Abstract

This paper presents the innovation possibilities of the crushers functional parts and the results of layers’ renovation analyses of the surfaces worn by biomass crusher hammers. The worn functional surfaces of hammers made of Hardox 400 material were renovated by manual arc welding method (welded with a filled wire electrode with its own protection). As an additive material, Lincore 60-O tubular wire from Lincoln Electric was used. The quality of weld layers was assessed on the metallographic sections, where the presence of internal defects was monitored, and the microstructures of welds were identified. In addition to the metallographic analysis, the microhardness in terms of EN ISO 9015-2 was assessed. Based on the performed experiments, it is suitable for the crusher innovation to recommend the chain replacement with a shaped weldment made of Hardox 400 material, the weldability of which is very good, and to make at least one hardfacing layer on its functional surfaces. With this innovation, the service life of the crushing segment could be extended by more than ten-fold.

1. Introduction

The energy and the electricity generation sector are decarbonizing fast. The European Union has set priorities for energy production in order to minimize the impact of electricity generation on the environment. The European Commission is primarily considering the installation of low-carbon electricity generation technologies, in particular the use of solar and wind energy. It also seeks to utilize the energy of the seas. These "clean" energies are the so-called intermittent energy sources, the output of which cannot be increased flexibly (in a short-required time of 5–30 min), and thus, it endangers the balance of demand and supply [1,2,3]. We cannot influence their efficiency, as they are natural energy sources. Therefore, the current challenge is the creation and development of secondary flexible renewable electricity generation technologies that can enable flexible electricity supply to supplement any insufficient output of the primary sources. One of the possibilities is utilization of the so-called bioenergy, especially biogas evolved from a process known as anaerobic digestion (AD). Biogas is an environmentally advantageous energy source which is mostly comprised of methane (60%) and carbon dioxide (35–40%). Moreover, biogas contains a low quantity of other gasses, such as ammonia (NH3), hydrogen sulfide (H2S), hydrogen (H2), oxygen (O2), nitrogen (N2) and carbon monoxide (CO) [4,5]. AD is known as the degradation of organic compounds to simple substances by microorganisms which live as syntrophy under the lack of oxygen with releasing biogas [6,7].

The processing of biowaste for biogas production is an advantageous solution to minimize the negative impact of existing and constantly emerging waste, which can include sludge and feces produced by a growing population, as well as sludge from animal production [8,9,10,11,12,13,14]. Another extremely productive source of biogas is waste from agricultural production, for which it is possible to apply the so-called tailor-made organic substances accelerating biomass decomposition processes [15,16,17,18]. As Reference [19] shows, the decomposition efficiency of this crushed agricultural waste for AD is even higher. It is even higher than the sludges at mesophilic temperature separated from wastewater treatment plants, which are currently treated by conventional mesophilic anaerobic digestion (CMAD), but also in comparison with the so-called advanced mesophilic anaerobic digestion (AMAD). AD of organic waste offers some advantages, including the reduction of odor release, the decrease of pathogens and the low requirement for organic sludge. Furthermore, the treated organic waste (digestate) is used as an organic fertilizer for arable land instead of a mineral fertilizer and as an organic substrate for greenhouse cultivation [20,21,22,23,24].

As the Slovak Republic, as a member of the European Union, has committed itself to the goals of reducing the carbon burden in electricity generation, it is an effort to focus research attention on green technologies for electricity generation. Currently, the priority is to build hydroelectric power plants and solar fields. Due to the small area, there are only limited opportunities for the construction of wind farms, but due to the large agricultural and wood processing production, it is appropriate to focus on the construction of suitably located biogas plants. For their operation, they require a constant supply of sludge or biomass from agricultural production waste. It is an effort to process this waste in the largest possible volume and ecologically. One of the important parts of this chain is also biomass preparation procedures for biogas plants. The design solutions of biomass crushing plants are different. From single- and double-shaft shredders, through low speed, pre-shredders, up to high rotation chain or hammer crushers [25,26]. However, their functional parts have only a limited service-life due to the number of influencing tribodegradation factors. The functionality of crushers can be restored by replacing the worn parts with new ones, however the possibility of extending the service life of functional parts by applying conventional, eventually progressive renovation technologies appears to be a more advantageous economic option. The renovation of worn functional parts is still current. The aim of research is the application of new technologies, new surface renewal methods and their thermal and chemical-thermal treatment. The reasons are economic factors and cost savings, but also the environmental impact of new components’ production [27,28,29,30,31,32,33]. With these technologies, it is possible to create functional layers on exposed surfaces with higher resistance to degradation factors compared to new components. An interesting option is also the application of cheaper low-alloyed steel grades for manufacturing of large parts of crushers and creation of highly resistant hard layers resistant to the combined wear caused by crushed biomass on functional surfaces only. This paper deals with crusher design innovation in order to extend the service life of a crushing tool extremely stressed by tribodegradation, the frequent destruction of which caused frequent downtimes necessary for its replacement and resulted in reduced crushing productivity.

In biomass crushers (Figure 1, Figure 2 and Figure 3), a steel chain is conventionally used for crushing. Its advantage is a low price, but its lifespan is considerably limited. Depending on the crushing volume, the average service life of the chain is approximately 2.5 months, which is 420 working hours. The wear rate of the chain at an average pressure was 880 mg/h. Its lifetime is influenced by several tribodegradation factors. Abrasive wear with crushed waste is the primary effect. The secondary effect is the combined abrasive-adhesive wear which occurs by abrasion of the inner surfaces of the individual chain loops, but especially the inner surface of the first eye by the stem of the pin by which the chain is attached to the crusher head, as documented in Figure 4 and Figure 5. In addition to the combination of these tribological factors, the life of the chains is also affected by the chemical aggressiveness of the crushed medium, in particular its acidity. Due to the acidic environment of C3H6O3 (lactic acid), the silage subsequently settles around the perimeter of the crusher basket or inside the chain eye, which accelerates corrosion processes. The rate of wear is also negatively affected by the presence of non-organic waste (rocks, soil, etc.).

Figure 1.

Inside the crusher with crusher head and chain.

Figure 2.

Crushing of biomass in a crusher.

Figure 3.

Crusher head with chain attachment.

Figure 4.

Detail of a worn chain eye.

Figure 5.

Detail of a worn pin shank (ø 10 mm), by which the chain is attached to the head of the crusher.

The wear rate of the individual chains is different. A rare phenomenon is the rupture of one chain, which has a destructive effect on the entire crushing head in the process of crushing at high speeds. Wear of the chain and at the same time the pin changes the lengths of the individual chains (their extension), which can cause the crushers of the chain’s outer eye to rub against the inner casing of the crusher and thus damage it.

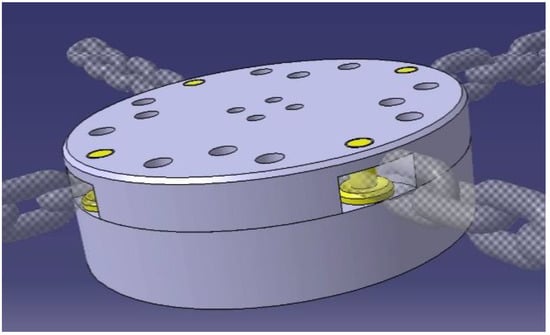

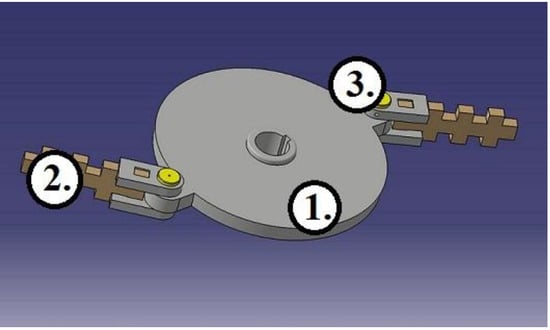

Four chains were replaced by two hammers made of abrasion-resistant Hardox 400 material as part of the crusher innovation (Figure 6). In addition to preventing the shredder from destroying when the chain is torn off, the reason for the innovation was also the possibility of renovating the functional surfaces of the hammers by arc welding processes. By applying hardfacing layers on functional surfaces, it is possible to increase the service life of hammers several times. Hardfacing layers are used in practice for friction surfaces of excavators, teeth of excavators, crushers, as well as for grinding parts of mills.

Figure 6.

Innovative design of the crusher head, 1.—crusher head, 2.—crushing hammer, 3.—pin.

2. Materials and Methods

The crusher head of the original variant with a chain (Figure 3) has a diameter of ø 220 mm and is made of X5CrNi18-10 EN 10028-7. The chain is made of steel 10S20 EN 87-70, PN 46-04 quality 100. The length of the chain is 320 mm and consists of 7 links. Pins of diameter ø 15 mm and length 35 mm used to clamp the chains to the head are made of material X5CrNi18-10 EN 10028-7. The proposed alternative solution is the crusher head in Figure 6.

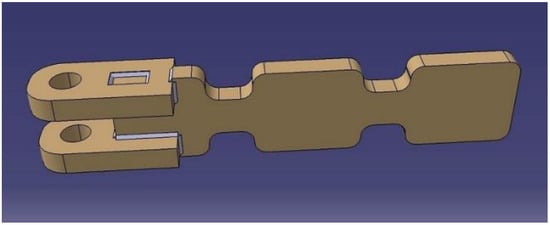

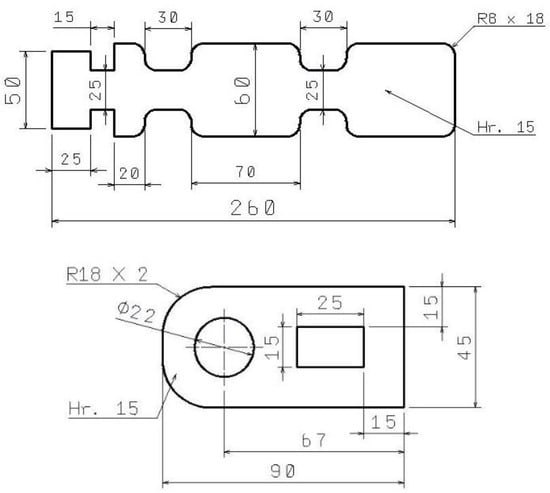

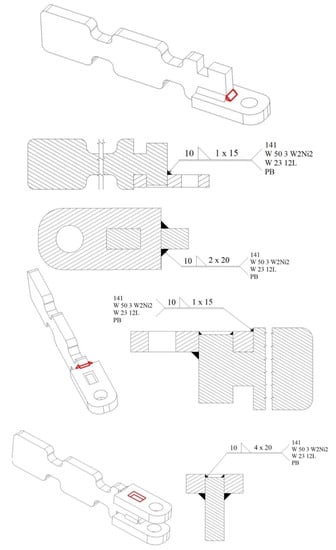

The crusher head (Figure 6, position 1) has a diameter ø 350 mm and a thickness of 50 mm. It is made of material X5CrNi18-10 EN 10028-7. The semi-finished product for the production of hammers was a Hardox 400 steel sheet from which the individual components were cut with the help of plasma. The crushing hammer (Figure 6, position 2) is made by welding plasma blanks made of abrasion-resistant Hardox 400 material, 15 mm thick, whose chemical composition and mechanical properties are in Table 1 and Table 2. The chemical composition of the test materials was verified using a Belec Compact Port spark portable chemical analyzer (Belec Spektrometrie Opto-Elektronik GmbH, Georgsmarienhütte, Germany). The mechanical properties are specified by the producer. The crushing effect of the four chains is replaced by two hammers. The articulated shape of the crushing hammers was chosen due to the higher crushing efficiency compared to the smooth shape of the hammer (Figure 7). The dimensions of the hammer are in millimeters, shown in Figure 8.

Table 1.

Chemical composition of steel Hardox 400 (% wt.).

Table 2.

Mechanical properties of the steel Hardox 400.

Figure 7.

Welded crushing hammer.

Figure 8.

Dimensions of the hammer and its clamping part are in millimeter.

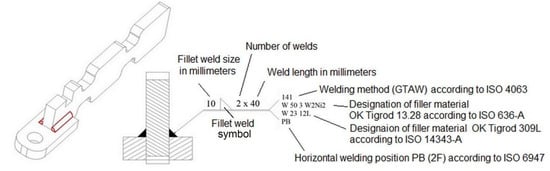

The crushing hammers were produced by GTAW (gas tungsten arc welding) method no. 141, of standard ISO 4063, in a protective atmosphere of a mixed gasoline, (Ferroline C6X1 produced by Messer Tatragas, Bratislava, Slovakia.) Welds were made in horizontal position 2F (PB) ISO 6947 on a Fronius MagicWave 4000 produced by Fronius International GMBH, Wels, Austria. Job welding equipment in accordance with Figure 9.

Figure 9.

Weldment production procedure—basic dimensions of hammer attachment welds.

Manual welding parameters of hammers are documented in Table 3. For welding Hardox 400 material, the manufacturer of filler materials ESAB recommends two types of consumables for GMAW. For welding of components that are not exposed to corrosive environments, the filler material OK Tigrod 13.28 (ER80S-Ni2 by standard SFA/AWS A5.28) is recommended. For weldments exposed to an aggressive corrosive environment, which is also the case with crushing hammers, the filler material OK Tigrod 309 (ER309L by standard SFA/AWS A5.9) is recommended. Chemical composition and mechanical properties given by the manufacturer are listed in Table 4.

Table 3.

Used parameters of hammer welding.

Table 4.

Chemical composition (in % wt.) and mechanical properties of the additive material OK Tigrod 309L (ER309L–SFA/AWS A5.9).

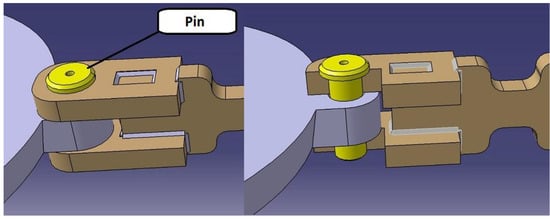

Hammers are connected to the crusher head by pins (Figure 10). Pins are made of the same material as the crusher head—X5CrNi18-10 EN 10028-7. The pin allows the swinging movement of the hammers, but especially the simple disassembly of the hammers in case of their maintenance and exchanges. The time for evaluating the effect of the abrasive medium on the exposed surfaces was set at 360 h. The crusher was in operation for 8 h daily—45 working days/approximately 2 months. The effect of biomass on functional surfaces was evaluated on the basis of weight loss of the crushing member. The chains showed the highest weight loss in a total of 317 g. Hammers without a welding layer showed a weight loss of 142 g. Cladded hammers showed weight losses of 29 g.

Figure 10.

Detachable connection of the crushing hammer with the crusher head.

An alternative solution to the construction of the crusher head also allows, in addition to extending the service life by exchanging the chains for hammers, the renovation of worn functional surfaces of hammers by arc welding, which was not feasible when using chains. The aim of the experiment was to design a suitable method and additive material for the restoration of worn surfaces and to verify the quality of the weld layers using non-destructive and destructive tests.

As this is a renovation of a small number of components per year, the so-called piece renovation can be considered from an economic point of view with manual arc welding methods. The following methods were considered according to ISO 4063:

- 111—

- Manual arc welding with coated electrode (MMAW),

- 114—

- Manual arc welding with filled electrode with self-protection (FCAW),

- 131—

- Manual arc welding with a melting electrode in a protective atmosphere of inert gas (GMAW/MIG),

- 135—

- Manual arc welding with a melting electrode in a protective atmosphere of active gas (GMAW/MAG),

- 136—

- Manual arc welding with a melting filled electrode in a protective atmosphere of active gas,

- 137—

- Manual arc welding with a melting filled electrode in a protective atmosphere of inert gas.

For welding renovation, the technology of manual arc welding with a filled electrode with its own protection (FCAW) was chosen, method no. 114, ISO 4063. The reason for choosing this welding technology was the possibility of welding without the use of protective atmospheres (inert or active) and it was compared to method no. 111, the automated method feeding of additional material allowing continuous welding. The disadvantage compared to technologies 131 and 135 using solid wires is the need to remove slag from the surface of the individual layers of the weld metal, but its advantage over these technologies is the offer of a wide range of chemical compositions of tubular wires.

2.1. Process of Renovating Hammers

At the beginning of the renovation process, the cleaning (pre-treatment) of the entire broken surface of the hammers was performed (residues from crushing biomass) by pneumatic blasting on the TJVP 320 device, produced by Škoda, Plzeň, Czech Republic. Corundum crumb with a mean grain diameter dz = 0.75 mm was used as the blasting agent. Renovation of the surfaces of the crushing hammers was carried out on a Cloos MC 303. The filler material for welding was Lincore® 60-O tubular wire (MF10–GF–60–CG DIN 8555-83), the chemical composition of which is provided by the manufacturer Lincoln Electric (Cleveland, OH, USA) (Table 5).

Table 5.

Chemical composition of filler material of Lincore 60-O (MF10–GF–60–CG–DIN 8555-83) (in % wt.).

The surfaces of the hammers were welded in two layers to eliminate mixing of the weld metal with the base material. Welding parameters are presented in Table 6.

Table 6.

Used welding parameters.

2.2. Methods of Inspection Used on Welds

The quality of welded joints and layers was evaluated using non-destructive and destructive methods. The chemical composition of the test materials was verified using a Belec Compact Port spark portable chemical analyzer (Belec Spektrometrie Opto-Elektronik GmbH, Georgsmarienhütte, Germany). The quality of welded joints as well as layers was evaluated by visual inspection according to ISO 17637. This method determined the presence of surface defects, such as, e.g., cavities, overflow of welds, dimensions of welds, number of layers, etc.

The suitability of the selected welding consumables as well as the welding parameters by method 141 was assessed on transverse sections using macroscopic and microscopic analysis in accordance with ISO 17639. The quality of the welding layers was also assessed. The shape and dimensions were monitored by macroscopic analysis. At 5x magnification with an Eschenbach magnifier, the presence of cracks, cavities, pores and inclusions in the welds as well as in the weld metal was evaluated. Using an Olympus CX 31 light microscope (Olympus, Waltham, MA, USA), the microstructures of the base material, welds, heat-affected areas as well as welding layers were analyzed.

A four-component etchant (10 mL methanol, 10 mL nitric acid, 20 mL hydrochloric acid, 20 mL glycerin) was used in accordance with the literature to visualize the structures of the evaluated high-alloyed welds [34].

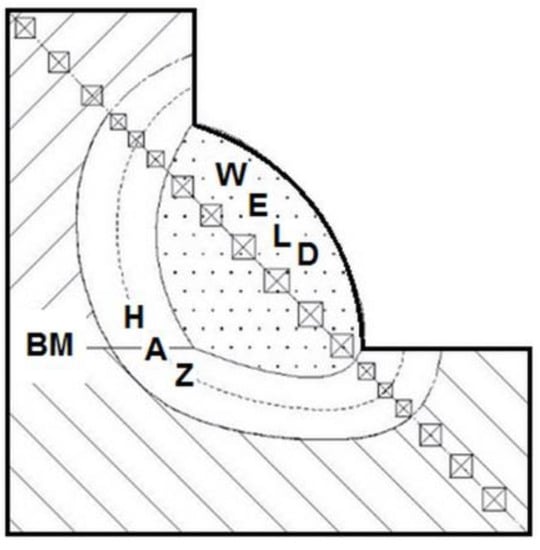

Vicker’s microhardness was evaluated on transverse sections in accordance with ISO 9015-2. The measurements were performed on a Shimadzu HMV 2 produced by Shimadzu, Kyoto, Japan device according to the scheme of Figure 11. A force of 980.1 Nm–1 acted on the indenter. The measured samples must be prepared in accordance with ISO 6507-1.

Figure 11.

Scheme of microhardness evaluation on fillet welds.

The evaluation of microhardness was also performed on transverse cuts of welds through both weld layers’ heat-affected zone (HAZ) into the base material (BM).

3. Analysis of Achieved Results

Visual inspection according to ISO 17637 did not only reveal the presence of external defects on the surface of welded joints and of weld layers.

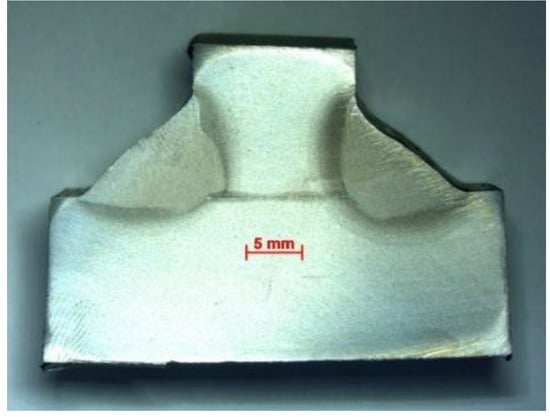

In Figure 12, the macrostructure of a double-sided fillet weld is visible. The presence of internal defects was not detected by macroscopic inspection on the fillets of the fillet welds. The depth of the weld corresponded to the used welding parameters. However, to increase the weld, it is possible to recommend increasing the welding current to 150 A at the root and 180 at the cover layer.

Figure 12.

Macrostructure of a double-sided fillet weld of a crushing hammer.

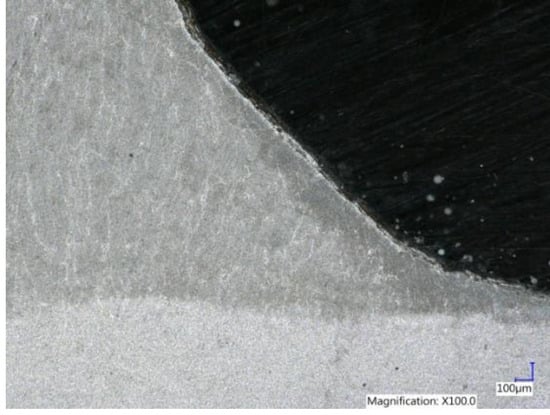

A detailed view of the fillet weld is documented in Figure 13. The figure shows the transition area between the weld metal and the base metal with a characteristic weld metal pattern—columnar arranged grains. Due to the purpose of the weldment, it is important to avoid the presence of undercuts in the transition area (defect No. 501 according to ISO 6520-1). This defect could initiate cracking and destruction at the joint due to the dynamic impact load of the weldment and the presence of an aggressive environment. There was no evidence of internal defects on the macrostructures of the welds.

Figure 13.

The microstructure of the transition area between fillet weld and the base material.

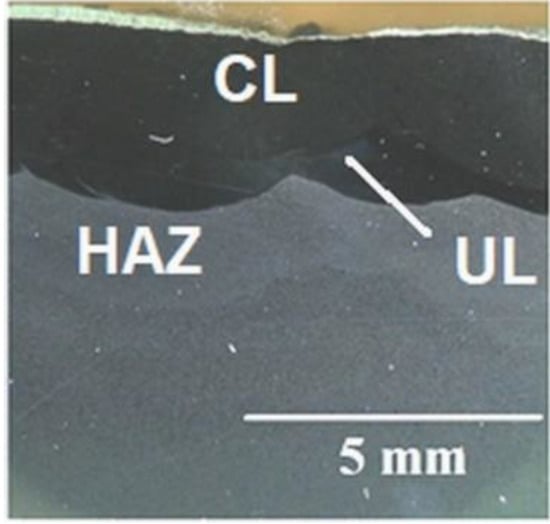

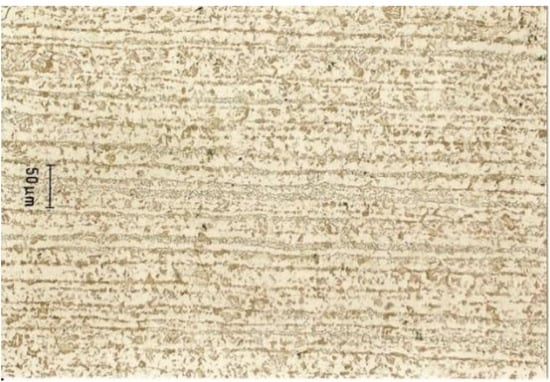

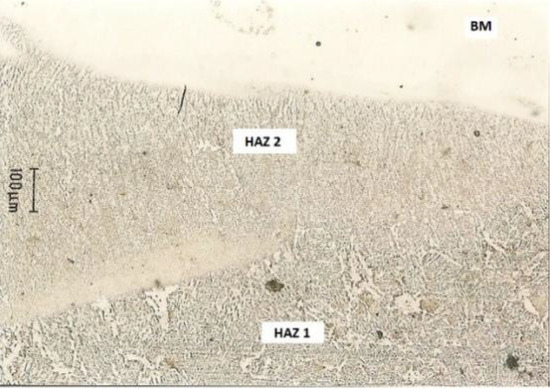

Figure 14 shows the macrostructure of a two-layer weld metal. The height of the weld metal layers, the drawing of the weld of the underlying weld beads, as well as the area of thermal influence are clear on the macrostructure. The presence of internal errors was not recorded on the evaluated sections. The base material, HARDOX 400 (Figure 15), has a structure formed by a linear fine-grained ferritic-pearlitic matrix, in which grains of bainite and martensite are found. Interestingly, there was the occurrence of a line of tempered martensitic structure passing exactly through the center of the sheet (Figure 16). This line was probably created during the thermomechanical processing of sheet metal during its production. The transition area of the weld metal to the base material is shown in Figure 17. Under the weld, it was possible to identify two heat-affected areas of the base material.

Figure 14.

Macrostructure of a two-layer weld metal. (HAZ—heat-affected zone, CL—cover layer, UL—Underlying layer).

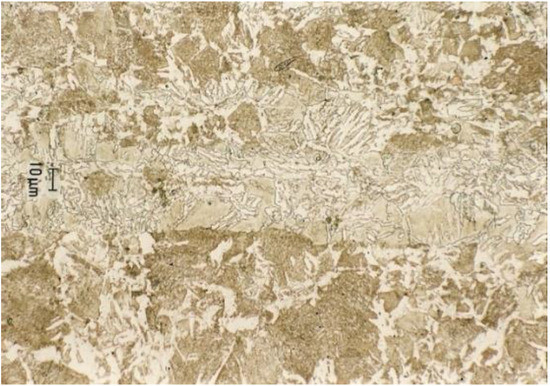

Figure 15.

Structure of base material of Hardox 400 sheet.

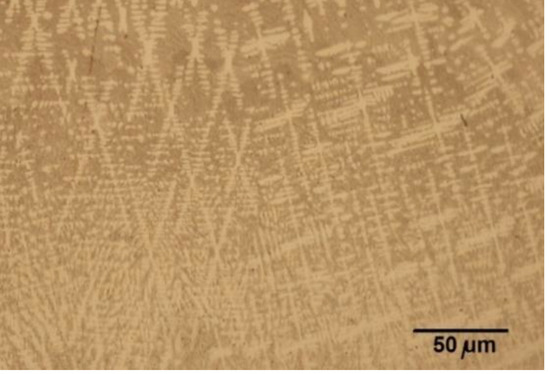

Figure 16.

Detail of a martensitic structure passing through the center of the sheet.

Figure 17.

Microstructure of the transition of weld metal to the base material. (HAZ—heat-affected zone).

The region HAZ 2 is formed by a fine-grained bainitic-martensitic structure with acicular ferrite and pseudo-eutectoid ferrite. The HAZ 1 region was formed by a coarse-grained structure formed by ferrite, perlite and martensite. In some places, it was possible to observe the Widmanstätten structure. The weld metal of the OK Tigrot 309L additive material has a structure formed by austenite and δ-ferrite (Figure 18). Using the constitutive Schaffler diagram, the δ-ferrite content in the weld metal is assumed to be 20%. The structure of the cladding layer made by the filler material Lincore 60-O is shown in Figure 19. The eutectic structure contains a number of primary carbides. Dendritic formations oriented in the direction of cooling of the weld are presented.

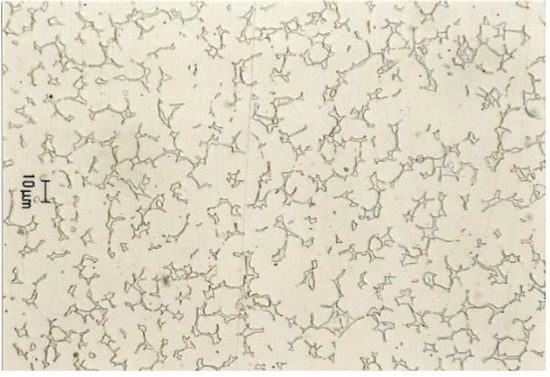

Figure 18.

Microstructure of weld metal (OK Tigrod 309L).

Figure 19.

Microstructure of cladding layer (Lincore 60-O).

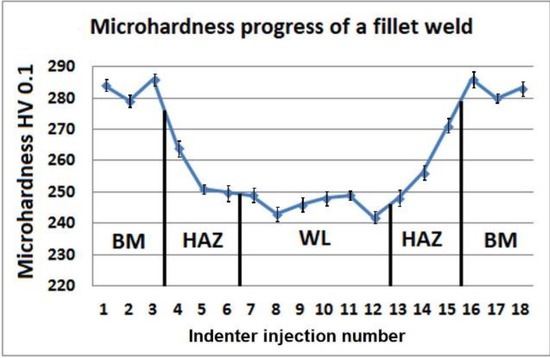

This type of structure is prone to cold cracks. The results of the microhardness evaluation are recorded in the graph in Figure 20. The course shows that the maximum values in the range 279–286 HV 0.1 were measured in the base material—Hardox 400. In HAZ, microhardness gradually decreased to the minimum hardness values in the range 242–249 HV 0.1, measured in the weld metal made of filler material OK Tigrot 309L. The waveforms of the measured microhardness values correspond to the chemical composition of the materials used and are also in accordance with the declared values of the manufacturers. This is the course of hardness based on the measurement scheme presented in Figure 11.

Figure 20.

The course of microhardness of the corner weld of a crushing hammer (BM: base material, HAZ: heat-affected zone, WL: weld).

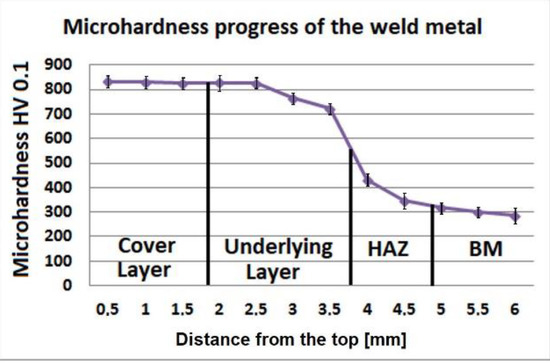

The measured values of the microhardness of the weld metal are recorded in the graph in Figure 21. The measurement was performed on transverse cuts at 0.5 mm intervals from the surface of the weld to the base material. Twelve indentations were made.

Figure 21.

The course of microhardness of the sample with welding.

The maximum values of microhardness were shown by the covering weld layer, namely 832–830 HV 0.1. The values of the base weld metal layer did not show a significant effect of mixing the weld metal with the base material, which can probably be attributed to the relatively small diameter of the filler material used (ø 1.6), which does not cause intensive mixing of molten metal during welding. Values in the range of 828–550 HV 0.1 were measured in the base layer. Microhardness values from 540 to 325 HV 0.1 were measured in HAZ. The minimum values of 318–286 were measured in the base material—Hardox 400.

4. Conclusions

This paper presented the possibilities of innovation of crushers’ functional parts. The original design solution used for shredding waste is biomass chains, and their disadvantage is their short lifespan. As an alternative solution, a modification of the crushing head and replacement of the chains with a crushing hammer was proposed. The semi-finished product for the production of hammers was a Hardox 400 steel sheet, from which the individual components were cut with the help of plasma. These were subsequently welded by the GTAW (gas tungsten arc welding) method with the additive material OK Tigrot 309L. In addition to an alternative solution of the functional part, a method of restoration of the functional surfaces of the hammer by welding was designed and verified, where hardfacing layers made of Lincore 60-O additive material by manual arc welding filled with an electrode with its own protection were used. It is this welding technology that is currently increasingly used in the restoration of functional parts of extremely stressed components. The properties of the proposed solution of the biomass crusher hammer construction were verified during practical tests. The crusher was in operation for 8 h daily—45 working days/approximately 2 months. The effect of biomass on functional surfaces was evaluated on the basis of weight loss of the crushing member. The chains showed the highest weight loss at a total of 317 g. Hammers without a welding layer showed a weight loss of 142 g, and cladded hammers showed weight losses of 29 g. The proposed solution with high-strength hardfacing layers will extend the life of the crusher.

Based on the performed experiments, it can be stated that the proposed additive materials, as well as the parameters of welding and surfacing, are suitable for a given type of components made of abrasion-resistant materials of the Hardox type.

Author Contributions

Conceptualization, J.V.; Formal analysis, J.B. (Janette Brezinová); Investigation, J.B. (Jakub Brezina); Project administration, P.H.; Validation, J.B. (Janette Brezinová); Writing—original draft, J.V.; Writing—review and editing, J.B. (Jakub Brezina). All authors have read and agreed to the published version of the manuscript.

Funding

This research is the result of the project supported by the Slovak Research and Development Agency, the Scientific Grant Agency, “Application of progressive technologies in restoration of functional surfaces of products” (1/0497/20), and the Cultural and Educational Grant Agency, “Modernization of teaching in the field of technologies for joining construction materials” (001STU-4/2019).

Conflicts of Interest

The authors declare no conflict of interest.

References

- Ayoub, N.; Yuji, N. Demand-driven optimization approach for biomass utilization networks. Comput. Chem. Eng. 2012, 36, 129–139. [Google Scholar] [CrossRef]

- O’Shea, R.; Wall, D.; Murphy, J.D. Modelling a demand driven biogas system for production of electricity at peak demand and for production of biomethane at other times. Bioresour. Technol. 2016, 216, 238–249. [Google Scholar] [CrossRef]

- Lafratta, M.; Thorpe, R.B.; Ouki, S.K.; Shana, A.; Germain, E.; Willcocks, M.; Lee, J. Dynamic biogas production from anaerobic digestion of sewage sludge for on-demand electricity generation. Bioresour. Technol. 2020, 310, 123415. [Google Scholar] [CrossRef]

- Chasnyk, O.; Sołowski, G.; Shkarupa, O. Historical, technical and economic aspects of biogas development: Case of Poland and Ukraine. Renew. Sustain. Energy Rev. 2015, 52, 227–239. [Google Scholar] [CrossRef]

- Sun, Q.; Li, H.; Yan, J.; Liu, L.; Yu, Z.; Yu, X. Selection of appropriate biogas upgrading technology-a review of biogas cleaning, upgrading and utilisation. Renew. Sustain. Energy Rev. 2015, 51, 521–532. [Google Scholar] [CrossRef]

- Merlin Christy, P.; Gopinath, L.R.; Divya, D. A review on anaerobic decomposition and enhancement of biogas production through enzymes and microorganisms. Renew. Sustain. Energy Rev. 2014, 34, 167–173. [Google Scholar] [CrossRef]

- Li, J.; Wei, L.; Duan, Q.; Hu, G.; Zhang, G. Semi-continuous anaerobic co-digestion of dairy manure with three crop residues for biogas production. Bioresour. Technol. 2014, 156, 307–313. [Google Scholar] [CrossRef] [PubMed]

- Manser, N.D.; Mihelcic, J.R.; Ergas, S.J. Semi-continuous mesophilic anaerobic digester performance under variations in solids retention time and feeding frequency. Bioresour. Technol. 2015, 190, 359–366. [Google Scholar] [CrossRef]

- Yong, Z.; Dong, Y.; Zhang, X.; Tan, T. Anaerobic co-digestion of food waste and straw for biogas production. Renew. Energy 2015, 78, 527–530. [Google Scholar] [CrossRef]

- Gebrezgabher, S.A.; Meuwissen, M.P.M.; Prins, B.A.M.; Lansink, A.G.J.M.O. Economic analysis of anaerobic digestion—A case of Green power biogas plant in the Netherlands. NJAS Wagening. J. Life Sci. 2010, 57, 109–115. [Google Scholar] [CrossRef]

- Çelik, I.; Demirer, G.N. Biogas production from pistachio (Pistacia vera L.) processing waste. Biocatal. Agric. Biotechnol. 2015, 4, 767–772. [Google Scholar] [CrossRef]

- Huang, R.; Mei, Z.; Long, Y.; Xiong, X.; Wang, J.; Guo, T.; Luo, T.; Long, E. Impact of optimized flow pattern on pollutant removal and biogas production rate using wastewater anaerobic fermentation. BioResources 2015, 10, 4826–4842. [Google Scholar] [CrossRef]

- Nitsos, C.; Matsakas, L.; Triantafyllidis, K.; Rova, U.; Christakopoulos, P. Evaluation of mediterranean agricultural residues as a potential feedstock for the production of biogas via anaerobic fermentation. Biomed Res. Int. 2015, 2015, 1–6. [Google Scholar] [CrossRef] [PubMed]

- Shen, Y.; Linville, J.L.; Urgun-Demirtas, M.; Mintz, M.M.; Snyder, S.W. An overview of biogas production and utilization at full-scale wastewater treatment plants (WWTPs) in the United States: Challenges and opportunities towards energy-neutral WWTPs. Renew. Sustain. Energy Rev. 2015, 50, 346–362. [Google Scholar] [CrossRef]

- Mauky, E.; Jacobi, H.F.; Liebetrau, J.; Nelles, M. Flexible biogas production for demand-driven energy supply-Feeding strategies and types of substrates. Bioresour. Technol. 2015, 178, 262–269. [Google Scholar] [CrossRef] [PubMed]

- Mauky, E.; Weinrich, S.; Jacobi, H.F.; Nägele, H.J.; Liebetrau, J.; Nelles, M. Demand-driven biogas production by flexible feeding in full-scale–Process stability and flexibility potentials. Anaerobe 2017, 46, 86–95. [Google Scholar] [CrossRef]

- Zealand, A.M.; Roskilly, A.P.; Graham, D.W. Effect of feeding frequency and organic loading rate on biomethane production in the anaerobic digestion of rice straw. Appl. Energy 2017, 207, 156–165. [Google Scholar] [CrossRef]

- Laperrière, W.; Barry, B.; Torrijos, M.; Pechiné, B.; Bernet, N.; Steyer, J.P. Optimal conditions for flexible methane production in a demand-based operation of biogas plants. Bioresour. Technol. 2017, 245, 698–705. [Google Scholar] [CrossRef] [PubMed]

- Batstone, D.J.; Keller, J.; Angelidaki, I.; Kalyuzhnyi, S.V.; Pavlostathis, S.G.; Rozzi, A.; Sanders, W.T.; Siegrist, H.; Vavilin, V.A. The IWA Anaerobic Digestion Model No 1 (ADM1). Water Sci. Technol. 2002, 45, 65–73. [Google Scholar] [CrossRef]

- Nasir, I.M.; Ghazi, T.I.M.; Omar, R.; Idris, A. Anaerobic digestion of cattle manure: Influence of inoculum concentration. Int. J. Eng. Technol. 2013, 10, 22–26. [Google Scholar]

- Ounnar, A.; Benhabyles, L.; Igoud, S. Energetic valorization of biomethane produced from cow-dung. Procedia Eng. 2012, 33, 330–334. [Google Scholar] [CrossRef]

- De Vries, J.W.; Vinken, T.M.W.J.; Hamelin, L.; De Boer, I.J.M. Comparing environmental consequences of anaerobic mono- and co-digestion of pig manure to produce bio-energy—A life cycle perspective. Bioresour. Technol. 2012, 125, 239–248. [Google Scholar] [CrossRef] [PubMed]

- Comparetti, A.; Greco, C.; Navickas, K.; Venslauskas, K. Evaluation of potential biogas production in Sicily. In Proceedings of the 11th International Scientific Conference Engineering for Rural Development, Jelgava, Latvia, 24–25 May 2012. [Google Scholar]

- Abdeshahian, P.; Lim, J.S.; Ho, W.S.; Hashim, H.; Lee, C.T. Potential of biogas production from farm animal waste in Malaysia. Renew. Sustain. Energy Rev. 2016, 60, 714–723. [Google Scholar] [CrossRef]

- Savani, J.B.; Kathiria, R.K.; Vagadia, V.R. Design and development of agricultural wastes shredder. AMA Agric. Mech. Asia Afr. Lat. Am. 2004, 35, 41–46. [Google Scholar]

- Abhishek, K.; Nithin, B.; Nithin, N.; Punith, K.; Samapth, P. Fabrication of Agricultural Waste Shredder Machine. Int. J. Sci. Eng. Technol. Res. 2018, 9, 112–116. [Google Scholar]

- Winczek, J.; Gucwa, M.; Mičian, M.; Koňár, R.; Parzych, S. The evaluation of the wear mechanism of high-carbon hardfacing layers. Arch. Metall. Mater. 2019, 64, 1111–1115. [Google Scholar] [CrossRef]

- Ťavodová, M.; Kalincová, D.; Slováková, I. Evaluation of Some Parameters of Hard Surfacing Treatment of the Functional Surfaces of Forestry Tools. Manag. Syst. Prod. Eng. 2018, 26, 222–226. [Google Scholar] [CrossRef]

- Sládek, A.; Patek, M.; Mičian, M. Behavior of steel branch connections during fatigue loading. Arch. Metall. Mater. 2017, 62, 1597–1601. [Google Scholar] [CrossRef]

- Mohyla, P.; Kubon, Z.; Cep, R.; Janasek, A.; Samardzic, I. Secondary hardening of low-alloyed creep-resistant steel welds. Metalurgija 2014, 53, 25–28. [Google Scholar]

- Turygin, Y.; Marônek, M.; Zubkova, Y. Investigation of the electron beam positioning accuracy at electron beam welding. Procedia Eng. 2016, 149, 489–494. [Google Scholar] [CrossRef][Green Version]

- Malotova, S.; Cep, R.; Zlamal, T.; Mohyla, P.; Czán, A.; Antić, A.; Budak, I.; Mircea, L. Evaluation of residual stresses after irregular interrupted machining. Teh. Vjesn. 2018, 25, 1009–1013. [Google Scholar] [CrossRef]

- Kalincová, D.; Ťavodová, M.; Čierna, H.; Beňo, P. Analysis of the causes of distortion castings after heat treatment. Acta Metall. Slovaca 2017, 23, 182–192. [Google Scholar] [CrossRef]

- Walker, P.; Tarn, W.H. CRC Handbook of Metal Etchants; CRC Press LCC: New York, NY, USA, 1990; p. 1428. [Google Scholar]

Publisher’s Note: MDPI stays neutral with regard to jurisdictional claims in published maps and institutional affiliations. |

© 2021 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (https://creativecommons.org/licenses/by/4.0/).