A Unified Adjustment Model for Gaussian Pulse Welding on Aluminum Alloys

Abstract

1. Introduction

2. Material and Methodology

2.1. Gaussian Pulse Welding Method

2.2. Unified Adjustment Model

2.3. Test Conditions

3. Test Results and Analysis

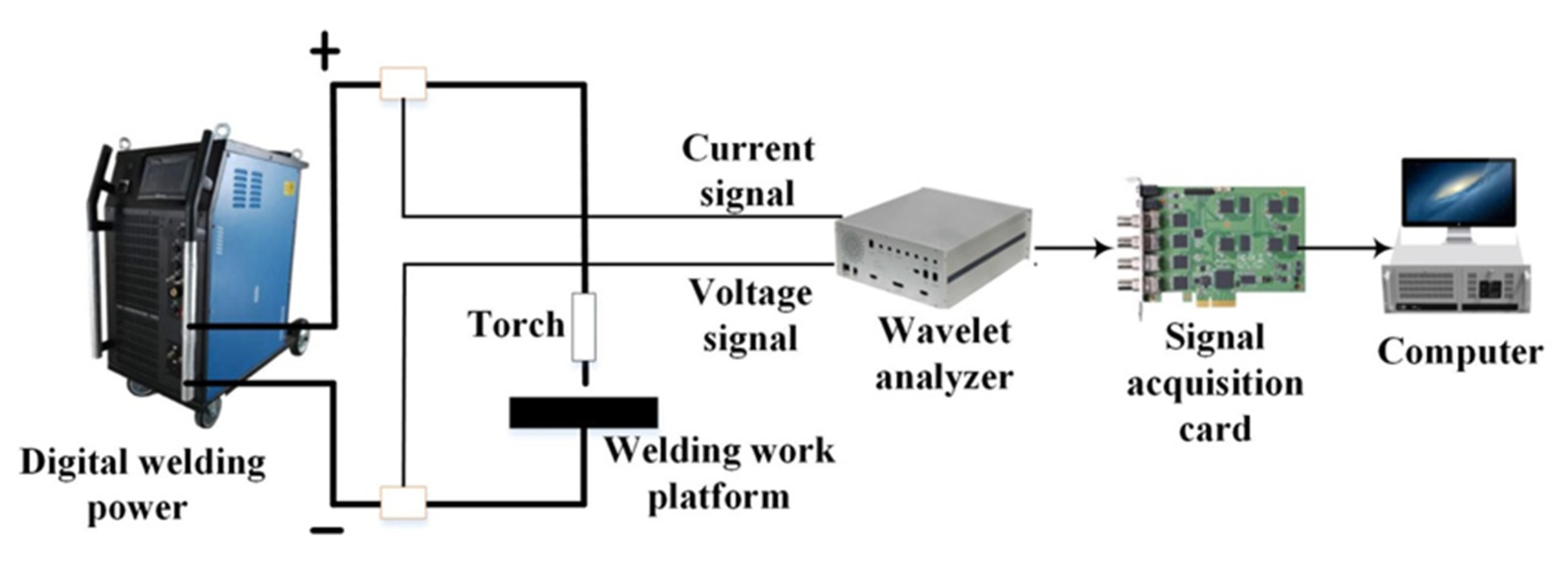

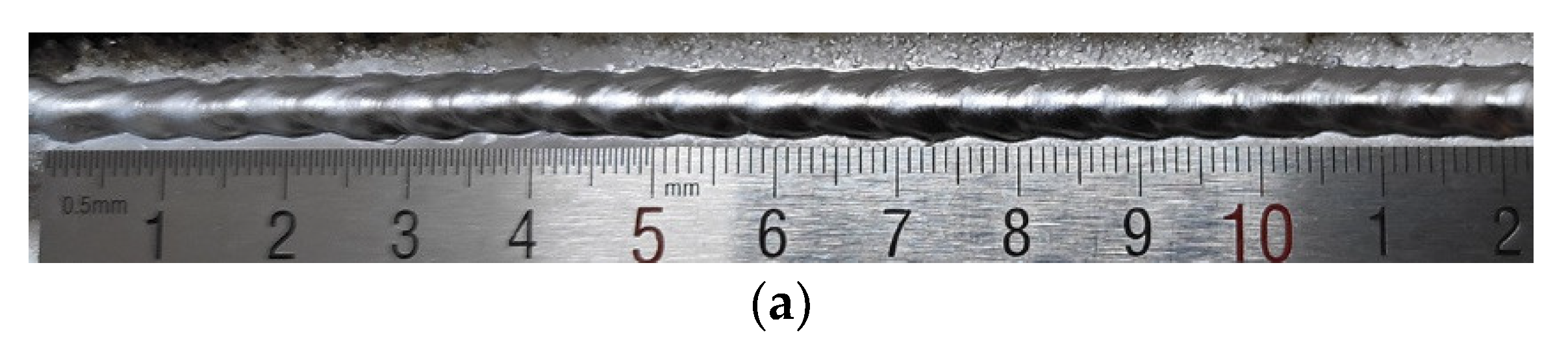

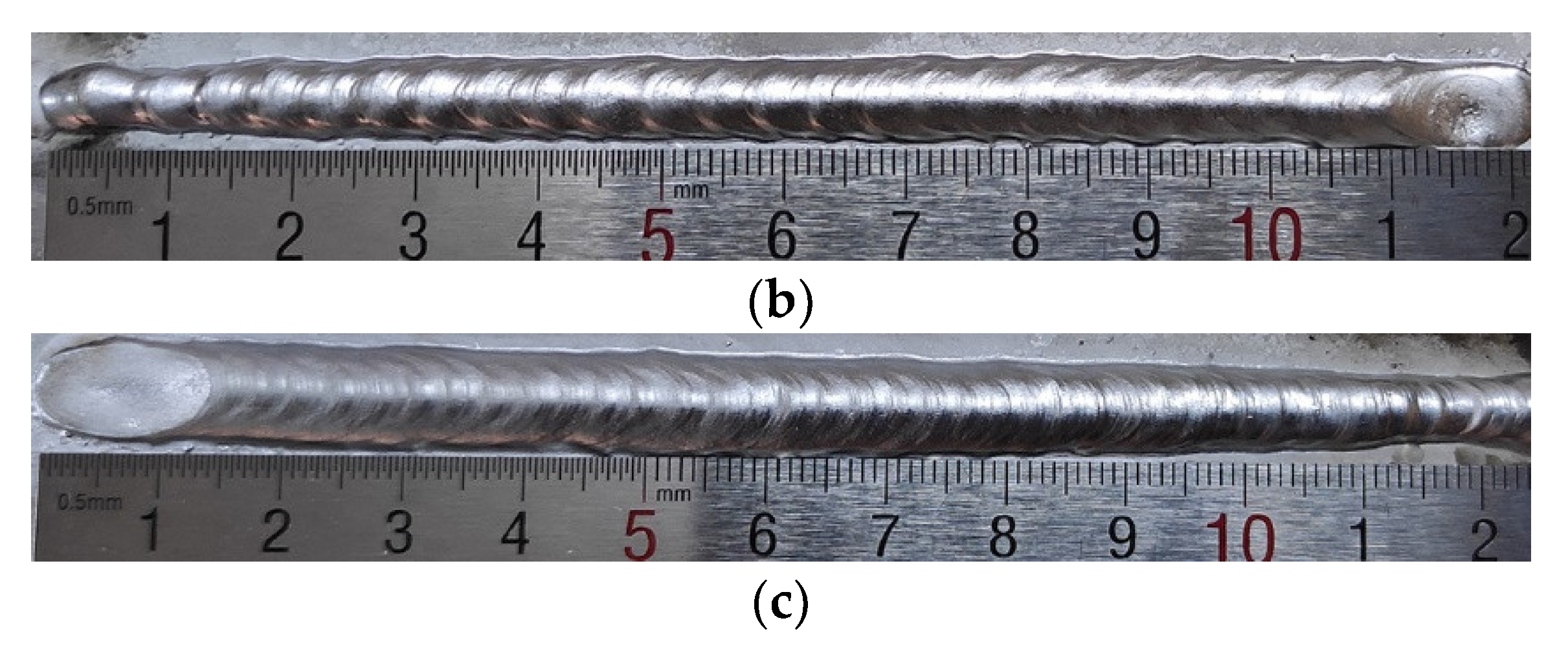

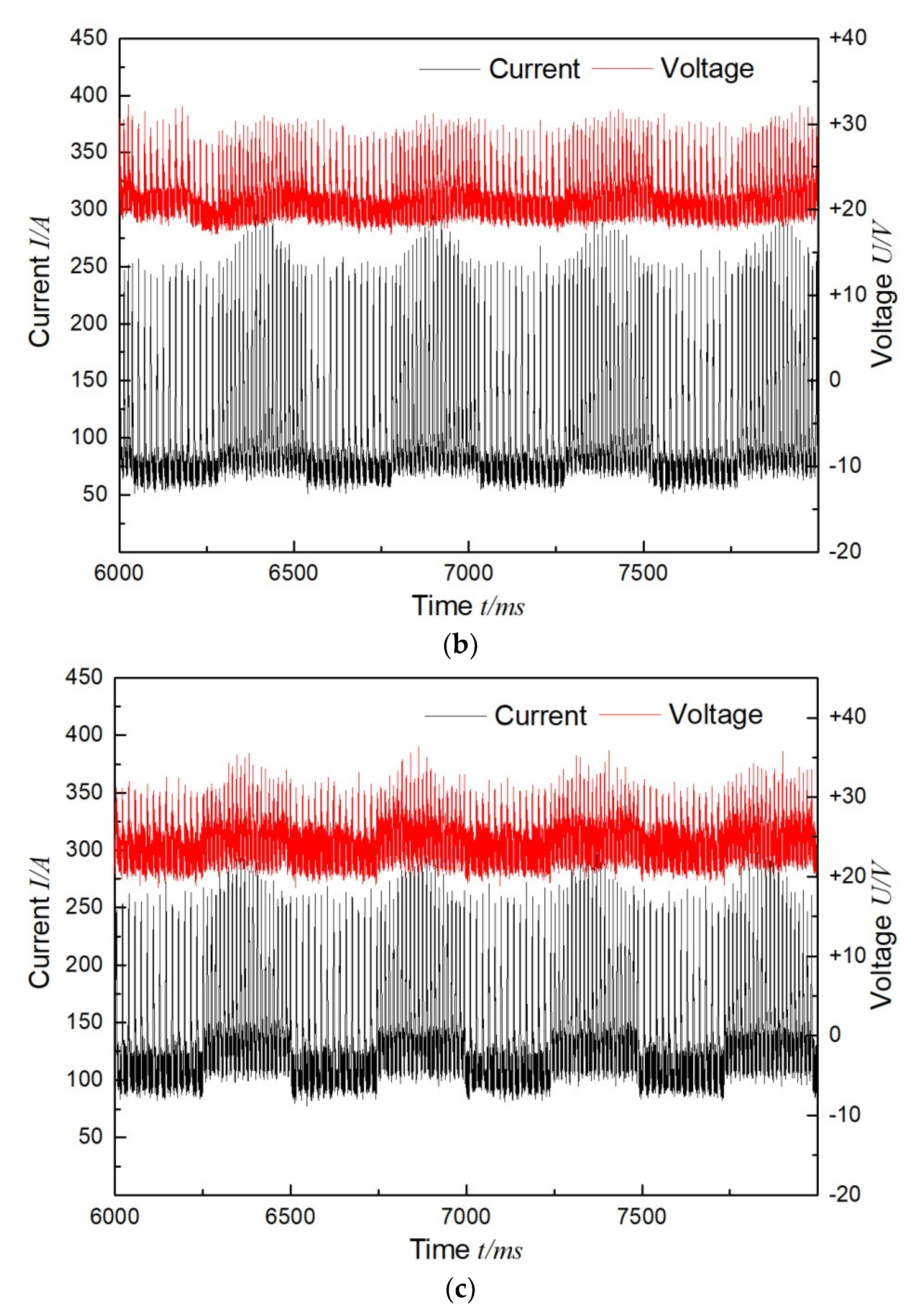

3.1. Stability of the Welding Process

3.2. Microstructure of Weld Beads

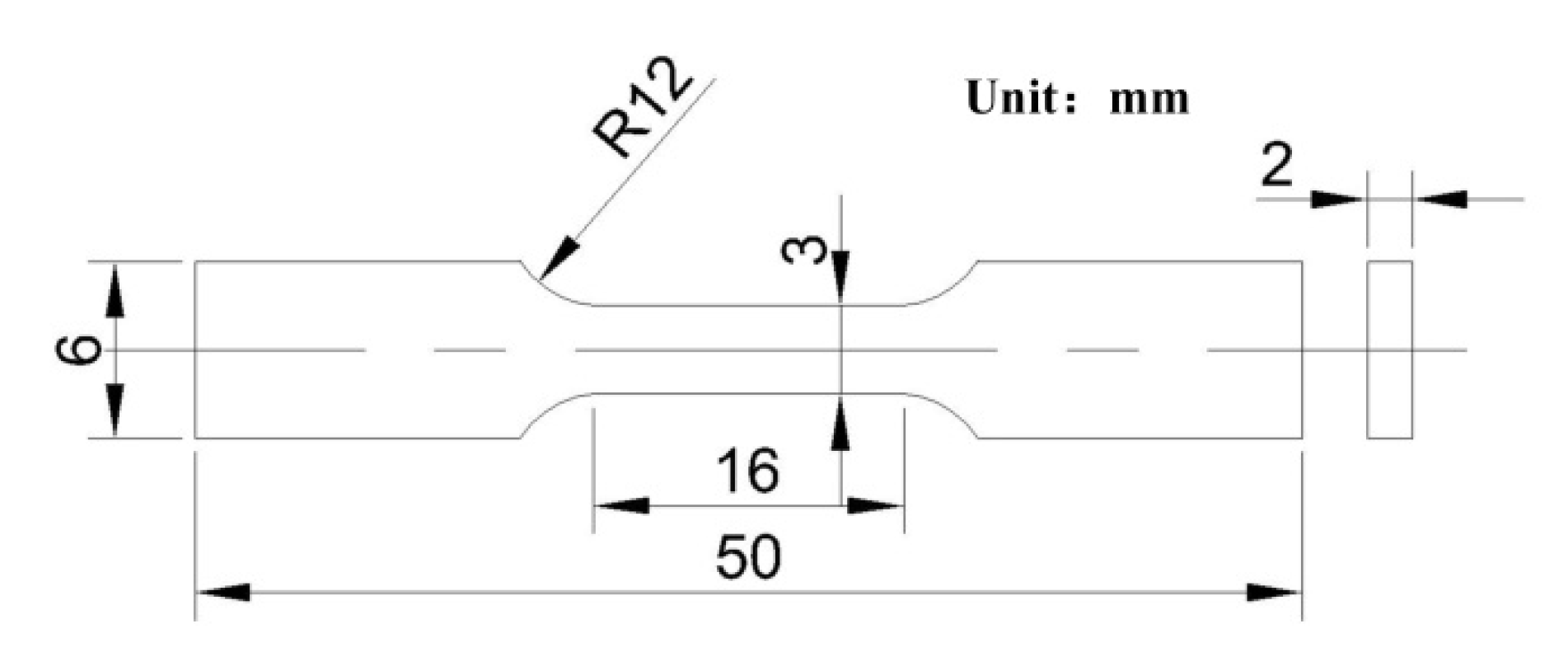

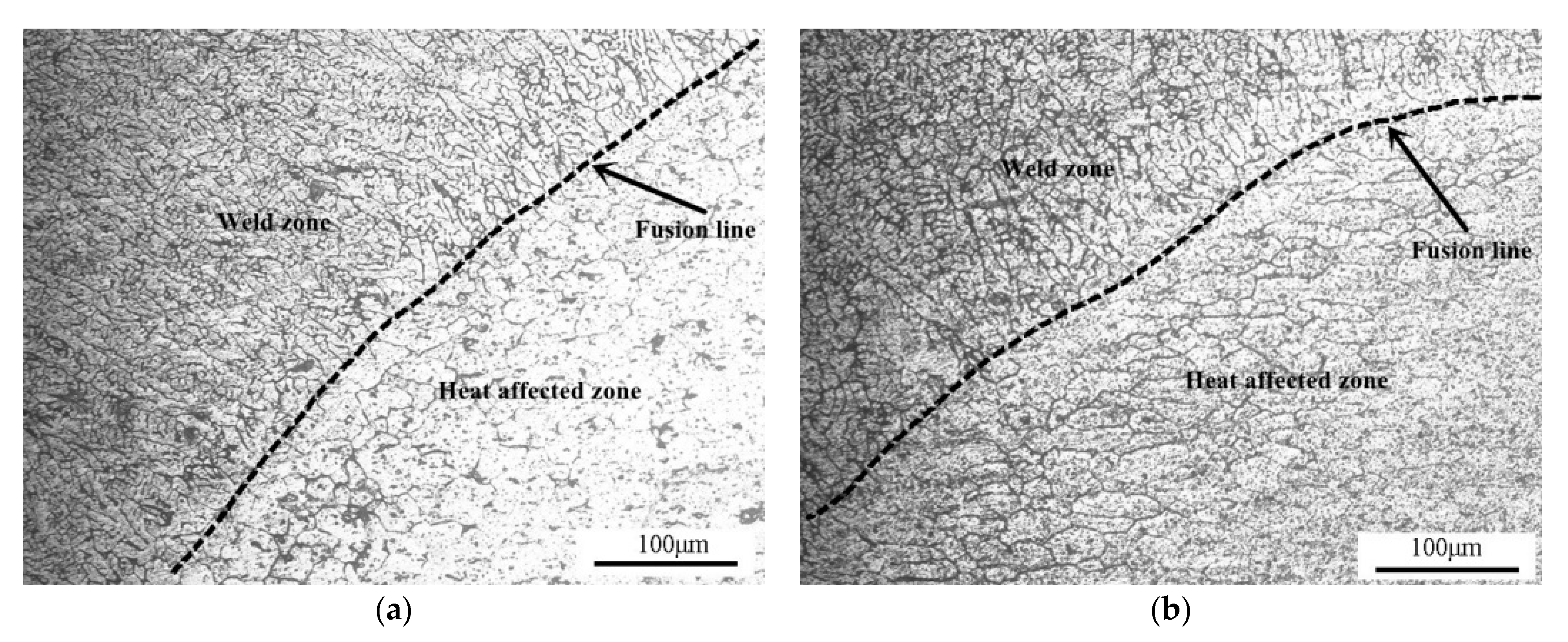

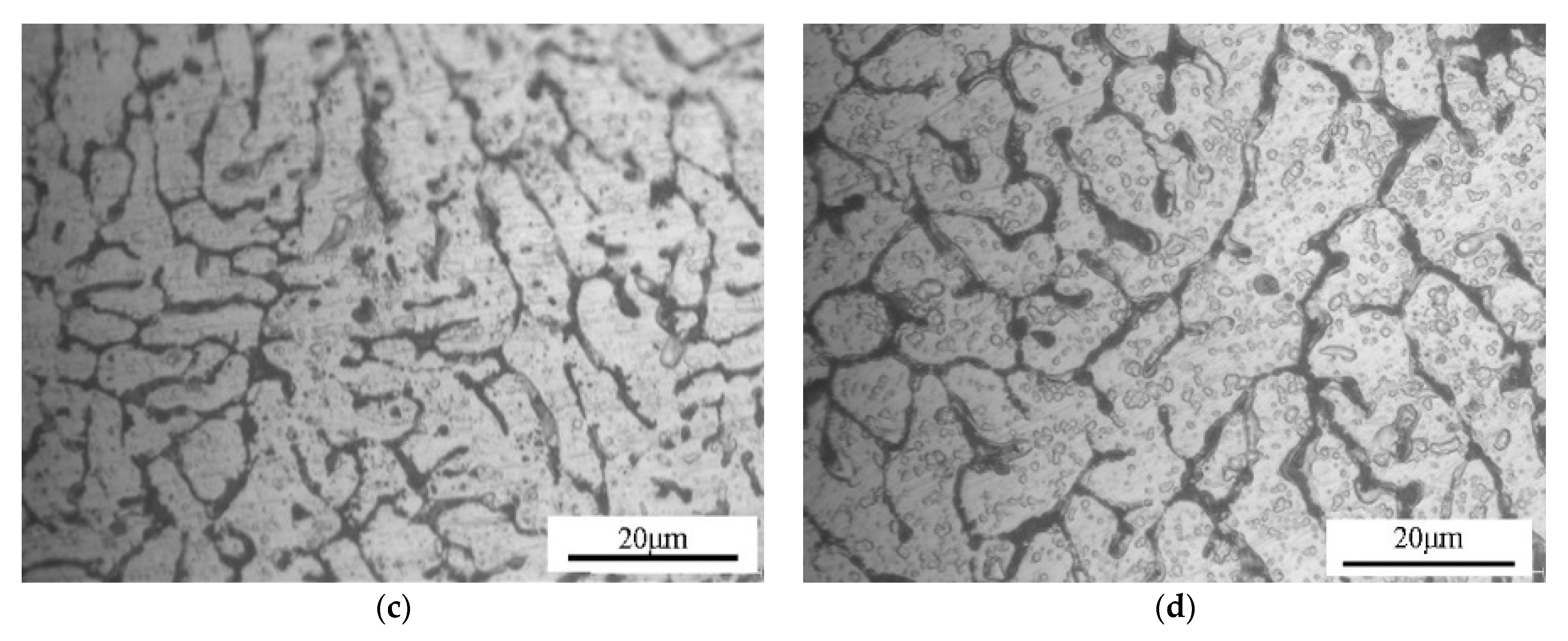

3.3. Mechanical Properties of Weld Beads

4. Conclusions

- (1)

- A mathematical model for simplifying the unified adjustment of Gaussian pulse welding currents for aluminum alloys has been established. This model realizes a new process of adjusting the average welding current input through the weak pulse groups’ base current. Furthermore, it reduces the difficulty in realizing the unified adjustment of the welding process, by establishing an expert database based on a large amount of experimental data.

- (2)

- The effectiveness of the unitary mathematical model has been verified by overlaying welding experiments on 2–5 mm thick 6061 aluminum alloy plates. The average current inputs of the three sets of tests were 72 A, 92 A, and 126 A, respectively, which were obtained by adjusting only one parameter. The three sets of test welds had bright surfaces with regular fish scale ripples, reduced spatter, and good repeatability of the current and voltage signals during welding.

- (3)

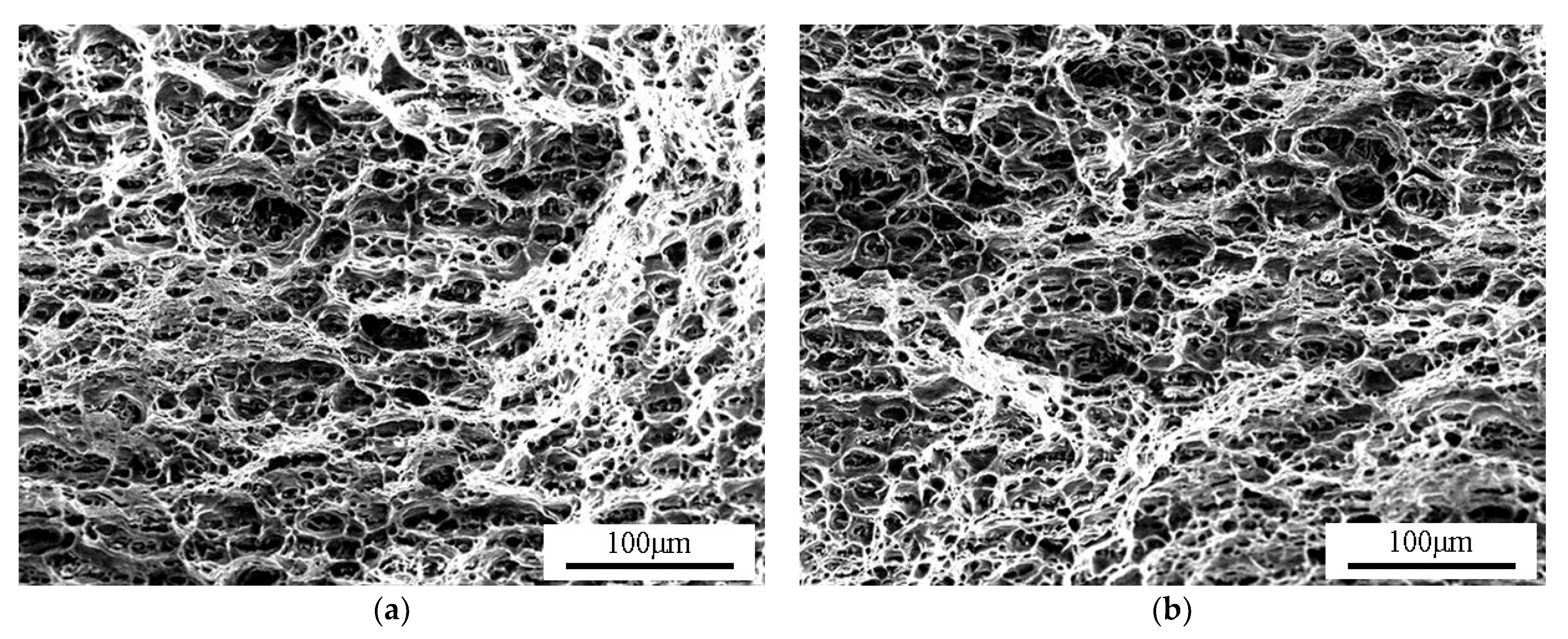

- The welds’ metallographic structures were mainly composed of fine dendrites, indicating good physical properties. The welded surfaces fractured in their heat-affected zones during tensile testing. The maximum tensile strength of Test 2 was 213 MPa, while the maximum tensile strength of Test 3 was 208 MPa, reaching about 68% of that of the base material. The average hardness of Test 2 was 72.32 HV, while the average hardness of Test 3 was 70.42 HV. The lowest hardness measured by the two sets of experiments always appeared in the heat-affected zone.

Author Contributions

Funding

Conflicts of Interest

References

- Liu, A.; Tang, X.; Lu, F. Arc profile characteristics of Al alloy in double-pulsed GMAW. Int. J. Adv. Manuf. Technol. 2013, 65, 1–7. [Google Scholar] [CrossRef]

- Reis, R.P.; Scotti, A.; Norrish, J.; Cuiuri, D. Investigation on welding arc interruptions in the presence of magnetic fields: Arc length, torch angle and current pulsing frequency influence. IEEE Tran. Plasma Sci. 2013, 41, 133–139. [Google Scholar] [CrossRef]

- Wang, L.; Wu, C.S.; Gao, J.Q. Suppression of humping bead in high speed GMAW with external magnetic field. Sci. Technol. Weld. Join. 2016, 21, 139–141. [Google Scholar] [CrossRef]

- Wang, L.L.; Jin, L.; Huang, W.J.; Xue, J.X. Effect of Thermal Frequency on AA6061 Aluminum Alloy Double Pulsed Gas Metal Arc Welding. Mater. Manuf. Process. 2015, 31, 2152–2157. [Google Scholar] [CrossRef]

- Jin, L.; Xue, J.X.; Hu, Y.; Zhang, Z. Effects of Thermal Frequency on Microstructures, Mechanical and Corrosion Properties of AA6061 Joints. Appl. Sci. 2018, 8, 540. [Google Scholar] [CrossRef]

- Chen, X.; Yu, G.; He, X.; Li, S.; Miao, H. Effect of droplet impact on molten pool dynamics in hybrid laser-MIG welding of aluminum alloy. Int. J. Adv. Manuf. Technol. 2018, 96, 209–222. [Google Scholar] [CrossRef]

- Chen, S.; Xu, B.; Jiang, F. Blasting type penetrating characteristic in variable polarity plasma arc welding of aluminum alloy of type 5A06. Int. J. Heat Mass. Transf. 2018, 118, 1293–1306. [Google Scholar] [CrossRef]

- Chang, Q.; Sun, D.; Gu, X.; Li, H. Microstructures and mechanical properties of metal inert-gas arc welded joints of aluminum alloy and ultrahigh strength steel using Al-Mg and Al-Cu fillers. J. Mater. Res. 2017, 32, 666–676. [Google Scholar] [CrossRef]

- Subramaniam, S.; White, D.R.; Jones, J.E.; Lyons, D.W. Droplet transfer in pulsed gas metal arc welding of aluminum. Weld. J. 1998, 77, 458–464. [Google Scholar]

- Yao, P.; Zhou, K.; Tang, H. Effects of Operational Parameters on the Characteristics of Ripples in Double-Pulsed GMAW Process. Materials 2019, 12, 2767. [Google Scholar] [CrossRef]

- Zhang, Z.H.; Xue, J.X. Profile Map of Weld Beads and Its Formation Mechanism in Gas Metal Arc Welding. Metals 2019, 146, 10. [Google Scholar] [CrossRef]

- Zhu, Q.; Xue, J.; Yao, P.; Dong, C.; Wang, L.; Heng, G.; Li, Z. Gaussian Pulsed Current Waveform Welding for Aluminum Alloys. Mater. Manuf. Process. 2015, 30, 1124–1130. [Google Scholar] [CrossRef]

- Chen, C.; Fan, C.L.; Cai, X.Y.; Lin, S.B.; Yang, C.L. Analysis of droplet transfer, weld formation and microstructure in Al-Cu alloy bead welding joint with pulsed ultrasonic-GMAW method. J. Mater. Process. Technol. 2019, 271, 144–151. [Google Scholar] [CrossRef]

- Jia, Y.Z.; Xiao, J.; Chen, S.J.; Huang, W.H. Pulsed laser enhanced metal transfer of aluminum alloy in GMAW. Opt. Laser. Eng. 2019, 121, 29–36. [Google Scholar] [CrossRef]

- Xue, J.X.; Lin, F.L.; Jin, L.; Hu, Y. Influence of pulse current waveform on mechanical properties of Tandem double wire MIG welding. Trans. China. Weld. Inst. 2019, 40, 6–10. [Google Scholar]

- Wu, W.; Xue, J.X.; Jin, L.; Zhang, Z.Z. Effect of modulating frequency in changing pulse numbers on aluminum alloy double pulsed welding. Trans. China. Weld. Inst. 2019, 40, 126–130. [Google Scholar]

- Balasubramanian, V.; Ravisankar, V.; Reddy, G.M. Effect of pulsed current welding on mechanical properties of high strength aluminum alloy. Int. J. Adv. Manuf. Technol. 2008, 36, 254–262. [Google Scholar] [CrossRef]

- Guzman, I.; Granda, E.; Acevedo, J.; Martinez, A.; Davila, Y.; Velazquez, R. Comparative in Mechanical Behavior of 6061 Aluminum Alloy Welded by Pulsed GMAW with Different Filler Metals and Heat Treatments. Materials 2019, 12, 4157. [Google Scholar] [CrossRef]

- Winiczenko, R.; Goroch, O.; Krzynska, A.; Kaczorowski, M. Friction welding of tungsten heavy alloy with aluminum alloy. J. Mater. Process. Technol. 2017, 246, 42–55. [Google Scholar] [CrossRef]

- Tomaz, I.D.; Colaco, F.H.G.; Sarfraz, S.; Pimenov, D.Y.; Gupta, M.K.; Pintaude, G. Investigations on quality characteristics in gas tungsten arc welding process using artificial neural network integrated with genetic algorithm. Int. J. Adv. Manuf. Technol. 2021, 113, 3569–3583. [Google Scholar] [CrossRef]

- Wang, Z.M.; Oliveira, J.P.; Zeng, Z.; Bu, X.Z.; Peng, B.; Shao, X.Y. Laser beam oscillating welding of 5A06 aluminum alloys: Microstructure, porosity and mechanical properties. Opt. Laser. Technol. 2019, 111, 58–65. [Google Scholar] [CrossRef]

- Ke, W.C.; Bu, X.Z.; Oliveira, J.P.; Xu, W.G.; Wang, Z.M.; Zeng, Z. Modeling and numerical study of keyhole-induced porosity formation in laser beam oscillating welding of 5A06 aluminum alloy. Opt. Laser. Technol. 2021, 133, 106540. [Google Scholar] [CrossRef]

| Material | Mg | Si | Fe | Cu | Mn | Cr | Al |

|---|---|---|---|---|---|---|---|

| 6061 | 0.96 | 0.52 | 0.25 | 0.25 | 0.12 | 0.26 | Bal. |

| ER 4043 | 0.05 | 5.60 | 0.8 | 0.3 | 0.05 | - | Bal. |

| Test Number | Size of Base Material mm × mm × mm | Ips I /A | ts t / ms | Ibs I /A | tgw t / ms | Iop I /A | Ibw I /A | tw t / ms | Iavg I /A | Flow f /Hz |

|---|---|---|---|---|---|---|---|---|---|---|

| 1 | 250 × 100 × 2 | vary with gaussian curve | 2.5 | 36 | 9.5 | 260 | 30 | 14.5 | 72 | 2 |

| 2 | 250 × 100 × 3 | 2.5 | 60 | 9.5 | 260 | 50 | 14.5 | 92 | 2 | |

| 3 | 250 × 100 × 5 | 2.5 | 108 | 9.5 | 260 | 90 | 14.5 | 126 | 2 |

Publisher’s Note: MDPI stays neutral with regard to jurisdictional claims in published maps and institutional affiliations. |

© 2021 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (https://creativecommons.org/licenses/by/4.0/).

Share and Cite

Zhu, Q.; Yao, P.; Yu, X.; Xie, B.; Xue, J.; Hu, H. A Unified Adjustment Model for Gaussian Pulse Welding on Aluminum Alloys. Metals 2021, 11, 671. https://doi.org/10.3390/met11040671

Zhu Q, Yao P, Yu X, Xie B, Xue J, Hu H. A Unified Adjustment Model for Gaussian Pulse Welding on Aluminum Alloys. Metals. 2021; 11(4):671. https://doi.org/10.3390/met11040671

Chicago/Turabian StyleZhu, Qiang, Ping Yao, Xiaoyan Yu, Bin Xie, Jiaxiang Xue, and Haibiao Hu. 2021. "A Unified Adjustment Model for Gaussian Pulse Welding on Aluminum Alloys" Metals 11, no. 4: 671. https://doi.org/10.3390/met11040671

APA StyleZhu, Q., Yao, P., Yu, X., Xie, B., Xue, J., & Hu, H. (2021). A Unified Adjustment Model for Gaussian Pulse Welding on Aluminum Alloys. Metals, 11(4), 671. https://doi.org/10.3390/met11040671