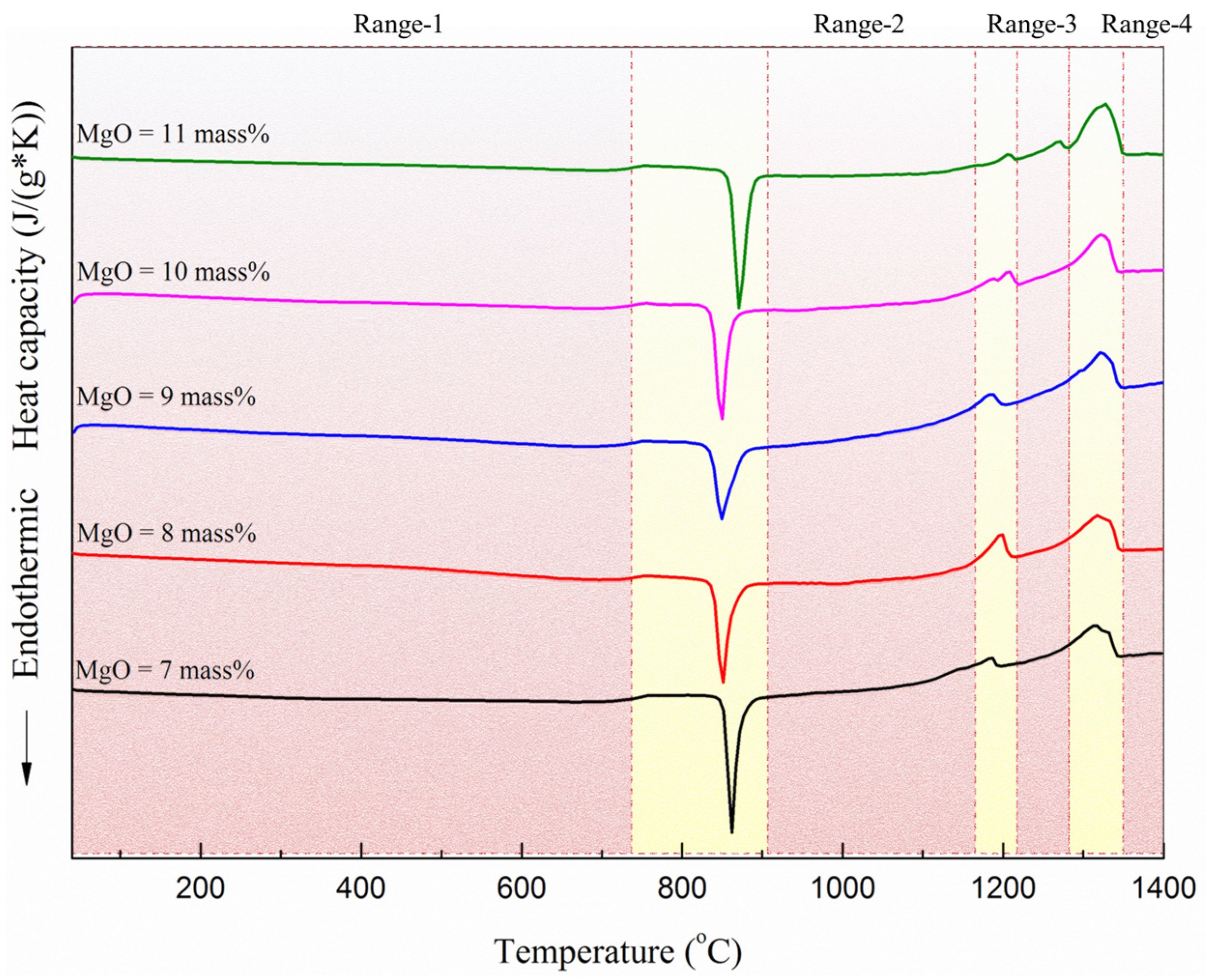

3.1. DSC Curves of BF Slag with Different Contents of MgO

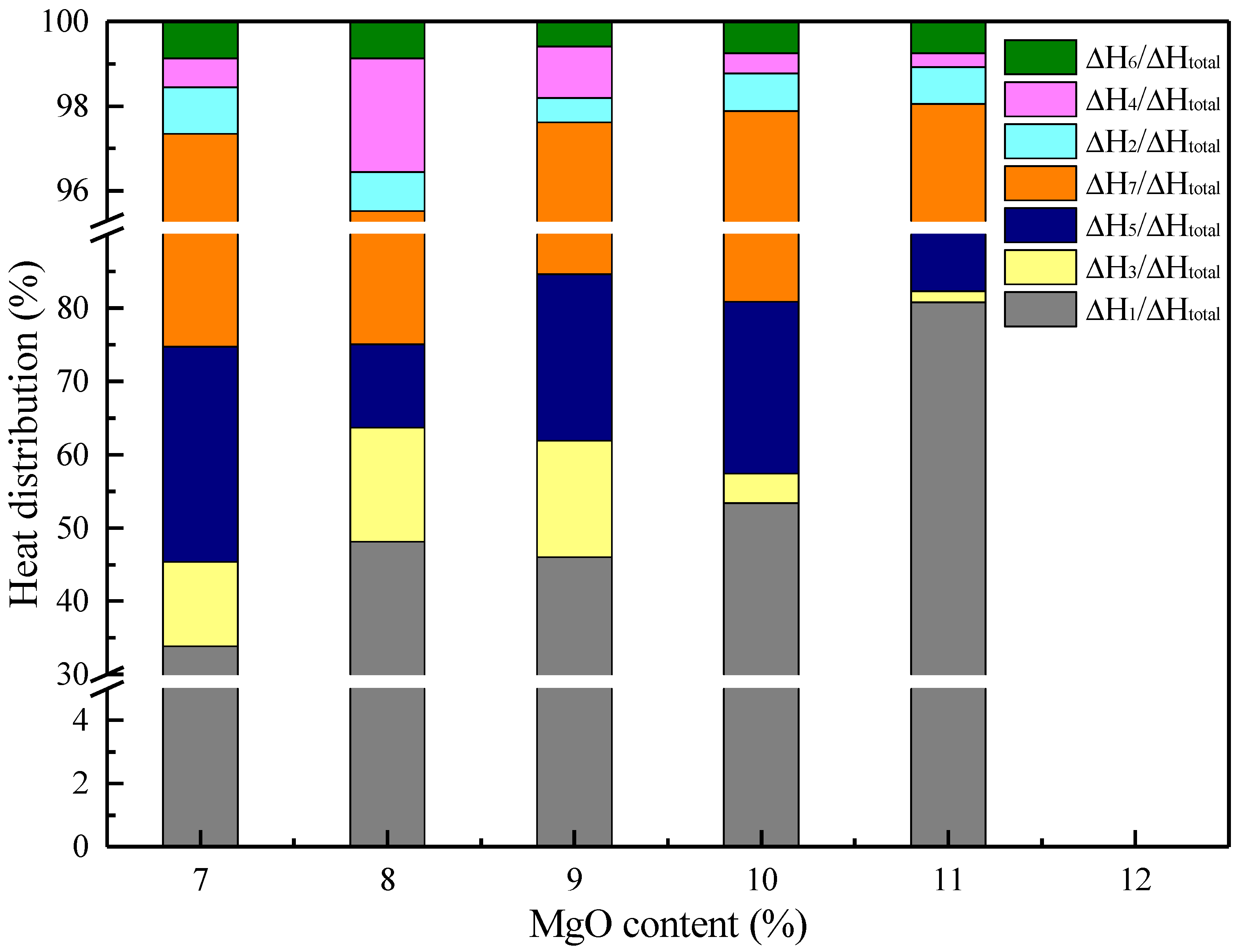

3.2. Specific Heat Capacity and Heat Cooling Release of BF Slag with Different Contents of MgO

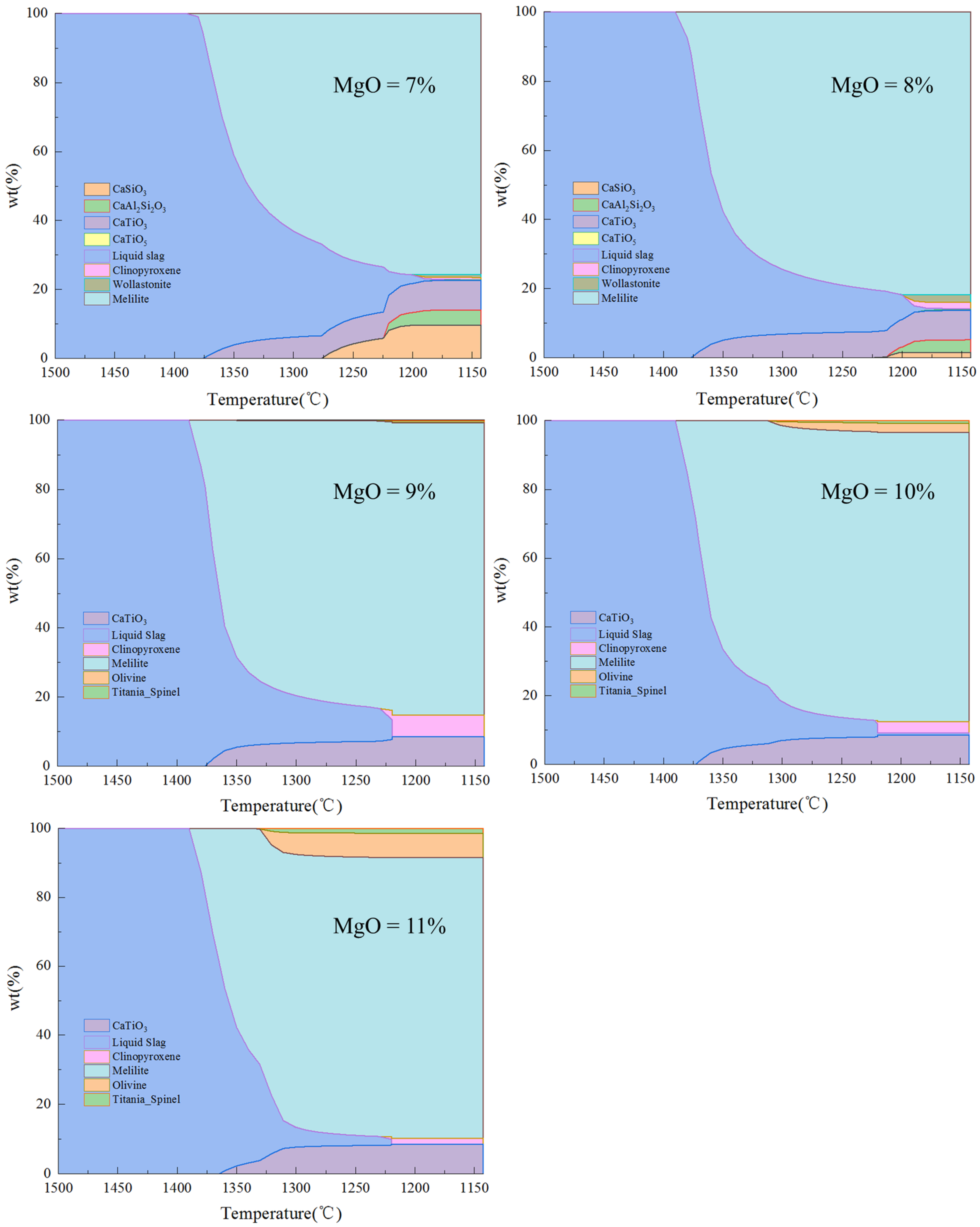

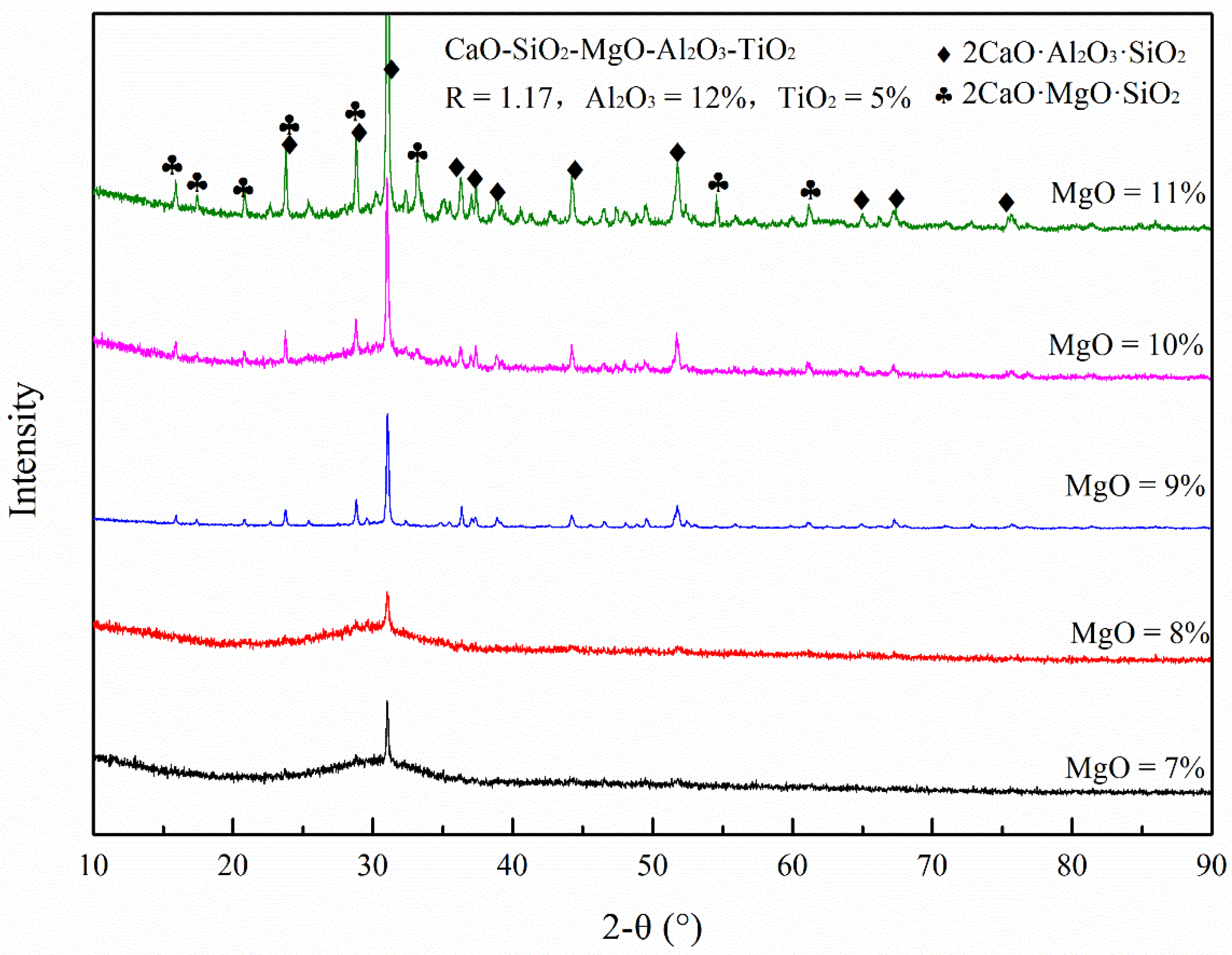

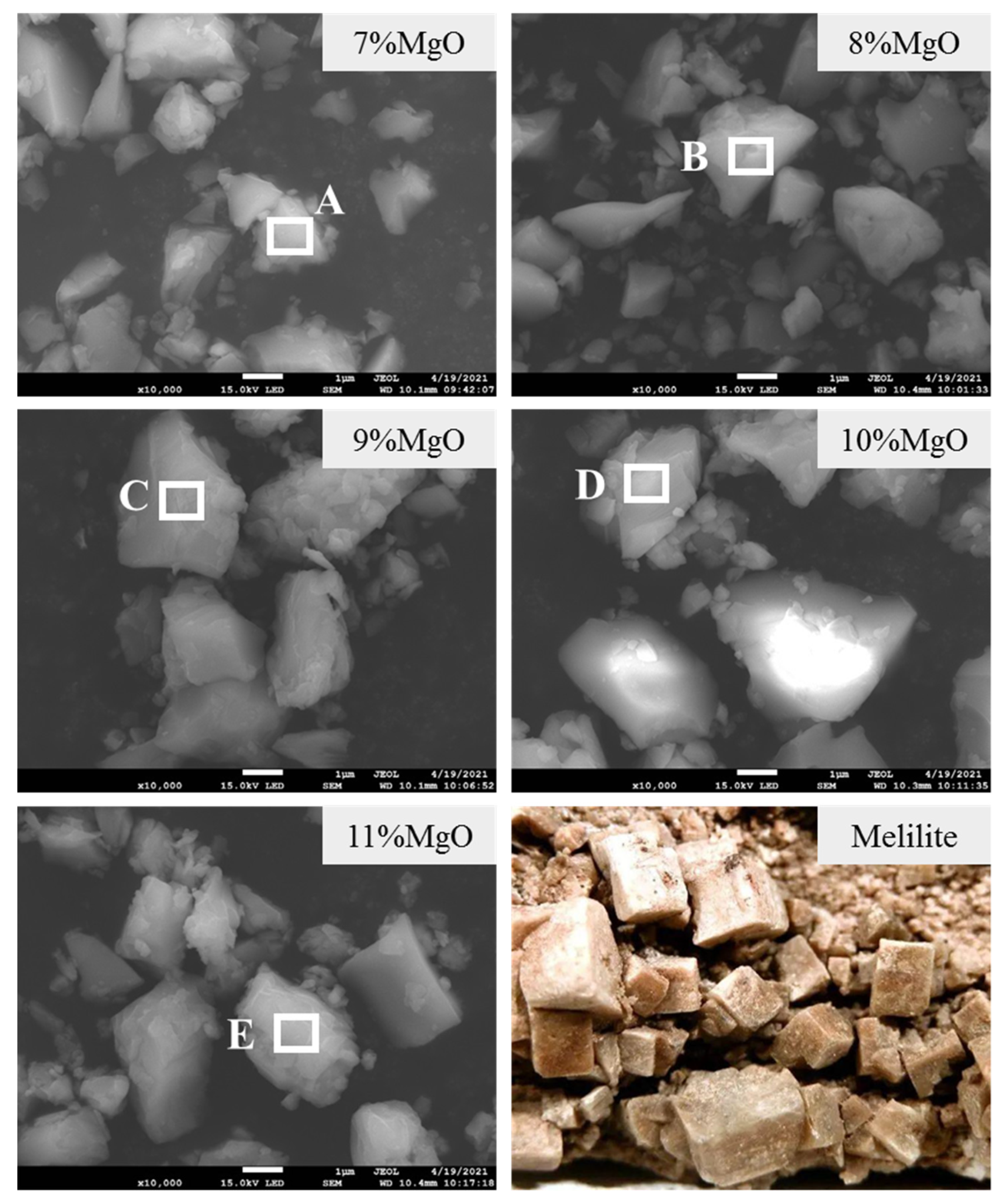

3.3. Analysis on Phase and Micro Morphology of BF Slag with Different Contents of MgO

4. Conclusions

- The basic database of the specific heat capacity of BF slag is improved.

- The proportion of sensible heat is far more than that of latent heat of crystallization, and the heat of this part has an extremely high recovery value.

- When the BF slag is cooled from 1400 °C to 35 °C, three crystallization regions correspond to the release of the crystallization latent heat, whereas four other regions correspond to the release of physical sensible heat. The physical sensible heat released at the temperature range of 35 °C–700 °C is the most.

- The heat release during the cooling process of the BF slag is directly related to the phase and micromorphology. The specific heat capacity of akermanite is almost equal to that of gehlenite.

Author Contributions

Funding

Institutional Review Board Statement

Informed Consent Statement

Data Availability Statement

Conflicts of Interest

References

- Yasipourtehrani, S.; Strezov, V.; Bliznyukov, S.; Tim, E. Investigation of thermal properties of BF slag to improve process energy efficiency. J. Clean. Prod. 2017, 149, 137–145. [Google Scholar] [CrossRef]

- Gao, J.; Feng, Y.; Feng, D.; Zhang, Z.; Zhang, X. Solidification with crystallization behavior of molten BF slag particle during the cooling process. Int. J. Heat Mass Transf. 2020, 146, 118888. [Google Scholar] [CrossRef]

- Peng, L. Thermodynamic analysis of waste heat recovery of molten BF slag. Int. J. Hydrogen Energy 2017, 42, 9688–9695. [Google Scholar]

- Hui, Z.; Hong, W.; Xun, Z.; Yong, Q.; Kai, L.; Rong, C.; Qiang, L. A review of waste heat recovery technologies towards molten slag in steel industry. Appl. Energy 2013, 112, 956–966. [Google Scholar]

- Sun, Y.; Zhang, Z.; Liu, L.; Wang, X. Two-stage high temperature sludge gasification using the waste heat from hot BF slags. Bioresour. Technol. 2015, 198, 364–371. [Google Scholar] [CrossRef]

- Peng, H.; Shan, X.; Kang, J.; Ling, X.; Wang, D. Influence of rotary disk configurations on droplets characteristics in molten slag granulation for waste heat recovery. Appl. Therm. Eng. 2018, 135, 269–279. [Google Scholar] [CrossRef]

- Purwanto, H.; Akiyama, T. Hydrogen production from biogas using hot slag. Int. J. Hydrogen Energy 2006, 31, 491–495. [Google Scholar] [CrossRef]

- Qin, Y.; Lv, X.; Bai, C.; Chen, P.; Qiu, G.; Zhang, J. Mechanism of Dry Molten Slag Granulation Using a Rotating Multi-Nozzle Cup Atomizer. Steel Res. Int. 2014, 85, 44–52. [Google Scholar]

- Shan, X.; Peng, H.; Lin, X.; Li, J. Experimental investigation on particles characteristics in molten aluminum ligament granulation for waste energy recovery. Energy Procedia 2019, 158, 4459–4464. [Google Scholar] [CrossRef]

- Ding, B.; Wang, H.; Zhu, X.; He, X.; Tan, Y.; Liao, Q. Prediction on crystallization behaviors of BF slag in a phase change cooling process with corrected optical basicity. Fuel 2018, 223, 360–365. [Google Scholar] [CrossRef]

- Zhu, X.; Ding, B.; Wang, H.; He, X.; Tan, Y.; Liao, Q. Phase evolution of BF slags with variation in the binary basicity in a variable cooling process. Fuel 2018, 219, 132–140. [Google Scholar] [CrossRef]

- Sun, Y.; Shen, H.; Wang, H.; Wang, X.; Zhang, Z. Experimental investigation and modeling of cooling processes of high temperature slags. Energy 2014, 76, 761–767. [Google Scholar] [CrossRef]

- Wang, H.; Wu, J.-J.; Zhu, X.; Liao, Q.; Zhao, L. Energy–environment–economy evaluations of commercial scale systems for BF slag treatment: Dry slag granulation vs. water quenching. Appl. Energy 2016, 171, 314–324. [Google Scholar] [CrossRef]

- Xin, Y.; Yu, Q.; Han, Z.; Xie, H.; Duan, W.; Qin, Q. Kinetic and experimental characterizations of biomass pyrolysis in granulated BF slag. Int. J. Hydrogen Energy 2018, 43, 9246–9253. [Google Scholar]

- Qin, Y.; Lv, X.; Bai, C.; Qiu, G. Waste Heat Recovery from BF Slag by Chemical Reactions. JOM 2012, 64, 997–1001. [Google Scholar] [CrossRef]

- Yagi, J.; Akiyama, T. Storage of thermal energy for effective use of waste heat from industries. J. Mater. Process. Technol. 1995, 48, 793–804. [Google Scholar] [CrossRef]

- Kasai Kitajima, T.; Akiyama, T.; Yagi, J.; Saito, F. Rate of Methane-steam Reforming Reaction on the Surface of Molten BF Slag: For Heat Recovery from Molten Slag by Using a Chemical Reaction. ISIJ Int. 1997, 37, 1031–1036. [Google Scholar] [CrossRef]

- Duan, W.; Yu, Q.; Wang, K.; Qin, Q.; Hou, L.; Yao, X.; Wu, T. ASPEN Plus simulation of coal integrated gasification combined BF slag waste heat recovery system. Energy Convers. Manag. 2015, 100, 30–36. [Google Scholar] [CrossRef]

- Jin, L.; Wang, H.; Liu, H.; Liu, H.; Hu, J. Mechanism research of calcined copper slag catalytic steam reforming jatropha oil. J. Renew. Sustain. Energy 2016, 8, 1–13. [Google Scholar] [CrossRef]

- Luo, S.; Yu, F. The production of fuel oil and combustible gas by catalytic pyrolysis of waste tire using waste heat of blast-furnace slag. Energy Convers. Manag. 2017, 136, 27–35. [Google Scholar] [CrossRef]

- Aune, R.E.; Hayashi, M.; Nakajima, K.; Seetharaman, S. Thermophysical properties of silicate slags. JOM 2002, 54, 62–69. [Google Scholar] [CrossRef]

- Mills, K.; Yuan, L.; Li, Z.; Zhang, H.; Chou, K. A Review of the Factors Affecting the Thermophysical Properties of Silicate Slags. High Temp. Mater. Process. 2012, 31, 301–321. [Google Scholar] [CrossRef]

- Liddington, R.; Bobkov, A. Differential Scanning Calorimetry (DSC). Therm. Anal. Polym. Fundam. Appl. 2008, 395, 1589–1611. [Google Scholar] [CrossRef]

- Schlesinger, M.E.; Jacob, S. Advances in high-temperature calorimetry: A comparison. JOM 2004, 56, 37–40. [Google Scholar] [CrossRef]

- Bernardes, C.; Santos, L.; da Piedade, M.E.M. A new calorimetric system to measure heat capacities of solids by the drop method. Meas. Sci. Technol. 2006, 17, 1405–1408. [Google Scholar] [CrossRef]

- Li, W.B.; Xue, F.; Cheng, R.S. Modification of DSC Method for Measuring Specific Heat Capacity. Chem. Res. Chin. Univ. 2005, 26, 2310–2313. [Google Scholar]

- Zheng, H.; Liang, L.; Du, J.; Zhou, S.; Jiang, X.; Gao, Q.; Shen, F. Mineral Transform and Specific Heat Capacity Characterization of Blast Furnace Slag with High Al2O3 in Heating Process. Steel Res. Int. 2020, 92, 2–10. [Google Scholar]

- Chang, Z.Y.; Jiao, K.X.; Zhang, J.L.; Ning, X.; Liu, Z. Effect of TiO2 and MnO on Viscosity of Blast Furnace Slag and Thermodynamic Analysis. ISIJ Int. 2018, 58, 2173–2179. [Google Scholar] [CrossRef] [Green Version]

- Kousksou, T.; Jamil, A.; Omari, K.E.; Zeraouli, Y.; Guer, L. Effect of heating rate and sample geometry on the apparent specific heat capacity: DSC applications. Thermochim. Acta 2011, 519, 59–64. [Google Scholar] [CrossRef]

- Ding, B.; Xian-Yan, H.; Liao, Q.; He, X.; Tan, Y.; Liao, Q. Crystallization Behaviors of Blast Furnace (BF) Slag in a Phase-Change Cooling Process. Energy Fuels 2016, 30, 3331–3339. [Google Scholar] [CrossRef]

- Lin, B.; Wang, H.; Liao, Q.; Ding, B. Crystallization properties of molten blast furnace slag at different cooling rates. Appl. Therm. Eng. 2016, 96, 432–440. [Google Scholar] [CrossRef]

- Qin, Y.; Liu, H.; Yang, Y. Structure evolution of blast furnace slag with high Al2O3 Content and 5 mass% TiO2 via molecular dynamics simulation and fourier transform infrared spectroscopy. Metall. Res. Technol. 2018, 115, 1–6. [Google Scholar]

- Gehlenite. Available online: https://www.mindat.org/min-1668.html (accessed on 6 June 2021).

| No. | CaO (wt%) | SiO2 (wt%) | MgO (wt%) | Al2O3 (wt%) | TiO2 (wt%) | R (CaO/SiO2) |

|---|---|---|---|---|---|---|

| 1 | 40.04 | 34.22 | 7.00 | 12.00 | 5.00 | 1.17 |

| 2 | 39.50 | 33.76 | 8.00 | 12.00 | 5.00 | 1.17 |

| 3 | 38.96 | 33.30 | 9.00 | 12.00 | 5.00 | 1.17 |

| 4 | 38.42 | 32.84 | 10.00 | 12.00 | 5.00 | 1.17 |

| 5 | 37.88 | 32.38 | 11.00 | 12.00 | 5.00 | 1.17 |

| T [°C] (Range-1) | R2 | T [°C] (Range-2) | R2 | |||||||

| a | b | c | a | b | c | d | ||||

| 37–712 | 1.9823 | –0.54 | 0.40 | 0.9913 | 907–1082 | –446.56 | 1.3509 | –0.14 | 0.50 | 0.9984 |

| 37–722 | 2.1408 | –0.31 | –0.08 | 0.9933 | 900–1169 | –338.3 | 1.0508 | –0.11 | 0.40 | 0.9837 |

| 46–715 | 3.5320 | –0.49 | –0.03 | 0.9908 | 900–1152 | 184.83 | –0.571 | 0.06 | –0.20 | 0.9977 |

| 46–720 | 2.6046 | –0.49 | 0.20 | 0.9922 | 890–1051 | 327.2 | –0.9905 | 0.10 | –0.30 | 0.9666 |

| 40–726 | 1.9726 | –0.25 | –0.04 | 0.9905 | 916–1098 | 160.02 | –0.4609 | 0.04 | –0.10 | 0.9727 |

| T [°C] (Range-3) | R2 | T [°C] (Range-4) | R2 | |||||||

| a | b | c | a | b | c | d | ||||

| 1222–1282 | 582.7 | –0.9665 | 0.40 | 0.9955 | 1352–1400 | 28,111 | –0.6142 | 0.0447 | –0.10 | 0.9642 |

| 1225–1297 | 934.6 | –1.5277 | 0.60 | 0.9963 | 1348–1400 | –5496 | 0.1199 | –0.0087 | 0.02 | 0.9931 |

| 1208–1295 | 472.1 | –0.8009 | 0.30 | 0.9961 | 1347–1400 | 18,920 | –0.4121 | 0.0299 | –0.07 | 0.9876 |

| 1219–1296 | 423.9 | –0.7198 | 0.30 | 0.9944 | 1347–1400 | –13,326 | 0.2902 | –0.0211 | 0.05 | 0.9859 |

| 1215–1291 | –230.21 | 0.3251 | –0.10 | 0.9762 | 1350–1400 | 11,741 | –0.2565 | 0.0187 | –0.05 | 0.9116 |

| MgO% | Heat Release (×106 kJ) | |||||||

|---|---|---|---|---|---|---|---|---|

| ΔH1 | ΔH2 | ΔH3 | ΔH4 | ΔH5 | ΔH6 | ΔH7 | ΔHtotals | |

| 7% | 0.4324 | –0.0139 | 0.1474 | 0.0088 | 0.3756 | 0.0112 | 0.2895 | 1.2788 |

| 8% | 0.6803 | –0.0130 | 0.2192 | 0.0378 | 0.1610 | 0.0124 | 0.2897 | 1.4134 |

| 9% | 1.0713 | –0.0133 | 0.3702 | 0.0282 | 0.5283 | 0.0139 | 0.3029 | 2.3281 |

| 10% | 0.7369 | –0.0123 | 0.0549 | 0.0066 | 0.3241 | 0.0103 | 0.2347 | 1.3798 |

| 11% | 1.2908 | –0.0138 | 0.0244 | 0.0053 | 0.1828 | 0.0120 | 0.0691 | 1.5982 |

| Elements | Weight % | ||||

|---|---|---|---|---|---|

| 7% MgO, A | 8% MgO, B | 9% MgO, C | 10% MgO, D | 11% MgO, E | |

| O | 49.63 | 54.39 | 50.30 | 48.39 | 50.45 |

| Mg | 5.48 | 6.10 | 5.42 | 6.20 | 8.11 |

| Al | 5.74 | 5.80 | 5.82 | 5.87 | 5.89 |

| Si | 15.36 | 14.27 | 14.45 | 15.30 | 14.17 |

| Ca | 21.15 | 17.20 | 21.73 | 23.03 | 18.92 |

| Ti | 2.64 | 2.25 | 2.28 | 1.22 | 2.46 |

| Totals | 100% | 100% | 100% | 100% | 100% |

Publisher’s Note: MDPI stays neutral with regard to jurisdictional claims in published maps and institutional affiliations. |

© 2021 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (https://creativecommons.org/licenses/by/4.0/).

Share and Cite

Yang, Y.; Lei, T.; Qin, Y. Effect of MgO Content on Heat Capacity of Synthetic BF Slag and Heat Release Behavior during Cooling Process. Metals 2021, 11, 1294. https://doi.org/10.3390/met11081294

Yang Y, Lei T, Qin Y. Effect of MgO Content on Heat Capacity of Synthetic BF Slag and Heat Release Behavior during Cooling Process. Metals. 2021; 11(8):1294. https://doi.org/10.3390/met11081294

Chicago/Turabian StyleYang, Yanhua, Ting Lei, and Yuelin Qin. 2021. "Effect of MgO Content on Heat Capacity of Synthetic BF Slag and Heat Release Behavior during Cooling Process" Metals 11, no. 8: 1294. https://doi.org/10.3390/met11081294

APA StyleYang, Y., Lei, T., & Qin, Y. (2021). Effect of MgO Content on Heat Capacity of Synthetic BF Slag and Heat Release Behavior during Cooling Process. Metals, 11(8), 1294. https://doi.org/10.3390/met11081294